Analyzing the Effects of Tactical Dependence for Business Process Reengineering and Optimization

Abstract

1. Introduction

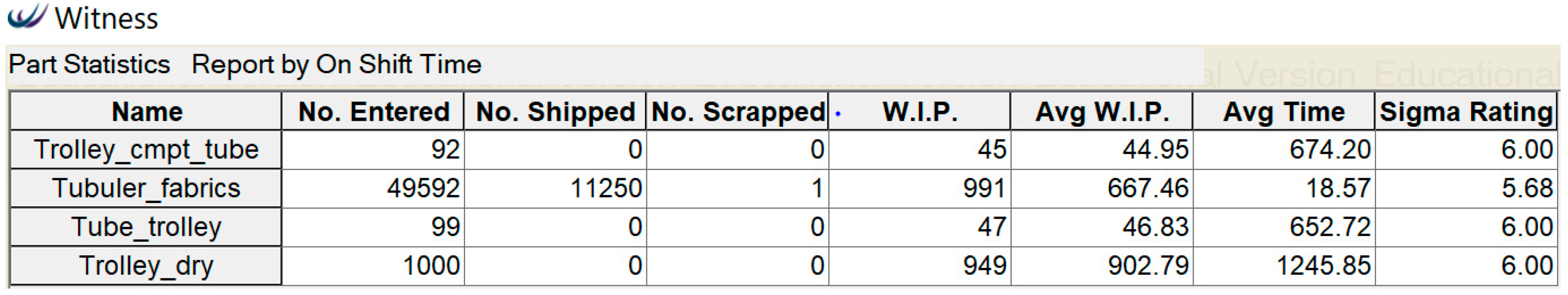

2. Methodology

KHB Methodology

- Interdependent if changes affect any of the similar factors between two sections (idle%, busy%, block%, number of operations/transaction), and increase the number of operations.

- Interdependent if changes affect any of the similar factors between the sections (idle%, busy%, block%, number of operations/transaction), and decrease the number of operations.

- Not interdependent if changes affect any of the similar factors between the sections (idle%, busy%, block%, number of operations/transaction), and the number of operations is unchanged.

- Not interdependent if the changes do not affect any of the similar factors (idle%, busy%, block%, number of operations/transaction), and the number of operations is unchanged.

3. Case Study

3.1. Process Identification

- Dewatering section (P);

- Quality inspection wet (Q);

- Drying section (R);

- Quality inspection drying (S);

- Compacting section (T).

3.2. Process Mapping, Data Collection, and Analysis

3.3. Process Verification

- Comp_lafa1 busy time, Ccb1 = 42.39%

- Comp_lafa2 busy time, Ccb2 = 74.09%

- Comp_tubtex busy time, Ccb3 = 42.39%

- Rc = Process run time = 1380 min

- Comp_lafa1 Cycle time, Ccc1 = 45 min

- Comp_lafa2 Cycle time, Ccc2 = 90 min

- Comp_tubetex Cycle time, Ccc3 = 45 min

- or,

- or,

- or,

- or,

- or,

- or,

- Comp_lafa1 = 3200 kg;

- Comp_lafa2 = 2800 kg;

- Com_tubtex = 3100 kg.

3.4. Reengineering Phase

3.4.1. Process Interdependencies

3.4.2. Interdependence Factors between Workstations and Data Filtration

3.4.3. Interdependence and Bottleneck Movement of the Process

3.4.4. Optimization and Validation

3.5. Implementation

4. Discussion and Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hammer, M.; Champy, J. Reengineering the corporation: A manifesto for business revolution. Bus. Horiz. 1993, 36, 90–91. [Google Scholar] [CrossRef]

- Ghanadbashi, S.; Ramsin, R. Towards a method engineering approach for business process reengineering. IET Softw. 2016, 10, 27–44. [Google Scholar] [CrossRef]

- Kumar, M.S.; Harshitha, D. Process Innovation Methods on Business Process Reengineering. Int. J. Innov. Technol. Explor. Eng. 2019. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Butt, J.; Mebrahtu, H.; Shirvani, H.; Alam, M.N. Data-Driven Process Reengineering and Optimization Using a Simulation and Verification Technique. Designs 2018, 2, 42. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Butt, J.; Mebrahtu, H.; Shirvani, H.; Sanaei, A.; Alam, M.N. Integration of Data-Driven Process Re-Engineering and Process Interdependence for Manufacturing Optimization Supported by Smart Structured Data. Designs 2019, 3, 44. [Google Scholar] [CrossRef]

- Cao, G.; Clarke, S.; Lehaney, B. A critique of BPR from a holistic perspective. Bus. Process Manag. J. 2001, 7, 332–339. [Google Scholar] [CrossRef]

- Chen, L.; Liu, B. A workflow model supporting dynamic BPR. In Proceedings of the Sixth International Conference on Grid and Cooperative Computing (GCC 2007), Los Alamitos, CA, USA, 16–18 August 2007. [Google Scholar]

- Davenport, T.H. Process Innovation Reengineering Work through Information Technology; Harvard Business School Press: Massachusetts, MA, USA, 1993. [Google Scholar]

- Eftekhari, N.; Akhavan, P. Developing a comprehensive methodology for BPR projects by employing IT tools. Bus. Process Manag. J. 2013, 19, 4–29. [Google Scholar] [CrossRef]

- Hussein, B. PRISM: Process Reengineering Integrated Spiral Model; VDM Verlag: Berlin, Germany, 2008. [Google Scholar]

- Hussein, B.; Bazzi, H.; Dayekh, A.; Hassan, W. Critical analysis of existing business process reengineering models: Towards the development of a comprehensive integrated model. J. Proj. Program Portf. Manag. 2013, 4, 30–40. [Google Scholar] [CrossRef]

- Hussein, B.; Hammoud, M.; Bazzi, H.; Haj-Ali, A. PRISM-process reengineering integrated spiral model: An agile approach to Business Process Reengineering (BPR). Int. J. Bus. Manag. 2014, 9, 134. [Google Scholar] [CrossRef]

- Sangers, J.; Hogenboom, F.; Frasincar, F. Event-Driven Ontology Updating; Erasmus University: Rotterdam, The Netherlands, 2013; p. 14. [Google Scholar]

- Măruşter, L.; van Beest, N.R. Redesigning business processes: A methodology based on simulation and process mining techniques. Knowl. Inf. Syst. J. 2009, 21, 267–297. [Google Scholar] [CrossRef]

- Mansar, S.L.; Reijers, H.A. Best Practices in business process redesign: A validation of a redesign framework. Comput. Ind. 2005, 56, 457–471. [Google Scholar] [CrossRef]

- Rao, L.; Mansingh, G.; Osei-Bryson, K.M. Buildingontology based knowledge maps to assist business process reengineering. Decis. Support Syst. 2012, 52, 577–589. [Google Scholar] [CrossRef]

- Musa, M.; Othman, M. Business Process Reengineering in Healthcare: Literature review on the methodologies and approaches. Can. Cent. Sci. Educ. 2016, 8, 20, ISSN 1918-7173 E-ISSN. [Google Scholar] [CrossRef][Green Version]

- Hossain, A.; Alfarhan, M.A.; AL-Ghamdi, A. BPR: Evaluation of existing methodologies and limitations. Int. J. Comput. Trends Technol. 2014, 7, 224–227. [Google Scholar]

- Musa, M.A.; Othman, M.S.; Al-Rahimi, W.M. Ontology knowledge map for enhancing health care services: A case of emergency unit of specialist hospital. Theor. Appl. Inf. Technol. 2014, 70, 196–209. [Google Scholar]

- Bahramnejad, P.; Sharafi, S.M.; Nabiollahi, A. A method for business process Reengineering based on enterprise ontology. Int. J. Sci. Eng. Appl. 2015, 6, 25. [Google Scholar] [CrossRef]

- Holliday, I.; Kwok, R.C. Governance in the information age: Building e-government in Hong Kong. New Media Soc. 2004, 6, 549–570. [Google Scholar] [CrossRef]

- Davenport, T. Business Process Reengineering: Where its been, where its going. In Business Process Change, Reengineering Concepts, Methods and Technologies; Grover, V., Kettinger, W., Eds.; IGI Global: Hershey, PA, USA, 1998; pp. 1–13. [Google Scholar]

- Wang, H.; Gong, Q.; Wang, S. Information processing structures and decision making delays in MRP and JIT. Int. J. Prod. Econ. 2017, 188, 41–49. [Google Scholar] [CrossRef]

- AbdEllatif, M.; Farhan, M.S.; Shehata, N.S. Overcoming business process reengineering obstacles using ontology-based knowledge map methodology. Future Comput. Inform. J. 2018, 3, 7–28. [Google Scholar] [CrossRef]

- Al-Mashari, M.; Irani, Z.; Zairi, M. Business process reengineering: A survey of international experience. Bus. Process Manag. J. 2001, 7, 437–455. [Google Scholar] [CrossRef]

- Kruger, D. Application of business process reengineering as a process improvement tool: A case study. In Proceedings of the 2017 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 9–13 July 2017; pp. 1–9. [Google Scholar]

- Herzog, N.V.; Polajnar, A.; Tonchia, S. Development and validation of business process reengineering (BPR) variables: A survey research in Slovenian companies. Int. J. Prod. Res. 2007, 45, 5811–5834. [Google Scholar] [CrossRef]

- McAdam, R.; O’Hare, C. An improved BPR approach for o_ine enabling processes: A case study on a maintaining process within the chemical industry. Bus. Process Manag. J. 1998, 4, 226–240. [Google Scholar] [CrossRef]

- Belmiro, T.R.; Gardiner, P.D.; Simmons, J.E.; Rentes, A.F. Are BPR practitioners really addressing business processes? Int. J. Oper. Prod. Manag. 2000, 20, 1183–1203. [Google Scholar] [CrossRef]

- Qu, Y.; Ming, X.; Ni, Y.; Li, X.; Liu, Z.; Zhang, X.; Xie, L. An integrated framework of enterprise information systems in smart manufacturing system via business process reengineering. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 2210–2224. [Google Scholar] [CrossRef]

- Eke, G.J.; Achilike, A.N. Business process reengineering in organizational performance in Nigerian banking sector. Acad. J. Interdiscip. Stud. 2014, 3, 113. [Google Scholar]

- Jafari, S.M.; Jandaghi, G.; Mohammadi, Z. Investigating the Effect of Components Implementation of Reengineering Projects of business Processes on Their Success. J. Product. Manag. 2017, 10, 67–90. [Google Scholar]

- Asikhia, U.O.; Awolusi, D.O. Assessment of critical success factors of business process re-engineering in the Nigerian oil and gas industry. S. Afr. J. Bus. Manag. 2015, 46, 1–14. [Google Scholar] [CrossRef][Green Version]

- Anand, A.; Wamba, S.F.; Gnanzou, D. A literature review on business process management, business process reengineering, and business process innovation. In Workshop on Enterprise and Organizational Modeling and Simulation; Springer: Berlin/Heidelberg, Germany, June 2013; pp. 1–23. [Google Scholar]

- Herzog, N.V.; Tonchia, S. An instrument for measuring the degree of lean implementation in manufacturing. Stroj. Vestn.-J. Mech. Eng. 2014, 60, 797–803. [Google Scholar] [CrossRef]

- Farughi, H.; Alaniaza, S.; Mousavipour, S.H. Presenting a Framework of Reengineering methodology for Organizational Diagnosis and Process Improvement (Case Study: Industrial Estate Company of Kurdistan). Inter. J. Manag. Acc. Econ. 2014, 1, 295–310. [Google Scholar]

- Pattanayak, S.; Roy, S. Synergizing business process reengineering with enterprise resource planning system in capital goods industry. Procedia-Soc. Behav. Sci. 2015, 189, 471–487. [Google Scholar] [CrossRef][Green Version]

- Al-Thuhli, A.; Al-Badawi, M. Business process reengineering using enterprise social network. In World Conference on Information Systems and Technologies; Springer: Berlin/Heidelberg, Germany, 2018; pp. 925–933. [Google Scholar]

- Abdolvand, N.; Albadvi, A.; Ferdowsi, Z. Assessing readiness for business process reengineering. Bus. Process Manag. J. 2008, 14, 497–511. [Google Scholar] [CrossRef]

- Sungau, J.J.; Ndunguru, P.C. Business process reengineering: A panacea for reducing operational cost in service organizations. Indep. J. Manag. Prod. 2015, 6, 141–168. [Google Scholar]

- Hammer, M.; Stanton, S. How process enterprises really work. Harv. Bus. Rev. 1999, 77, 108–120. [Google Scholar] [PubMed]

- Chen, J.H.; Yang, L.R.; Tai, H.W. Process reengineering and improvement for building precast production. Autom. Constr. 2016, 68, 249–258. [Google Scholar] [CrossRef]

- Dewi, A.R.; Anindito, Y.P.; Suryadi, H.S. Business Process Reengineering on Customer Service and Procurement Units in Clinical Laboratory. Telkomnika 2015, 13, 644–653. [Google Scholar]

- Guimaraes, T.; Paranjape, K. Testing success factors for manufacturing BPR project phases. Int. J. Adv. Manuf. Technol. 2013, 68, 1937–1947. [Google Scholar] [CrossRef][Green Version]

- Kasemsap, K. The roles of business process modeling and business process reengineering in e-government. In Open Government: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2020; pp. 2236–2267. [Google Scholar]

- Gorissen, B.L.; Yanıkoğlu, İ.; den Hertog, D. A practical guide to robust optimization. Omega 2015, 53, 124–137. [Google Scholar] [CrossRef]

- Ben-Tal, A.; den Hertog, D.; de Waegenaere, A.; Melenberg, B.; Rennen, G. Robust solutions of optimization problems affected by uncertain probabilities. Manag. Sci. 2013, 59, 341–357. [Google Scholar] [CrossRef]

- Yanıkoğlu, İ.; Gorissen, B.L.; den Hertog, D. A survey of adjustable robust optimization. Eur. J. Oper. Res. 2019, 277, 799–813. [Google Scholar] [CrossRef]

- Moré, J.J.; Wild, S.M. Benchmarking derivative-free optimization algorithms. SIAM J. Optim. 2009, 20, 172–191. [Google Scholar]

- Yousefi, M.; Yousefi, M.; Ferreira, R.P.M.; Kim, J.H.; Fogliatto, F.S. Chaotic genetic algorithm and Adaboost ensemble metamodeling approach for optimum resource planning in emergency departments. Artif. Intell. Med. 2018, 84, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Körkel, S.; Qu, H.; Rücker, G.; Sager, S. Derivative based vs. derivative free optimization methods for nonlinear optimum experimental design. In Current Trends in High Performance Computing and Its Applications; Springer: Berlin/Heidelberg, Germany, 2005; pp. 339–344. [Google Scholar]

- Prasetio, Y.M. Simulation-Based Optimization for Complex Stochastic Systems. Ph.D. Thesis, University of Washington, Seattle, DC, USA, 2003. [Google Scholar]

- Leiva, J.E.D. Simulation-Based Optimization for Production Planning: Integrating Meta-Heuristics, Simulation and Exact Techniques to Address the Uncertainty and Complexity of Manufacturing Systems; The University of Manchester: Manchester, UK, 2016. [Google Scholar]

- Amaran, S.; Sahinidis, N.V.; Sharda, B.; Bury, S.J. Simulation optimization: A review of algorithms and applications. Ann. Oper. Res. 2016, 240, 351–380. [Google Scholar] [CrossRef]

- Dengiz, B.; Akbay, K.S. Computer simulation of a PCB production line: Metamodeling approach. Int. J. Prod. Econ. 2000, 63, 195–205. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Lidberg, S. Real-world simulation-based manufacturing optimization using cuckoo search. In Proceedings of the 2012 Winter Simulation Conference (WSC), Berlin, Germany, 9–12 December 2012; pp. 1–12. [Google Scholar]

- Yang, X.S.; Deb, S. Cuckoo search via Lévy flights. In Proceedings of the 2009 World Congress on Nature & Biologically Inspired Computing (NaBIC), Coimbatore, India, 9–11 December 2009; pp. 210–214. [Google Scholar]

- Mebrahtu, H.; Walker, R.; Dionysopoulos, T.; Mileham, T. Manufacturing performance optimization: The simulation—Expert mechanism approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1625–1634. [Google Scholar] [CrossRef]

- Knuplesch, D.; Reichert, M. A visual language for modelling multiple perspectives of business process compliance rules. Softw. Syst. Modeling 2017, 16, 715–736. [Google Scholar] [CrossRef]

- Jacobson, I. The use-case construct in object-oriented software engineering. In Scenario-based design: Envisioning work and technology in system development; ACM Digital Library: Auckland, New Zealand, 1995; pp. 309–336. [Google Scholar]

- Bhaskar, H.L. Business process reengineering framework and methodology: A critical study. Int. J. Serv. Oper. Manag. 2018, 29, 527–556. [Google Scholar]

- Zuhaira, B.; Ahmad, N.; Saba, T.; Haseeb, J.; Malik, S.U.R.; Manzoor, U.; Balubaid, M.A.; Anjum, A. Identifying deviations in software processes. IEEE Access 2017, 5, 20319–20332. [Google Scholar] [CrossRef]

- Johansson, H.J.; McHugh, P.J. Pendlebury e WA Wheeler, Business Process Reengineering: Breakpoint Strategies for Market Dominance; Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Davenport, T.H.; Stoddard, D.B. Reengineering: Business change of mythic proportions? Mis. Q. 1994, 18, 121–127. [Google Scholar] [CrossRef]

- Jafari, M.; Bastani, P.; Ibrahimipour, H.; Dehnavieh, R. Attitude of health information system managers and officials of the hospitals regarding the role of information technology in reengineering the business procedures: A qualitative study. HealthMED 2012, 6, 208–215. [Google Scholar]

- Dassisti, M. HY-CHANGE: A hybrid methodology for continuous performance improvement of manufacturing processes. Inter. J. Prod. Res. 2010, 48, 4397–4422. [Google Scholar] [CrossRef]

- Briano, E.; Caballini, C.; Mosca, R.; Revetria, R. Using WITNESS™ Simulation Software as a validation tool for an industrial plant layout. In Proceedings of the 9th WSEAS International Conference on System Science and Simulation in Engineering (ICOSSSE’10), Wisconsin, WI, USA, 4 October 2010; pp. 201–206. [Google Scholar]

- Hamzas, M.F.M.A.; Bareduan, S.A.; Bahari, M.S.; Zakaria, S.; Zakaria, M.Z. Double-sided assembly line optimization using witness simulation. In AIP Conference Proceedings; AIP Publishing LLC: Mangalore, India, 2019; Volume 2129, p. 020151. [Google Scholar]

- Khan, M.A.A.; Mebrahtu, H.; Shirvani, H.; Butt, J. Manufacturing optimization based on agile manufacturing and big data. Adv. Transdiscipl. Eng. 2017. [Google Scholar] [CrossRef]

| Change Cycle Time | Workstations | Busy% | Number of Operations | Idle% | TO | Interdependent (Condition a, b) | Not Interdependent (Condition c, d) | Filtered Data (SSD)/Required Change |

|---|---|---|---|---|---|---|---|---|

| Interdependence between dewatering (P) and quality inspection (Q) | ||||||||

| Decrease | Dewatering (P) | Decrease | Increase | Unchanged | Increase | N | ||

| Quality inspection (Q) | Increase | Increase | Decrease | |||||

| Increase | Dewatering (P) | Unchanged | Decrease | Unchanged | Decrease | |||

| Quality inspection (Q) | Decrease | Decrease | Increase | |||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | No | ||||

| Decrease | Quality inspection (Q) | Decrease | Unchanged | Increase | ||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | No | ||||

| Increase | Quality inspection (Q) | Unchanged | Unchanged | Unchanged | ||||

| Interdependence Between dewatering (P) and Drier (R) | ||||||||

| Decrease | Dewatering (P) | Decrease | Increase | Unchanged | Increase | N | ||

| Drier (R) | Increase | Increase | Decrease | |||||

| Increase | Dewatering (P) | Unchanged | Decrease | Unchanged | Decrease | |||

| Drier (R) | Decrease | Decrease | Increase | |||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | |||||

| Decrease | Drier (R) | Decrease | Increased | Increased | ||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | |||||

| Increase | Drier (R) | Increase | Increase | Decreased | ||||

| Change Cycle Time | Workstations | Busy% | Number of Operations | Idle% | Interdependent (Condition a, b) | Not Interdependent (Condition c, d) | Filtered Data (SSD)/Required Change |

|---|---|---|---|---|---|---|---|

| Interdependence between dewatering (P) and quality inspection dry (S) | |||||||

| Decrease | Dewatering (P) | Decrease | Increase | Unchanged | |||

| Quality inspection Dry (S) | Increase | Unchanged | Decrease | ||||

| Increase | Dewatering (P) | Unchanged | Decrease | Unchanged | |||

| Drier (R) | Increase | Unchanged | Decrease | ||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | ||||

| Decrease | Quality inspection Dry (s) | Increase | Unchanged | Decreased | |||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | ||||

| Increase | Quality inspection Dry (s) | Increase | Unchanged | Decreased | |||

| Interdependence between dewatering (P) and compacting (T) | |||||||

| Decrease | Dewatering (P) | Decrease | Increase | Unchanged | N | ||

| Compactor (T) | Increase | Increase | Decrease | ||||

| Increase | Dewatering (P) | Unchanged | Decrease | Unchanged | |||

| Compactor (T) | Decrease | Decrease | Increase | ||||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | ||||

| Decrease | Compactor (T) | Decreased | Increased | Increased | |||

| Dewatering (P) | Unchanged | Unchanged | Unchanged | ||||

| Increase | Compactor (T) | Increased | Decreased | Decreased | |||

| Bottleneck Movement | Interdependence Movement | Interdependent | Not. Interdependent | Interdependence Parameters | |||

|---|---|---|---|---|---|---|---|

| P-T | P∩Q, P′∩Q′, | Q∩R, Q′∩R′ | R∩S, R′∩S′ | S∩T, S′∩T′ | P∩Q, P′∩Q′, R∩S, R′∩S′ | Q∩R, Q′∩R′, S∩T, S′∩T′ | N, |

| n | |||||||

| N | |||||||

| B, N, i | |||||||

| T-P | Q∩P, Q′∩P′ | R∩Q, R′∩Q′ | S∩R, S′∩R′ | T∩S, T′∩S′ | R∩Q, S∩R, S′∩R′ T′∩S′ | Q∩P, Q′∩P′, R′∩Q′, | b, I |

| B, i | |||||||

| T∩S | B, i | ||||||

| i | |||||||

| P-T | P∩R, P′∩R′ | Q∩S, Q′∩S′ | R∩T, R′∩′ | P∩R, P′∩R′ R∩T, R′∩T′ | Q∩S, Q′∩S′ | N | |

| n | |||||||

| N | |||||||

| i | |||||||

| R∩P, R′∩P′ | S∩Q, S′∩Q′ | T∩R, T′∩R′ | T′∩R′ | R∩P, R′∩P′, S∩Q, S′∩Q′, | B, i | ||

| T′∩R′ | |||||||

| P∩S, P′∩S′ | Q∩T, Q′∩T′ | P∩S, P′∩S′, Q∩T, Q′∩T′ | |||||

| S∩P, S′∩P′ | T∩Q, T′∩Q′ | T∩Q | S∩P, S′∩P′, T′∩Q′ | i, I | |||

| P∩T, P′∩T′ | P∩T, P′∩T′ | N | |||||

| n | |||||||

| T∩P, T′∩P′ | T∩P, T′∩P′ | ||||||

| Components/Sections | Existing Model | KHB Methods Suggested Factors and Output | Implementation and Output Achieved | |

|---|---|---|---|---|

| Trolley | Dewatering Section | 45 | 65 | 65 |

| Drying Section | 45 | 65 | 65 | |

| Compacting Section | 55 | 60 | 60 | |

| Cycle time (minute) | Dewatering Section | Dewatering_Tubular = 60 | 55 | 55 |

| Dewatering_Tubular2 = 60 | 55 | 55 | ||

| Drying Section | Dryer_Lk1 = 60 | No change | No change | |

| Dryer_Lk2 = 60 | No change | No change | ||

| Ruch_dryer = 90 | No change | No change | ||

| Compacting Section | Comp_tubtex = 45 | 40 | 40 | |

| Comp_lafa1 = 45 | 40 | 40 | ||

| Comp_lafa2 = 90 | 80 | 80 | ||

| Compensated Set-up time | Dewatering Section | Dewatering_Tubular = 52 | 40 | 40 |

| Dewatering_Tubular2 = 50 | 42 | 42 | ||

| Drying Section | Dryer_Lk1 = 90 | 70 | 70 | |

| Dryer_Lk2 = 90 | 75 | 75 | ||

| Ruch_dryer = 80 | 60 | 60 | ||

| Compacting Section | Comp_tubtex = 60 | 50 | 50 | |

| Comp_lafa1 = 60 | 50 | 50 | ||

| Comp_lafa2 = 70 | 55 | 55 | ||

| Total output | 9200 kg (avg) | 11,250 kg | 10,880 Kg | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.A.A.; Butt, J.; Mebrahtu, H.; Shirvani, H. Analyzing the Effects of Tactical Dependence for Business Process Reengineering and Optimization. Designs 2020, 4, 23. https://doi.org/10.3390/designs4030023

Khan MAA, Butt J, Mebrahtu H, Shirvani H. Analyzing the Effects of Tactical Dependence for Business Process Reengineering and Optimization. Designs. 2020; 4(3):23. https://doi.org/10.3390/designs4030023

Chicago/Turabian StyleKhan, Md Ashikul Alam, Javaid Butt, Habtom Mebrahtu, and Hassan Shirvani. 2020. "Analyzing the Effects of Tactical Dependence for Business Process Reengineering and Optimization" Designs 4, no. 3: 23. https://doi.org/10.3390/designs4030023

APA StyleKhan, M. A. A., Butt, J., Mebrahtu, H., & Shirvani, H. (2020). Analyzing the Effects of Tactical Dependence for Business Process Reengineering and Optimization. Designs, 4(3), 23. https://doi.org/10.3390/designs4030023