Abstract

This research investigates the communication barriers between designers and engineers in designing 4D Printing parts. We have proposed a conceptual design framework for 4D Printing symbols as the communication tool. Then, we have recruited sixty-fifty designers and engineers who participated in our online experiments. The focus of the online survey is to find out how designers and engineers understand reciprocal communication by using the proposed symbols. Our results showed that 85% of participants could understand the 4D Printing symbols correctly. The study concludes that using the conceptual framework can help designers and engineers communicate 4D Printing element information and stimulate design ideas effectively.

1. Introduction

In recent years, 3D Printing, also known as additive manufacturing (AM) bringing many changes to several important industries. Companies have begun printing everything from fully functioning cars to the food design manufacturing field [1]. Moreover, medical research institutions have even experimented with printing functioning body parts using additive manufacturing. Recently, 3D Printing has become a tool in tackling some of the unprecedented challenges posed by COVID-19 by helping supply health workers with personal protective equipment and patient with ventilators [2]. However, the conventional 3D Printing technology is used to fabricate static structures from single or morph elements that cannot meet dynamic structures’ needs and their relevant applications such as soft grippers, self-assembled and self-healing polymers. An innovative concept of printing technology has emerged to solve these bottleneck issues known as 4D Printing [3].

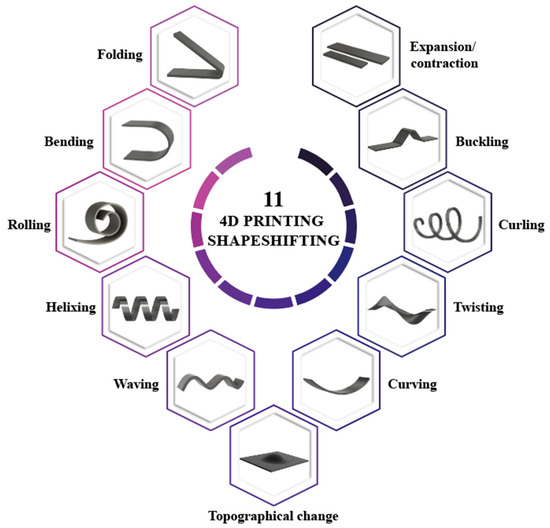

Over the last few years, a new term has emerged as 4D Printing (Four-Dimensional Printing), which utilises additive manufacturing methods to print stimulus-responsive products subjected to specific stimuli. It is generally regarded as the further evolution of 3D Printing. The 4D printing technology idea was first introduced by Skylar Tibbits, co-director and founder of the Self-Assembly Lab housed at the Massachusetts Institute of Technology (MIT’s) International Design Center [4]. 4D Printing adds the fourth coordinate of time and the traditional 3D coordinate. Therefore, it can regard 4D Printing as giving the printed structure the capability to change its form or function with time under external stimuli such as heat, water, UV light pressure and others [5]. The core elements of 4D printing technology are smart-material, which provides a more flexible, expandable, deformable characteristic of printed products to respond to specific stimuli. Moreover, 4D Printing is a progressive evolution of 3D Printed structures that can be changeable in terms of saved property and its functions over time [6].

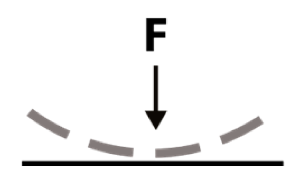

4D Printing can achieve self-assembly, self-recovery, and multi-functional purposes, providing time-dependent, predictable, reprogrammable properties. The concept of 4D Printing mainly depends on five factors which are, 3D printers, stimulus-responsive material, stimuli, interaction mechanism and mathematical modelling [7]. 4D Printing opens the door to new fields with potential applications that depend on its structure. It also can be equated from one state to another under the element stimulus, and it involves soft robotics self-repair device and responsive structure [8]. Figure 1 shows the example of the 4D Printed object where the flat 3D Printed structure is turned into a truncated octahedron shape with the stimulus of water. The smart material reacts with the water and gains shape without mechanical energy [9].

Figure 1.

The example of a 4D Printed object that changes shape in water (reproduced from, [9] with permission from Springer International Publishing, 2018).

1.1. The Barriers in Communicating 4D Printing

Communication can define as the transmission interpretation and exchange of information [10]. Typically these parties are two human beings, and the classic example of communication is an eye-to-eye conversation when spoken language was not yet developed [11]. Since we live in a new era and globally connected technologies and high-tech machines are part of our everyday lives, there’s are more to say about communication, which consists of the transmission, interpretation, and exchange of information. Thus, communication is one of the important parts of 4D Printing design evaluation, as it has repeatedly been shown in several studies [12]. By focusing on communication, decision-making in design that is usually subjective will make it much easier to achieve the goal [13].

Recently, theoretical and practical research topics on 4D Printing have gained increasing interest from numerous researchers in various disciplines and practices [14]. There is a wealth of information regarding 4D Printing technology since it is a current topic of interest in the technology field. However, finding related and reliable sources of information on how to communicate 4D Printing was a challenge for us as there were very few and limited studies. For this reason, our primary research is visual communication, and we work to communicate complex shape-shifting of 4D Printing ideas accessible by using symbols. Furthermore, we work to develop theoretical underpinnings for automated Charles Sanders Peirce signs semiotics during methods. Pierce was a philosopher and one of the pioneers or ‘founding fathers’ of semiotics theories in the 18th century. He made important discoveries in fields responsible for creating the general theory of signs. The Pierce theory of signs visually represents sets and our relationships [15]. Although he carried out this work centuries ago, signs and symbols were used since language did not exist. These early methods of communication have been taken seriously as an alternative to formal visual communications [16]. Pierce theory has been influential in this study to create ways to visually communicate the shape-changes behaviour of 4D Printing. Designers and engineers have actively changed the way of designing 4D Printing parts in which they communicate, address problems and ultimately generate solutions together.

To bridge the communication gap between engineers and designers in 4D Printing, a method of selecting communicative tools is being explored, as it forces communication in specific directions. As a result, you may limit the amount of unrelated information that can be introduced to the conversation and may interfere with the practice abilities of either participant. In this way, some of the challenges of selecting the correct information to transfer can eliminate. Further, researchers investigate how can symbol be a better communication tool to designers and engineers in 4D Printing. Based on these considerations, the study investigated the factors that influence the lack of communication in 4D Printing. The idea of creating a symbol for 4D Printing is to achieve information delivery and improve designers and engineers’ engagement with 4D Printing.

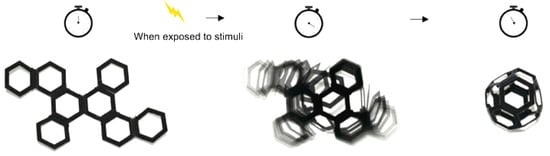

As illustrated in Figure 2 shows how the 4D Printing process referred to 3D Printing transforming over time. According to [17] the process begins with (1) 4D Printing made from 3D printed parts for the fabrication of multi-material structures (2) 4D printed structure is usually created by the combination of different types or grades smart-materials in the appropriate distribution into a single, one-time printed structure. (3) Stimuli is required to trigger the shape deformation of a 4D printed structure. (4) Next, the differences in material properties will lead to the desired shape-changes behaviour. (5) Finally, the 4D Printing parts can self-morphing or self-recovery [18].

Figure 2.

4D Printing process.

There are five communication barriers: physical, phycological, organisational, mechanical, and semantic barriers. The physical barriers are the environmental factor that obstructs or reduce the sending and receiving of communication. For example, physical distance, disturbing noises, or other interferences can lead to physical barriers. Second is the personal or social-psychological barriers, which arise from motivated attitudes, judgement, emotions, and social values, creating psychological distances similar to physical distances. Psychological distance prevents the communication or filters part of it out of cause misinterpretation as a person differs in their motive, attitudes or sentiments. Third, the communication barriers in organisational structure that create problems in communication, a filter of information by superiors, covering of information in their way, diversion of information, status, consciousness, and bossism are organisational in communication. Next is the semantic barrier, which is also called the language barrier. Semantic refers to a symbol that makes different meanings to a different person and leads to misunderstanding. The main symbols in the communication process are language, pictures and action. Lastly, the mechanical barriers include inadequate transmission of new facts, poor official layout, defective procedures and practices. The use of wrong media lead to power communication; it is imperative to overcome these communication barriers so that organisation can work effectively and smoothly [19].

1.2. The Influence of Visual Communication on 4D Printing

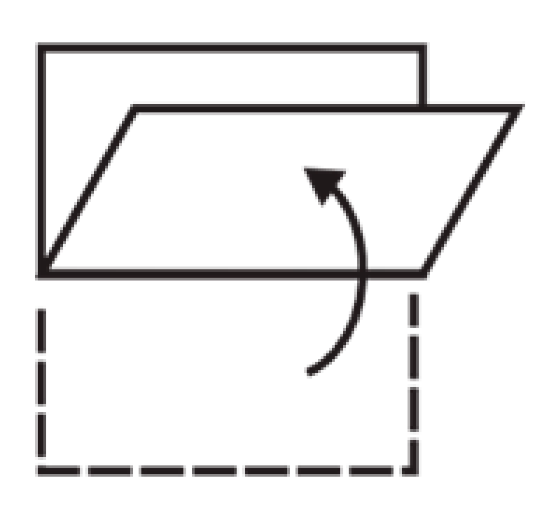

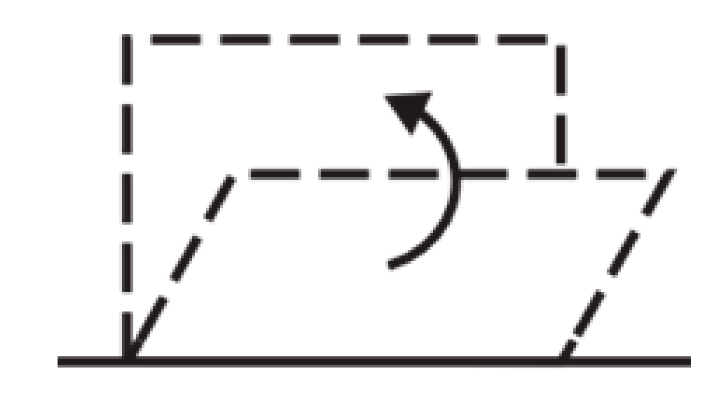

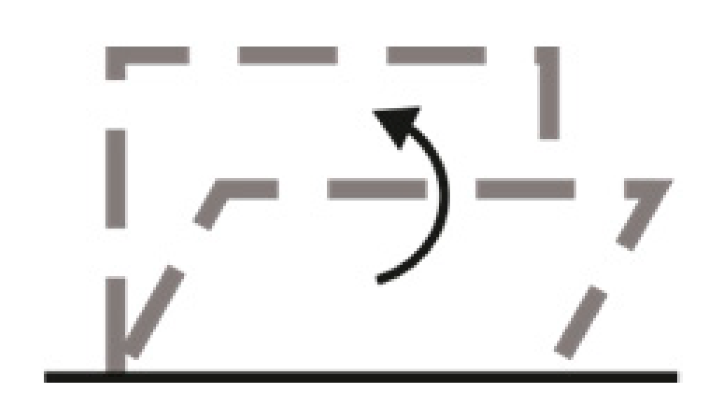

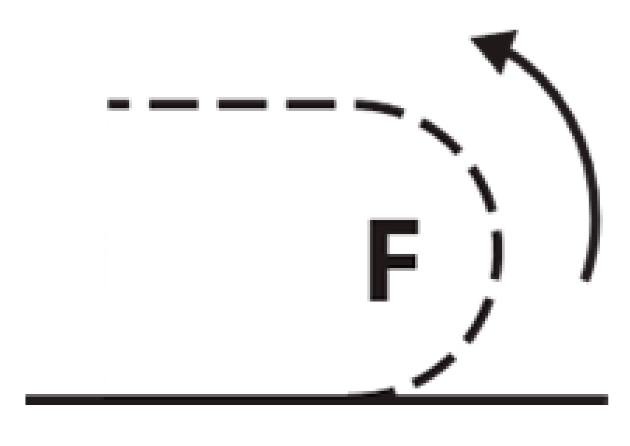

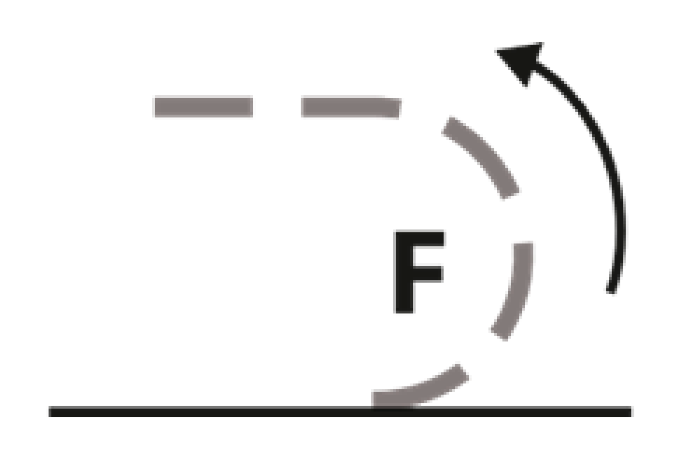

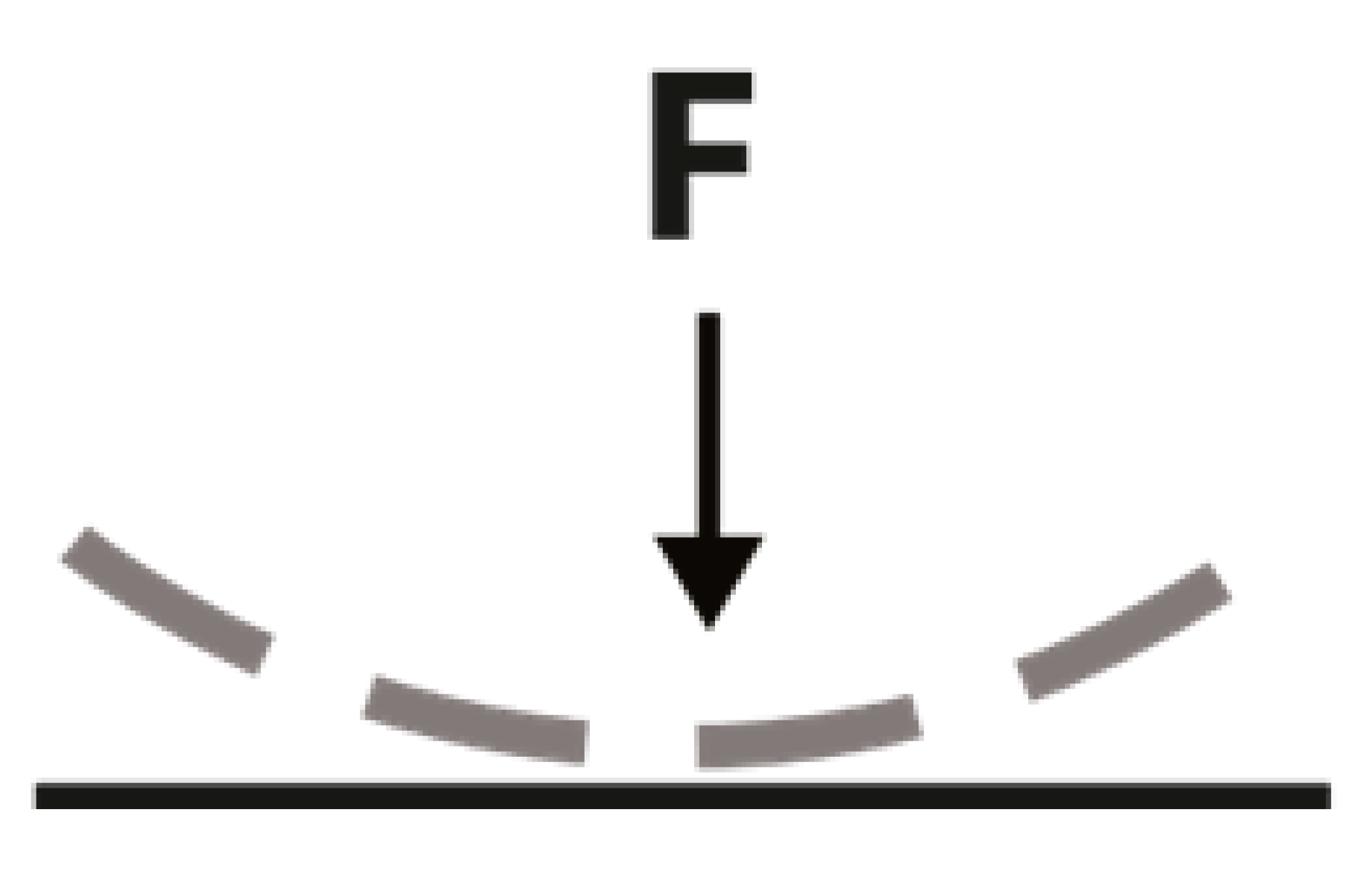

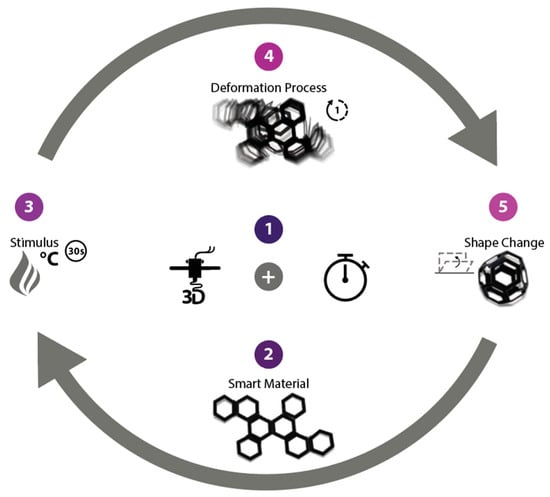

In this study, symbols were chosen to convey the core message effortlessly. This paper describes the study in which the main objective was to evaluate whether established symbols could effectively communicate the shape-change effect of 4D Printed parts. With the findings provided by [20], the researcher divided the 4D Printing shape changes behaviours into three stages from basic, complex and combination deformation processes. However, this study covered only the 11 shape-changes behaviours, as shown in Figure 3.

Figure 3.

The 11 shape-changes behaviours of 4D Printing.

The objective of this study was to develop a usable symbol 4D Printing information stage by including three main elements in the symbols design process. Our approach included (1) exploring the barriers of 4D Printing communication, (2) a user analysis for an effective communication tool completed by engineer and designer, (3) selection of alternative symbol designs based on the results of the survey expert advice, and design guidelines. (4) Implementation of final 4D Printing symbol design after being evaluated by the British Standards Institution (BSI) experts. (5) Structuring conceptual framework of the 4D Printing symbol information system with the selected symbols by designing a 4D Printing symbol website. As long as people have been writing, creative people have drawn out their ideas using different concepts and techniques [21]. Drawing can be divided into three types that designers and engineers use: conceptual sketches, diagrams, and technical drawings. Whenever we think about this drawing, we have to visualise and draw.

Visualisation can be defined as creating and manipulating what a person wants to draw or create in mind. Drawing can put the images they created in mind onto paper or another medium [22]. In the standard graphic form designers use, a conceptual sketch allows an idea to be expressed quickly. Next, diagrams often use abstract symbols rather than actual pictures to represent things [23]. Following the example shown in Table 1, the technical drawing presents the information necessary for the objects construction to serve as a reference to the engineer when the design is ready to build [24].

Table 1.

Example symbol used in standard technical drawing.

Whether spoken or written, human communication involves using words structured and conventional. The definition of semiotic in ‘Peirce’s Sign Theory’ is the study of signs and the use or interpretation, where the signs can be classified into three types: symbol, icon and index [25]. A symbol pattern refers to its object through interpretive habit or reference. The relationship is arbitrary or conventional rather than literal [26]. In this study, 4D Printing symbols convey communication for developing materials through processing and structural modifications and engineering design and manufacturing. It is challenging to select which elements need to be added to the overall symbols. The symbol with good interaction will eventually assist the completion of in-depth communication between designer and engineer in 4D Printing [27].

Based on previous research results, some of the development from the initial symbol sketch until the final process in my symbol library, as shown in Table 2, the design of the initial symbol was selected [28]. An experiment was conducted to explore participants’ degree of understandability. Online experiments suggest increasing information retrieval tasks using the proposed 4D Printing symbol. According to [29], online data collection is provided more useable data than other data collection methods. Furthermore, participants interactions with the online survey are standardised; as a result, interviewer bias is eliminated.

Table 2.

The symbol development process for shape-changes behaviours.

Moreover, symbol design has a good track record as a communication tool to transmit information [30]. Based on the International Organization for Standardization (ISO), ISO 19,027 symbols, as visual expressions internationally, solve the communication barriers if the symbols are understandable and applied regardless of regional or cultural differences [31]. Hence, the designer uses visual representation as a tool for an external process in various ideas through visualisation. This plan effectively utilises skills and is also suited for designers to develop visual communication skills supporting their nonverbal arguments in 4D Printing [32].

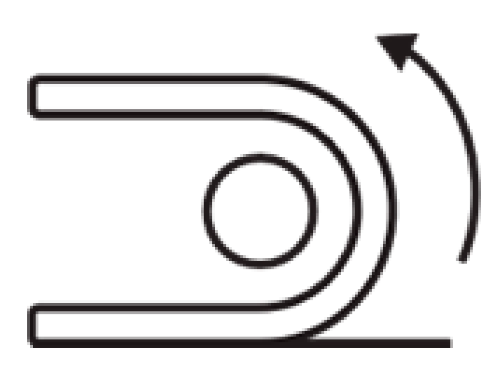

Table 3 shows the preferred 11 shape-changes symbols for 4D Printing by participants. As mentioned in the introduction, the capabilities of 4D Printing are to respond to the environment over time. 4D Printing, unlike 3D Printing, is characterised by its ability to shape-change the behaviour of the printed object [33]. Moreover, the shape-changes behaviours in 4D printed objects produced by the different external stimuli cause programmed morphing such as folding, contracting, wriggling, or other printed objects.

Table 3.

The most preferred 4D Printing 11 shape-changes behaviours symbol.

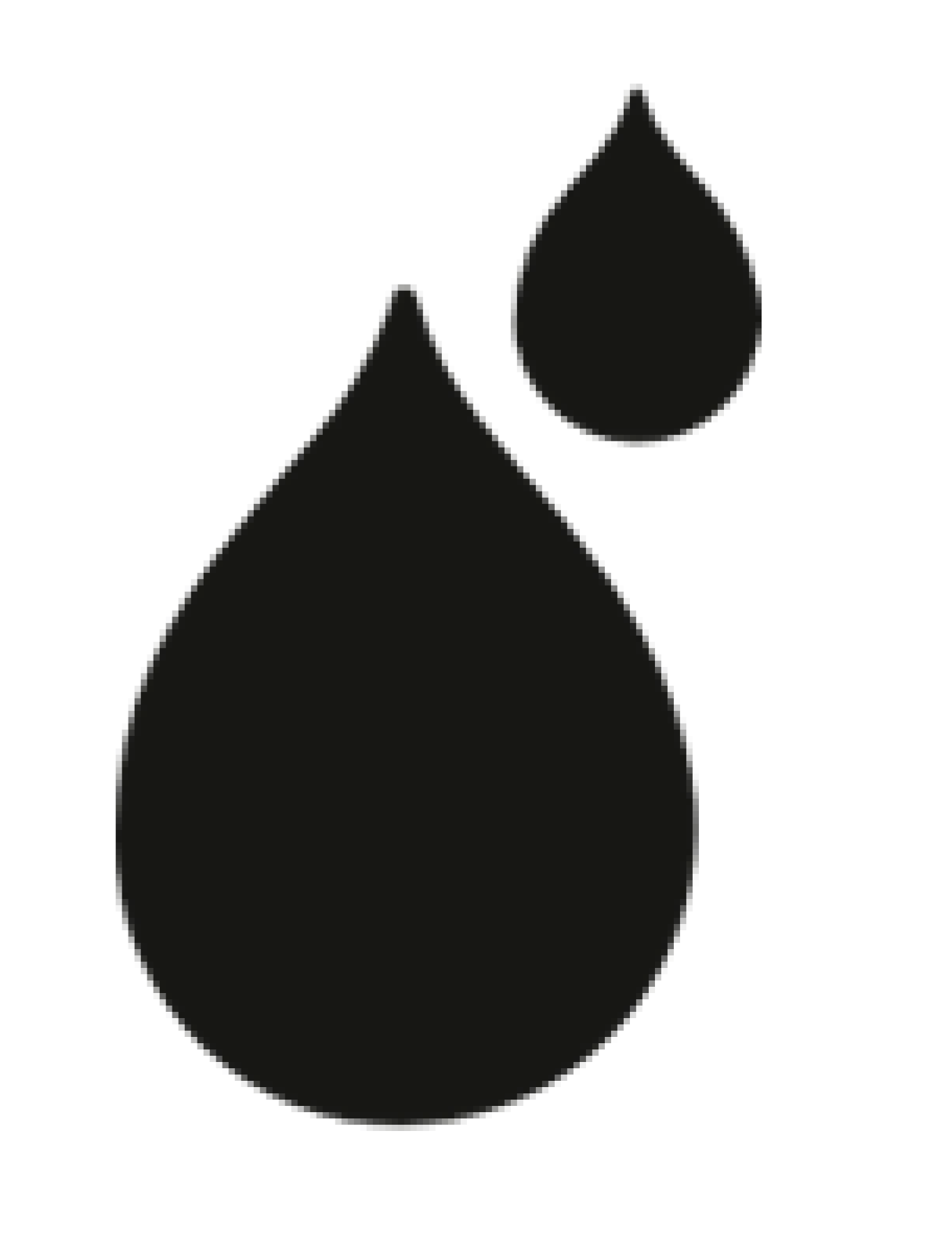

Table 4 shows the e set of five stimuli symbols for 4D Printing preferred by participants. A stimulus is something that elicits a response by design and material. The typical external stimuli causing the transformation in the properties of the material used in 4D Printing are heat, water, UV light, pH (potential of hydrogen), magnetic field and others [34].

Table 4.

The most preferred 4D Printing stimuli symbols.

2. Methodology

The previous study identified existing challenges for 4D Printing to be communicated during the early stages of the design process. We found that participants made random marks on paper, and there were no recognised or established symbols available for communication to represent 4D Printing shape-changes behaviours. It is also reported the outcomes of a focus group study that served as a preliminary evaluation of the conceptual framework.

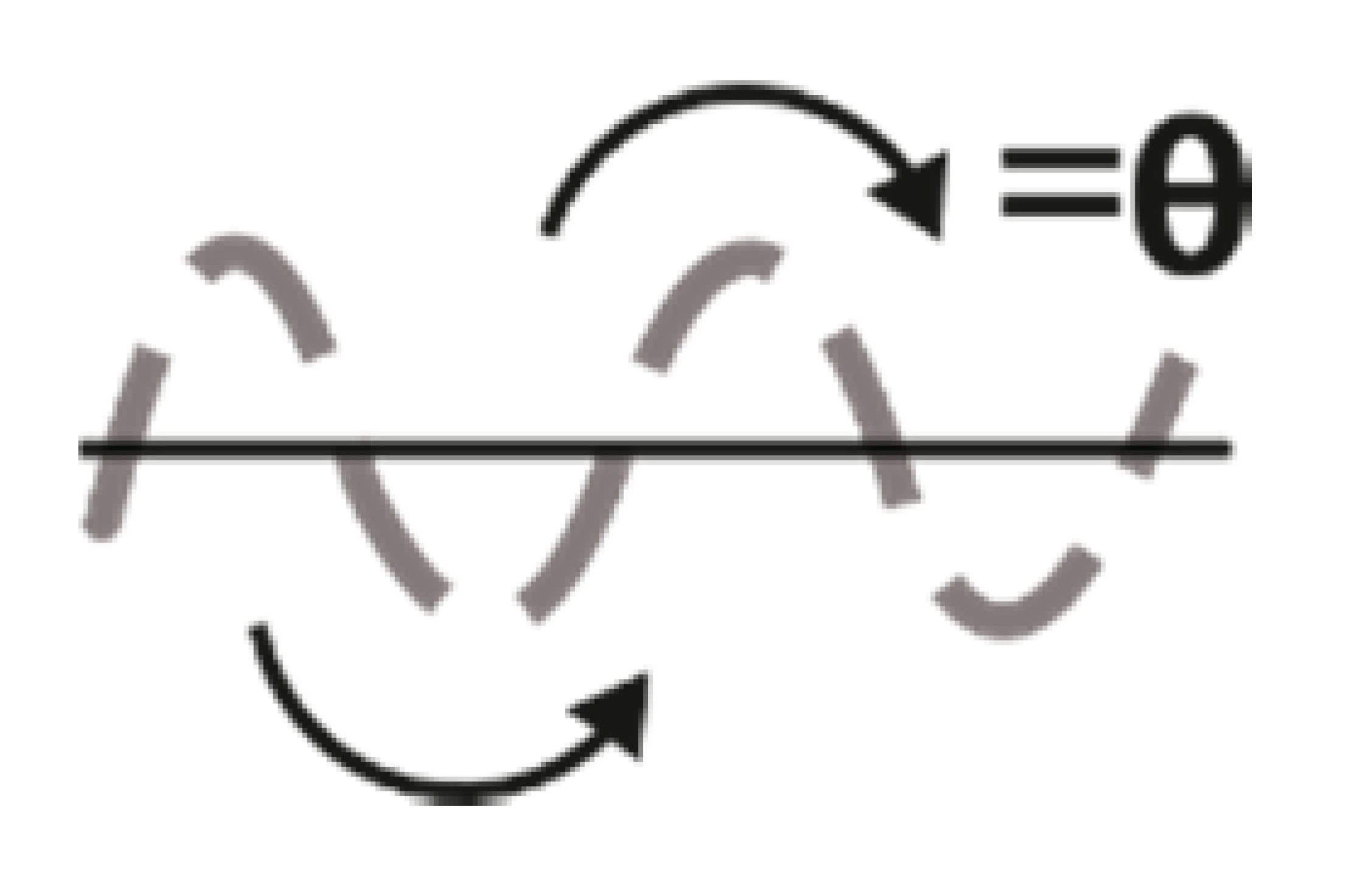

The 4D Printing symbol was developed in the earlier stage based on ‘enactivism’ as a methodology. Enactivism is a theory of learning about learning in which we learn new things within a context that we have partly created ourselves [35]. This investigation process was characterised by a flexible and dynamic interdependence between researchers and context [36]. In this study, iterative and reflexive processes of co-emergence have been developed and refined by integrating multiple perspectives and the continuous refinement of methods and approaches to data analysis. Before designing any symbols, we define symbols based on the main elements of 4D Printing that make them useful. However, the development of 4D Printing symbol designing and testing stages was developed using the user-centred development method. The type of symbols preferred and interpreted accurately is also considered the amount of recognition. These main elements for 4D Printing are Shape-change behaviour, Stimuli and Timed sequence. After the initial and three other development symbol designs were selected, a research instrument was undertaken to explore their degree of understandability.

The sample comprises a nonprobability convenience sample with sixty-five participants who participated in the study—using a mailing list to Brunel University London and Universiti Teknikal Malaysia postgraduate email for inviting people to participate in the online experiment. To get responses for our online experiment, we divided into two different backgrounds: designer and engineer. However, due to the limitations discussed above, participants were recruited with selected backgrounds, such as manufacturing engineers, product designers, graphic designers, and architects. However, knowledge of 4D Printing technology and how symbols work are required to obtain accurate results. To collect data, an instrument is designed (present in Results and Discussion). This instrument contains three tasks: ‘Elemental Arrangement, Insertion and Feedback’. The instrument we have created to collect data is an online experiment with different questions with different functions. A comparative analysis of the answers will identify similarities and differences. From the 4D Printing symbols developments shown in Table 5, we developed a conceptual framework to combine the 4D Printing elements to create an ideal symbol used as a communication tool. The conceptual framework found that the symbol is supported by the three main 4D Printing elements under different attributes.

Table 5.

List of the research instruments and tasks for the 4D Printing symbol development.

The methods for identifying sources for this study include a multiple research database. In this study, broad search terms were initially used to establish a list of research articles that were the primary sources and peer-reviewed. Then, the source was analysed according to several criteria, such as the source having to be in line with the purpose of the literature review based on the study’s research questions. The search terms selected for this literary analysis consisted of 4D Printing, communication, visual language, shape-changes, smart-materials, designers, engineers and manufacturing process. In considering the purpose of this study, each term used was selected based on its appropriateness and relevance. We also examined articles or journals that would characterise their respective fields.

In addition, we ensured that the majority of cited and references had the most recent publication dates, going back no further than 2010, as 4D Printing is a relatively new field. A few researchers were included from previous decades to establish foundational concepts that continue today. After considering these factors, we analysed the data itself.

When examining the data in the articles, we looked for statements that indicated proper research procedures being conducted. Before the broader study started, the study was reviewed by the Research Ethics Committee of the College of Engineering, Design and Physical Sciences (CEDPS) at Brunel University London before we conducted any research. Finally, in examining qualitative and quantitative data, we examined the collection procedures data to verify that the study had adhered to practices that would ensure reliability and validity.

3. Results and Discussion

3.1. Experiment 1: Elemental Arrangement

Participants took part in the study via a web link provided by the researcher that navigated them to an online experiment. Sixty-five designers and engineers from different backgrounds were participated to test the design of the symbols. Before beginning, participants were asked to read and agree with an informed consent form. The experiment was divided into three parts’ elemental arrangement’, ‘insertion’, and ‘feedback’. Before taking the questions, the participants were given a brief overview and explanation of the study. The ‘elemental arrangement’ task was performed first. Participants were not timed; they were given sufficient time to determine their 4D Printing symbol arrangement preferences.

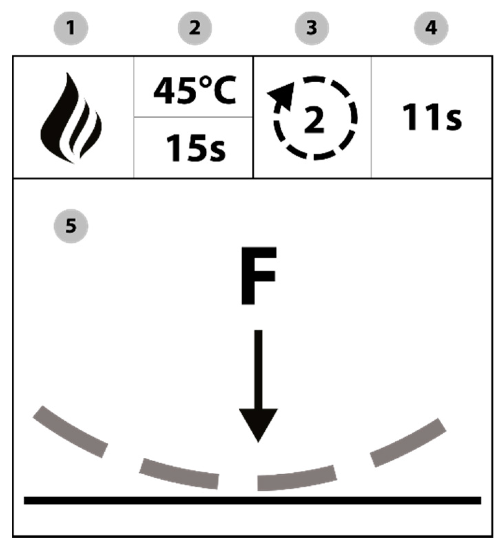

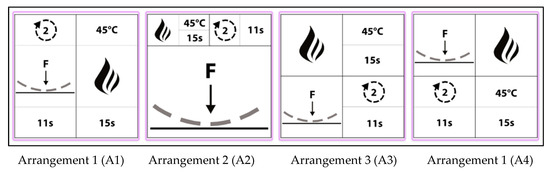

The first experiment of this research is called ‘elemental arrangement’. The task’s objective is to determine which symbol arrangement is suitable to represent as the complete 4D Printing symbol. In this first experiment task, participants were asked to select the preferable arrangement on the website provided. The set of four 4D printing alternative arrangement symbols was served, as shown in Figure 4. The four arrangement boxes represent each of the five elements for 4D Printing: ‘shape changes, stimuli, timed sequence, speed, intensity and duration of stimuli being applied’. The highest rates of preference can measure the effectiveness of this task. This result indicates designers and engineers have similarities on preferred the ‘Arrangement 2 (A2)’ to be the most preferred arrangement for the 4D Printing symbol.

Figure 4.

The four alternative arrangements of 4D Printing symbols.

The results obtained from the questionnaire revealed that ‘Arrangement 2 (A2)’ became the participants highest ratings to the preferable symbol arrangement, as shown in Figure 5a. There was strong correspondence among designers. This result may be because the shape-changes behaviour symbol in ‘Arrangement 2 (A2)’ is more significant and transparent than the other arrangement, as shown in Figure 5b. With these arrangement tasks, we can use the preferred arrangement for the 4D Printing symbol as a tool for designers and engineers to communicate with each other.

Figure 5.

(a). Elemental task result (b). The most suitable arrangement.

3.2. Experiment 2: Insertion

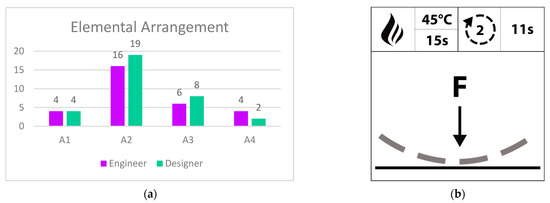

To examine whether the 4D Printing symbols were able for communicating the 4D Printing, researchers created the second experiment. The goal of this task was to determine whether the proposed 4D Printing symbols were understandable. The symbols used in this experiment were those obtained from the previous survey. Participants were required to complete three tasks in the ‘insertion’ part. Participants needed to arrange the most suitable symbols for 4D Printing in technical drawing by observing the animation provided on the website prepared.

In addition, by adding the animated 3D parts, the researcher gives participants an idea of how the 4D printing part transforms. The participants can play the animation repeatedly to give them an idea of how 4D Printing is deformed. Then, participants were asked to match the 4D Printing symbols to the correct boxes provided in the technical drawing, as shown in Figure 6. Additionally, we envision conducting usability testing with the designer and engineer to assess and improve the design.

Figure 6.

A task designed for the ‘Insertion’.

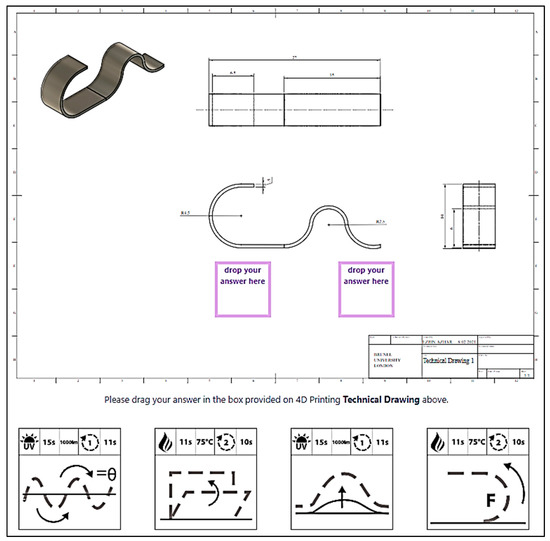

The influence on approached symbol effectiveness and efficiency to use for communicating 4D Printing were tested on this experiment. Figure 7a,b show the results from the first question in the ‘insertion task’. Participants correctly answer the question in which they need to choose the ‘bending’ and ‘waving’ symbols. However, for the waving, some participants choose C where it represents ‘buckling’, which we think this decision making made by participants who just focus on the sample figure rather than read the question correctly and lead to picking the wrong symbols.

Figure 7.

(a). Results from (Insertion task-Question1—Bending) (b). Results from (Insertion task-Question1—Waving)

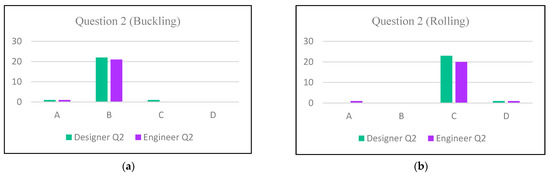

Next, Figure 8a,b shows the results from the second question in the ‘insertion task’. Participants need to answer the correct symbols for ‘buckling’ and ‘rolling’. There were tiny differences in participants answers. It means that the designer and engineer agreed and understood which symbol represented the 4D Printing shape-changes symbol for buckling and rolling.

Figure 8.

(a). Results from (Insertion task-Question2—Buckling) (b). Results from (Insertion task-Question2—Rolling)

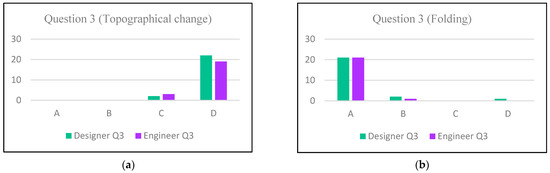

For the final task question in the ‘insertion task’ section shown in Figure 9a,b, the participant was asked to choose the correct symbols for ‘topographical change’ and ‘folding’. The results are delighted where almost all participants answer correctly. The survey found that most participants chose the correct answer for all three questions in the ‘Insertion’ task to match the 4D Printing symbols from the experiment. According to participants’ feedback, they inform that the animation provided was intended to help them better understand to match the 4D Printing symbol correctly and that they would later understand the meanings of the symbols. After completing entire tasks in the second experiment, participants continued to the next section to complete the feedback session.

Figure 9.

(a). Results from (Insertion task-Question3—Topographical change) (b). Results from (Insertion task-Question3—Folding)

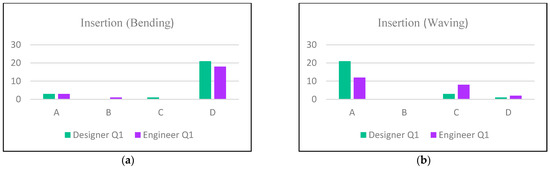

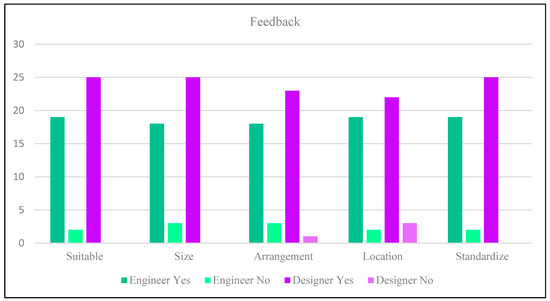

At the end of the experiment, we asked six questions to participants to get their feedback regarding the 4D Printing symbol. As a measure of comprehending 4D Printing, participants were asked to decide if they agreed or disagreed with the questions asked about the symbol. If they did agree, the participant should click the button “Yes”. If they disagreed with the symbol’s questions, they should press the button “No”. Positive feedback was received concerning its usefulness and usability. The experiments show that designers and engineers can quickly communicate to the 4D Printing design part using the approach symbols.

As shown in Figure 10 above, the first feedback part mapped out 4D Printing symbol usage with the following questions: “Are the symbols shown suitable to communicate the information for 4D Printed parts?”. Next, for the second question, participants were asked about the dimension of the 4D Printing symbol “Are the size of the symbols clear?”. In the third question, the participants were asked to “Is the arrangement of the symbols clearly communicated?”. The following question asked participants to give their opinion “ Do you think the location of the symbols inside the technical drawing is suitably placed?”. Finally, the feedback question asked, “Do you think having standardised symbols can help designers and engineers to communicate 4D Printing information?”.

Figure 10.

Participants feedback results.

At the end of the feedback question section, participants were encouraged to give as detailed and specific descriptions as they could of their suggestions to improve the 4D Printing symbol. While discussing the feedback, some of the participants’ suggestions suggested adding colours to the approached symbols. Next, participants also suggested adding the type of material and size of the 4D Printing part. Lastly, they give an opinion to include the required time for the component to be placed in the stimuli.

4. Analysis

This research attempts to offer a clearer picture of communication using symbols in 4D Printing. The elemental arrangement in Table 6. explained the five elements in 4D Printing: stimuli, the intensity of stimuli, duration of stimuli being applied, timed sequence, speed of shape change, and the shape-change behaviour associated with the 4D Printed part. The researcher also addresses the barrier of using a symbol in technical drawing since no existing 4D Printing symbols have been created.

Table 6.

4D Printing combination symbol.

There will always be ongoing specific work done as different industries or sectors recognise either new processes or new controls to be done or new messages to be sent. Standardisation in graphical symbols is a new language without words that can be demonstrated and communicated successfully [37]. Precision and consistency are the keys when we are trying to communicate a message. This is why we have presented our approached 4D Printing symbols to British Standards Institution (BSI) and Technical Product Requirements (TPR) teams. This meeting was to get the evaluation from both teams regarding the approached 4D Printing symbols. We also asked them a few questions to get feedback from both teams. As a result, they considered the symbols ‘timeless’ and could be standardised symbols by expanding the research area.

The online experiment process was interesting to interact with; they assumed the task designs were more effective, more usable, and more understandable. In addition, participants also believed that this process produces better designs, which will allow for instantaneously using by them for communicate in 4D Printing. The symbols designed were tested based on a focus group to verify their usability and the importance of communication between engineers and designers in designing 4D Printing parts. Participants’ feedback will be considered in future research, such as to added more elements into the 4D Printing symbol together as one complete symbol.

This experiment revealed both tasks showed that acquaintance may have influenced participants preferences. The outcomes of this study confirm the findings of Easterby and Hakiel (1981), who illustrate the effects of acquaintance on participants [38]. Thus, despite the significant effects of acquaintance, participants preferred the approached 4D Printing symbol should be considered meaningful [39].

Throughout this paper, by using 3D Printing symbol design as a case study, this study has identified the practices and attitudes of designers and engineers toward user involvement in graphic symbol design at the conceptual design stage. Differences between engineers and designers were also discussed. Furthermore, related to the development of this study, the focus of communication study has more towards functionality and usability of inspirational interaction design and semantic meanings conveyed by pictorial or visual display. To support this statement, the primary function of using visual displays is to utilise specific conventions to communicate information by using semantic displays.

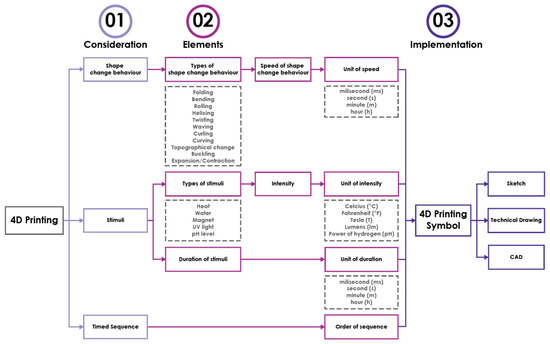

5. Conceptualisation of 4D Printing Symbol Framework

There is no doubt that 4D Printing is not a simple printing process and requires a combination of several components [40]. We develop a conceptual framework to enhance communication between product designers and manufacturing engineers when designing 4D Printed parts to address these issues. The conceptual framework of the 4D Printing Symbol has three stages of analysis, as in the above Figure 11. A conceptual framework is an analytical tool with several variations and context which illustrates what we expect to find through the research. It defines and visualises the relevant variable for the study, maps out how they are related, and organises ideas. After defining our research questions, we outlined a conceptual framework that explains the constructs to be studied visually or in words and their relationships. We develop a conceptual framework which the purpose of (1) deciding which variables are relevant to the study, (2) deciding how to define variables during data analysis and (3) interpreting models results. Using this approach, a general explanatory model would include one outcome and multiple hypotheses associated factors. In this study, we used a sequential diagram to demonstrate related pathways hypothesised and measured between an exposure and an outcome for the conceptual framework.

Figure 11.

The conceptual framework for the 4D Printing symbol, created by the authors as per related literature.

This study attempts to develop an effective 4D Printing symbol system. We provide a conceptual framework to support the right approach and methods to design a tool to communicate 4D Printing. The 4D Printing Symbol (4DPS) conceptual framework aims to improve the symbol implementation of 4D Printing communication. As a conceptual framework for 4D Printing symbols, it is intended to support only certain aspects of 4D Printing symbols, such as the collection of 11 shape-change behaviour, the type of stimuli, and information about the timed sequence. This conceptual framework enhances communication between designers and engineers when designing 4D Printed parts. To frame a crucial part of our conceptual framework design system in this research, we place the general phase in the boxes and list specific variables under those phases. We have divided it into three phases: ‘consideration’, ‘elements’, and ‘implementation’, as shown in Figure 11.

5.1. Phase1: Considerations

Every phase and variable are connected in the first phase of the 4DPS conceptual framework. Under the ‘consideration’, we identified the three main elements of 4D Printing, which are the shape-changes behaviour, stimuli, and timed sequence. The first element in 4D Printing is (shape-changes behaviour), which is an action of the 4D Printing objects deformed, for example, folding, bending, twisting and others. (Stimuli) is the second element where it will change the shape according to the programmable setting. And the third element to be considered in 4D Printing is (timed sequence) since sequence means that every detail is connected, step by step. At the same time, order is a generalised term for things to be in order, no matter if it lacks one process or detail as long as it is the next closest one.

5.2. Phase2: Elements

The second phase involves the key ‘elements’ similar to ‘consideration’. To be more specific, in this phase, we specified all the details of 4D Printing main elements. We divided it into nine variables to communicate the 4D Printing symbol. The first variable is the (type of shape-change), where we listed the 11 shape-changes of 4D Printing, which are folding, bending, rolling, helixing, twisting, waving, curling, curving, topographical change, buckling and expansion or contraction in the dotted line box. Then, we added the (speed of shape-change), speed here taken from where 4D Printing can change shape over time. To show the accurate deformation time of the shape-changes, we added another variable called the (unit of speed). The International System of Units (SI) contains the unit of time with a symbol to define millisecond, second, minute and hour.

Next, we divided it into two categories for the stimuli variable where all of it connected. First is the (type of stimuli), where we listed five common stimuli: heat, water, magnet, UV light, and pH level in the dotted line box. Moreover, since 4D Printing is a known object made by 3D printed with time adding response and external stimuli, we need an (intensity). The (unit of intensity), Celsius, Fahrenheit, Tesla, Lumens, and hydrogen power are defined. Then, (duration of stimuli), which is related to (unit of duration) also using the (SI) to show 4D Printed object takes time to morph or recovery. Lastly, we added (order of sequence) to describe the timed sequence, to arrange the period for 4D Printing when deformation process.

This phase focuses on how and where designers and engineers can use this 4D Printing symbol to communicate. These graphic symbols also can be applied in the near future, such as in the early design stage, where designers use sketches to visualise their idea. In addition, it is also can be used in technical drawing, where engineers used a symbol before the manufacturing process. 4D Printing symbols can also be used in Computer-Aided Design (CAD) software. It can help increase productivity, improve the quality of designs, effectively communicate design information for the manufacturing process. It includes only 11 shape-changes in 4D Printing for searching. Instead, designers and engineers are expected to combine symbols with other tools to fulfil these functions. However, this 4DPS conceptual framework is not intended to be an integrated symbol system but becomes one of the communication approaches.

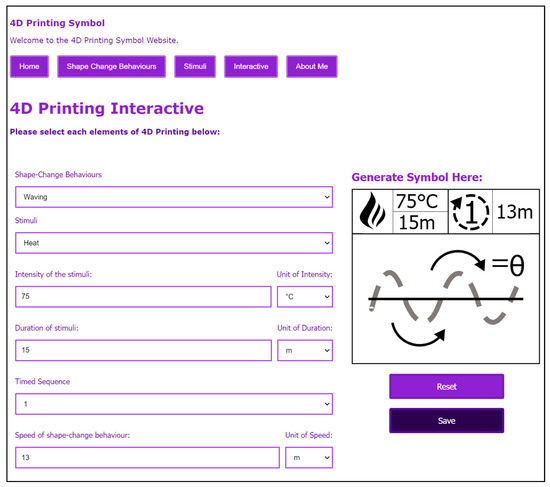

As part of this study, symbols are used to relay information between engineers and designers on the design aspect of 4D Printing. To use the 4D Printing graphic symbols, the researcher created a toolkit (website: https://symbols.ezrinazhar.com/, access on 27 December 2021 ) for designers and engineers to communicate with each other. The toolkit also shows the step by step on how to use the interactive part in the website. Figure 12 illustrates how all the elements of 4D Printing can be combined into symbols for 4D Printing.

Figure 12.

4D Printing symbol toolkit created by Ezrin Azhar 2021.

6. Conclusions and Future Work

This 4D Printing symbol conceptual framework can significantly reduce development times, reduce errors in system specification communication and ultimately benefit the end consumer in a quality 4D Printing product. Moreover, this whole study was undertaken at the University of Brunel London, Universiti Teknikal Malaysia (UTM) and British Standard Institution (BSI), demonstrating the critical and significant impact academic research can have in the industry. To conclude, we make several recommendations for future implementations of 4D Printing symbols. This study’s main theoretical and methodological contribution is the analysis of visual usability and effectively as a cognitive process, that is, the clarification of the partly unconscious process. Users find symbols visually practical and usable to communicate 4D Printing. There are many other aspects of the 4D Printing technology that make it a great choice for applications in addition to its own advantages.

Our conclusion derives from our research; symbols analysis is necessary to ensure they are easily understood and similarly interpreted across a different field that can be used from sketching for the idea until technical drawing and perhaps CAD software. Regardless, a symbol is significant in design or artwork, and it is a massive part of this art conversation. With the development of science and technology, there are more and more communication methods, advanced, convenient and fast ways of communication. It is how we communicate, what we ponder about, and what makes it possible for design to have meaning. We hope that our approach can play a role and be helpful to engineers and designers communicating in designing 4D Printing parts. And also to induce innovation in both 4D Printing processes and their applications.

Author Contributions

Conceptualization, F.E.A.; investigation, F.E.A.; writing—original draft preparation, F.E.A.; writing—review and editing, E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of United Kingdom, and approved by the Institutional Review Board (or Ethics Committee) of BRUNEL UNIVERSITY LONDON (protocol code 18717-LR-Oct/2019- 20769-1 and 28 October 2019).” for studies involving humans.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fernanda, C.G.; Bhesh, R.B.; Sangeeta, P.; Min, Z. Fundamentals of 3D Food Printing and Applications; Elsevier Science & Technology: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Longhitano, G.A.; Nunes, G.B.; Candido, G.; da Silva, J.V.L. The role of 3D Printing during COVID-19 pandemic: A review. Progress Addit. Manuf. 2019, 6, 19–37. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef] [Green Version]

- Skylar, T. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2019, 26, 564–585. [Google Scholar] [CrossRef]

- Shie, M.-Y.; Shen, Y.-F.; Astuti, S.D.; Lee, A.K.-X.; Lin, S.-H.; Dwijaksara, N.L.B.; Chen, Y.-W. Review of Polymeric Materials in 4D Printing Biomedical Applications. Polymers 2019, 11, 1864. [Google Scholar] [CrossRef] [Green Version]

- Mondal, K.; Tripathy, P.K. Preparation of Smart Materials by Additive Manufacturing Technologies: A Review. Materials 2021, 14, 6442. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H. Technological considerations for 4D Printing: An overview. Progress Addit. Manuf. 2018, 3, 95–107. [Google Scholar] [CrossRef] [Green Version]

- Judge, S.; Randall, N.; Goldbart, J.; Lynch, Y.; Moulam, L.; Meredith, S.; Murray, J. The language and communication attributes of graphic symbol communication aids—A systematic review and narrative synthesis. Disabil. Rehabil. Assist. Technol. 2020, 15, 652–662. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Li, H.-L.; Wu, J.; Bi, W. Cross-Cultural Communication in Design Collaboration, Cross-Cultural Design. Methods Tools Users 2018, 31–42. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H.; Nam, S.W.; Azhar, E.F. Programming 4D Printed Parts through Shape-Memory Polymers and Computer-Aided-Design. In International Conference of Progress in Digital and Physical Manufacturing; Springer: Cham, Switzerland, 2019; pp. 143–151. [Google Scholar]

- McKay, E.N. UI Is Communication: How to Design Intuitive, User Centered Interfaces by Focusing on Effective Communication; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Griffin, J. The State of Creativity: The Future of 3D Printing, 4D Printing and Augmented Reality; Edward Elgar Publishing: Cheltenham, UK; Camberley, UK; Northampton, MA, USA, 2019. [Google Scholar]

- Berger, A.A. What Objects Mean: An Introduction to Material Culture, 2nd ed.; Routledge, Taylor & Francis Group: Abingdon, UK, 2016; p. 272. [Google Scholar]

- Binger, C.; Kent-Walsh, J.; Harrington, N.; Hollerbach, Q.C. Tracking Early Sentence-Building Progress in Graphic Symbol Communication. Lang. Speech Hear. Serv. Sch. 2020, 51, 317–328. [Google Scholar] [CrossRef]

- Momeni, F.; Liu, X.; Ni, J. A review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Azhar, F.E.; Pei, E. Investigating the Communication of 4D Printing among Product Designers and Manufacturing Engineers; Brunel University Research Archive(BURA): London, UK, 2019. [Google Scholar]

- Nam, S.; Pei, E. A taxonomy of shape-changing behavior for 4D printed parts using shape-memory polymers. Progress Addit. Manuf. 2019, 4, 167–184. [Google Scholar] [CrossRef] [Green Version]

- Technical Product Documentation and Specification, 6th ed.; BSI Standards Publication: London, UK, 2011; p. 100.

- Schmidgall, S.P.; Eitel, A.; Scheiter, K. Why do learners who draw perform well? Investigating the role of visualisation, generation and externalisation in learner-generated drawing. Learn. Instruct. 2019, 60, 138–153. [Google Scholar] [CrossRef]

- Jonson, B. Design ideation: The conceptual sketch in the digital age. Des. Stud. 2005, 26, 613–624. [Google Scholar] [CrossRef]

- Simmons, C.H.; Maguire, D.E.; Phelps, N. Manual of Engineering Drawing: Technical Product Specification and Documentation to British and International Standards, 4th ed.; Elsevier: Amsterdam, The Netherlands; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Gallegos, S.A. Models as Signs: Extending Kralemann and Lattman’s Proposal on Modeling Models within Peirce’s Theory of Signs; Springer: Cham, The Netherlands, 2019; Volume 196, pp. 5115–5136. [Google Scholar]

- Barham, L.; Everett, D. Semiotics and the Origin of Language in the Lower Palaeolithic. J. Archaeol. Method Theory 2021, 28, 535–579. [Google Scholar] [CrossRef]

- Trpković, A.; Subotić, I.; Reković, P.; Vukobratović, I.; Mostafa, N. Standardisation, design and use of graphic symbols in traffic engineering. Put Saobraćaj 2018, 64, 43–47. [Google Scholar] [CrossRef]

- Azhar, F.E.; Pei, E. An Exploratory Study about Communicating 4D Printing between Product Designers and Manufacturing Engineers. Des. Cult. Cumulus Conf. Proc. Roma 2021. Available online: https://cumulusroma2020.org/proceedings-files/DC(s)_MAKING_track.pdf (accessed on 19 November 2021).

- Rhodes, S.D.; Bowie, D.A.; Hergenrather, K.C. Collecting behavioural data using the world wide web: Considerations for researchers. J. Epidemiol. Commun. Health 2003, 57, 68–73. [Google Scholar] [CrossRef] [PubMed]

- Salman, Y.B.; Cheng, H.-I.; Patterson, P.E. Icon and user interface design for emergency medical information systems: A case study. Int. J. Med. Inf. 2011, 81, 29–35. [Google Scholar] [CrossRef]

- IOS. ISO 19027: Design Principles for Communication Support Board Using Pictorial Symbols; International Organization for Standardisation: Geneva, Switzerland, 2016. [Google Scholar]

- Cezzar, J. Teaching the Designer of Now: A New Basis for Graphic and Communication Design Education. J. Des. Econ. Innov. 2020, 6, 213–227. [Google Scholar] [CrossRef]

- Apsite, I.; Biswas, A.; Li, Y.; Ionov, L. Microfabrication Using Shape-Transforming Soft Materials. Adv. Funct. Mater. 2020, 30, 1908028. [Google Scholar] [CrossRef] [Green Version]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct Ink Writing Based 4D Printing of Materials and Their Applications. Adv. Sci. 2020, 7, 29. [Google Scholar] [CrossRef]

- Lozano, M.-D. Using enactivism as a methodology to characterise algebraic learning. ZDM Math. Educ. 2015, 47, 223–234. [Google Scholar] [CrossRef]

- Trigueros, M.; Lozano, M.D. Developing Resources for Teaching and Learning Mathematics with Digital Technologies: An Enactivist Approach. Learn. Math. 2007, 27, 45–51. [Google Scholar]

- Karal, Y.; Karal, H.; Silbir, L.; Altun, T. Standardization of a Graphic Symbol System as an Alternative Communication Tool for Turkish. Educ. Tec. Soc. 2016, 19, 53–66. [Google Scholar]

- Ng, A.W.; Chan, A.H. Visual and cognitive features on icon effectiveness. In Proceedings of the International Multiconference of Engineers and Computer Scientists, Hongkong, China, 19–21 March 2008; Volume 2. [Google Scholar]

- Leiman, T. Where are the graphics?: Communicating legal ideas effectively using images and symbols. Legal Edu. Rev. 2016, 26, 47–67. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.C.K.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).