3D Printed Radar Lenses with Anti-Reflective Structures

Abstract

1. Introduction

2. Materials and Methods

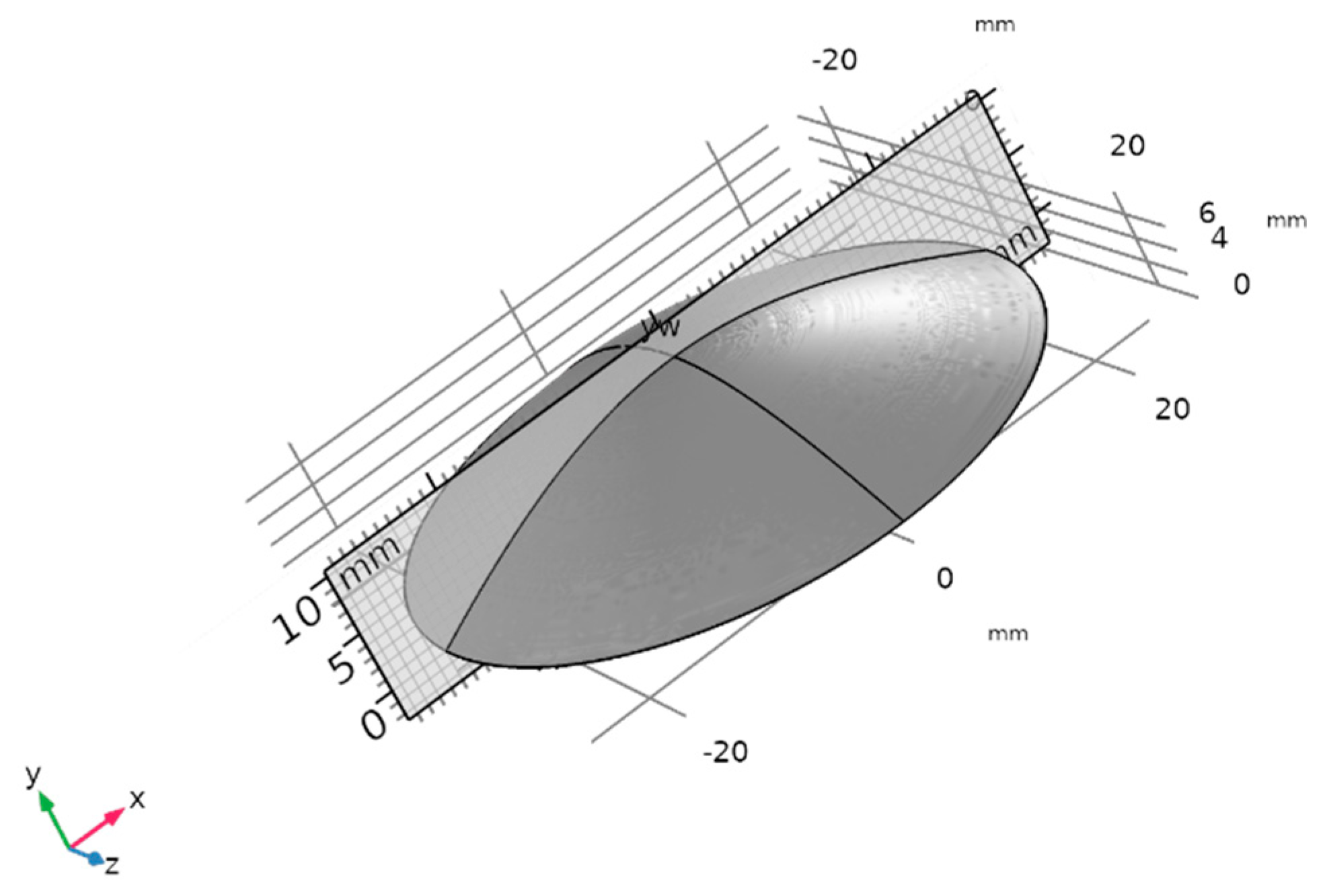

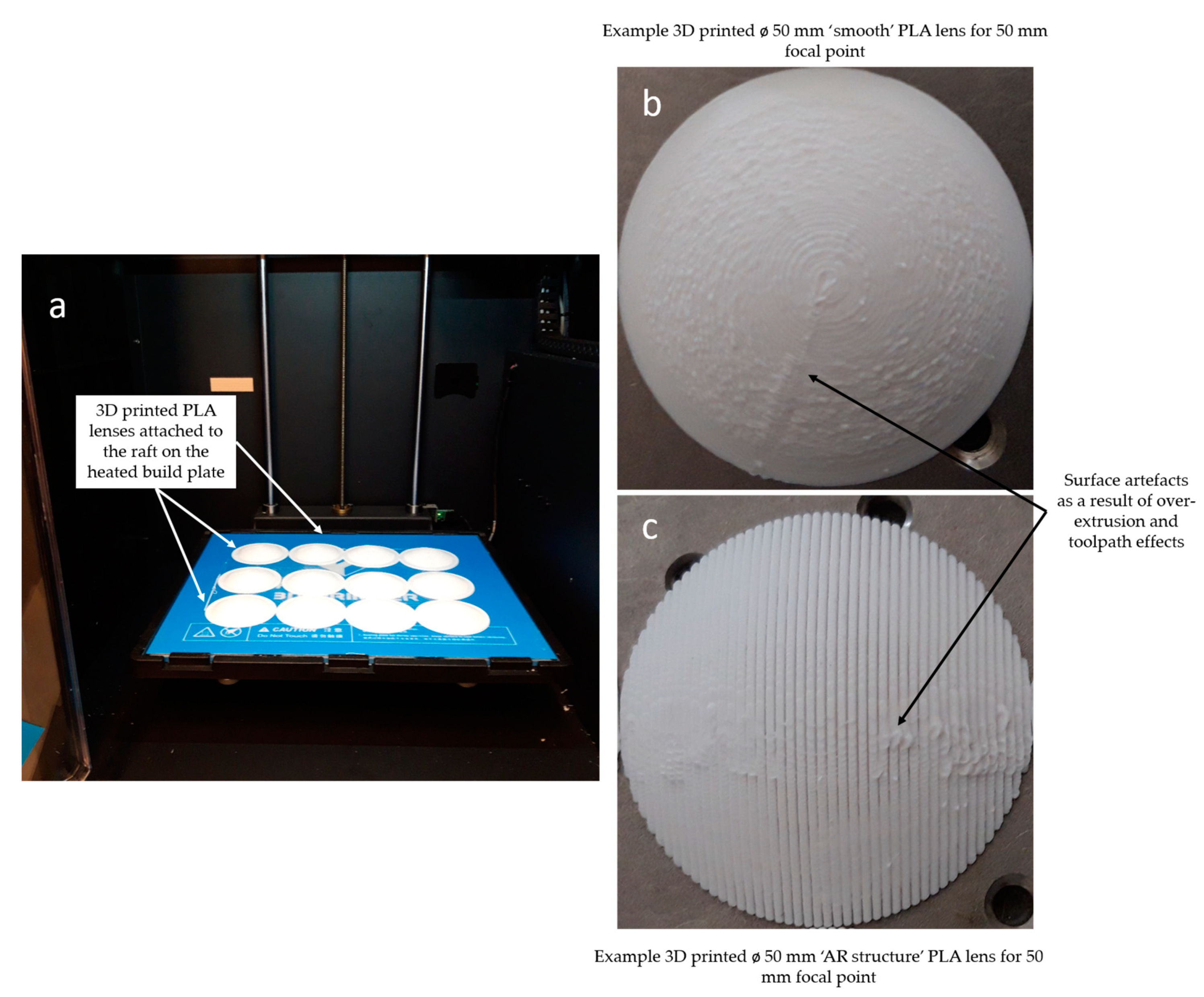

2.1. Lens Design and Fabrication

- A raft was enabled to prevent curvature of the lens’s flat face during production.

- To ensure accuracy, ‘high print accuracy’ settings were used: a 0.12 mm layer height (0.20 mm for first layer) a print speed of 50 mm/s and a travel speed of 70 mm/s.

- To ensure that the refractive index of the material did not vary throughout the lens structure, 100% infill (hexagon fill pattern with combined infill every 2 layers) was chosen.

- For PLA material, an extrusion temperature of 220 °C was used with a 50 °C platform temperature that was found to be high enough to minimize temperature-induced distortions during production. This was coupled with automatic cooling fan control to further improve build accuracy.

- A 0.4 mm aperture brass extrusion nozzle was utilized for all fabrication.The .stl files required for the 3D printing process were generated within the SolidWorks software directly from the 3D models using the following tessellation settings:

- ⚬

- A binary file type.

- ⚬

- A deviation tolerance of 0.0043 mm.

- ⚬

- An angular tolerance of 0.5°.

2.2. FEKO Simulation

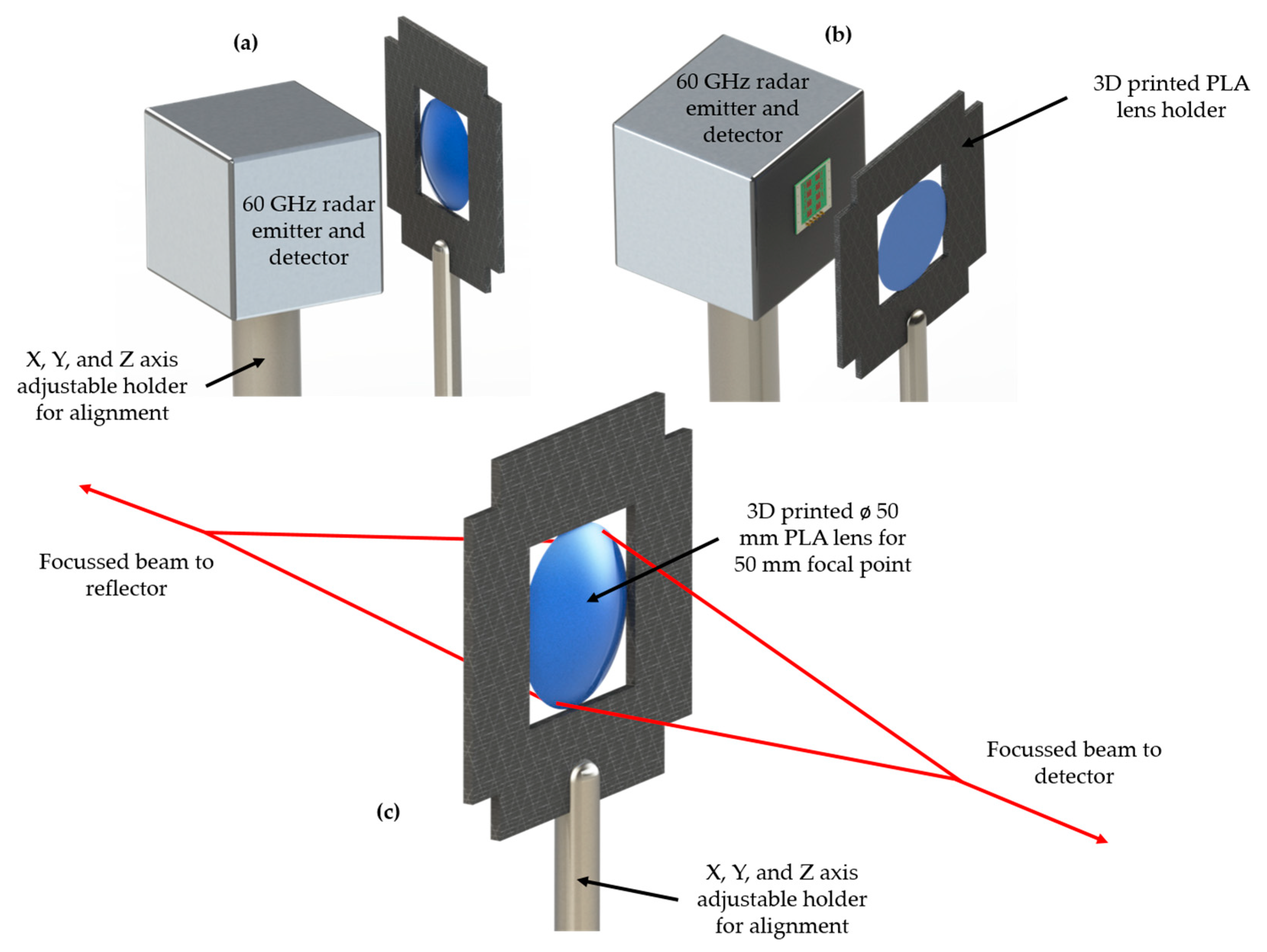

2.3. Radar Setup and Intensity Measurement

3. Results

3.1. Lens Fabrication

3.2. FEKO Electromagnetic Simulation

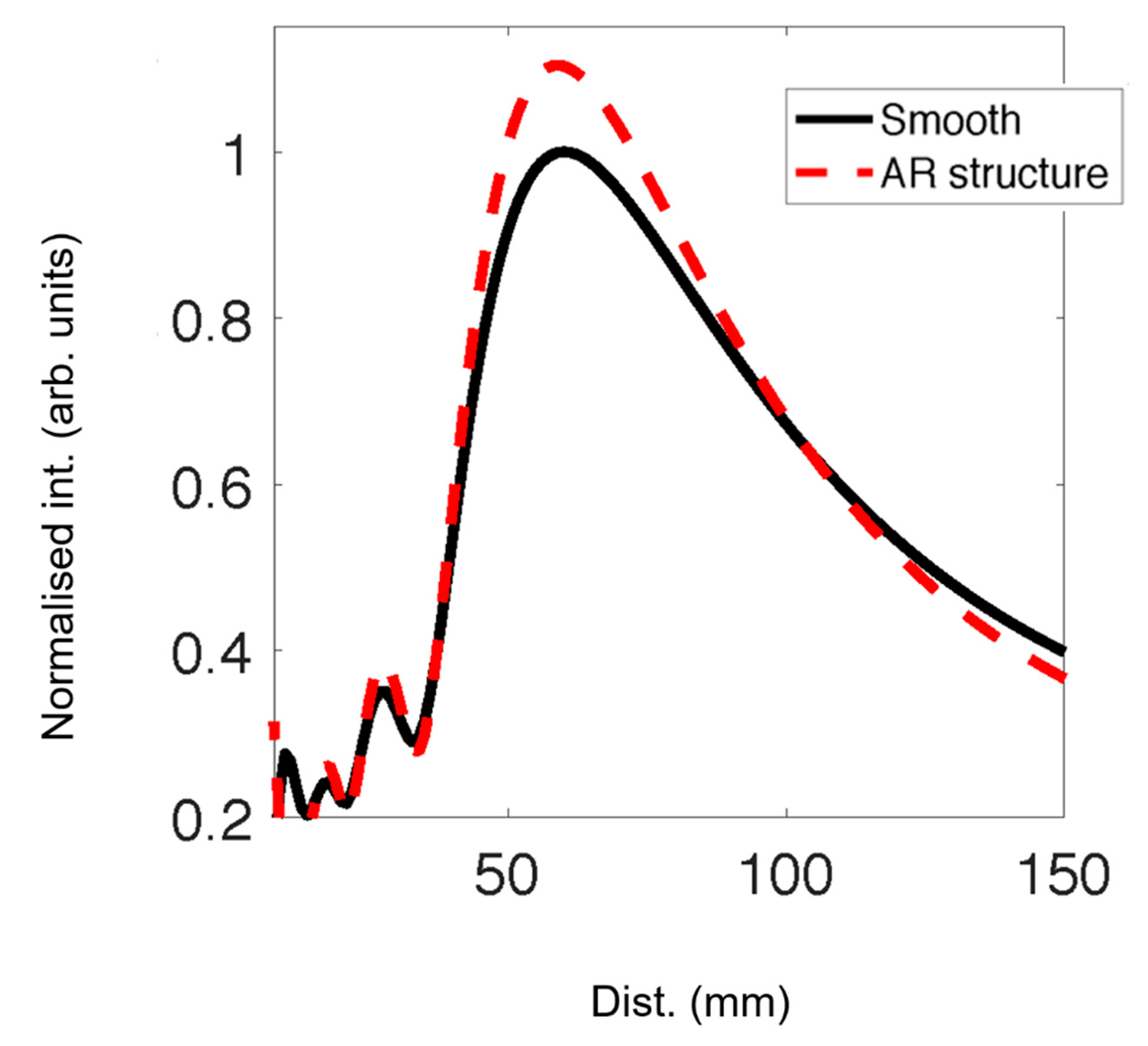

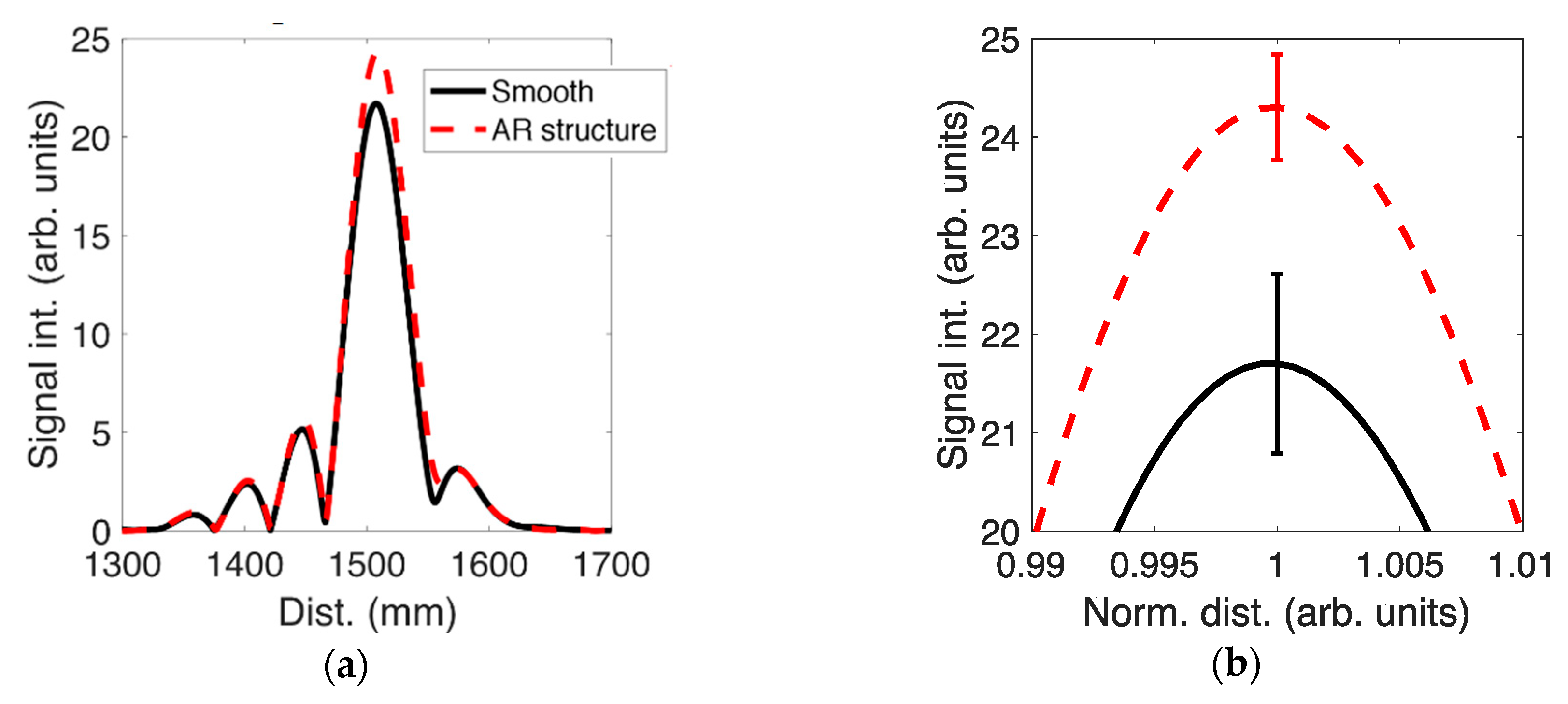

3.3. Intensity Measurement

4. Discussion

4.1. Lens Fabrication

4.2. FEKO Simulation and Intensity Measurement

Author Contributions

Funding

Conflicts of Interest

References

- Evans, R.J.; Farrell, P.M.; Felic, G.; Duong, H.T.; Le, H.V.; Li, J.; Li, M.; Moran, W.; Skafidas, E. Consumer radar: Opportunities and challenges. In Proceedings of the 2014 11th European Radar Conference, Rome, Italy, 8–10 October 2014; IEEE: New York, NY, USA, 2014; pp. 5–8. [Google Scholar]

- Dickmann, J.; Klappstein, J.; Hahn, M.; Appenrodt, N.; Bloecher, H.L.; Werber, K.; Sailer, A. Automotive radar the key technology for autonomous driving: From detection and ranging to environmental understanding. In Proceedings of the 2016 IEEE Radar Conference (RadarConf), Philadelphia, PA, USA, 2–6 May 2016; IEEE: New York, NY, USA, 2016; pp. 1–6. [Google Scholar]

- Sánchez-Oro, J.; Fernández-López, D.; Cabido, R.; Montemayor, A.S.; Pantrigo, J.J. Urban Traffic Surveillance in Smart Cities Using Radar Images; Springer: Berlin/Heidelberg, Germany, 2013; pp. 296–305. [Google Scholar]

- Diraco, G.; Leone, A.; Siciliano, P. A Radar-Based Smart Sensor for Unobtrusive Elderly Monitoring in Ambient Assisted Living Applications. Biosensors 2017, 7, 55. [Google Scholar] [CrossRef] [PubMed]

- Goldsmith, P.F. Quasi-optical techniques. Proc. IEEE 1992, 80, 1729–1747. [Google Scholar] [CrossRef]

- Piksa, P.; Zvanovec, S.; Cerny, P. Elliptic and Hyperbolic Dielectric Lens Antennas in mm-Waves. Radioengineering 2011, 20, 270–275. [Google Scholar]

- Goulas, A.; Friel, R.J. Laser sintering of ceramic materials for aeronautical and astronautical applications. Laser Addit. Manuf. 2017, 373–398. [Google Scholar] [CrossRef]

- Paolella, A.C.; Fisher, C.D.; Corey, C.; Foster, D.; Silva-Saez, D. 3-D Printed Millimeter-Wave Lens Systems at 39 GHz. IEEE Microw. Wirel. Components Lett. 2018, 28, 464–466. [Google Scholar] [CrossRef]

- Lacombe, E.; Gianesello, F.; Bisognin, A.; Lacombe, E.; Luxey, C.; Bisognin, A.; Titz, D.; Gulan, H.; Zwick, T.; Costa, J.; et al. Low-cost 3D-printed 240 GHz plastic lens fed by integrated antenna in organic substrate targeting sub-THz high data rate wireless links. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017; IEEE: New York, NY, USA, 2017; pp. 5–6. [Google Scholar]

- Yi, H.; Qu, S.W.; Ng, K.B.; Chan, C.H.; Bai, X. 3-D Printed Millimeter-Wave and Terahertz Lenses with Fixed and Frequency Scanned Beam. IEEE Trans. Antennas Propag. 2016, 64, 442–449. [Google Scholar] [CrossRef]

- Ratni, B.; de Lustrac, A.; Piau, G.P.; Burokur, S.N. 3D printed gradient index dielectric metasurface for beam steering applications. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; IEEE: New York, NY, USA, 2017; pp. 3402–3404. [Google Scholar]

- Ernst, R.; Nilsson, E.; Viberg, P.-A. 60GHz vital sign radar using 3D-printed lens. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016; IEEE: New York, NY, USA, 2016; pp. 1–3. [Google Scholar]

- Hagström, A.L.; Vass, L.A.M.; Liu, F.; Gerling, M.; Karlsson, P.O.; Nilsson, E.; Andreasson, B.P. An iterative approach to determine the refractive index of 3D printed 60GHz PLA lenses. In Proceedings of the Loughborough Antennas & Propagation Conference 2018 (LAPC 2018), Loughborough, UK, 12–13 November 2018; IET: London, UK, 2018. [Google Scholar]

- Pourahmadazar, J.; Denidni, T.A. Towards Millimeter-wavelength: Transmission-Mode Fresnel-Zone Plate Lens Antennas using Plastic Material Porosity Control in Homogeneous Medium. Sci. Rep. 2018, 8, 5300. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.W.; Wang, Z.; Feng, X.M.; Li, B.; Mu, Z.Z.; Zhang, J.Q.; Niu, S.C.; Ren, L.Q. Antireflective surface inspired from biology: A review. Biosurf. Biotribol. 2016, 2, 137–150. [Google Scholar] [CrossRef]

- Ransom, P.; Larimore, Z.; Jensen, S.; Mirotznik, M.S. Fabrication of wideband antireflective coatings using fused deposition modelling. Electron. Lett. 2016, 52, 352–354. [Google Scholar] [CrossRef]

- Larimore, Z.; Jensen, S.; Parsons, P.; Good, B.; Smith, K.; Mirotznik, M. Use of space-filling curves for additive manufacturing of three dimensionally varying graded dielectric structures using fused deposition modeling. Addit. Manuf. 2017, 15, 48–56. [Google Scholar] [CrossRef]

- Qu, S.W.; Yi, H.; Chan, C.H.; Ng, K.B. Low-cost discrete dielectric terahertz lens antenna using 3D printing. In Proceedings of the 2014 IEEE Conference on Antenna Measurements & Applications (CAMA), Antibes Juan-les-Pins, France, 16–19 November 2014; IEEE: New York, NY, USA, 2014; pp. 1–3. [Google Scholar]

- Jahn, D.; Weidenbach, M.; Becker, L.; Lehr, J.; Busch, S.F.; Monnai, Y.; Balzer, J.C.; Koch, M. 3D printed chirped dielectric waveguide for focusing applications. In Proceedings of the 2016 41st International Conference on Infrared, Millimeter, and Terahertz waves (IRMMW-THz), Copenhagen, Denmark, 1 December 2016; IEEE: New York, NY, USA, 2016; pp. 1–2. [Google Scholar]

- Gulkis, P.; Kollberg, S.; Winnesser, E.; Kaufmann, G. Quasi-Optical Techniques. In Coherent Detection at Millimeter Wavelengths and Their Applications, Les Houches Series; Encrenaz, G., Laurent, P., Gulkis, C., Kollberg, S., Winnesser, E., Eds.; Nova Science Publishers: Hauppauge, New York, NY, USA, 1991. [Google Scholar]

- Busse, L.E.; Frantz, J.A.; Shaw, L.B.; Aggarwal, I.D.; Sanghera, J.S. Review of antireflective surface structures on laser optics and windows. Appl. Opt. 2015, 54, 303. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friel, R.J.; Gerling-Gerdin, M.; Nilsson, E.; Andreasson, B.P. 3D Printed Radar Lenses with Anti-Reflective Structures. Designs 2019, 3, 28. https://doi.org/10.3390/designs3020028

Friel RJ, Gerling-Gerdin M, Nilsson E, Andreasson BP. 3D Printed Radar Lenses with Anti-Reflective Structures. Designs. 2019; 3(2):28. https://doi.org/10.3390/designs3020028

Chicago/Turabian StyleFriel, Ross J., Maria Gerling-Gerdin, Emil Nilsson, and Björn P. Andreasson. 2019. "3D Printed Radar Lenses with Anti-Reflective Structures" Designs 3, no. 2: 28. https://doi.org/10.3390/designs3020028

APA StyleFriel, R. J., Gerling-Gerdin, M., Nilsson, E., & Andreasson, B. P. (2019). 3D Printed Radar Lenses with Anti-Reflective Structures. Designs, 3(2), 28. https://doi.org/10.3390/designs3020028