1. Introduction

With given elastic and damping features, passive vehicle suspensions show poor ride quality when traveling in severe operating conditions, e.g., low frequency bumps, pit holes, and high frequency road irregularities [

1]. In contrast, active vehicle suspensions (AVSs) adjust these properties to external disturbances in a broadband frequency range for improving ride comfort and handling performance [

2]. Semi-active suspensions provide a compromised solution between passive and active suspensions in terms of performance and cost (i.e., energy consumption) [

3,

4].

The linear quadratic Gaussian (LQG) and linear quadratic regular (LQR) techniques have been used in the design of AVSs [

5,

6,

7,

8]. In these LQG/LQR-based AVS designs, forward speed, payload, center of gravity (CG) position, and other system parameters are generally assumed as constants. It is demonstrated that these LQG/LQR-based controllers exhibit poor robustness to operating condition variations, parametric uncertainties, unmodelled dynamics, and external disturbances [

9,

10].

To address the poor robustness of these LQG/LQR-based controllers, robust control techniques, e.g.,

[

11] and sliding-mode control [

12,

13,

14,

15], have been applied to the design of active vehicle safety systems. Robustness is a fundamental requirement for a controller design due to the differences between the dynamic model utilized for devising the controller and the actual physical system [

16]. Attempts have been made to compare the robust control characteristics of

/

-synthesis control and sliding-mode control for different active vehicle safety systems [

17,

18]. The

control technique has been successfully used for addressing robustness problems on models with external disturbances and parametric uncertainties [

19,

20,

21].

However, due to the complex conflicting suspension design requirements on ride quality, suspension working space, and dynamic tire loading [

22], the

-based AVS controllers reported in the literature have not adequately addressed the trade-off design problem [

23]. Moreover, one of the challenges in the

controller design is parameters’ tuning for weighting functions [

16]. The weighting functions pose significant impacts on the performance and robustness of the respective

controller design. Conventionally, the parameters of weighting functions are tuned by the trial and error approach [

24]. This parameter tuning process is time-consuming and tedious.

To tackle the aforementioned problems associated with the -based AVS controller designs, this paper proposes a design synthesis method for the controller of AVSs. A robust loop-shaping controller (LSC) is designed for an AVS of a vehicle represented by a quarter-car model. In the controller design, vehicle parametric uncertainties are considered. The frequency weighting functions are specified by selecting optimal values for the parameters through solving a multi-objective optimization problem with the expensive computation loads handled by a parallel computing technique provided in Matlab. Numerical simulation is performed to demonstrate the effectiveness of the proposed design synthesis method.

The remainder of the paper is organized as follows.

Section 2 introduces the vehicle model.

Section 3 formulates the

controller design problem. The proposed design synthesis method is described in

Section 4.

Section 5 presents selected simulation results. Conclusions are drawn in

Section 6.

2. Vehicle Model

To investigate the ride comfort of road vehicles, various dynamic models have been generated and used. In particular, to study the ride comfort and handling characteristics of a passenger car, a 7 degrees of freedom (DOF) ‘full-car’ model was proposed [

4,

25]. In this model, the bounce, roll, and pitch of the vehicle body, as well as the bounce of the four wheels are considered. Assuming that the car travels on a good road and the difference between right and left wheel track undulations can be ignored, we may neglect the roll motion of the vehicle body, and the 7-DOF model may be reduced to a 4-DOF ‘half-car’ model [

25]. In the 4-DOF model, the bounce and pitch of the vehicle body, as well as the bounce of the front and rear wheels are taken into consideration. For the half-car model, it is assumed that the sprung mass, i.e., the mass of the vehicle body, is distributed at three points, that is, the point of attachment of front suspension to the vehicle body, the CG, and the point of attachment of rear suspension to the vehicle body. Considering the fact that for conventional passenger cars, the sprung mass distribution coefficient is within the range of 0.9 to 1.0 [

26], the concentrated mass at the CG of the half-car model is approximately zero, and the motions of the front and rear suspensions of the half-car model are uncoupled. Thus, the 4-DOF half-car model can be further simplified and reduced to a 2-DOF ‘quarter-car’ model, which considers the bounce of the sprung and unsprung mass [

15]. Note that the sprung mass distribution coefficient is defined as

, where

denotes the radius of gyration of the half-car sprung mass with respect to the lateral axis (i.e., y axis) of the body fixed coordinate system,

the distance between the CG to the front axle, and

the distance between the CG to the rear axle.

A road vehicle represents a sophisticated vibration system with many degrees of freedom. In general, the vehicle model fidelity increases with the degrees of freedom of the model. However, the analysis burden becomes increasingly heavy while increasing the degrees of freedom. It is rational to simplify the complex vibration system by considering only its major motions. To gain a qualitative insight into the functions of the suspension and, in particular, the effects of the sprung and unsprung mass, spring stiffness, and damping on vehicle vibrations, a linear 2-DOF quarter-car model may be used [

26]. With the aforementioned considerations, this study selects the linear 2-DOF quarter-car model to explore the robust controllers for AVSs.

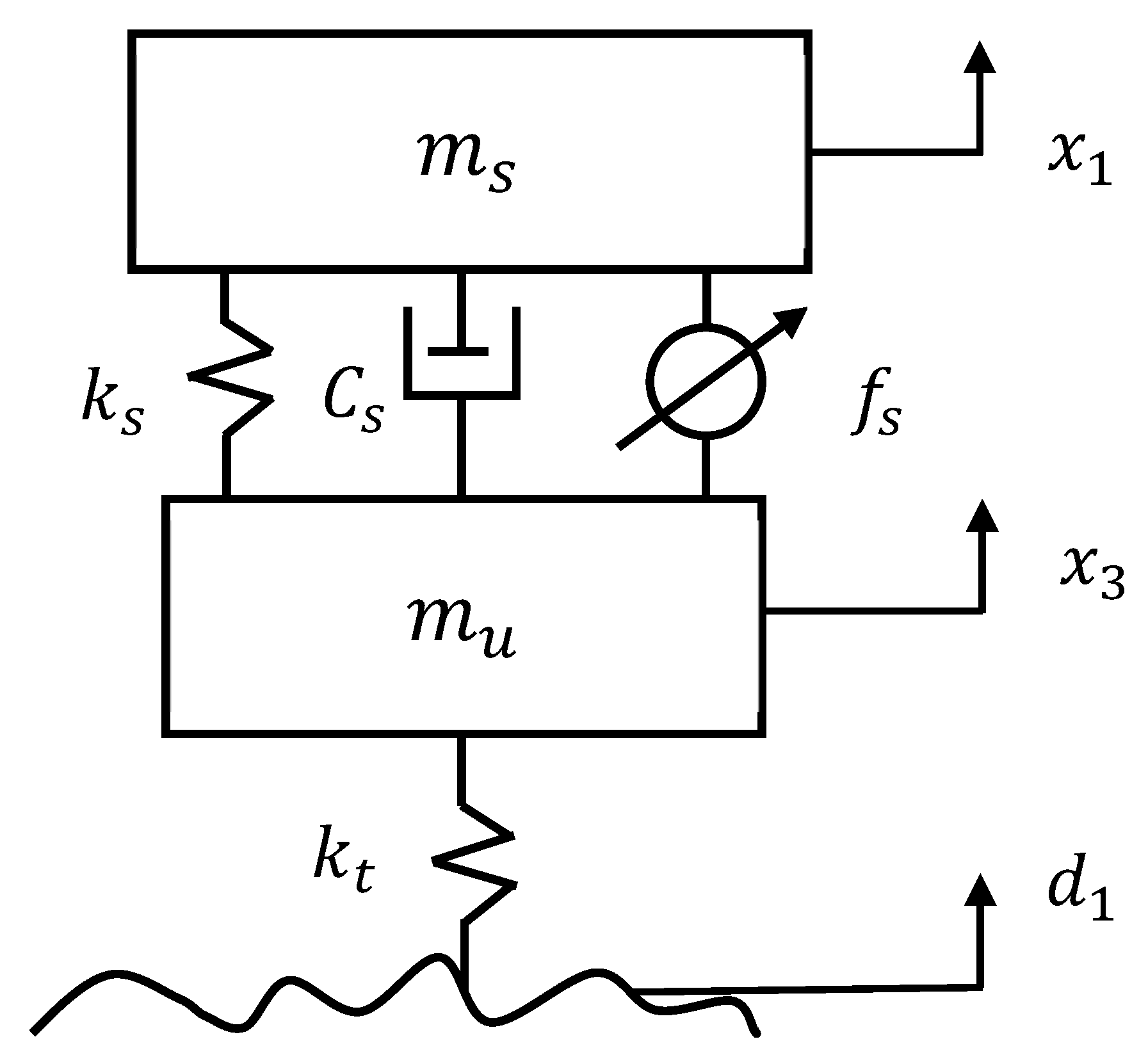

Figure 1 illustrates the linear 2-DOF quarter-car model with an unsprung mass

, sprung mass

, tire spring stiffness

, and a suspension with a linear spring with stiffness

, as well as a linear damper with damping coefficient

[

8]. As shown in the figure,

denotes the external disturbance due to the road roughness,

the actuator force,

the sprung mass vertical displacement,

the sprung mass vertical acceleration,

the unsprung mass vertical displacement, and

the suspension dynamic deflection. With the assumption of

and

, the governing equations of motion of the 2-DOF vehicle model can be expressed in the state-space form as:

where the state, control, and output variable vector are defined as

,

, and

, respectively, matrices

,

,

and

are provided in

Appendix A.

Considering parametric uncertainties, the system parameters

,

,

,

, and

can be modeled as a combination of the respective nominal value and a corresponding possible relative perturbation as:

where

,

,

,

, and

are the nominal values of the system parameters

,

,

,

, and

, respectively, similarly

,

,

,

, and

the respectively possible relative variations, and

,

,

,

and

variable coefficients, which are bounded as

. The system parameters with uncertainties can be represented as upper linear fractional transformations (LFTs) [

16] as

,

,

,

, and

with:

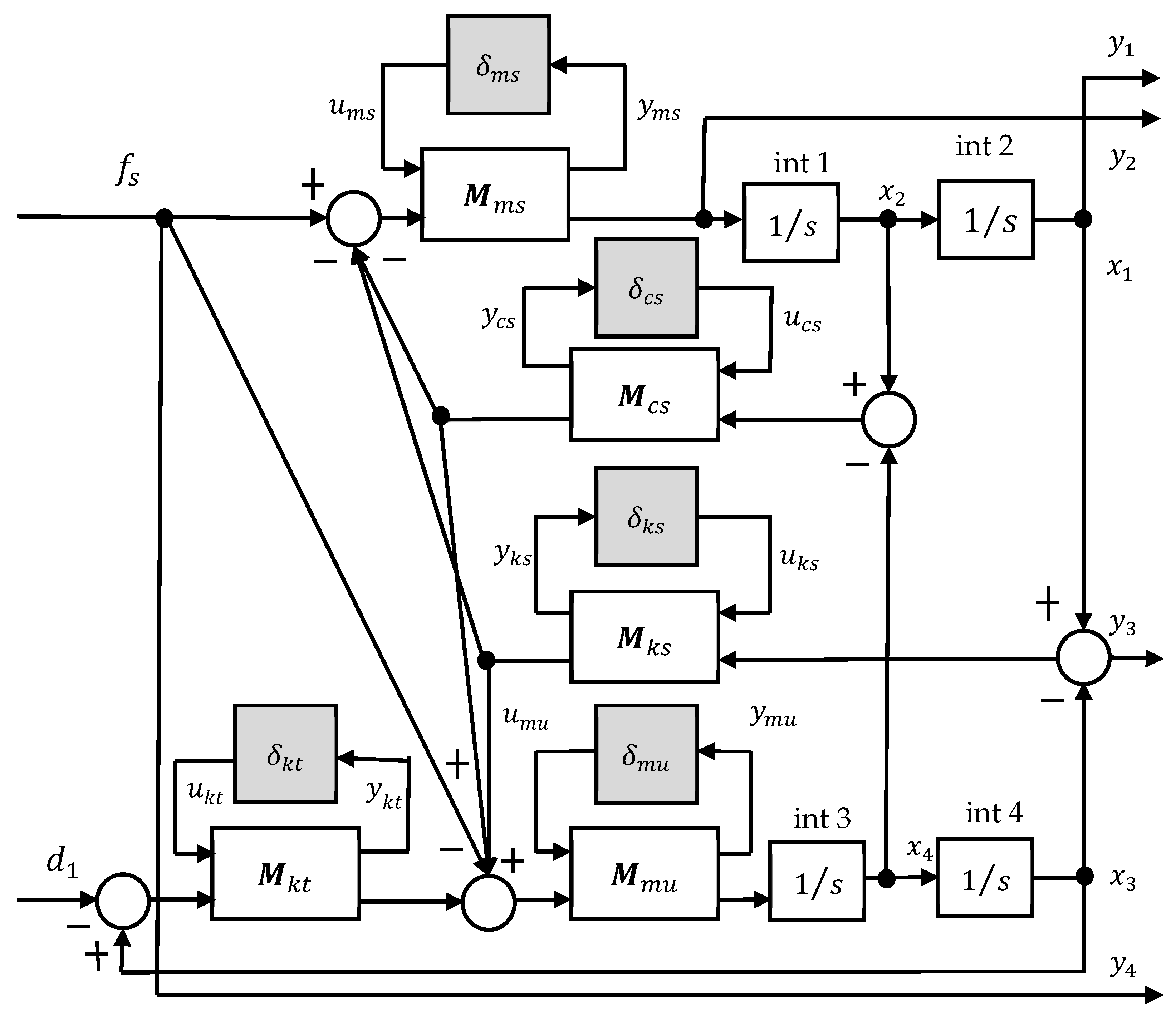

Figure 2 illustrates the block diagram to represent the 2-DOF vehicle model with system parameters featured with uncertainties defined by Equations (2a–e) and (3a–e). With the above-defined system parameters with uncertainties, Equation (1a,b), which represents the dynamics of the 2-DOF vehicle model shown in

Figure 1, can be rewritten as:

where matrix

, vector

, and

are defined as follows:

and matrices

,

,

,

, as well as

are provided in

Appendix A.

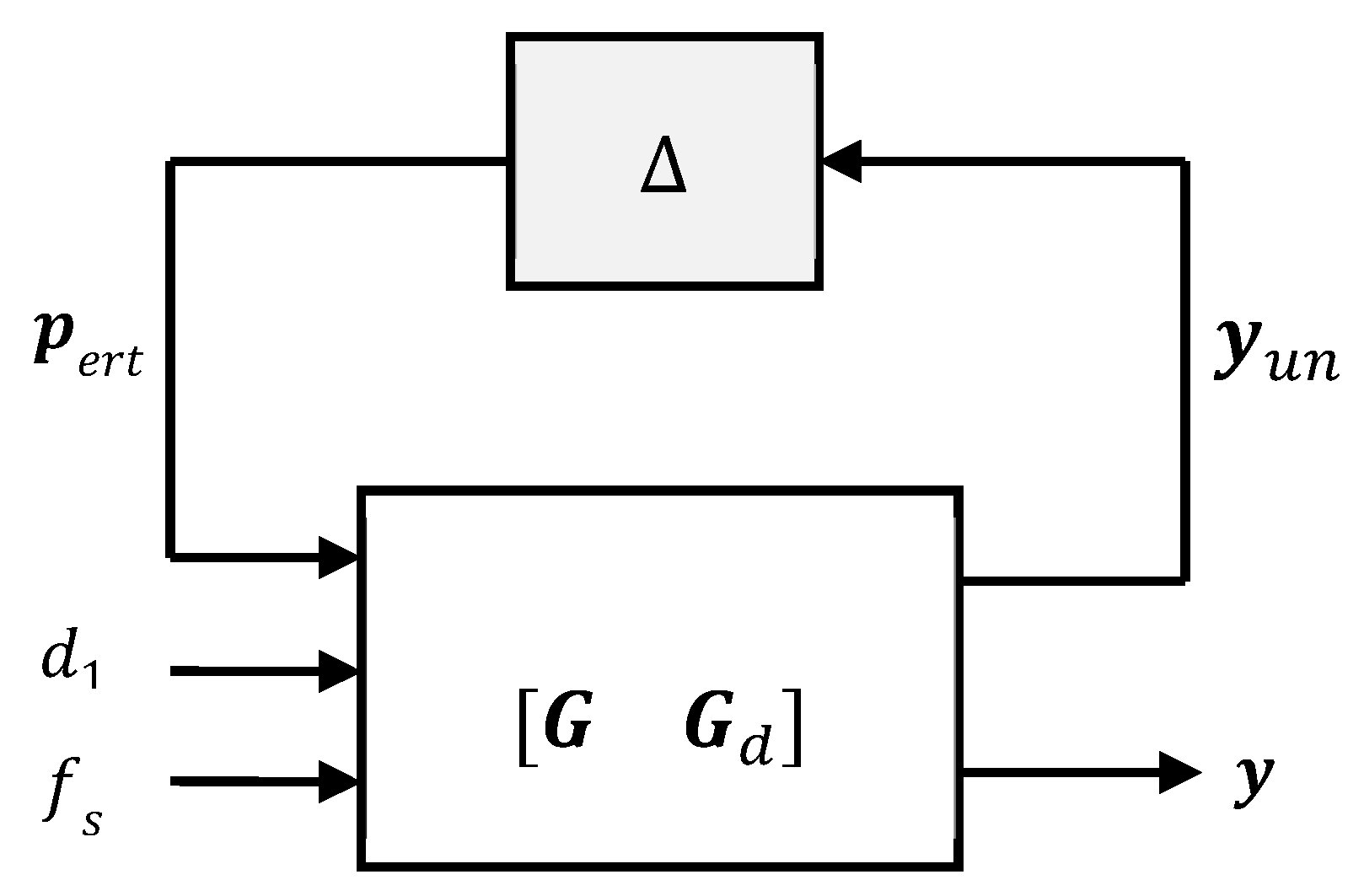

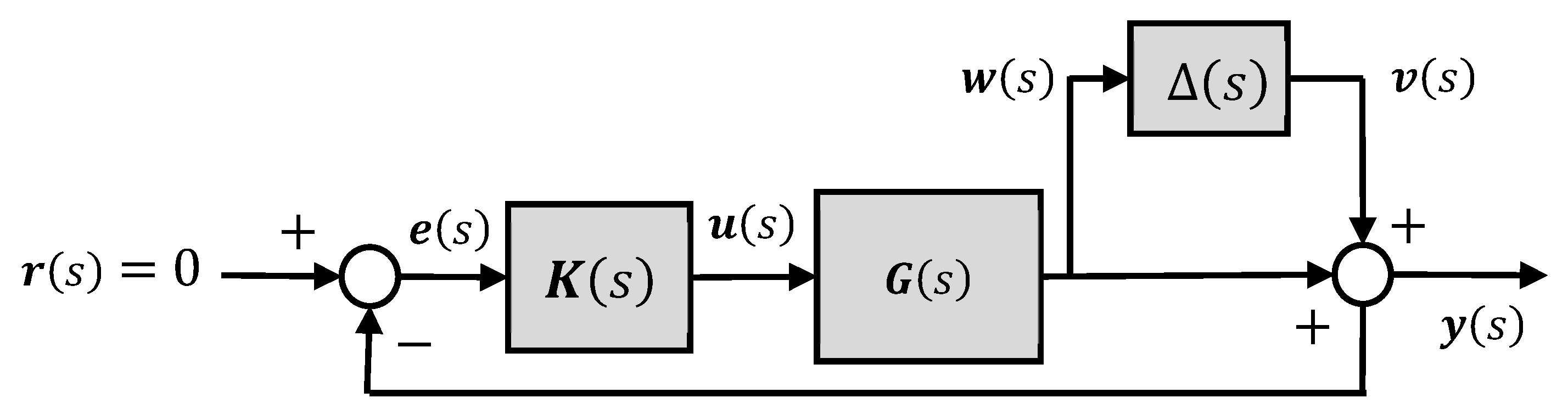

Extracting parametric uncertainties, Equation (3a–e) can be described in an LFT form as illustrated in

Figure 3, in which

and

denote the transfer function of control input and road disturbance, respectively, and

is the diagonal parametric uncertainty matrix with singular values equal or less than unity.

4. Proposed Design Synthesis Method

Figure 8 shows the proposed design synthesis method for robust controllers of active vehicle suspensions. This is a two-layer design optimization approach. In the design optimization of the

loop-shaping controller for AVSs, all the parameters for the relevant weighting functions of the controller are treated as design variables. Initially,

n sets of the design variables are randomly selected in the design space by a genetic algorithm (GA) at the top layer [

30]. Considering the expensive computational loads due to the application of the GA, we use the parallel computing technique available in Matlab [

31]. The scheduler parallelly sends each of the

n design variable sets to the respective Worker of the parallel computing system. At the bottom layer, with a given design variable set, such as set

i, the respective Worker

i ‘operates’ the virtual vehicle with the

LSC-based AVS under a specified testing maneuver. After the virtual testing, the required performance measures denoted by

, which are acquired from the respective numerical simulation response. After the virtual test for all the Workers from

, we can achieve a performance measure matrix

with the size of

. With the performance measure matrix, the defined constraints and the objective function are evaluated.

Similar to the cost function defined in [

8], in this research, we specify the objective function at the top layer as:

where

,

are weighting factors,

,

,

, and

are the root mean square (RMS) values of the vertical acceleration of sprung mass, vertical acceleration of unsprung mass, suspension dynamic deflection, and wheel deflection achieved by the

LSC-based AVS, while

,

,

, and

represent the RMS values of the passive suspension relative to

,

,

, and

, respectively. With the objective function defined by (22), the number (

) of performance measures acquired for each virtual testing during the process shown in

Figure 8 is 4, and we have the performance measure matrix

with the size of

after the virtual test for all the Workers from

. Note that the number (

) of Workers of the design optimization is dependent on the slave notes of the master-slave computer cluster used for the design optimization [

32,

33]. In (22), the objective function is formulated in the form of the so-called scalarization [

34,

35], which converts a multi-objective optimization problem into a single objective one. This will significantly facilitate design optimization. The use of normalization aims at ensuring the same order of digital value of each performance measure involved in the objective function.

After the objective function evaluations, the performance index vector, i.e., , is achieved for the n sets of design variables. At this point, if the convergence criteria, e.g., a predefined total generation number, an acceptable error between the best objective function values of the last two generations, etc., are satisfied, the optimization process terminates; otherwise, this performance index vector is feedbacked to the GA at the top layer. Based on the returned performance index values corresponding to the given sets of design variables, the GA creates the next generation of design variable sets using genetic operators, such as selection, crossover, and mutation. This process repeats until the optimal variable set, i.e., the best weighting function parameter set for the LSC controller is identified.

5. Results and Discussion

To perform the design optimization of the vehicle suspension system with the

loop-shaping controller, the vehicle model parameters take the nominal values listed in

Table 1. To assess the performance of the AVS designs, the road disturbance is defined by:

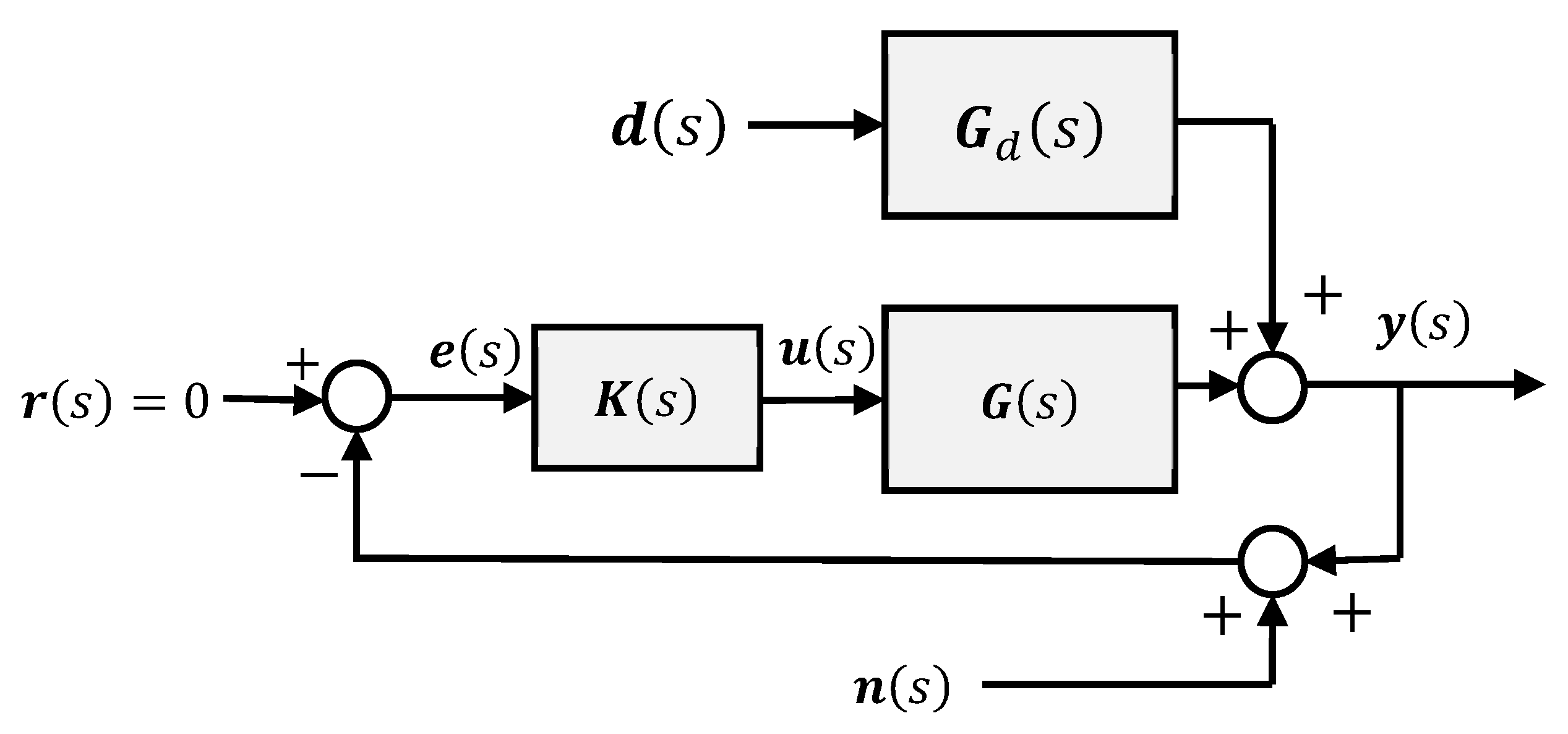

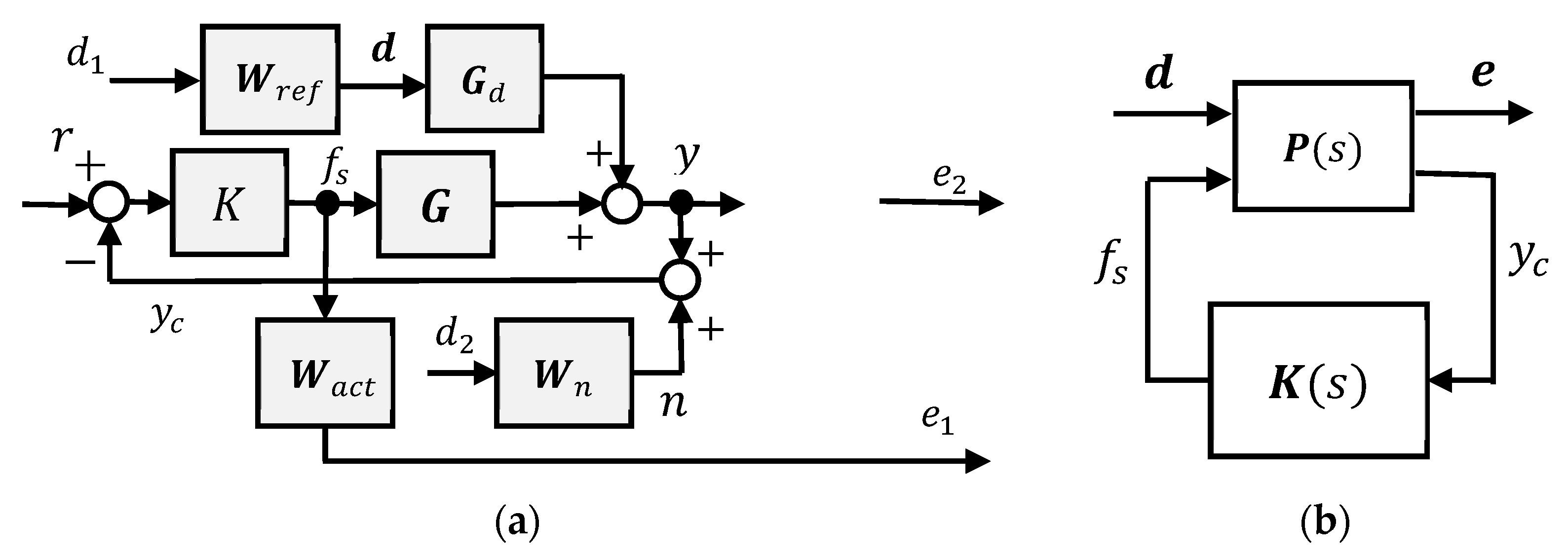

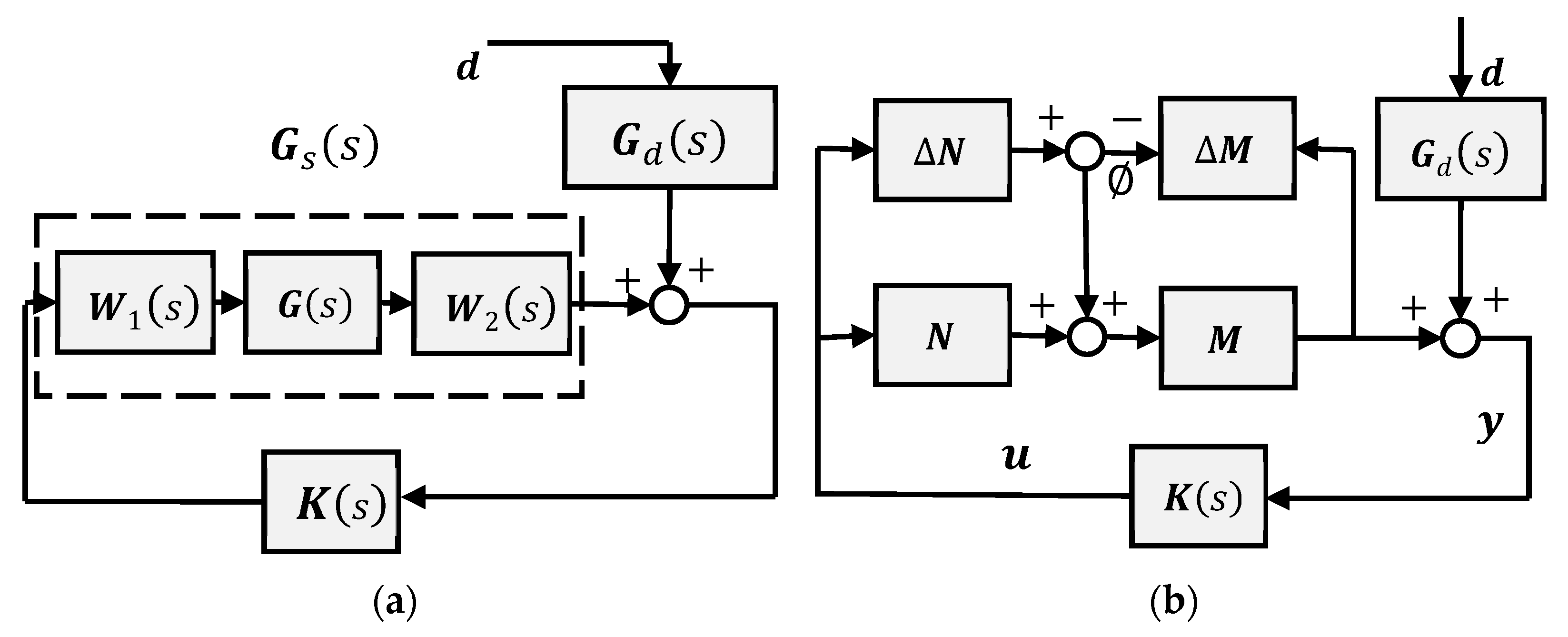

Table 2 lists the weighting functions and compensators, which are designed with the conventional frequency shaping technique [

27,

28]. These weighting functions are applied to road disturbance

, measurement noise

, control input

, as well as outputs

,

, and

to reshape the closed- and open-loop frequency characteristics while designing the

loop-shaping controllers as shown in

Figure 6a and

Figure 7a, respectively.

Table 3 provides the respective weighting functions derived from the design optimization using the method shown in

Figure 8.

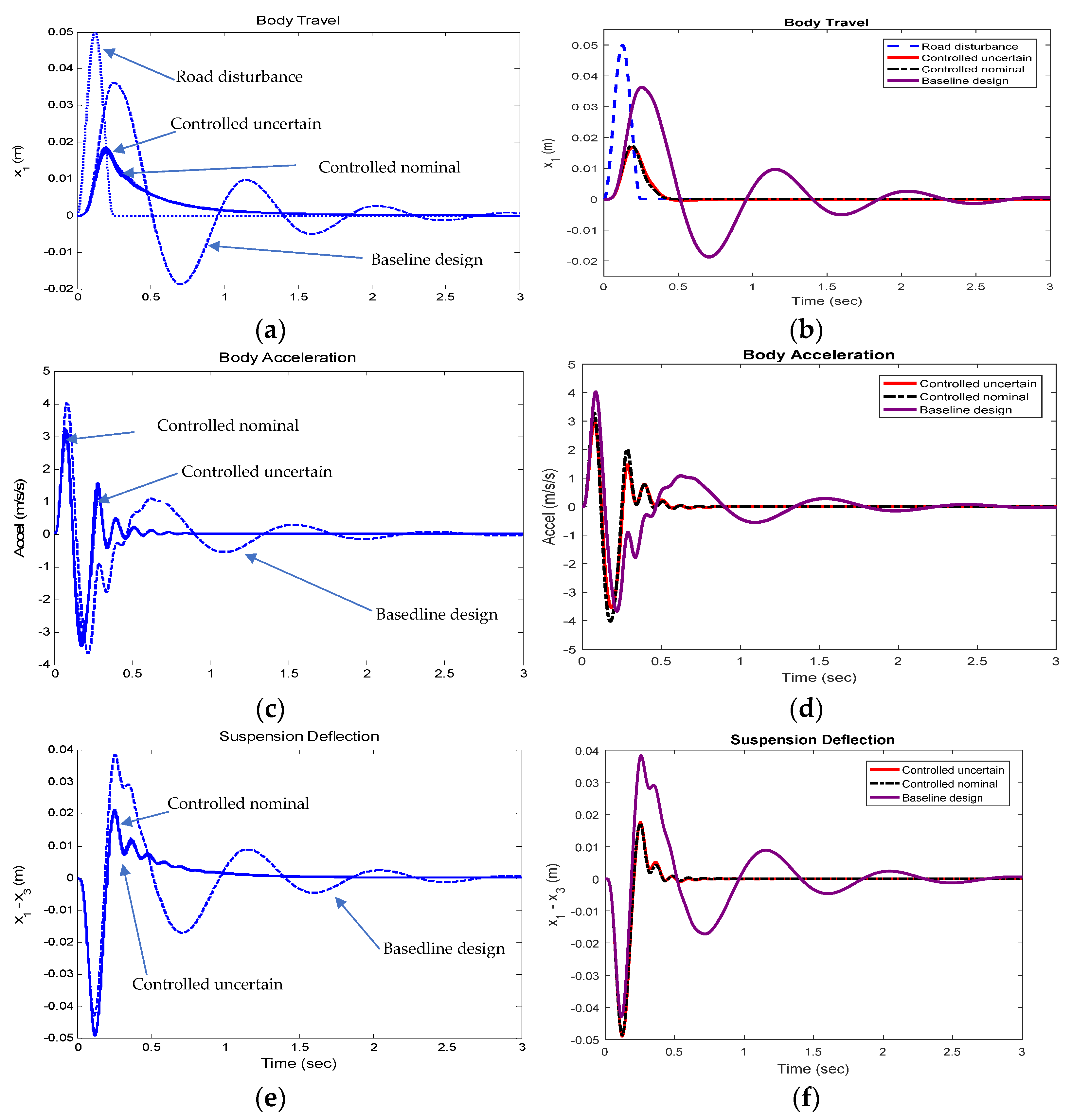

The performance of the

LSC-based AVSs is compared against that of the baseline design. For the benchmark, three designs are considered: (1) the baseline design, i.e., the vehicle model shown in

Figure 1 without the force actuator

; (2) the controlled nominal design, that is, the

LSC-based AVS is designed with the vehicle model parameters taking the nominal values listed in

Table 1 and with the application of weighting functions listed in

Table 2 and

Table 3 the controlled uncertain design, in which the vehicle system is modeled with uncertain parameters and the

LSC-based AVS is optimally devised using the proposed design synthesis method. For simplicity, hereafter the three designs are denoted by Design 1, 2 and 3. For Design 3, 100 design cases are obtained with the maximum parametric uncertainty of

for sprung mass

and the maximum parametric uncertainty of

for all other vehicle model parameters. The performance comparison of the three designs is shown in

Figure 9.

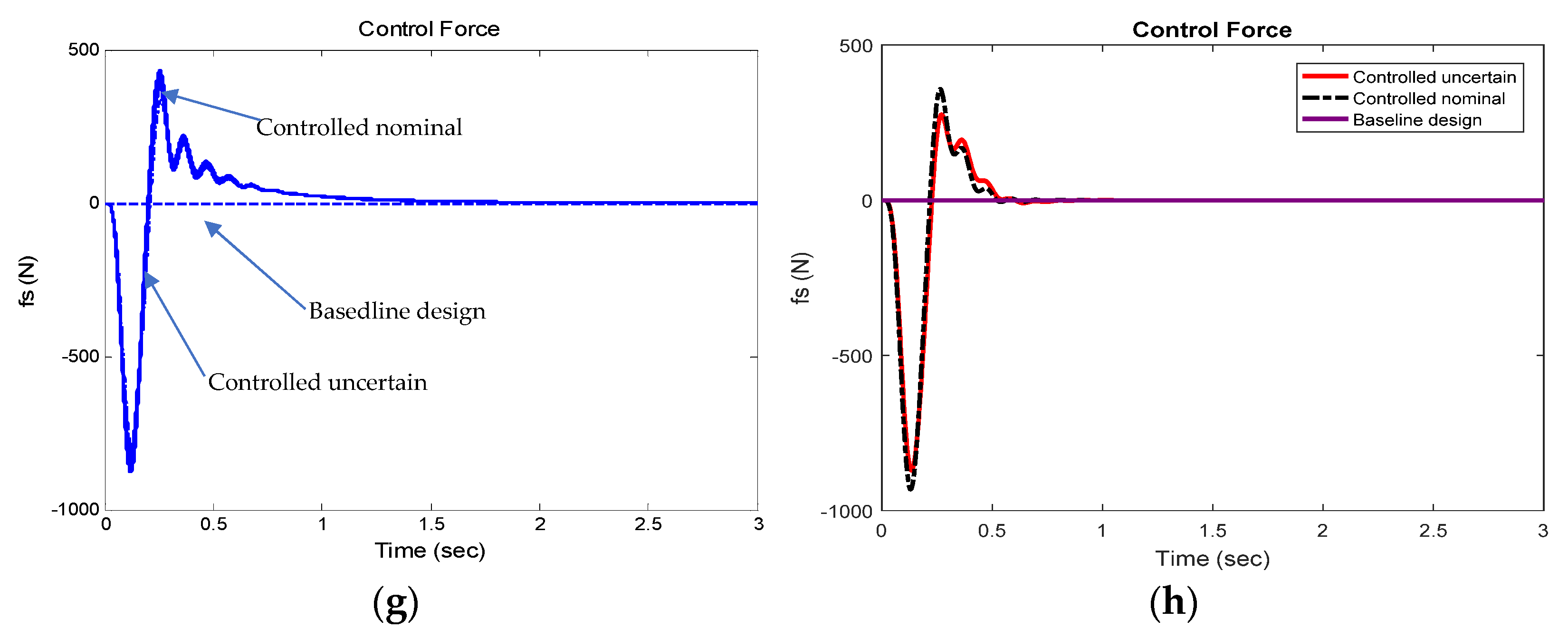

Figure 9a,c,e,g show the performance of the three designs in terms of time-history of sprung mass vertical displacement, sprung mass vertical acceleration, suspension dynamic deflection, and actuator force, respectively. Since the curves of Design 3 (with 100 design cases) overlap their counterparts of Design 2 in the aforementioned figures, and it is difficult to distinguish the curves of Design 3 from the respective curves of Design 2, we replot the curves of Designs 1 and 2 shown in

Figure 9a,c,e,g in

Figure 9b,d,f,h, respectively. Moreover, to facilitate the performance comparison, the curves for the average performance measures of the 100 cases of Design 3 are used to represent the performance of this design, and the respective average performance curves are also shown in

Figure 9b,d,f,h.

To facilitate quantitative comparison of the performance measures among the three designs, the maximum performance measure values shown in

Figure 9b,d,f,h are listed in

Table 4. Compared with Design 1, Design 2 significantly reduces the maximum sprung mass travel by 52.34% and marginally decreases the maximum sprung mass vertical acceleration by 0.52% at the expense of degrading the maximum suspension dynamic deflection by 13.16% and consuming the control effort with the maximum peak actuator force of 940.476 N. Moreover, with respect to Design 1, Design 2 responds to the road disturbance faster in terms of all system outputs. A close observation of the performance difference between Designs 2 and 3 discloses that, within the given bounded model parameter variation ranges, the parametric uncertainties pose no significance on the sprung mass travel, suspension dynamic deflection, and sprung mass acceleration. To quantitatively compare the performance measures of Design 2 and 3, we assume that the latter is represented by the average design of the 100 design cases. With respect to Design 2, Design 3 improves performance by reducing the maximum sprung mass vertical displacement by 3.47%, the maximum sprung mass vertical acceleration by 12.11%, and the maximum actuator force by 7.59% at the cost of marginally increasing the maximum suspension dynamic deflection by 1.02%. Interestingly, compared with and Design 2, Design 3 improves the performance in maximum sprung mass travel, maximum sprung mass vertical acceleration, maximum control effort, and maintaining approximately the same maximum peak value of suspension deflection. This implies that the optimal design of the

LSC controller with parameter uncertainty attenuates the level of conflicting performance measures of the AVS with a

sub-optimal controller reported in [

36]. This benefit of the

LSC controller may be attributed to the application of the proposed design synthesis method for optimally tuning the parameters of the weighting functions to compromise the trade-offs among the conflicting performance measures of AVSs.

The above observation indicates that, for Design 3 with the given bounded model parameter variation ranges, parametric uncertainties pose minor impacts on the performance of the AVS. To further examine this issue, we conduct a parametric sensitivity analysis for this design. Each time, only one parameter is allowed to be varied and others are fixed at their nominal values. The selected parameter varies until it approaches a value, at which the controller loses its stability. This value is denoted as the threshold value of this parameter, and the variation range constrained by the threshold value is defined as the threshold uncertainty.

Table 5 lists the threshold uncertainties of all the model parameters.

6. Conclusions

This paper proposes a design synthesis method for robust controllers of active vehicle suspensions (AVSs). This method provides a framework for two-layer design optimization problems. At the top layer, the specified objective function and constraints are evaluated, and an evolutionary algorithm, i.e., a genetic algorithm, is introduced to search in the design space to find optimal design variables for the robust controller. At the bottom layer, the robust controller and the vehicle model are integrated to form a virtual vehicle with robust active suspensions. With a design variable set from the top layer, the robust controller is updated, and a numerical simulation is performed to mimic a testing maneuver and to extract performance measures from the dynamic responses of the simulation. The acquired data are feedbacked to the top layer for evaluating the objective function and constraints. The proposed method is applied to the search of optimal parameters for the weighting functions of an loop-shaping controller for a vehicle with AVS. To address the problem of expensive computational loads of design optimization, a parallel computing technique is recommended.

The proposed method systematically deals with parametric uncertainties and unmodelled dynamics of a vehicle model with AVS. The optimal loop-shaping controller designed using the method achieves robust stability and performance with specified parameter uncertainties. With the given testing condition and the specified vehicle model parameter variation ranges, compared with the loop-shaping controller design with the nominal model parameter values and the weighting functions determined using the conventional technique, the optimal controller design based on the proposed method improves performance by reducing the maximum sprung mass vertical displacement by 3.47%, the maximum sprung mass vertical acceleration by 12.11%, and the maximum actuator force by 7.59% at the cost of marginally increasing the maximum suspension dynamic deflection by 1.02%. With the resulting robust controller, the stability margin of the active suspension system on individual parametric uncertainties can be easily identified. The achieved parametric uncertainty thresholds may be used as a guideline for robust controller designs of active vehicle suspensions. Simulation results indicate that a compromised design solution can be achieved for the conflicting performance measures of active suspension by optimally tuning the weighting functions of the loop-shaping controller. The application of the proposed method can be extended to the robust controller designs for other active vehicle safety systems, e.g., active steering and anti-roll systems.