Study of Energy Loss for Distributed Power-Flow Assignment in a Smart Home Environment

Abstract

:1. Introduction

- Introduce a system model of fluctuating DPFA to study balancing RE resources and power loads with the presence of ESSs in a smart home.

- Propose power-flow assignment algorithms for the energy system to efficiently assign the required power for single and multiple power loads, i.e., single-load power-flow assignment (SPFA) and multiple-load power-flow assignment (MPFA) algorithms, respectively.

- Reveal through simulation results that the proposed PFA algorithms ensure that the total energy from PGs from RE resources are completely supplied to all the PLs in order to reduce energy loss due to ESSs.

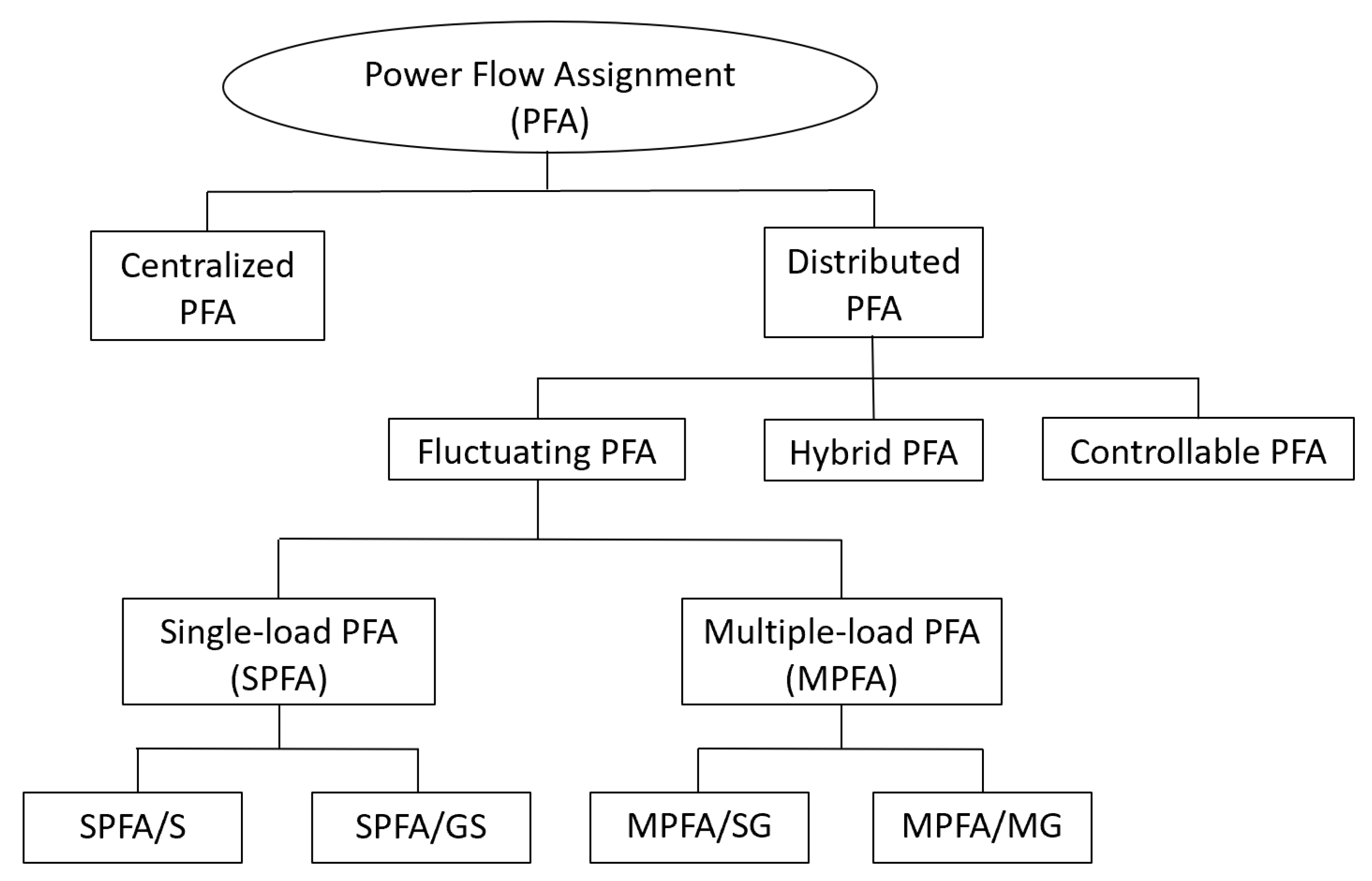

2. Background

3. Related Works

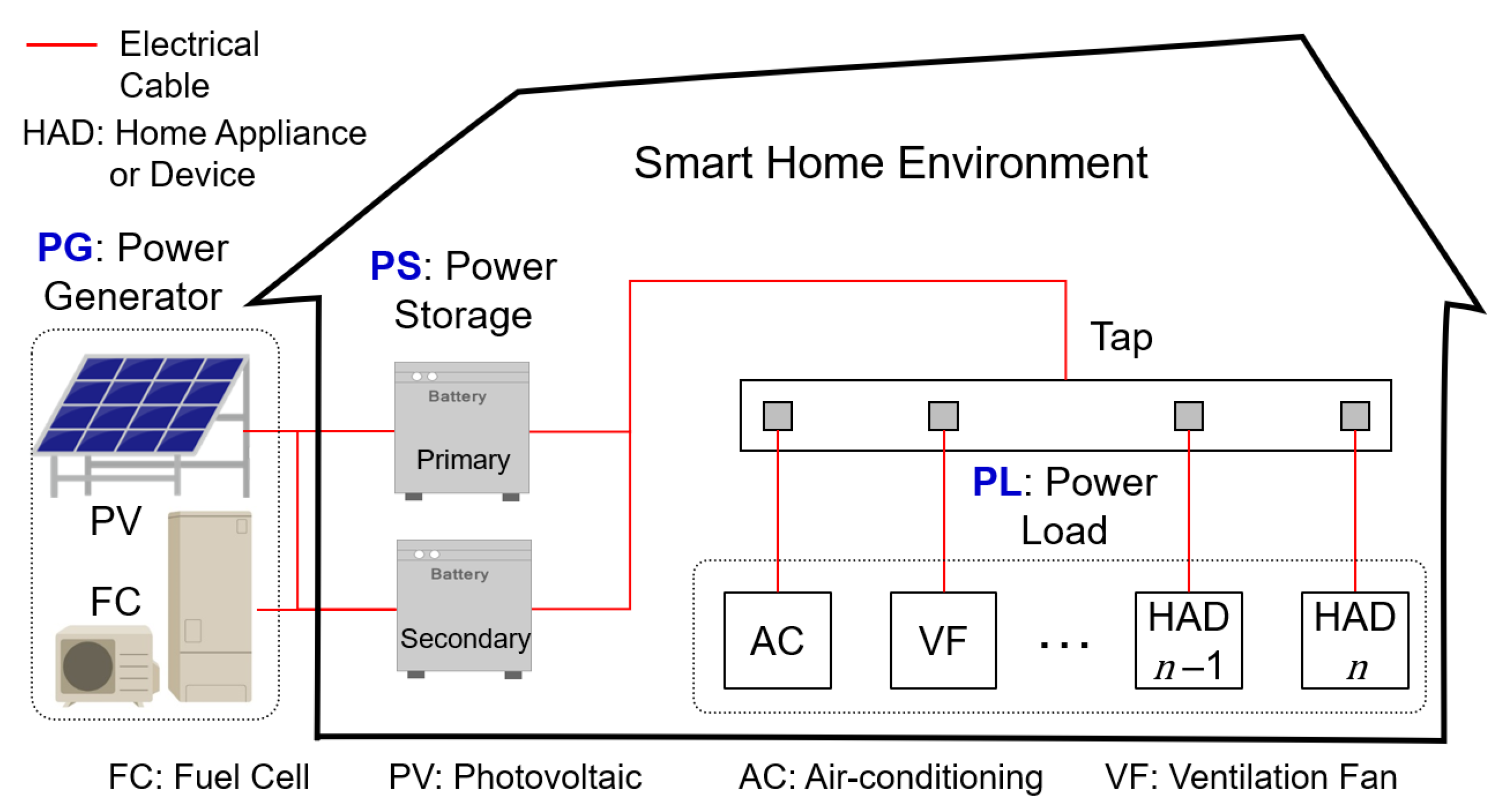

4. System Model

4.1. Preliminaries

4.2. Power Generators and Loads

4.3. Power Storage Systems

4.4. Energy Loss of Power Storage System

5. Fluctuating Distributed Power-Flow Assignment

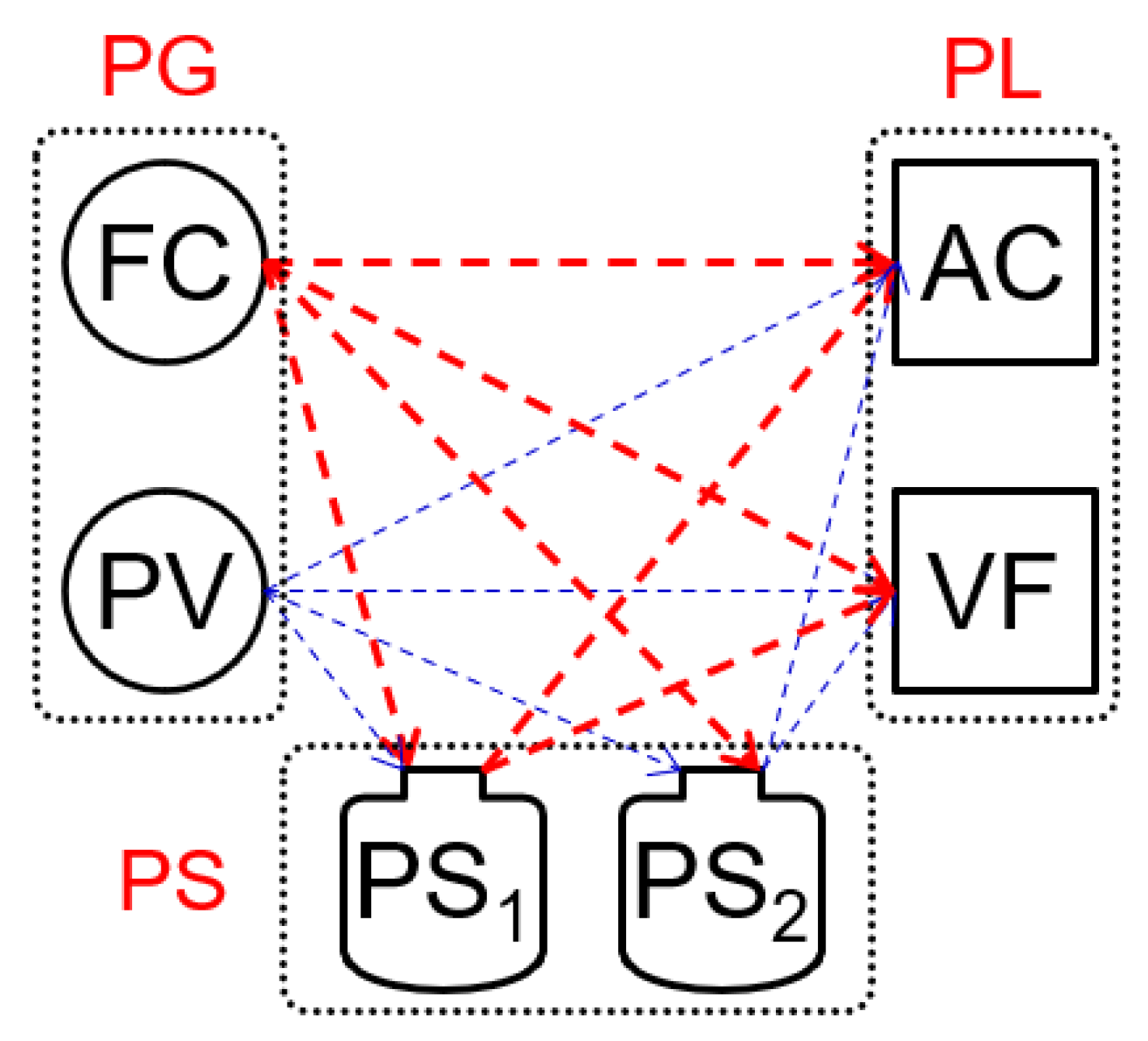

5.1. Single-Load and Multiple-Load Power-Flow Assignment

5.2. Single-Load Power-Flow Assignment Algorithm

| Algorithm 1 SPFA/GS Algorithm |

| Definition: Assume the total energy remaining at time t is , the total energy lacking at time t is , and M=N=H |

| 1: function SPFA/GS |

| 2: while not assigned to any power generator do |

| 3: for to N, to M, to H do |

| 4: if then |

| 5: turns on |

| 6: Compute |

| 7: Assign |

| 8: else if then |

| 9: turns on |

| 10: Compute |

| 11: Assign |

| 12: else |

| 13: turns off |

| 14: Assign |

| 15: end if |

| 16: end for |

| 17: end while |

| 18: end function |

5.3. Multiple-Load Power-Flow Assignment Algorithm

| Algorithm 2 MPFA/SG Algorithm |

| Definition: Assume the total energy remaining at time t is , total energy lacking at time t is , and M=N=H |

| 1: function MPFA/SG |

| 2: while not assigned to any power generator do |

| 3: for to N, to M, to H do |

| 4: if then |

| 5: turns on |

| 6: Compute |

| 7: Assign |

| 8: else if then |

| 9: turns on |

| 10: Compute |

| 11: Assign |

| 12: else |

| 13: turns off |

| 14: Assign |

| 15: end if |

| 16: end for |

| 17: end while |

| 18: end function |

| Algorithm 3 MPFA/MG Algorithm |

| Definition: Assume the total energy remaining at time t is , total energy lacking at time t is , total charging energy at time t is , total discharging energy at time t is , and M=N=H |

| 1: function MPFA/MG |

| 2: while not assigned to any power generator do |

| 3: for to N, to M, to H do |

| 4: if then |

| 5: turns on |

| 6: Compute |

| 7: Compute |

| 8: Assign |

| 9: else if then |

| 10: turns on |

| 11: Compute |

| 12: Compute |

| 13: Assign |

| 14: else |

| 15: turns off |

| 16: Compute |

| 17: Assign |

| 18: end if |

| 19: end for |

| 20: end while |

| 21: end function |

6. Numerical Studies

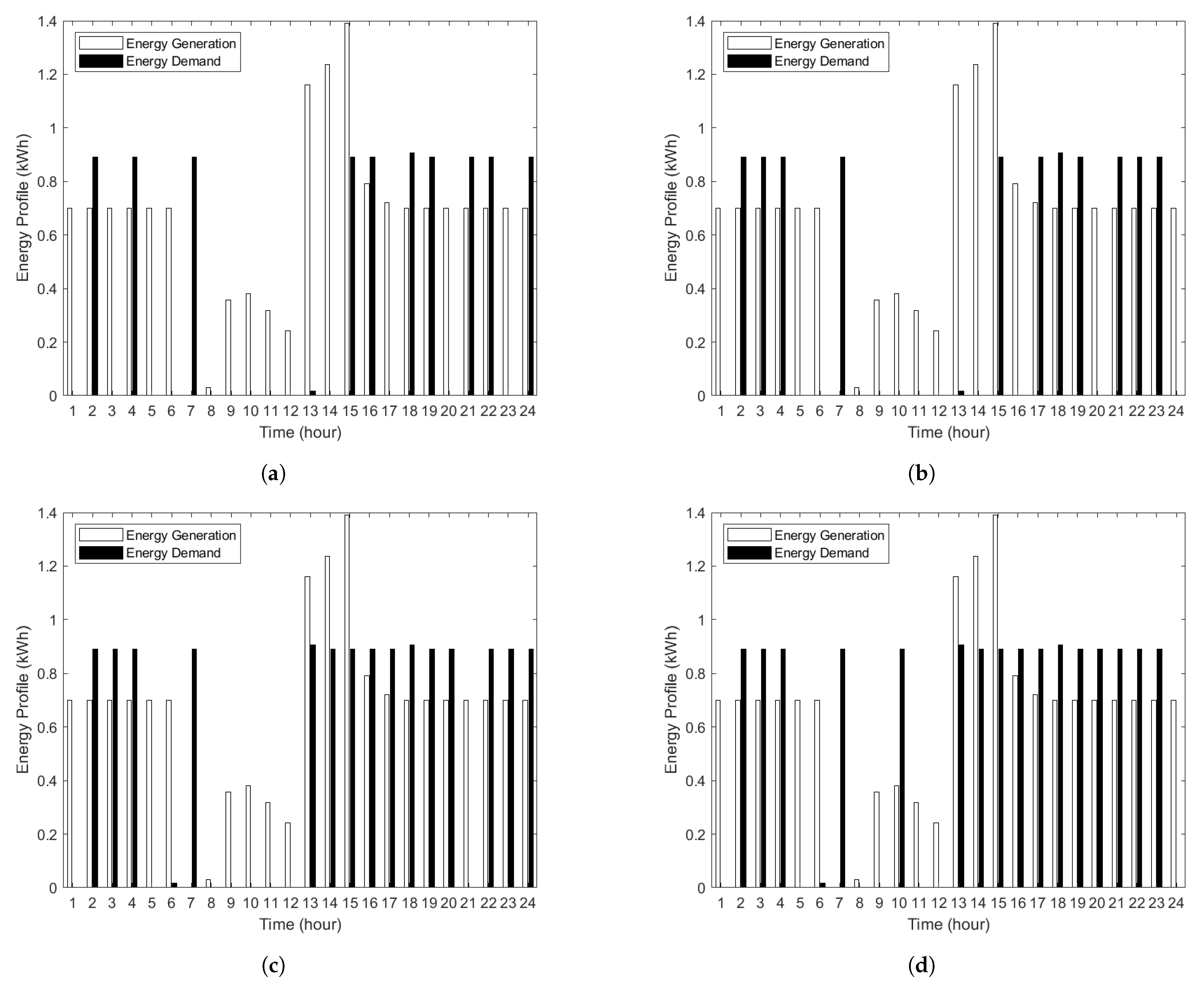

6.1. Simulation Setup and Scenario

6.2. Four Different Logical Power Connections

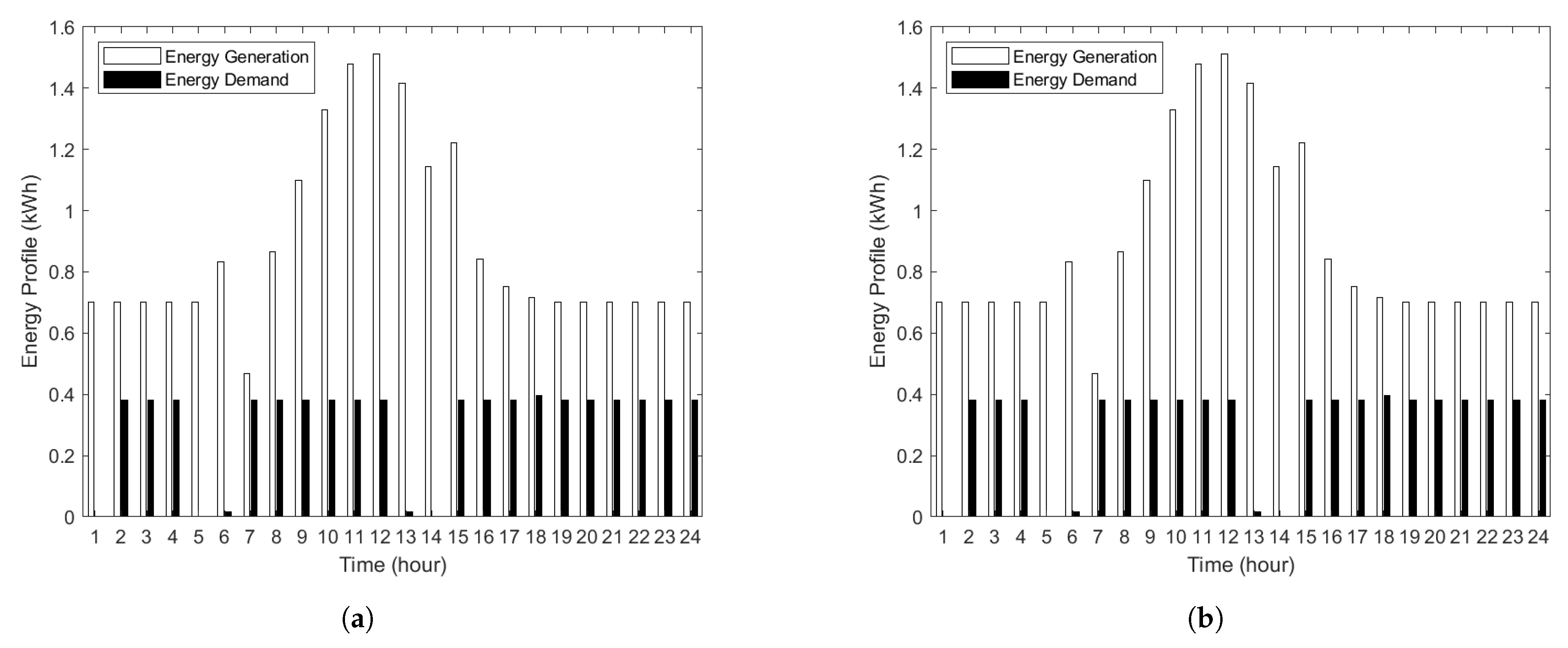

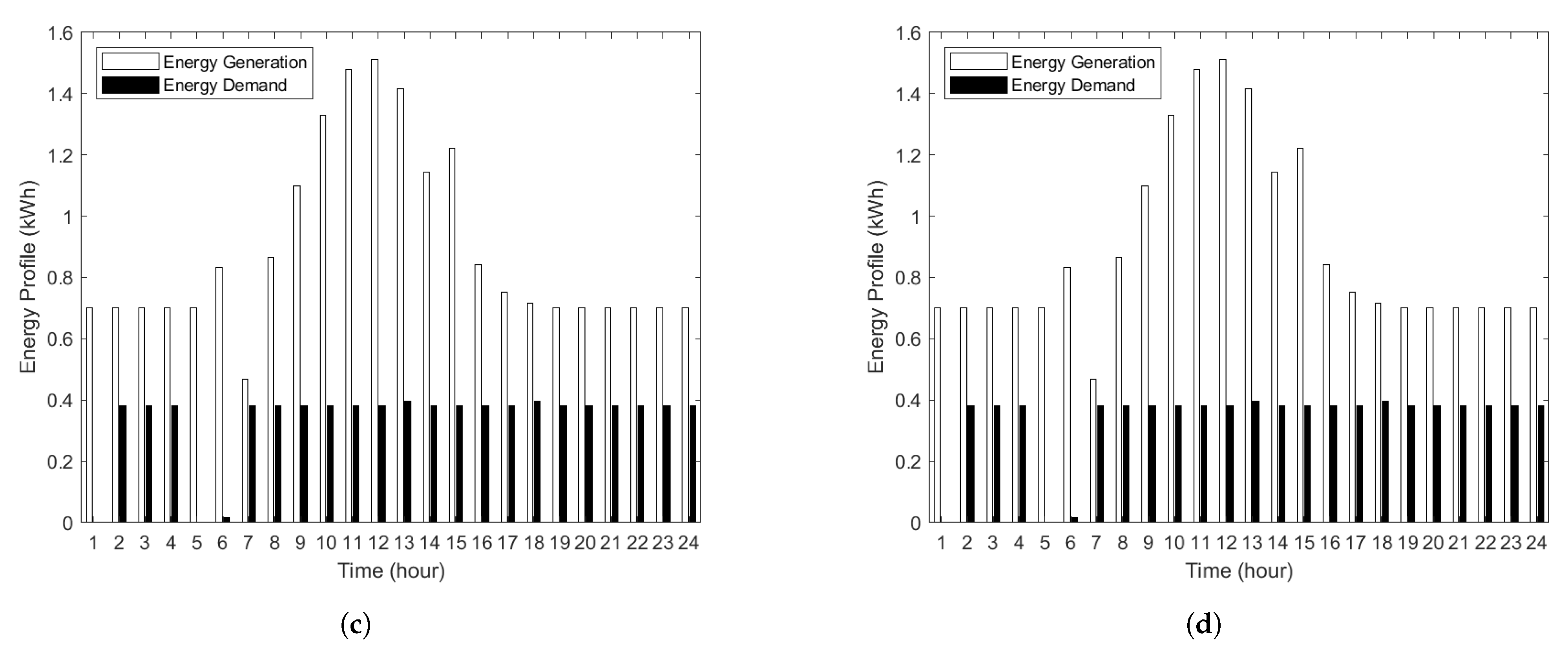

6.3. Energy Profile

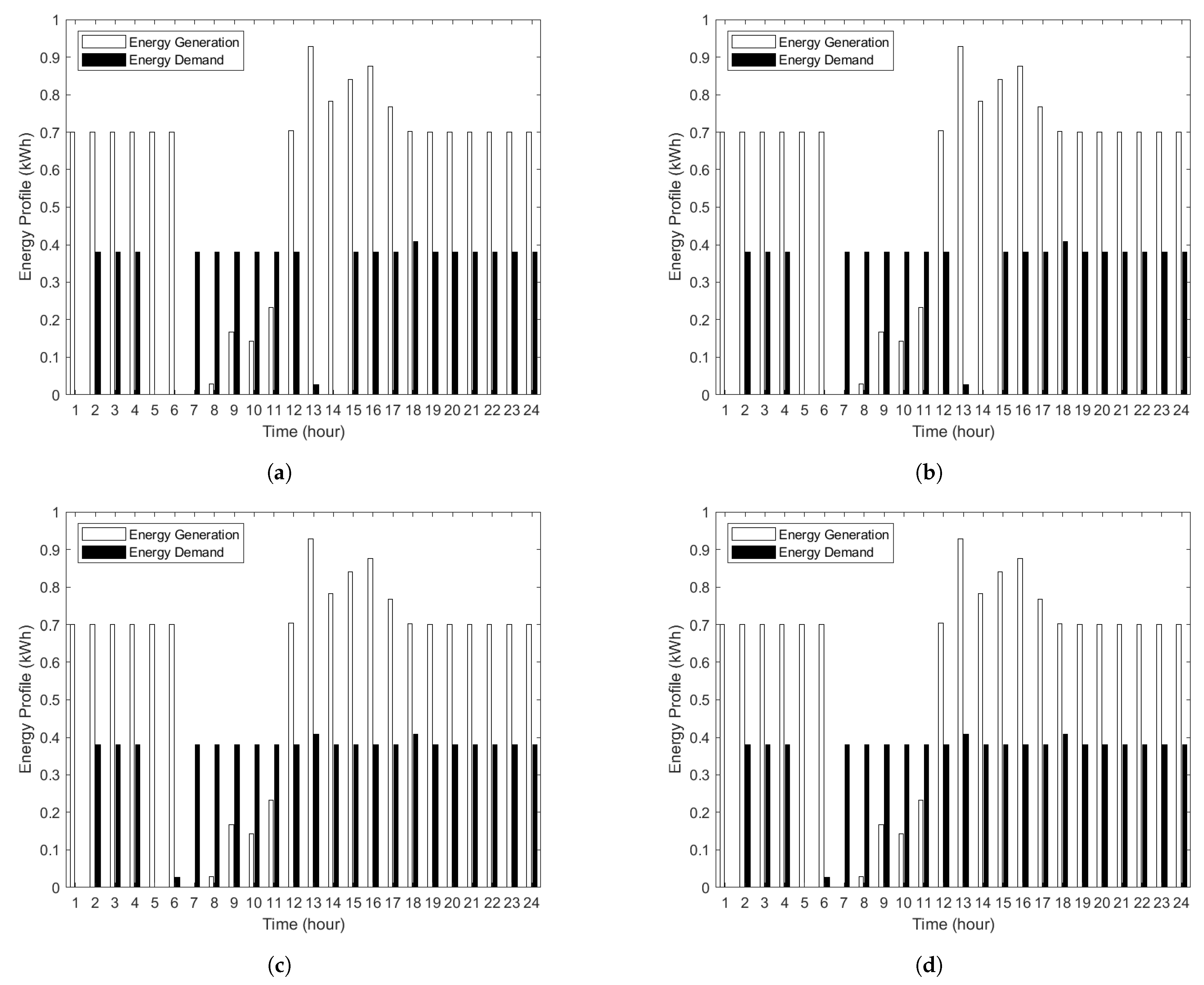

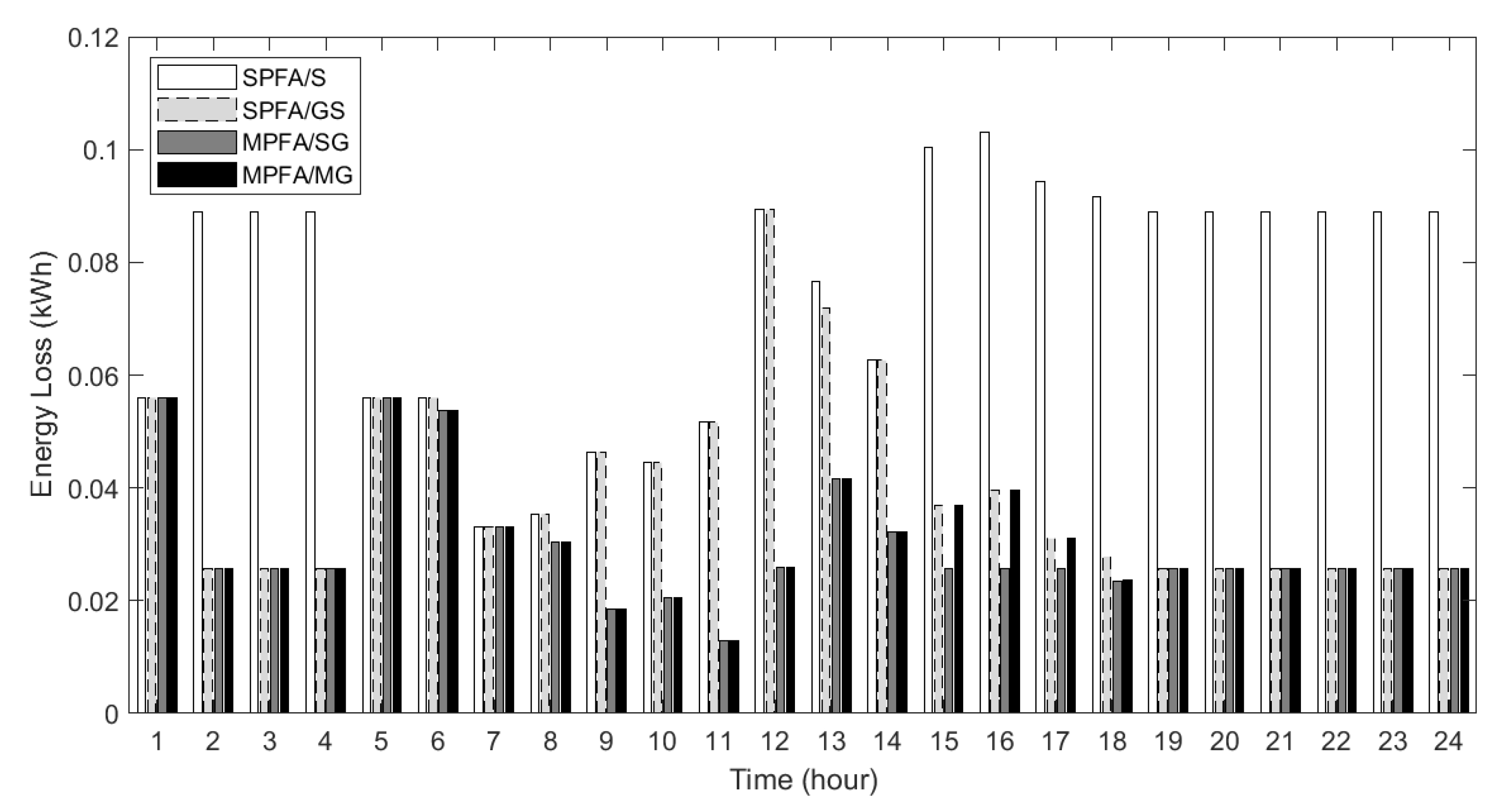

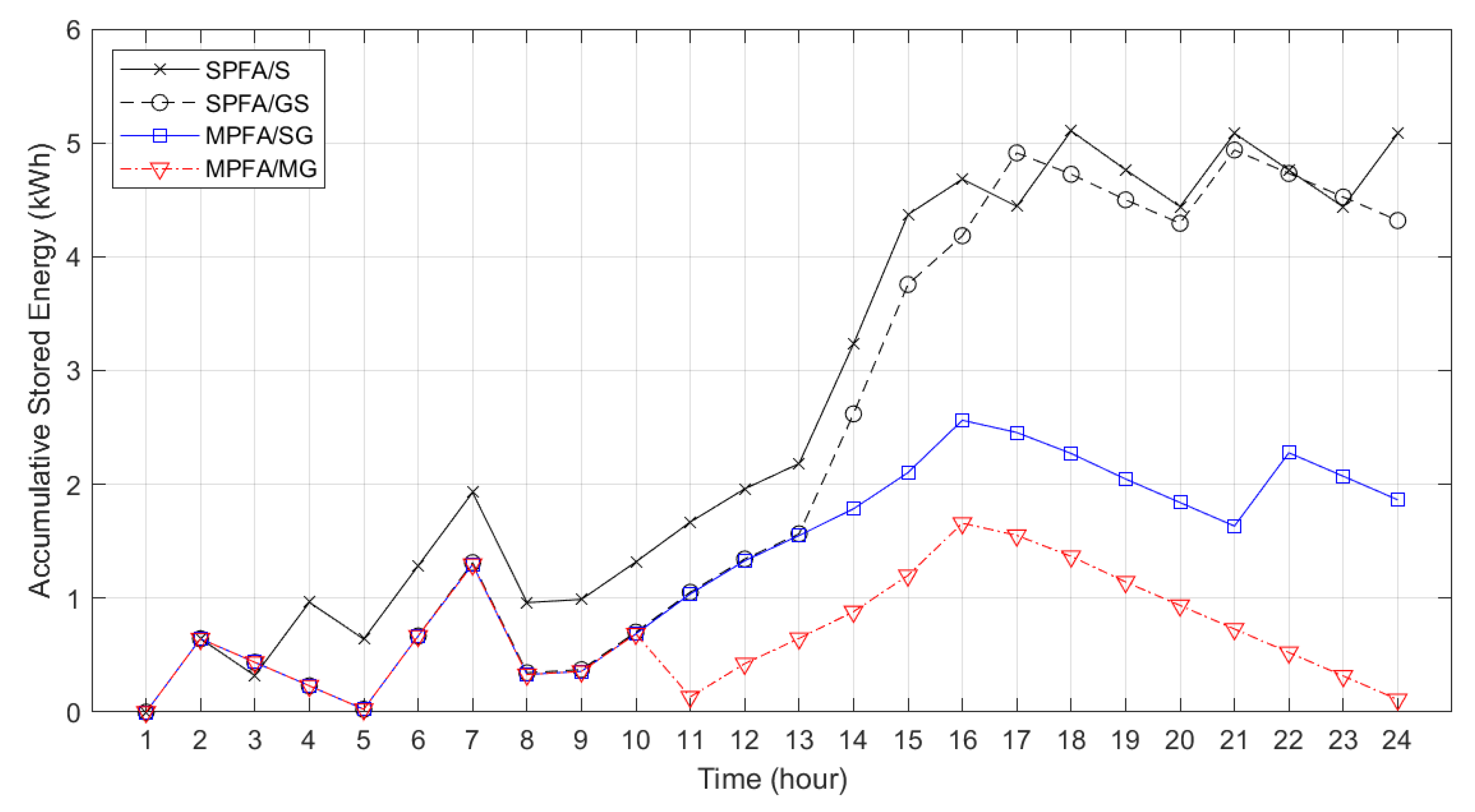

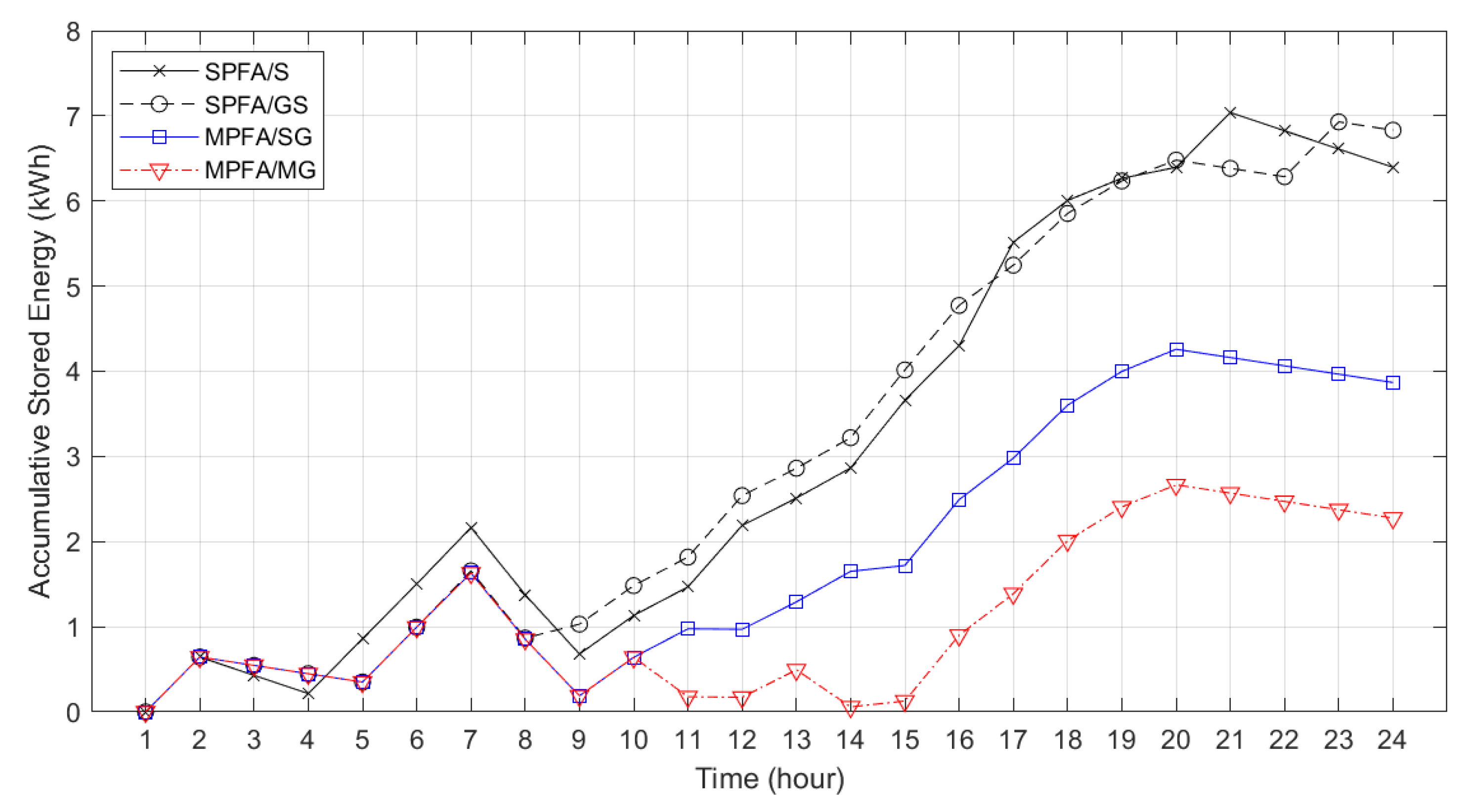

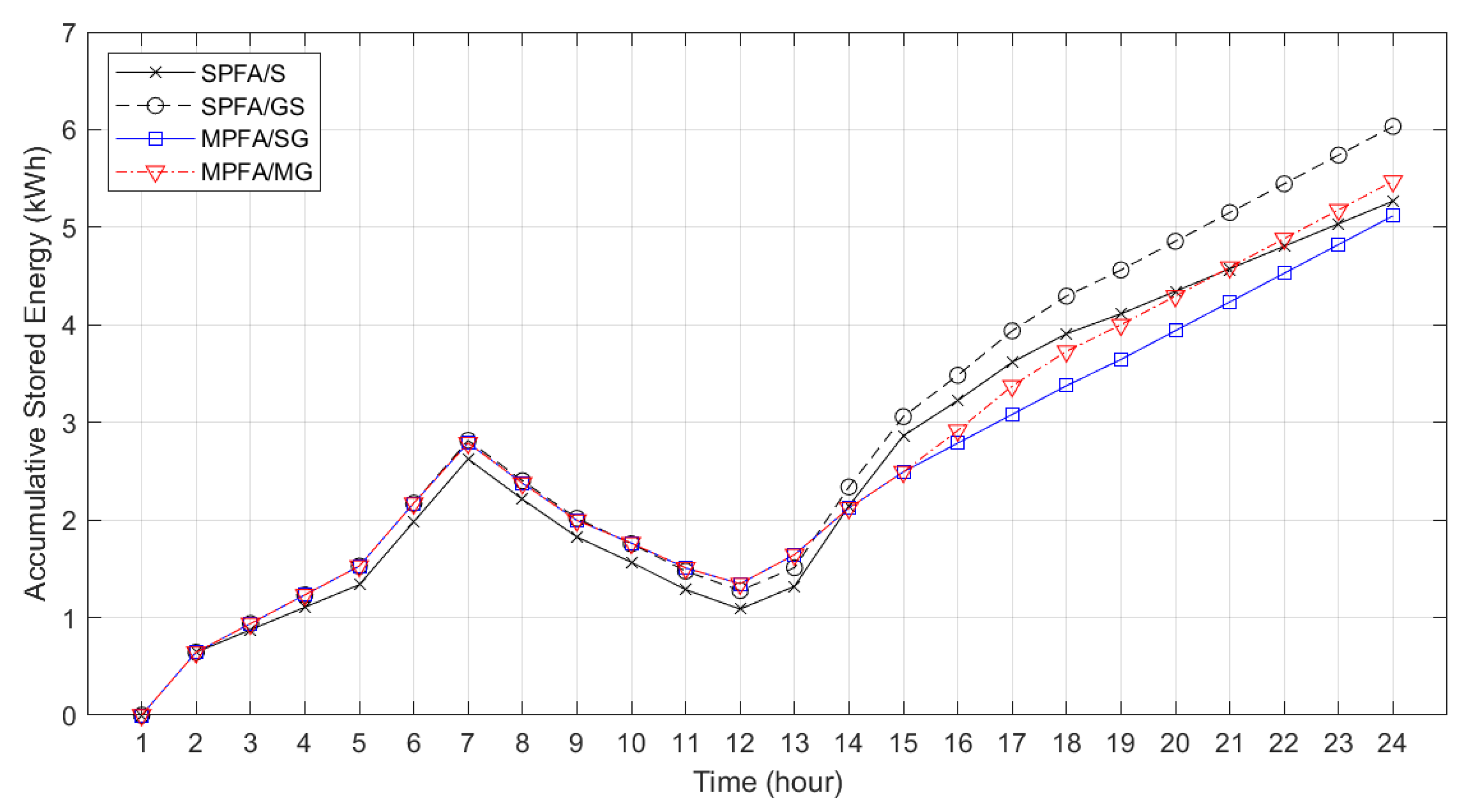

6.4. Analysis and Discussion of Energy Loss and Stored Energy of ESS

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Air Conditioning |

| BLE | Bluetooth Low Energy |

| CPFA | Centralized Power-flow Assignment |

| DPFA | Distributed Power-flow Assignment |

| ESS | Energy Storage System |

| FC | Fuel Cell |

| IoT | Internet of Things |

| MPFA | Multiple-load Power-flow Assignment |

| MPFA/SG | Multiple-load Power-flow Assignment: Single Generator-to-Storage |

| MPFA/MG | Multiple-load Power-flow Assignment: Multiple Generators-to-Storage |

| PFA | Power-flow Assignment |

| PG | Power Generator |

| PL | Power Load |

| PLC | Power Line Communication |

| PoE | Power over Ethernet |

| PS | Power Storage |

| PV | Photovoltaic |

| QoES | Quality of Energy Service |

| RE | Renewable Energy Resources |

| SoC | State of Charge |

| SPE | Single-Pair Ethernet |

| SPFA | Single-load Power-flow Assignment |

| SPFA/S | Single-load Power-flow Assignment: Storage source |

| SPFA/GS | Single-load Power-flow Assignment: Generator and Storage sources |

| VF | Ventilation Fan |

Nomenclature

| m | mth power generator |

| n | nth power load |

| h | hth power storage |

| A set of power generators | |

| A set of power loads | |

| A set of power storages | |

| Energy generation level of mth fluctuating power generator at time t | |

| Energy demand level of nth fluctuating power load at time t | |

| Minimum state of charge of hth power storage | |

| Maximum state of charge of hth power storage | |

| Initial state of charge of hth power storage | |

| Stored energy of hth power storage at time t | |

| Charge or discharge energy of hth power storage at time t | |

| Charging loss of hth power storage at time t | |

| Discharging loss of hth power storage at time t | |

| Capacity of hth power storage | |

| Logical power-flow connections from X to Y at time t | |

| Instantaneous power level of mth fluctuating power generator at time t | |

| Instantaneous power level of nth fluctuating power load at time t | |

| Minimum instantaneous power level limitations of mth fluctuating power generator | |

| Maximum instantaneous power level limitations of mth fluctuating power generator | |

| Minimum instantaneous power level limitations of nth fluctuating power load | |

| Maximum instantaneous power level limitations of nth fluctuating power load | |

| Instantaneous input power of hth power storage at time t | |

| Instantaneous output power of hth power storage at time t | |

| Minimum instantaneous input power level limitations of hth power storage | |

| Maximum instantaneous input power level limitations of hth power storage | |

| Minimum instantaneous output power level limitations of hth power storage | |

| Maximum instantaneous output power level limitations of hth power storage | |

| Charging efficiency of power storage | |

| Discharging efficiency of power storage | |

| Total remaining energy to be charged at time t | |

| Total energy lacking to be discharged at time t | |

| Total charging energy at time t | |

| Total discharging energy at time t |

References

- IEA. Global Energy & CO2 Status Report; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Hung, D.Q.; Mithulananthan, N. Multiple distributed generator placement in primary distribution networks for loss reduction. IEEE Trans. Ind. Electron. 2011, 60, 1700–1708. [Google Scholar] [CrossRef]

- IRENA. Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017; Volume 164. [Google Scholar]

- Harper, R. Inside the smart home: Ideas, possibilities and methods. In Inside the Smart Home; Springer: Berlin/Heidelberg, Germany, 2003; pp. 1–13. [Google Scholar]

- Werth, A.; Kitamura, N.; Tanaka, K. Conceptual study for open energy systems: Distributed energy network using interconnected DC nanogrids. IEEE Trans. Smart Grid 2015, 6, 1621–1630. [Google Scholar] [CrossRef]

- Vossos, V.; Gerber, D.L.; Gaillet-Tournier, M.; Nordman, B.; Brown, R.; Bernal Heredia, W.; Ghatpande, O.; Saha, A.; Arnold, G.; Frank, S.M. Adoption pathways for DC power distribution in buildings. Energies 2022, 15, 786. [Google Scholar] [CrossRef]

- Reick, B.; Konzept, A.; Kaufmann, A.; Stetter, R.; Engelmann, D. Influence of charging losses on energy consumption and CO2 emissions of battery-electric vehicles. Vehicles 2021, 3, 736–748. [Google Scholar] [CrossRef]

- Lim, Y.; Takano, S.; Javaid, S.; Tan, Y. Admission control scheme with balancing power negotiation algorithm for home energy management and control system. In Proceedings of the 2021 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW), Penghu, Taiwan, 15–17 September 2021; pp. 1–2. [Google Scholar]

- Javaid, S.; Kaneko, M.; Tan, Y. System condition for power balancing between fluctuating and controllable devices and optimizing storage sizes. Energies 2022, 15, 1055. [Google Scholar] [CrossRef]

- Lim, Y.; Javaid, S.; Khwanrit, R.; Tan, Y. Seasonal storage capacity design for distributed power flow system with safe operation conditions. In Proceedings of the 2022 IEEE International Conference on Consumer Electronics-Taiwan, Taipei, Taiwan, 6–8 July 2022; pp. 577–578. [Google Scholar]

- Javadi, M.; Lotfi, M.; Osório, G.J.; Ashraf, A.; Nezhad, A.E.; Gough, M.; Catalão, J.P. A multi-objective model for home energy management system self-scheduling using the epsilon-constraint method. In Proceedings of the 2020 IEEE 14th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Setubal, Portugal, 8–10 July 2020; Volume 1, pp. 175–180. [Google Scholar]

- Almeida, T.; Lotfi, M.; Javadi, M.; Osório, G.J.; Catalão, J.P. Economic analysis of coordinating electric vehicle parking lots and home energy management systems. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Javadi, M.; Nezhad, A.E.; Firouzi, K.; Besanjideh, F.; Gough, M.; Lotfi, M.; Anvari-Moghadam, A.; Catalão, J.P. Optimal operation of home energy management systems in the presence of the inverter-based heating, ventilation and air conditioning system. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Rezaee Jordehi, A. Enhanced leader particle swarm optimisation (ELPSO): A new algorithm for optimal scheduling of home appliances in demand response programs. Artif. Intell. Rev. 2020, 53, 2043–2073. [Google Scholar] [CrossRef]

- Fortenbacher, P.; Mathieu, J.L.; Andersson, G. Modeling and optimal operation of distributed battery storage in low voltage grids. IEEE Trans. Power Syst. 2017, 32, 4340–4350. [Google Scholar] [CrossRef] [Green Version]

- Farrokhifar, M.; Grillo, S.; Tironi, E. Loss minimization in medium voltage distribution grids by optimal management of energy storage devices. In Proceedings of the 2013 IEEE Grenoble Conference, Dresden, Germany, 26–27 September 2013; pp. 1–5. [Google Scholar]

- Jannesar, M.R.; Sedighi, A.; Savaghebi, M.; Guerrero, J.M. Optimal placement, sizing, and daily charge/discharge of battery energy storage in low voltage distribution network with high photovoltaic penetration. Appl. Energy 2018, 226, 957–966. [Google Scholar] [CrossRef] [Green Version]

- Sardi, J.; Mithulananthan, N.; Hung, D.Q.; Bhumkittipich, K. Load levelling and loss reduction by ES in a primary distribution system with PV units. In Proceedings of the 2015 IEEE Innovative Smart Grid Technologies-Asia (ISGT ASIA), Bangkok, Thailand, 3–6 November 2015; pp. 1–6. [Google Scholar]

- Chen, Z.; Xia, B.; Mi, C.C.; Xiong, R. Loss-minimization-based charging strategy for lithium-ion battery. IEEE Trans. Ind. Appl. 2015, 51, 4121–4129. [Google Scholar] [CrossRef]

- Chen, Z.; Shu, X.; Sun, M.; Shen, J.; Xiao, R. Charging strategy design of lithium-ion batteries for energy loss minimization based on minimum principle. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–6. [Google Scholar]

- Liu, K.; Hu, X.; Yang, Z.; Xie, Y.; Feng, S. Lithium-ion battery charging management considering economic costs of electrical energy loss and battery degradation. Energy Convers. Manag. 2019, 195, 167–179. [Google Scholar] [CrossRef]

- Schimpe, M.; Piesch, C.; Hesse, H.C.; Paß, J.; Ritter, S.; Jossen, A. Power flow distribution strategy for improved power electronics energy efficiency in battery storage systems: Development and implementation in a utility-scale system. Energies 2018, 11, 533. [Google Scholar] [CrossRef] [Green Version]

- Cho, S.M.; Yun, S.Y. Optimal power assignment of energy storage systems to improve the energy storage efficiency for frequency regulation. Energies 2017, 10, 2092. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.Y.; Choi, I.S.; Ahn, G.H.; Won, D.J. Advanced power sharing method to improve the energy efficiency of multiple battery energy storages system. IEEE Trans. Smart Grid 2016, 9, 1292–1300. [Google Scholar] [CrossRef]

- Tewari, J. Basic Electrical Engineering; New Age International: Delhi, India, 2003. [Google Scholar]

- Li, X.; Hui, D.; Lai, X. Battery energy storage station (BESS)-based smoothing control of photovoltaic (PV) and wind power generation fluctuations. IEEE Trans. Sustain. Energy 2013, 4, 464–473. [Google Scholar] [CrossRef]

- Kularatna, N.; Gunawardane, K. Energy Storage Devices for Renewable Energy-Based Systems: Rechargeable Batteries and Supercapacitors; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Javaid, S.; Kaneko, M.; Tan, Y. Safe operation conditions of electrical power system considering power balanceability among power generators, loads, and storage devices. Energies 2021, 14, 4460. [Google Scholar] [CrossRef]

- Birke, K.P. Modern Battery Engineering: A Comprehensive Introduction; World Scientific: Toh Tuck Link, Singapore, 2019. [Google Scholar]

- NHK Broadcasting Culture Research Institute. Time Habits of Japanese in 2005: A NHK Survey Regarding the Use of Time in the Daily Life of Japanese Citizens; Japan Broadcasting Publishers Association: Tokyo, Japan, 2006. [Google Scholar]

- Lim, Y.; Tang, N.T.; Makino, Y.; Teo, T.K.; Tan, Y. Simulation of solar photovoltaic and fuel cell energy system for smart community simulator. In Proceedings of the IEICE Technical Committee on Information Networks (IN), Fukuoka, Japan, 16–17 November 2017; Volume 117, pp. 1–6. [Google Scholar]

- Toshiba. TOSHIBA Household Fuel Cell System: ECOFARM. Available online: https://www.toshiba.co.jp/product/fc/products/pdf/TENA-chofu16-7.pdf (accessed on 19 September 2022).

| Season | AC (Wh) | VF (Wh) |

|---|---|---|

| Winter | 890 | 16.5 |

| Spring | 380 | 16.5 |

| Summer | 790 | 27.8 |

| Autumn | 380 | 27.8 |

| Season | SPFA/S | SPFA/GS | MPFA/SG | MPFA/MG |

|---|---|---|---|---|

| Winter | 2.035 | 0.941 | 0.668 | 0.682 |

| Summer | 2.199 | 0.925 | 0.700 | 0.712 |

| Spring | 2.342 | 1.509 | 1.068 | 1.068 |

| Autumn | 1.798 | 0.968 | 0.712 | 0.742 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khwanrit, R.; Lim, Y.; Javaid, S.; Kittipiyakul, S.; Tan, Y. Study of Energy Loss for Distributed Power-Flow Assignment in a Smart Home Environment. Designs 2022, 6, 99. https://doi.org/10.3390/designs6060099

Khwanrit R, Lim Y, Javaid S, Kittipiyakul S, Tan Y. Study of Energy Loss for Distributed Power-Flow Assignment in a Smart Home Environment. Designs. 2022; 6(6):99. https://doi.org/10.3390/designs6060099

Chicago/Turabian StyleKhwanrit, Ruengwit, Yuto Lim, Saher Javaid, Somsak Kittipiyakul, and Yasuo Tan. 2022. "Study of Energy Loss for Distributed Power-Flow Assignment in a Smart Home Environment" Designs 6, no. 6: 99. https://doi.org/10.3390/designs6060099

APA StyleKhwanrit, R., Lim, Y., Javaid, S., Kittipiyakul, S., & Tan, Y. (2022). Study of Energy Loss for Distributed Power-Flow Assignment in a Smart Home Environment. Designs, 6(6), 99. https://doi.org/10.3390/designs6060099