Numerical Method for Internal Structure and Surface Evaluation in Coatings

Abstract

1. Introduction

2. Materials and Methods

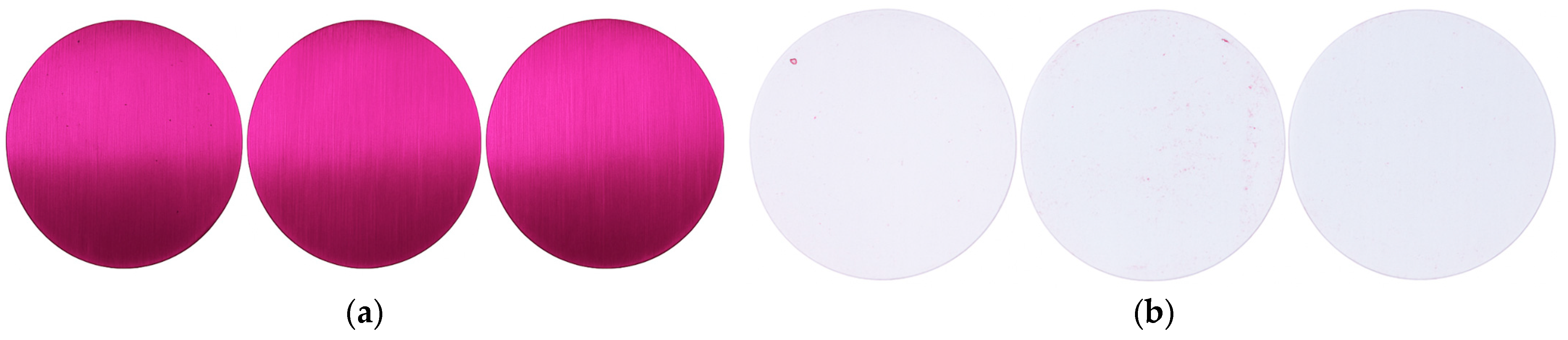

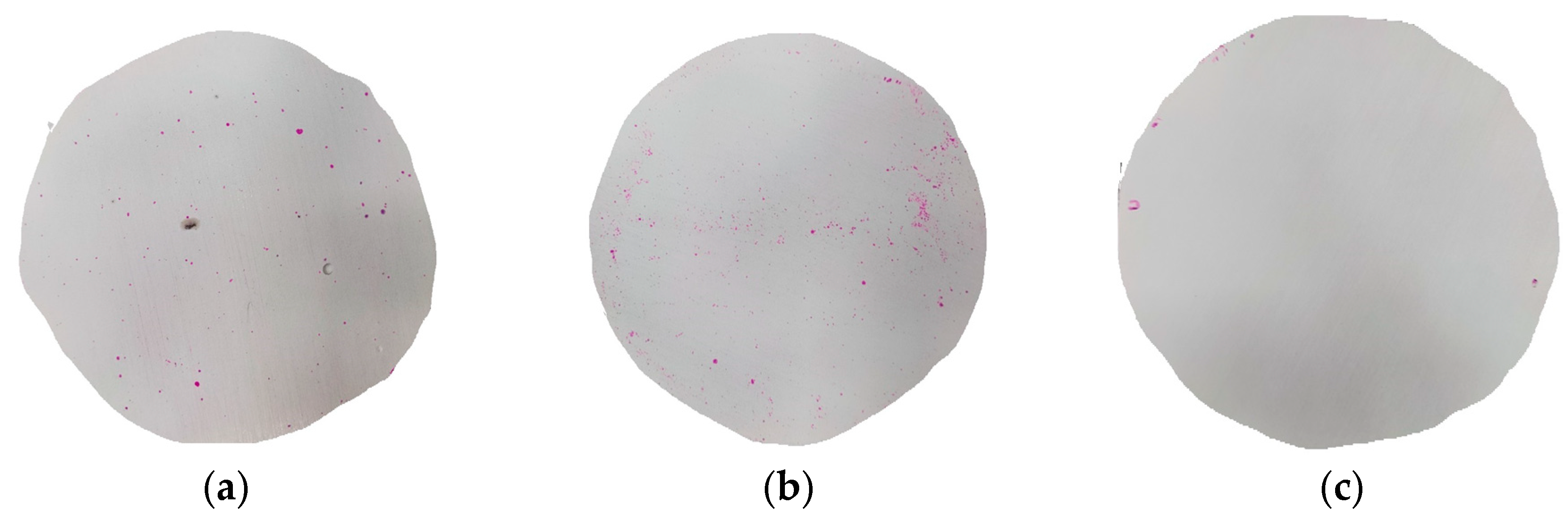

2.1. Penetrant Testing

- MR® 67 water and solvent removable penetrant (red and fluorescent)—Type II and III, sensitivity level 2 (acc. EN ISO 3452:2) [67]; carrier medium water, Jumbo-Pen type (MR Chemie GmbH, Nordstraße 61–63, 59427 Unna, Germany).

- MR® 70 solvent-based developer, carrier medium solvent; Jumbo-Pen type (MR Chemie GmbH, Nordstraße 61–63, 59427 Unna, Germany).

- MR® 88 Penetrant remover and pre-cleaner; Class 2 according to AMS 2644; Method C according to EN ISO 3452-2; alcohol mixture, free of hydrocarbons (MR Chemie GmbH, Nordstraße 61–63, 59427 Unna, Germany).

- UNI-T UT381 Luxmeter (0~20,000 Lux); high-precision digital visible light sensor with 8-bit microprocessor (Uni-Trend Technology (Dongguan) Limited, Dong Fang Da Dao, Bei Shan Dong Fang Industrial Development District, Hu Men Town, Dongguan City, Guang Dong Province, China).

- Thermometer Testo 830-T4 (infrared −30 to +400 °C and Type K (NiCr-Ni) −50 to +500 °C); resolution—0.1 °C (Testo SE & Co. KGaA, Celsiusstraße 2, 79822 Titisee-Neustadt, Germany)

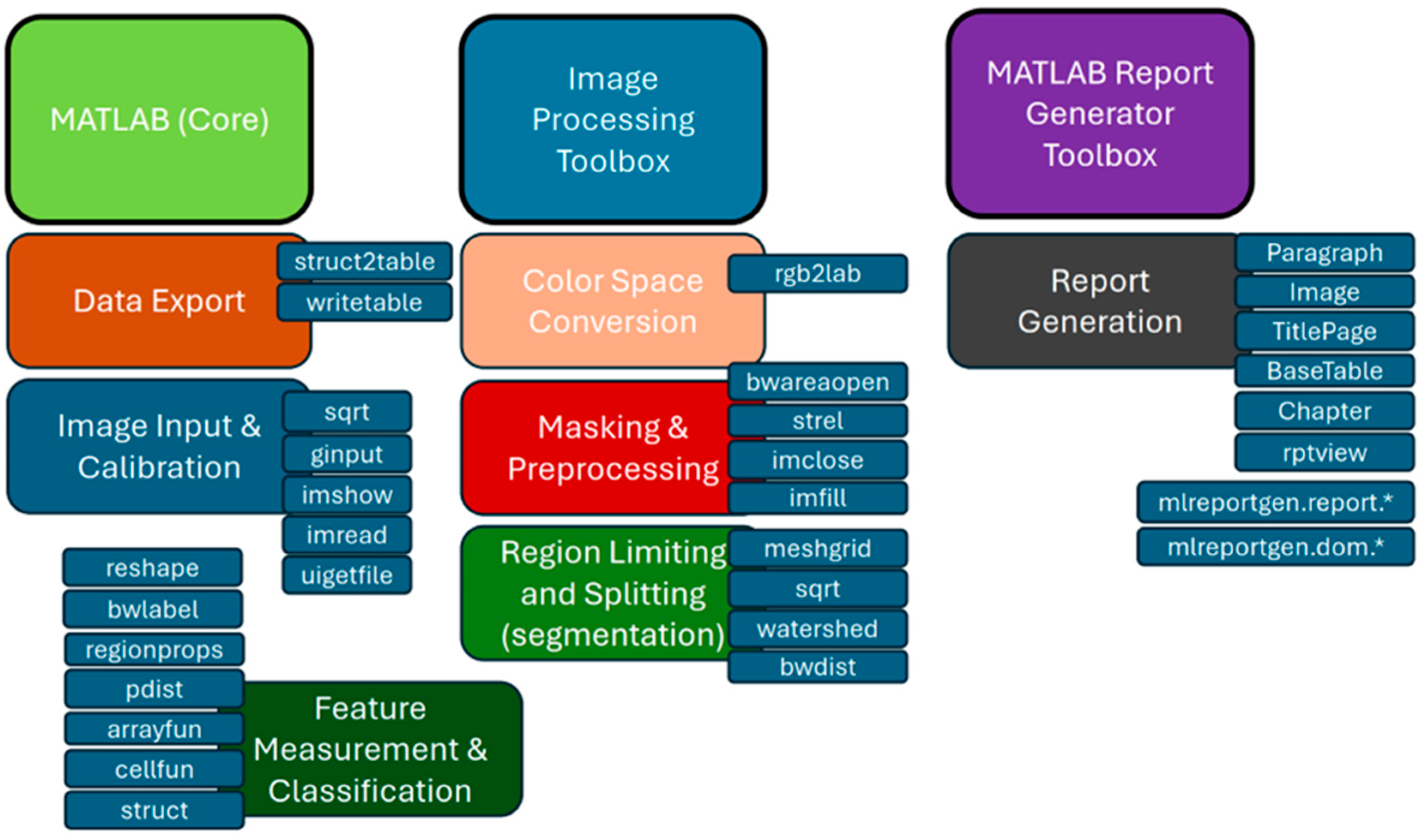

- MATLAB ® software (MathWorks, 1 Apple Hill Drive, Natick, MA 01760-2098, USA).

evaluationLevel = 'B';

structuringElementSize = 10;

minRegionSize = 35;

pinkRange = [75 5 -15; 100 60 20];

groupingDistance = 2; % mm

aspectRatioThreshold = 3;

criteria = struct(...

'A', struct('linearMax', 0, 'nonlinearMax', 3, 'areaPerDm2', 10), ...

'B', struct('linearMax', 0, 'nonlinearMax', 4, 'areaPerDm2', 20), ...

'C', struct('linearMax', 0, 'nonlinearMax', 5, 'areaPerDm2', 50), ...

'D', struct('linearMax', 0, 'nonlinearMax', 6, 'areaPerDm2', 125), ...

'E', struct('linearMax', 7, 'nonlinearMax', 8, 'areaPerDm2', 250));

crit = criteria.(evaluationLevel);

image = imread('sample_PT_image.jpg');

if isempty(pixelPerMm)

figure; imshow(image); title('Click across 100 mm diameter');

[x, y] = ginput(2);

measuredPixels = sqrt((x(2)-x(1))^2 + (y(2)-y(1))^2);

pixelPerMm = measuredPixels / 100;

close;

end

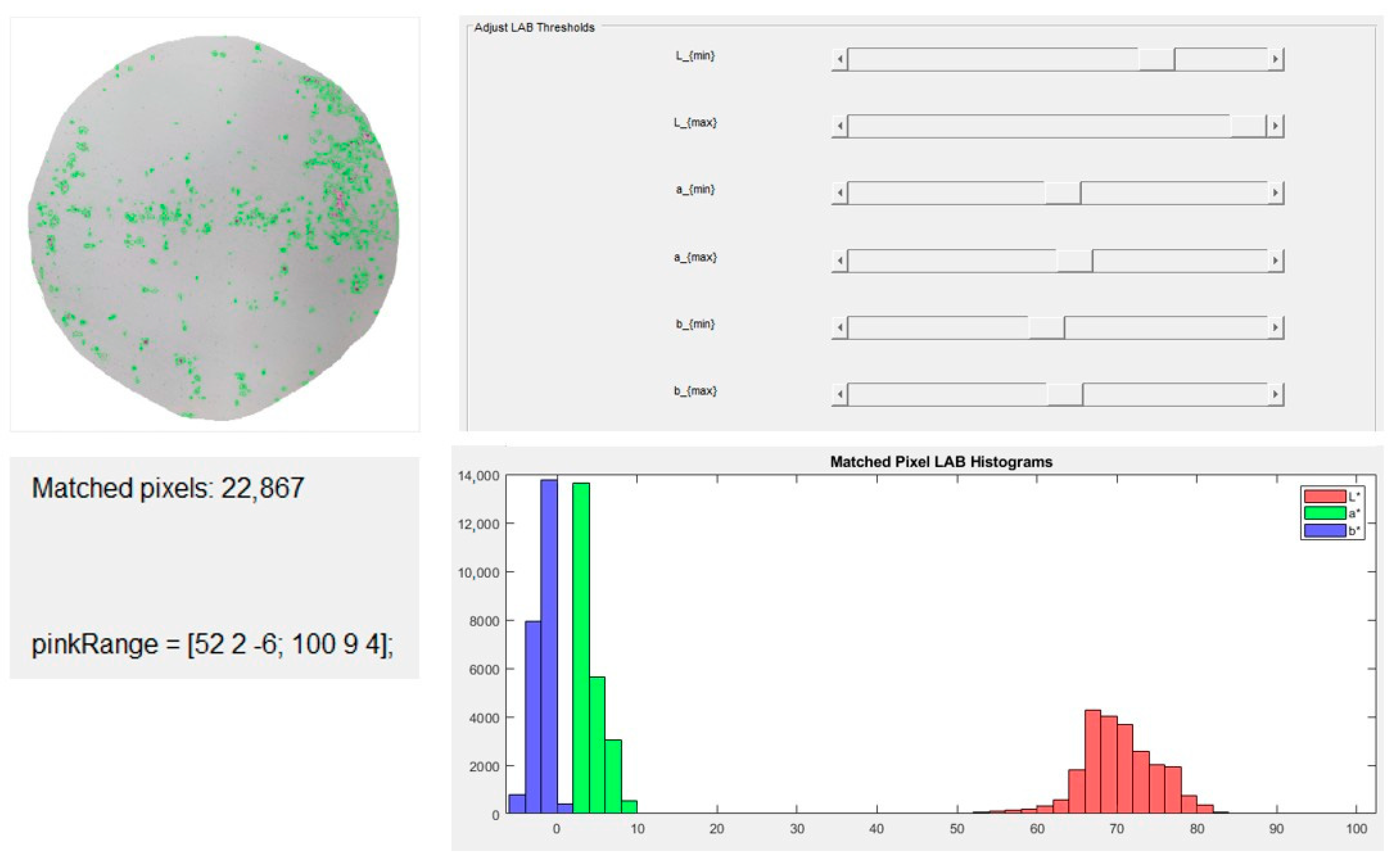

labImage = rgb2lab(image);

pinkMask = (labImage(:,:,2) >= pinkRange(1,2) & labImage(:,:,2) <= pinkRange(2,2)) & ...

(labImage(:,:,3) >= pinkRange(1,3) & labImage(:,:,3) <= pinkRange(2,3));

se = strel('disk', structuringElementSize);

pinkMask = imclose(pinkMask, se);

pinkMask = imfill(pinkMask, 'holes');

pinkMask = bwareaopen(pinkMask, minRegionSize);

[rows, cols, ~] = size(image); centerX = cols / 2; centerY = rows / 2; sampleRadiusPx = (100 / 2) * pixelPerMm; [X, Y] = meshgrid(1:cols, 1:rows); distFromCenter = sqrt((X - centerX).^2 + (Y - centerY).^2); circularMask = distFromCenter <= sampleRadiusPx; pinkMask = pinkMask & circularMask;

distanceTransform = -bwdist(~pinkMask); distanceTransform(~pinkMask) = -Inf; watershedMask = watershed(distanceTransform); pinkMask(watershedMask == 0) = 0;

labeledMask = bwlabel(pinkMask);

stats = regionprops(labeledMask, 'Area', 'BoundingBox', ...

'Centroid', 'MajorAxisLength', 'MinorAxisLength');

minBoxDistance = @(b1,b2) sqrt( ...

max(0, max(b1(1),b2(1)) - min(b1(1)+b1(3), b2(1)+b2(3)))^2 + ...

max(0, max(b1(2),b2(2)) - min(b1(2)+b1(4), b2(2)+b2(4)))^2 );

groupLabels = 1:numel(stats);

changed = true;

while changed

changed = false;

for i = 1:numel(stats)

for j = i+1:numel(stats)

d = minBoxDistance(stats(i).BoundingBox, stats(j).BoundingBox) / pixelPerMm;

if d <= groupingDistance && groupLabels(i) ~= groupLabels(j)

minLabel = min(groupLabels(i), groupLabels(j));

maxLabel = max(groupLabels(i), groupLabels(j));

groupLabels(groupLabels == maxLabel) = minLabel;

changed = true;

end

end

end

end

for k = 1:numel(stats)

major = stats(k).MajorAxisLength / pixelPerMm;

minor = stats(k).MinorAxisLength / pixelPerMm;

area = stats(k).Area / (pixelPerMm^2);

aspect = major / minor;

if aspect >= aspectRatioThreshold

shape = 'Linear';

status = 'FAIL';

elseif (major + minor)/2 > crit.nonlinearMax

shape = 'Non-linear';

status = 'FAIL';

else

shape = 'Non-linear';

status = 'PASS';

end

end

sampleAreaDm2 = pi * (100/2)^2 / 10000;

indicatedAreaPerDm2 = sum([stats.Area]) / (pixelPerMm^2 * sampleAreaDm2);

if indicatedAreaPerDm2 > crit.areaPerDm2

disp('FAIL: Area exceeds limit');

else

disp('PASS: Within allowable limits');

end

imshow(image); hold on;

for i = 1:numel(stats)

rectangle('Position', stats(i).BoundingBox, 'EdgeColor', 'r', 'LineWidth', 2);

text(stats(i).BoundingBox(1), stats(i).BoundingBox(2)-10, ...

num2str(i), 'Color', 'yellow', 'FontSize', 9, 'Font-Weight', 'bold');

end

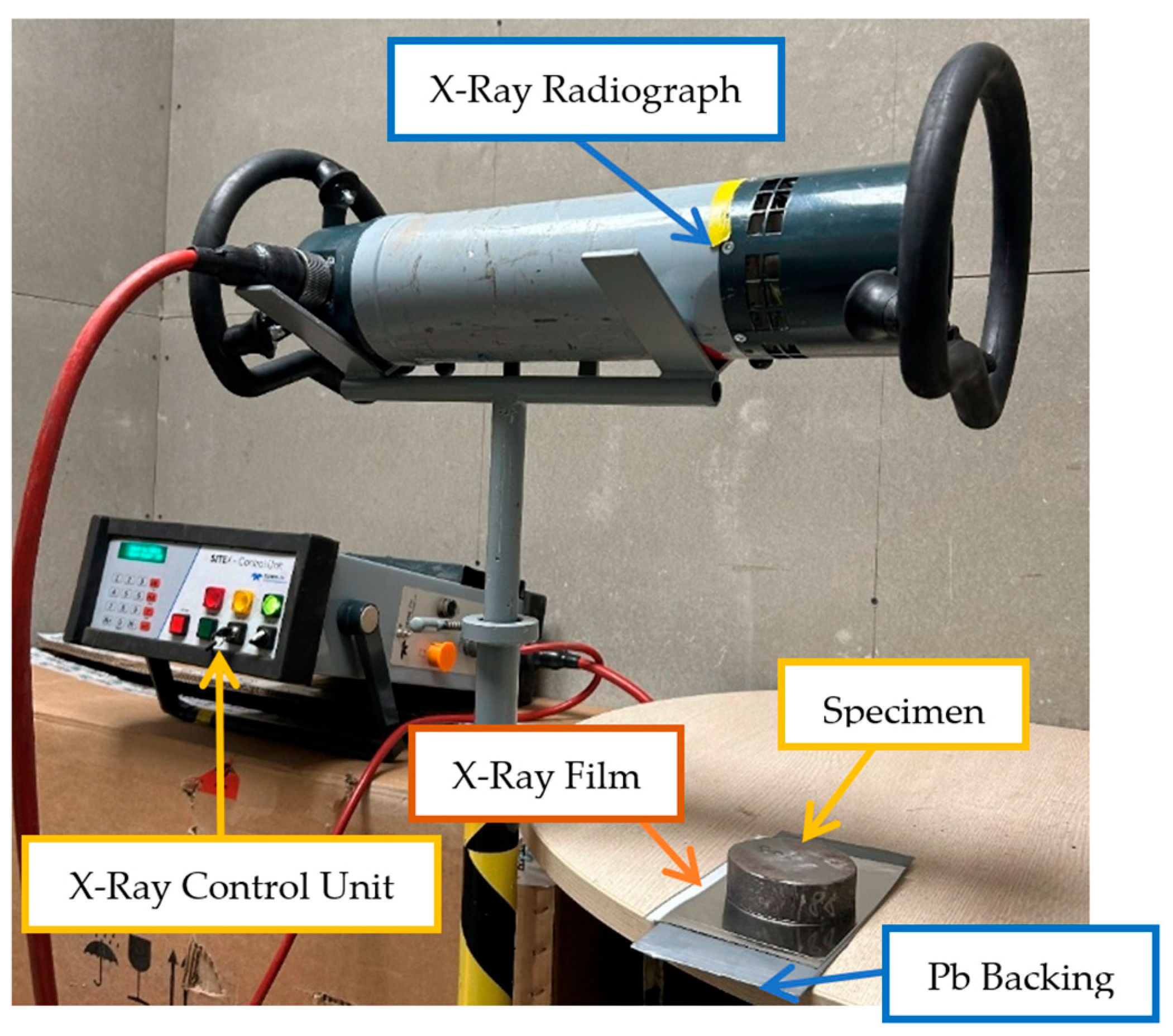

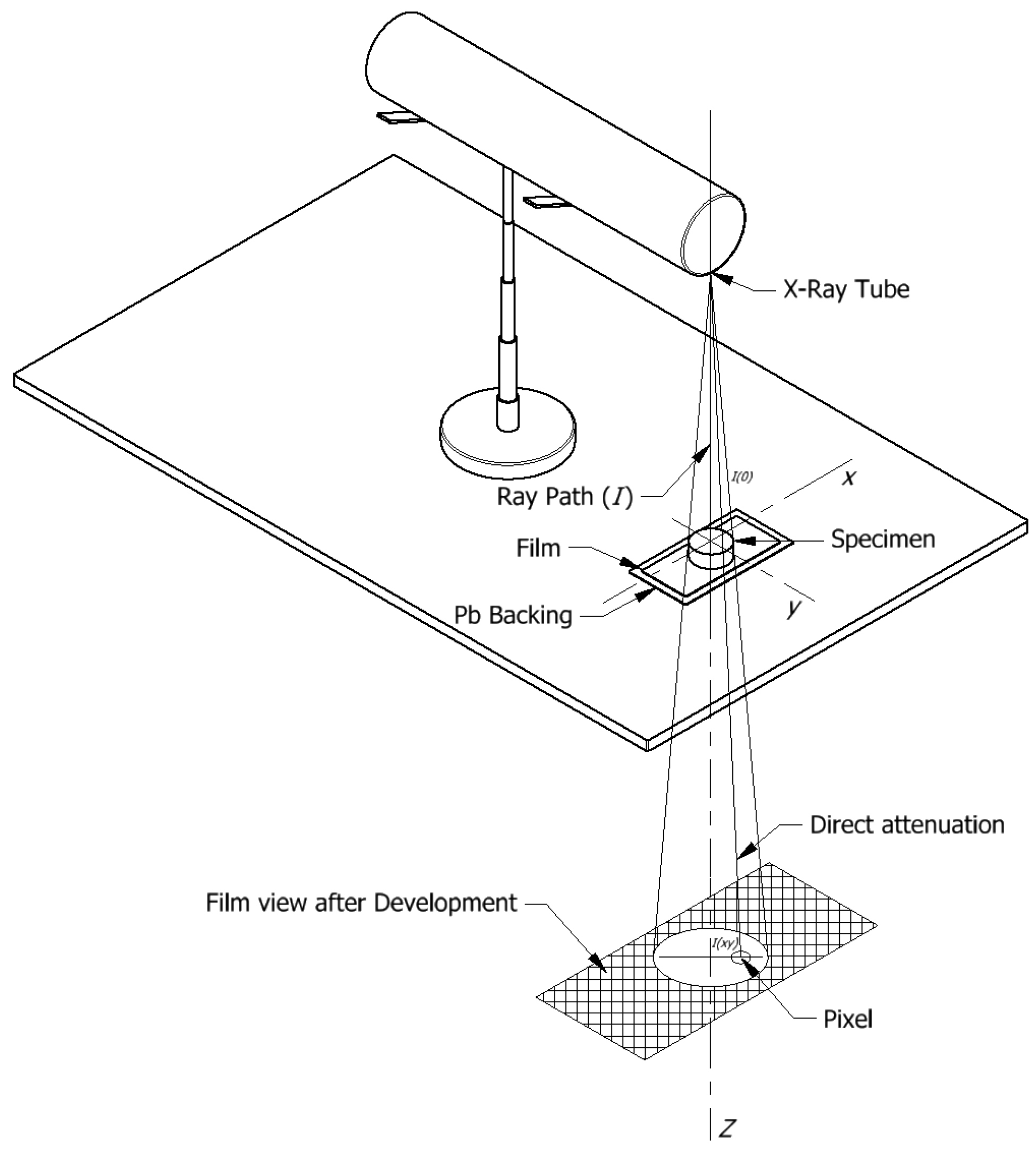

2.2. Radiography Testing

evaluationLevel = 'B';

structuringElementSize = 15;

minRegionSize = 15;

minRegionArea_mm2 = 0.035;

maxRegionArea_mm2 = 1500;

minCompactness = 0.1;

minGroupSpan_mm = 2;

minGroupSize = 4;

groupingDistance = 2;

aspectRatioThreshold = 3;

minContrast = 3.5;

criteria = struct( ...

'A', struct('linearMax', 0, 'nonlinearMax', 3, 'areaPerDm2', 10), ...

'B', struct('linearMax', 0, 'nonlinearMax', 4, 'areaPerDm2', 20), ...

'C', struct('linearMax', 0, 'nonlinearMax', 5, 'areaPerDm2', 50), ...

'D', struct('linearMax', 0, 'nonlinearMax', 6, 'areaPerDm2', 125), ...

'E', struct('linearMax', 7, 'nonlinearMax', 8, 'areaPerDm2', 250));

crit = criteria.(evaluationLevel);

image = imread('sample_RT_image.png');

if size(image,3) == 3, image = rgb2gray(image); end

grayImage = image;

if isempty(pixelPerMm)

figure; imshow(image); title('Click 2 points across 100 mm');

[x, y] = ginput(2);

pixelPerMm = sqrt((x(2)-x(1))^2 + (y(2)-y(1))^2) / 100;

close;

end

enhanced = adapthisteq(image);

inverted = imcomplement(enhanced);

bw = imbinarize(inverted, 'adaptive', 'Sensitivity', 0.2);

se = strel('disk', structuringElementSize);

bw = imclose(bw, se);

bw = imfill(bw, 'holes');

bw = bwareaopen(bw, minRegionSize);

[rows, cols] = size(bw); center = [cols, rows] / 2; [X,Y] = meshgrid(1:cols, 1:rows); r = sqrt((X - center(1)).^2 + (Y - center(2)).^2); bw(r > (50 * pixelPerMm)) = 0;

D = -bwdist(~bw); D(~bw) = -Inf; L = watershed(D); bw(L==0) = 0;

labeled = bwlabel(bw);

stats = regionprops(labeled, 'Ar-ea','BoundingBox','Centroid','MajorAxisLength', ...

'MinorAxisLength','Perimeter','PixelIdxList');

areas_mm2 = [stats.Area] / pixelPerMm^2;

compactness = (4 * pi * [stats.Area]) ./ ([stats.Perimeter].^2);

valid = [];

for i = 1:numel(stats)

pix = stats(i).PixelIdxList;

regionVals = double(grayImage(pix));

borderMask = imdilate(labeled == i, strel('disk',2)) & ~(labeled == i);

backgroundVals = double(grayImage(borderMask));

if isempty(regionVals) || isempty(backgroundVals), continue; end

contrastDiff = abs(mean(regionVals) - mean(backgroundVals));

if areas_mm2(i) >= minRegionArea_mm2 && areas_mm2(i) <= maxRegionArea_mm2 && ...

compactness(i) > minCompactness && contrastDiff >= minContrast

valid(end+1) = i;

end

end

stats = stats(valid);

labeled = ismember(labeled, valid);

groupLabels = 1:numel(stats);

minBoxDistance = @(b1, b2) sqrt( ...

max(0, max(b1(1), b2(1)) - min(b1(1)+b1(3), b2(1)+b2(3)))^2 + ...

max(0, max(b1(2), b2(2)) - min(b1(2)+b1(4), b2(2)+b2(4)))^2 );

changed = true;

while changed

changed = false;

for i = 1:numel(stats)

for j = i+1:numel(stats)

d = minBoxDistance(stats(i).BoundingBox, stats(j).BoundingBox) / pixelPerMm;

if d <= groupingDistance && groupLabels(i) ~= groupLabels(j)

minLabel = min(groupLabels(i), groupLabels(j));

groupLabels(groupLabels == groupLabels(j)) = minLabel;

changed = true;

end

end

end

end

for g = unique(groupLabels)

idx = find(groupLabels == g);

coords = reshape([stats(idx).Centroid], 2, []).';

span_mm = max(pdist(coords)) / pixelPerMm;

if numel(idx) >= minGroupSize && span_mm >= minGroupSpan_mm

shape = "Grouped"; status = "FAIL (Grouped)";

else

for k = idx

major = stats(k).MajorAxisLength / pixelPerMm;

minor = stats(k).MinorAxisLength / pixelPerMm;

aspect = major / minor;

shape = "Non-linear"; status = "PASS"; sizeVal = (major + minor)/2;

if aspect >= aspectRatioThreshold && major > 2

shape = "Linear"; sizeVal = major; status = "FAIL";

elseif sizeVal > crit.nonlinearMax

status = "FAIL";

end

end

end

end

imshow(image); hold on;

for i = 1:length(results)

box = results(i).BoundingBox;

switch results(i).Shape

case "Linear", col = [1 0.2 0.2];

case "Non-linear", col = [0.2 1 0.2];

case "Grouped", col = [0.2 0.5 1];

otherwise, col = [0.8 0.8 0.8];

end

rectangle('Position', box, 'EdgeColor', col, 'LineWidth', 2);

text(box(1), box(2)-10, num2str(results(i).Index), 'Color', col, ...

'FontSize', 9, 'FontWeight', 'bold');

end

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ratkovac, M.; Gerards-Wunsche, P.; Thiele, M.; Brackrock, D.; Stamm, M. Detection and monitoring of fatigue crack growth on welds—Application-oriented use of NDT methods. Procedia Struct. Integr. 2024, 57, 560–568. [Google Scholar] [CrossRef]

- Deepak, J.R.; Bupesh Raja, V.K.; Srikanth, D.; Surendran, H.; Nickolas, M.M. Non-destructive testing (NDT) techniques for law carbon steel welded joints: A review and experimental study. Mater. Today Proc. 2021, 44, 3732–3737. [Google Scholar] [CrossRef]

- Aramburu, A.B.; da Cruz, J.A.; da Silva, A.A.X.; Acosta, A.P.; Minillo, L.Q.; de Avila Delucis, R. Non-destructive testing techniques for pressure vessels manufactured with polymer composite materials: A systematic review. Measurement 2025, 246, 116729. [Google Scholar] [CrossRef]

- Waqar, M.; Memon, A.M.; Sabih, M.; Alhems, L.M. Composite pipelines: Analyzing defects and advancements in non-destructive testing techniques. Eng. Fail. Anal. 2024, 157, 107914. [Google Scholar] [CrossRef]

- Pasupulla, A.P.; Agisho, H.A.; Seetharaman, S.; Vijayakumar, S. Characterization and analysis of TIG welded stainless steel 304 alloy plates using radiography and destructive testing techniques. Mater. Today Proc. 2022, 51, 935–938. [Google Scholar] [CrossRef]

- Yenumula, L.; Acharya, R.V.; Lingade, B.M.; Borgohain, A.; Maheshwari, N.K.; Kumar, U.; Selvam, T.P.; Dash, A. Radiographic evaluation of gas tungsten arc welding joints used in nuclear applications by X- and gamma-rays. NDT E Int. 2019, 102, 144–152. [Google Scholar] [CrossRef]

- Song, Z.; Du, K.; Li, K.; Wang, F.; Xu, M.; Ma, C.; Xiao, T. Nondestructive testing of defects at pixel level with move contract X-ray imaging. NDT E Int. 2025, 155, 103400. [Google Scholar] [CrossRef]

- Lin, L.; Xie, M.; Wang, J.; Li, X.; Chen, F.; Wang, Y.; Xing, F.; Bai, Y. Enhancing carbonation assessment in cementitious materials using X-ray computed tomography: A greyscale calibration approach. Constr. Build. Mater. 2025, 489, 142234. [Google Scholar] [CrossRef]

- Assias, S.L.G.; Camerini, C.G.; Kotik, H.G.; Ipina, J.E.P. 3D characterization of splits in tested fracture mechanics specimens using X-ray computed tomography. JTMS 2024, 5, 100033. [Google Scholar] [CrossRef]

- Revenko, A.G.; Tsvetyansky, A.L.; Eritenko, A.N. X-ray fluorescence analysis of solid-state films, layers, and coatings. Rad. Phys. Chem. 2022, 197, 110157. [Google Scholar] [CrossRef]

- Valdez, J.J.R.; De la Cruz Terrazas, E.C.; Conzalez, E.R. Design, construction and Programming of a low-cost pulsed high-voltage direct current power supply for the electrophoretic deposition of silicon carbide mixed with graphite and/or alumina for thermoelectric applications. Inventions 2024, 9, 40. [Google Scholar] [CrossRef]

- Kohlscheen, J.; Bareiss, C. Combinatorial deposition and wear testing of HiPIMS W-C films. Coatings 2025, 15, 115. [Google Scholar] [CrossRef]

- Aliasghari, S.; Skeldon, P.; Zhou, X.; Gholinia, A.; Zhang, X.; Valizadeh, R.; Pira, C.; Junginger, T.; Burt, G.; Withers, P.J. X-ray computed tomographic and focused ion beam/electron microscopic investigation of coating defects in niobium coated copper superconducting radio-frequency cavities. Mater. Chem. Phys. 2021, 273, 125062. [Google Scholar] [CrossRef]

- Ferreira, C.G.; Lopes, R.T.; dos Santos, T.M.P.; Oliveira, D.F.; Martins, F.D.F.; Pereira, G.R. Non-destructive inspection of laminated pipe joints in polymeric composite material reinforced by fiberglass. Nucl. Instrum. Meth. A 2020, 954, 161154. [Google Scholar] [CrossRef]

- Florian, T.; Schricker, K.; Zenz, C.; Otto, A.; Schmidt, L.; Diegel, C.; Friedmann, H.; Seibold, M.; Hellwig, P.; Frohlich, F.; et al. Combining in situ synchrotron X-ray imagining and Multiphysics simulation to reveal pore formation dynamics in laser welding of copper. Int. J. Mach. Tools Manuf. 2025, 204, 104224. [Google Scholar] [CrossRef]

- Moreno, M.; Andersson, J.M.; Eriksson, J.; Alm, P.; Hedstrom, K.; Saoubi, R.M.; Schramm, I.C.; Schell, N.; Johansson-Joessar, M.P.; Oden, M.; et al. Strain and phase evolution in TiAIN coatings during high-speed metal cutting: An in operando high-energy x-ray diffraction study. Acta Mater. 2024, 263, 119538. [Google Scholar] [CrossRef]

- Sun, S.; Miller, J.D.; Choi, Y.R.; Turk, S.; Donnelly, D. Detectability by X-ray micro computed tomography of fatigue initiating void defects in laser powder-bed additively manufactured Ti-6Al-4V coupons. Addit. Manuf. 2024, 81, 103986. [Google Scholar] [CrossRef]

- Hu, Y.; He, N.; Xie, L.; Chen, D.; Gao, C.; Ding, H. Improved automatic defect detection from X-ray scans for aluminum conductor composite core wire based on modified Skip-GANomaly. NDT E Int. 2024, 143, 103050. [Google Scholar] [CrossRef]

- Hangai, Y.; Kawato, D.; Ando, M.; Ohashi, M.; Morisada, Y.; Ogura, T.; Fujii, H.; Nagahiro, R.; Amagai, K.; Utsunomiya, T.; et al. Nondestructive observation of pores during press forming of aluminum foam by X-ray radiography. Mater. Charact. 2020, 170, 110631. [Google Scholar] [CrossRef]

- Gorgannejad, S.; Martin, A.A.; Nicolino, J.W.; Strantza, M.; Guss, G.M.; Khairallah, S.; Forien, J.-B.; Thampy, V.; Liu, S.; Quan, P.; et al. Localized keyhole pore prediction during laser powder bed fusion via multimodal process monitoring and X-ray radiography. Addit. Manuf. 2023, 78, 103810. [Google Scholar] [CrossRef]

- Sufian, A.; Russell, A.R. Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int. J. Rock Mech. Min. Sci. 2013, 57, 119–131. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Roveda, I.; Kupsch, A.; Muller, B.R.; Bruno, G. Synchrotron X-ray refraction detects microstructure and porosity evolution during in-situ heat treatment. Mat. Sci. Eng. A Struct. 2022, 838, 142732. [Google Scholar] [CrossRef]

- Galos, J.; Ghaffari, B.; Hetrick, E.T.; Jones, M.H.; Benoit, M.J.; Wood, T.; Sanders, P.G.; Easton, M.A.; Mouritz, A.P. Novel non-destructive technique for detecting the weld fusion zone using a wire of high x-ray contract. NDT E Int. 2021, 124, 102537. [Google Scholar] [CrossRef]

- Liu, M.; Xie, J.; Hao, J.; Zhang, Y.; Chen, X.; Chen, Y. A lightweight and accurate recognition framework for signs of X-ray weld imagines. Comput. Ind. 2022, 135, 103559. [Google Scholar] [CrossRef]

- Nielsen, M.-A.; Gloy, J.F.; Lott, D.; Sun, T.; Muller, M.; Staron, P. Automatic melt pool recognition in X-ray radiography images from laser-molten Al alloy. J. Mater. Res. Technol. 2022, 21, 3502–3513. [Google Scholar] [CrossRef]

- Cho, H.M.; Cho, H.S.; Kim, K.S.; Lim, H.W.; Park, S.Y.; Lee, S.R.; Kim, K.C.; Je, U.K.; Park, Y.O.; Hong, D.K.; et al. Experimental study on the application of a compressed-sensing (CS)-based deblurring method in x-ray nondestructive testing and its image performance. NDT E Int. 2015, 75, 1–7. [Google Scholar] [CrossRef]

- Kim, K.S.; Kang, S.Y.; Kim, W.S.; Cho, H.S.; Park, C.K.; Lee, D.Y.; Kim, G.A.; Park, S.Y.; Lim, H.W.; Lee, H.W.; et al. Improvement of radiographic visibility using an image restoration method based on a simple radiographic scattering model for x-ray nondestructive testing. NDT E Int. 2018, 98, 117–122. [Google Scholar] [CrossRef]

- Forien, J.-B.; Calta, N.P.; DePond, P.J.; Guss, G.M.; Roehling, T.T.; Mattews, M.J. Detecting keyhole pore defects and monitoring process signature during laser powder bed fusion: A corelation between in situ pyrometry and ex situ X-ray radiography. Addit. Manuf. 2020, 35, 101336. [Google Scholar] [CrossRef]

- Ramirez, I.S.; Marquez, F.P.G.; Papaelias, M. Review on additive manufacturing and non-destructive testing. J. Manuf. Syst. 2023, 66, 260–286. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, R.; Yao, J.; Zhang, Q.; Wang, L. Stellite alloy mixture hardfacing via laser cladding for control valve seat sealing surfaces. Surf. Coat. Tech. 2017, 329, 97–108. [Google Scholar] [CrossRef]

- Nowodzinski, A.; Ndjoye-Kogou, O.; Mourier, V.; Nonglaton, G.; Bouchu, D.; Fain, B.; Giroud, S. Capacitive micromachined ultrasonic transducers leak detection by dye penetrant test. Microelectron. Reliab. 2020, 114, 113908. [Google Scholar] [CrossRef]

- Guirong, X.; Xuesong, G.; Yuliang, Q.; Yan, G. Analysis and innovation for penetrant testing for airplane parts. Procedia Eng. 2015, 99, 1438–1442. [Google Scholar] [CrossRef]

- Tan, Y.T.; Yu, T.; Dutta, S.; Sinha, A.; Feirstein, D.; Lizotte, A.; Karigiannis, J.; Liu, S.; Chang, Q. Hierarchical robot learning method for industrial fluorescent penetrant inspection. Manuf. Lett. 2024, 41, 1334–1341. [Google Scholar] [CrossRef]

- Shipway, N.J.; Huthwaite, P.; Lowe, M.J.S.; Barden, T.J. Using ResNets to perform automated defect detection for fluorescent penetrant inspection. NDT E Int. 2021, 119, 102400. [Google Scholar] [CrossRef]

- Stolt, R.; Elgh, F.; Andersson, P. Design for inspection—Evaluating the inspectability of aerospace components in the early stages of design. Procedia Manuf. 2017, 11, 1193–1199. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, X.; Rao, X.; Yuan, C. Effect of defects on the structural integrity of ship piping welds under simulated piping conditions. Ocean Eng. 2024, 308, 118372. [Google Scholar] [CrossRef]

- Jalaja, K.; Ranjith, R.; Krishna, S.C.; Manwatkar, S.K.; Gupta, R.K.; Karhikeyan, M.K.; Bajargan, G. Investigation of crack-like defect in 15CDV6 (ESR) steel forging for aerospace applications. Eng. Fail. Anal. 2024, 159, 108040. [Google Scholar] [CrossRef]

- de Oliveira, B.J.S.; Campanelli, L.C.; Oliveira, D.P.; de Bribean Guerra, A.P.; Bolfarini, C. Surface characterization and fatigue performance of a chemical-etched Ti-wAl-4V femoral stem for cementless hip arthroplasty. Surf. Coat. Techn. 2017, 309, 1126–1134. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, F.Q.; Zhang, L.; Li, J.D.; Zhang, J.W. Microstructure evolution and high temperature corrosion behavior of FeCrBSi coatings prepared by laser cladding. Ceram. Int. 2020, 46, 17233–17242. [Google Scholar] [CrossRef]

- Guo, Y.; Ruhge, F.R. Comparison of detection capability for acoustic thermography, visual inspection and fluorescent penetrant inspection on gas turbine components. In AIP Conf. Proc. Review of Progress in Quantitative Nondestructive Evaluation, Proceedings of the 35th Annual Review of Progress in Quantitative Nondestructive Evaluation, Chicago, IL, USA, 20–25 July 2008; AIP Publishing: Melville, NY, USA, 2009; Volume 1096, pp. 1848–1854. [Google Scholar] [CrossRef]

- Tran, Y.H.; Vo, T.T.G.; Nguyen, N.-N.; Vo, H.V. Investigation of the permeability of concrete by penetration method and numerical analysis. In Proceedings of the Third International Conference on Sustainable Civil Engineering and Architecture, Proceedings of the Sustainable Civil Engineering and Architecture, Da Nang City, Vietnam, 19–21 July 2023; Reddy, J.N., Wang, C.M., Luong, V.H., Le, A.T., Eds.; Springer: Singapore, 2024; pp. 876–883. [Google Scholar]

- Mohamed, A.M.; Tayeh, B.A.; Ahmed, T.I.; Bashir, M.O.; Tobbala, D.E. Influence of nano=silica and nano-ferrite particles on mechanical and durability of sustainable concrete: A review. Nanotechnol. Rev. 2025, 14, 20250151. [Google Scholar] [CrossRef]

- Ismail, M.F.; Sultan, M.T.H.; Hamdan, A.; Shah, A.U.M.; Jawaid, M. Low velocity impact bahaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [Google Scholar] [CrossRef]

- Mozammil, S.; Verma, R.; Karloopia, J.; Jha, P.K. Investigation and measurement of porosity in Al+4.5Cu/6wt%TiB2 in situ composite: Optimization and statistical modelling. J. Mater. Res. Technol. 2020, 9, 8041–8057. [Google Scholar] [CrossRef]

- Deivanai, S.; Soni, M. Non destructive testing and analysis of friction stir welded aluminium alloy 2024 pipes. Mater. Today Proc. 2022, 56, 3721–3726. [Google Scholar] [CrossRef]

- Reddy, K.A. Non-destructive testing, evaluation of stainless steel materials. Mater. Today Proc. 2017, 4, 7302–7312. [Google Scholar] [CrossRef]

- Dell’Avvocato, G.; Rashkovets, M.; Mancini, E.; Contuzzi, N.; Casalino, G.; Palumbo, D.; Galietti, U. Innovative non-destructive thermographic evaluation of mechanical properties in dissimilar aluminium probeless friction stir spot welded (P-FSSW) joints. Eng. Fail. Anal. 2025, 177, 109675. [Google Scholar] [CrossRef]

- Manikandan, K.R.; Sivagurunathan, P.A.; Ananthan, S.S.; Moshi, A.A.M.; Bharathi, S.R.S. Study on the influence of temperature and vibration on indications of liquid penetrant testing of A516 low carbon steel. Mater. Today Proc. 2021, 39, 1559–1564. [Google Scholar] [CrossRef]

- Ou, Y.; Xu, T.; Fan, J.; Xu, B.; Cai, H.; Zhao, J. Vision-based quality evaluation method towards automated penetrant testing. NDT E Int. 2025, 153, 103334. [Google Scholar] [CrossRef]

- Karigiannis, J.; Liu, S.; Harel, S.; Bian, X.; Zhu, P.; Xue, F.; Bouchard, S.; Cantin, D.; Beaudoin-pouliot, M.; Bewlay, B.P.; et al. Multi-robot system for automated fluorescent penetrant indication inspection with deep neural nets. Procedia Manuf. 2021, 53, 735–740. [Google Scholar] [CrossRef]

- Zheng, J.; Xie, W.F.; Viens, M.; Birglen, M.; Mantegh, I. Design of an advanced automatic inspection system for aircraft parts based on fluorescent penetrant inspection analysis. Insight Non-Destr. Test. Cond. Monit. 2015, 57, 18–34. [Google Scholar] [CrossRef]

- Michael, M.; Al Fath, T.; Alexander, V.; Hasibuan, G.C.R.; Syukri, M.; Ginting, M.H.S.; Sidabutar, R.; Dalimunthe, N.F. MATLAB empowered brightness defect prediction system in pulp processing bleaching stage: An empirical modelling approach. Case Stud. Chem. Environ. Eng. 2024, 10, 100934. [Google Scholar] [CrossRef]

- Zou, J.; Li, Z.; Liu, X.; Tong, H. MSCPDPLab: A MATLAB toolbox for transfer learning based multi-source cross-project defect prediction. SoftwareX 2023, 21, 101286. [Google Scholar] [CrossRef]

- Vagga, A.; Aherrao, S.; Pol, H.; Borkar, V. Flow visualization by Matlab based image analysis of high-speed polymer melt extrusion film casting process for determining necking defect and quantifying velocity profiles. Adv. Ind. Eng. Polym. Res. 2022, 5, 1–11. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, J.; Sharma, S.; Li, C.; Krolczyk, G.; Eldin, E.M.T.; Wojciechowski, S. Identification of localized defects and fault size estimation of taper roller bearing (NBC_30205) with signal processing using the Shannon entropy method in MATLAB for automotive industries applications. Heliyon 2022, 8, e12053. [Google Scholar] [CrossRef] [PubMed]

- ISO 3452-1:2021; Non-Destructive Testing—Penetrant Testing. Part 1: General Principles. International Organization for Standartization: Geneve, Switzerland, 2021.

- ISO 17636-1:2022; Non-Destructive Testing of Welds—Radiographic Testing. Part 1: X-and Gamma-Ray Techniques with Film. International Organization for Standartization: Geneve, Switzerland, 2022.

- Niccolai, A.; Caputo, D.; Chieco, L.; Grimaccia, F.; Mussetta, M. Machine learning-based detection technique for NDT in industrial manufacturing. Mathematics 2021, 9, 1251. [Google Scholar] [CrossRef]

- García-Pérez, A.; Gómez-Silva, M.J.; de la Escalera Hueso, A. Automated defect recognition of castings using neural networks. J. Nondestruct. Eval. 2022, 41, 1–15. [Google Scholar] [CrossRef]

- ISO 4386-3:2018; Plain Bearings—Metallic Multilayer Plain Bearings—Part 3: Non-Destructive Penetrant Testing. International Organization for Standartization: Geneve, Switzerland, 2018.

- ISO 5817:2023; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. International Organization for Standartization: Geneve, Switzerland, 2023.

- Lee, S.-H.; Park, S.-J. Automatic detection of welding defects in radiographic images using faster R-CNN. Appl. Sci. 2020, 10, 8629. [Google Scholar] [CrossRef]

- Torbali, M.; Taktak, M.; Polat, Y.; Sabuncu, A.; Aytekin, H.; Karakoc, H.K. A state-of-the-art review of non-destructive testing image fusion and critical insights on the inspection of aerospace composites towards sustainable maintenance repair operations. Appl. Sci. 2023, 13, 2732. [Google Scholar] [CrossRef]

- Say, D.; Zidi, S.; Qaisar, S.M.; Krichen, M. Automated categorization of multiclass welding defects using X-ray image augmentation and convolutional neural network. Sensors 2023, 23, 6422. [Google Scholar] [CrossRef]

- Hütten, N.; Alves Gomes, M.; Hölken, F.; Andricevic, K.; Meyes, R.; Meisen, T. Deep learning for automated visual inspection in manufacturing and maintenance: A survey of open-access papers. Appl. Syst. Innov. 2024, 7, 11. [Google Scholar] [CrossRef]

- Singh, R. Penetrant testing. In Applied Welding Engineering, 3rd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 339–345. [Google Scholar] [CrossRef]

- ISO 3452-2:2021; Non-Destructive Testing—Penetrant Testing. Part 2: Testing of Penetrant Materials. International Organization for Standartization: Geneve, Switzerland, 2021.

- Sahoo, S.K.; Narasimha Rao, R.; Srinivas, K.; Buragohain, M.K.; Sri Chaitanya, C. A novel NDE approach towards evaluating adhesive bonded interfaces. Mater. Today Proc. 2020, 26, 1191–1197. [Google Scholar] [CrossRef]

- Witte Robert, S.; Witte John, S. Statistics, 11th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; p. 496. [Google Scholar]

- ISO 10675-1:2021; Non-Destructive Testing of Welds—Acceptance Levels for Radiography Testing. Part 1: Steel, Nickel, Titanium and Their Alloys. Organization for Standartization: Geneve, Switzerland, 2021.

- Boaretto, N.; Centeno, T.M. Automated detection of welding defects in pipelines from radiographic images DWDI. NDT E Int. 2017, 86, 7–13. [Google Scholar] [CrossRef]

- Yun, G.-h.; Oh, S.-j.; Shin, S.-c. Image preprocessing method in radiographic inspection for automatic detection of ship welding defects. Appl. Sci. 2022, 12, 123. [Google Scholar] [CrossRef]

- Buckman, J.; Bankole, S.A.; Board, S.J.; Bridges, C.J.; Smalley, P.C. Quantifying porosity through automated image collection and batch image processing: Case study of three carbonates and an aragonite cemented sandstone. Geosciences 2017, 7, 70. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 4th ed.; Pearson Education Limited: New York, NY, USA, 2017; p. 1024. ISBN 1-292-22304-9. [Google Scholar]

- Kountchev, R.K.; Todorov, V.; Kountcheva, R. Defects detection in X-ray imagines and photos. In Proceedings of the 10th WSEAS International Conference on Signal Processing, Robotics and Automation, Cambridge, UK, 20–22 February 2011; Available online: https://www.researchgate.net/publication/228638382 (accessed on 4 April 2025).

- Stoev, K. Development of radiographic image processing algorithms at CNL. In Proceedings of the NDT in Canada 2019, Edmonton, AB, Canada, 18–20 June 2019; Available online: https://www.researchgate.net/publication/335169622 (accessed on 7 April 2025).

- Lu, M.; Chen, C.-L. Detection and classification of bearing surface defects based on machine vision. Appl. Sci. 2021, 11, 1825. [Google Scholar] [CrossRef]

- Bora, D.J.; Gupta, A.K.; Khan, F.A. Comparing the performance of L*A*B* and HSV color spaces with respect to color image segmentation. arXiv 2015, arXiv:1506.01472. [Google Scholar]

- Woo, J.; Lee, H. Nonlinear and dotted defect detection with CNN for multi-vision-based mask inspection. Sensors 2022, 22, 8945. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Liu, W.; Yu, X.; Kang, D.; Xiong, Z.; Lv, X.; Huang, S.; Li, Y. Deep learning-based automated detection of welding defects in pressure pipeline radiograph. Coatings 2025, 15, 808. [Google Scholar] [CrossRef]

- Xu, H.; Yan, Z.; Ji, B.; Huang, P.; Cheng, J. Defect detection in welding radiographic images based on semantic segmentation methods. Measurement 2022, 188, 110569. [Google Scholar] [CrossRef]

- Song, Y.; Wu, X. An analytical solution for vertical coils near a multi-layered metallic pipe in Pulsed Eddy Current Testing. NDT E Int. 2022, 125, 102570. [Google Scholar] [CrossRef]

- Zhu, P.; Cheng, Y.; Banerjee, P.; Tamburrino, A. A novel machine-learning model for eddy-current testing with uncertainty estimation. NDT E Int. 2019, 101, 104–112. [Google Scholar] [CrossRef]

- Prabhakar, D.V.N.; Sreenivasa Kumar, M.; Gopala Krishna, A. A novel hybrid transform approach with integration of fast fourier, discrete wavelet and discrete shear let transforms for prediction of surface roughness on machined surfaces. Measurement 2020, 164, 108011. [Google Scholar] [CrossRef]

- Lujan-Moreno, G.A.; Howard, P.R.; Rojas, O.G.; Montgomery, D.C. Design of experiments and response surface methodology to tune machine learning hyperparameters, with a random forest case-study. Expert Syst. Appl. 2018, 109, 195–205. [Google Scholar] [CrossRef]

| Chemical element | Fe | Al | Cu | As | Pb | Zn | Sb | Bi | Sn |

| Amount [wt.%] | 0.090 | 0.002 | 5.60 | 0.007 | 0.094 | 0.006 | 13.40 | 0.001 | Bal. |

| Row No | Name of Equipment | Manufacturer, Model Name | Technical Characteristics, Specification |

|---|---|---|---|

| 1 | X-ray radiographer | Teledyne ICM SiteX D1802 | 0.8 × 0.8 mm (EN 12543-2:2021) |

| 2 | Negatoscope | Kowolux M1 (NDT Supply. Com, Inc., 7952 Nieman Road, Lenexana, KS, USA) | Optical density up to 4.15 |

| 3 | Densitometer | Kowotest Densorapid D (NDT Supply. Com, Inc., 7952 Nieman Road, Lenexana, KS, USA) | Optical density up to 5.0 |

| 4 | X-ray film | Carestream Industrex MX125 contacktpak | C3 (EN ISO 11699-1:2008) lead (Pb) |

| 5 | Screens for radiation suppression | Lead (Pb) | Front—0.027; rear—0.027; additional distance from the rear—0.2 mm |

| 6 | Film-developing apparatus | DURR XR 24 NDT | Automatic |

| 7 | Developer volume | XR D NDT Developer | - |

| 8 | Fixer volume | XR F NDT Fixer | - |

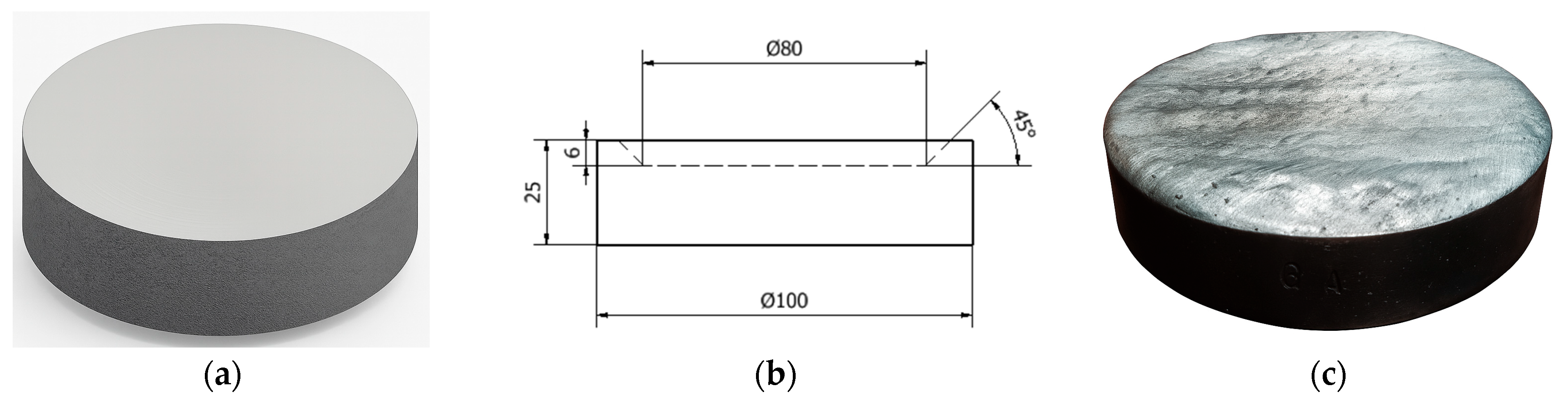

| Row No. | Parameter | Set/Controlled Value | Notes |

|---|---|---|---|

| 1 | Ambient temperature, °C | +20 °C | Rh 25% |

| 2 | Illumination, lx | 500 lx | Artificial |

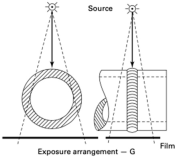

| 3.1 | Test scheme according to EN | No. 11/12  | EN ISO 17636-1:2022 |

| 3.2 | ASME test scheme | T-271.2(b)(2) | ASME BPVC Section V edition 2021 |

| 4 | Object thickness, mm | 25.00 mm | Primary metal with coating |

| 5 | Object material(s) | White metal/carbon steel | 2 materials |

| 6 | Focal length, mm | 500 mm | Fixed |

| 7 | Anode voltage, kV | 180 kV | Max. 180 kV |

| 8 | Anode current, mA | 2.0 mA | Max. 3 mA, at 180 kV—2 mA |

| 9 | Exposure time, min | 9.6 min | SiteX software |

| 10 | Sensitivity indicator position | From the source | Points 3.1 and 3.2 |

| 11 | Sensitivity indicator type | 10FEEN | ISO 19232-1:2013 |

| 12 | Sensitivity indicator minimum sensitivity | W14 | ISO 19232-1:2013 |

| 13 | Film sensitivity, mm | 0.016 mm | ISO 19232-1:2013 |

| 14 | Resulting optical density | 2.8 | Kowotest Densorapid D |

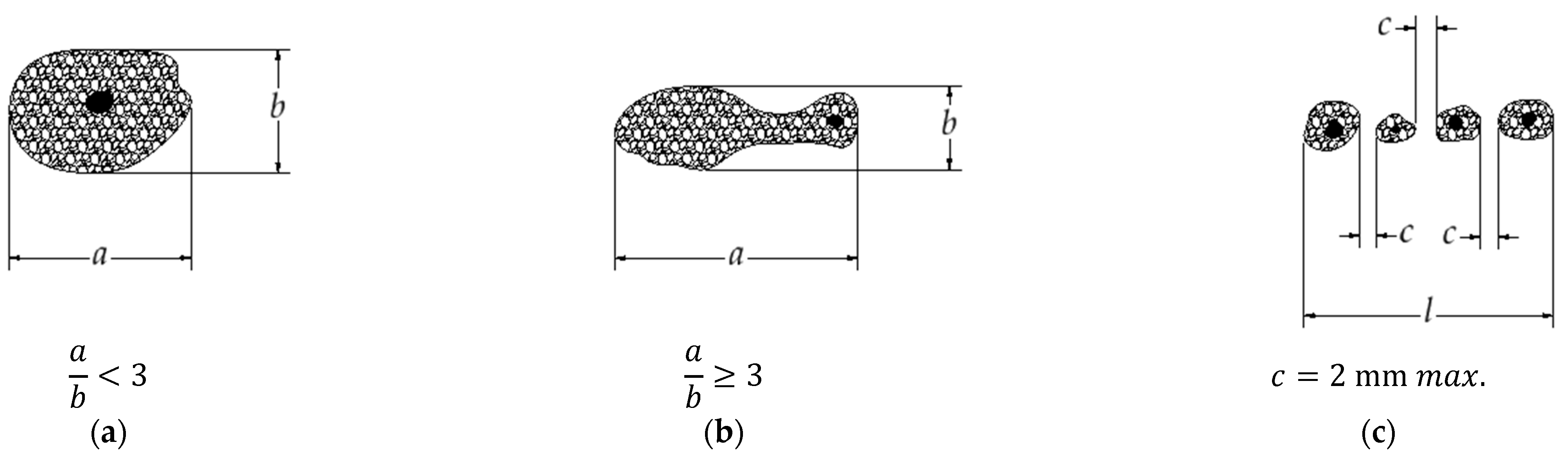

| Indication Type | Evaluation Criteria | ||||

|---|---|---|---|---|---|

| A | B | C | D | E | |

| Linear indication | Not allowed | Not allowed | Not allowed | Not allowed | a > 7 mm |

| Non-linear indication | a > 3 mm | a > 4 mm | a > 5 mm | a > 6 mm | a > 8 mm |

| Grouped indications | Not allowed | Not allowed | Not allowed | l > 10 mm | l > 16 mm |

| Non-linear indications per area | 2/6.3 dm2 | 4/16 dm2 | 6/40 dm2 | 11/100 dm2 | 20/250 dm2 |

| Maximum indication area | 10 mm2/dm2 | 20 mm2/dm2 | 50 mm2/dm2 | 125 mm2/dm2 | 250 mm2/dm2 |

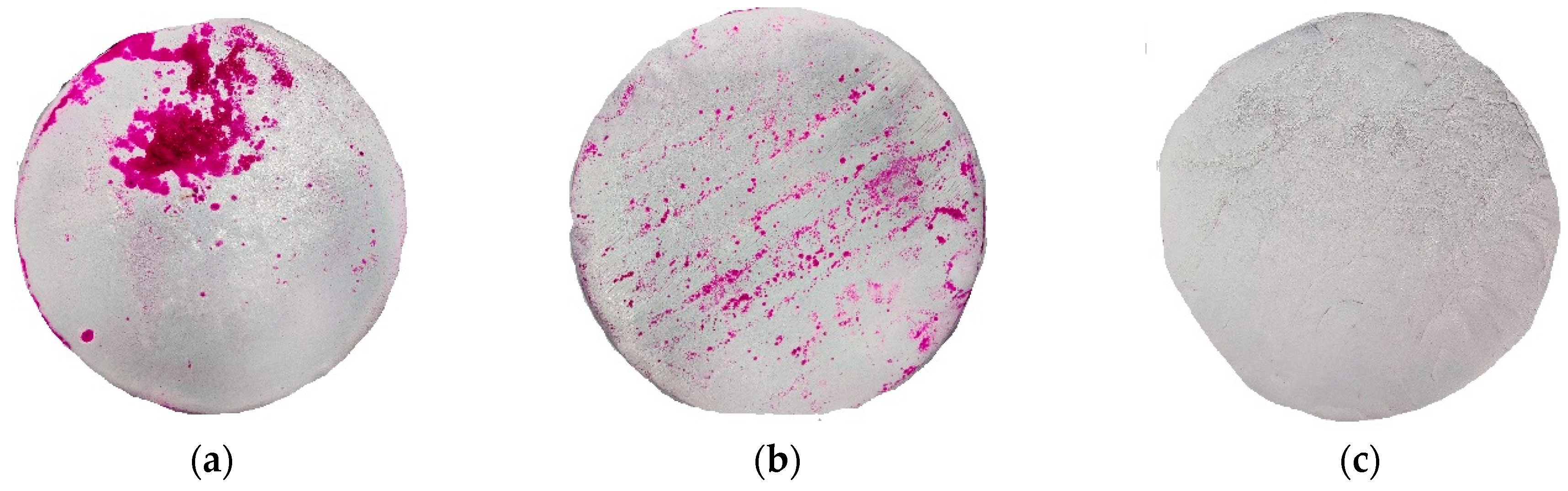

| No. | Results | Image Analysis |

|---|---|---|

| SC Specimen | ||

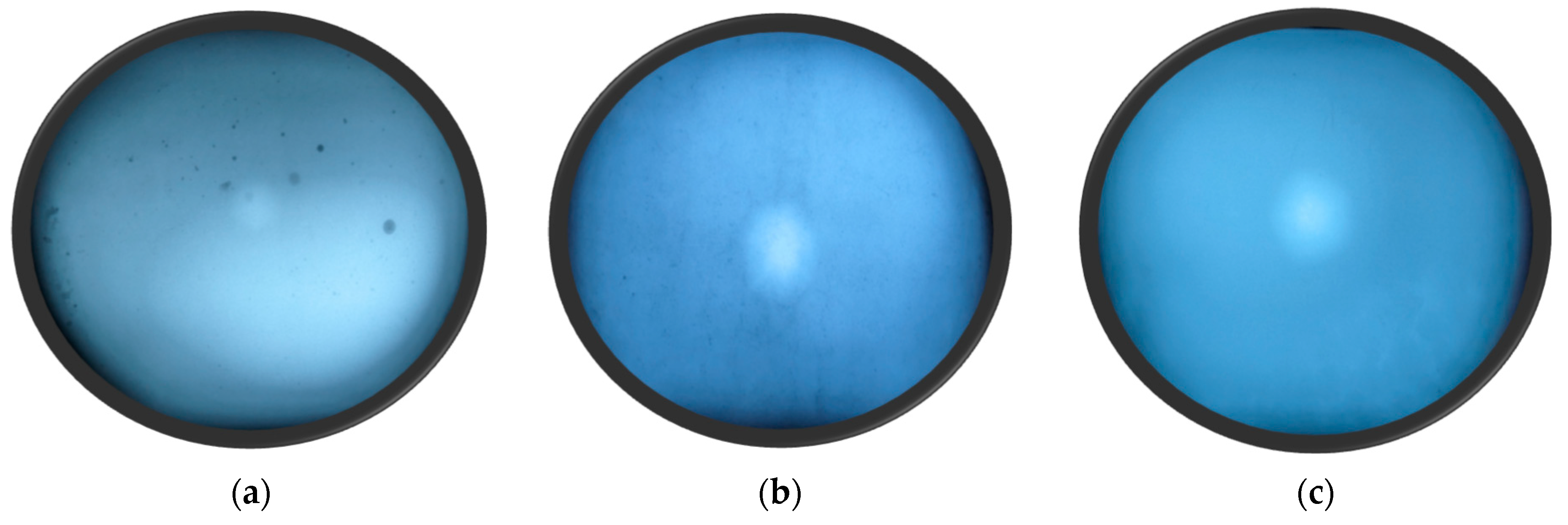

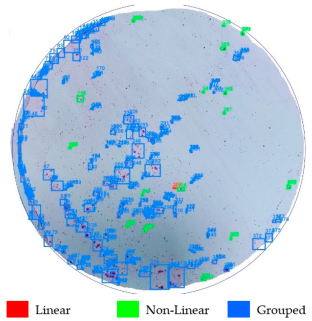

| 1 | Non-linear indications per dm2: 1440.03 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 2852.33 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 1112 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 2240.21 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 2852.33 mm2. | |

| FS Specimen | ||

| 1 | Non-linear indications per dm2: 3278.59 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 2866.98 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 2562 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 2251.72 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 2866.98 mm2. | |

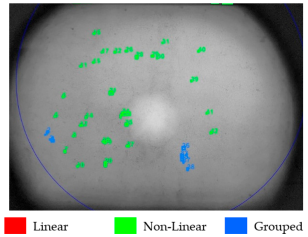

| CW Specimen | ||

| 1 | Non-linear indications per dm2: 53.48 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 8.82 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 32 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 6.93 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 8.82 mm2. | |

| No. | Results | Image Analysis |

|---|---|---|

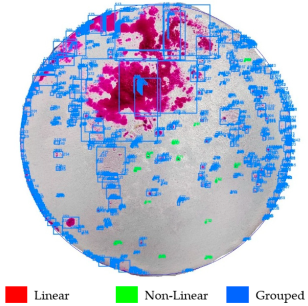

| SC Specimen | ||

| 1 | Non-linear indications per dm2: 315.76 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 243.63 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 209 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 191.35 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 243.63 mm2. | |

| FS Specimen | ||

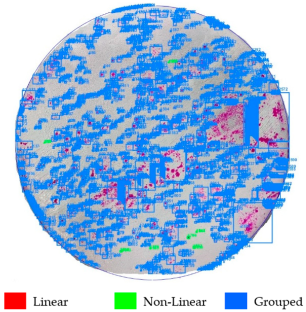

| 1 | Non-linear indications per dm2: 482.56 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 533.53 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 355 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 419.03 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 533.53 mm2. | |

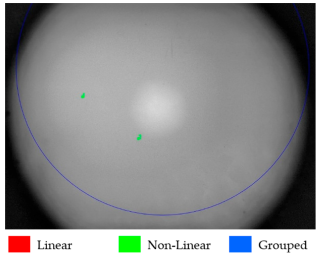

| CW Specimen | ||

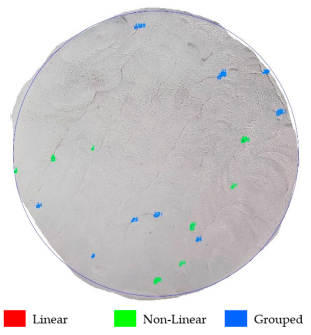

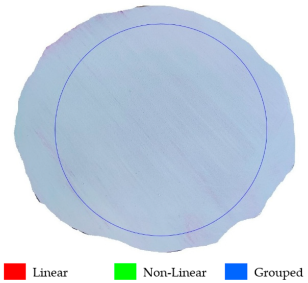

| 1 | Non-linear indications per dm2: 0 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 0 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 0 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 0 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 0 mm2. | |

| No. | Results | Image Analysis |

|---|---|---|

| SC Specimen | ||

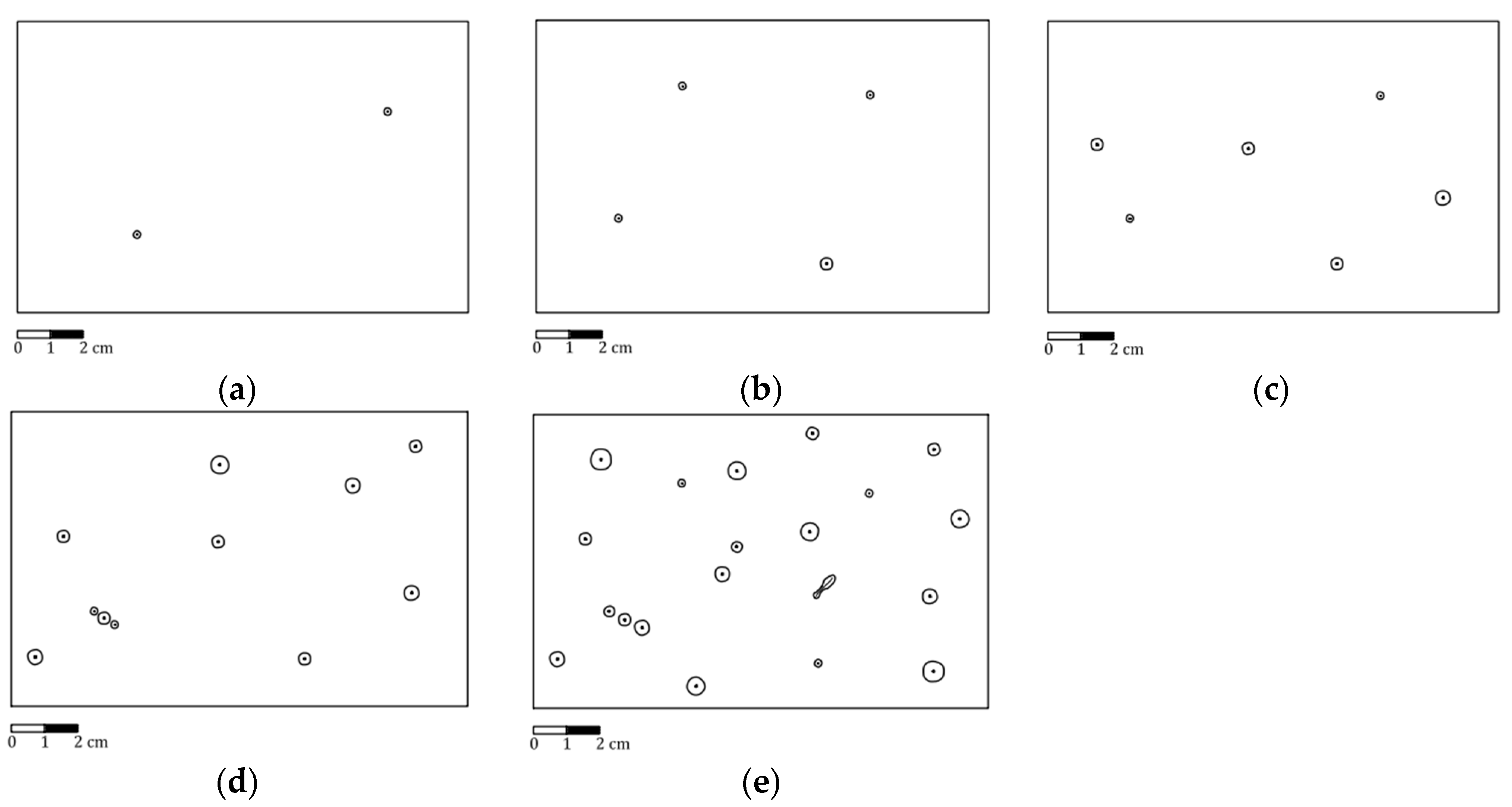

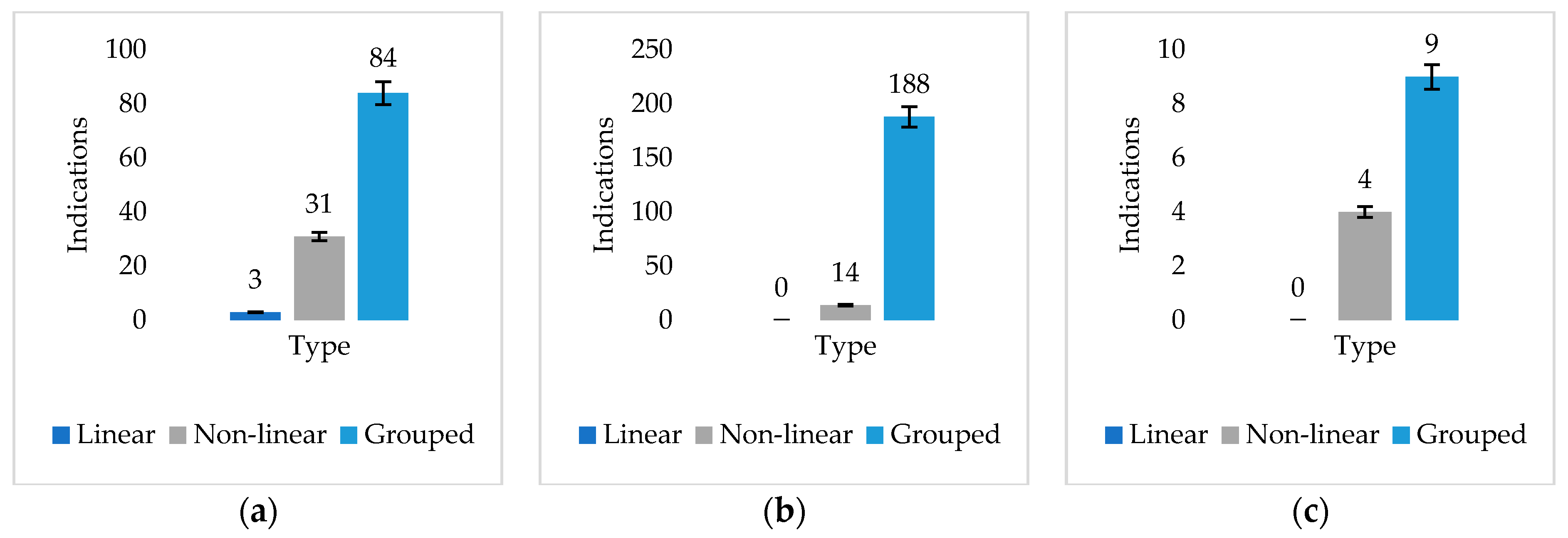

| 1 | Non-linear indications per dm2: 146.42 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 62.25 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 84 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 48.89 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 62.25 mm2. | |

| FS Specimen | ||

| 1 | Non-linear indications per dm2: 257.19 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 402.57 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 188 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 316.17 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 402.57 mm2. | |

| CW Specimen | ||

| 1 | Non-linear indications per dm2: 16.55 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 17.15 mm2. Allowed for level B: 20.00 mm2 | |

| 3 | Grouped indications: 9 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 13.47 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 17.15 mm2. | |

| No. | Results | Image Analysis |

|---|---|---|

| SC Specimen | ||

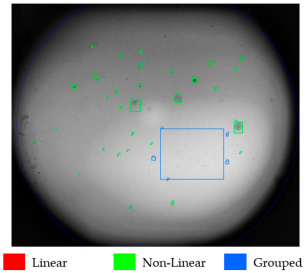

| 1 | Non-linear indications per dm2: 50.93 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 325.44 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 13 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 650.88 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 511.20 mm2. | |

| FS Specimen | ||

| 1 | Non-linear indications per dm2: 56.02 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 48.46 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 20 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 96.93 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 76.12 mm2. | |

| CW Specimen | ||

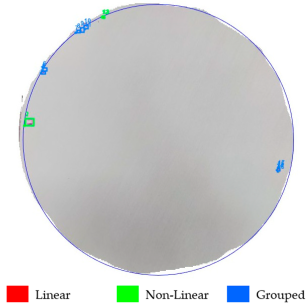

| 1 | Non-linear indications per dm2: 2 pcs. Allowed for level B: 4 pcs per 16 dm2. |  |

| 2 | Indicated area per dm2: 4.97 mm2. Allowed for level B: 20.00 mm2. | |

| 3 | Grouped indications: 0 pcs. Accepted grouped indication: not allowed (level B). | |

| 4 | Total indicated area: 9.91 mm2. Allowed maximum for level B: 20.00 mm2 per dm2. | |

| 5 | Sample area: 0.79 dm2. Indicated area per dm2: 7.81 mm2. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kačinskas, T.; Baskutis, S. Numerical Method for Internal Structure and Surface Evaluation in Coatings. Inventions 2025, 10, 71. https://doi.org/10.3390/inventions10040071

Kačinskas T, Baskutis S. Numerical Method for Internal Structure and Surface Evaluation in Coatings. Inventions. 2025; 10(4):71. https://doi.org/10.3390/inventions10040071

Chicago/Turabian StyleKačinskas, Tomas, and Saulius Baskutis. 2025. "Numerical Method for Internal Structure and Surface Evaluation in Coatings" Inventions 10, no. 4: 71. https://doi.org/10.3390/inventions10040071

APA StyleKačinskas, T., & Baskutis, S. (2025). Numerical Method for Internal Structure and Surface Evaluation in Coatings. Inventions, 10(4), 71. https://doi.org/10.3390/inventions10040071