Abstract

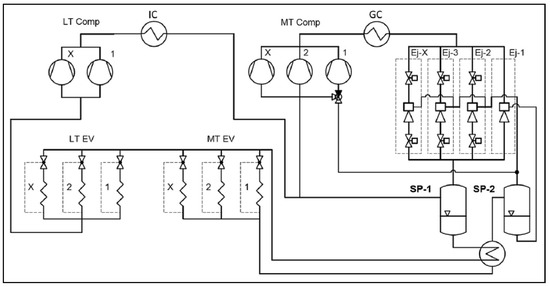

Two-phase ejectors play a major role as refrigerant expansion devices in vapor compression systems and can find potential applications in many other industrial processes. As a result, they have become a focus of attention for the last few decades from the scientific community, not only for the expansion work recovery in a wide range of refrigeration and heat pump cycles but also in industrial processes as entrainment and mixing enhancement agents. This review provides relevant findings and trends, characterizing the design, operation and performance of the two-phase ejector as a component. Effects of geometry, operating conditions and the main developments in terms of theoretical and experimental approaches, rating methods and applications are discussed in detail. Ejector expansion refrigeration cycles (EERC) as well as the related theoretical and experimental research are reported. New and other relevant cycle combinations proposed in the recent literature are organized under theoretical and experimental headings by refrigerant types and/or by chronology whenever appropriate and systematically commented. This review brings out the fact that theoretical ejector and cycle studies outnumber experimental investigations and data generation. More emerging numerical studies of two-phase ejectors are a positive step, which has to be further supported by more validation work.

1. Introduction

Ejectors have been extensively studied for decades mainly for use in ejector cooling and refrigeration systems, as a potential alternative to conventional compression systems or more generally to assist conventional systems and improve their overall performance. Ejectors may be used with almost any fluid without any need for lubricants. They are simple passive components, reliable, low cost and almost maintenance-free.

Today, ejectors may be found in several fields of applications such as vacuum creation, fluid circulation, water desalination or refrigerant expansion, as reported in previous papers such as Elbel and Hrnjak [1], Kumar et al. [2] to name only two cases. In novel refrigeration systems, they can operate in single-phase mode to boost or even replace the compressor, in two-phase mode to recover the energy usually lost in the throttling valve of refrigeration or heat pump cycles. Irrespective of their type, ejectors offer good opportunities to build cycles potentially more efficient and less energy demanding than the conventional mechanical refrigeration systems [3]. In view of the many potential uses, different ejector types are available. They are categorized as single-phase or two-phase devices.

Single phase, liquid–liquid ejectors generally serve as feed pumps and flow circulators. An application example was considered by Li et al. [4] for water chillers where the ejector worked as a liquid recirculation component in a horizontal tube falling-film evaporator with R134a. Supersonic gas–gas ejectors can recover waste heat and they have been the most widely studied to date (see Part 1 of this review for details).

Two-phase ejectors refer generally to the condensing ejector (vapor stream condenses in the ejector), or to the conventional two-phase ejector (two-phase, liquid–vapor flow throughout the ejector) [5]. Two-phase ejectors where a primary liquid drives a secondary vapor are finding an increased use as expansion devices. They reduce throttling losses and recover expansion work (replacement of expansion valves) in heat pumps, air-conditioning and refrigeration systems.

Available literature reviews dedicated to two-phase ejectors and their applications focused mainly on refrigeration and heat pumps [1,3,6,7,8,9,10]. Elbel and Hrnjak [1] summarized the historical background of the ejector technology and its development in air-conditioning and refrigeration. Two-phase ejector application to CO2 heat pumps occupies an important place among the available works. Sarkar [6] compared several important such cycles with transcritical CO2 for the purpose of expansion recovery. Elbel [7], building on previous work [1], provided a detailed account of the transcritical CO2 ejector application in air-conditioning, in addition to analytical and experimental results on system performance improvements. Further work by Sumeru et al. [3] extended the investigation to issues like thermodynamic modeling and comparison with the conventional cycle, irrespective of the refrigerant type. Around the same time, Sarkar [8] also proposed a review of ejector expansion cycle including geometric parameters, refrigerant and operating considerations. This work included a good description of various cycle configurations as well as performance characteristics of both subcritical and transcritical systems. A recent paper by Besagni [11], gives a concise rundown of last two-year achievements in areas of ejector-based refrigeration, power conversion and chemical processes, with future research and development perspectives.

Colarossi and Yazdani teams [12,13] summarized the first trials for the determination of spatial fields (Mach number, pressure and quality) inside CO2 ejector passages by means of validated CFD modeling. The recent work of Elbel and Lawrence [10] provided more information on emerging CFD efforts, new control measures, alternate cycle configurations and progress towards the development of applications based on ejectors for expansion recovery in cooling-refrigeration setups.

Given the large amount of ejector material accumulated over the years and the availability of well-documented works in the literature, focus here will be put on highlighting the main characteristics of the technology and the latest development trends.

This work therefore presents updates of representative and recent progress in two-phase ejector modeling, integration in air-conditioning, refrigeration and heat pump cycles as well as in diverse potential applications.

2. Two-Phase Ejector Characteristics

Like other ejector types, two-phase ejectors are simple devices with no moving parts and similar geometric components: a primary nozzle, a mixing chamber and a diffuser. Two fluid streams, a liquid phase and a gas (or vapor phase) are involved. Generally, both phases are of the same fluid such as is the case with conventional refrigerants or water. Depending on the role of each phase, a different type of ejector is obtained with its specific design, local geometry, operation and application [14].

If the vapor is the moving agent of the liquid, the device generally represented by this configuration is the condensing ejector (often called steam injector) [15].

If on the contrary, the liquid is the moving agent of the vapor, then the device is simply called two-phase ejector [16,17,18].

2.1. Ejector Types

2.1.1. Gas–Liquid Injectors

A condensing ejector (also known as steam injector) uses vapor at high pressure as a motive stream to pump cold liquid at low pressure, and to produce an outlet pressure potentially higher than the vapor inlet pressure. Its operation relies only on thermodynamic processes of mass, momentum, and heat transfer between the two phases in order to produce the compression effect. Such a device can be used as a safety pump in light water reactors, as steam supply is generally available in power plants and a high-pressure water supply can be useful for heat removal in case of incident [14,19,20].

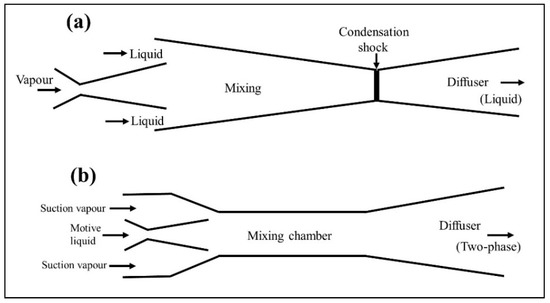

A schematic representation of a steam injector is shown in Figure 1a, where four zones can be distinguished. The first zone is the vapor nozzle, with a converging–diverging shape, where the vapor is accelerated to supersonic velocity through a nearly isentropic expansion. Liquid feeds into the injector by means of the liquid nozzle. Two nozzle arrangements can be found in the literature: vapor-central or liquid-central. In this figure the arrangement shown is a vapor-central nozzle and an annular outer liquid nozzle for illustration purposes.

Figure 1.

Typical geometry of two-phase ejectors: (a) vapor–liquid ejector; (b) liquid–vapor ejector.

In the mixing section, vapor and liquid exchange heat, momentum and mass (due to condensation of steam on the water droplets extracted from the water cone at the exit of the water nozzle). Condensation is achieved in the shock wave occurring at the exit of the mixing section in the form of condensation shock. The major pressure rise results from this process, further liquid slow down and a low-pressure increase is obtained in the diffuser [21]. Review details on injector modeling and application may be found in [22]. In a recent paper, Miwa et al. [23] extended their previous experimental study on steam injectors with central liquid jet to widen the operating range and improve pumping performance. The conditions investigated were within 0.02–0.81 MPa for inlet steam pressure and 0.21–0.80 kg/s for inlet water flow rate, respectively. The authors considered the liquid jet break-up length to assess the injector operation mode, confirming the existence of inlet water flow rate and steam pressure limits; by using the liquid jet stability analysis, they also proposed an explanation to its operating range.

Bergander [24] used this concept to propose a modified vapor compression cycle for refrigeration with R22 where the condensing ejector was used. In such a system, the mechanical compressor pressurized the vapor to approximately 2/3 of the final pressure. The ejector device provided additional compression, therefore significantly reducing the amount of mechanical energy required by the compressor. A thermodynamic analysis of the system showed a potential efficiency improvement of 38% above the conventional vapor compression cycle and preliminary experiments on a 10 kW prototype suggested about 16% energy savings.

2.1.2. Liquid–Gas Ejectors

Additionally referred to, as two-phase ejectors, they use the potential energy of the liquid flow (primary motive stream) to entrain a secondary fluid of the same or of a different type (gas or vapor stream) and impress on it some compression effect (generally weak in comparison to single-phase supersonic ejectors). The geometry consists of a convergent or convergent–divergent nozzle, a mixing chamber and a diffuser, as shown in Figure 1b. In the commonly intended ejector-expansion refrigeration cycle application, the motive liquid stream, is provided by the condenser at high, saturated pressure, or slightly sub-cooled. Nearly isentropic expansion occurs in the primary nozzle, accelerating the liquid into the mixing chamber where a secondary vapor stream from the evaporator is drawn and entrained. In the zone of the mixing chamber with constant cross-section, sometimes called the ejector second throat, the resulting two-phase mixture is assumed to go through a process of shock wave formation before heading towards the diffuser for final compression. This mixing process is not yet well understood and due to its complexity, little confirmed information is available in the literature. Two-phase ejector modest compression is likely due, mainly to weak shocks and to the limited compressibility of the two-phase mixture [25].

2.2. Ejector Geometry

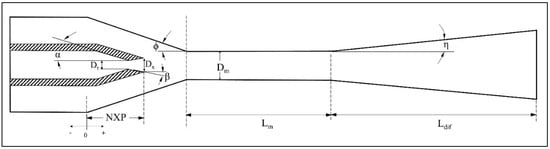

The geometrical features of an ejector have an important influence on performance, irrespective of its type. Typical parameters, commonly identified to affect optimal ejector design for maximized performance are generally the area ratio (ϕ) which is the ratio of the constant area cross-section zone or second throat to the nozzle throat cross-section area, the nozzle exit position (NXP) and the constant area cross-section zone length (Lm) as defined in Figure 2. The mixing chamber and the diffuser angles (respectively φ and η) as well as the angle of the primary nozzle divergent β, also are sometimes considered.

Figure 2.

Typical ejector geometry parameters.

As previously discussed (Part 1 of this review), two alternate ejector geometry concepts proposed by Keenan et al. [26] are the constant pressure mixing (CPM) and constant mixing area (CMA). In spite of the fact that the CPM concept is usually preferred for its secondary flow entrainment capability under given conditions, both concepts are equally used, depending on the ejector intended use and its environment conditions. Very recent work of Atmaca et al. [27] compared the two mixing concepts by means of thermodynamic analysis. Similar performance improvement of the expansion ejector refrigeration cycle, under both CAM and CPM configurations, was found.

In heat pump and refrigeration applications, the geometric parameters used for two-phase ejectors are essentially the same as those used to qualify single-phase ejectors. In the case of ejectors serving other purposes in industrial and process applications some slight differences in the definitions and terminology may sometimes be encountered in the literature. Geometric parameters have an effect on ejector performance and operation to various extents, depending on the ejector type, the working fluids, the application and operating conditions. The nozzle exit position, NXP is the relative nozzle distance to the mixing chamber throat inlet and sometimes reported in non-dimensional form as NXP/Dm. It generally has an effect on both the entrainment and the compression ratios of ejectors.

Liu et al. [28] investigated the effects of various ejector geometries and operating conditions on the performance of an air conditioner working with CO2 under transcritical conditions. A maximum COP value was reached when the motive nozzle exit positioned before the mixing chamber inlet was three times the diameter of the constant-area mixing section. Hu et al. [29] experimented a two-phase ejector with the refrigerant R410A, in an air-conditioning system. The distance between the nozzle outlet and the constant section mixing chamber was varied from 0 to 9 mm. An optimal position of the nozzle for system capacity and performance was found to be 3 mm. Experimental results obtained by Wang and Yu [30] with R600a two-phase ejector showed no optimal position for the nozzle. A slight increase of entrainment ratio with NXP was observed, but at 6 mm upstream of the mixing chamber, the entrainment ratio tended to remain constant. Unlike this trend, experiments of Ameur and Aidoun [31] with R134a two-phase ejector have shown an optimal position of the primary nozzle in the ejector, and this position was not very sensitive to operational conditions. The authors noticed a sharp drop in performance of the ejector when the nozzle was placed close to the inlet of the constant-area section.

Nehdi et al. [32] showed by means of thermodynamic analysis the importance of the area ratio on EERC system’s performance for several refrigerants. A maximum COP was obtained for ϕ value around 10. Along the same lines of investigations, Sarkar [33] thermodynamic analysis of EERC with ammonia, isobutane and propane confirmed the importance of the area ratio on performance. In the conditions of the study (Te = 5 °C and Tc = 40 °C), isobutane yielded maximum COP improvement of 21.6% followed by propane (17.9%) and ammonia (11.9%), for area ratios of 10, 7.7 and 5.7 respectively.

The area of the mixing chamber cross-section affects ejector performance differently, depending on inlet conditions. Small mixing areas are more favorable with low inlet pressures in terms of entrainment and compression ratios while larger cross-section areas are more suitable with high ejector pressures or low temperatures for more capacity [8].

Nakagawa et al. [34] experimentally showed 10% COP difference between smallest and largest mixing areas. As shown by Hu et al. [29] by means of thermodynamic analysis and experiments on an EERC type air-conditioning apparatus working with R410A, NXP and the area ratio ϕ sensibly affected system performance by exhibiting optimum working conditions.

The effects of the second throat length (i.e., the zone of the mixing chamber with constant cross-section) were identified to play a role in ejector performance. Nakagawa et al. [35] investigated the effects experimentally of the mixing section’s geometry on the performance of a two-phase ejector with R12. Results indicated an enhancement of the pressure recovery by increasing the length and decreasing the diameter of the mixing section. Tested Lm/Dm ratios ranged from 4 to 21. However, no significant improvement in pressure recovery was observed beyond Lm/Dm = 16.

In another paper, Nakagawa et al. [36] analyzed experimentally the effect of mixing length of a transcritical CO2 two-phase ejector with rectangular cross-section. Three mixing lengths were experimented (5 mm, 15 mm, and 25 mm); the 15 mm case yielded the highest ejector efficiency and COP in all tested conditions. Along the same lines of investigations with transcritical CO2 two-phase ejector, Banasiak et al. [37] tested three mixing section length (Lm/Dm = 5, 10 and 20); the ratio Lm/Dm = 10 was associated with the highest ejector efficiency. In a recent study, Jeon et al. [38], investigated the effects of Dt and Dm on the performance of an ejector expansion air conditioner using R410A, under various climatic conditions. Dt was varied from 1.04 to 1.21 mm, and Dm from 7 to 13 mm, while the ratio Lm/Dm was fixed at 10. At the smallest Dt, the maximum COP increase was observed. The optimum Dm was determined to be 9 mm. Dm was optimized based on the climatic conditions. The optimum Dm increased with an increase in the average annual outdoor temperature.

In general, results about mixing length indicated that an optimization procedure might be crucial for proper ejector design. Indeed, a substantial length can result in considerable friction forces with a negative impact on the mechanism of pressure recovery, whereas a shorter length may result in an inefficient mixing of the two streams. Angles φ and η do not seem to have a systematic influence despite some cases where said influence was reported [29,39,40].

Nakagawa et al. [41] investigated the effect of the divergent angle of the primary nozzle, showing that it played an important role in the decompression boiling phenomena of transcritical CO2, such that the pressure profiles did not correspond to the predictions of the isentropic homogeneous equilibrium model because the flow was in a non-equilibrium and supersaturated state.

More recently, the variable nozzle throat area was proposed and thus the area ratio, as control means to improve the operating performance of the transcritical CO2 ejector refrigeration system [42].

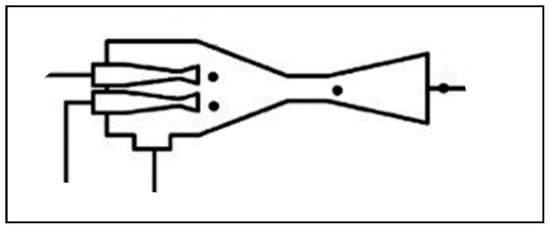

A further geometry concept of the two-phase ejector was introduced by Zhou et al. [43] as the dual ejector, shown in Figure 3. It is equipped with two nozzles and will be further discussed in a later Section 5.2.1.

Figure 3.

Dual-nozzle ejector [43].

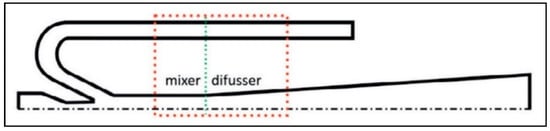

Recent work by Bodys et al. [44] proposed a two-phase ejector for CO2 with a bypass on the suction nozzle duct (Figure 4). The study assessed numerically the bypass positioning and its angle of incidence under several working conditions. Encouraging preliminary results in the order of 22.4% to 30.4% efficiency improvement at low-pressure conditions were obtained but more work is needed for higher pressures.

Figure 4.

Ejector with a bypass [44].

2.3. Ejector Performance

Two-phase ejector performance in the refrigeration context is defined in the same manner as for the familiar single phase, supersonic ejector. The entrainment ratio ω, characterizes the capacity of the ejector to draw secondary mass flow rate by a primary mass flow rate determined by the inlet conditions,

and the compression ratio relates the outlet to secondary inlet pressures.

In the context of EERC, primary and secondary inlet pressures are typically defined by the condenser and the evaporator temperatures, affecting both the entrainment and compression ratios.

As was shown by Disawas and Wongwises [45], the motive mass flow rate of the ejector is highly dependent on the heat sink temperature and independent of the heat source temperature. This is due to the fact that choked flow occurs at the motive nozzle, and the upstream condition has a significant effect on the mass flow rate. On the other hand, the heat source and heat sink temperatures have a significant effect on the cooling capacity. Liquid sub-cooling was shown to have an effect on performance. The entrainment ratio is generally higher for small amounts of sub-cooling [46].

2.3.1. Ejector Efficiency

The performance characterization of all ejector types requires two performance parameters, the entrainment and the compression ratios defined above, respectively as ω and τ. During ejector operations, these parameters vary in opposite direction: if ω increases, τ decreases and vice-versa, while it is generally desired that both factors be simultaneously maximized. This represents a limitation for comparing ejector design alternatives in practical conditions. As a result, ways were sought to represent ejector performance by a single characteristic factor, accounting for both aspects of entrainment and compression. Hence, various efficiency definitions were proposed, differing particularly on their interpretation of the energy accounting and the required steps for their computation.

Lawrence and Elbel [47], compared several different ejector efficiency definitions, noting that each definition resulted in a different numerical value for the same ejector operating conditions. They discussed their respective features and the requirements for their application. They concluded that the performance of ejectors from different studies were not directly comparable unless they were measured with the same efficiency. They also noted that in the case of efficiencies developed for single-phase ejectors, the large enthalpy differences between saturated liquid and vapor hinder their application in two-phase ejectors.

For these reasons, Elbel and Hrnjak [48] efficiency definition seems to be better adapted to handle two-phase situations without having recourse to assumptions on internal non-measured parameter values. They defined the ejector efficiency as the actual work recovered by the ejector, divided by the theoretical maximum amount that could be recovered by an isentropic expansion of the motive stream from motive inlet to diffuser outlet pressure, as shown in Equation (3). This efficiency was introduced by Koehler et al. [49] and was subsequently confirmed by Elbel and Hrnjak [48] with a different derivation procedure.

Thermodynamic models accuracy depends largely on ejector component efficiencies. Some studies were dedicated to assess the ejector internal efficiencies [50,51,52,53]. An analysis based on measured parameters allowed Liu et al. [28] to generate information and operational data on parameters affecting ejector performance and components efficiencies in the cycle. These results served to establish correlations for the ejector internal efficiencies. In a subsequent work, the authors found that ejector component efficiencies do not remain constant but rather vary with internal geometry and operating conditions. They further established and incorporated empirical correlations into a CO2 air-conditioning system model to estimate ejector component efficiencies at different ejector geometries and operating conditions [52].

2.3.2. Second Law Analysis of Ejectors

Analysis of irreversibility in an ejector refrigeration cycle (ERC or EERC) and its contribution to overall performance represents a further step in the evaluation process. Entropy and exergy approaches allow identifying the distribution of irreversible losses in the system, their magnitude and makes comparisons possible with other processes.

Banasiak et al. [54] numerically analyzed the contribution of the local irreversibility losses to the overall entropy increase in CO2 ejectors by introducing a new factor to evaluate performance, based on the reference entropy increase in a classic expansion valve. The parameter ςej introduced by the authors quantifies the entropy increase avoided with the use of an ejector relative to a reference process:

where ΔSej and ΔSref are the generated entropies across the ejector and reference process respectively. In the case of an EERC, ΔSref represents the throttling stage of a standard refrigeration cycle under the same operating conditions.

For an experimental EERC with CO2, Banasiak et al. [54] observed ςej in the range (−0.062; 0.223). Negative ςej values mean that more irreversibilities were generated across the ejector than the reference did. In addition, the influence of the diameter and length of the mixing chamber was shown to significantly affect performance. In the conditions considered in this study, an enlargement of the mixing cross section area by 17.4% and shortening the mixing length by 33.3% resulted in an increase of the overall entropy growth rate by 8.9% and 5.4%, respectively.

Another useful performance parameter resulting from the second law is the exergy efficiency ξχ, defined as the ratio of outlet to input exergy flow rates:

with being the exergy flow rate, that is: the maximum work rate theoretically available between the thermodynamic conditions at surface i and a reference dead state 0:

Typical reference (or dead state) choices for isolated ejector studies are the secondary inlet state or the working fluid at normal conditions (1 atm and 288 K). For refrigeration cycles, it is usual to choose the condenser inlet conditions. The value of ξχ represents the amount of potential work recovered using an ejector.

Ersoy and Bilir [50] assessed the effects of two-phase ejector internal efficiencies on performance and for a given set of these efficiencies, a comparison of the exergy destruction in the cycle components with and without ejector. The results indicated that increased ejector efficiencies enhanced cycle performance, exergy efficiency and reduced the optimum ejector area ratio.

Later, Bilir et al. [55] experimentally compared the performance of a vapor compression refrigerator using R134a and its ejector-expander equivalent under the same conditions. The ejector-expander refrigeration system’s coefficient of performance was higher than that of the basic system by 7.34–12.87%, while the exergy efficiency values were 6.6–11.24% higher. The authors measured ξej ≈ 98% for an EERC with R134a. The exergy efficiency of the whole EERC system was on average 18%, always two points over that of the standard refrigeration system without ejector tested under the same operating conditions.

2.4. Internal Flow Structure

The flow structure inside the ejector influences operation and performance. Information on flow distribution is therefore necessary to explore gas–liquid phenomena and the nature of streams interaction. Global analyses resulting from thermodynamic treatment or experimental operations hardly give access to this type of information. Theoretical and experimental studies conducted in order to establish links between the internal structure and performance are still scarce. Multi-dimensional numerical studies based CFD are emerging in two-phase ejector area but need more local validation. Visualization experiments are important in boosting numerical capabilities to reliably predict the complex flow structure inside ejectors and link it to their operation.

Most visualization experiments available in the literature are single-phase ejectors, with air, nitrogen or steam at low to moderate pressures. Visualization techniques commonly employed in theses cases are the Schlieren, Shadowgraph and laser tomography methods as discussed in Part 1 of this work. However, limited studies were conducted to illustrate the mixing process and shock patterns in two-phase ejectors.

Banasiak et al. [9] pointed out in relation to experimental methods of flow visualization in transcritical CO2 ejectors, the scarcity of experimental identification or classification of flow patterns for the two-phase CO2 ejector passages. In this respect and for two-phase ejector internal flow structures in general, visualization methods with high resolution are needed to capture shock phenomena in specially limited component sizes such as found in two-phase ejectors operating with common and natural refrigerants. Schlieren visualization and PIV techniques applied in single-phase devices are also progressively introduced to capture two-phase flow structures and velocity effects.

Experiments supported by visualization techniques in two-phase flow are performed in nozzles as they are utilized in many applications. For example, pressure drop mechanisms as well as flow choking conditions that determine mass flow rate in refrigerant expansion devices are relevant to heat pumps and refrigerators, areas where expansion work recovery is nowadays one of the privileged methods to improve refrigeration cycle performance [56].

Two-phase ejector flow visualization was first applied with water, air, steam or other gases before the conventional refrigerants and carbon dioxide.

In the development context of a suitable standard for the design of jet pumps for chemical industries, Takashima [57] conducted a theoretical and experimental study on several water–air ejector geometries. The jet-pump setup was made out of two pairs of steel plates forming the internal shape, inserted between two Perspex plates in order to allow visual observation by trans-illumination. The author did not detail his observations of the actual motion of the liquid–gas compound, which he considered as too intricate to be analyzed. However, these preliminary visualizations served as guidance to simplifying assumptions for modeling the flow.

Much later, and in order to develop a CFD application of a large-scale steam injector, Narabayashi et al. [19] conducted visualization experiments on a reduced scale injector to generate the needed information. The mixing nozzle was made of stacked heat-resisting acrylic resin annuluses to visualize water and the steam jet inside. The central nozzle introduced a water jet, while the steam jet was blown into the mixing nozzle through the annulus gap formed by water jet and the mixing nozzle. Steam velocity measurement, made by means of a Laser Doppler Velocimetry (LDV) system, consisted of 1 W laser source, transmitting optics, a fiber-optic probe, receiving optics and a high-speed signal processor (up to 150 MHz). A frequency shifting technique was used to decrease the observed Doppler frequency. The laser beam was such that mist droplets moving with the steam could be used as tracer particles.

Moreover, and considering the fact that an ejector can be viewed as a combination of an internal nozzle (motive) and an external nozzle (main body) many studies on nozzle flow are relevant to ejectors. Therefore, some visualization work on two-phase nozzle operation is worth mentioning. In this respect, Simoes-Moreira et al. [58] performed flashing liquid jet experiments in a simple convergent with iso-octane, using Shlieren images to analyze flashing jet structure and geometry. Berana et al. [59] conducted visualization experiments on two-phase flow fluid structure in a converging–diverging nozzle operating with CO2 in transcritical conditions. Images of flashing CO2 flow were captured for both under-expanded and over-expanded flow by using an analog microscope and a camera. The flows could be observed through the transparent polycarbonate wall on one side of the nozzle.

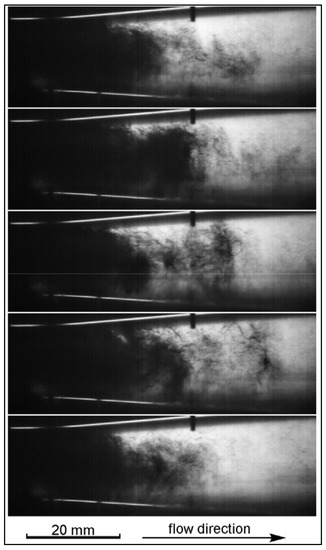

Ohira et al. [60] conducted their study on cavitation instability behavior of sub-cooled cryogenic liquid flows in a converging–diverging circular nozzle with several throat diameters (Figure 5). The working fluid was sub-cooled liquid nitrogen and the flow visualization of cavitation phenomena was undertaken at the outlet of a converging–diverging nozzle, using a high-speed video camera with imaging at a high frame rate and backlighting, so that the bubble clouds appeared as shadows.

Figure 5.

Photographs of cavitation at nozzle throat (Dt = 1.5 mm) [60].

Kim et al. [61] tested a two-phase injector to study hydrodynamic characteristics of the annular type ejector system. In contrast to Narabayashi et al. [19] device, steam was the central stream and water the annular stream. The injector module was made of acrylic materials to allow visual observation of the formation of air bubbles by PIV measurement. A high-speed camera and a 12 W LED lamp used as a continuous volume illumination light source to get bubble images were installed. Flow visualization revealed that water/air mixed flow was immediately generated in the throat region of the mixing chamber. The instantaneous shadow images of bubbles illuminated by the LED lamp showed typical characteristics of homogeneous bubbly flow. At high water flow rate, the whole section was filled with small bubbles. However, buoyant effects are partially observed at low water flow rate.

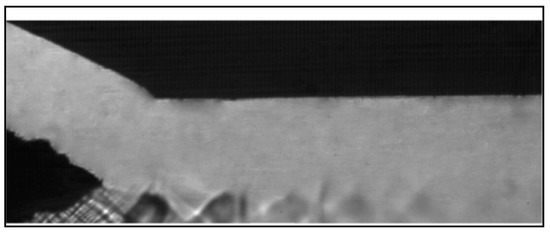

In a similar configuration as Kim et al. [61], Kwidzinski [62] investigated the condensation wave structure in a steam–water injector for validation purposes and visualized the phenomenon with a high-speed video camera. To this end, the light source was placed behind the observed flow section and the two-phase parts of the flow, which were translucent, appeared dark in the still frames (Figure 6). This recording synchronized with the measurements of pressure and temperature along the mixing chamber and diffuser walls, helped reveal the flow dynamics and the structures associated with the final stages of condensation.

Figure 6.

Condensation wave structure [62].

Subsequently, Choi et al. [63] used the same visualization procedure for the case of recovering air pollutant generated in an oil tank into the crude oil using a gas–liquid ejector system. The flow visualization experiments were conducted on an air–water ejector, using a high speed, 60 mm lens camera. An LED lamp rated at 12 W, installed at the back of a rectangular visualization chamber made of transparent acrylic, served as the light source to obtain bubble images through a light scattering.

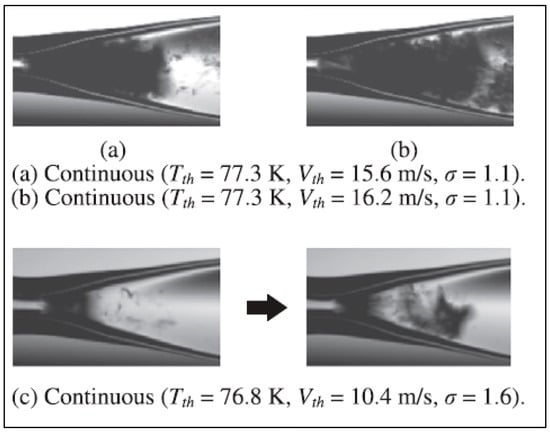

Relevant to refrigeration studies, Little and Garimella [64] designed a transparent ejector test section which they tested in an ejector-based chiller operating with R134a. The undistorted visual access allowed for detailed shadowgraph visualization of the motive jet in the mixing section at various degrees of condensation. They used high-speed imaging with measured temperatures and pressures at the ejector inlets for model validation purposes (Figure 7).

Figure 7.

Motive jet condensation in mixing chamber inlet [64].

The interest in the use of Carbone Dioxide in transcritical heat pump and refrigerator cycles paved the way for the first visualization works on the flow structure in these devices.

Elbel and Hrnjak [65] in their investigations on high-side pressure control of a transcritical R744 two-phase ejector system to maximize the COP, used a semi-transparent ejector on which images of the mixing section were taken through high-speed flow visualization and under realistic operating conditions. In addition, their measurements of the static wall pressure distributions along the axis of the ejector allowed them to identify the existence of mixing shock waves, confirmed by visualization.

Deng et al. [66] visual investigation of a two-phase ejector for a transcritical CO2 cycle was based on a shadowgraph visualization approach. The study concerned the mixing chamber and focused on suction and mixing processes as well as configuration variations in flow structure with operational parameters or geometry features such as primary pressure conditions, cross-section area mixing and the primary nozzle divergent length. Images of the mixing process showed that these parameters played an important role in premixed vortex formations, their size and their location in the suction chamber. The geometry features in particular, seemed to substantially influence the stream mixing and the flow homogeneity, a condition that affects performance.

More recently, Zhu et al. [67] investigated the internal structure of a CO2 two-phase ejector operating in transcritical flow conditions, relying of visualization experiments by direct photography. The method used a single lens reflex camera and a light film for uniform light and more brightness adjustment to better distinguish vapor and liquid droplets in the flow medium.

The Schlieren method was used without success to visualize the flow field, because this approach, based on the deflection of light by the refractive index gradient was very sensitive to CO2 and oil droplets in the flow. The results of the investigations have shown the influence of parameters such as the inlet pressures and the expansion angle at the nozzle exit.

2.5. Applications Potential of the Two-Phase Ejector

As early as 1858, Henri Giffard [68] patented a two-phase ejector to supply water for steam locomotives. Nowadays, significant efforts are undertaken to use the two-phase ejector in several applications such as fuel cells [69,70], desalination system [2,71], ballast water treatment [72], nuclear power plant [22], evacuation and exhaust of gases [73].

Two-phase ejectors unique feature of static devices with no moving parts, which makes them particularly reliable and requiring no or minimal maintenance is most attractive for many applications in industry. They can handle phase-changing streams and two-phase mixtures, irrespective of the fluid nature and its level of cleanliness. They are widely used as mixing devices or for pumping corrosive fluids, slurries, fumes and dust-laden gases. In chemical industries and in biochemical industry they are used in gas–liquid reactions, serve for absorption and stripping [74]. Ejectors produce high mass transfer rates by generating small bubbles/droplets, which can then be injected into a reaction vessel thereby improving the contact between phases. In this context, numerical and experimental studies were made, showing that there was an optimum area ratio, at which the liquid entrainment rate was the highest. The liquid entrainment rate increased with the pressure difference between the water surface in the suction chamber and the throat exit for a wide variety of ejector geometries and operating conditions [40,75,76,77]. For example, the Kandakure et al. [76] use of two-phase ejector as a liquid–gas contactor, relied on CFD in order to assess the hydrodynamic characteristics with reference to the ejector geometry. In this case water as the motive fluid and air as the entrained fluid were considered. It was found that there was an optimum area ratio for the maximum air entrainment rate.

Liquid–gas ejectors were studied experimentally by Choi et al. [63] to explore methods of dissolving the volatile organic compounds generated from crude oil into the oil itself, in an oil tanker. These unique features make them a potential alternative to several competing technologies for energy integration schemes in a wide range of industries.

In nuclear plants, two-phase, vapor–water ejectors serve as emergency systems [22,78].

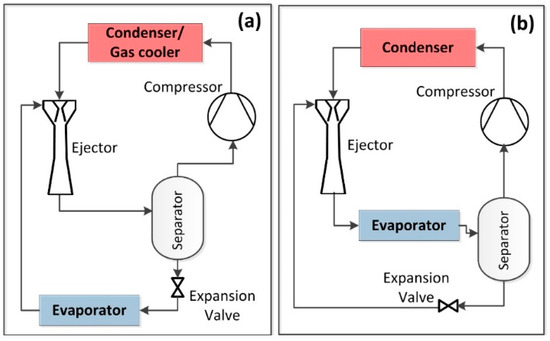

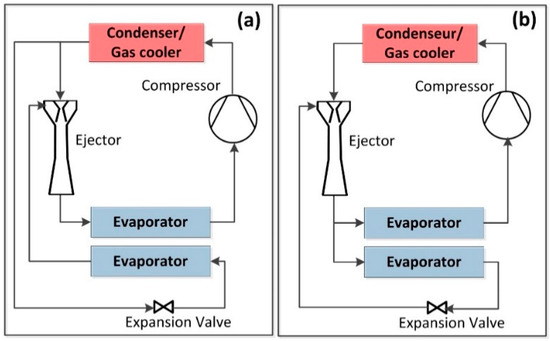

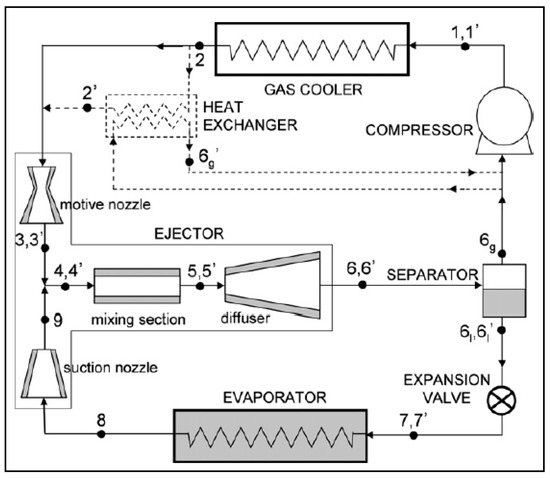

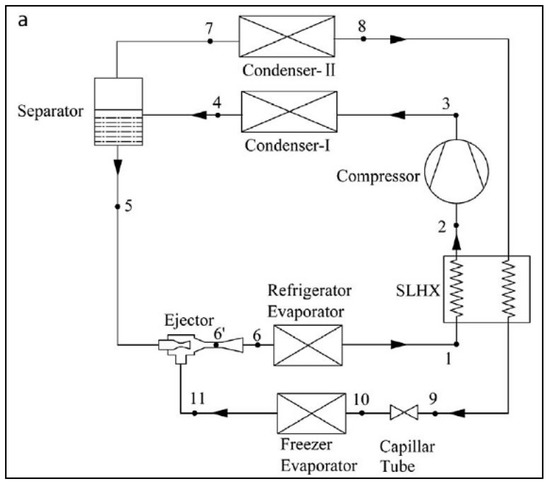

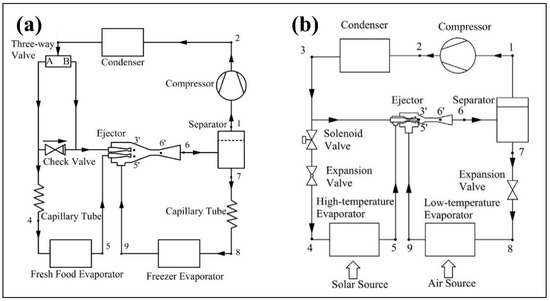

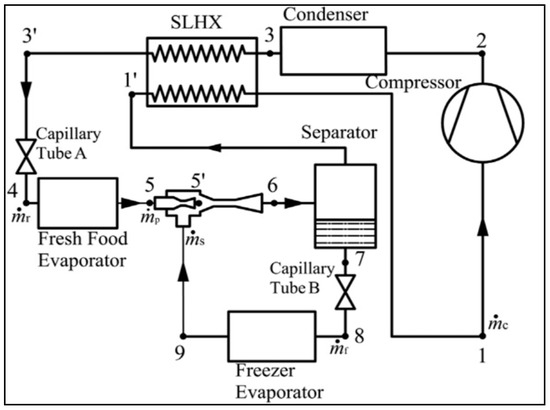

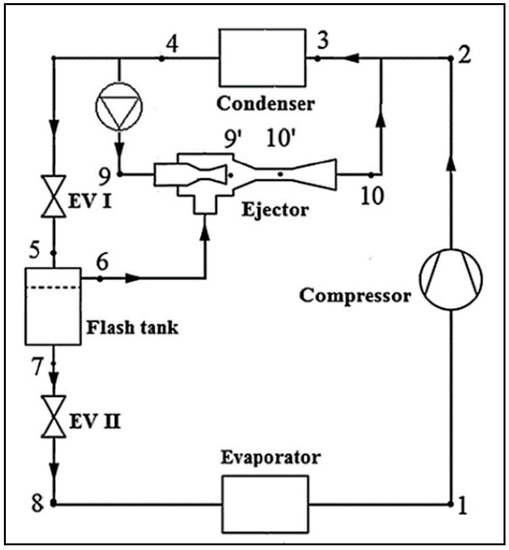

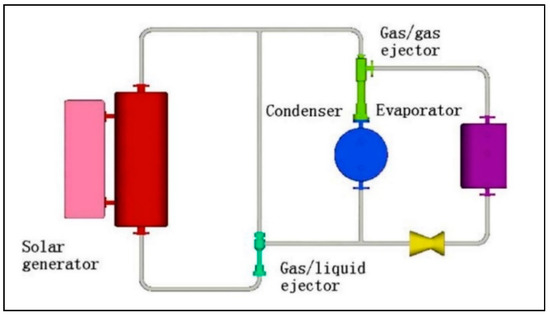

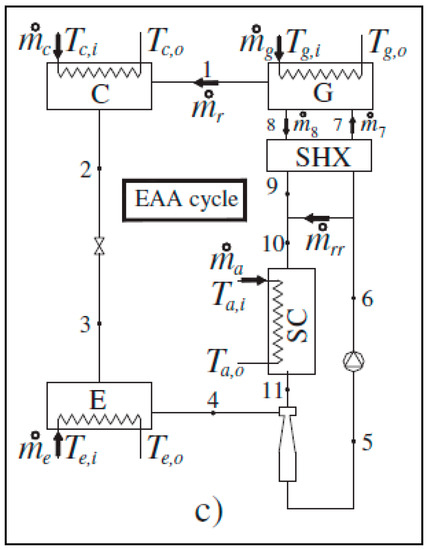

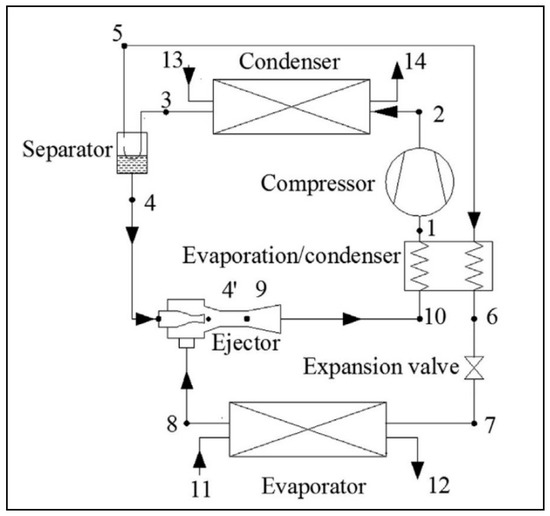

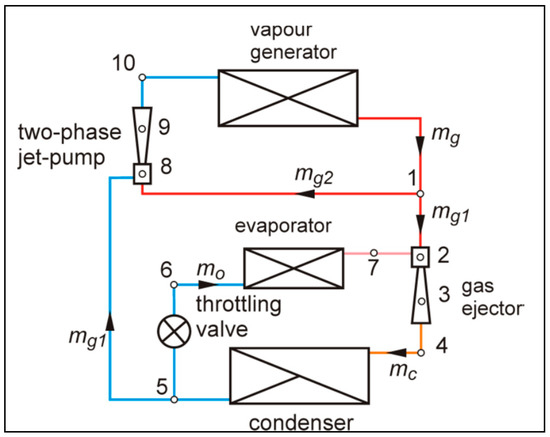

The sector of cooling, refrigeration and heat pumps seems the most promising for the two-phase ejector. In this field, the two-phase ejector is mainly used according to two approaches: ejector as an expander (Figure 8a) and ejector as a recirculator (Figure 8b).

Figure 8.

Refrigeration cycles with two-phase ejector: (a) ejector-expander (EERC); (b) ejector-recirculator (ERC).

The conventional EERC (Figure 8a) was patented by Kemper in 1966 [79]. The acronym EERC refers to refrigeration, but also to air-conditioning applications and heating. Depending on the working fluid, two types of EERC cycles are reported in the published literature: subcritical cycles [30,80] and transcritical CO2 cycle [48,81]. The performances of the transcritical CO2 cycles are generally superior to the other refrigerants.

The second way to use the two-phase ejector is as a liquid recirculator (ERC) (Figure 8b). The benefit of this cycle configuration is essentially due to a more performant evaporator. Overfeeding the evaporator allows a better heat transfer [82,83].

There are several variants of the conventional cycle with two-phase ejector as an expander, such as those with two evaporators and no separator (Figure 9). More details on different cycles with two-phase ejector are presented in Section 5.2.

Figure 9.

Variants of the conventional EERC: (a) Condenser outlet split cycle (COS) [84]; (b) diffuser outlet split cycle (DOS) [85].

3. Two-Phase Ejector Modeling

The modeling of two-phase ejectors and cycles for heat pumps, refrigeration an air-conditioning presents a high interest for the optimization because performance can be predicted for the ejector in terms of its specific efficiency parameters and for EERC or its variants in terms of COP and other efficiency expressions discussed in previous paragraphs. The design of cycle components can be handled to ensure overall maximized performance for the system. A great deal of research and development work along this path is available in the literature.

A major part of design and simulation effort consists of one-dimensional and thermodynamic modeling, depending on the nature of the task. Typically, cycle design and simulation is based on thermodynamic, first and second law modeling. Ejector modeling is more generally handled by 1-D and thermodynamic approaches. Methods combining thermodynamic considerations and experimental based correlations were useful in specific cases [33,86,87].

Multi-dimensional CFD methods have been relatively scarce due to the flow complexity in two-phase ejectors (in comparison with the supersonic type) and the high computational cost but due to the progress in computational power becoming increasingly available, studies based on these techniques are emerging [88,89]. A good description of the progress in two-phase ejector modeling up to 2015 can be found in the review of Elbel and Lawrence [10].

3.1. Thermodynamic and Analytical Modeling

Methods of ejector analysis based on thermodynamics and the solution of the integral form of conservation equations are generally the simplest way to estimate the influence of geometry and operating conditions on performance, provided that simplifying assumptions on two-phase flow structure and conditions are adopted in different zones of the device. A key component in the development of these models is the motive nozzle which, according to experimental observations has a considerable influence on ejector operations and performance.

A great deal of research has been devoted to nozzle flow, due to its importance in many fields of applications, driven by the impetus for developing ways to convert fluid energy at high pressure and/or temperature in the form of velocity to favor momentum transfer between streams and in the case of ejectors to accurately determine the primary mass flow rate for fluid maximized entrainment and compression ratios.

Flashing nozzles have been most researched for ejector use because their conditions of moderate to low sub-cooling and low quality mixtures are the most encountered in EERC machines. Effects of inlet sub-cooling, fluid quality and flashing inception in expanding fluid flow on mass flow rates, have been among the main elements in the quest for relevant information on nozzle design criteria and mostly experimental [90,91,92,93].

Later, Liu et al. [94] modeled sub-cooled water flow in a convergent–divergent nozzle with the flashing process occurring immediately past the throat. They considered an oblique evaporation wave with a velocity direction change of the supersonic flow downstream the shock occurrence. Expansion downstream was assumed to be in Isentropic Homogeneous Equilibrium (IHE) except near the throat. In this zone, heterogeneous equilibrium conditions were considered to prevail and the length of said zone increased with the inlet degree of sub-cooling.

Further theoretical modeling of convergent–divergent nozzles was performed for CO2 by Banasiak and Hafner [95], who investigated the influence of the phase transition model on the mass flow rate prediction. The delayed equilibrium model with homogeneous nucleation, superimposed to homogeneous and heterogeneous nucleation was used for the purpose of the metastable state analysis of a transcritical flow with delayed flashing over the motive nozzle.

In two-phase ejector studies, the liquid–vapor flow mixture reaches sonic conditions at fairly low stream velocity. However, determining the choked conditions is particularly difficult since a reliable speed of sound computation still remains an open question, despite the many works available so far [25,96]. A convenient way to overcome this issue is by maximizing the mass flow rate per unit area G which, for an isentropic expansion, can be expressed as:

Local enthalpy, h and density ρ, solely depend on P and S0. At choking conditions, the mass flux G is maximized. There is therefore less need to determine the local speed of sound for this particular purpose and the mass flux approach can be easily applied in two-phase flows, where critical conditions lie mostly over the saturation line. The model of Ameur et al. [18,25] employs this approach to compute the thermodynamic properties of liquid–vapor in the primary nozzle in critical conditions. In the application to ejectors for EERCs, deviations of up to 7–14% and 6–14% were respectively observed in the primary jet critical mass flow rate and the compression ratios.

The relative simplicity, the low cost in terms of computational memory and time with the ability to rapidly generate results is an advantage of the thermodynamic approach over 1-D modeling, which remains based on the resolution of a differential form of the conservation equations.

Some representative theoretical highlights from previous work with respect to two-phase ejectors are worth mentioning first. They relate to two-phase ejector modeling proposed for flash system use in refrigeration, where a refrigerant condensate close to saturation is expanded.

Kornhauser [97] developed a thermodynamic model for two-phase ejectors, widely cited in the literature and used by many researchers, given its simplicity [98,99,100,101]. Kornhauser [97] first set up such a simple model extended to the ejector which he applied with various refrigerants, mainly halocarbons. The approach used the Homogeneous Equilibrium Model (HEM), the assumption of constant pressure mixing and isentropic efficiencies to account for friction losses. An updated version by Menegay and Kornhauser [102] accounted for under-expansion of the flow, a condition found to favor better overall ejector efficiency.

Improvements to the Kornhauser model were subsequently brought by researchers such as Nakagawa et al. [35] who proposed a hybrid approach, consisting of a combination of 1-D and thermodynamic considerations. The isentropic flow treatment was used to model the primary nozzle while a 1-D approach was applied in the remaining zones to both phases in terms of the momentum equation conservation, where a wall friction coefficient was only used in the vapor phase which was assumed to be in contact with the wall. In this way the authors could analyze the geometric characteristics of the mixing chamber.

Liu and Groll [103] computed the critical flow in the primary nozzle of the ejector by assuming choking conditions at the throat. They evaluated the sonic velocity with an equation derived by Attou and Seynhaeve [104]. Momentum exchange in the mixing chamber was accounted for by the conventional coefficient method and a recovery factor was used in the diffuser according to the recommendation of Owen et al. [105]. Later Liu and Groll [52] used this model to study performance characteristics of a transcritical CO2 EERC.

The effects of thermal and mechanical non-equilibrium taking place between vapor and liquid were modeled by Kwidziński [106] for the case of a steam–water ejector. The model simulations were compared with experiments which they predicted within 15% in terms of discharge pressure and 1 K in terms of temperature.

A similar line of development was followed by Banasiak et al. [37,95,107] in the context of expansion work recovery by means of two-phase ejectors. The authors proposed a 1-D method utilizing the Delayed Equilibrium Model along with the homogeneous nucleation theory, the treatment of the metastable state analysis for a transcritical CO2 flow with delayed flashing over the motive nozzle.

More recent analytical work regarding the treatment of CO2 expansion process in ejectors was proposed. Zhu and Jiang [87], in a study of transcritical CO2 ejector expansion refrigeration cycle proposed an analytical model taking into account non-equilibrium effects by means of a correlation based on experimental data of several case studies and capable of predicting primary and secondary mass flow rates. A further correlation simplifying computations at the ejector throat was developed for the primary mass flow rate. Accounting for non-equilibrium was to be important when the liquid mass fraction at the nozzle throat was higher than 0.65. A number of analytical and thermodynamic ejector models are reported in Table 1.

Table 1.

Ejector global models.

3.2. CFD Modeling of Two-Phase Ejectors

Computational Fluid Dynamics techniques allow the detailed study of ejector flow, based on the solution of the Navier–Stokes (NS) equations. In order to manage the otherwise prohibitive computational cost, a statistically averaged version of these equations in the form of the Favre-Averaged Navier–Stokes (FANS) or compressible Reynolds-Averaged Navier–Stokes (RANS) equations is commonly solved. In such an approach, the mean features of the flow are all preserved but extra terms for turbulent effects need to be handled by means of turbulence models in order to close the system of equation. In addition, an equation of state relating pressure, temperature and density is required. As discussed earlier for supersonic ejectors, turbulence models need to be carefully selected on a case-by-case basis and the issue is no different for two-phase ejectors. Regarding the fluid properties, NIST database for refrigerants, REFPROP is generally used.

The computational power and the simulation flexibility provided by the recent CFD platforms have resulted in the treatment of several two-phase ejectors being undertaken. The CFD modeling of two-phase flows (flashing liquid or vapor condensation) is a challenging task. Many phenomena on the local scale are not yet well understood, such as nucleation characteristics and bubble-droplet growth. The complex structure of the gas–liquid interface and the transfer mechanism require more elaborate models with empirical correlations or assumptions which are so far insufficiently tested [108,109].

3.2.1. Treatment of Two-Phase CO2 Ejectors

Bulinski et al. [110] conducted a preliminary CFD work on CO2 transonic ejector flow by using homogeneous and heterogeneous flow models in order to account for non-equilibrium effects. They then compared the predictions of both approaches in terms of pressure distribution in the mixing chamber, which were well predicted by both approaches. Unfortunately, this partial validation was insufficient since the heterogeneous approach predicted the lowest pressure by an order of magnitude right after the nozzle throat. In addition, according to the authors, entrainment ratio predictions were also different.

Colarossi et al. [13] built a multi-dimensional simulation model based on a pseudo-fluid concept where two phases mass, momentum and energy conservation equations were treated as a single fluid with combined transport equations. The flow was assumed to be in non-equilibrium state and a modified form of the homogenous relaxation model (HRM) was employed to describe the delay in nucleation. Standard k-ε turbulence model was used and the fluid properties were obtained from REFPROP database. Simulations performed with CO2 as the working fluid were based on Nakagawa et al. [36] for validation in terms of pressure recovery. Even though the trends of the results were comparable, the discrepancies between simulations and experiments were important. The authors attributed this poor concordance to the challenges of modeling two-phase, turbulent non-equilibrium flow and the selection of the turbulence model.

This paper was followed by the work of Yazdani et al. [12], consisting of a numerical model of transcritical CO2 ejector-expander applications for refrigeration and heat pumps. It is a non-homogeneous mixture model, including several sub-models for local interphase energy and mass transfer, two-phase velocity of sound formulation and real fluid properties of the refrigerant. The turbulence model formulation used was the k-ω SST type and the thermophysical properties of CO2 were obtained from the NIST-REFPROP database. The simulations indicated that the ejector performance was only slightly influenced by the inclusion of the slip model. The cavitation portion of phase change was generally small but could be dominant near the walls and at the motive nozzle throat. Compression and entrainment ratios were predicted to within 10% of experimental data and there was a threshold diameter at which performance was characterized with a gentle shock in the mixing zone. In a subsequent investigation, Yazdani et al. [111] put more focus on the flow process of transcritical and subcritical cases of CO2 in converging–diverging nozzles. This study showed that phase change is generally small but can be dominant near the walls and at the motive nozzle throat. Choking occurred downstream of the throat, where void generation promoted flow acceleration while leading to a drop in the sound speed. The nozzle configuration and the upstream operating conditions were found to shape the two-phase jet and affect the void generation rate.

Back to ejector simulation, Smolka et al. [112] three-dimensional CFD model of a transcritical CO2 ejector was developed on the assumption of homogeneous equilibrium flow. An enthalpy-based formulation, in which the specific enthalpy, instead of the temperature, as an independent variable was employed. Gas–liquid mechanical and thermal equilibrium between phases was assumed for two-phase flow and the turbulence effects were modeled by the RNG k-ε turbulence model. In addition, NIST-REFPROP database was again used for the extraction of the fluid properties. Maximum discrepancies on the prediction of primary and secondary flows were respectively 14% and 19.7%.

Lucas et al. [113] numerical model also based on the homogeneous equilibrium approach and validated by the authors’ data with and without suction in order to isolate effects of mixing and friction. High Reynolds k-ω SST turbulence model in its standard implementation in OpenFOAM was used. The numerical results were compared with experimental data previously published by the authors for validation needs. Simulations allowed for the prediction of the driving mass flux and the pressure recovery within an error margin of 10%. However, this error increased to 20% when the ejector was operated with a suction flow.

In the conditions of a supermarket application CFD modeling was applied as well in order to test the validity of HEM model for ejector transcritical CO2 operations. The comparison of the experimental and computational results showing accurate results could be obtained when operating near or above the critical point. The model accuracy decreased with the decreasing temperature and decreasing distance to the saturation line [114].

More recently, Haida et al. [115] applied the HRM model to CO2 two-phase ejectors. The predictive accuracy of the motive nozzle mass flow rate improved, in comparison to currently available numerical models for subcritical regimes. For operating regimes in transcritical conditions, comparable high accuracy to the HEM model was found. Further, the authors reported that HRM application for motive pressures above 59 bar predicted motive flow within 15% accuracy. Below 59 bar, the motive mass flow rate prediction was 5% to 10% more accurate than with HEM formulation.

The CFD approach was also employed to assess locally the ejector’s internal irreversibility. Banasiak et al. [54] analyzed numerically the overall entropy increase in CO2 ejectors by introducing a new factor to evaluate the ejector performance based on the reference entropy increase in a classic expansion valve. They found that the shock train at the primary nozzle outlet and the turbulent interaction process in the mixing chamber were a major source of irreversibility. Moreover, and based on the model predictions, the authors recommend that all ejector dimensions must be optimized simultaneously, otherwise, the irreversibility reduction in one ejector section may translate into an increase in the next section, thus neutralizing the overall gain. In addition, the influence of the diameter and length of the ejector mixing chamber was shown to significantly affect performance.

In addition to CFD investigation mainly focusing on the ejector component and the local flow characteristics, Palacz et al. [116] conducted their study on the ejector from the viewpoint of shape optimization and efficiency enhancements. More particularly, the authors applied a scheme combining CFD and a genetic algorithm to optimize CO2 ejectors for refrigeration systems. They worked on ejector geometries to adjust several parameters for maximized performance. The optimization of the results showed that the ejector efficiency could be improved by up to 6%. A recently published paper by Haida et al. [117] numerically assessed the effects of heat transfer on the wall of a CO2 ejector in the context of air-conditioning. The results indicated the reduction of the mass entrainment ratio could be as high as 13%, as a result of the non-adiabatic assumption condition.

3.2.2. Phase Change in the Motive Nozzle

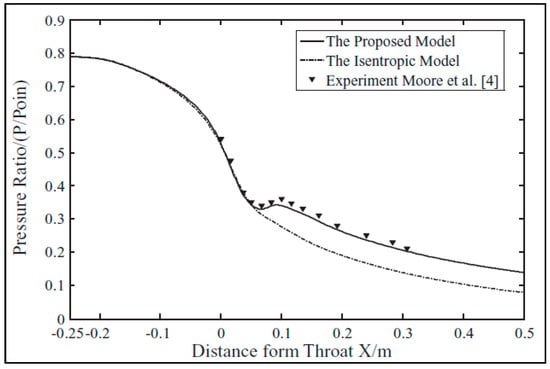

Vapor condensation phenomena in convergent–divergent nozzles were well described by Mikasser [118]. Generally, superheated vapor at the nozzle inlet first expands with a decrease in temperature until the saturation condition is reached. Beyond this point the expansion process is no more in equilibrium but continues in metastable conditions (non-equilibrium) until a maximum sub-cooling is attained accompanied by a sudden appearance of a cloud of droplets (Wilson point). This spontaneous condensation releases latent heat which is absorbed by the vapor flow, elevating its temperature to near thermodynamic equilibrium. Vapor phase change reduces the specific volume, decelerating the supersonic flow and producing a local characteristic compression increase, known as a condensation shock Figure 10. Further theoretical and experimental details of this process showed that spontaneous condensation reduced the overall Mach number along the nozzle diverging section but increased the entropy generation linked to droplet nucleation, an effect found to be reduced by injecting droplets mixed with the inlet flow [119,120].

Figure 10.

Pressure distribution along the nozzle centerline with condensation shock [120].

Spontaneous condensation may produce unstable flow conditions at the nozzle exit, especially when it takes place immediately after the nozzle throat. The nozzle should be designed in such a way as to move the nucleation inception downstream of the throat in order to avoid flow oscillations across the sonic threshold. In the case of ejector design where the ideal gas assumption was commonly used, Grazzini et al. [121] undertook to check the validity of such an assumption for the condition of their refrigeration case, since high-speed flow generally prevailed in the primary nozzle, suggesting the existence of metastable conditions. Their findings indicated that the isentropic expansion of vapor through the nozzle, modeled as ideal gas was well within the metastable zone and the classic nucleation theory showed that the Wilson line was crossed at the nozzle throat.

Wang et al. [122] numerical simulations of steam spontaneous condensation in the motive nozzle, resulted in 10% higher outlet pressure than predicted by the perfect gas assumption and an equally higher temperature. The analysis demonstrated that the steam condensation would hinder the supersonic expansion process in the divergent and reduce the nozzle efficiency, which in turn would affect the pumping performance of the steam-jet pump. Similar work by Ariafar et al. [123] investigated this effect in a steam ejector and nozzles with different area ratios. Wet steam simulations showed that nozzle static pressures were higher than those predicted by the ideal gas model. Enhanced mixing between streams, which arises because primary stream condensation reduces compressibility in the mixing layer, was proposed to explain the increased entrainment ratio predicted by wet steam ejector simulations.

Little and Garimella [64,124] suggested a simple way to promote the formation of liquid droplets by adjusting the degree of superheat at the motive nozzle inlet. Depending on the time scale of this expansion and the kinetics of droplet formation, droplets may form to produce a “wet” motive jet at the nozzle exit. Information on its metastable states and sub-cooled droplet nucleation and growth, critical to understanding the mechanisms of suction flow entrainment and overall ejector performance was the focus of the numerical and visual studies undertaken by the authors on an R134a heat-driven ejector-based chiller. It was found that shadowgraph imaging combined with a numerical assessment based on k-ε RNG turbulence model that the assumption of motive flow leaving the primary nozzle in thermodynamic equilibrium was reasonable. Shock and expansion wave inceptions were observed to start at the motive nozzle throat and dissipate in the mixing section. Moreover, a decrease of enthalpy at nozzle inlet increased the amount of condensate at the outlet which in turn, expanded to span the entire width of the mixing section, steadily deteriorating in the process the ejector entrainment ratio. However, no information on the critical pressure was reported.

Another aspect that attracted the interest of researchers was the influence of droplets injection on supersonic ejector performance. The point of injection may be the inlet of the primary stream or any favorable location in the mixing chamber. The injection of droplets in the primary inlet has for main objective the reduction of the velocity mismatch at the mixing section by decelerating the motive flow while maintaining its momentum, reducing entropy generation and enhancing mixing [125]. The intensity of shocks in the constant area section may be attenuated by droplet injection before the shock wave occurrence [126]. However, the amount of research on this subject is still very limited to draw reliable conclusions.

Al-Ansary and Jeter [125] first experimented the effect of droplets on ejector performance, by introducing 17 μm droplets in the primary nozzle inlet of air ejector. Numerically, these droplets were considered as spherical, inert particles with constant size and simulated in a Lagrangian frame of reference. In off-design operation corresponding to a pressure range of 107 kPa to 446 kPa, an increase of up to 98% of suction flow was achieved experimentally in the best case, within a range of liquid injection between 4.3% and 11.2% in terms of pressure ratio. The reliability of these results may be limited, due to uncontrolled liquid–air phase-change exchanges, water accumulation in the ejector due to wall effects and the additional air from the atomizing device. Further investigations were later conducted numerically and experimentally by Hemidi et al. [127]. They indicated that with a liquid injection of 1%, the presence of water droplets had no significant effect at on-design operation but beyond the critical point (off-design operation) it reached on average 10–40% increase with some loss in back pressure. These findings somewhat disagree with the numerical findings of the same authors indicating that performance decreased by the addition of water droplets. It is worth underlining, however, that the abovementioned studies were based on an air–water ejector operation. In the refrigeration context, the working fluids are generally the phases of the same fluid with different thermophysical properties and likely significantly different overall operational behavior.

Very recent thermodynamic and CFD modeling development work of Croquer [126] concerned about the effect of droplet injection in the mixing chamber. Vapor and liquid were both of R134a and the investigation was performed in the context of refrigeration. The droplets were injected normally to the flow in the first half of the mixing chamber throat and had a negative impact on the ejector performance. No noticeable changes in the internal flow structure were observed until mass fractions of about 10% of the primary flow mass flow rate were attained. At these conditions, the shock wave intensity decreased by 8% and thus the entropy associated with these shocks but for a given entrainment condition, the compression ratio was diminished by 10%, relative to the case without injection. These negative results were attributed to the additional losses generated by the mixing interaction between the droplets and the primary stream as well as the additional entropy of the injection process. Table 2 contains a few relevant two-phase ejector CFD studies from current literature.

Table 2.

Two-phase ejector computational fluid dynamics (CFD) studies.

4. Experiments on Ejectors

Much experimental work currently available in the literature about two-phase ejectors was generated to support the theoretical developments discussed in the previous sections. A large percentage of this endeavor was intended to validate theories. Other studies were devoted to generate data as well as operational information. A good deal of the experiments was formulated in terms of characteristic performance indicators, that is the entrainment and compression ratio or accessorily thermodynamic first and second law efficiencies previously introduced. These studies are very important because they establish the link between the ejector and its application environment. Similarly, to single-phase ejectors, local experiments in two-phase ejectors are limited to wall pressure distribution.

As pointed out in the previous section, numerical work requires more local information in terms of variable distributions and flow visualization, since the effort is mainly concentrated on internal flow structure and the complex interactions between various phenomena influencing the ejector operation. Less experimental work was devoted to this aspect so far due to its cost, even though the prospects are encouraging as more focus is increasingly being put on this task. Indeed, the highly complex internal ejector flow structure has not yet fully been clarified despite a very extensive ground breaking work, and most existing experimental literature does not provide a complete picture linking ejector operation under various conditions and its internal structure.

A sample of the relevant work on nozzle flow includes the studies of Menegay and Starkman [80,90] and two consecutive papers of Nakagawa [41,59,128]. More specifically, the Starkman [90] experimental investigation had for main objective the determination of mass flow rate in nozzles under choked two-phase flow operations. The data analysis indicated that the nozzles were operating in over-expanded conditions. Shock waves were observed to occur inside the nozzles with a deleterious effect on efficiency. Menegay and Kornhauser [80] used on the other hand, flashing flow motive nozzles in tests of a refrigeration system incorporating a two-phase ejector. In later tests, the researchers attempted to improve nozzle efficiency by seeding the motive flow with small bubbles.

Nakagawa et al. [128] in a first instance carried out experiments on a rectangular converging–diverging nozzle in which CO2 was expanded. The decompression pressure profile was recorded. It was found that the optimum supersonic decompression before shock waves occurrence obeyed the homogeneous equilibrium model, while behind the shock, the pressure profile displayed no equilibrium condition as indicated by the thickness of the shock waves and the subsonic flow behind them. These measurements indicated that the decompression process in the motive nozzle divergent could not be correctly predicted by the IHE model, which hinted to a thermal and mechanical non-equilibrium state. In a subsequent work, Nakagawa et al. [41] observed and experimentally addressed the CO2 decompression phenomena in the nozzle divergent when metastable fluid flashes to low quality two-phase flow. As was previously established, the fluid in the nozzle was in temperature and pressure equilibrium, in accordance with the experimental measurements. Two-phase flow results through converging–diverging nozzles with divergence angles ranging from 0.07° and 0.612° at inlet pressure and temperature conditions of 6 to 9 MPa and about 20 to 37 °C, respectively were gathered. The authors confirmed by both calculation and experiment that optimum decompression for the largest divergent angles (>0.306°) and inlet temperature above 35 °C, was in homogeneous equilibrium condition. Similar experimental observations were reported by Berana et al. [59] who also measured the wall pressure along the nozzle divergent in an attempt to trace the shock wave occurrence.

An interesting experimental and numerical study performed by Kim et al. [61] is that of a water-driven annular type ejector loop, designed and constructed for air absorption. The application of annular ejectors can be found in the ship-building industry for the recovery of volatile organic compound which is grossly generated during crude oil shipping and transporting process [129]. Airflow rate measurement and PIV experiments were performed. Visualizations revealed that water/air mixed flow was immediately generated in the throat region of the annular ejector. Different bubble-liquid flow regimes were observed and served to guide comparative CFD simulations on air/water arrangements. Little and Garimella [64] is probably the only visualization work with R134a refrigerant, currently available for two-phase ejector in a real EERC system. The authors conducted a detailed shadowgraph visualization of the ejector motive jet at various degrees of condensation. The main intent was to clarify the effect of the condensation on momentum and heat transfer characteristics in the mixing section.

Further visualization studies are available with CO2, in view of the growing interest for this refrigerant. Berana et al. [59] investigated the two-phase flow field in a converging–diverging nozzle with transcritical pressure CO2. This work concerned a flashing flow with different lengths but with the same divergence angle and in the presence of shocks and non-equilibrium effects measurements.

Kwidzinski [62] experimentally investigated the structure of condensation waves in steam–water injectors by means of a high-speed video camera. Simultaneous recordings of pressure and temperature distributions were captured. Vapor clouds were observed to form and then disappear accompanied by pressure pulses. Simultaneous pressure fluctuations were sensed at the injector outlet. It was observed that these pressure variations had no influence on upstream conditions indicating supersonic conditions in the mixing chamber.

More recent visualization experiments were conducted on an ejector running on CO2 by Zhu et al. [67]. The flow structure was recorded by means of direct photography under various operating conditions in the zones of suction and mixing after the primary nozzle exit. Observations highlighted the effect of inlet pressures on the primary mass flow rate. The primary flow angle at the nozzle exit decreased with increasing secondary pressures. Large expansion angles of the primary flow reduced the entrainment of the secondary stream. It was also observed that both primary and the secondary flows mix over short mixing region in the chamber and the resulting stream became rapidly uniform.

Experimental studies on two-phase ejectors also concerned geometry aspects such as those presented by Butrymowicz et al. [130] with the refrigerant R123. These authors evaluated the effects of the mixing chamber geometry in terms of area ratio and the operating conditions on ejector efficiency. Their results suggested that for the operating conditions of the investigation corresponding to air-conditioning environment, the liquid to vapor density ratio was very high, resulting in a small mass entrainment ratio and isothermal compression in the ejector.

Similar investigations were also conducted in the context of a chemical process, generally as liquid–gas-contacting devices. Due to their favorable mass transfer and mixing characteristics, ejectors are being increasingly used in diverse processes of this industry. In this respect, the work of Kim et al. [75] is an example of such an application. Effects of the ejector geometry and the operating conditions on the hydraulic characteristics in a rectangular bubble column with a horizontal flow ejector were analyzed. Gas phase holdup obtained in the water column was shown to increases with increasing liquid circulating rate and decreases with increasing liquid level in the column and nozzle diameter.

Further experiments on an ejector cycle operating with R600a were generated under various conditions of operation by Wang and Yu [53]. Combining the measured data with the predictions of an ejector model, a computational procedure was devised by the authors in order to derive the efficiencies of the characteristic components for two-phase ejectors, including the motive nozzle, the mixing chamber and the diffuser. Operating conditions and geometry were shown to influence component efficiencies which vary sensibly within the range of the conditions considered. The results generated by this study were gathered to build empirical correlations for two-phase ejector design purposes.

Even more recently, Ameur et al. [46,93] reported new experiments on the operation of a two-phase ejector run on R134a with no induced flow and aimed at generating data in addition to information about the effects of the primary stream conditions and primary geometry on the flow through a converging–diverging nozzle. The intent was to develop a better understanding of the parameters and conditions influencing the critical flow, necessary for efficient and stable ejector operation, generally desirable to increase EERC overall performance. Tests conducted with two nozzles of different divergent lengths over a range of inlet pressures, inlet sub-cooling and geometry led to several observations. The inlet sub-cooling played a more important role than motive pressure in the ejector operation. The critical flow was strongly influenced by the nozzle geometry and the operating conditions. The influence of inlet sub-cooling appeared to be at least as important as the pressure in this process. Compared with an isenthalpic expansion valve, a two-phase ejector was shown to be a pseudo-isentropic device which produced less refrigerant flashing, a fact that may translate into potential efficiency improvements of the conventional refrigeration cycle.

Ejector using spindle to adjust the throat area of primary nozzle is a common solution to control the ejector performance across variable operating conditions [131]. Recently, Zhu and Elbel [132] experimentally tested a novel nozzle flow control mechanism called vortex control. Without changing the nozzle geometry, the authors showed that the strength of the nozzle inlet vortex could change the restrictiveness of the two-phase convergent–divergent nozzle with initially sub-cooled R134a. The nozzle becomes more restrictive as the strength of the vortex increases. Representative experiments on ejector are summarized in Table 3.

Table 3.

Experiments on ejector operation.

5. Two-Phase Ejector Cycles and Systems

Up to this point in the present review, the main focus was put on the study of the ejector as a key component in terms of physics, operation, design, experimentation and modeling. Modeling as shown was essentially handled by analytical or numerical methods validated by dedicated test bench experiments. However, the end purpose of ejector developments is its application in many areas of industry as previously discussed, even though the present discussion is limited to the refrigeration and heat pumping area which has been by far the most researched [5,8,10].

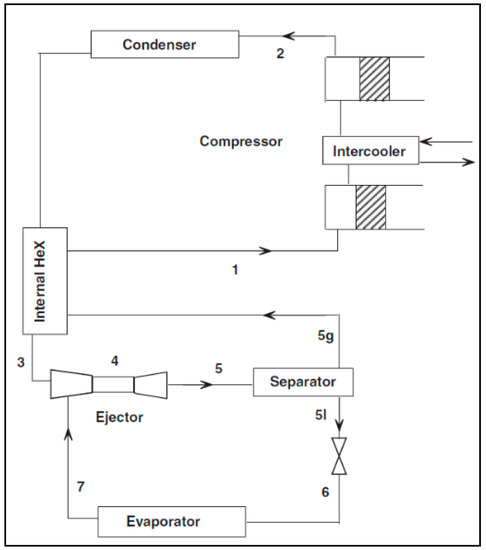

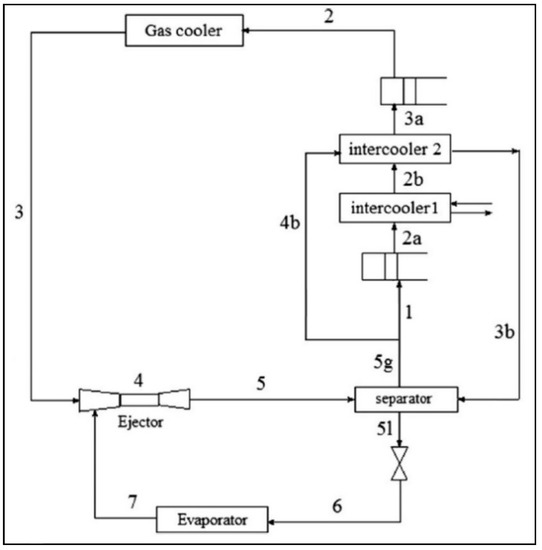

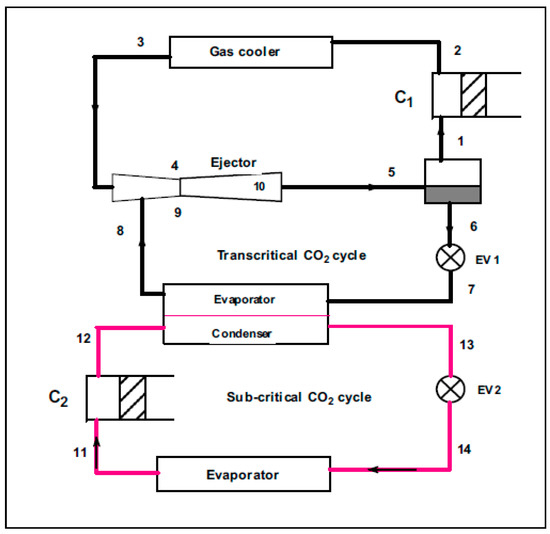

Research in refrigeration, air-conditioning and heat pumps has been structured around key aspects such as cycle refinement, refrigerant type, modeling approach among other things. The most basic ejector cycle is the simplest configuration to produce a cooling effect at low cost but its operating range is very limited, a fact that led to further work on hybrid cycles to extend the application range and increase efficiency with no or minor complexity and cost. Theoretical and experimental papers handling this aspect aim to go beyond air-conditioning applications and make ejector systems available for refrigeration as well. Refrigerant properties are known to impact ejector-based and hybrid cycles. Moreover, depending on the cycle configuration, refrigerant mixtures or more than one refrigerant may be used in the cycle loops for more flexibility. Several recent studies investigated refrigerants ranging from synthetic refrigerants to hydrocarbons and more recently some HFOs, due to their performance potential but the current trend demonstrated by the number of published papers leans toward CO2 as a natural refrigerant with good thermophysical properties and performance potential in transcritical cycles [133]. Relevant theoretical and experimental developments in two-phase ejector treating these aspects are briefly presented in the next subsections.

5.1. The Conventional Ejector Expansion Refrigeration Cycle