A Topology of DC-DC Converter Based on Multi-Winding Transformer for Grid Integration of Multiple Renewable Energy Resources

Abstract

1. Introduction

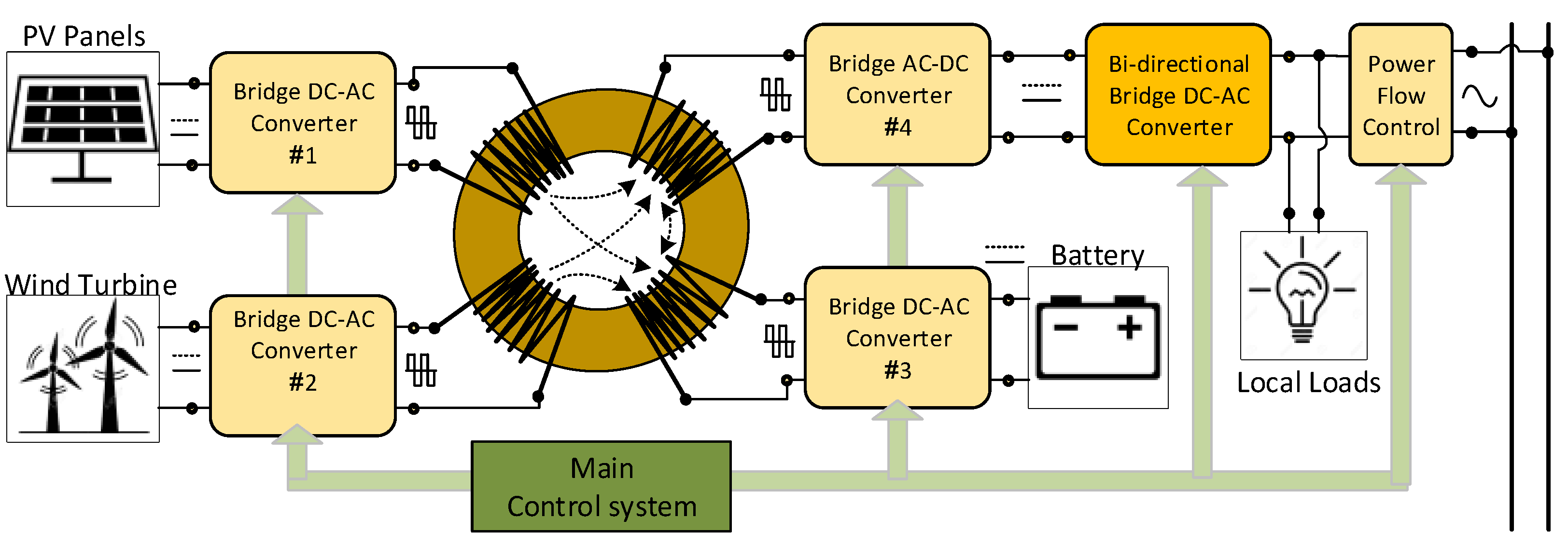

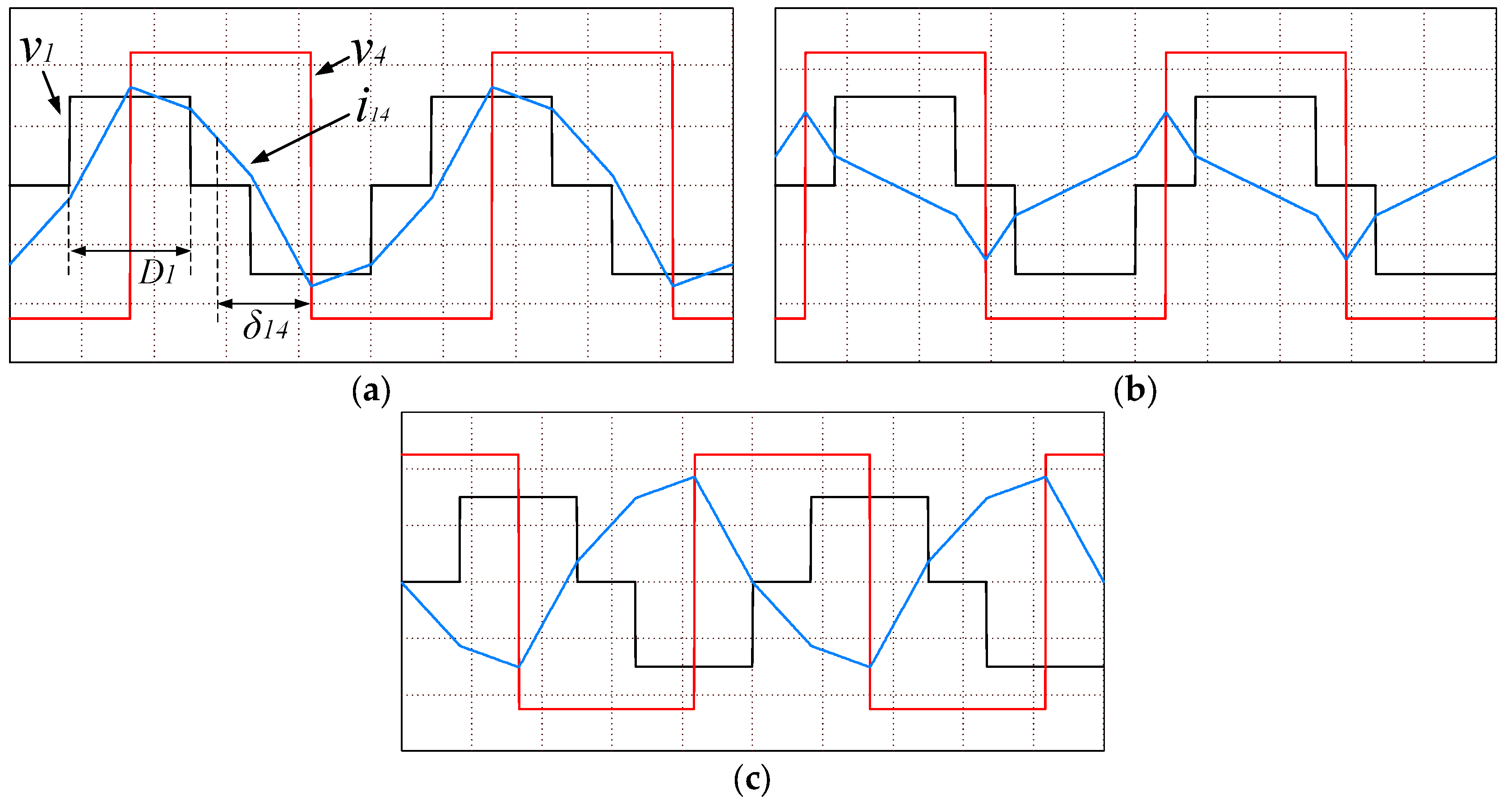

2. Materials and Methods

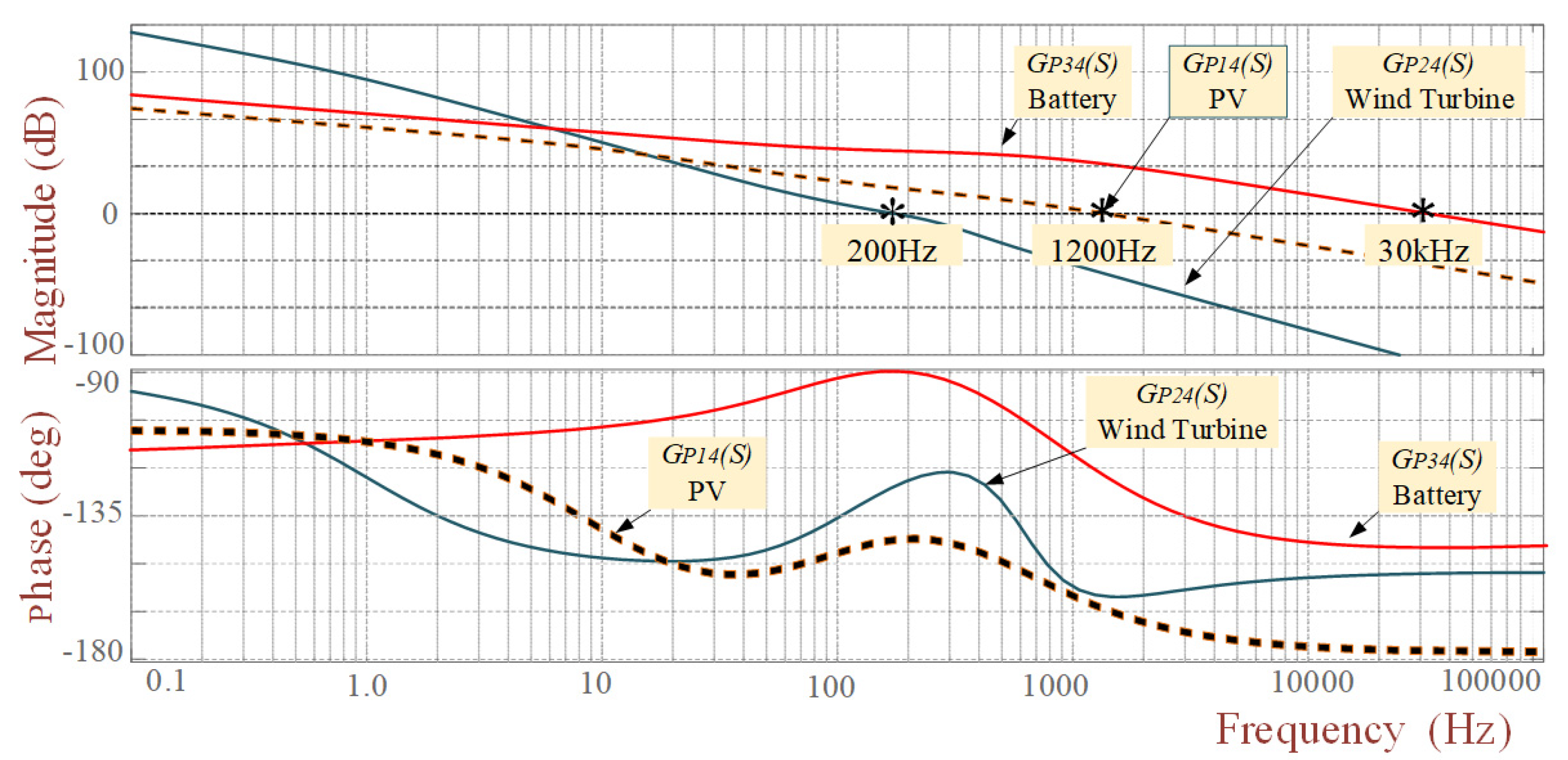

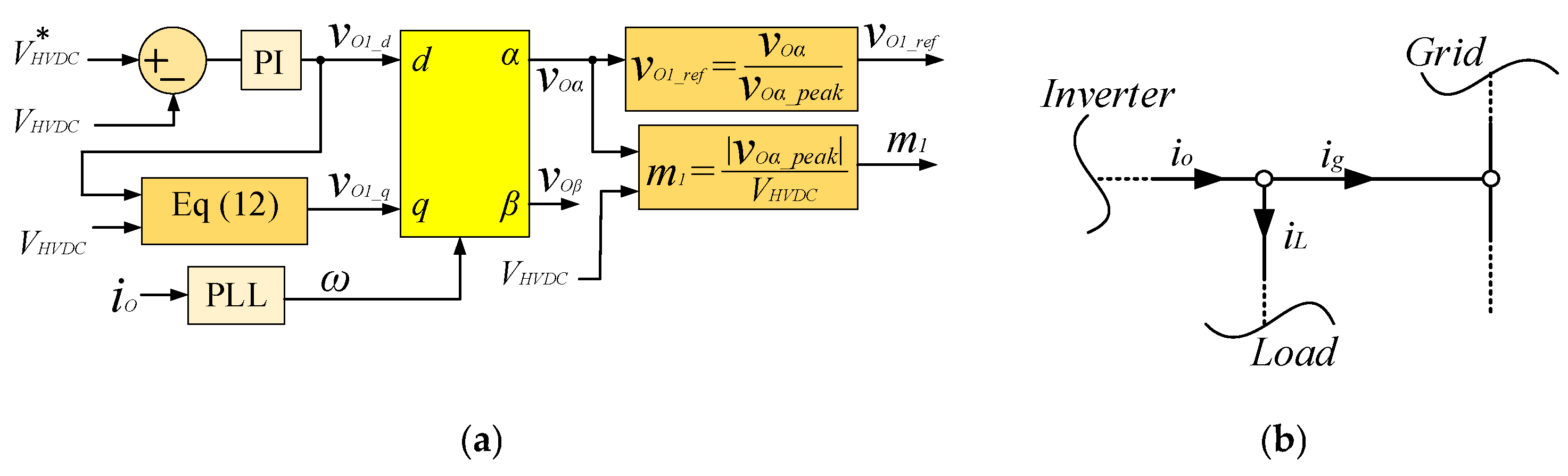

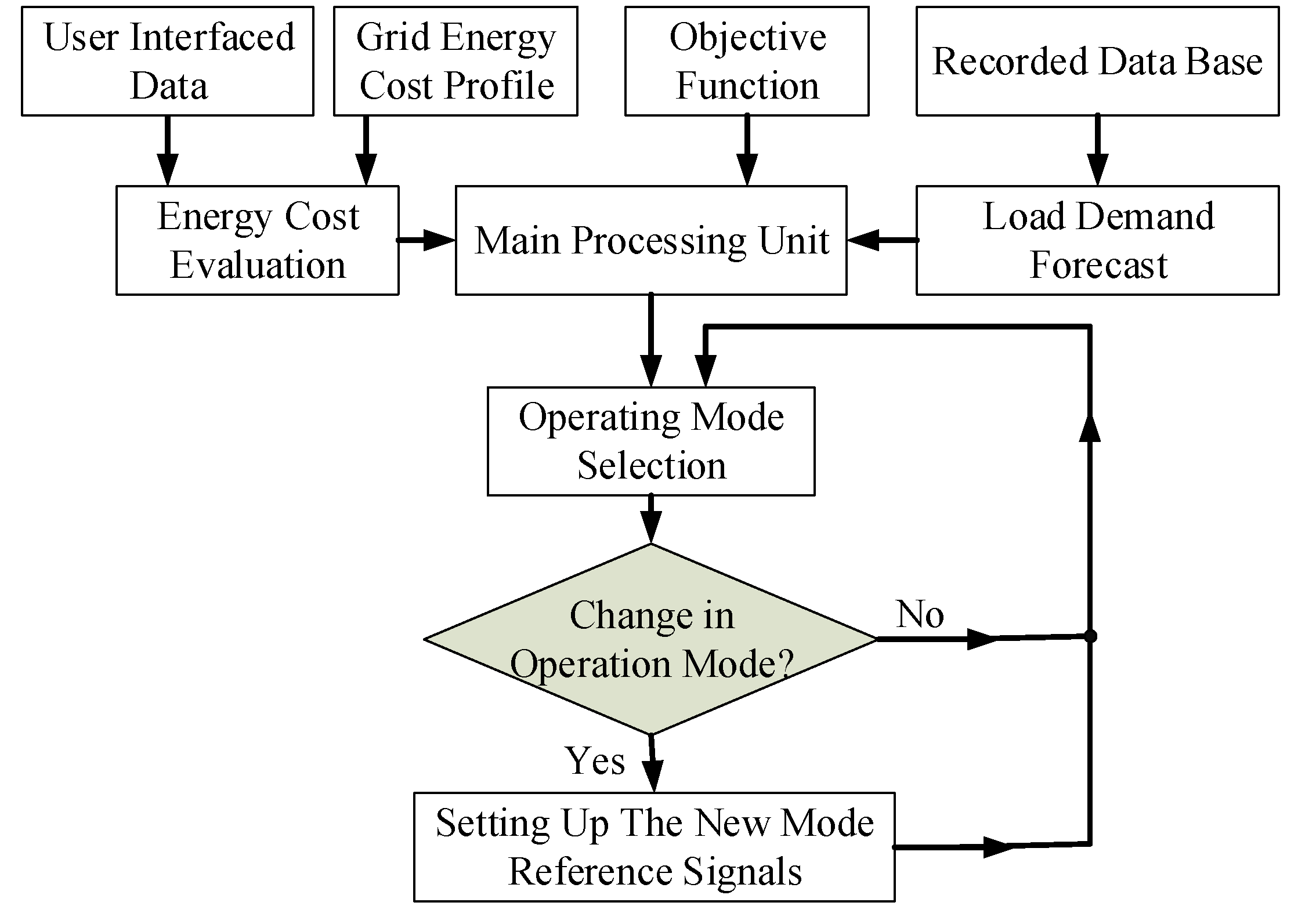

3. Analysis of Control System

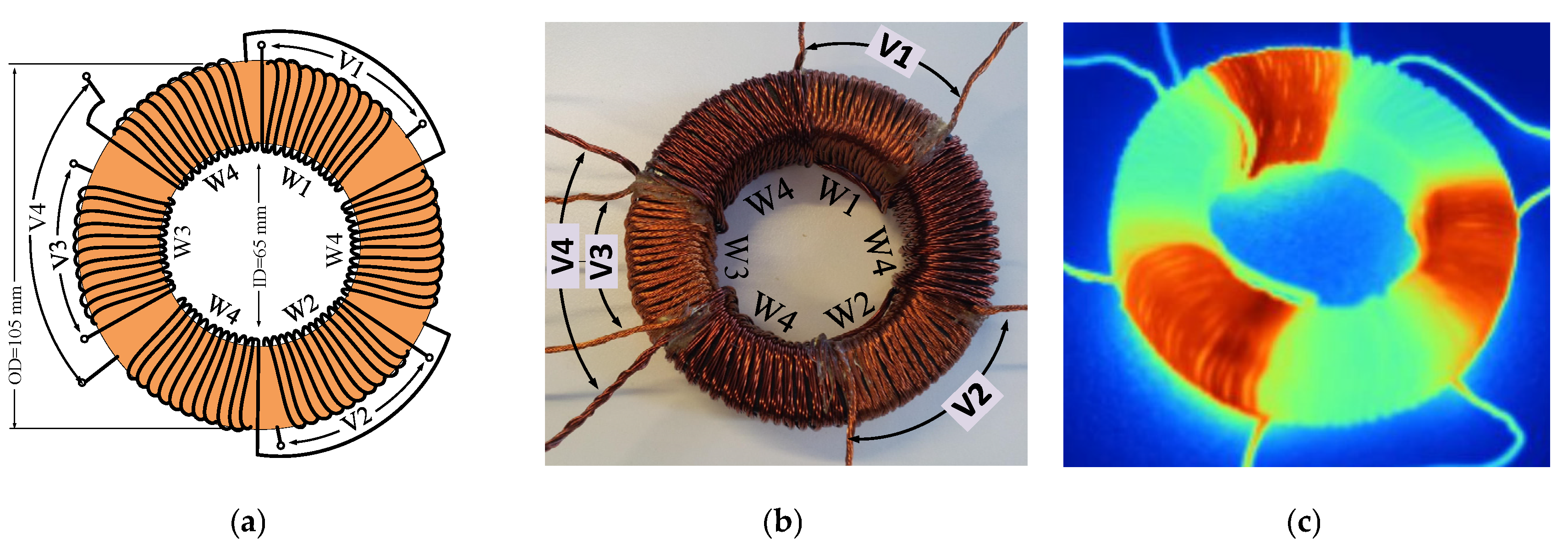

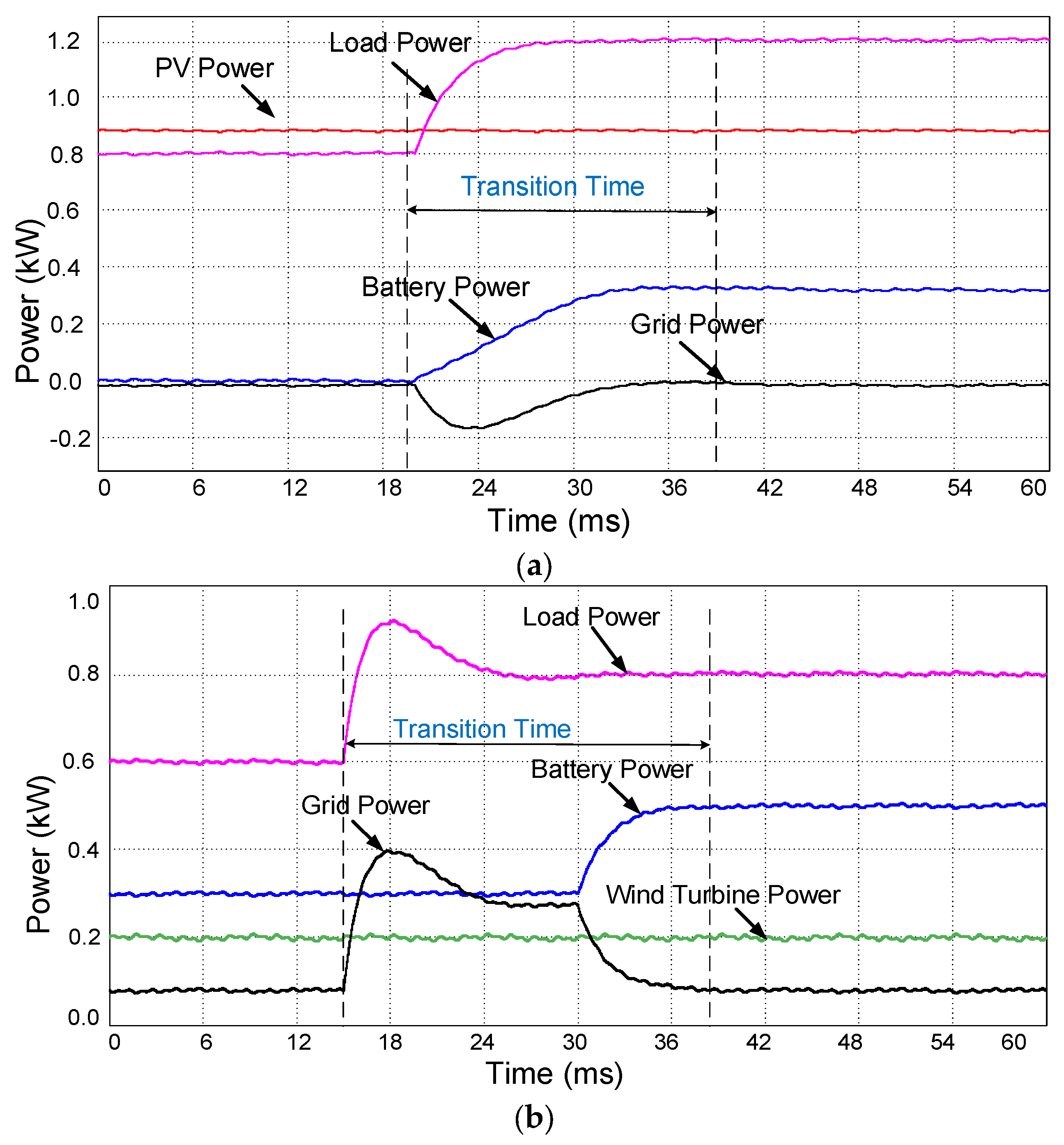

4. High-Frequency Transformer Design

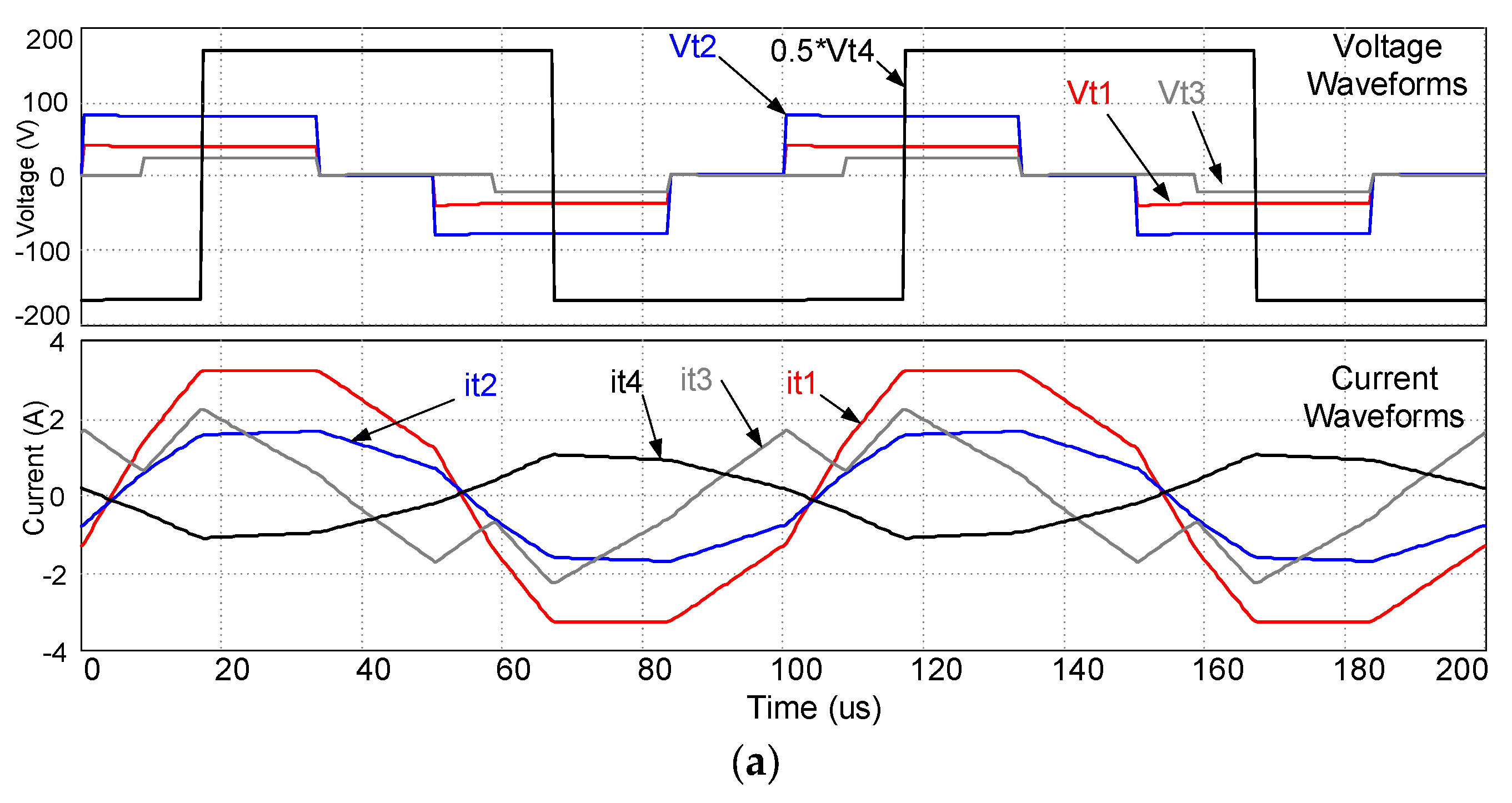

5. Numerical Simulations

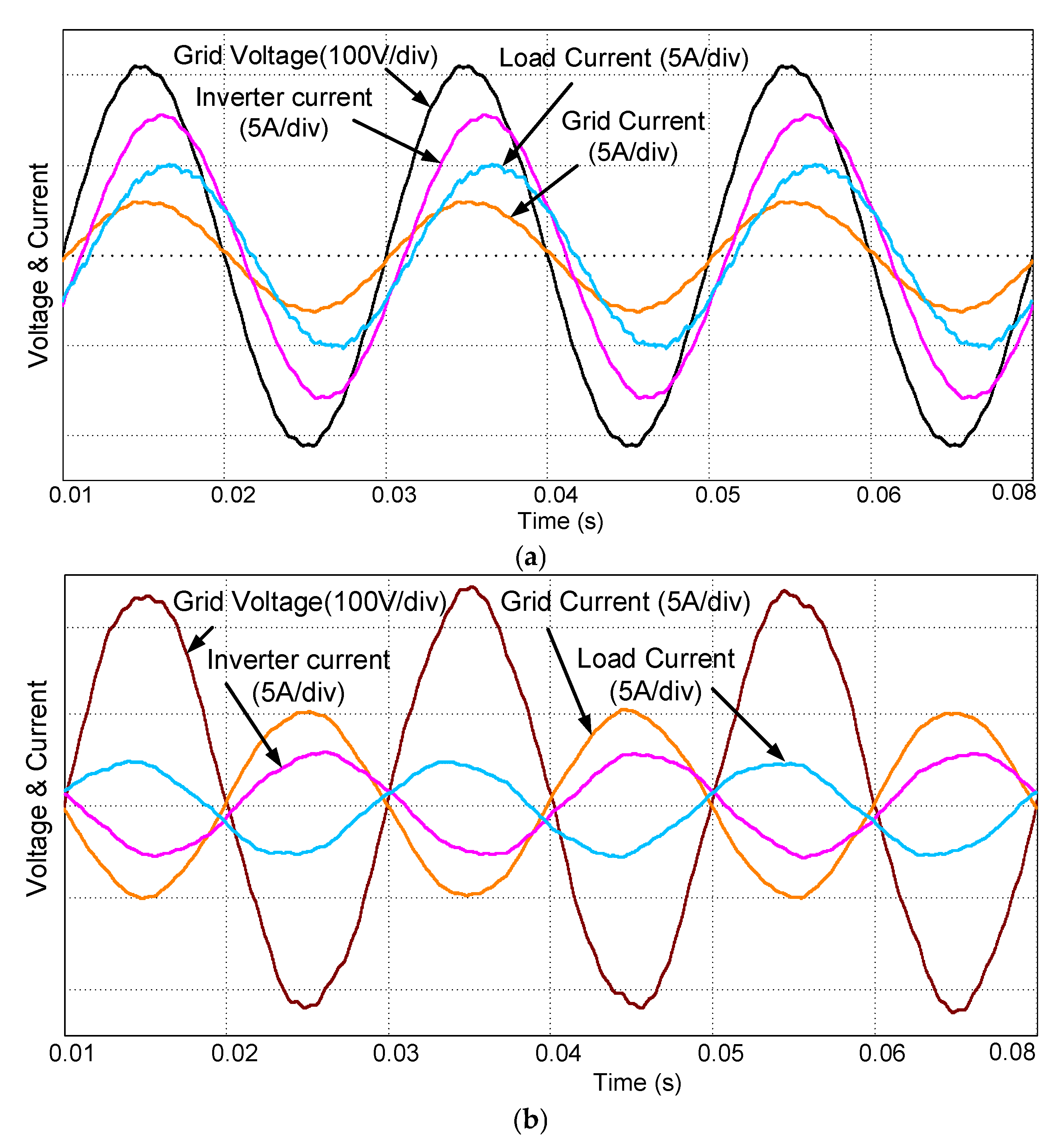

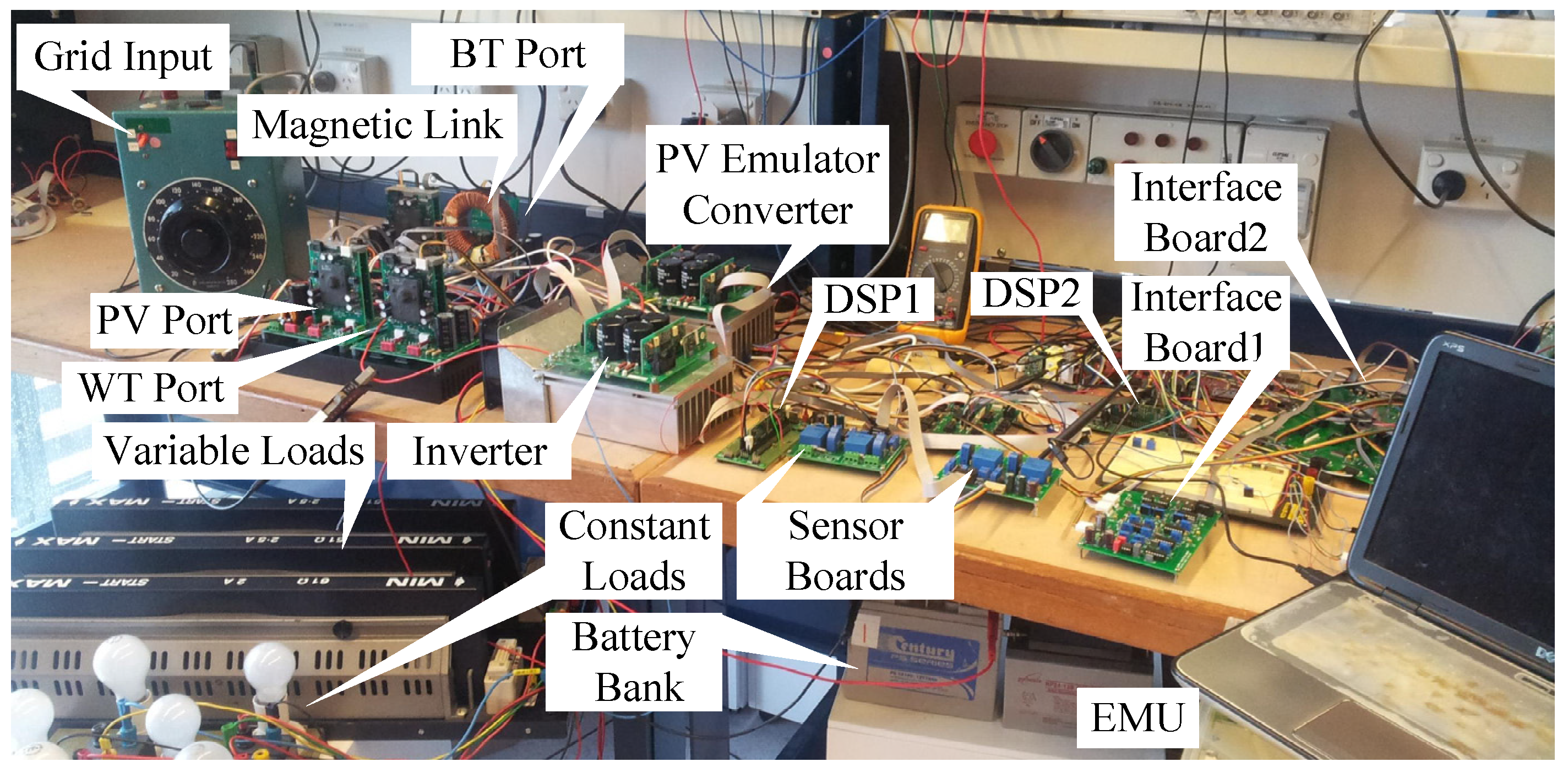

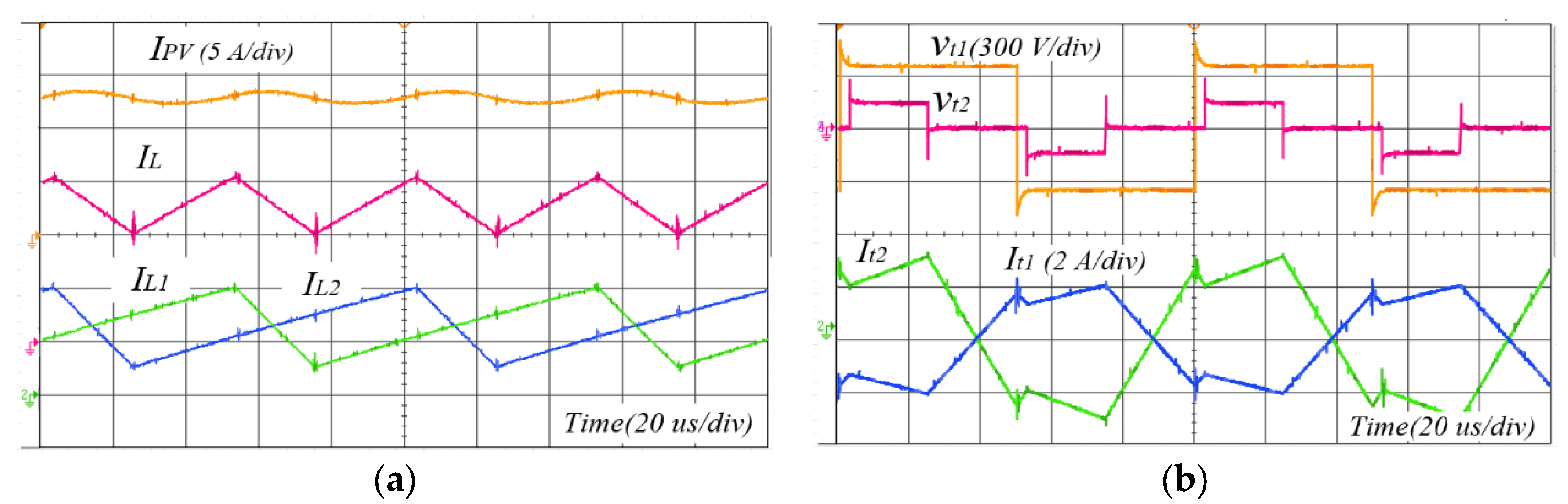

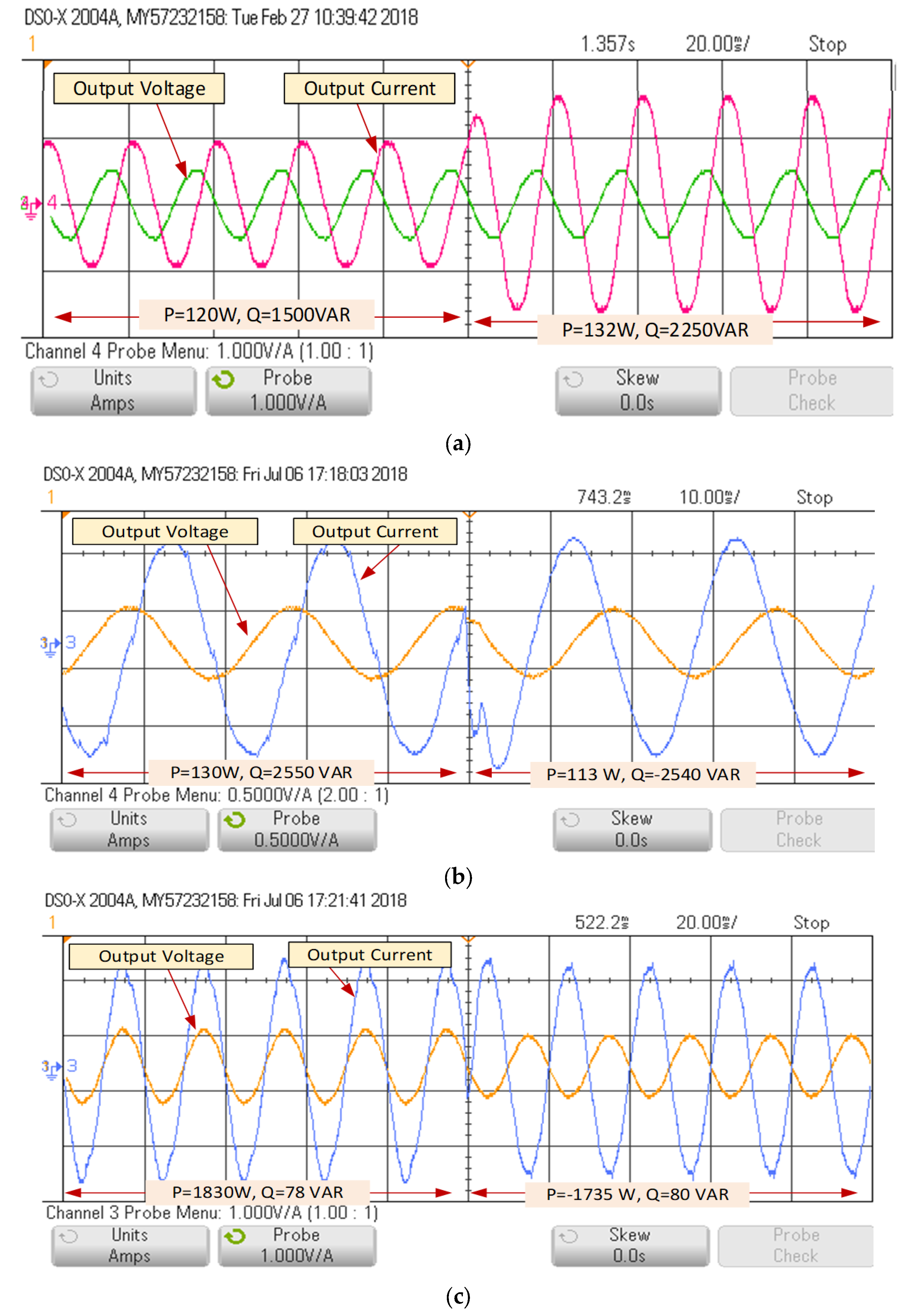

6. Experimental Tests

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| DAB | Dual Active Bridge | δij | Phase shift angle port i to j |

| DSP | Digital Signal Processor | fs | Switching frequency |

| PI | Proportional Integral | Pij | Power flow from port i to j |

| PV | Photovoltaic | Lij | Summation of leakage inductances of windings in ports i and j |

| MPPT | Maximum Power Point Tracking | Di | Duty cycle in port i |

| RNM | Reluctance Network Modeling | Kp, Ki | Proportional and integral controller coefficients |

| UPS | Uninterruptible Power Supply | φm, Gm | Phase margin, gain margin |

References

- Tao, H.; Duarte, J.L.; Hendrix, M. Three-port triple-half-bridge bidirectional converter with zero-voltage switching. IEEE Trans. Power Electron. 2008, 23, 782–792. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J. Design, analysis and control of a magnetically-coupled multi-port multi-operation-mode residential micro-grid. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Zhao, C.; Round, S.; Kolar, J.W. Buck and boost start-up operation of a three-port power supply for hybrid vehicle applications. In Proceedings of the IEEE 36th Conference on Power Electronics Specialists Conference, Recife, Brazil, 16 June 2005; pp. 1851–1857. [Google Scholar]

- Malekjamshidi, Z.; Jafari, M.; Imanieh, M. Implementation of a full bridge series-parallel resonant DC-DC converter using ANN and SSM controllers. In Proceedings of the 2011 IEEE National Aerospace and Electronics Conference (NAECON), Dayton, OH, USA, 20–22 July 2011; pp. 203–210. [Google Scholar]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J.; Jafari, M. Design, simulation and implementation of an intelligent MPPT using a ZVCS resonant DCDC converter. In Proceedings of the 2012 IEEE International Conference on Power and Energy (PECon), Kota Kinabalu, Malaysia, 2–5 December 2012; pp. 280–285. [Google Scholar]

- Jafari, M.; Malekjamshidi, Z.; Islam, M.R.; Zhu, J. Comparison of singular and modular structures of multiport converters for residential applications in smart grids. In Proceedings of the 2014 IEEE Innovative Smart Grid Technologies-Asia (ISGT ASIA), Kuala Lumpur, Malaysia, 20–23 May 2014; pp. 606–611. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z. Design, Simulation and implementation of an adaptive controller on base of artificial neural networks for a resonant DC-DC converter. In Proceedings of the 2011 IEEE Ninth International Conference on Power Electronics and Drive Systems, Singapore, 5–8 December 2011; pp. 1043–1046. [Google Scholar] [CrossRef]

- Malekjamshidi, Z.; Jafari, M.; Islam, R.; Zhu, J. A comparative study on characteristics of major topologies of voltage source multilevel inverters. In Proceedings of the 2014 IEEE Innovative Smart Grid Technologies—Asia (ISGT ASIA), Kuala Lumpur, Malaysia, 20–23 May 2014; pp. 612–617. [Google Scholar] [CrossRef]

- Savitha, K.P.; Kanakasabapathy, P. Multi-port DC-DC converter for DC microgrid applications. In Proceedings of the 2016 IEEE 6th International Conference on Power Systems (ICPS), New Delhi, India, 4–6 March 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Chen, Y.-M. A systematic approach to synthesizing multi-input DC–DC converters. IEEE Trans. Power Electron. 2009, 24, 116–127. [Google Scholar] [CrossRef]

- Benavides, N.; Chapman, P. Power budgeting of a multiple-input buck-boost converter. IEEE Trans. Power Electron. 2005, 20, 1303–1309. [Google Scholar] [CrossRef]

- Jafari, M.; Hunter, G.; Zhu, J.; Jafari, M. A new topology of multi-input multi-output Buck-Boost DC-DC Converter for microgrid applications. In Proceedings of the 2012 IEEE International Conference on Power and Energy (PECon), Kota Kinabalu, Malaysia, 2–5 December 2012; pp. 286–291. [Google Scholar]

- Jafari, M.; Malekjamshidi, Z. Optimal energy management of a residential-based hybrid renewable energy system using rule-based real-time control and 2D dynamic programming optimization method. Renew. Energy 2020, 146, 254–266. [Google Scholar] [CrossRef]

- Duarte, J.L.; Hendrix, M.; Simões, M.G. Three-port bidirectional converter for hybrid fuel cell systems. IEEE Trans. Power Electron. 2007, 22, 480–487. [Google Scholar] [CrossRef]

- Tao, H.; Kotsopoulos, A.; Duarte, J.; Hendrix, M. Family of multiport bidirectional DC–DC converters. IEE Proc. Electr. Power Appl. 2006, 153, 451. [Google Scholar] [CrossRef]

- Tao, H. Integration of Sustainable Energy Sources through Power Electronic Converters in Small Distributed Electricity Generation Systems. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2008. [Google Scholar]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J. Accurate copper loss analysis of a multi-winding high-frequency transformer for a magnetically-coupled residential micro-grid. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Islam, R.; Zhu, J.; Mohammad, J. Modeling of magnetic flux in multi-winding toroidal core high frequency transformers using 3D reluctance network model. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, NSW, Australia, 9–12 June 2015; pp. 413–418. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J.; Khooban, M.H. A novel predictive fuzzy logic-based energy management system for grid-connected and off-grid operation of residential smart microgrids. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 1391–1404. [Google Scholar] [CrossRef]

- Tao, H.; Kotsopoulos, A.; Duarte, J.L.; Hendrix, M.A.M. Transformer-coupled multiport ZVS bidirectional DC–DC converter with wide input range. IEEE Trans. Power Electron. 2008, 23, 771–781. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J. Copper loss analysis of a multiwinding high-frequency transformer for a magnetically-coupled residential microgrid. IEEE Trans. Ind. Appl. 2018, 55, 283–297. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J. A magnetically coupled multi-port, multi-operation-mode micro-grid with a predictive dynamic programming-based energy management for residential applications. Int. J. Electr. Power Energy Syst. 2019, 104, 784–796. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Lei, G.; Wang, T.; Platt, G.; Zhu, J. Design and implementation of an amorphous high-frequency transformer coupling multiple converters in a smart Microgrid. IEEE Trans. Ind. Electron. 2016, 64, 1028–1037. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J. Design and development of a multi-winding high-frequency magnetic link for grid integration of residential renewable energy systems. Appl. Energy 2019, 242, 1209–1225. [Google Scholar] [CrossRef]

- Chen, Y.-M.; Liu, Y.-C.; Wu, F.-Y. Multi-input DC/DC converter based on the multiwinding transformer for renewable energy applications. IEEE Trans. Ind. Appl. 2002, 38, 1096–1104. [Google Scholar] [CrossRef]

- Michon, M.; Duarte, J.; Hendrix, M.; Simoes, M. A three-port bi-directional converter for hybrid fuel cell systems. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004; pp. 4736–4742. [Google Scholar] [CrossRef]

- Zhao, C.; Kolar, J. A novel three-phase three-port UPS employing a single high-frequency isolation transformer. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004; pp. 4135–4141. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Lu, D.D.C.; Zhu, J. Development of a fuzzy-logic-based energy management system for a multiport multioperation mode residential smart microgrid. IEEE Trans. Power Electron. 2018, 34, 3283–3301. [Google Scholar] [CrossRef]

- Jafari, M.; Platt, G.; Malekjamshidi, Z.; Zhu, J. Technical issues of sizing Lead-Acid batteries for application in residential renewable energy systems. In Proceedings of the 2015 4th International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, UAE, 24–26 November 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Liu, D.; Li, H. A ZVS Bi-directional DC–DC converter for multiple energy storage elements. IEEE Trans. Power Electron. 2006, 21, 1513–1517. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Li, L.; Zhu, J.; Jafari, M. Performance analysis of full bridge, boost half bridge and half bridge topologies for application in phase shift converters. In Proceedings of the 2013 International Conference on Electrical Machines and Systems (ICEMS), Busan, Korea, 26–29 October 2013; pp. 1589–1595. [Google Scholar]

- Jafari, M.; Malekjamshidi, Z.; Platt, G.; Zhu, J.; Dorrell, D.G. A multi-port converter based renewable energy system for residential consumers of smart grid. In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 5168–5173. [Google Scholar] [CrossRef]

- Shi, Y.; Li, R.; Xue, Y.; Li, H. High-frequency-link based grid-tied PV system with small DC-link capacitor and low-frequency ripple-free maximum power point tracking. IEEE Trans. Power Electron. 2015, 31, 1. [Google Scholar] [CrossRef]

- Chen, G.; Xu, D.; Wang, Y.; Lee, Y.-S. A new family of soft-switching phase-shift bidirectional DC-DC converters. In Proceedings of the 2001 IEEE 32nd Annual Power Electronics Specialists Conference, Vancouver, BC, Canada, 12–21 June 2002; pp. 859–865. [Google Scholar]

- Jafari, M.; Islam, R.; Malekjamshidi, Z.; Zhu, J. Modeling of multi-winding high-frequency transformers as a common magnetic-link in smart micro-grids. In Proceedings of the 2015 International Conference on Electrical & Electronic Engineering (ICEEE), Rajshahi, Bangladesh, 4–6 November 2015; pp. 249–252. [Google Scholar] [CrossRef]

- Kheraluwala, M.H.; Gascoigne, R.W.; Divan, D.M.; Baumann, E.D. Performance characterization of a high-power dual active bridge DC-to-DC converter. IEEE Trans. Ind. Appl. 1992, 28, 1294–1301. [Google Scholar] [CrossRef]

- Vangen, K.; Melaa, T.; Bergsmark, S.; Nilsén, R. Efficient high-frequency soft-switched power converter with signal processor control. In Proceedings of the Thirteenth International Telecommunications Energy Conference—INTELEC 91, Kyoto, Japan, 5–8 November 1991; pp. 631–639. [Google Scholar]

- Vangen, K.; Melaa, T.; Adnanes, A. Soft-switched high-frequency, high power DC/AC converter with IGBT. In Proceedings of the PESC’92 Record. 23rd Annual IEEE Power Electronics Specialists Conference, Toledo, Spain, 29 June–3 July 1992; pp. 26–33. [Google Scholar]

- Vangen, K.; Melaa, T.; Adnanes, A.K.; Kristiansen, P.E. Dual active bridge converter with large soft-switching range. In Proceedings of the Fifth European Conference on Power Electronics and Applications (EPE’93), Brighton, UK, 13–16 September 1993; pp. 328–333. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, D.M.; Qian, Z. An improved dual active bridge DC/DC converter. In Proceedings of the 2001 IEEE 32nd Annual Power Electronics Specialists Conference, Vancouver, BC, Canada, 17–21 June 2001; pp. 232–236. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, F.; Xie, X.; Jiao, D.; Qian, Z. A novel ZVS DC/DC converter for high power applications. IEEE Trans. Power Electron. 2004, 19, 420–429. [Google Scholar] [CrossRef]

- Jafari, M.; Malekjamshidi, Z.; Zhu, J.; Mohammad, J. Analysis of operation modes and limitations of dual active bridge phase shift converter. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, NSW, Australia, 9–12 June 2015; pp. 393–398. [Google Scholar]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Leakage inductance of transformer windings | L1 = 0.012 mH, L2 = 0.01 mH, L3 = 0.008 mH, L4 = 0.02 mH | Switching frequency of multi-port converter | fsc = 15 kHz |

| Number of turns of each winding of the transformer | N1 = 18, N2 = 18, N3 = 18, N4 = 54 | DC bus voltage | V1 = 110 V, V2 = 110 V, V3 = 110 V, V4 = 300 V |

| Magnetizing inductance Lm | Lm = 1.12 mH | Switching frequency of Inverter | fsi = 10 kHz |

| Rated power in each input of the converter | PPV = 800 W, PBT = 600 W PWT = 800 W | Utility grid parameters | f = 50 Hz, V(rms) = 150 V |

| PV characteristics (Totally 4 Panels) | Each panel: Vo = 35 V, Imax = 6 A Pmax = 200 W | Wind turbine characteristics | V = 100 V DC, P = 800 W, Imax = 9 A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari, M.; Malekjamshidi, Z. A Topology of DC-DC Converter Based on Multi-Winding Transformer for Grid Integration of Multiple Renewable Energy Resources. Inventions 2020, 5, 31. https://doi.org/10.3390/inventions5030031

Jafari M, Malekjamshidi Z. A Topology of DC-DC Converter Based on Multi-Winding Transformer for Grid Integration of Multiple Renewable Energy Resources. Inventions. 2020; 5(3):31. https://doi.org/10.3390/inventions5030031

Chicago/Turabian StyleJafari, Mohammad, and Zahra Malekjamshidi. 2020. "A Topology of DC-DC Converter Based on Multi-Winding Transformer for Grid Integration of Multiple Renewable Energy Resources" Inventions 5, no. 3: 31. https://doi.org/10.3390/inventions5030031

APA StyleJafari, M., & Malekjamshidi, Z. (2020). A Topology of DC-DC Converter Based on Multi-Winding Transformer for Grid Integration of Multiple Renewable Energy Resources. Inventions, 5(3), 31. https://doi.org/10.3390/inventions5030031