Design and Research Sowing Devices for Aerial Sowing of Forest Seeds with UAVs

Abstract

1. Introduction

2. Materials and Methods

2.1. Existing Types of Sowing Devices

2.1.1. Metering Systems

- -

- dosing of seeds at a predetermined rate (for example, kg or the number of seeds per running meter);

- -

- dosing of seeds with the required accuracy (interval) in accordance with the sowing scheme (for example, row sowing, sowing by quad groups);

- -

- minimal damage to the seed during metering.

2.1.2. Seed Distribution Systems

- -

- stable transfer of seed from the unloading point of the seed meter to the ground surface;

- -

- ensuring the accuracy of distribution (distance between seeds) when they are laid on the soil surface;

- -

- providing (if necessary) additional acceleration of seeds to penetrate into the surface layer of the soil.

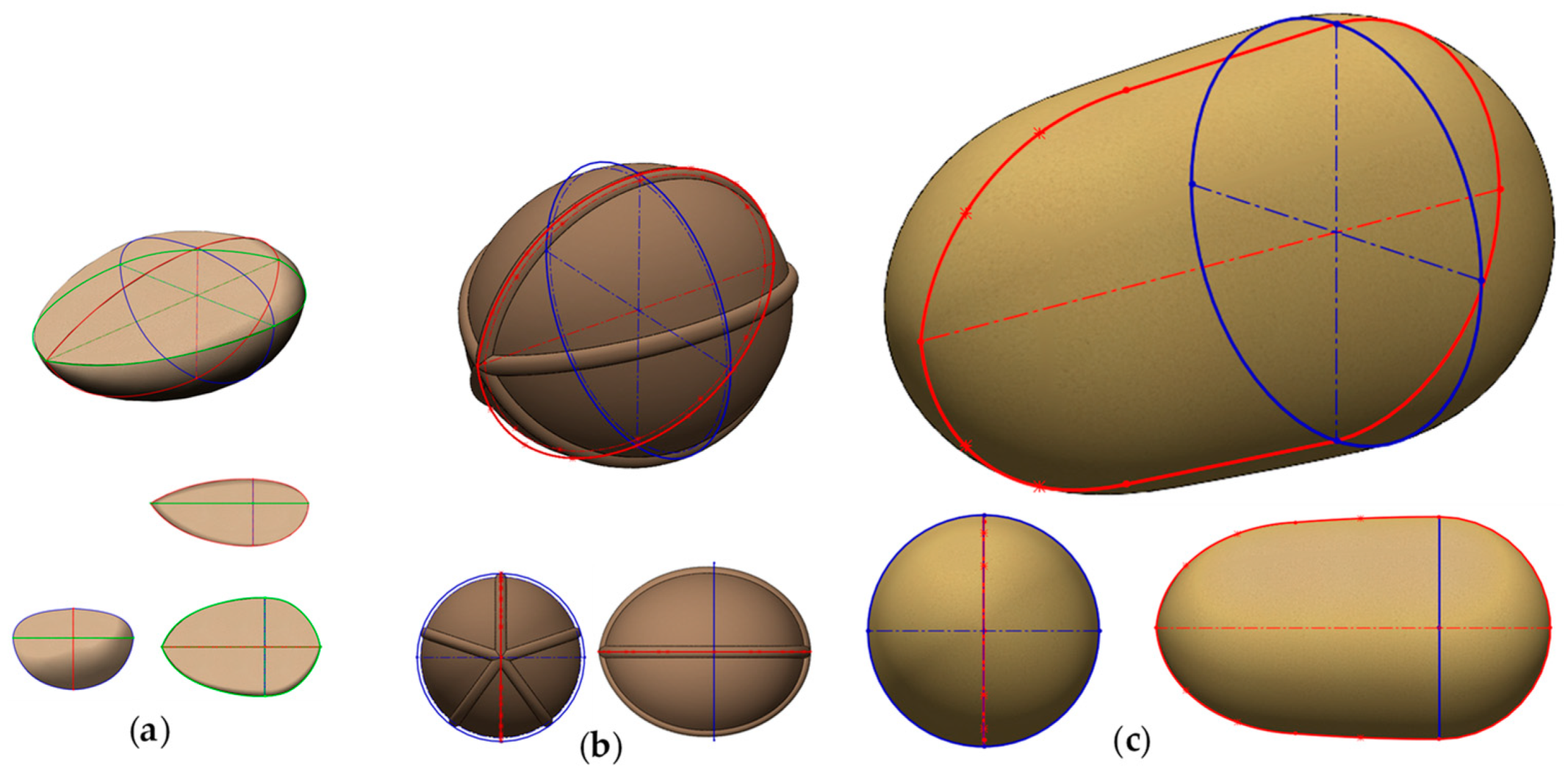

2.2. The Main Seeding Material Used for Aerial Sowing

- -

- small (spruce, pine, birch);

- -

- medium (cedar, fir, viburnum, linden);

- -

- large (oak, hazel, hazelnuts, walnuts).

- -

- spherical (linden, hazel, hazelnuts, walnuts);

- -

- ellipsoidal (spruce, pine, oak, cedar);

- -

- flat (yellow acacia).

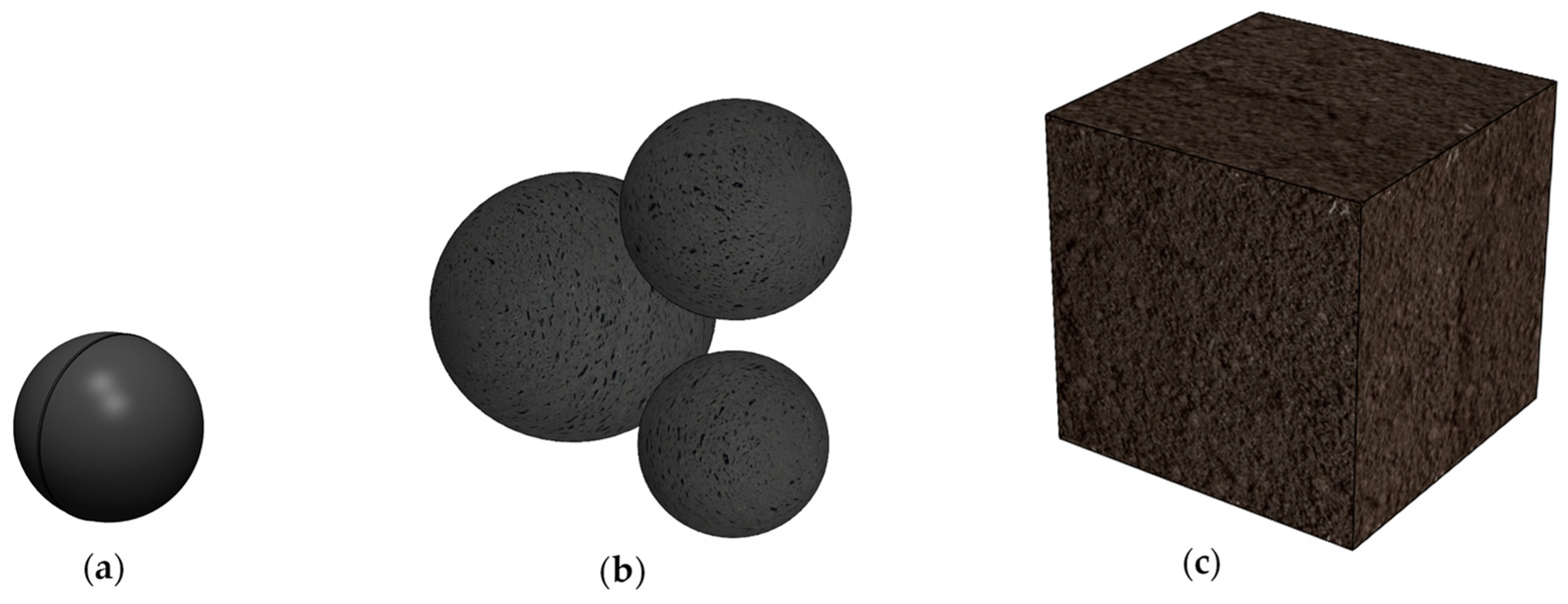

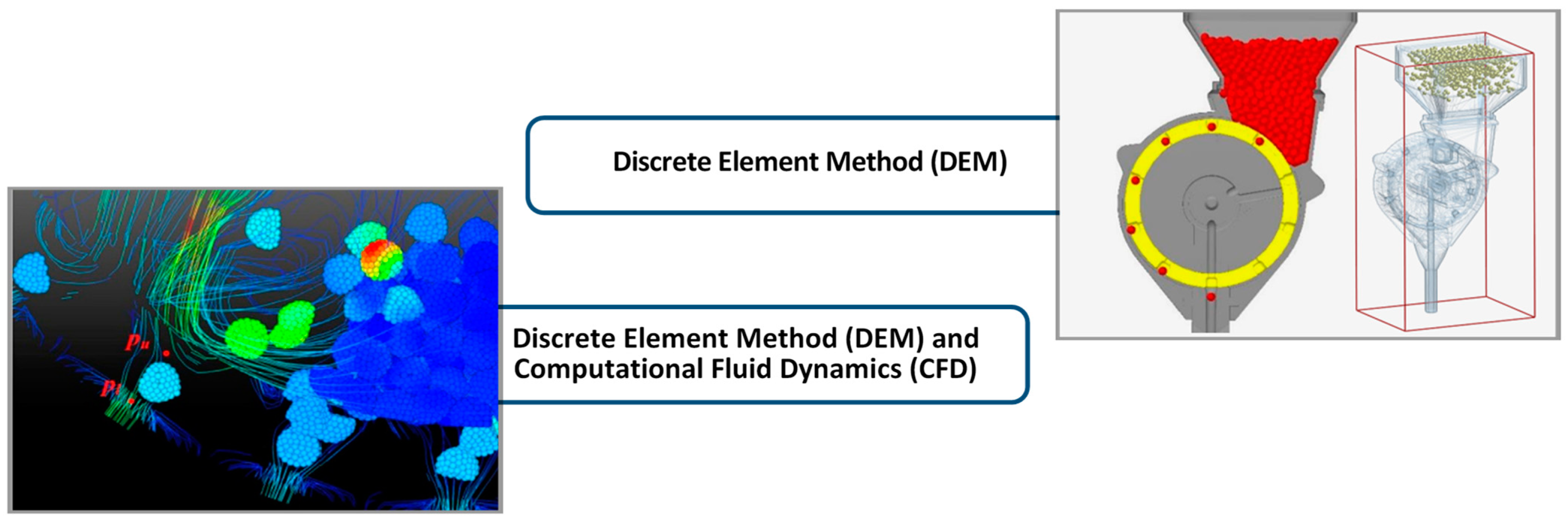

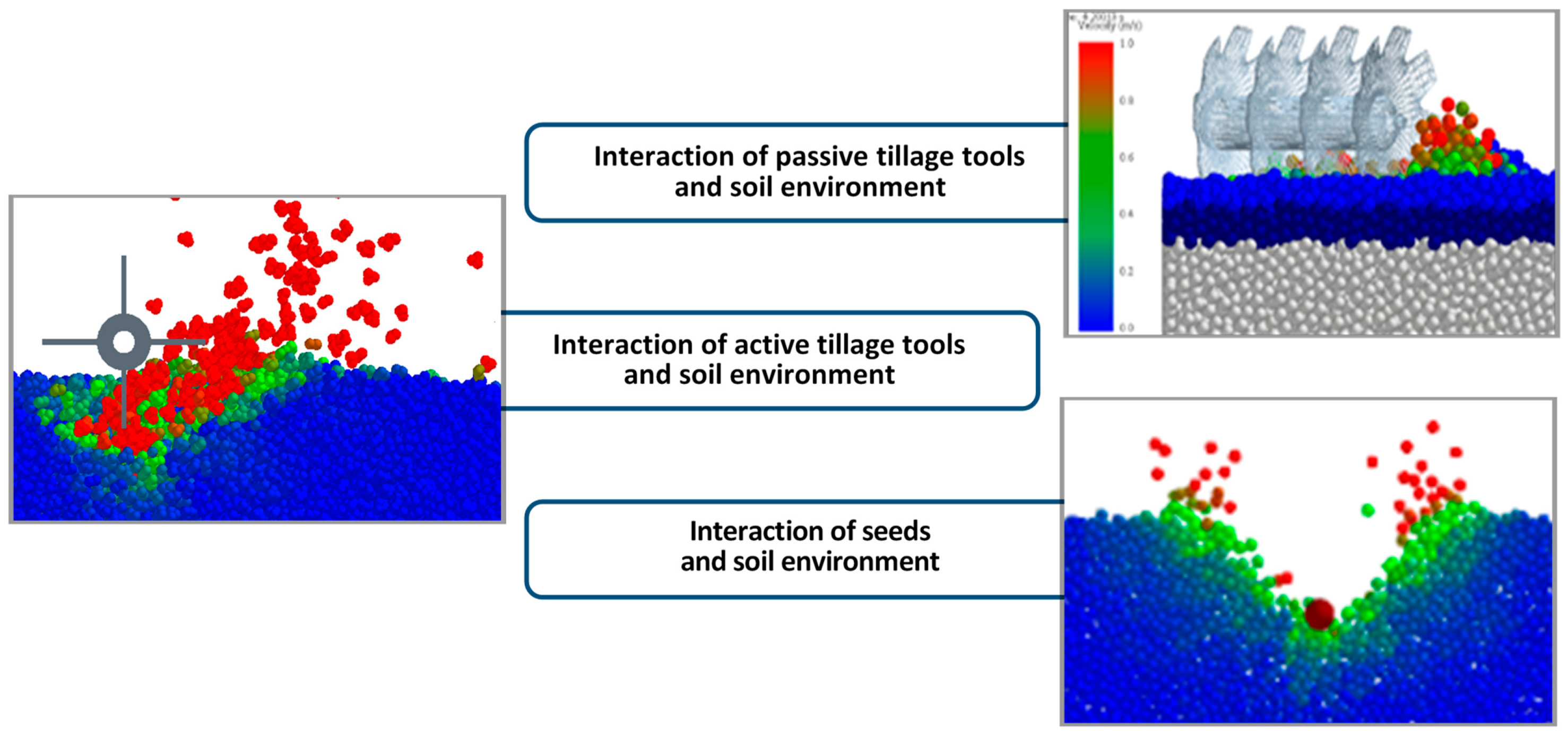

2.3. Existing Methods of Simulating Sowing Device

- -

- DEM modeling can be successfully applied to study the working processes of periodically (stationary) open metering device, fluted roller device, mechanical vertical plate precision device, centrifugal spreaders and other similar mechanical types;

- -

- collaborative DEM-CFD modeling allows to reliably investigate the operation of various vacuum metering device, air-blowing device, air flow distributors and pneumatic distributors.

3. Results and Discussion

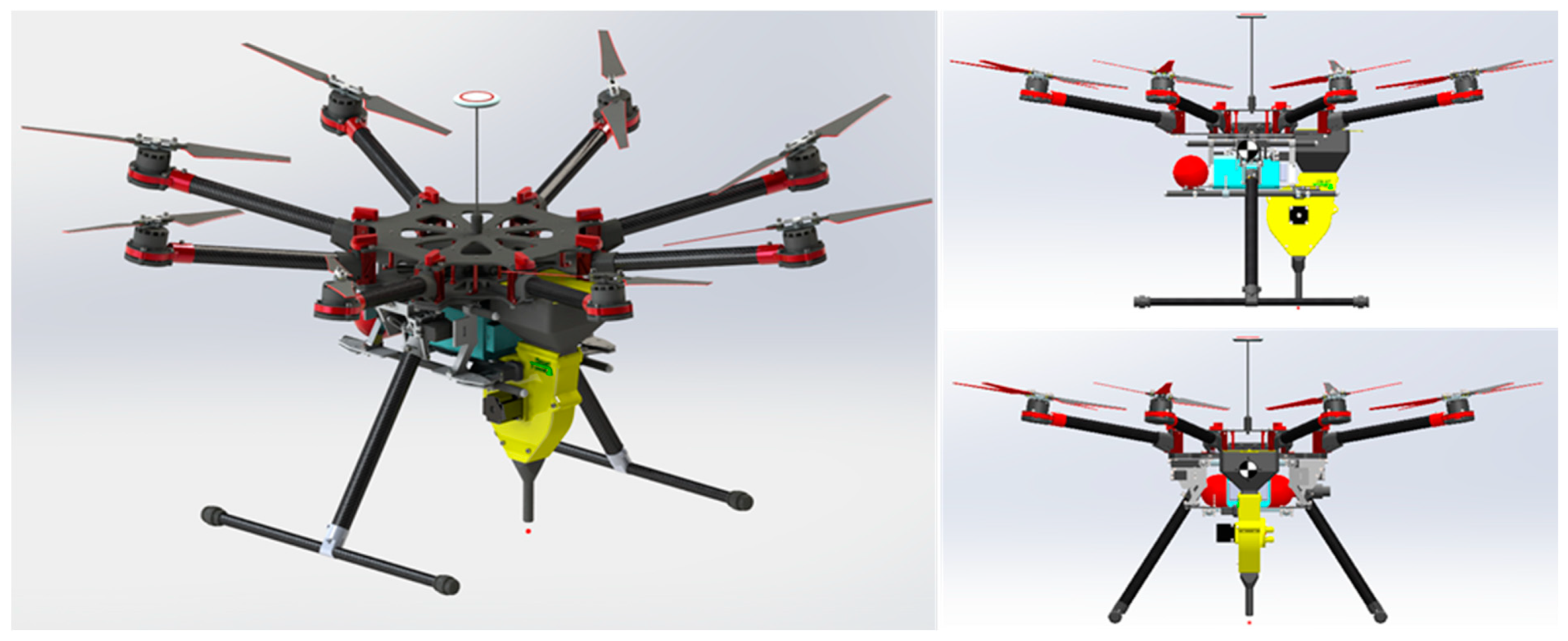

3.1. Conceptual Synthesis of Designs of Sowing Device for UAVs in a 3D CAD

3.2. Evaluation of Selected Design Solutions

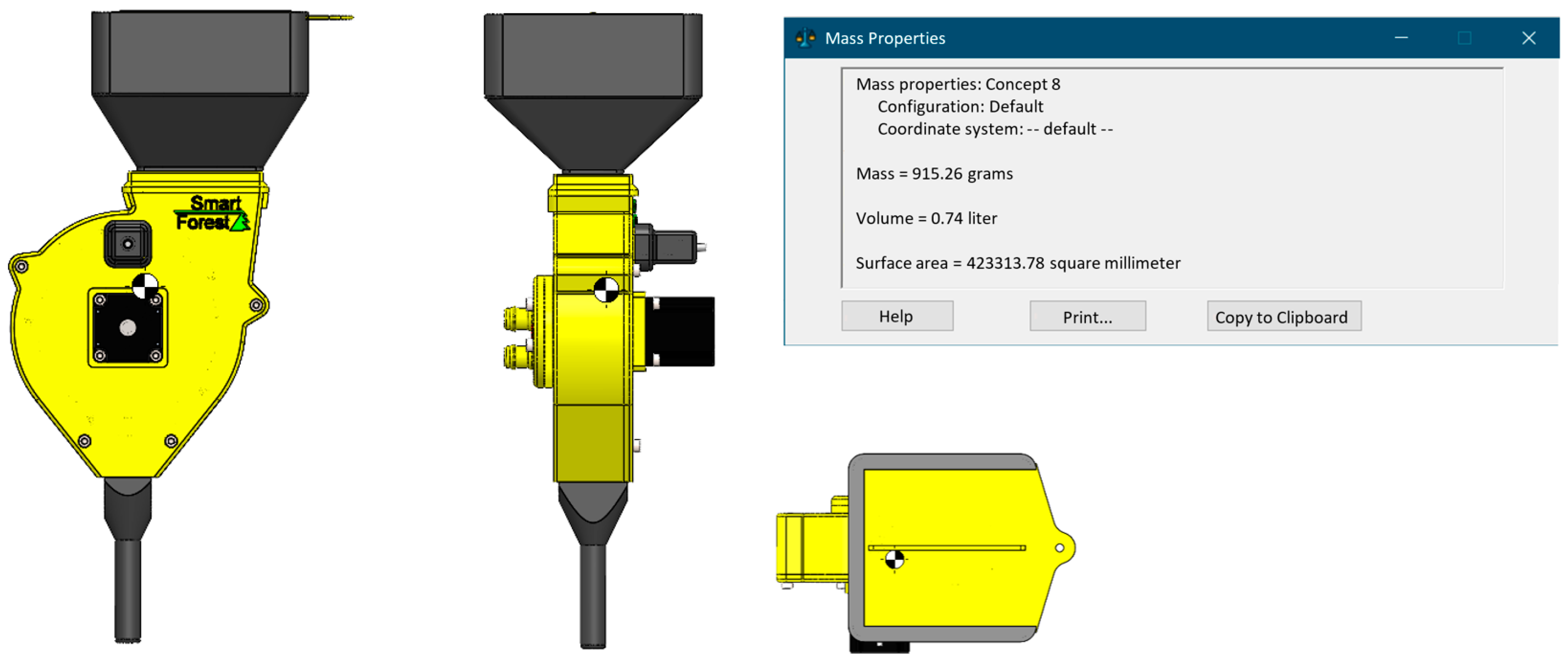

3.2.1. Investigation of Mass Inertial Characteristics of Sowing Devices

3.2.2. Research of Technological Applicability of Sowing Devices

- -

- the possibility of sowing pelleted calibrated seeds of Scots pine;

- -

- the need for deepening into the surface layer;

- -

- implementation of row sowing with exact adherence to sowing patterns.

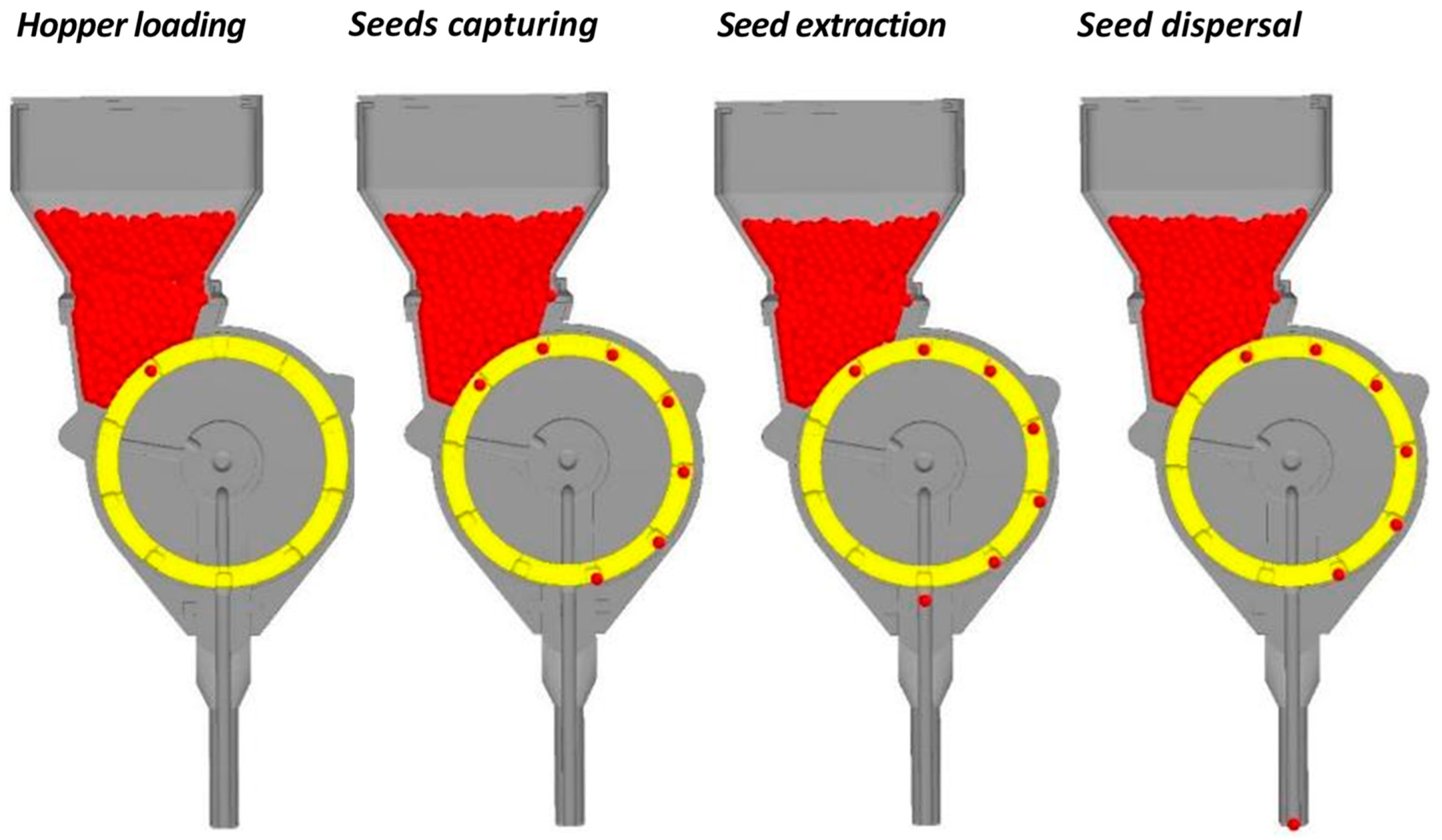

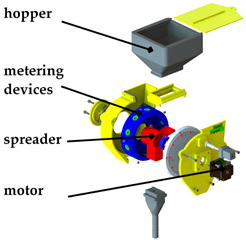

3.2.3. Description of the Design of the Investigated Sowing Device

3.3. Simulation of the Sowing Complex Using the Discrete Element Method (DEM)

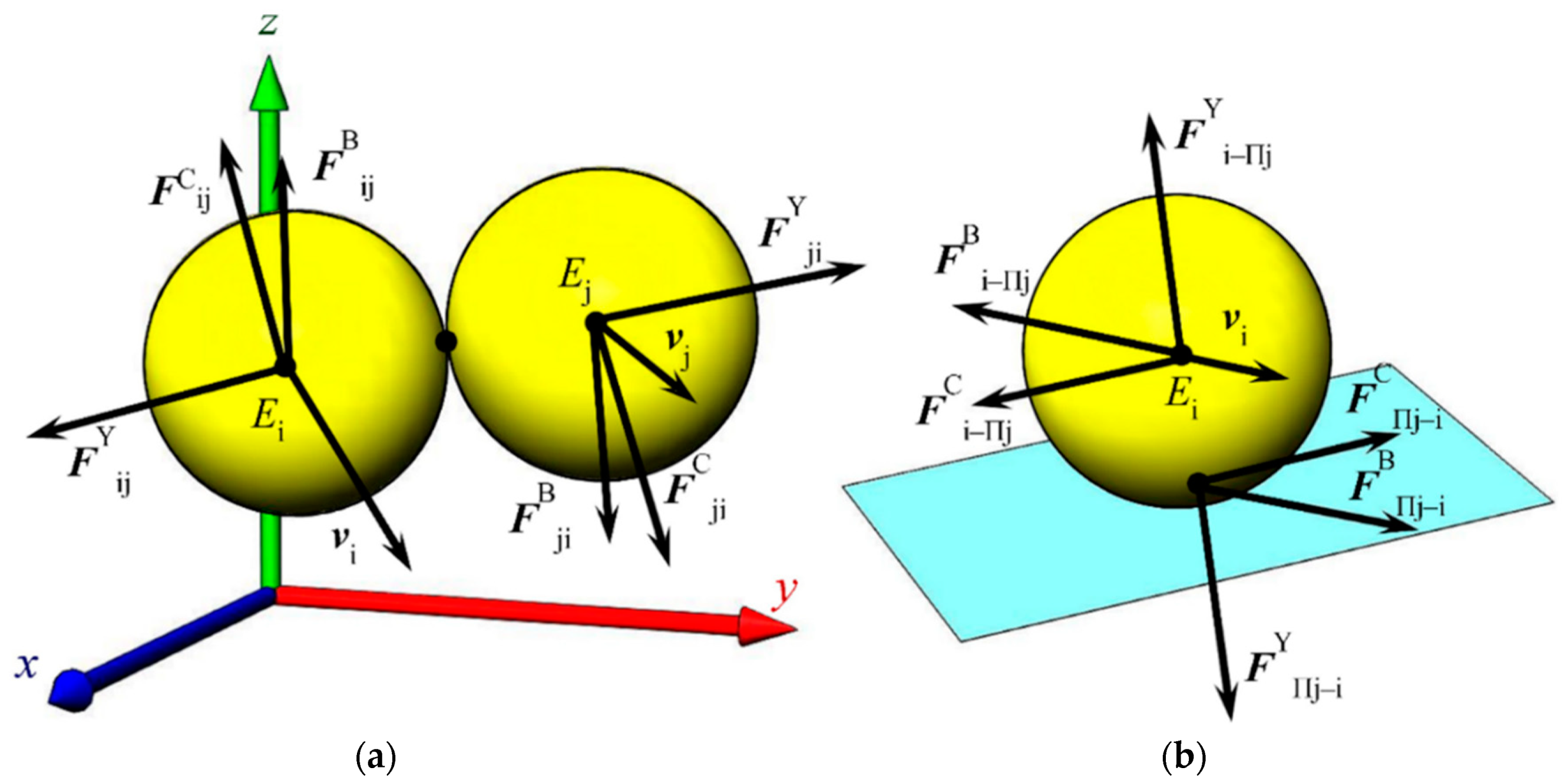

3.3.1. Description of the Virtual Stand for Researching the Operation of the Sowing Device

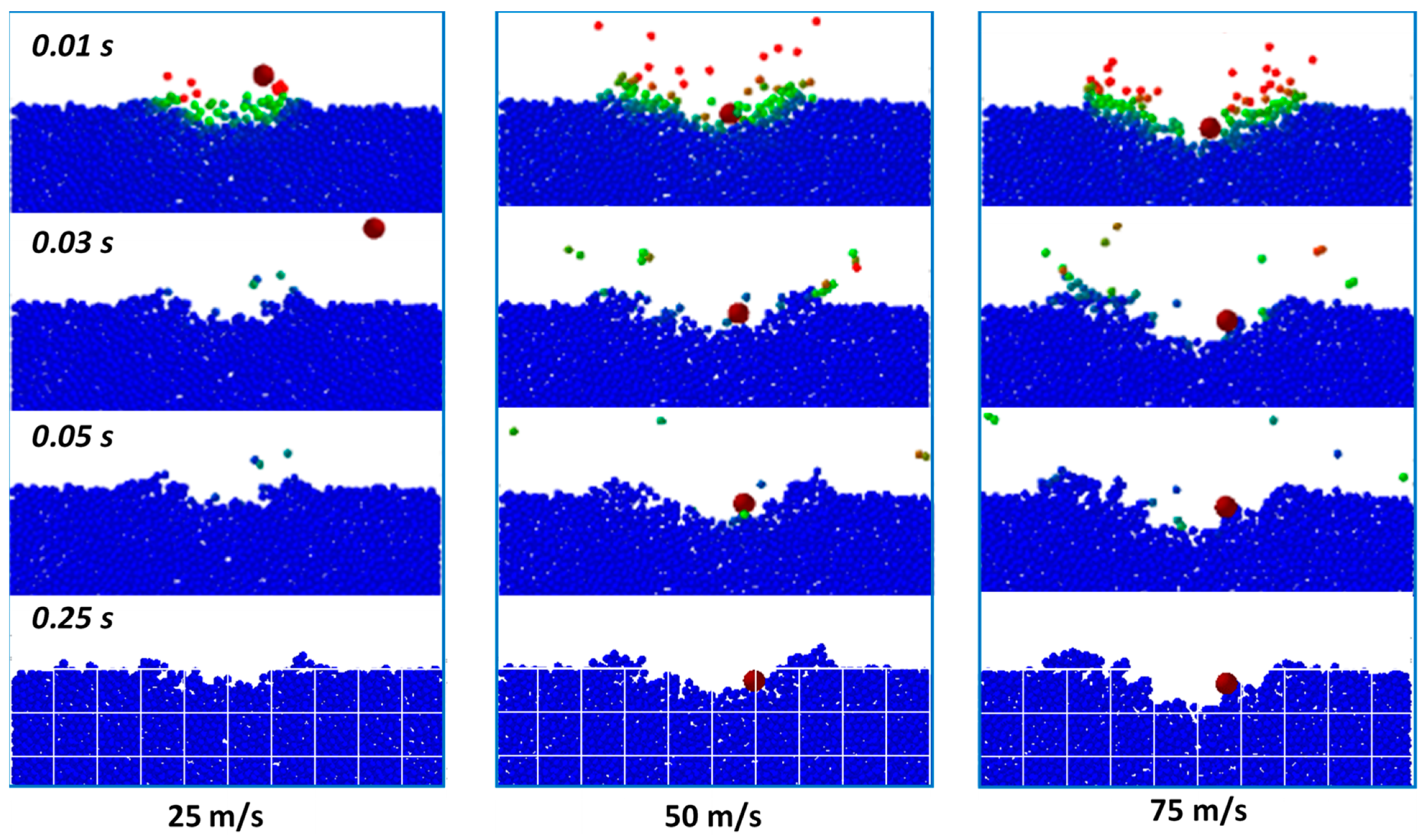

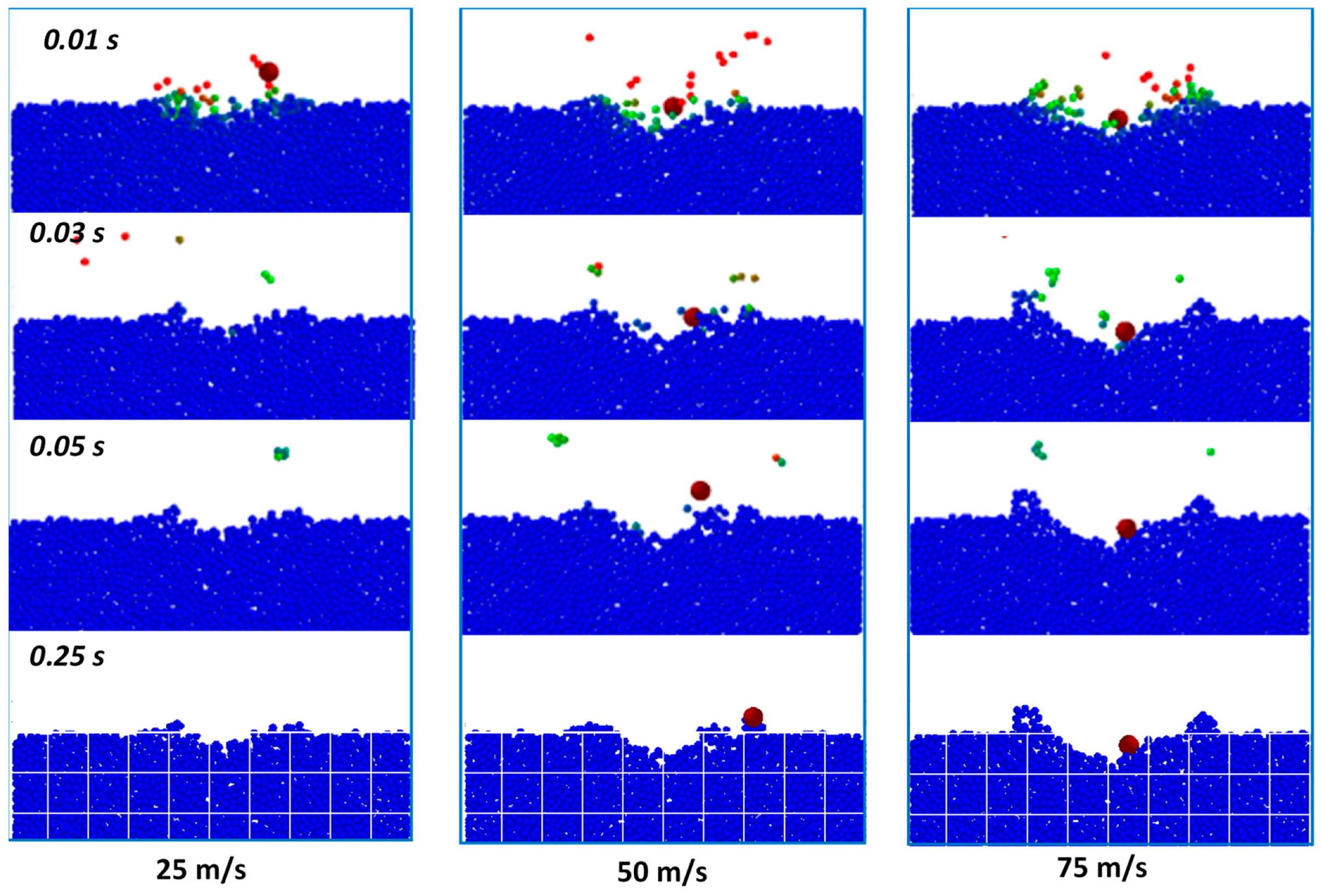

3.3.2. Description of the Virtual Stand for Studying the Process of Interaction of Pelleted Seed with the Soil Environment

3.3.3. Description of the Discrete Interaction Model

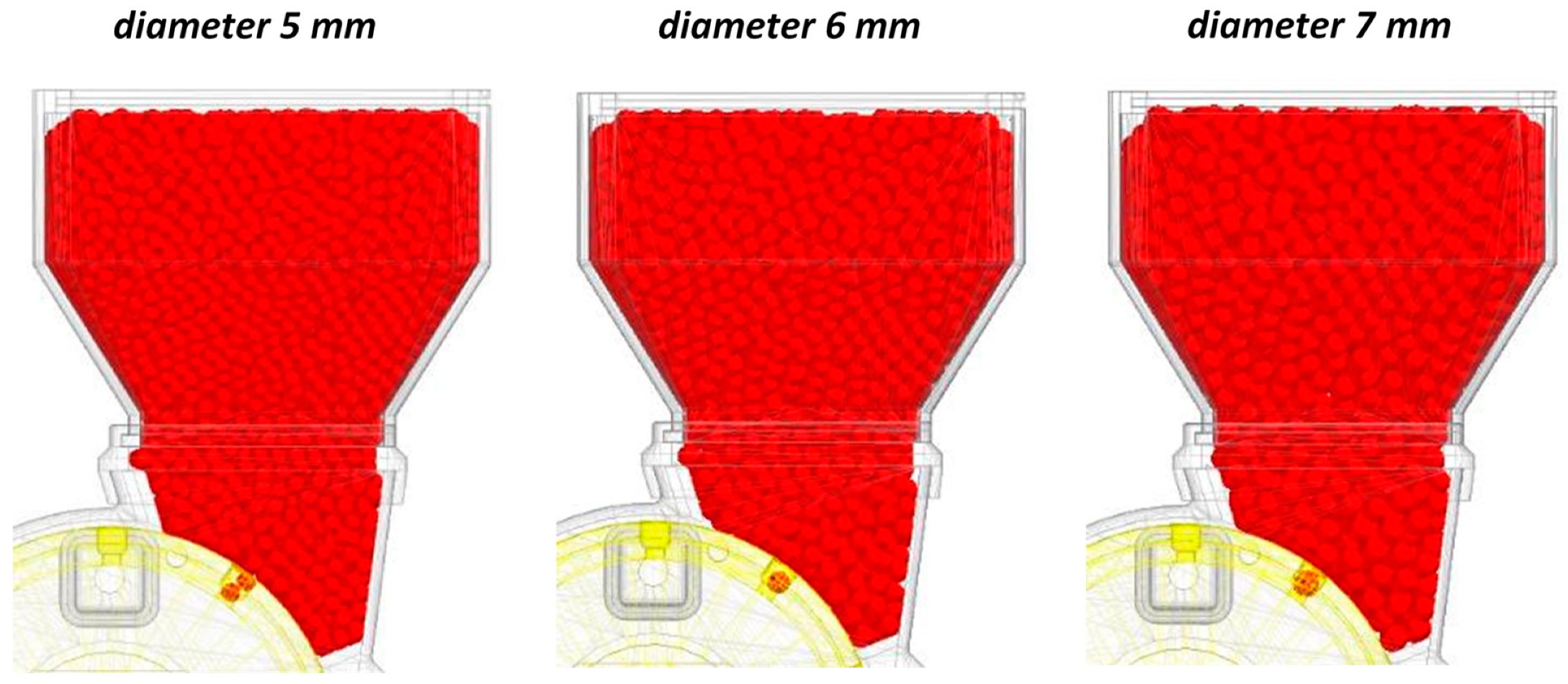

3.4. The Results of Simulation Modeling of the Full Load of the Hopper of the Metering Device

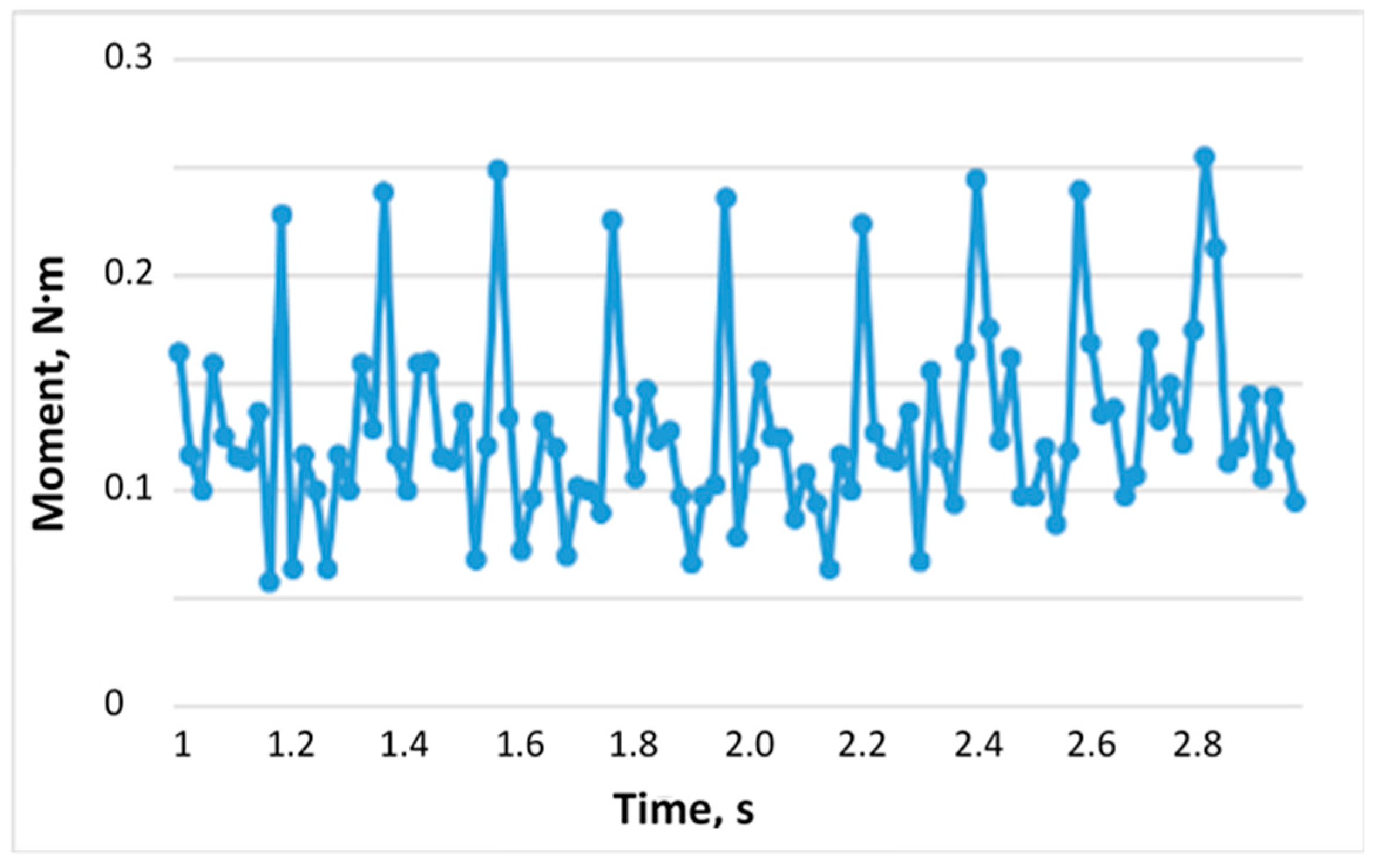

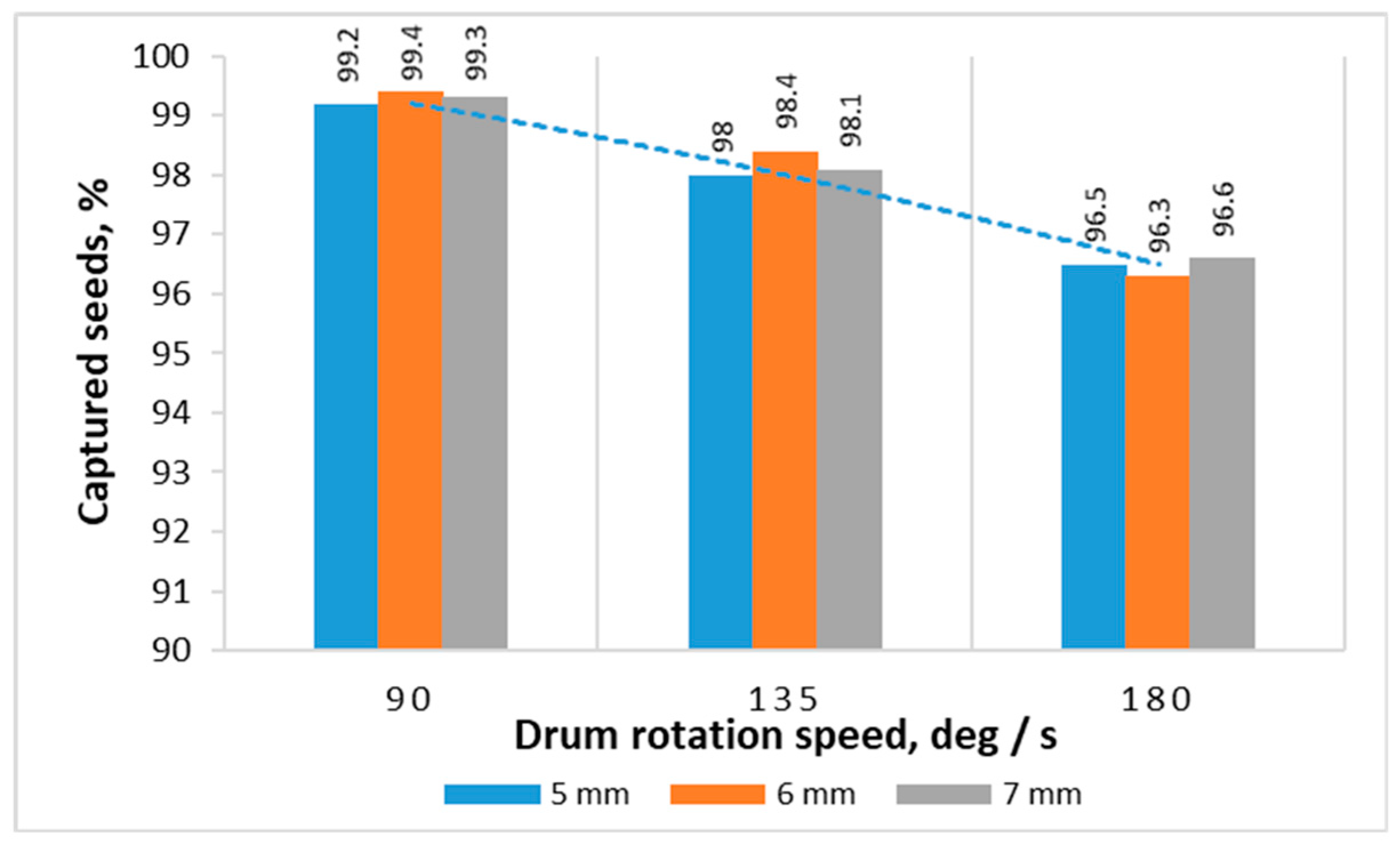

3.5. DEM Simulation of the Sowing Device

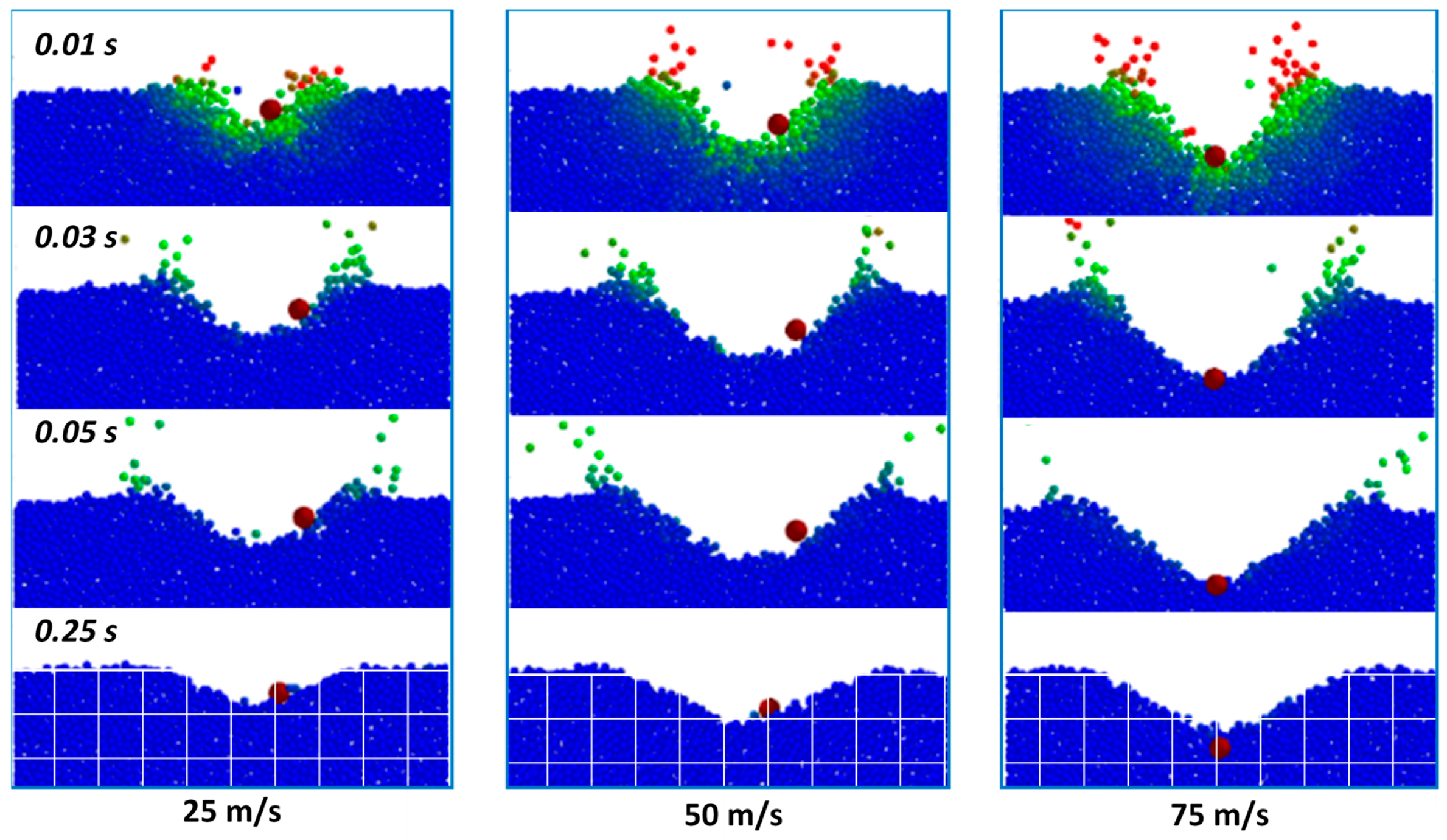

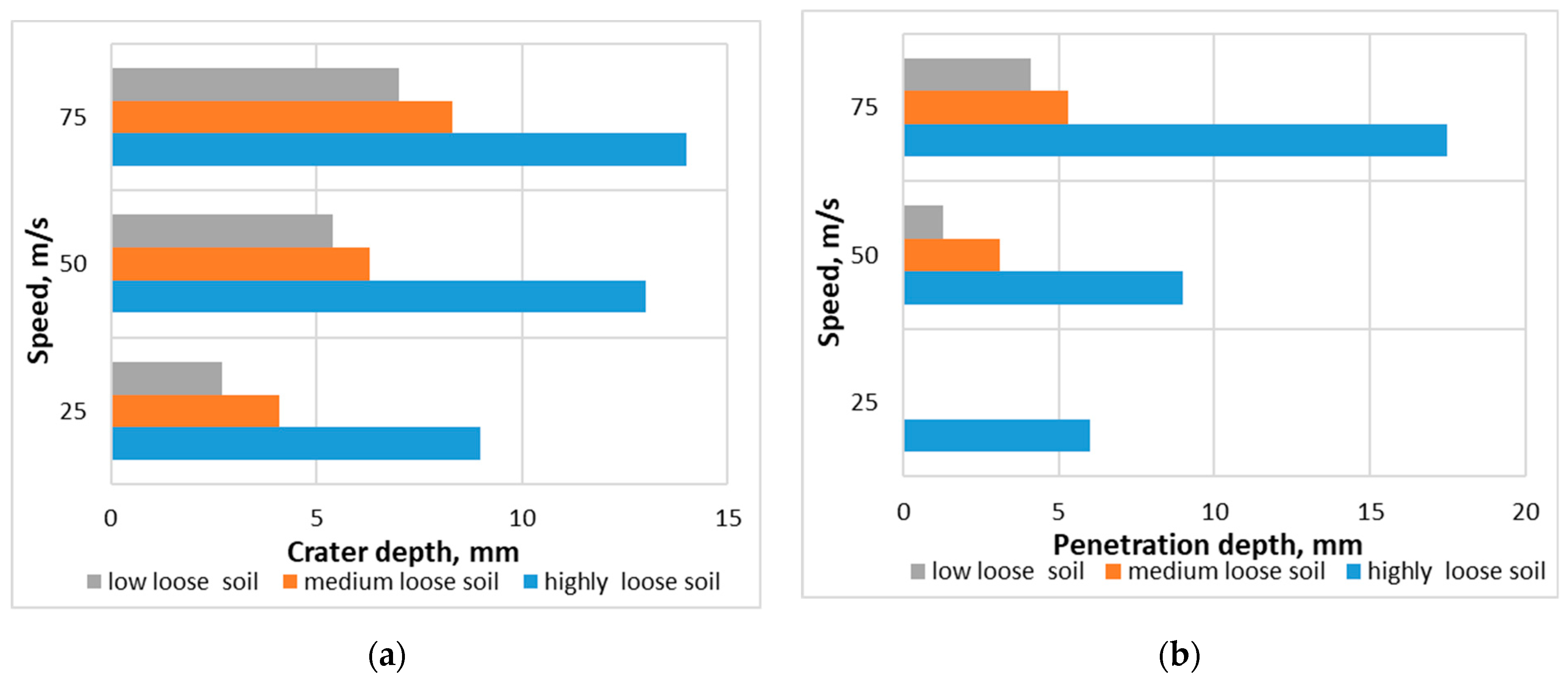

3.6. DEM Modeling of Interaction of Seeds and Soil Environment

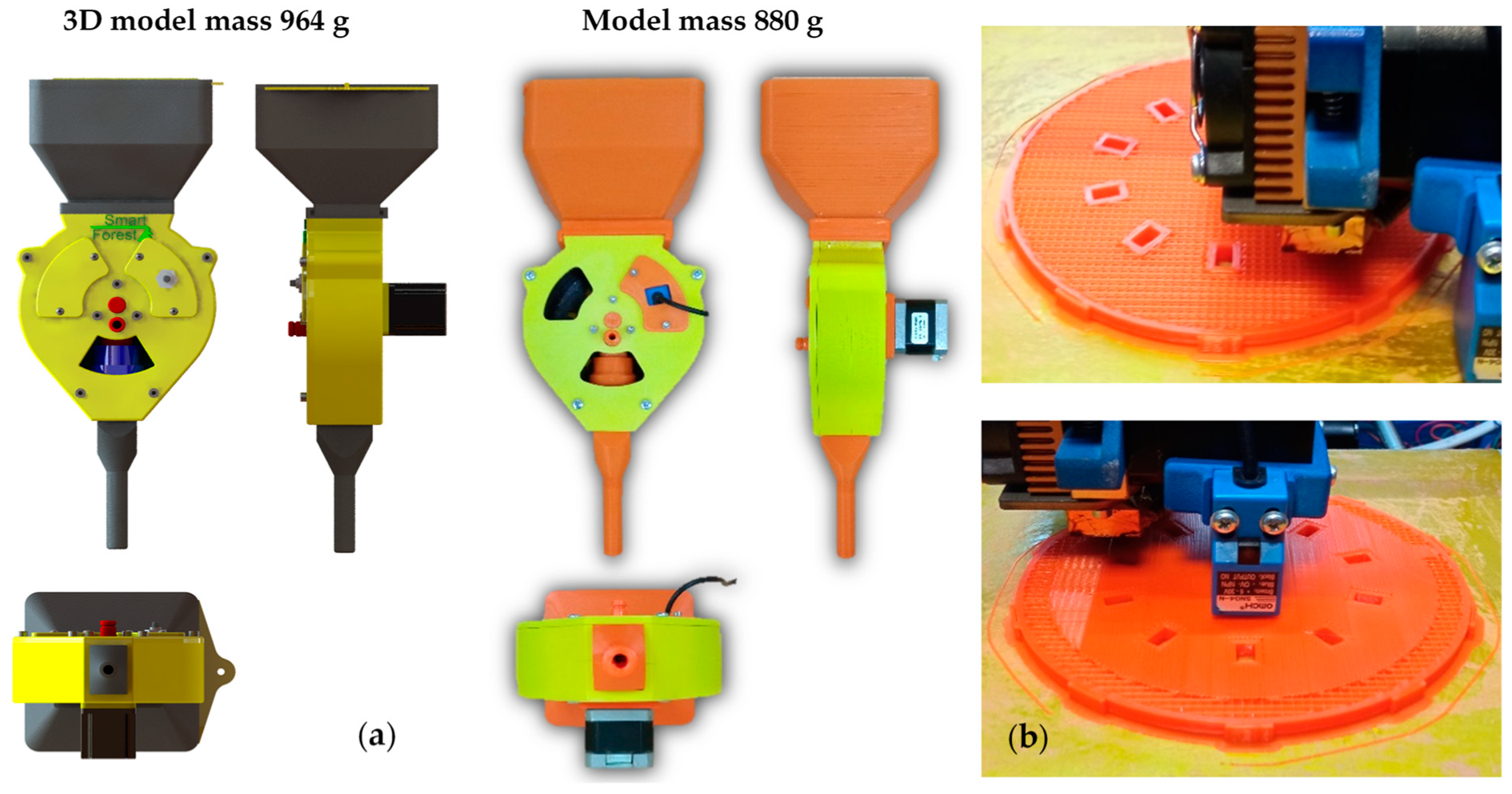

3.7. Creation of an Experimental Sample of the Sowing Device and the Study of Its Mass Characteristics

- -

- comparability of technological parameters;

- -

- mass characteristics;

- -

- ease of manufacture and accuracy requirements;

- -

- manufacturability of the design and the possibility of using it for the manufacture of 3D printing;

- -

- operational reliability.

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mohan, M.; Richardson, G.; Gopan, G.; Aghai, M.M.; Bajaj, S.; Galgamuwa, G.A.P.; Vastaranta, M.; Arachchige, P.S.P.; Amorós, L.; Corte, A.P.D.; et al. UAV-supported forest regeneration: Current trends, challenges and implications. Remote Sens. 2021, 13, 2596. [Google Scholar] [CrossRef]

- Novikov, A.I.; Ersson, B.T. Aerial seeding of forests in Russia: A selected literature analysis. IOP Conf. Ser. Earth Environ. Sci. 2019, 226, 012051. [Google Scholar] [CrossRef]

- Order of the Ministry of Natural Resources and Environment of the Russian Federation Dated 04.12.2020 No. 1014. Available online: http://publication.pravo.gov.ru/Document/View/0001202012180052?index=1&rangeSize=1 (accessed on 18 October 2021).

- Rudoy, E.V.; Petukhova, M.S.; Ryumkin, S.V.; Truflyak, E.V.; Kurchenko, N.Y. Scientifically Grounded Forecast of the Development of Precision Farming in Russia; ITS NGAU «Zolotoy kolos»: Novosibirsk, Russia, 2021. [Google Scholar]

- JetSeed Granule Spreading System—XAG. Available online: https://www.xa.com/en/jetseed (accessed on 23 September 2021).

- Bacherikov, I.V.; Novikov, A.I.; Petrishchev, E.P. Discrete seed feeder designing for mobile apparatus: Early results for Pinus Sylvestris l. species. Inventions 2021, 6, 14. [Google Scholar] [CrossRef]

- Drone Granula Spreadying System China Manufacturer. Available online: https://www.jmrdrone.com/agriculture-drone-parts/57412215.html (accessed on 23 July 2021).

- Amorós, L.; Ledesma, J. Aerial robotics for forest management and seeding. Refor. Biodivers. Carbon Capture Livelihoods 2015, 151, 10–17. [Google Scholar]

- Murray, J.R.; Tullberg, J.N.; Basnet, B.B. Planters and their components. Types, attributes, functional requirements, classification and description. Aust. Cent. Int. Agric. Res. 2006. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, S.; Luo, C.; Li, W.; Liao, Y. Design and experimentation of an aerial seeding system for rapeseed based on an air-assisted centralized metering device and a multi-rotor crop protection UAV. Appl. Sci. 2020, 10, 8854. [Google Scholar] [CrossRef]

- UGS-2G—Specifications. Available online: https://www.cfr-innovations.com/product-page/ugs-2g (accessed on 23 July 2021).

- User Guide T Series Spreading System. Available online: http://www.dji.com (accessed on 23 September 2021).

- OSA HEXA S-1. Available online: https://bozon.aero/cat/koptery-c1/osa-hexa-s-1-i3.html (accessed on 14 October 2021).

- Reforestation. AirSeed Technologies. Australia. Available online: https://www.airseedtech.com/ (accessed on 16 July 2021).

- Dendra Systems: Automation and Intelligence for the Natural World. Available online: https://www.dendra.io/ (accessed on 16 July 2021).

- Tree-Planting Drones to Speed Up Reforestation Efforts. Available online: https://newatlas.com/tree-planting-drones-droneseed/45259/ (accessed on 23 September 2021).

- Flash Forest. Available online: https://flashforest.ca/ (accessed on 14 September 2021).

- Tylek, P.; Demidov, D.N.; Lysych, M.N.; Petrishchev, E.P.; Maklakova, E.A. The features designed of mechatronic system of adaptive hopper’s feeder: Case study for Scots pine seeds morphometry. IOP Conf. Ser. Earth Environ. Sci. 2020, 595, 012054. [Google Scholar] [CrossRef]

- JetSeed Система разбрасывания гранул—XAG. Available online: https://xag.com.ru/jetseed (accessed on 23 July 2021).

- Система распыления T Series Spreading System 2.0 купить в официальном магазине с доставкой. Available online: https://4vision.ru/products/sistema-raspyleniya-mg-series-spreading-system-20.html (accessed on 23 July 2021).

- Rapid Reforestation|DroneSeed. Available online: https://droneseed.com/ (accessed on 1 October 2021).

- Bangura, K.; Gong, H.; Deng, R.; Tao, M.; Liu, C.; Cai, Y.; Liao, K.; Liu, J.; Qi, L. Simulation analysis of fertilizer discharge process using the Discrete Element Method (DEM). PLoS ONE 2020, 15, e0235872. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, B.; Yao, Y.; Ding, S.; Zhang, J.; Zhu, R. Parameter optimization of fluted-roller meter using discrete element method. Int. J. Agric. Biol. Eng. 2018, 11, 65–72. [Google Scholar] [CrossRef]

- Marcinkiewicz, J.; Selech, J.; Staszak, Ż.; Gierz, Ł.; Ulbrich, D.; Romek, D. DEM simulation research of selected sowing unit elements used in a mechanical seeding drill. MATEC Web Conf. 2019, 254, 02021. [Google Scholar] [CrossRef]

- Wu, Z.; Li, M.; Lei, X.; Wu, Z.; Jiang, C.; Zhou, L.; Ma, R.; Chen, Y. Simulation and parameter optimisation of a centrifugal rice seeding spreader for a UAV. Biosyst. Eng. 2020, 192, 275–293. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Lombard, S.G. Discrete element method modelling of a centrifugal fertiliser spreader. Biosyst. Eng. 2011, 109, 308–325. [Google Scholar] [CrossRef]

- Van Liedekerke, P.; Tijskens, E.; Dintwa, E.; Rioual, F.; Vangeyte, J.; Ramon, H. DEM simulations of the particle flow on a centrifugal fertilizer spreader. Powder Technol. 2009, 190, 348–360. [Google Scholar] [CrossRef]

- Li, S.; Student, M.; District, H. The modal analysis and simulation of gramineae-leguminous mixed seeding based on EDEM. ASABE Annu. Int. Meet. Pap. 2015, 152189675, 1–5. [Google Scholar]

- Lai, Q.; Hu, Z.; Xing, J.; Ma, W. Simulation and verification for seed-filling performance of cell wheel precision seed metering device based on discrete element method. MATEC Web Conf. 2018, 169, 01035. [Google Scholar] [CrossRef][Green Version]

- Li, Y.S.P.S.; Xing, S.; Li, S.; Liu, L.; Zhang, X.; Song, Z.; LI, F. Seeding performance simulations and experiments for a spoon- wheel type precision cottonseed-metering device based on EDEM. Mech. Eng. Sci. 2020, 2, 2. [Google Scholar] [CrossRef]

- Woo, S.M.; Uyeh, D.D.; Sagong, M.S.; Ha, Y.S. Development of seeder for mixed planting of corn and soybeans. Int. J. Agric. Biol. Eng. 2017, 10, 95–101. [Google Scholar]

- Hongxin, L.; Lifeng, G.; Lulu, F.; Shifa, T. Study on multi-size seed-metering device for vertical plate soybean precision planter. Int. J. Agric. Biol. Eng. 2015, 8, 1–8. [Google Scholar]

- Jinwu, W.; Han, T.; Jinfeng, W.; Xin, L.; Huinan, H. Optimization design and experiment on ripple surface type pickup finger of precision maize seed metering device. Int. J. Agric. Biol. Eng. 2017, 10, 61–71. [Google Scholar]

- Hong, F.; Changrui, W.; Cong, J. Development of digital design software platform AgriDEM for agricultural machinery parts. Trans. Chinese Soc. Agric. Eng. 2017, 33, 1–9. [Google Scholar]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Zhang, Q.; Wang, L.; Liao, Q. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat. Comput. Electron. Agric. 2018, 150, 98–109. [Google Scholar] [CrossRef]

- Lysych, M.N. Review of numerical methods for modeling the interaction of soil environments with the tools of soil tillage machines. J. Phys. Conf. Ser. 2019, 1399, 044014. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Li, P.; Lee, S. Analyzing the mixing performance of a rotary spader using digital image processing and discrete element modelling (DEM). Comput. Electron. Agric. 2018, 151, 1–10. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Ma, S.; He, J.; Wang, Q.; Lu, C.; Zheng, Z. The effect of various edge-curve types of plain-straight blades for strip tillage seeding on torque and soil disturbance using DEM. Soil Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Gong, H.; Zeng, Z.; Qi, L. A discrete element model of seed-soil dynamics in soybean emergence. Plant Soil 2019, 437, 439–454. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Y.; Sadek, M.A. Modelling of soil e seed contact using the Discrete Element Method (DEM). Biosyst. Eng. 2014, 121, 56–66. [Google Scholar] [CrossRef]

- Ding, S.; Bai, L.; Yao, Y.; Yue, B.; Fu, Z.; Zheng, Z.; Huang, Y. Discrete element modelling (DEM) of fertilizer dual-banding with adjustable rates. Comput. Electron. Agric. 2018, 152, 32–39. [Google Scholar] [CrossRef]

- Boudet, J.F.; Amarouchene, Y.; Kellay, H. Dynamics of impact cratering in shallow sand layers. Phys. Rev. Lett. 2006, 96, 1–4. [Google Scholar] [CrossRef] [PubMed]

- De Vet, S.J.; De Bruyn, J.R. Shape of impact craters in granular media. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2007, 76, 1–6. [Google Scholar] [CrossRef]

- Goldman, D.I.; Umbanhowar, P. Scaling and dynamics of sphere and disk impact into granular media. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2008, 77, 1–14. [Google Scholar] [CrossRef]

- Royer, J.R.; Corwin, E.I.; Eng, P.J.; Jaeger, H.M. Gas-mediated impact dynamics in fine-grained granular materials. Phys. Rev. Lett. 2007, 99, 99–102. [Google Scholar] [CrossRef]

- Wu, S.M.; Zhu, H.P.; Yu, A.B.; Zulli, P. Numerical investigation of crater phenomena in a particle stream impact onto a granular bed. Granul. Matter 2007, 9, 7–17. [Google Scholar] [CrossRef]

- Ye, X.; Wang, D.; Zheng, X. Influence of particle rotation on the oblique penetration in granular media. Phys. Rev. 2012, 061304, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Wada, K.; Senshu, H.; Matsui, T. Numerical simulation of impact cratering on granular material. Icarus 2006, 180, 528–545. [Google Scholar] [CrossRef]

- Lysych, M.N. Computer simulation of the process soil treatment by tillage tools of soil processing machines. Comput. Res. Model. 2020, 12, 607–627. [Google Scholar] [CrossRef]

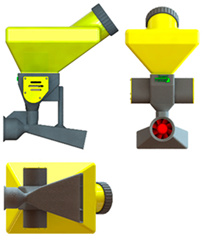

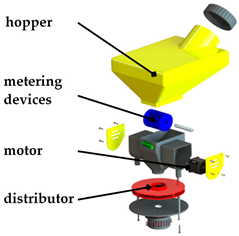

| 3D Concept | Isometric View with Spaced Parts | View in Three Projections (Side, Front, Bottom) |

|---|---|---|

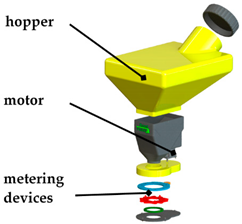

| 1. Periodically opening sowing device (Periodically opening metering devices + Gravity drop distributor) |  |  |

| ||

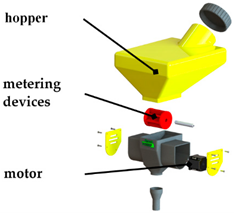

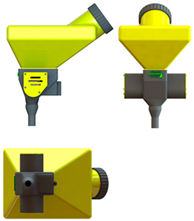

| 2. Fluted roller sowing devices (Fluted roller metering devices + Gravity drop distributor) |  |  |

| ||

| 3. Air flow sowing devices (Fluted roller metering devices + Air flow distributor) |  |  |

| ||

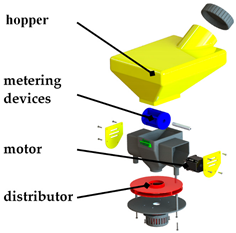

| 4. Centrifugal sowing devices (Fluted roller metering devices + Centrifugal distributor) |  |  |

|

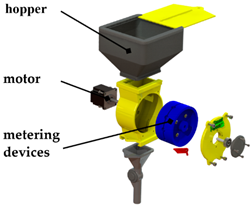

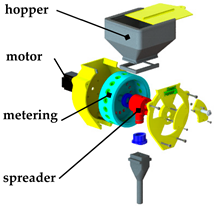

| 3D Concept | Isometric View with Spaced Parts | View in Three Projections (Side, Front, Bottom) |

|---|---|---|

| 5. Vacuum disc precision sowing devices (Vacuum disc precision metering devices + Gravity drop distributor) |  |  |

| ||

| 6. Mechanical vertical plate precision sowing devices (Mechanical vertical plate precision metering devices + Gravity drop distributor) |  |  |

| ||

| 7. Mechanical-pneumatic vertical plate precision sowing devices (Mechanical vertical plate precision metering devices + Pneumatic distributor) |  |  |

| ||

| 8. Vacuum-pneumatic vertical plate precision sowing devices (Vacuum vertical plate precision metering devices+ Pneumatic distributor) |  |  |

|

| Criterion (Mass, g) | 3D Concept | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Sowing devices | 799 | 998 | 1201 | 1297 | 773 | 543 | 964 | 915 |

| Payload | 3186 | 2944 | 2944 | 2944 | 920 | 946 | 952 | 1008 |

| Additional batteries | 200 | 200 | 500 | 500 | 500 | 200 | 200 | 500 |

| Additional equipment | ––– | ––– | ––– | ––– | 1000 | ––– | 1000 | 2000 |

| Total mass | 4185 | 4142 | 4645 | 4741 | 3193 | 1689 | 3116 | 4423 |

| Criterion (Technological Applicability) | 3D Concept | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Precise sowing | – | – | – | – | o | o | + | + |

| Row sowing | o | + | – | – | + | + | + | + |

| Area sowing | o | o | + | + | o | o | o | o |

| Deepening into the soil | – | – | – | – | – | – | + | + |

| Small seeds (1–4 mm) | + | + | + | + | + | + | + | + |

| Average seeds (5–9 mm) | + | o | o | o | – | + | + | + |

| Large seeds (10 mm) | + | – | – | – | – | o | o | o |

| Application of seeds of various shapes | + | + | + | + | – | o | – | – |

| Application of seeds of different sizes | + | o | o | o | – | – | – | – |

| Parameter | Value |

|---|---|

| Seed diameter, mm | 5; 6; 7 |

| Seed density, kg/m3 | 1900 |

| Seed mass, g | 0.124; 0.215; 0.341 |

| Particle volume, m3 | 0.655 × 10−7; 1.131 × 10−7; 1.796 × 10−7 |

| Metering drum rotation speed, deg/s | 90; 135; 180 |

| Parameter | Value |

|---|---|

| Seed diameter, mm | 5 |

| Soil particle diameter, mm | 2 |

| Soil density, kg/m3 | 2500 |

| Seed density, kg/m3 | 1900 |

| Seed mass, g | 0.124 |

| Seed volume, m3 | 0.655 × 10−7 |

| Seed speed, m/s | 25; 50; 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lysych, M.; Bukhtoyarov, L.; Druchinin, D. Design and Research Sowing Devices for Aerial Sowing of Forest Seeds with UAVs. Inventions 2021, 6, 83. https://doi.org/10.3390/inventions6040083

Lysych M, Bukhtoyarov L, Druchinin D. Design and Research Sowing Devices for Aerial Sowing of Forest Seeds with UAVs. Inventions. 2021; 6(4):83. https://doi.org/10.3390/inventions6040083

Chicago/Turabian StyleLysych, Mikhail, Leonid Bukhtoyarov, and Denis Druchinin. 2021. "Design and Research Sowing Devices for Aerial Sowing of Forest Seeds with UAVs" Inventions 6, no. 4: 83. https://doi.org/10.3390/inventions6040083

APA StyleLysych, M., Bukhtoyarov, L., & Druchinin, D. (2021). Design and Research Sowing Devices for Aerial Sowing of Forest Seeds with UAVs. Inventions, 6(4), 83. https://doi.org/10.3390/inventions6040083