Model Development for Optimum Setup Conditions that Satisfy Three Stability Criteria of Centerless Grinding Systems

Abstract

:1. Introduction

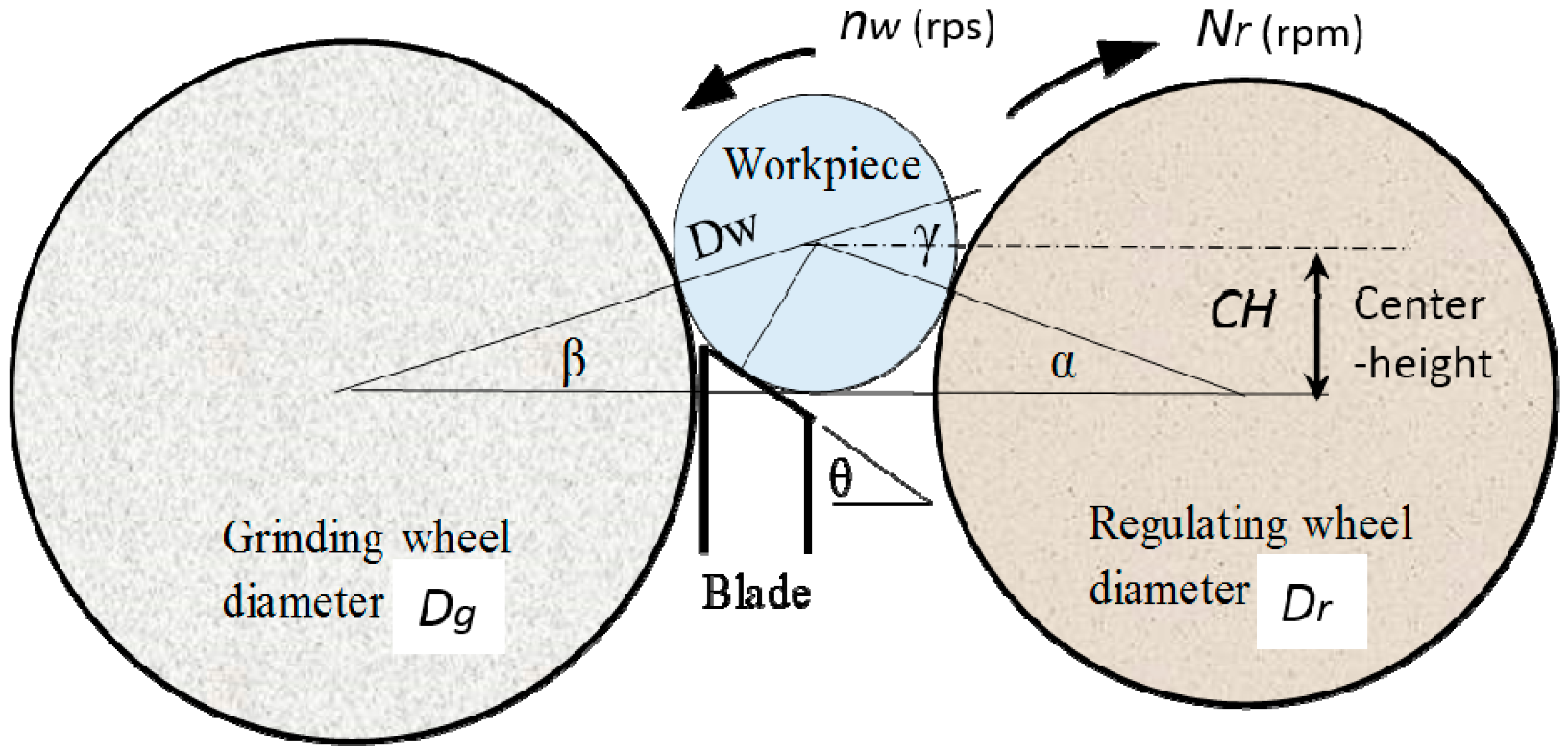

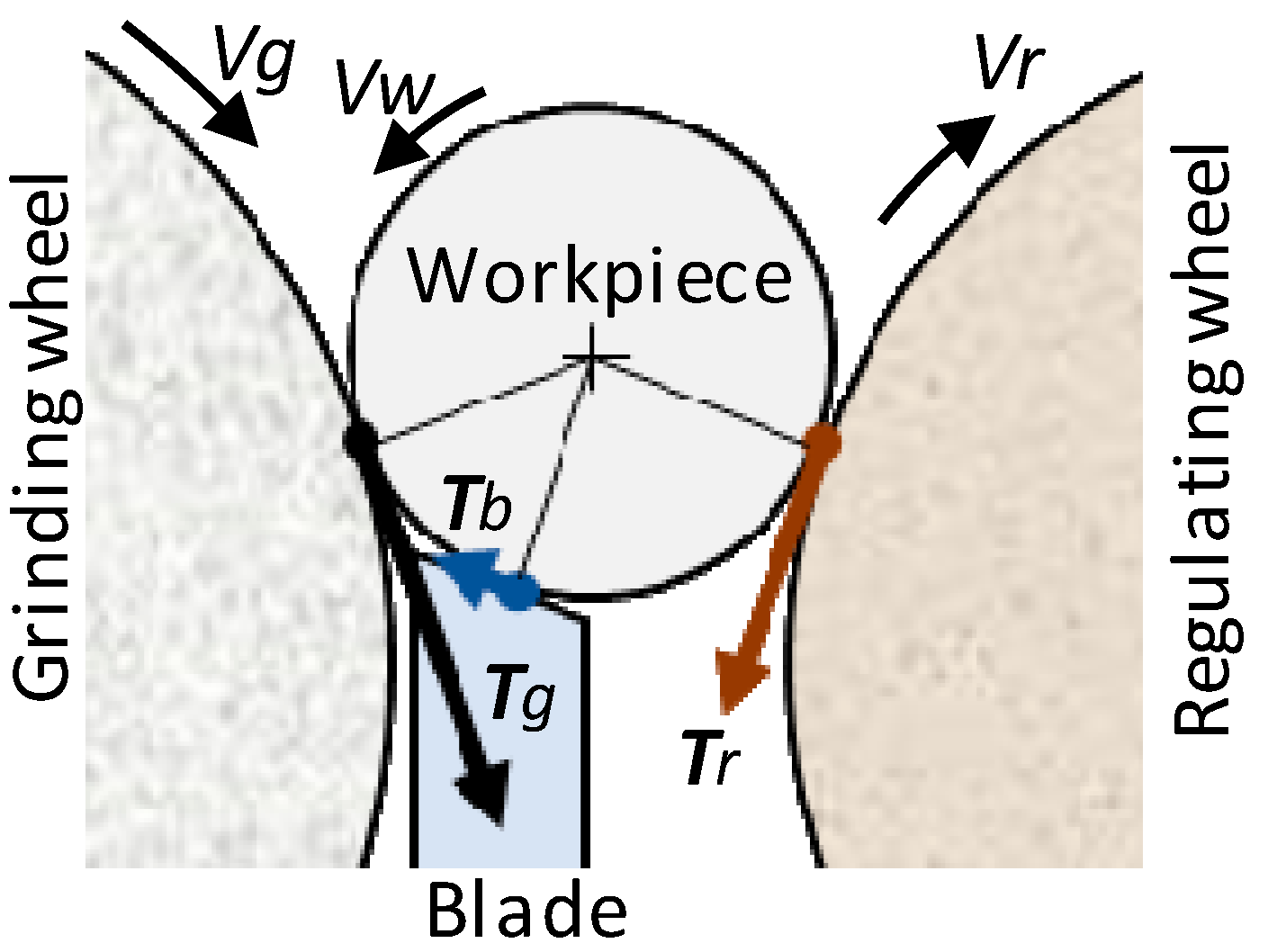

2. Basic Setup Conditions in Centerless Grinding

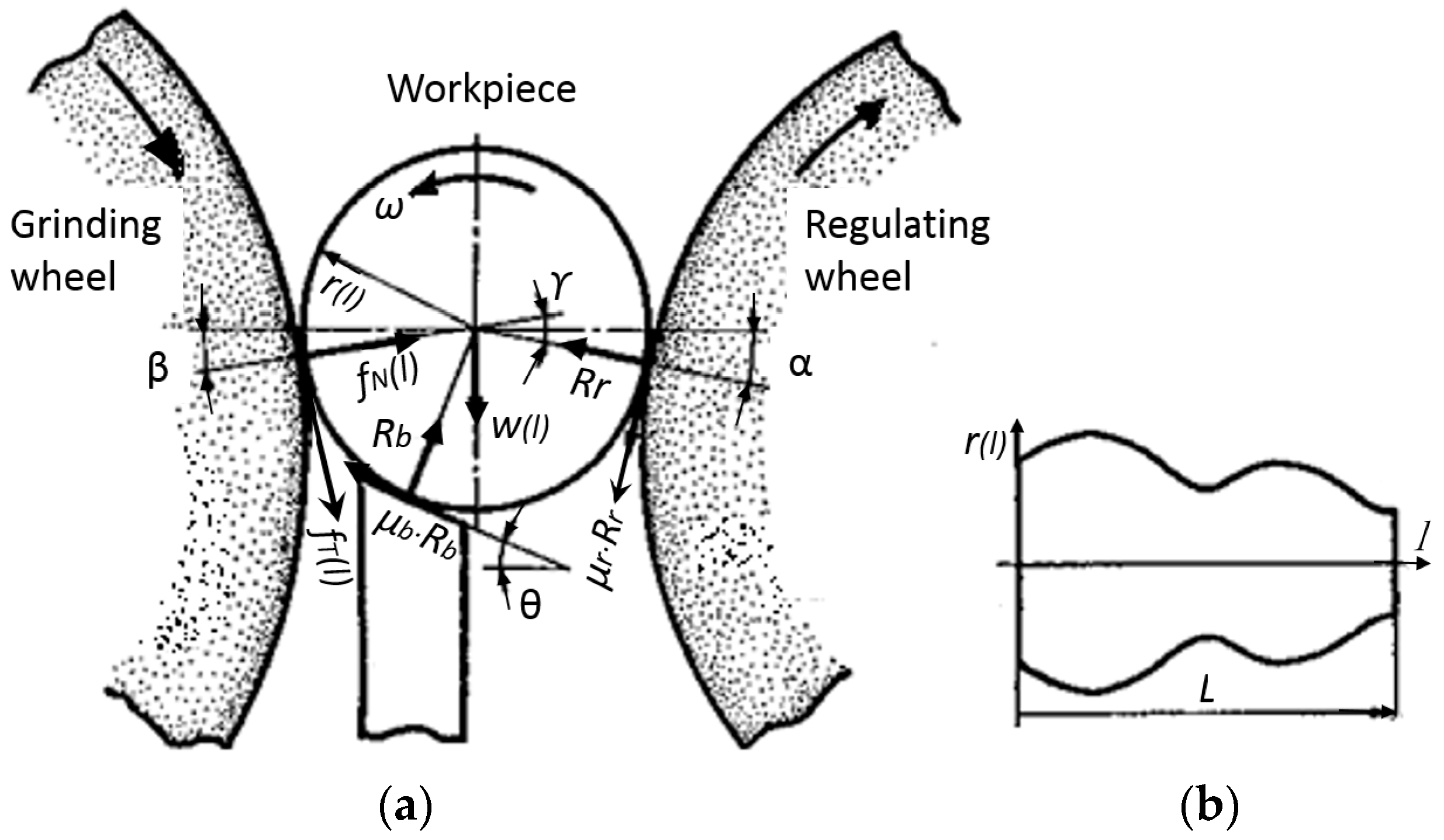

3. Centerless Grinding Systems and the Characteristic Equation

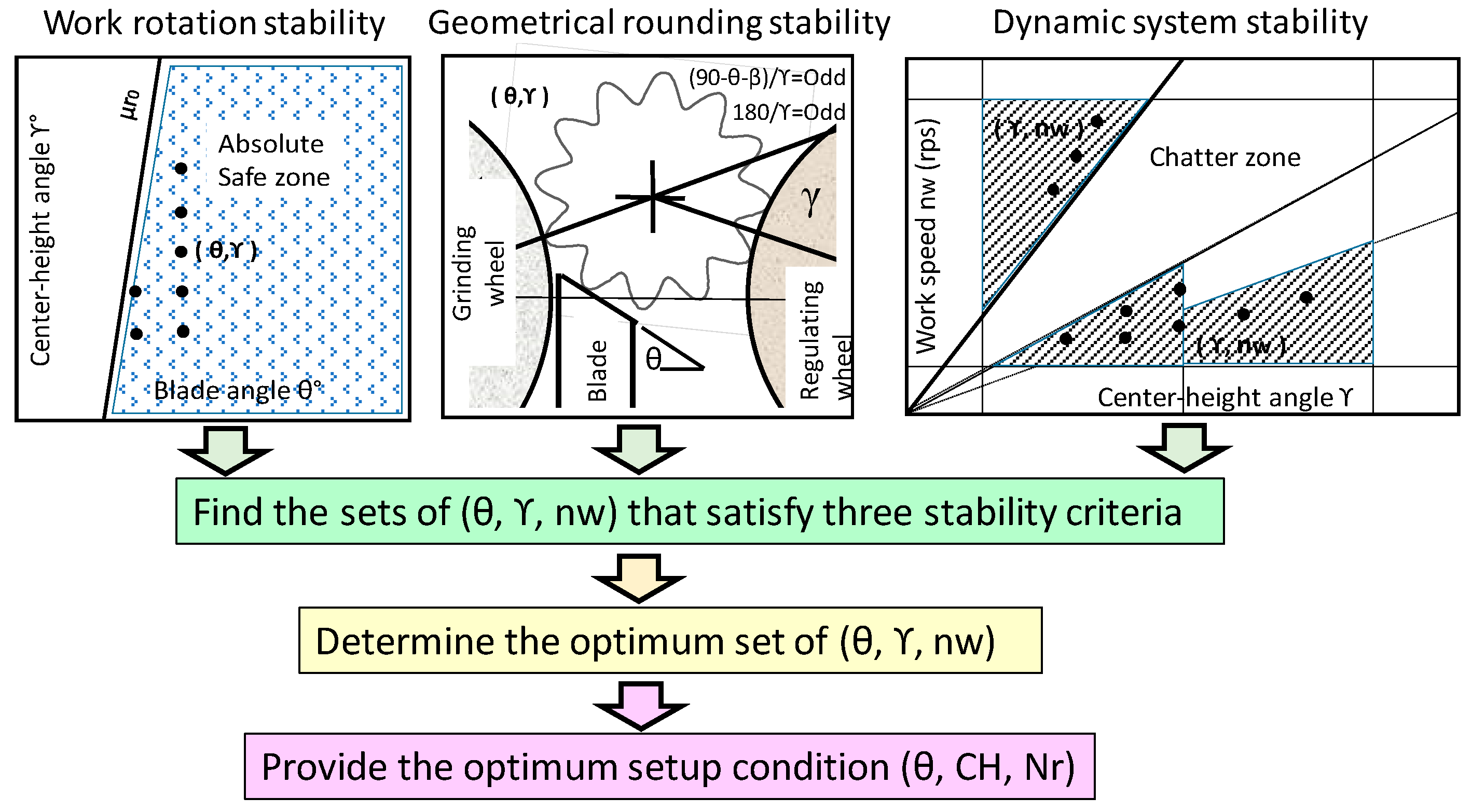

4. Three Stability Criteria in Centerless Grinding

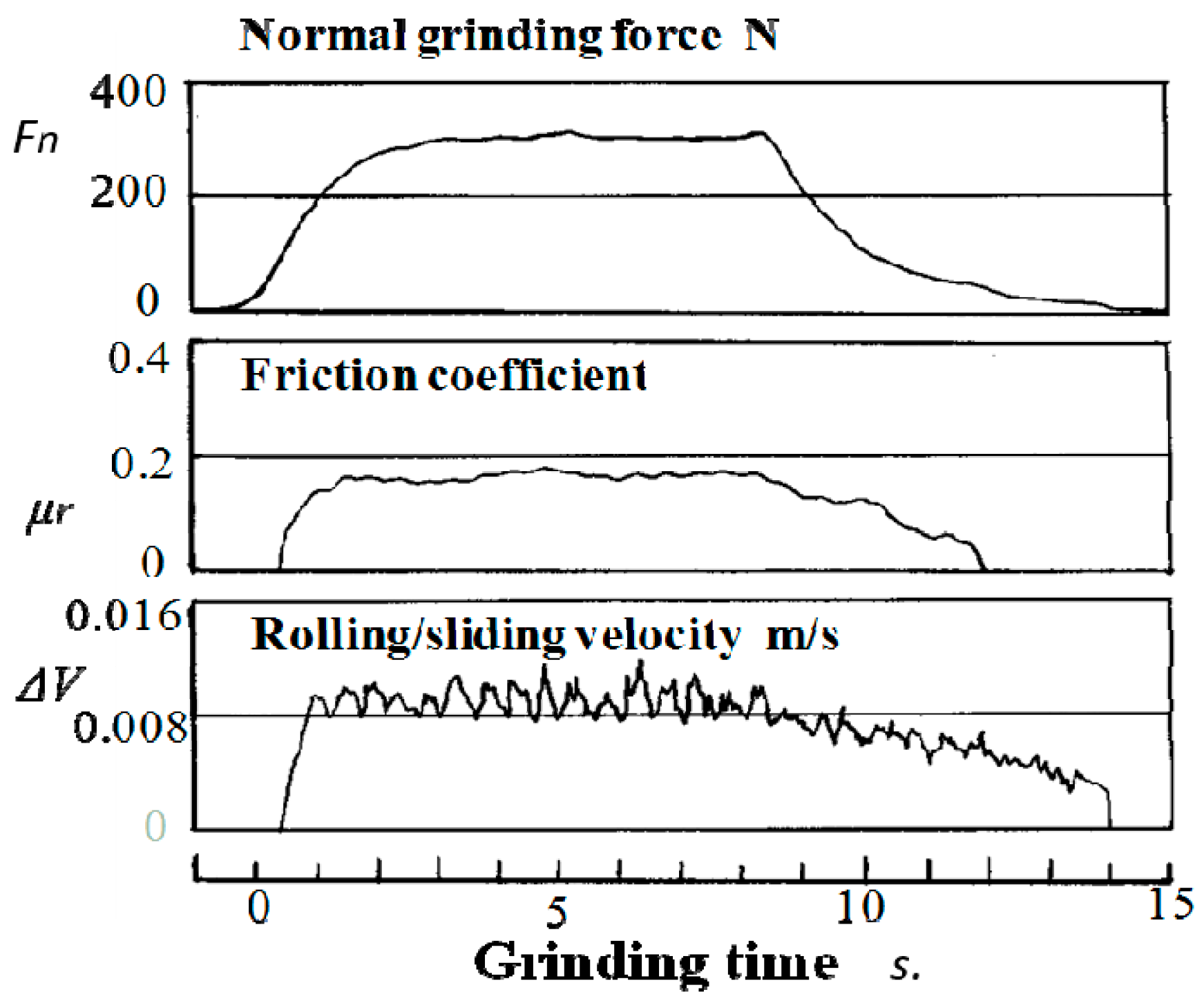

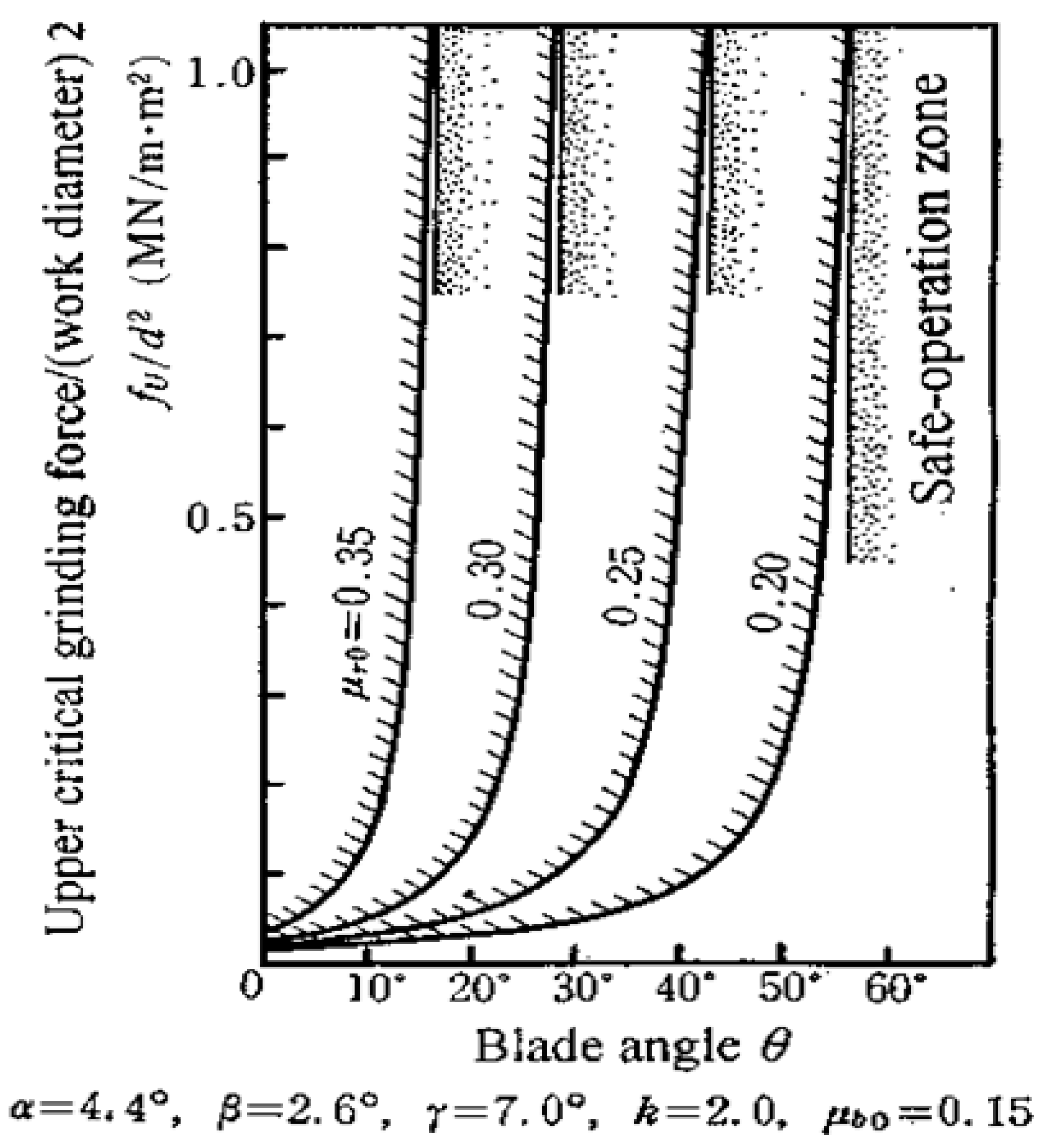

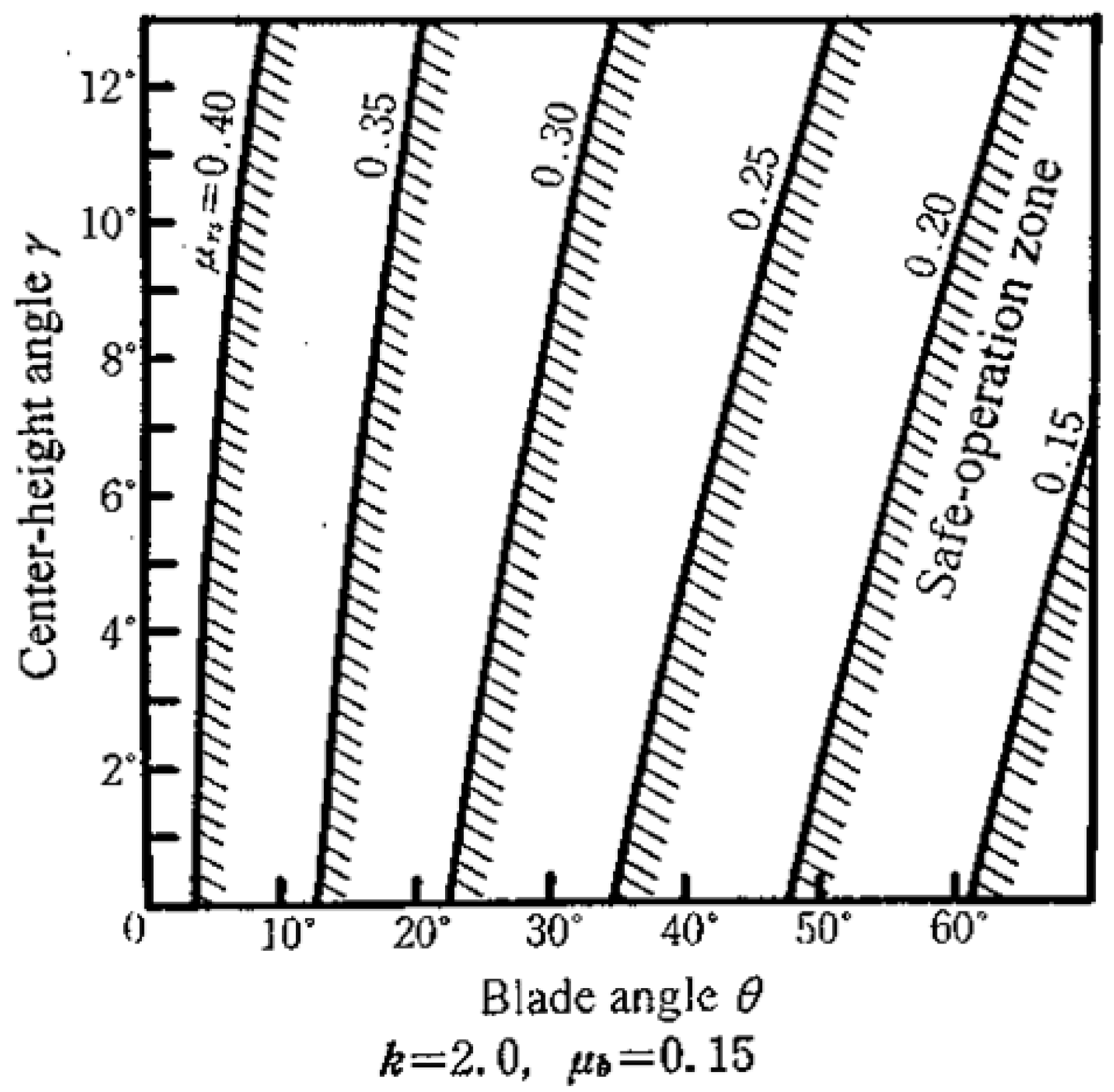

4.1. Work Rotation Stability Criterion

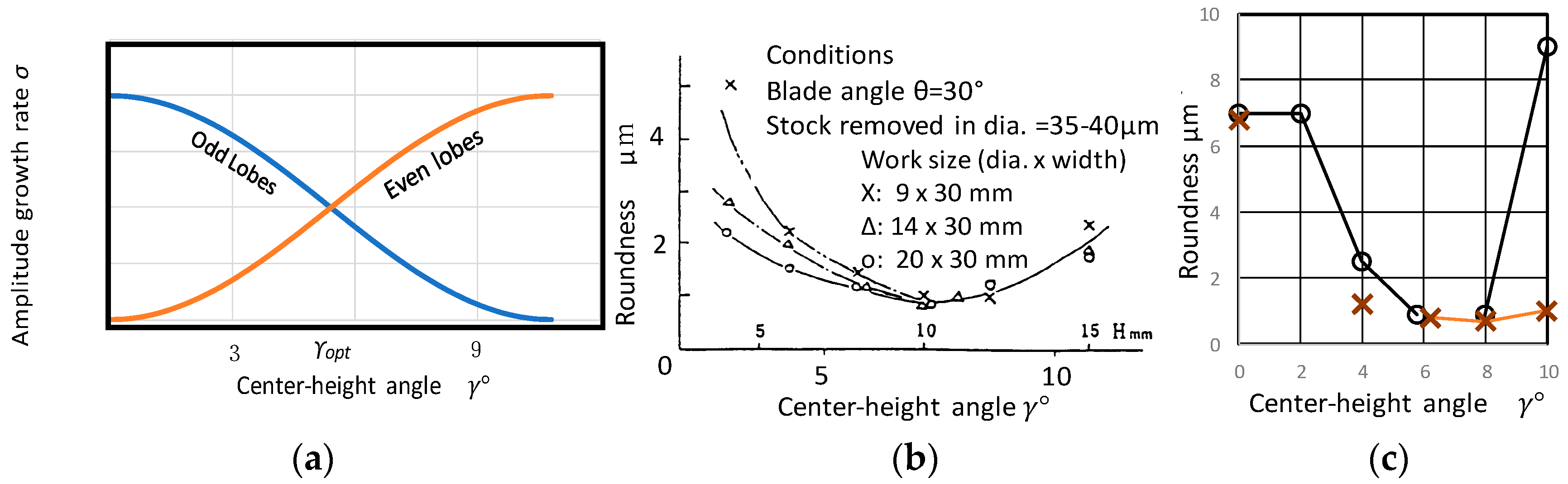

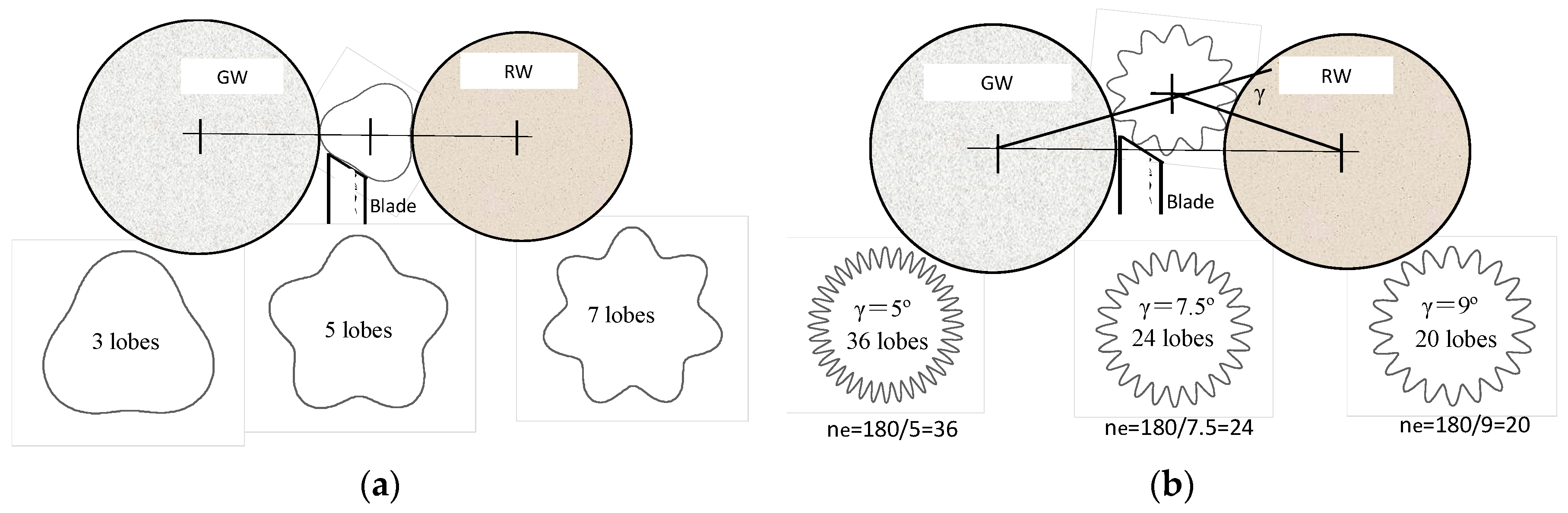

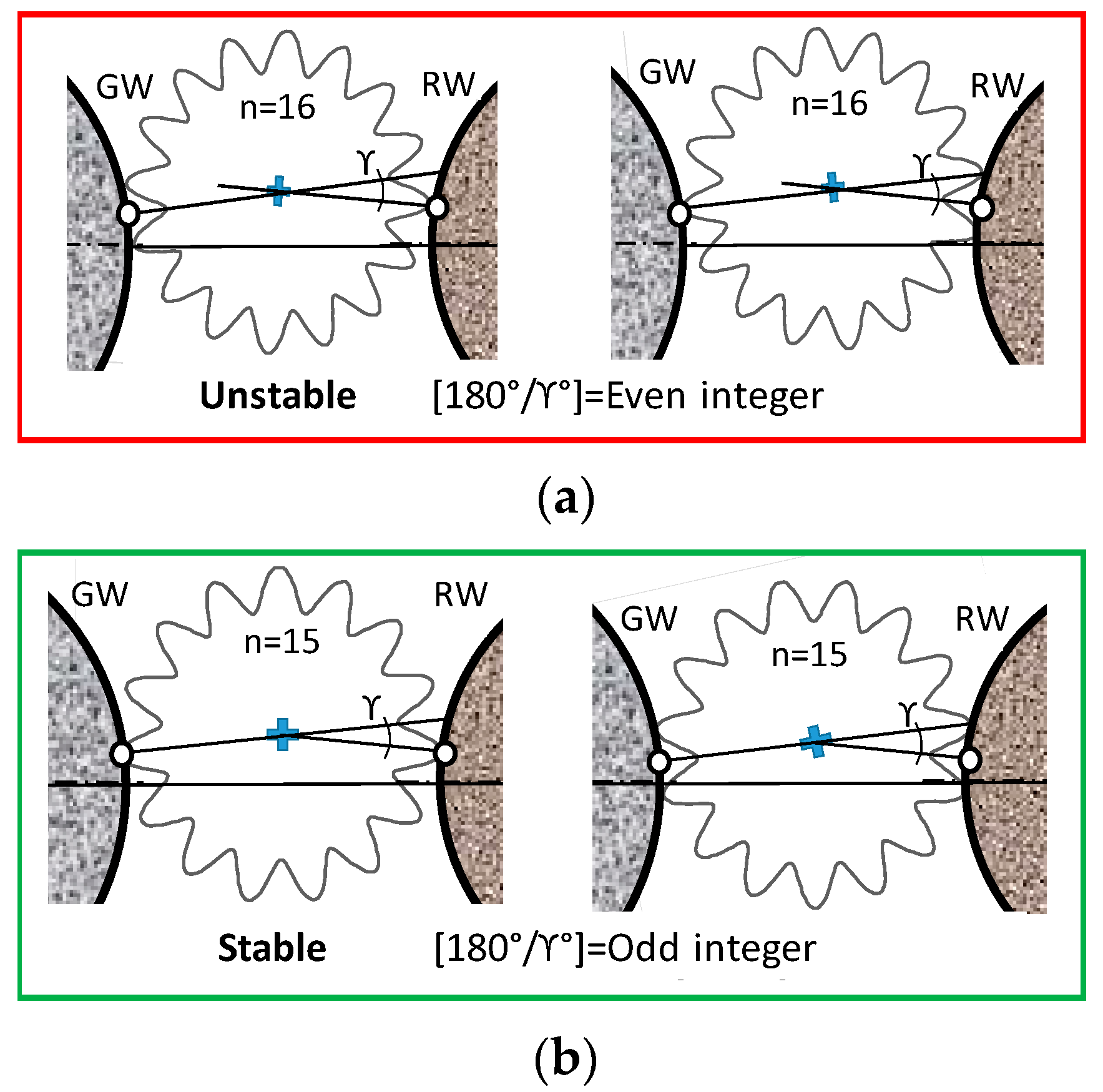

4.2. Geometrical Rounding Stability Criterion

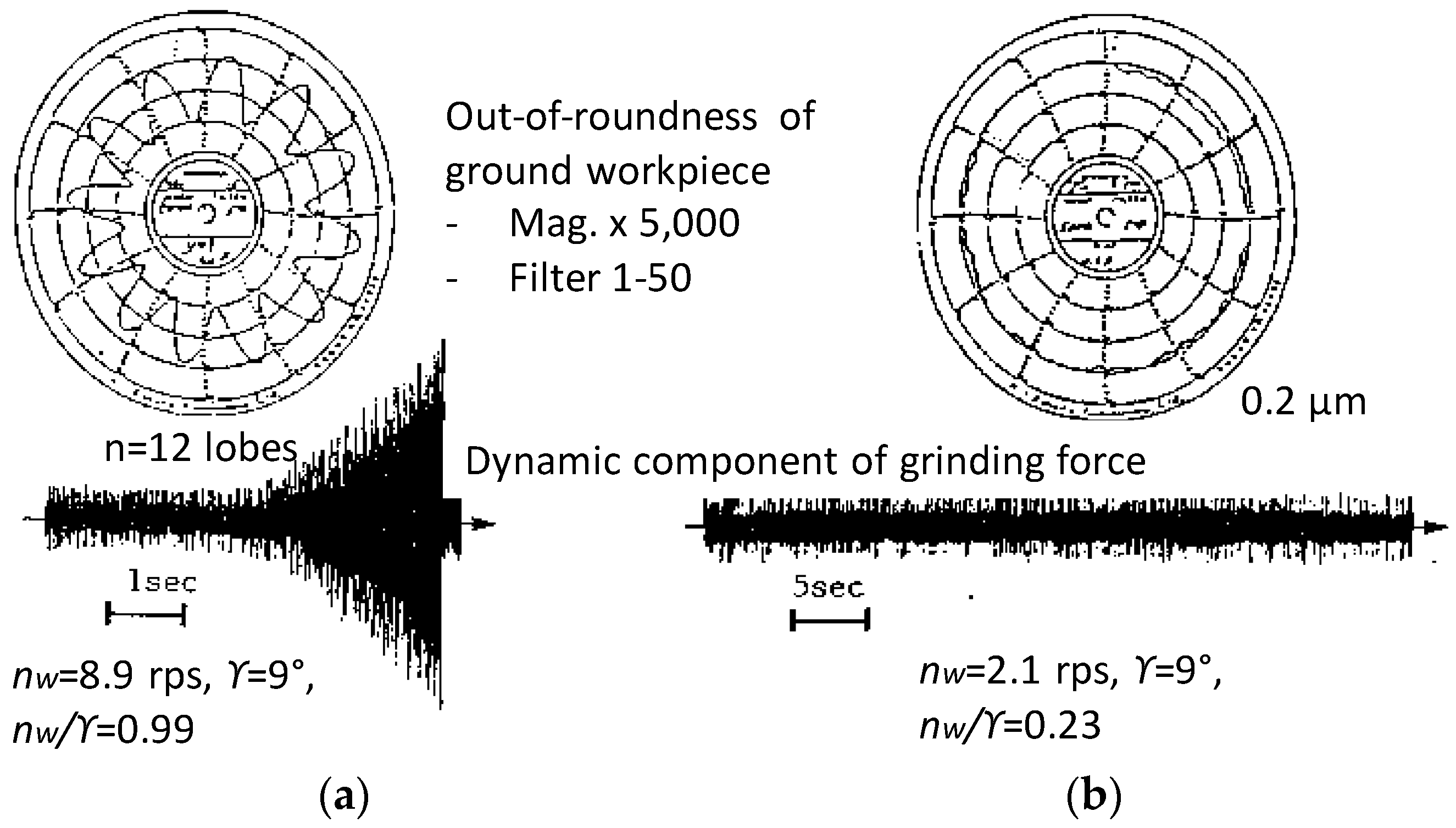

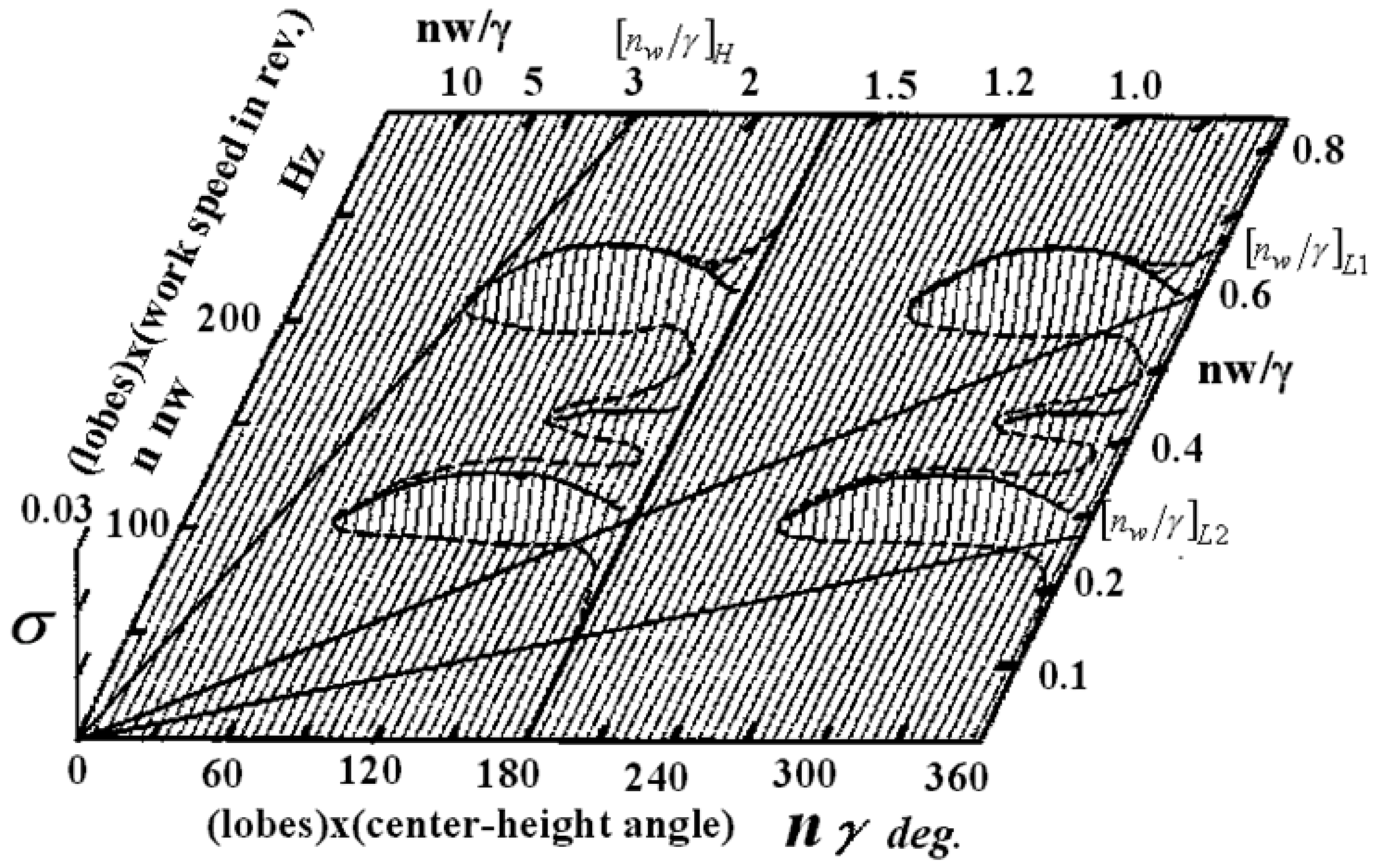

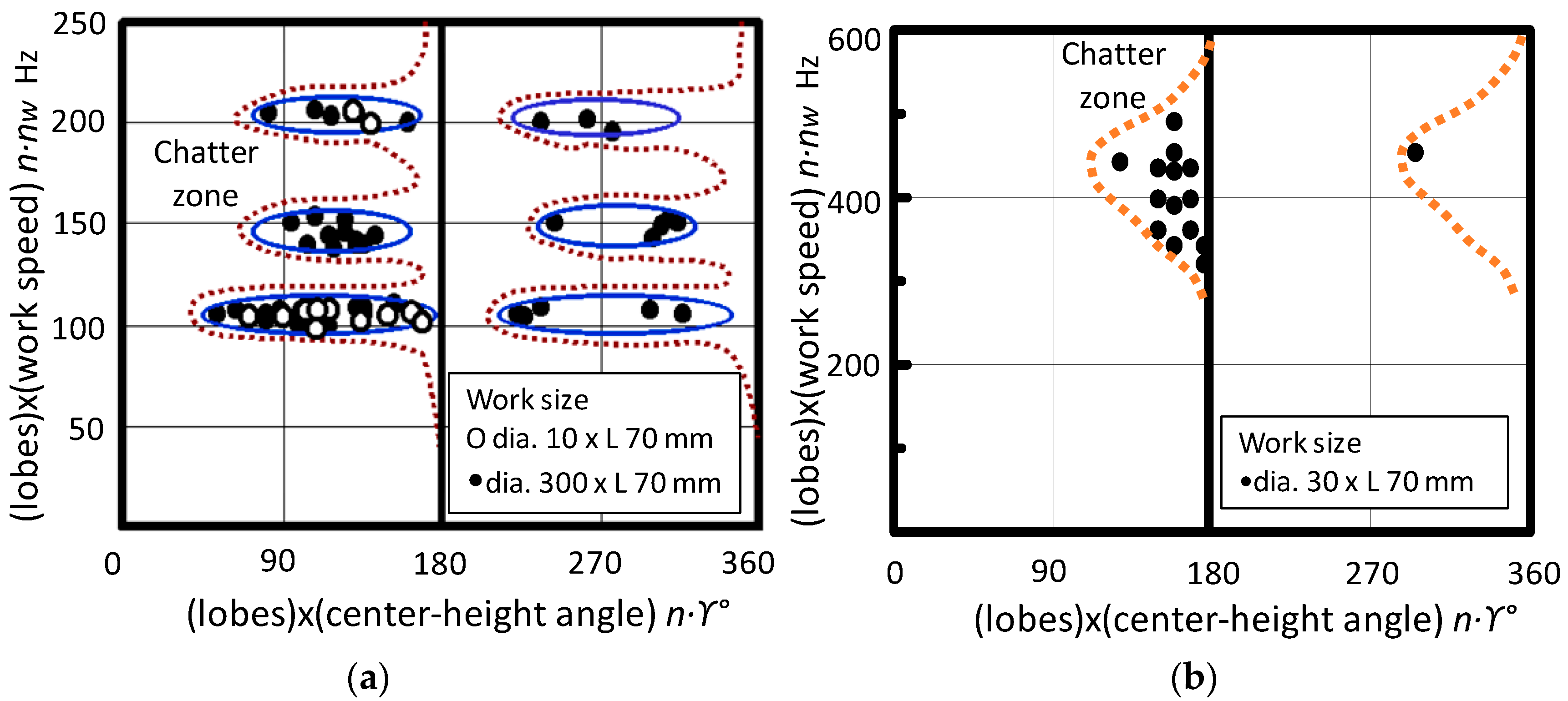

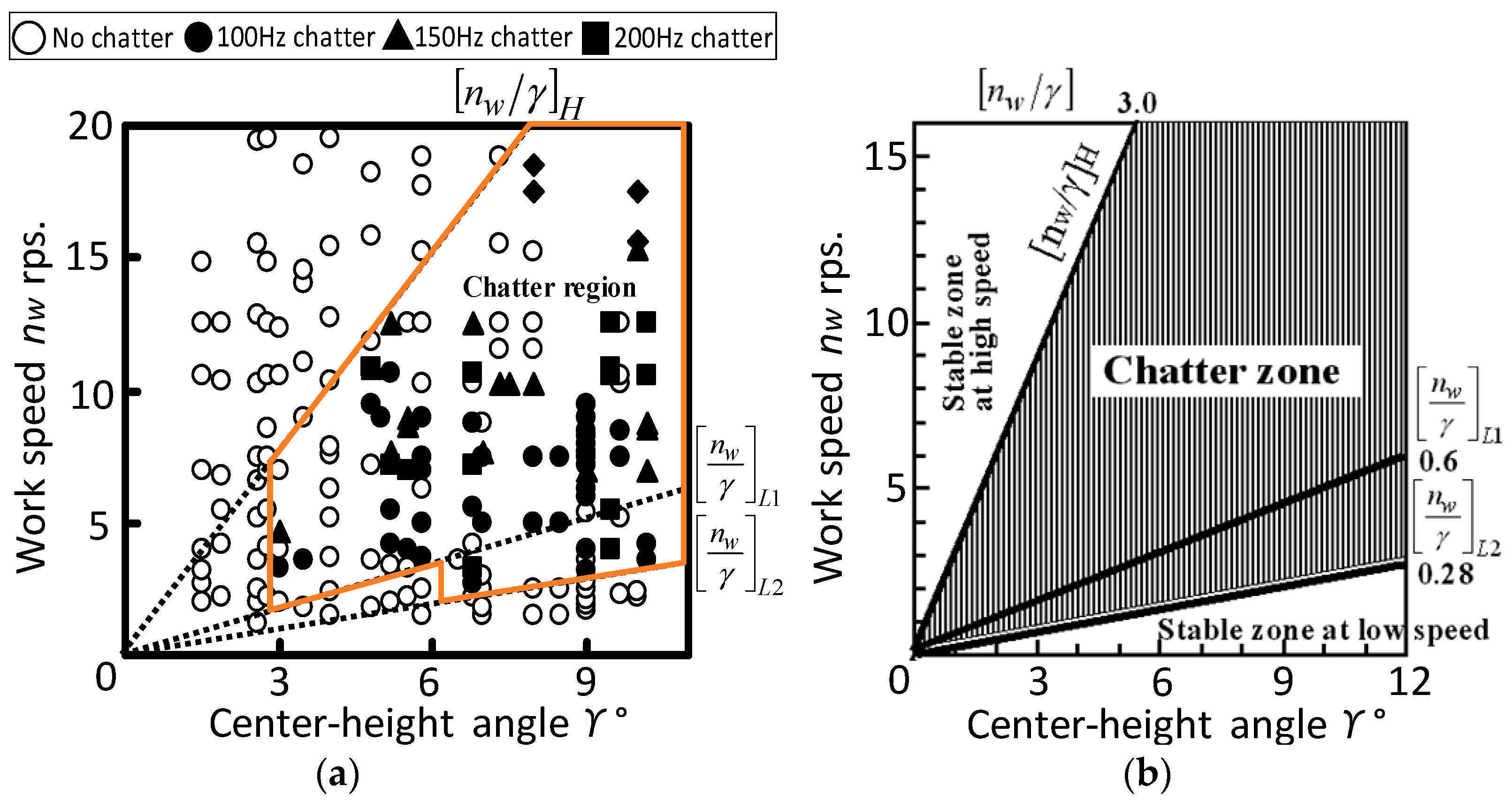

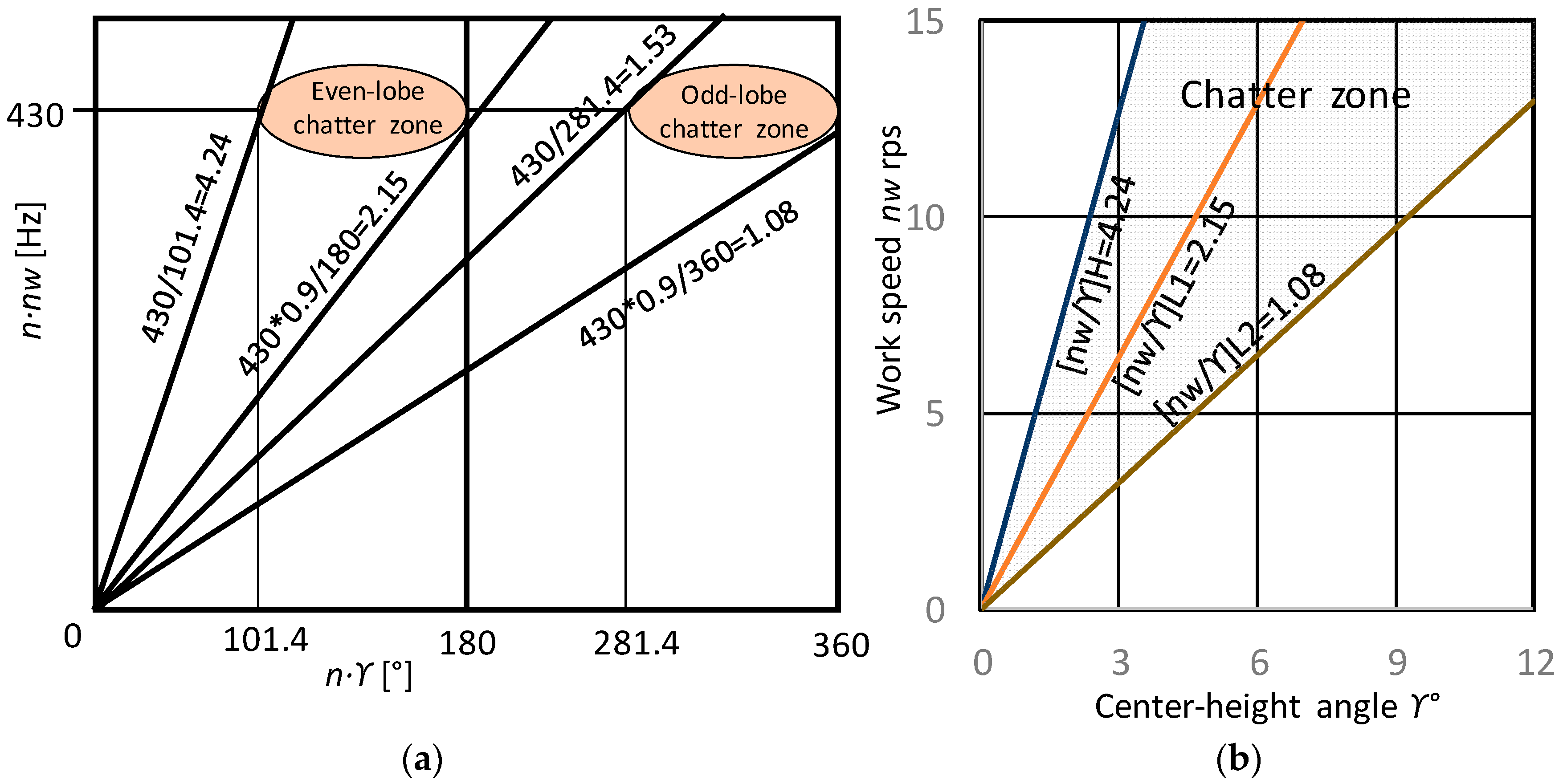

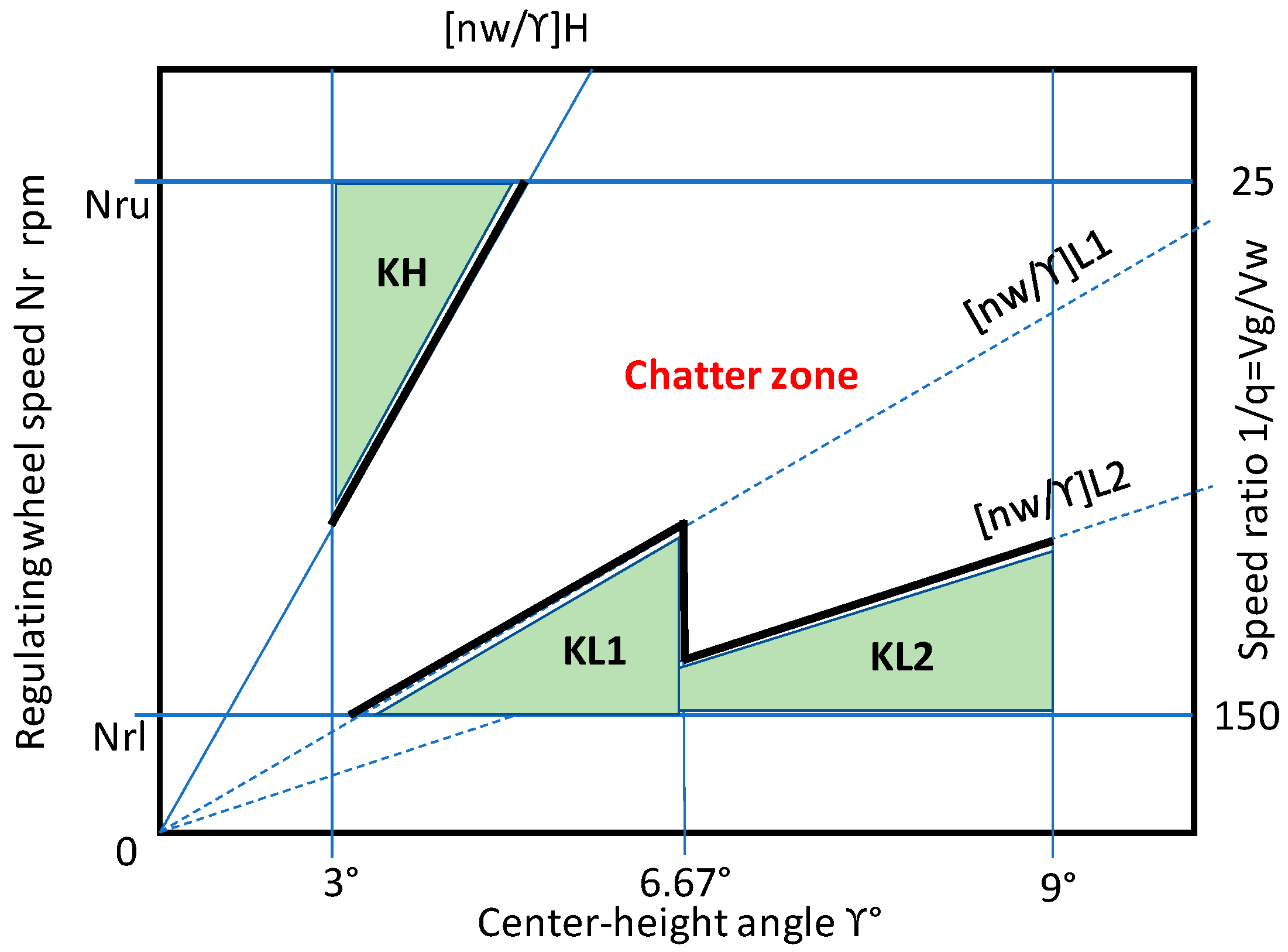

4.3. Dynamic System Stability Criterion

- 1.

- (nw/γ) H > 3.0 (high-speed chatter-free zone; KH)

- 2.

- (nw/γ) L1 < 0.6 when γ is lower (low-speed chatter-free zone 1; KL1)

- 3.

- (nw/γ) L2 < 0.28 when γ is higher (low-speed chatter-free zone 2; KL2)

- 4.

- (nw/γ) H > 4.24 (KH)

- 5.

- (nw/γ) L1 < 2.15 (KL1) for γ < 6.67°

- 6.

- (nw/γ) L2 <1.08 (KL2) for γ > 6.67°

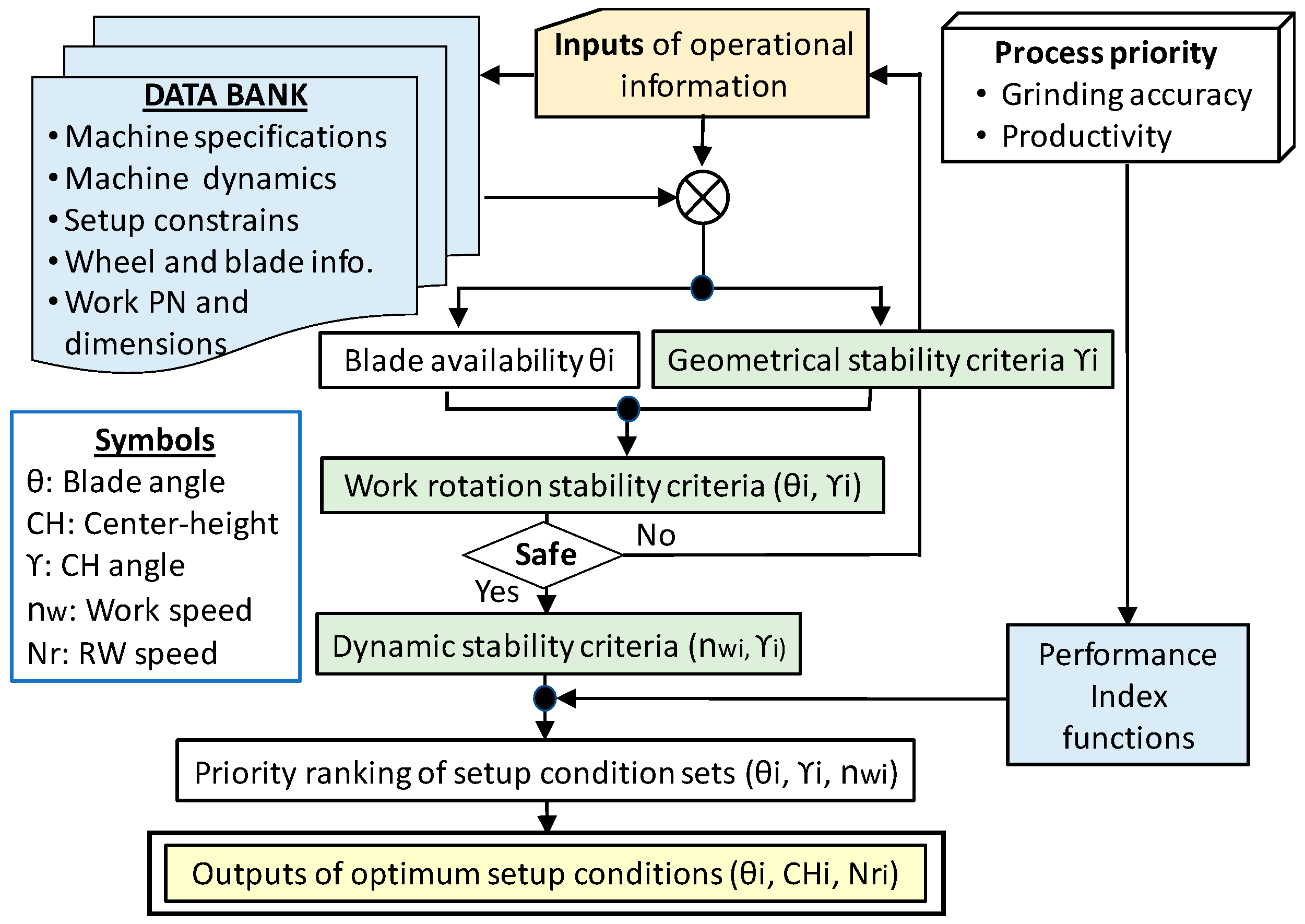

5. Modeling to Find the Optimum Setup Conditions that Satisfy the Three Stability Criteria of Centerless Grinding

- (1)

- machine B is applied

- (2)

- the process aim is accuracy-oriented

- (3)

- the work shape and the size are a cylindrical workpiece with 40 mm (D) × 60 mm (L)

- (4)

- the rubber bonded RW is dressed with leadr = 0.5 mm/rev by SPD

- (5)

- the GW diameter is 453 mm

- (6)

- the RW diameter is 350 mm

- (7)

- the available blade angles are θ = 27.5° and θ = 40.3°

6. Conclusions

- (1)

- Accepts various shapes of workpiece: cylindrical, tapered, spherical and multi-stepped

- (2)

- Applicable to any centerless grinding machine

- (3)

- Data management via a data bank

- (4)

- Inputs are easy to enter and outputs are readily usable

- (5)

- Designed for operators

- (6)

- Provides scientific parameters for engineers/managers

- (7)

- Finds all setup conditions satisfying the three stability criteria of centerless grinding systems

- (8)

- Outputs the optimum condition based on process aim

Conflicts of Interest

References

- Hashimoto, F.; Gallego, I.; Oliveira, J.F.G.; Barrenetxea, D.; Takahashi, M.; Sakakibara, K.; Stålfelt, H.-O.; Staadt, G.; Ogawa, K. Advances in Centerless Grinding Technology. CIRP Ann. Manuf. Technol. 2012, 61, 747–770. [Google Scholar] [CrossRef]

- Hashimoto, F.; Suzuki, N.; Kanai, A.; Miyashita, M. Critical Range of Set-up Conditions of Centerless Grinding and Problem of Safe Machining Operation. Jpn. Soc. Precis. Eng. 1982, 48, 996–1001. [Google Scholar] [CrossRef]

- Hashimoto, F.; Lahoti, G.; Miyashita, M. Safe Operations and Friction Characteristics of Regulating Wheel in Centerless Grinding. Ann. CIRP 1998, 47, 281–286. [Google Scholar] [CrossRef]

- Abrasive Industry. Anon, Centerless Grinding Operation; Abrasive Industry: Auckland, New Zealand, 1925; pp. 102–105. [Google Scholar]

- Dall, A.H. Rounding Effect in Centerless Grinding. Mech. Eng. 1946, 68, 325–332. [Google Scholar]

- Ogawa, M.; Miyashita, M. On Centerless Grinding (1)—Theoretical Treatise on Rounding Action. Jpn. Soc. Precis. Eng. 1957, 24, 89–94. [Google Scholar] [CrossRef]

- Reeka, D. On the Relationship between the Geometry of the Grinding Gap and the Roundness Error in Centerless Grinding. Ph.D. Thesis, RWTH, Aachen University, Aachen, Germany, 1967. [Google Scholar]

- Rowe, W.B.; Barash, M.M.; Koenigsberger, F. Some Roundness Characteristics of Centerless Grinding. Int. J. Mach. Tool Des. Res. 1965, 5, 203–215. [Google Scholar] [CrossRef]

- Yonetsu, S. Study on Centerless Grinding—First Report. Jpn. Soc. Mech. Eng. 1953, 19, 53–59. [Google Scholar]

- Gurney, J.P. An Analysis of Centerless Grinding. Trans. ASME J. Eng. Ind. 1964, 86, 163–174. [Google Scholar] [CrossRef]

- Furukawa, Y.; Miyashita, M.; Shiozaki, S. Vibration Analysis and Work Rounding Mechanism in Centerless Grinding. Int. J. Mach. Tool Des. Res. 1970, 44, 145–175. [Google Scholar] [CrossRef]

- Hashimoto, F.; Zhou, S.S.; Lahoti, G.D.; Miyashita, M. Stability Diagram for Chatter Free Centerless Grinding and Its Application in Machine Development. Ann. CIRP 2000, 49, 225–230. [Google Scholar] [CrossRef]

- Gallego, I. Intelligent Centerless Grinding: Global Solution for Process Instabilities and Optimal Cycle Design. Ann. CIRP 2007, 56, 347–352. [Google Scholar] [CrossRef]

- Hashimoto, F.; Lahoti, G.D. Optimization of Set-up Conditions for Stability of the Centerless Grinding Process. Ann. CIRP 2004, 53, 271–274. [Google Scholar] [CrossRef]

- Hashimoto, F. Effects of Friction and Wear Characteristics of Regulating Wheel on Centerless Grinding. In Proceedings of the SME, Third International Machining and Grinding Conference, Cincinnati, OH, USA, 4–7 October 1999; pp. 1–18. [Google Scholar]

- Rowe, W.B.; Koenigsberger, F. The Work-Regenerative Effect in Centerless Grinding. Int. J. Mach. Tool Des. Res. 1964, 4, 175–187. [Google Scholar] [CrossRef]

- Snoeys, R.; Brown, D. Dominating Parameters in Grinding Wheel and Workpiece Regenerative Chatter. In Proceedings of the 10th International Machine Tool Design and Research Conference, LanPleacaster, UK, 10–14 September 1969; Pergamon Press: Oxford, UK, 1970; pp. 325–348. [Google Scholar]

| Inputs | Action | Parameters Referred to Data Bank |

|---|---|---|

| Machine name | Select | Machine specifications, Machine dynamic characteristics (Natural frequencies, damping ratios) |

| Workpiece shape | Select | Cylindrical (CYD), Tapered (TPD), Spherical (SRL), Multi-stepped (STD) |

| Workpiece part-number | Select | Dimensions (diameter, length, etc.), profile |

| GW diameter | Measure | New, worn, measured |

| RW diameter | Measure | New, worn, measured |

| RW dresser type and dress lead | Select | Single point dress, Rotary dress, Friction coefficient of RW |

| Blade availability | Select | Blade angle θ, blade thickness t |

| Setup Parameters | Symbol | Unit. | Min. | Max. | Typical |

|---|---|---|---|---|---|

| Range of speed ratio | 1/q = Vg/Vw | - | 25 | 150 | 100 |

| Range of blade angle | θ | ° | 15 | 45 | 30 |

| Range of Center-height angle | γ | ° | 3 | 9 | 6.67 |

| Range of regulating wheel speed | Nr | rpm | 15 | 100 | 50 |

| Range of GW diameter | Dg | mm | 375 | 455 | 450 |

| Range of RW diameter | Dr | mm | 275 | 350 | 345 |

| Range of Workpiece diameter | Dw | mm | 5 | 100 | 40 |

| Grinding wheel speed in revolution | Ng | rpm | 1260 | 2300 | 1890 |

| Grinding speed | Vg | m/s | 30 | 45 | 45 |

| Process Aim | PI Function | Weighting Factors | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | ||

| Accuracy | PIa = A × I θ − 27.5 I + B × I γ − 6.67 I + C × I Nr − 50 I + D × FL + E × STYP | 0.2 | 2 | 0.1 | 0.01 | 2 |

| Productivity | PIr = A × I θ − 45 I + B × I γ − 5.15 I + C × I Nr − 50 I + D × FL + E × STYP | 0.1 | 2 | 0.12 | 0.5 | 2 |

| Priority | Optimum Set Up Conditions | Engineering Parameter | Stability Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ranking | Blade Angle | Blade Thickness | Center-Height | RW Speed | CH Angle | Work Speed | 1/q Ratio | (nw/γ) | Stable Zone | RW − GRSC | Blade − GRSC |

| No. | θ (°) | t (mm) | CH (mm) | Nr (rpm) | γ (°) | nw (rps) | Vg/Vw | (1/s) | KH/KL1/KL2 | 180/γ | (90 − θ − β)/γ |

| 1 | 40.3 | 20 | 12.68 | 41.8 | 6.68 | 6.1 | 25 | 0.91 | KL2 | 27 | 7 |

| 2 | 40.3 | 20 | 12.66 | 83.5 | 6.67 | 12.2 | 25 | 1.83 | KL1 | 27 | 7 |

| 3 | 40.3 | 20 | 13.67 | 45.1 | 7.2 | 6.58 | 25 | 0.91 | KL2 | 27 | 6.5 |

| Case No. | Work Dia.x L. | Machine | Blade Angle | C-H Angle | RW Speed | Chatter DSSC | Chatter Stable Zone | RW − GRSC | Blade – GRSC |

|---|---|---|---|---|---|---|---|---|---|

| mm | A/B | θ (°) | γ (°) | Nr (rpm) | (nw/γ) | KH/KL1/KL2 | 180/γ | (90 − θ − β)/γ | |

| 1 | 10 × 20 | A | 27.5 | 6.67 | 38.6 | 3.37 | KH | 27 | 9 |

| 2 | B | 27.5 | 6.67 | 64.1 | 5.61 | KH | 27 | 9 | |

| 3 | 20 × 30 | A | 27.5 | 6.67 | 77.1 | 3.37 | KH | 27 | 9 |

| 4 | B | 27.5 | 6.67 | 41.8 | 1.83 | KL1 | 27 | 9 | |

| 5 | 30 × 50 | A | 40.3 | 6.67 | 14.6 | 0.43 | KL1 | 27 | 7 |

| 6 | B | 40.3 | 6.67 | 62.7 | 1.83 | KL1 | 27 | 7 | |

| 7 | 40 × 60 | A | 40.30 | 6.67 | 19.4 | 0.43 | KL1 | 27 | 7 |

| 8 | B | 40.30 | 6.68 | 41.8 | 0.91 | KL2 | 27 | 7 | |

| 9 | 50 × 70 | A | 40.30 | 6.67 | 24.3 | 0.43 | KL1 | 27 | 7 |

| 10 | B | 40.30 | 6.68 | 52.3 | 0.91 | KL2 | 27 | 7 | |

| 11 | 60 × 80 | A | 40.30 | 6.67 | 29.1 | 0.43 | KL1 | 27 | 7 |

| 12 | B | 40.30 | 6.68 | 62.7 | 0.91 | KL2 | 27 | 7 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashimoto, F. Model Development for Optimum Setup Conditions that Satisfy Three Stability Criteria of Centerless Grinding Systems. Inventions 2017, 2, 26. https://doi.org/10.3390/inventions2040026

Hashimoto F. Model Development for Optimum Setup Conditions that Satisfy Three Stability Criteria of Centerless Grinding Systems. Inventions. 2017; 2(4):26. https://doi.org/10.3390/inventions2040026

Chicago/Turabian StyleHashimoto, Fukuo. 2017. "Model Development for Optimum Setup Conditions that Satisfy Three Stability Criteria of Centerless Grinding Systems" Inventions 2, no. 4: 26. https://doi.org/10.3390/inventions2040026

APA StyleHashimoto, F. (2017). Model Development for Optimum Setup Conditions that Satisfy Three Stability Criteria of Centerless Grinding Systems. Inventions, 2(4), 26. https://doi.org/10.3390/inventions2040026