Reliability-Based Design Optimization of Load Sharing Systems Using SSI-Markov Models

Abstract

:1. Introduction

Assumptions

- Only the brittle failures are considered in our approach. The plastic deformation phase of the system/components with respect to time is not considered in addition to other material related phenomena such as corrosion, change in material properties over time, etc. However, these changes could be incorporated into our RBDO formulation when the material’s deterioration rate is known. In such cases, the system cost will vary from the cost obtained from this approach since we add more information about the failure into the model. When the strength degrades with respect to time, the cost of the components increases in order to meet the reliability requirement.

- The system is assumed to have zero-simultaneous failure probability. This means that all the components in the system cannot fail simultaneously from a single load application.

- The loading duration on a component and load redistribution time after a component failure are assumed to be constant and occur in a very short interval of time. Hence, they are considered negligible.

- The component repair time is not considered, i.e., once a component fails, it is removed from operation and not put back into operation. However, the component repair process can be easily included in the transition probability/rate matrix in SSI-DTMC/CTMC to find the optimum design.

2. Materials and Methods

2.1. SSI–DTMC Load Sharing Model

2.2. SSI–CTMC Load Sharing Model

2.3. Matrix Decomposition Approach

Eigenvalue Method

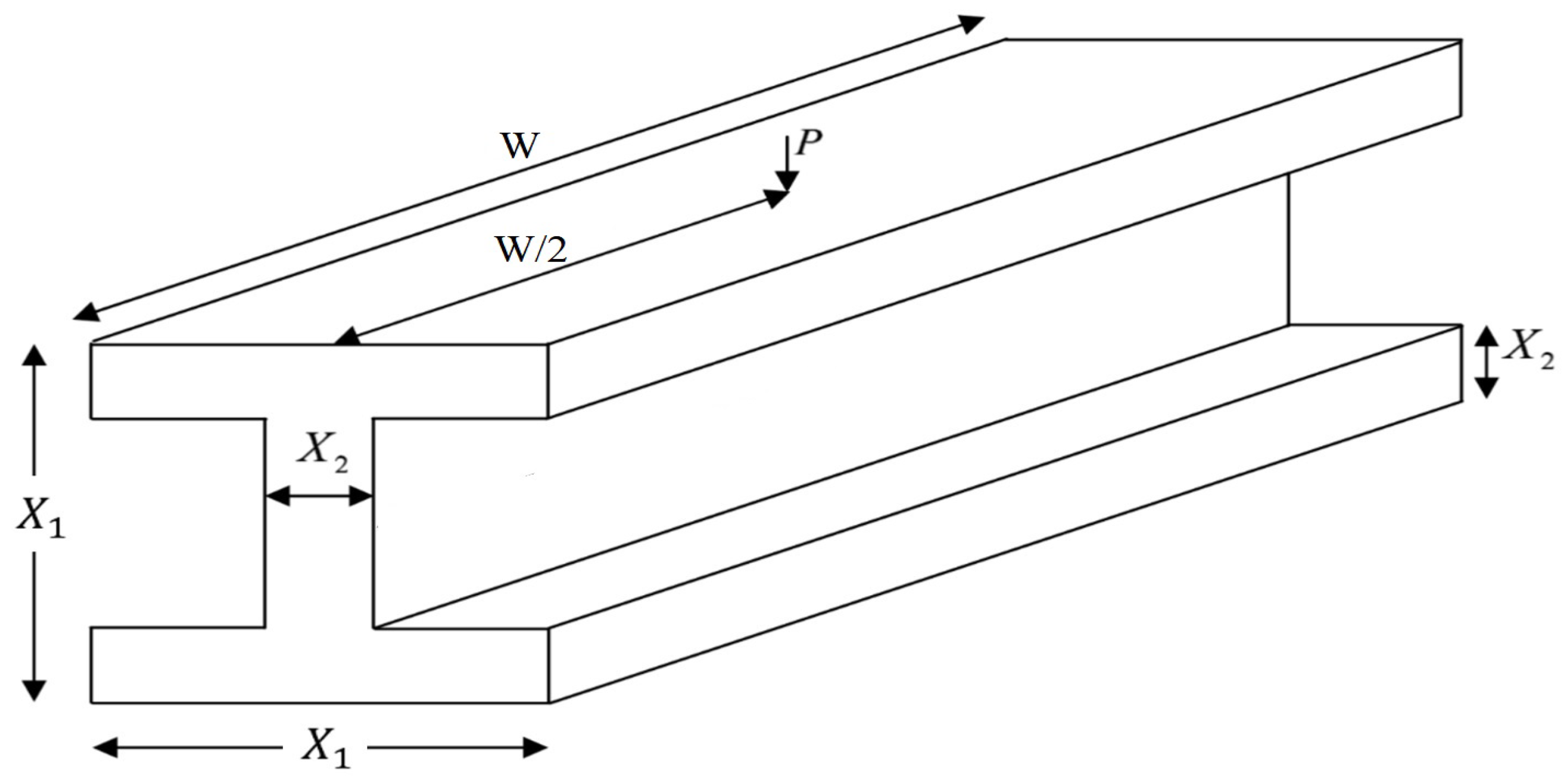

3. Case Study: System with Two Identical Components

3.1. SSI–DTMC Formulation

3.2. SSI–CTMC Formulation

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| f(d, ) | Cost function with design parameter “d” and mean () of random design variable “X”. |

| P(X) | Probability of random variable X = x, where x is any real number. |

| Most Probable Point (MPP) obtained by transforming the random design variable “X” to | |

| standard normal space. | |

| Limit state function for component “i” in terms of MPP. | |

| T | Total number of components. |

| L | Load acting on the system. |

| Yield strength of the component. | |

| Loading rate at time t. | |

| Failure rate at time t. | |

| Reliability index for each limit state i. | |

| Negative normalized gradient vector of limit state i. | |

| Z | Transition probability matrix consisting of state of each components. |

| n | Number of steps (DTMC). |

| t | Time (CTMC). |

| Probability of failure at time t. | |

| D | Matrix of eigenvalues of Z. |

| M | Matrix of eigenvectors of Z. |

| M | Inverse Matrix of eigenvectors of Z. |

| System reliability target. | |

| J | Set of all states of components that keeps the system in operation. |

| Probability of system in state “j”, . | |

| Y | Set of all states of components that represents system failure. |

| Probability of system in state “y”, ∀ y ∈ Y. | |

| Z | State of the system at n = 0 or t = 0. |

| K | Set consisting the condition of components at n = 0 or t = 0. |

References

- McDonald, M.; Mahadevan, S. Design Optimization with System-Level Reliability Constraints. J. Mech. Des. 2008, 130, 021403. [Google Scholar] [CrossRef]

- Yu, X.; Choi, K.; Chang, K. A mixed design approach for probabilistic structural durability. Struct. Multidisc. Optim. 1997, 14, 81–90. [Google Scholar] [CrossRef]

- Youn, B.; Choi, K.; Yang, R.; Gu, L. Reliability-based design optimization for crashworthiness of vehicle side impact. Struct. Multidisc. Optim. 2004, 26, 272–283. [Google Scholar] [CrossRef]

- Enevoldsen, I.; Sorensen, J. Reliability-based optimization in structural engineering. Struct. Saf. 1994, 15, 169–196. [Google Scholar] [CrossRef]

- Cheng, Y.; Du, X. System Reliability Analysis with Dependent Component Failures During Early Design Stage—A Feasibility Study. ASME J. Mech. Des. 2016, 138, 051405. [Google Scholar] [CrossRef]

- Royset, O.J.; Der Kiureghian, A. Reliability-Based Optimal Design of Series Structural Systems. J. Eng. Mech. 2001, 127, 607–614. [Google Scholar] [CrossRef]

- Royset, O.J.; Der Kiureghian, A.; Polak, E. Reliability-Based Optimal Structural Design by Decoupling Approach. Reliabil. Eng. Syst. Saf. 2001, 73, 213–221. [Google Scholar] [CrossRef]

- Der Kiureghian, A.; Ditlevsen, O. Aleatory or epistemic does it matter. Struct. Saf. 2009, 31, 105–112. [Google Scholar] [CrossRef]

- Tu, J.; Choi, K.K.; Park, Y.H. A New Study On Reliability Based Design Optimization. ASME J. Mech. Des. 1999, 121, 557–564. [Google Scholar] [CrossRef]

- Du, X.; Chen, W. Sequential Optimization and Reliability Assessment Method for Efficient Probabilistic Design. J. Mech. Des. 2004, 126, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, X. Product Design Optimization under Epistemic Uncertainty. Ph.D. Dissertation, Arizona State University, Tempe, AZ, USA, 2012; pp. 1–124. [Google Scholar]

- Zhuang, X.; Pan, R. A Sequential Sampling Strategy to Improve Reliability-Based Design Optimization with Implicit Constraint Functions. J. Mech. Des. 2012, 134, 021002. [Google Scholar] [CrossRef]

- Zhuang, X.; Pan, R.; Du, X. Enhancing Product Robustness in Reliability-Based Design Optimization. Reliabil. Eng. Syst. Saf. 2015, 138, 145–153. [Google Scholar] [CrossRef]

- Zheng, W.; Zengquan, W.; Wang, A.N. Failure Rate calculating Method of Components based on the Load Strength Interference Model. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; pp. 783–787. [Google Scholar]

- Pandey, M.D. An Effective Approximation to Evaluate Multinormal Integrals. Struct. Saf. 1998, 20, 51–67. [Google Scholar] [CrossRef]

- Gao, P.; Xie, L. Dynamic reliability models of mechanical load sharing parallel systems considering strength degradation of components. J. Mech. Eng. Sci. 2015, 229, 2484–2495. [Google Scholar] [CrossRef]

- Shah, J.; Lamberson, L.R. Modeling a Shared Load k out of n:G System. IEEE Trans. Reliabil. 1991, 40, 205–209. [Google Scholar] [CrossRef]

- Lewis, E. A Load-Capacity Interference Model for Common-Mode Failures in 1-out-of-2: G Systems. IEEE Trans. Reliabil. 2001, 50, 47–51. [Google Scholar] [CrossRef]

- Ross, S.M. Chapter 4: Markov Chains. In Introduction to Probability Models, 10th ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 183–275. ISBN 978-0123756862. [Google Scholar]

- Moler, C.; Van Loan, C. Nineteen dubious ways to compute the exponential of a matrix. SIAM Rev. 1978, 20, 801–836. [Google Scholar] [CrossRef]

- Huang, Z.; Jin, Y. Extension of Stress and Strength Interfernce Theory for Conceptual Design-for-reliability. J. Mech. Des. 2009, 131, 071001. [Google Scholar] [CrossRef]

- Bala Subramaniyan, A.; Pan, R. Reliability Based Design Optimization of Load Sharing Systems. In Proceedings of the Industrial and Systems Engineering Research Conference (ISERC 2016), Anaheim, CA, USA, 21–24 May 2016; pp. 1–6. [Google Scholar]

- Liang, J.; Mourelatos, Z.; Nikolaidis, E. A single-loop approach for system reliability-based design optimization. J. Mech. Des. 2007, 129, 1215–1224. [Google Scholar] [CrossRef]

- Shan, S.; Wang, G. Reliable design space and complete singleloop reliability-based design optimization. Reliabil. Eng. Syst. Saf. 2008, 93, 1218–1230. [Google Scholar] [CrossRef]

- Ramakumar, R. Reliability Evaluation of Engineering Systems. In Engineering Reliability—Fundamentals and Application; Prentice Hall: Upper Saddle River, NJ, USA, 1993; pp. 53–200. ISBN 978-0132767590. [Google Scholar]

- Sanchis, J.; Martinez, M.; Blasco, X. Integrated multiobjective optimization and a priori preferences using genetic algorithms. Inf. Sci. 2008, 178, 931–951. [Google Scholar] [CrossRef]

- Chang, K. Chapter 10: Reliability Analysis. In e-Design. Computer-Aided Engineering Design; Academic Press: Cambridge, MA, USA, 2015; pp. 523–700. ISBN 978-0123820389. [Google Scholar]

- Moler, C.; Van Loan, C. Nineteen dubious ways to compute the exponential of a matrix, twenty-five years later. SIAM Rev. 2003, 45, 3–49. [Google Scholar] [CrossRef]

- Ahmed, S.; Shapiro, A. Solving Chance-Constrained Stochastic Programs via Sampling and Integer Programming. Tutor. Oper. Res. INFORMS 2008, 261–269. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Xie, M.; Kuo, W. Reliability modeling and preventive maintenance of load-sharing systems with degrading components. IIE Trans. 2016, 10, 699–709. [Google Scholar] [CrossRef]

| State | Component A | Component B |

|---|---|---|

| AB | working | working |

| A’B | failed | working |

| AB’ | working | failed |

| A’B’ | failed | failed |

| Type | Method | Duration | cm | cm | Cost ($) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Static | 95 | 93.23 | - | 41.32 | 0.92 | 224.70 | 94.21 | 96.12 | |

| Single loop | DTMC | 95 | 96.48 | 100 steps | 36.71 | 1.21 | 260.65 | 97.56 | 98.39 |

| CTMC | 95 | 99.62 | 25 years | 50.22 | 1.14 | 338.30 | 99.28 | 99.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subramaniyan, A.B.; Pan, R.; Du, X. Reliability-Based Design Optimization of Load Sharing Systems Using SSI-Markov Models. Designs 2019, 3, 34. https://doi.org/10.3390/designs3030034

Subramaniyan AB, Pan R, Du X. Reliability-Based Design Optimization of Load Sharing Systems Using SSI-Markov Models. Designs. 2019; 3(3):34. https://doi.org/10.3390/designs3030034

Chicago/Turabian StyleSubramaniyan, Arun Bala, Rong Pan, and Xiaoping Du. 2019. "Reliability-Based Design Optimization of Load Sharing Systems Using SSI-Markov Models" Designs 3, no. 3: 34. https://doi.org/10.3390/designs3030034

APA StyleSubramaniyan, A. B., Pan, R., & Du, X. (2019). Reliability-Based Design Optimization of Load Sharing Systems Using SSI-Markov Models. Designs, 3(3), 34. https://doi.org/10.3390/designs3030034