Overcoming Chip Shortages: Low-Cost Open-Source Parametric 3-D Printable Solderless SOIC to DIP Breakout Adapters

Abstract

1. Introduction

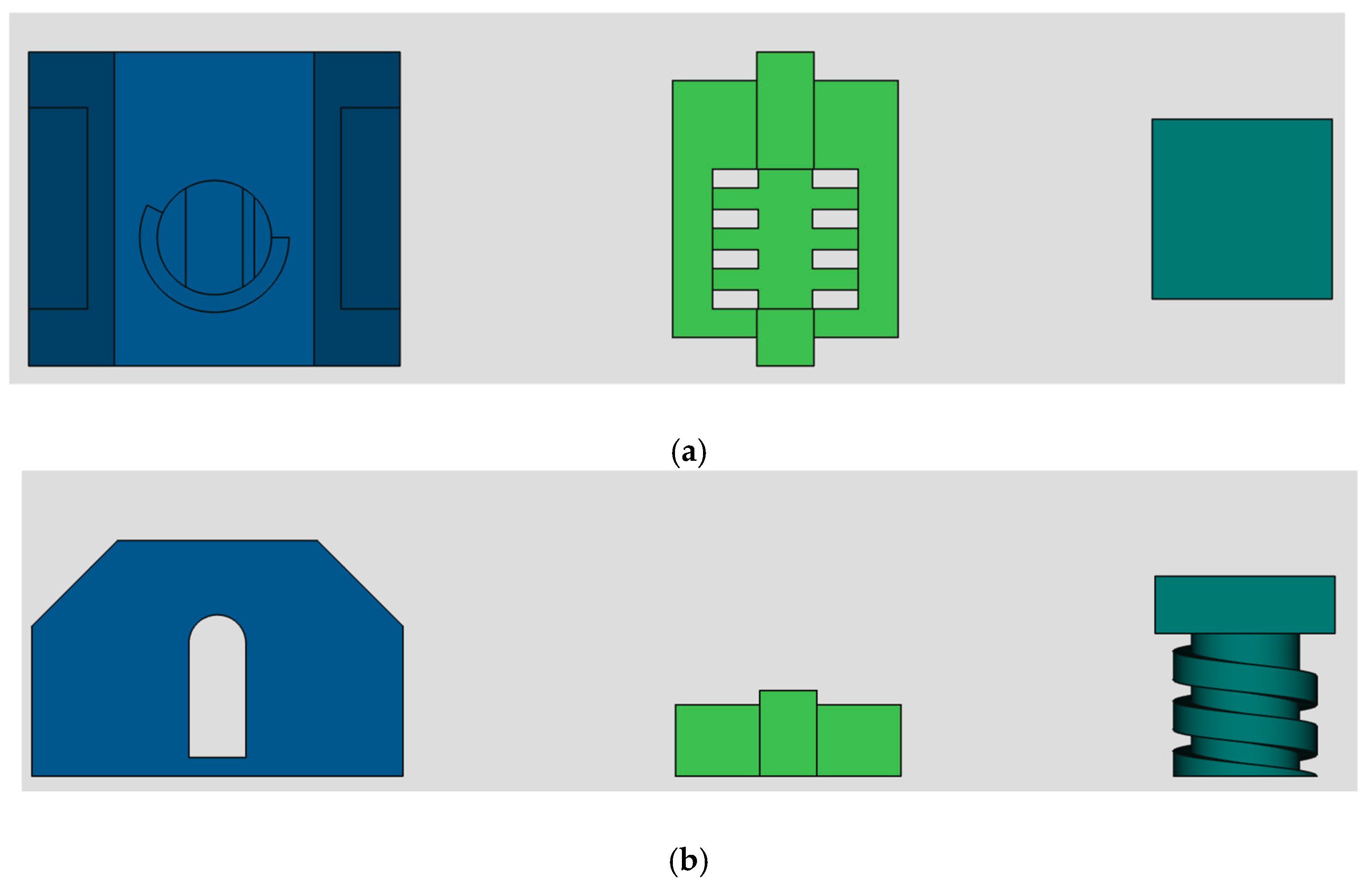

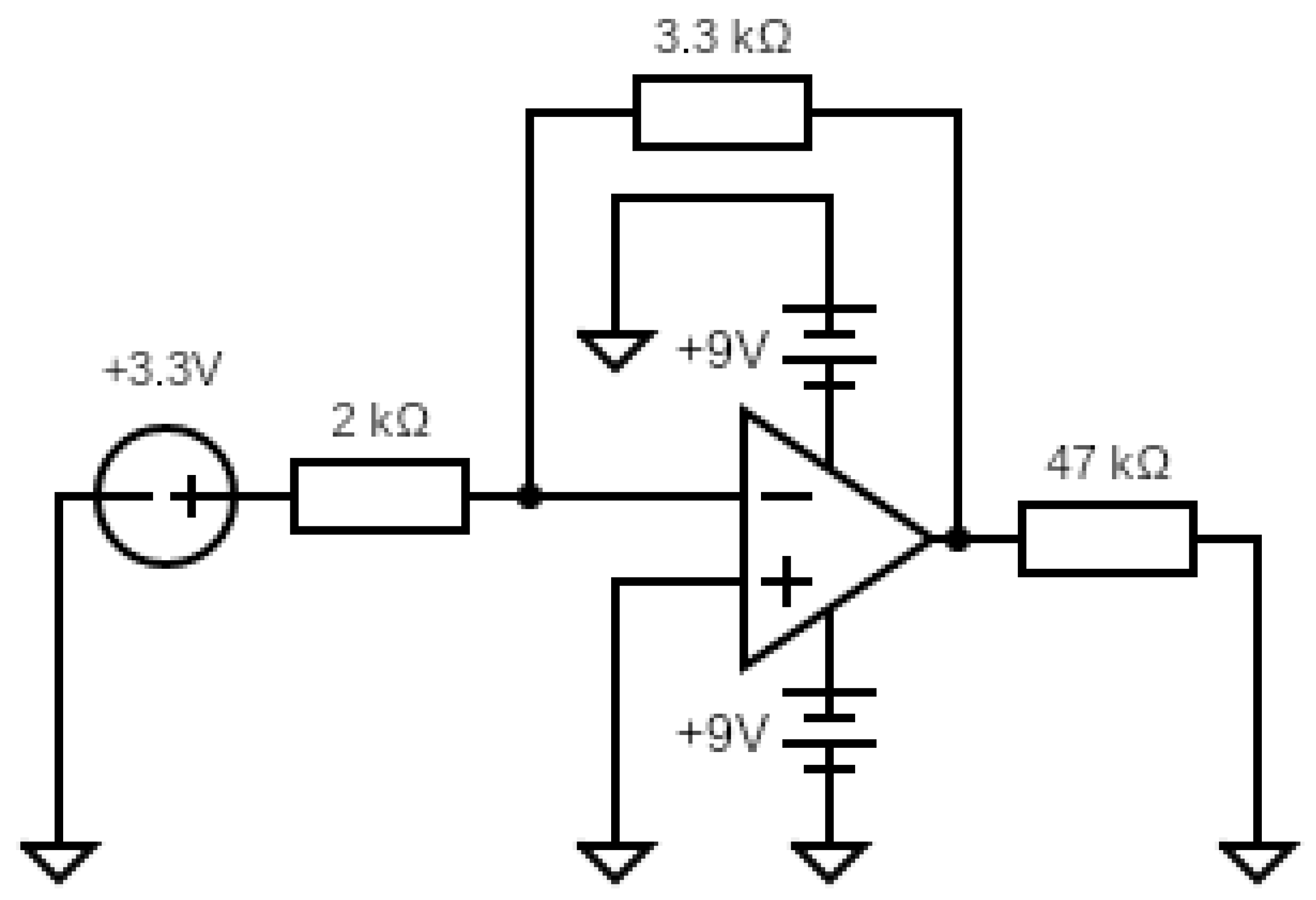

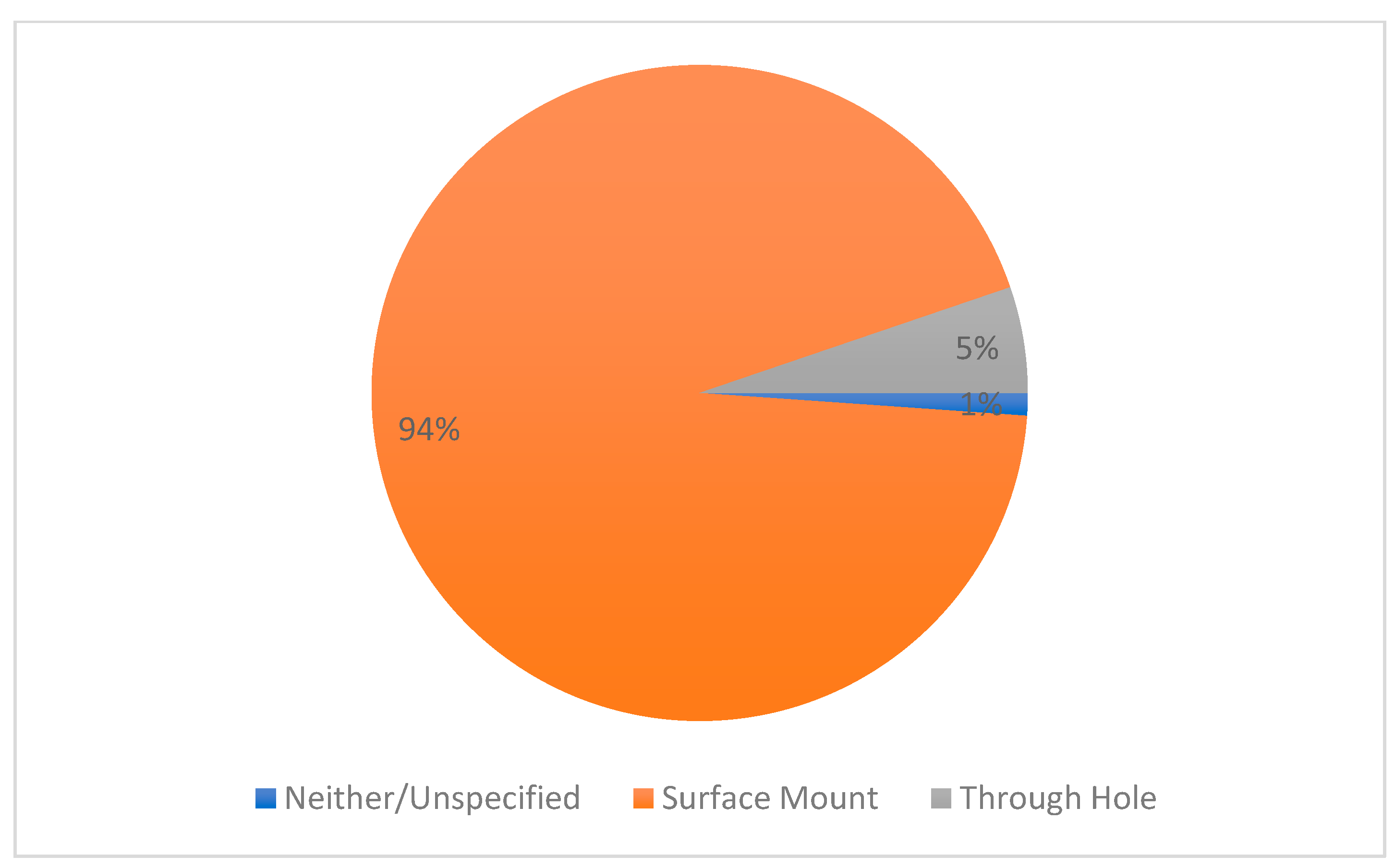

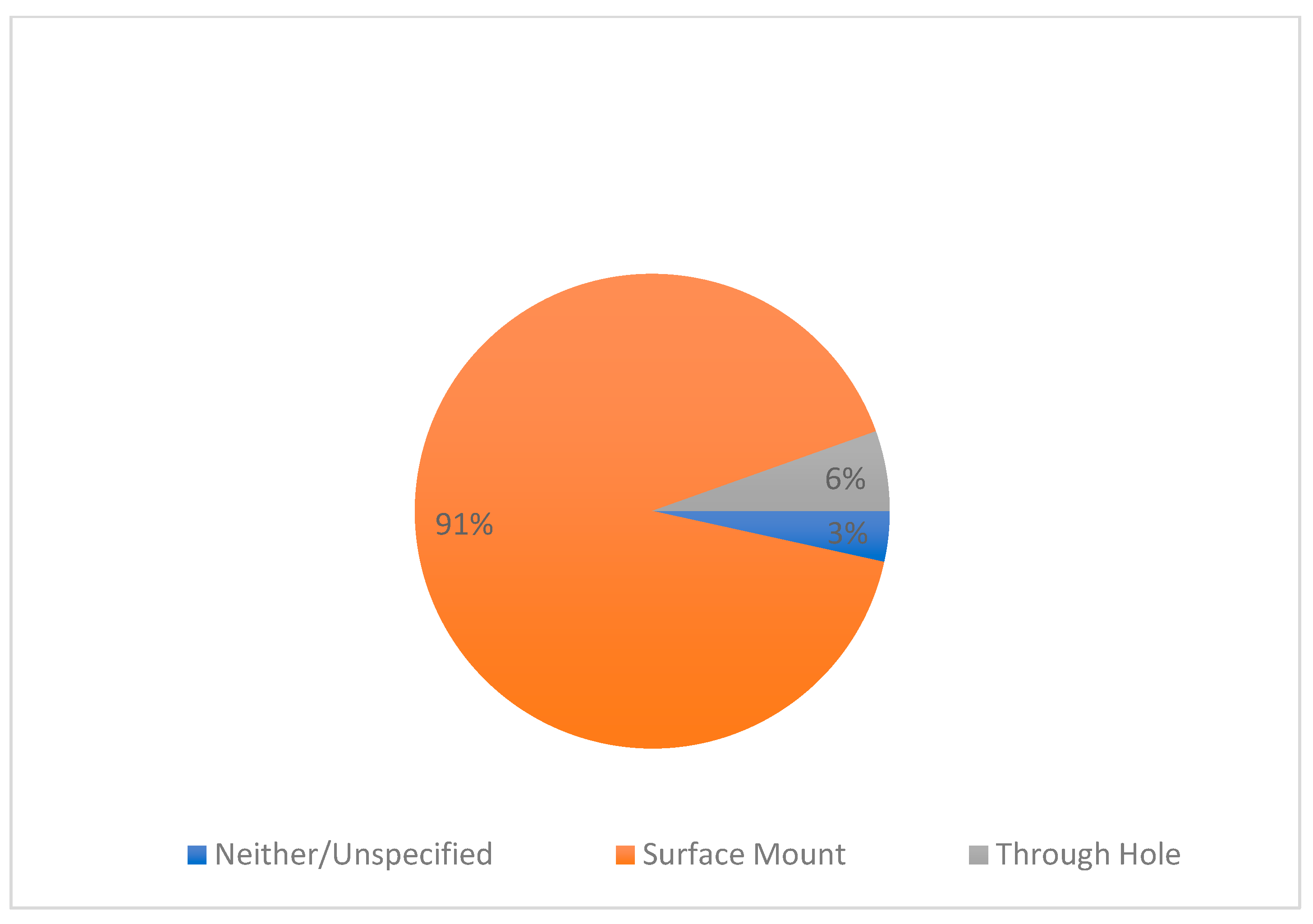

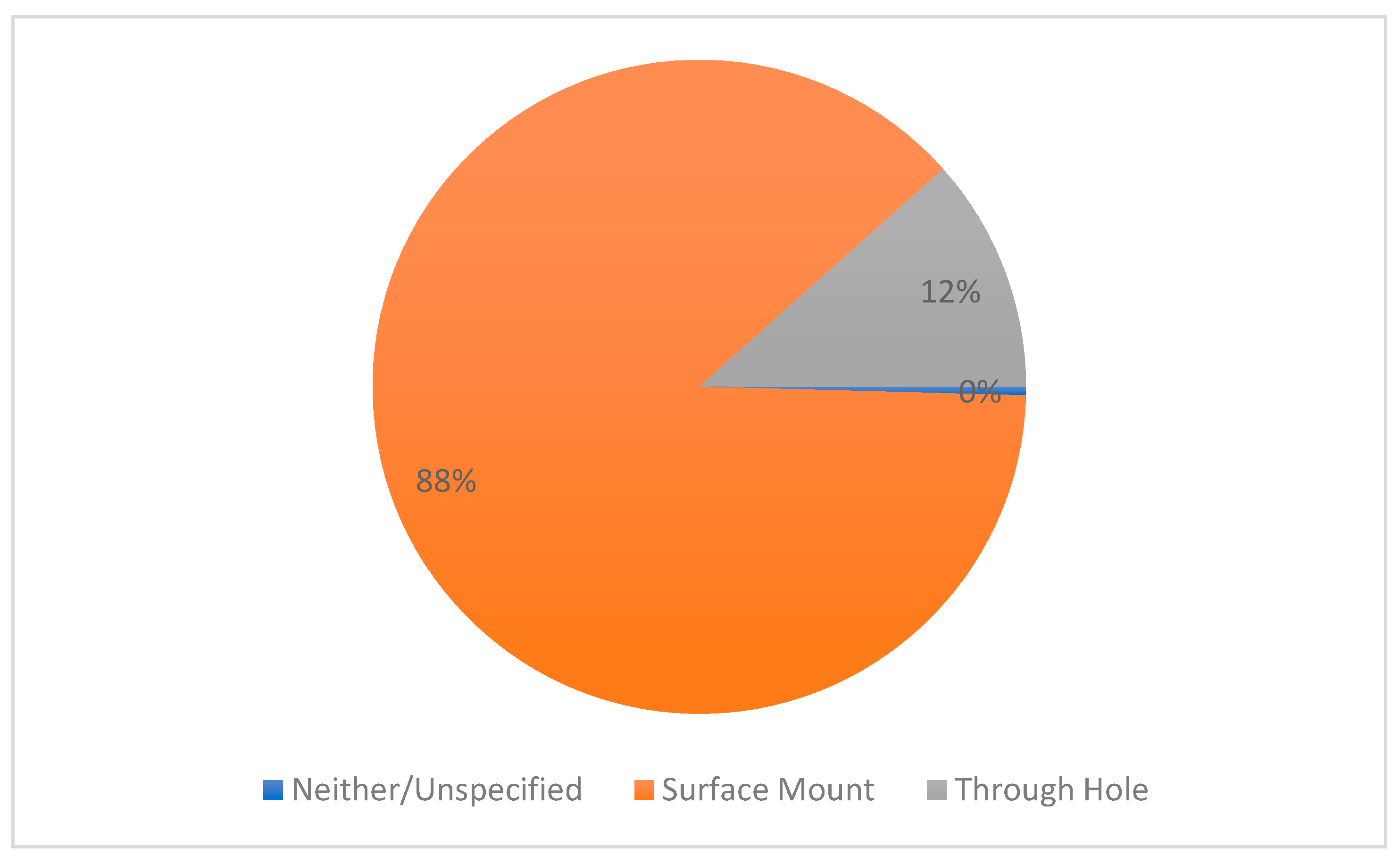

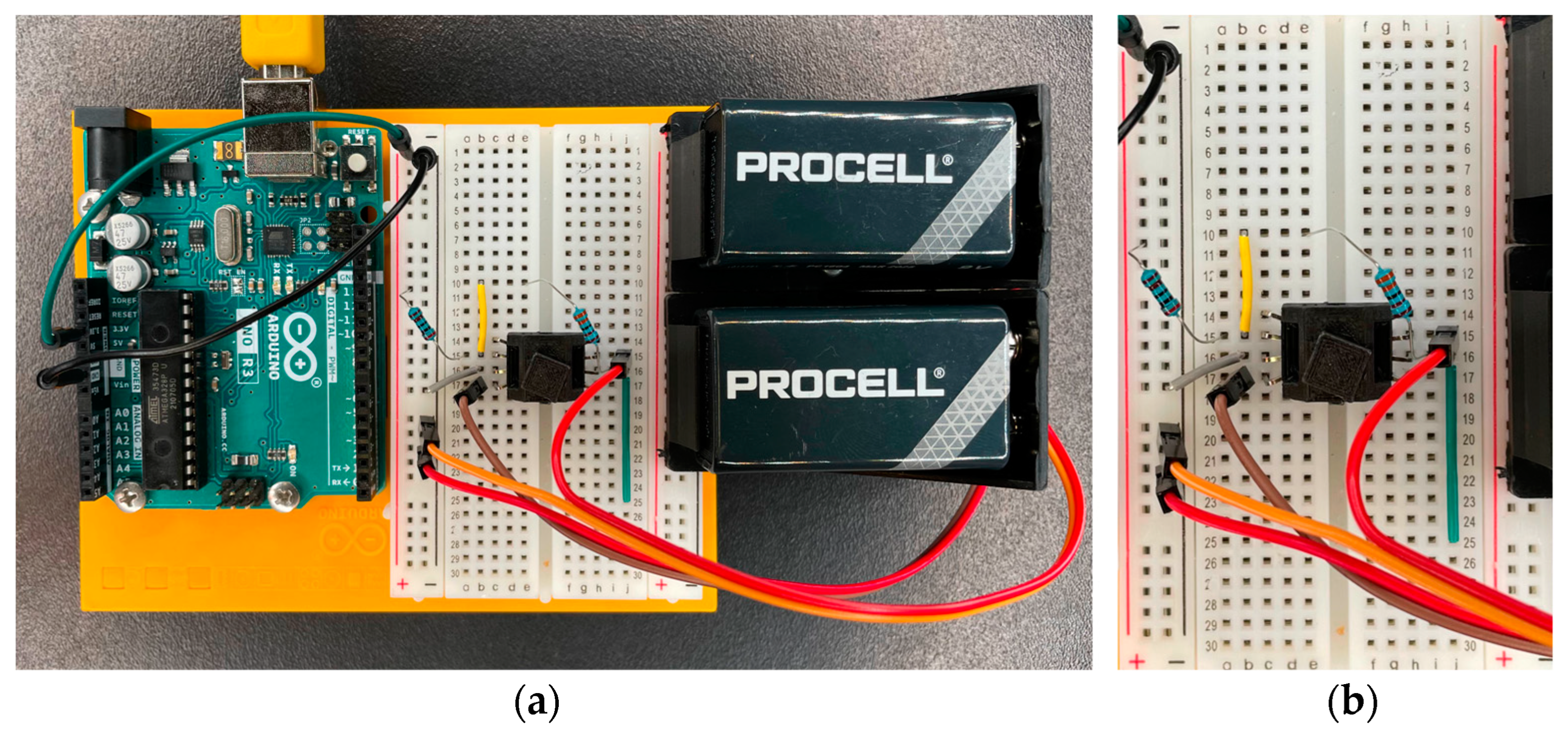

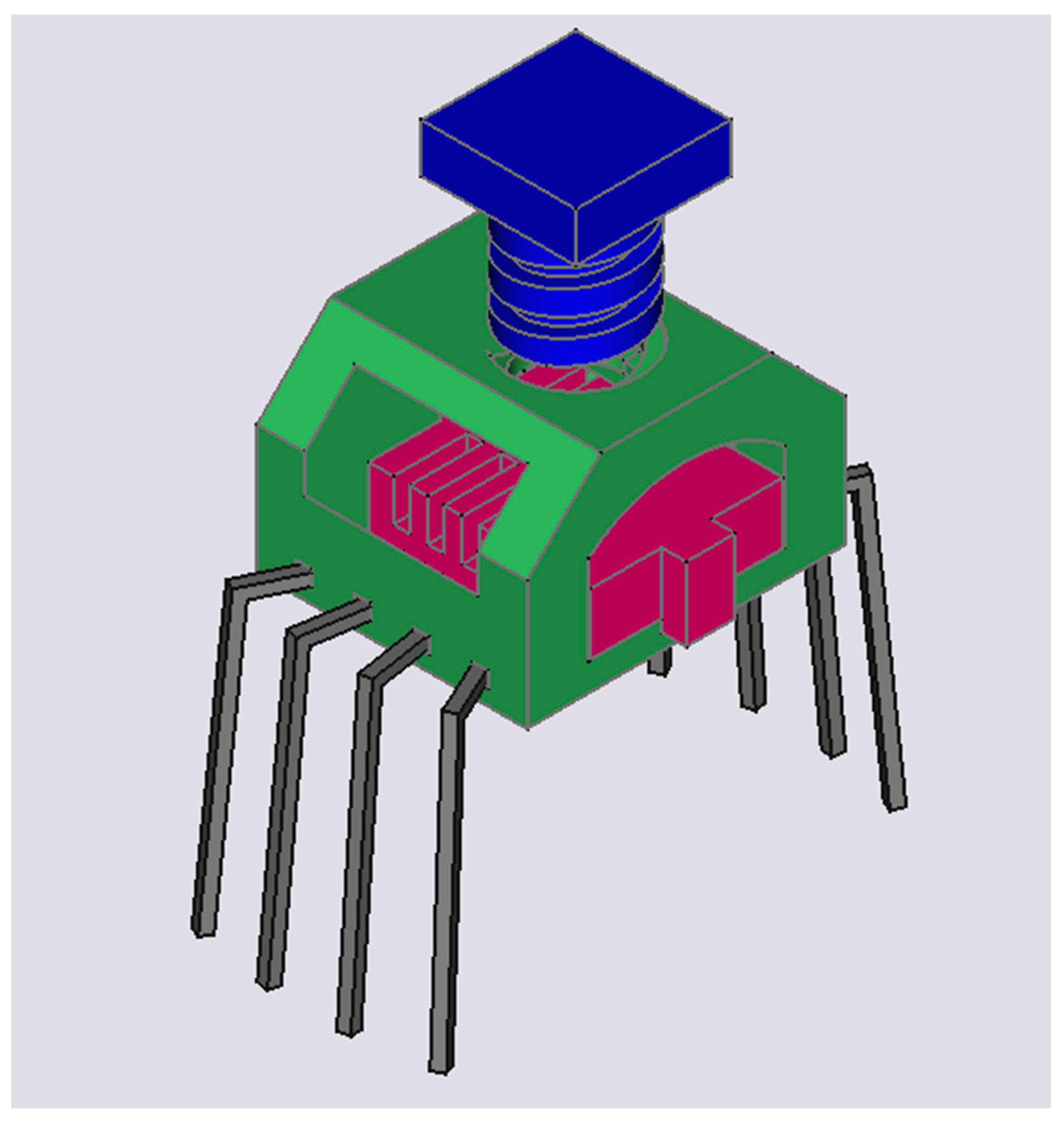

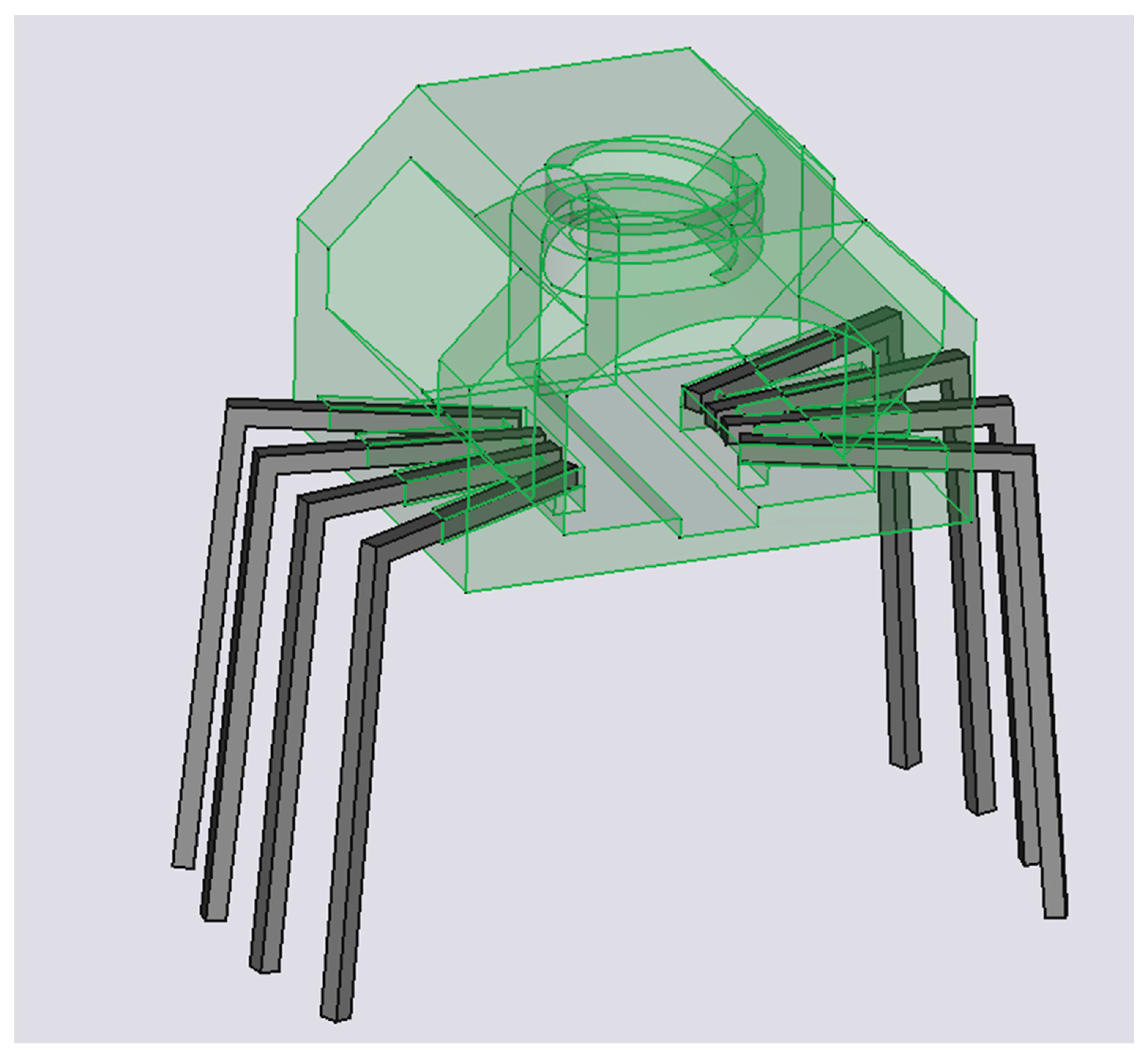

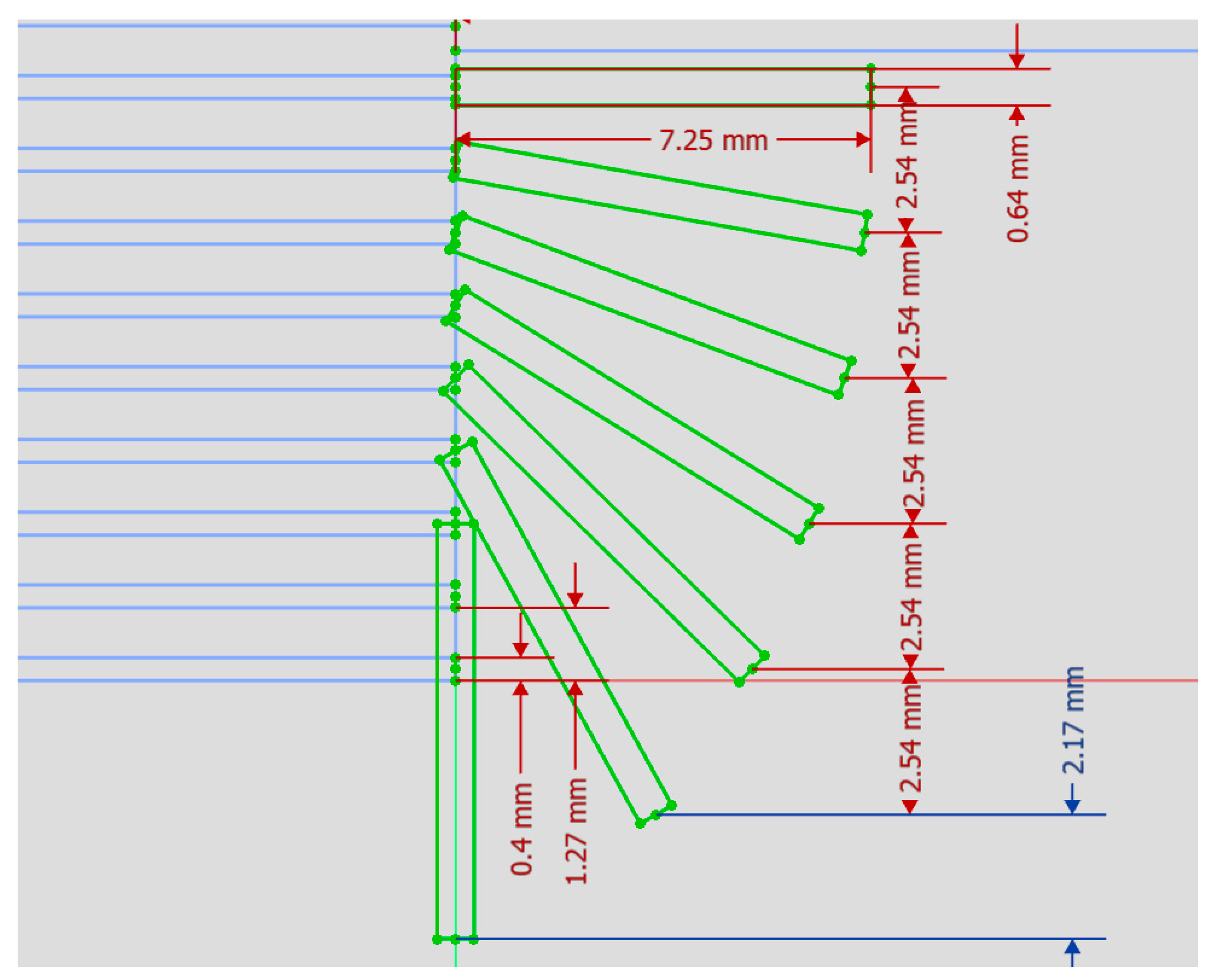

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Helmold, M.; Yılmaz, A.K.; Dathe, T.; Flouris, T.G. Global Supply Chains. In Supply Chain Risk Management: Cases and Industry Insights; Helmold, M., Yılmaz, A.K., Dathe, T., Flouris, T.G., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 79–89. [Google Scholar] [CrossRef]

- Yu, Z.; Razzaq, A.; Rehman, A.; Shah, A.; Jameel, K.; Mor, R.S. Disruption in global supply chain and socio-economic shocks: A lesson from COVID-19 for sustainable production and consumption. Oper. Manag. Res. 2021, 15, 233–248. [Google Scholar] [CrossRef]

- Bhaskar, S.; Tan, J.; Bogers, M.L.A.M.; Minssen, T.; Badaruddin, H.; Israeli-Korn, S.; Chesbrough, H. At the Epicenter of COVID-19–the Tragic Failure of the Global Supply Chain for Medical Supplies. Front. Public Health 2020, 8, 562882. [Google Scholar] [CrossRef] [PubMed]

- Armani, A.M.; Hurt, D.E.; Hwang, D.; McCarthy, M.C.; Scholtz, A. Low-tech solutions for the COVID-19 supply chain crisis. Nat. Rev. Mater. 2020, 5, 403–406. [Google Scholar] [CrossRef] [PubMed]

- Chagas, A.M.; Molloy, J.C.; Prieto-Godino, L.L.; Baden, T. Leveraging open hardware to alleviate the burden of COVID-19 on global health systems. PLoS Biol. 2020, 18, e3000730. [Google Scholar] [CrossRef]

- Stirling, J.; Bowman, R. The COVID-19 Pandemic Highlights the Need for Open Design Not Just Open Hardware. Des. J. 2021, 24, 299–314. [Google Scholar] [CrossRef]

- Pearce, J.M. Distributed Manufacturing of Open Source Medical Hardware for Pandemics. J. Manuf. Mater. Process. 2020, 4, 49. [Google Scholar] [CrossRef]

- Saripalle, S.; Maker, H.; Bush, A.; Lundman, N. 3D printing for disaster preparedness: Making life-saving supplies on-site, on-demand, on-time. In Proceedings of the 2016 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 13–16 October 2016; pp. 205–208. [Google Scholar] [CrossRef]

- Jafferson, J.; Pattanashetti, S. Use of 3D printing in production of personal protective equipment (PPE)—A review. Mater. Today Proc. 2021, 46, 1247–1260. [Google Scholar] [CrossRef]

- Flanagan, S.T.; Ballard, D.H. 3D Printed Face Shields: A Community Response to the COVID-19 Global Pandemic. Acad. Radiol. 2020, 27, 905–906. [Google Scholar] [CrossRef]

- Novak, J.I.; Loy, J. A quantitative analysis of 3D printed face shields and masks during COVID-19. Emerald Open Res. 2020, 2, 42. [Google Scholar] [CrossRef]

- Vaňková, E.; Kašparová, P.; Khun, J.; Machková, A.; Julák, J.; Sláma, M.; Hodek, J.; Ulrychová, L.; Weber, J.; Obrová, K.; et al. Polylactic acid as a suitable material for 3D printing of protective masks in times of COVID-19 pandemic. PeerJ 2020, 8, e10259. [Google Scholar] [CrossRef]

- Ballard, D.H.; Jammalamadaka, U.; Meacham, K.W.; Hoegger, M.J.; Burke, B.A.; Morris, J.A.; Scott, A.R.; O’Connor, Z.; Gan, C.; Hu, J.; et al. Quantitative Fit Tested N95 Respirator-Alternatives Generated With CT Imaging and 3D Printing: A Response to Potential Shortages During the COVID-19 Pandemic. Acad. Radiol. 2020, 28, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Imbrie-Moore, A.; Park, M.; Zhu, Y.; Paulsen, M.; Wang, H.; Woo, Y. Quadrupling the N95 Supply during the COVID-19 Crisis with an Innovative 3D-Printed Mask Adaptor. Healthcare 2020, 8, 225. [Google Scholar] [CrossRef]

- Skrzypczak, N.G.; Tanikella, N.G.; Pearce, J.M. Open source high-temperature RepRap for 3-D printing heat-sterilizable PPE and other applications. HardwareX 2020, 8, e00130. [Google Scholar] [CrossRef]

- Nicholson, K.; Henke-Adams, A.; Henke, D.M.; Kravitz, A.V.; Gay, H.A. Modified full-face snorkel mask as COVID-19 personal protective equipment: Quantitative results. HardwareX 2021, 9, e00185. [Google Scholar] [CrossRef] [PubMed]

- Hubbard, B.R.; Pearce, J.M. Conversion of self-contained breathing apparatus mask to open source powered air-purifying particulate respirator for fire fighter COVID-19 response. HardwareX 2020, 8, e00129. [Google Scholar] [CrossRef] [PubMed]

- Gallup, N.; Pringle, A.M.; Oberloier, S.; Tanikella, N.G.; Pearce, J.M. Parametric nasopharyngeal swab for sampling COVID-19 and other respiratory viruses: Open source design, SLA 3-D printing and UV curing system. HardwareX 2020, 8, e00135. [Google Scholar] [CrossRef] [PubMed]

- Manoj, A.; Bhuyan, M.; Banik, S.R.; Sankar, M.R. 3D printing of nasopharyngeal swabs for COVID-19 diagnose: Past and current trends. Mater. Today Proc. 2020, 44, 1361–1368. [Google Scholar] [CrossRef]

- Abuzairi, T.; Sumantri, N.I.; Irfan, A.; Mohamad, R.M. Infrared thermometer on the wall (iThermowall): An open source and 3-D print infrared thermometer for fever screening. HardwareX 2020, 9, e00168. [Google Scholar] [CrossRef]

- Santhosh, R.; Yadav, S. Low Cost Multipurpose UV-C Sterilizer box for protection against COVID’19. In Proceedings of the 2021 International Conference on Artificial Intelligence and Smart Systems (ICAIS), Coimbatore, India, 25–27 March 2021; pp. 1495–1498. [Google Scholar] [CrossRef]

- Bentancor, M.; Fernández, S.; Viera, F.; Etcheverry, S.; Poradosú, C.; D’Angelo, P.; Montemuiño, H.; Mirazo, S.; Irigoyen, Á.; Sanabria, A.; et al. LUCIA: An open source device for disinfection of N95 masks using UV-C radiation. HardwareX 2021, 9, e00181. [Google Scholar] [CrossRef]

- Oberloier, S.; Gallup, N.; Pearce, J. Overcoming supply disruptions during pandemics by utilizing found hardware for open source gentle ventilation. HardwareX 2021, 11, e00255. [Google Scholar] [CrossRef]

- Pearce, J.M. A review of open source ventilators for COVID-19 and future pandemics. F1000Research 2020, 9, 218. [Google Scholar] [CrossRef] [PubMed]

- Abuzairi, T.; Irfan, A. Basari COVENT-Tester: A low-cost, open source ventilator tester. HardwareX 2021, 9, e00196. [Google Scholar] [CrossRef] [PubMed]

- Read, R.L.; Clarke, L.; Mulligan, G. VentMon: An open source inline ventilator tester and monitor. HardwareX 2021, 9, e00195. [Google Scholar] [CrossRef]

- Voas, J.; Kshetri, N.; DeFranco, J.F. Scarcity and Global Insecurity: The Semiconductor Shortage. IT Prof. 2021, 23, 78–82. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P.; Chowdhury, T.; Chakrabortty, R.K.; Moktadir, A. Operational challenges during a pandemic: An investigation in the electronics industry. Int. J. Logist. Manag. 2021, 34, 336–362. [Google Scholar] [CrossRef]

- Coughlin, T. Impact of COVID-19 on the Consumer Electronics Market. IEEE Consum. Electron. Mag. 2020, 10, 58–59. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, C.; Du, W. An Analysis on the Crisis of “Chips shortage” in Automobile Industry—Based on the Double Influence of COVID-19 and Trade Friction. J. Phys. Conf. Ser. 2021, 1971, 012100. [Google Scholar] [CrossRef]

- Miller, F.A.; Young, S.B.; Dobrow, M.; Shojania, K.G. Vulnerability of the medical product supply chain: The wake-up call of COVID-19. BMJ Qual. Saf. 2020, 30, 331–335. [Google Scholar] [CrossRef]

- Sajjad, A. The COVID-19 pandemic, social sustainability and global supply chain resilience: A review. Corp. Gov. Int. J. Bus. Soc. 2021, 21, 1142–1154. [Google Scholar] [CrossRef]

- Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J. 3D printing electronic components and circuits with conductive thermoplastic filament. Addit. Manuf. 2017, 18, 156–163. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B.; Jiang, J.; Wu, K.; Guo, C.F.; Wu, Z. High-Fidelity Conformal Printing of 3D Liquid Alloy Circuits for Soft Electronics. ACS Appl. Mater. Interfaces 2019, 11, 7148–7156. [Google Scholar] [CrossRef]

- Czyżewski, J.; Burzyński, P.; Gaweł, K.; Meisner, J. Rapid prototyping of electrically conductive components using 3D printing technology. J. Mater. Process. Technol. 2009, 209, 5281–5285. [Google Scholar] [CrossRef]

- Olivas, R.; Salas, R.; Muse, D.; MacDonald, E.; Wicker, R.; Newton, M.; Church, K. Structural Electronics through Additive Manufacturing and Micro-Dispensing. Int. Symp. Microelectron. 2010, 2010, 000940–000946. [Google Scholar] [CrossRef]

- Min, H.; Lee, B.; Jeong, S.; Lee, M. Fabrication of 10 µm-scale conductive Cu patterns by selective laser sintering of Cu complex ink. Opt. Laser Technol. 2017, 88, 128–133. [Google Scholar] [CrossRef]

- Sigmarsson, H.H.; Kinzel, E.C.; Xu, X.; Chappell, W.J. Selective Laser Sintering of Multilayer, Multimaterial Circuit Components. In Proceedings of the 2006 IEEE MTT-S International Microwave Symposium Digest, San Francisco, CA, USA, 11–16 June 2006; pp. 1788–1791. [Google Scholar] [CrossRef]

- Palmer, J.A.; Summers, J.L.; Davis, D.W.; Gallegos, P.L.; Chavez, B.D.; Yang, P.; Medina, F.; Wicker, R.B. Realizing 3-D Interconnected Direct Write Electronics Within Smart Stereolithography Structures. In Proceedings of the ASME 2005 International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005; pp. 287–293. [Google Scholar] [CrossRef]

- Lopes, A.J.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Digi-Key Corporation. Digi-Key Company History. Available online: https://web.archive.org/web/20160416045752/https://www.digikey.com/en/resources/about-digikey (accessed on 7 July 2022).

- Digi-Key Corporation. Embedded–Microsontrollers. Available online: https://www.digikey.ca/en/products/filter/embedded-microcontrollers/685 (accessed on 3 July 2022).

- Selenium. Software Freedom Conservancy. 2022. Available online: https://pypi.org/project/selenium/ (accessed on 3 July 2022).

- Beautiful Soup. Leonard Richardson. 2022. Available online: https://pypi.org/project/beautifulsoup4/ (accessed on 3 July 2022).

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2009; pp. 568–580. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- What Is OpenSCAD? Openscad 2021.01. 2022. Available online: https://github.com/openscad/openscad (accessed on 7 July 2022).

- FreeCAD 0.20. FreeCAD. 2022. Available online: https://github.com/FreeCAD/FreeCAD (accessed on 27 June 2022).

- Prusa Firmware MK3. Prusa3D. 2022. Available online: https://github.com/prusa3d/Prusa-Firmware (accessed on 27 June 2022).

- PrusaSlicer. Prusa3D. 2022. Available online: https://github.com/prusa3d/PrusaSlicer (accessed on 27 June 2022).

- Open Science Foundation. Additive Manufacture Breakout Board. Available online: https://osf.io/dh6uy/ (accessed on 11 July 2022).

- LondonHydro, “Hydro One”. Available online: https://www.hydroone.com:443/rates-and-billing/rates-and-charges/electricity-pricing-and-costs (accessed on 7 July 2022).

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Alexandre, A.; Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers. 3D Print. Addit. Manuf. 2020, 7, 237–247. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- King, D.L.; Babasola, A.; Rozario, J.; Pearce, J. Mobile Open-Source Solar-Powered 3-D Printers for Distributed Manufacturing in Off-Grid Communities. Chall. Sustain. 2014, 2, 18–27. [Google Scholar] [CrossRef]

- Wong, J.Y. Ultra-Portable Solar-Powered 3D Printers for Onsite Manufacturing of Medical Resources. Aerosp. Med. Hum. Perform. 2015, 86, 830–834. [Google Scholar] [CrossRef]

- Gwamuri, J.; Franco, D.; Khan, K.Y.; Gauchia, L.; Pearce, J.M. High-Efficiency Solar-Powered 3-D Printers for Sustainable Development. Machines 2016, 4, 3. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Vidler, C.; Rosson, L.; Long, J. The Recycling of E-Waste ABS Plastics by Melt Extrusion and 3D Printing Using Solar Powered Devices as a Transformative Tool for Humanitarian Aid. In Proceedings of the 2018 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2017, 128, 48–58. [Google Scholar] [CrossRef]

- Oellermann, M.; Jolles, J.W.; Ortiz, D.; Seabra, R.; Wenzel, T.; Wilson, H.; Tanner, R. Harnessing the Benefits of Open Electronics in Science. arXiv 2021, arXiv:2106.15852. [Google Scholar]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open Labware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Chagas, A.M. Haves and have nots must find a better way: The case for open scientific hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef] [PubMed]

| Description | Theoretical Value (V) | Value (V) |

|---|---|---|

| Input signal | +3.3 | +3.41 |

| Positive rail | +9.0 | +8.96 |

| Negative rail | −9.0 | −8.28 |

| Output signal | −5.5 | −5.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brooks, C.K.; Peplinski, J.E.; Pearce, J.M. Overcoming Chip Shortages: Low-Cost Open-Source Parametric 3-D Printable Solderless SOIC to DIP Breakout Adapters. Inventions 2023, 8, 61. https://doi.org/10.3390/inventions8020061

Brooks CK, Peplinski JE, Pearce JM. Overcoming Chip Shortages: Low-Cost Open-Source Parametric 3-D Printable Solderless SOIC to DIP Breakout Adapters. Inventions. 2023; 8(2):61. https://doi.org/10.3390/inventions8020061

Chicago/Turabian StyleBrooks, Cameron K., Jack E. Peplinski, and Joshua M. Pearce. 2023. "Overcoming Chip Shortages: Low-Cost Open-Source Parametric 3-D Printable Solderless SOIC to DIP Breakout Adapters" Inventions 8, no. 2: 61. https://doi.org/10.3390/inventions8020061

APA StyleBrooks, C. K., Peplinski, J. E., & Pearce, J. M. (2023). Overcoming Chip Shortages: Low-Cost Open-Source Parametric 3-D Printable Solderless SOIC to DIP Breakout Adapters. Inventions, 8(2), 61. https://doi.org/10.3390/inventions8020061