1. Introduction

In recent decades, the manufacturing industry has evolved significantly with the adoption of new technologies, with collaborative robots (Cobots) emerging as a prominent innovation. Unlike traditional robots designed for repetitive or hazardous tasks in isolated settings, Cobots are engineered to work in close collaboration with human operators. This capability enhances workplace safety, operational flexibility, and productivity, making Cobots suitable for a variety of industrial applications [

1]. Reviews have highlighted Cobots advanced human interaction capabilities, their compliance with safety standards, and their roles in current industrial applications, stressing the importance of proper deployment strategies for maximum efficiency [

2,

3]. The integration of ergonomic design and human factors is essential to optimize Cobot implementation, ensuring safe and productive human-robot interaction [

3]. Cobots contribute significantly to smart manufacturing and Assembly 4.0, where they enhance efficiency, reduce downtime, and minimize operational costs [

4,

5]. The challenges associated with designing and controlling hybrid human-robot systems have been thoroughly studied, with solutions proposed to improve their practical application [

6]. Cutting-edge developments, such as brain-computer interfaces, are being explored to improve communication and control between humans and Cobots, promoting intuitive and user-friendly interfaces [

7]. Future roadmaps emphasize the necessity of strong safety protocols and seamless interaction systems for continued human-robot collaboration [

8]. Optimizing the performance of robotic manipulators is vital for improving Cobot efficiency. Research has shown that the optimization of serial robotic systems, including tendon-driven 4R planar arms, can lead to enhanced flexibility and operational effectiveness [

9,

10]. Parallel robots have also benefited from technological advancements, as demonstrated through the experimental validation of the CaPaMan (Cassino Parallel Manipulator) as an earthquake simulator, showcasing their application in complex dynamic scenarios [

11,

12]. The precision and stability of robotic systems have been enhanced through the mechatronic design and sophisticated control of 3-RPS parallel manipulators, reflecting substantial progress in the field [

13]. Cobots have also made significant advancements in the medical and rehabilitative sectors. Reviews underline their potential to improve patient care, reduce the workload of healthcare professionals, and enhance overall treatment outcomes [

14]. During the COVID-19 pandemic, Cobots were effectively used to minimize healthcare workers’ exposure risks [

15]. Systematic reviews in nursing have pinpointed existing applications and gaps that require further research to expand their use in patient care [

16]. The development of robotic skin technology has contributed to safer and more immersive interactions, improving teleoperation and emotional engagement between users and robotic systems [

17]. In the realm of Healthcare 4.0, Cobots are envisioned to play a crucial role in homecare, providing personalized support and improving the quality of life for patients [

18]. Rehabilitation robotics, focusing on upper limb assistance and cooperative control strategies, have demonstrated improvements in therapeutic efficacy and the optimization of exoskeleton performance [

19,

20,

21]. Safety is a paramount concern in human-robot interactions: reviews emphasize the critical need for stringent safety protocols and industry standards to prevent accidents and ensure reliable integration [

22]. The role of Cobots in Industry 4.0 is transformative, as they offer increased productivity, adaptability, and flexibility [

23]. The anticipated shift towards Industry 5.0 highlights the potential advantages of Cobots over traditional industrial robots, emphasizing their importance in future human-centric manufacturing systems [

24].

Recent advancements in kinematic modelling have significantly enhanced the precision and flexibility of robotic systems. A validated method for inverse kinematics in 6-DOF (degree of freedom) industrial robots with offset and spherical joints offers interactive tools for real-time control [

25]. Additionally, a kinematic model for a 6-DOF manipulator has been experimentally validated, providing a solid foundation for offline programming and calibration [

26]. In collaborative robotics, new kinematic models address both direct and inverse kinematics in shared human-robot tasks, improving system efficiency [

27]. For medical applications, an innovative closed-form solution for inverse kinematics in puncture robotics enhances surgical accuracy and optimizes workspace configurations [

28]. A versatile kinematic analysis for open architecture 6R robot controllers allows for adaptable models across various robot types, proving accurate in both forward and inverse kinematics [

29]. In ecological applications, an improved algorithm for a Tree-Planting Robot significantly enhances trajectory planning and reduces deviation [

30]. Furthermore, a comparative study of kinematic analysis methods using the KUKA manipulator shows that particle swarm optimization achieves the highest accuracy, while RoboAnalyzer is the fastest, highlighting the importance of method selection [

31]. Moreover, innovations in 5-DoF robot designs combining prismatic and revolute joints have shown potential in replacing traditional 6-DoF robots with greater efficiency and cost-effectiveness [

32]. Lastly, improvements in trajectory optimization algorithms, such as an enhanced chicken swarm algorithm, have been validated to improve convergence speed, solution accuracy, and stability in robotic arm applications [

33].

Human-robot interaction has become increasingly important in the context of collaborative robotics, where precise control strategies are essential for effective task execution. In particular, force control techniques play a critical role in ensuring stability and adaptability in dynamic and unstructured environments, as demonstrated in recent studies on rough terrain locomotion [

34] and horizon-stability control for wheel-legged robots [

35].

Thus, although several kinematic models of 6R serial manipulators can be found in literature, instead to merely use commercial and/or available software packages, as RoboDK [

27], RoboAnalyzer and Peter Corke Toolbox [

31], in this paper, a specific parametric and open-source algorithm for the direct and inverse kinematics of a UR5e Cobot has been formulated and implemented in Matlab, with the aim to analyze the UR5e Cobot kinematic performance for simulation purposes of industrial applications. Moreover, in order to obtain a reliable algorithm, this has been experimentally validated in terms of direct and inverse kinematics, by using a UR5e Cobot and reading the corresponding tool and joint positions by the tech-pendant for several robot poses.

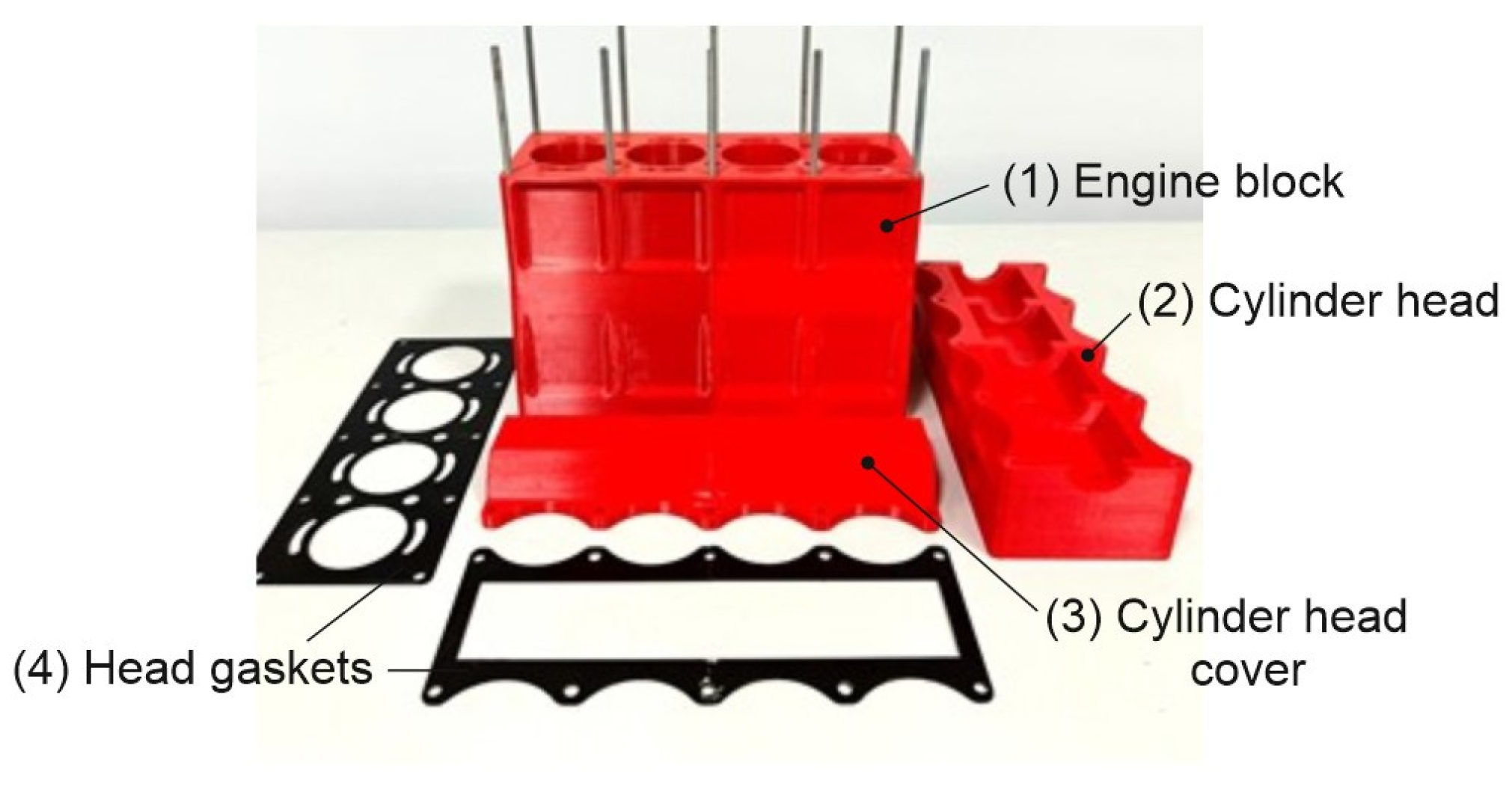

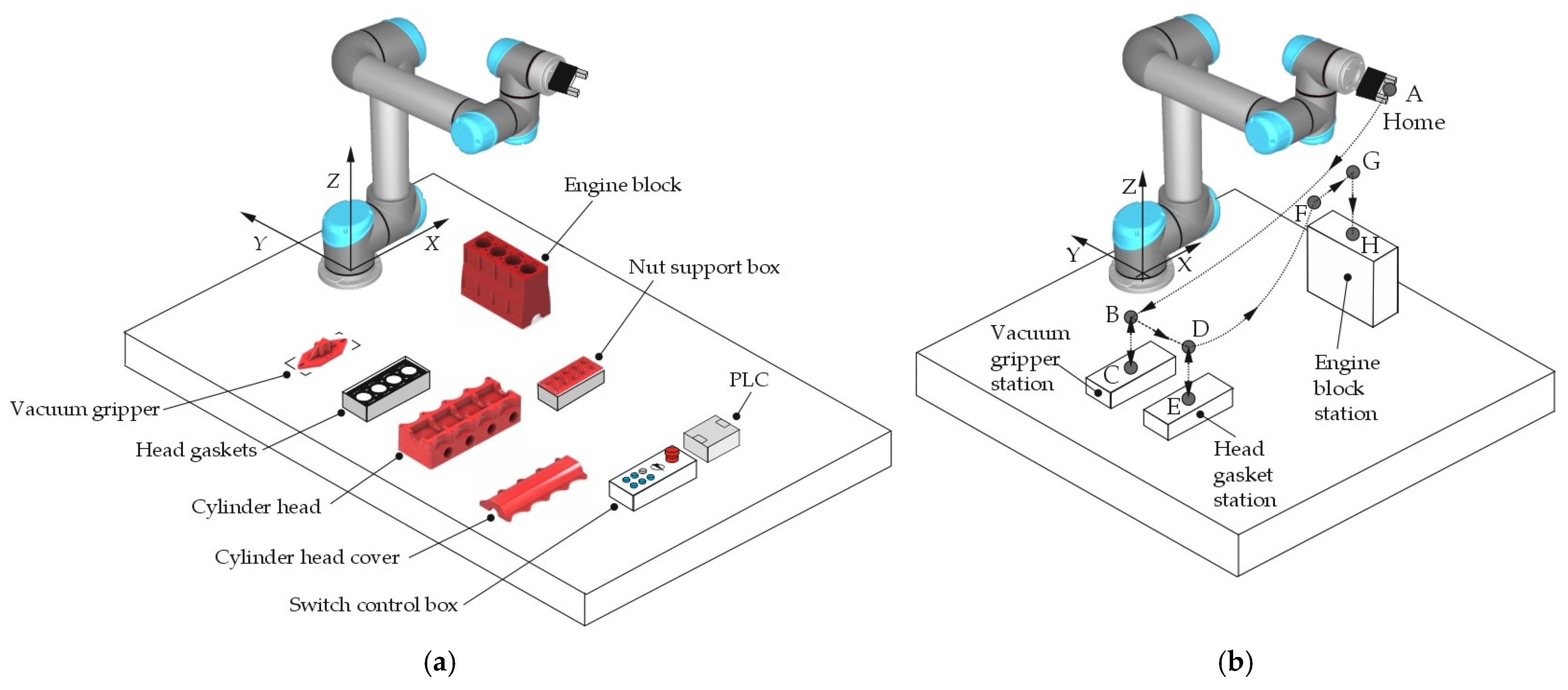

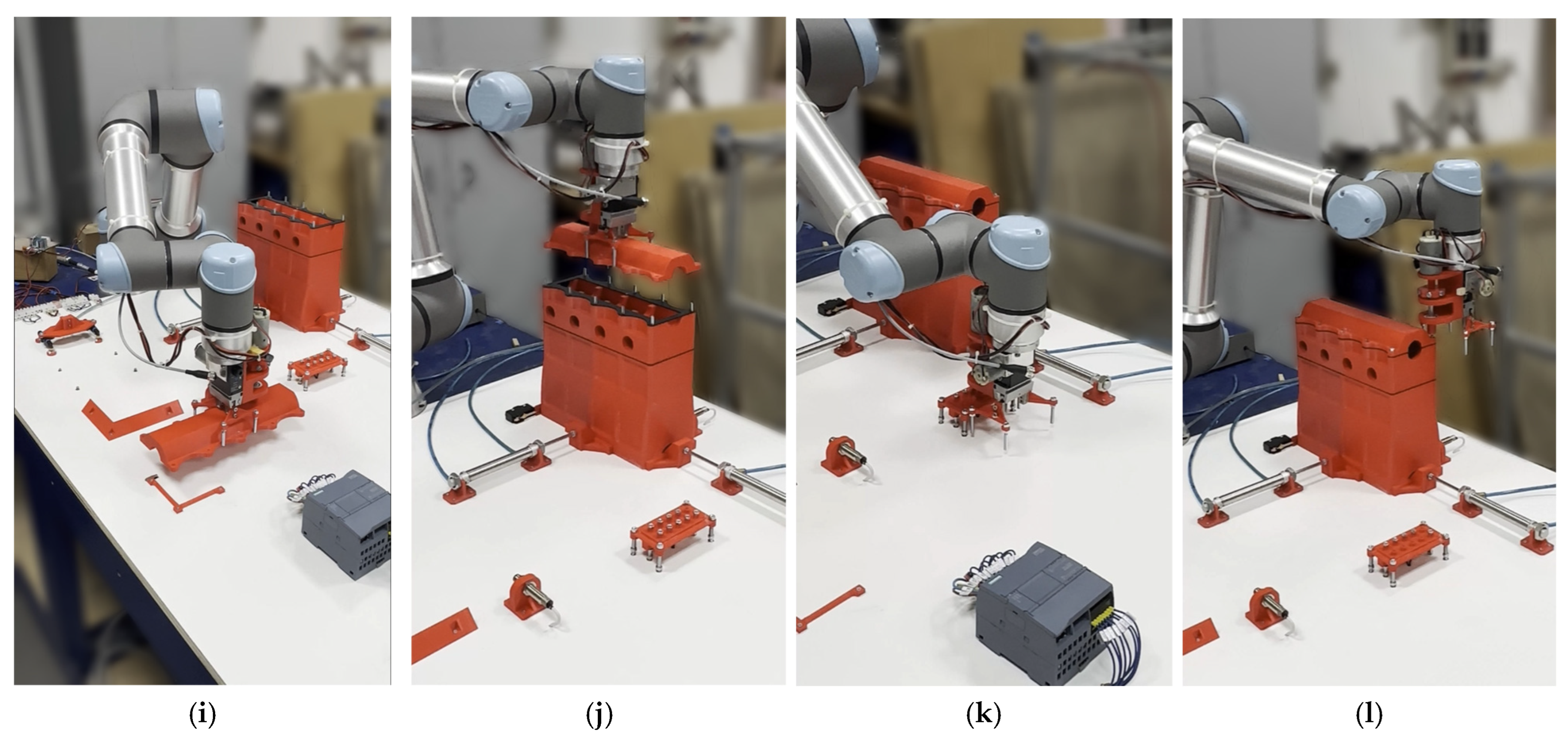

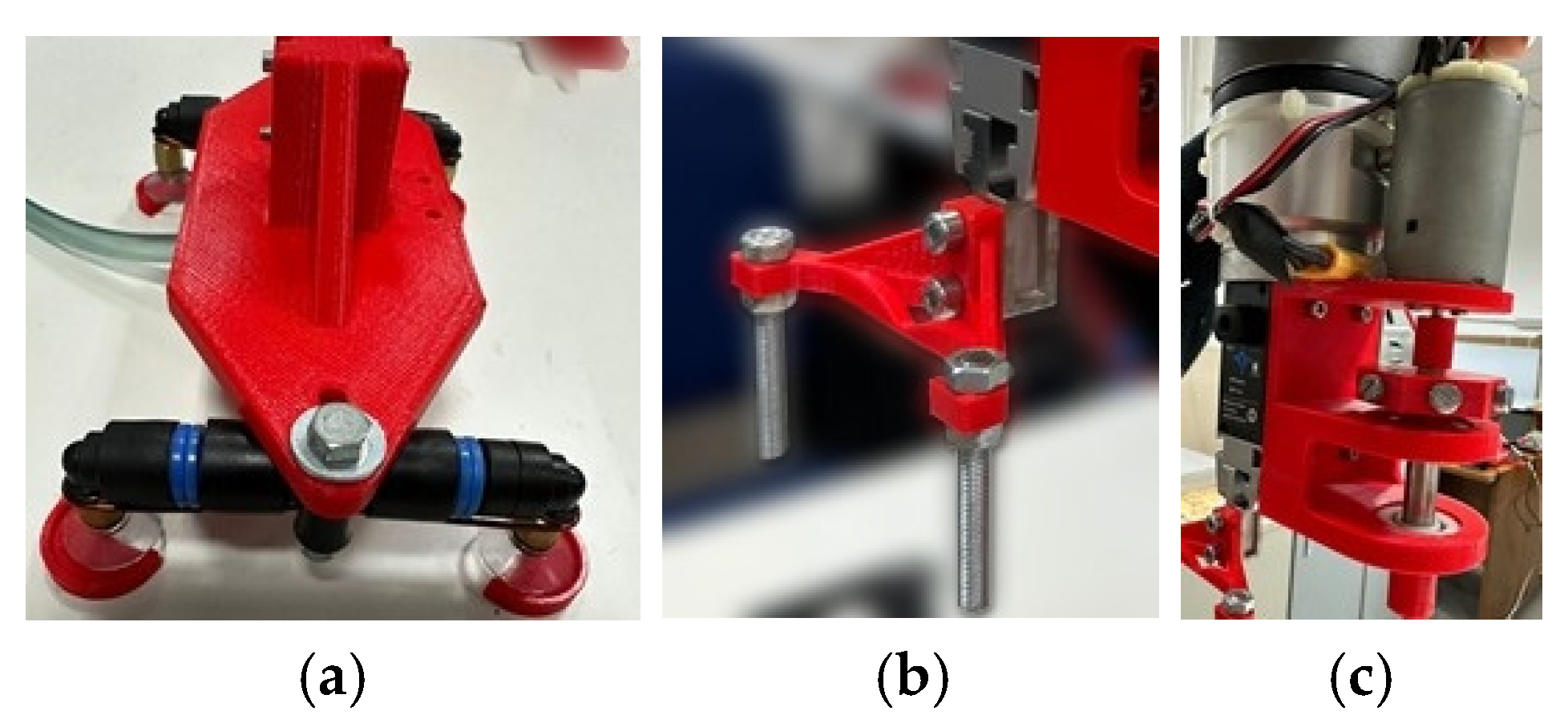

Finally, a specific industrial application regarding the robotized assembling of a multi-cylinder IC engine has been designed in terms of layout, built and experimentally tested. In particular, the IC engine in scale of 1:5 and specific parts of the end-effector, which takes the role of vacuum gripper and torque limiting screwdriver, have been designed and manufactured by using a 3D printer. Thus, the main contributions are:

a suitable parametric and open-source algorithm is formulated by using the inverse matrices only;

this algorithm has been implemented in Matlab, and a numerical validation has been carried out;

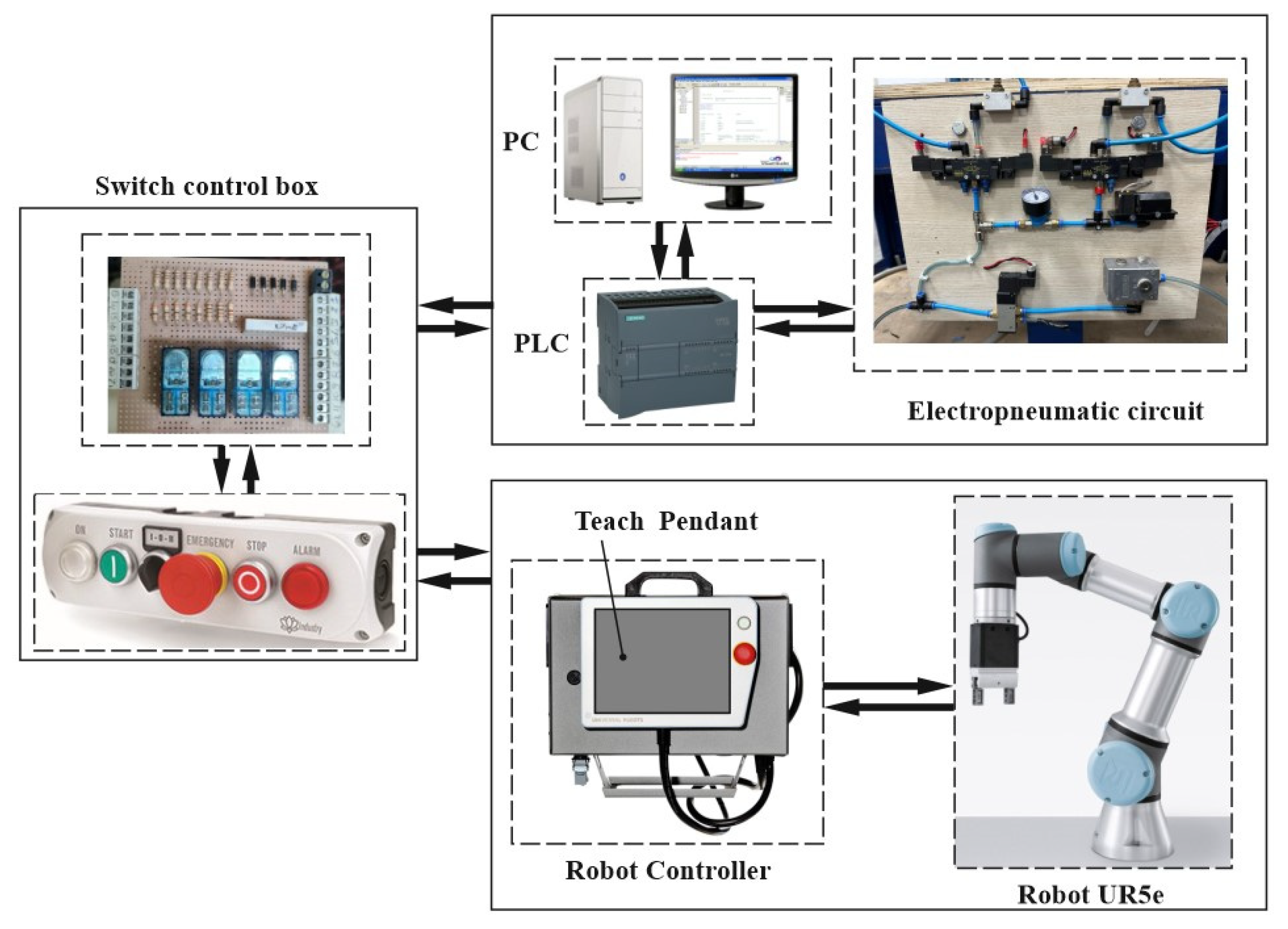

a specific robotized cell that includes novel mechatronics devices has been designed and built at LARM (Lab. of Robotics and Mechatronics) in Cassino;

the proposed algorithm has been also experimentally validated;

the accuracy percentage of the Cobot UR5e has been determined.

The remainder of this paper is structured as follows:

Section 1 introduces the back-ground and motivation for the proposed kinematic model and algorithm.

Section 2 pre-sents the kinematic model of the UR5e Cobot, including both direct and inverse kinemat-ics formulations.

Section 3 describes the experimental setup for the robotized work cell, including the design, implementation, and testing of the multi-cylinder IC engine assem-bly. Finally,

Section 4 concludes the paper, summarizing the main contributions and the experimental validation results.

2. Materials and Methods

The Cobot kinematic model is formulated by using the standard D-H method to define the coordinate system that is attached to each link of the serial chain, along with the four corresponding D-H parameters. Thus, the total homogeneous transformation matrix is obtained between the end-effector moving frame and the fixed base frame.

The direct kinematics (DK) problem is crucial for developing manipulator algorithms, because the joint positions are typically measured by the corresponding sensors, which give the relative position between two consecutive links. Thus, the DK problem is solved by calculating the homogeneous transformation matrix between the end-effector moving frame and the fixed base frame. On the other hand, the inverse kinematics (IK) can be developed by determining the joint variable as function of a given end-effector configuration.

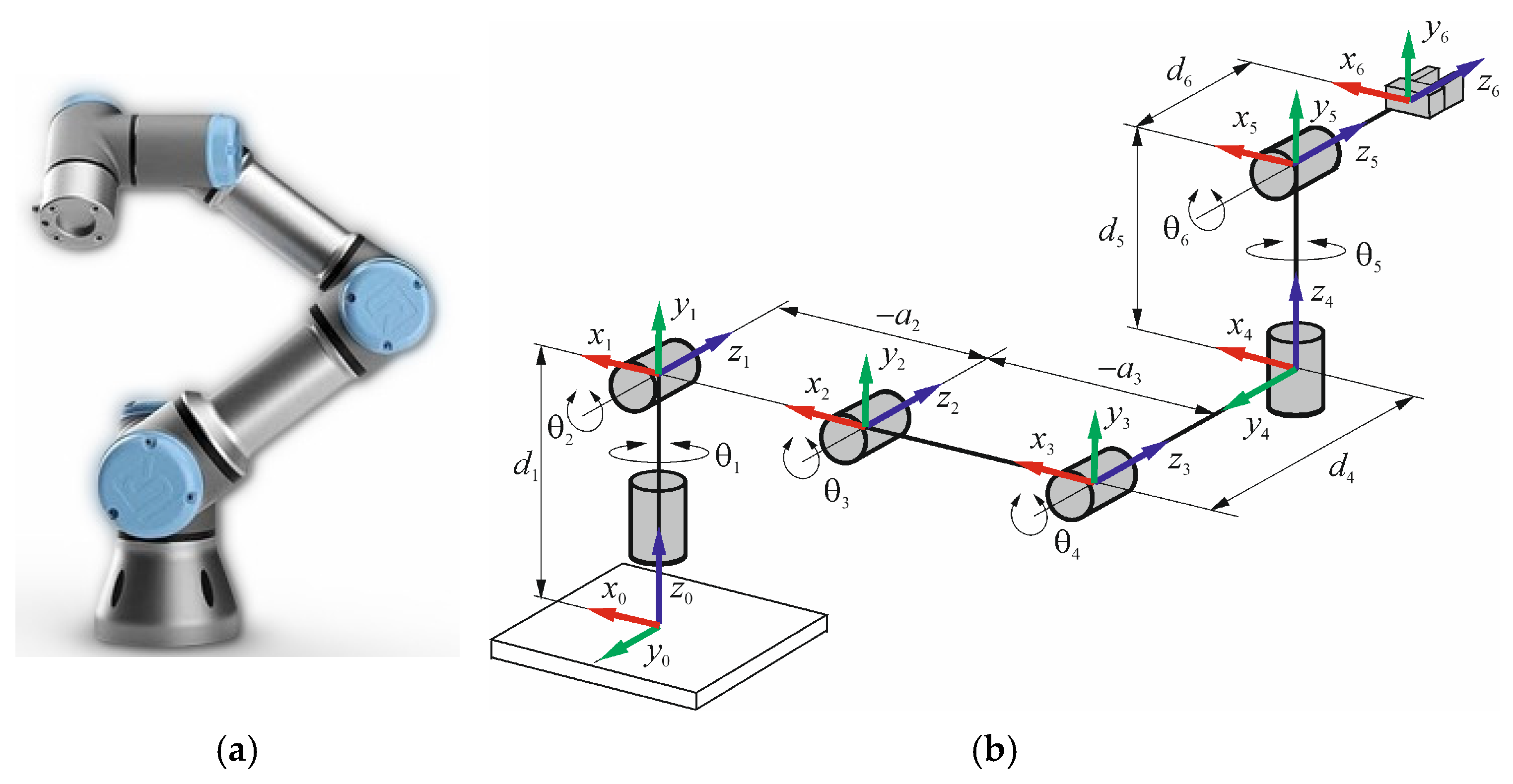

Figure 1 shows a typical 6R serial kinematic chain of 6 (DOFs), which also corresponds to that of the UR5e robotic arm (

Figure 1a), along with D-H reference frames (

Figure 1b). In particular, the fixed frame

x0y0z0 is attached to the robot base, while the

i-th moving frame

xiyizi is considered as attached to the

i-th link for

i = 1, …, 6, where the

zi-axis is along the joint axis direction, the

xi-axis is perpendicular to both

zi and

zi−1 axis, and the

yi-axis is chosen in agreement with the right-hand rule.

The D-H parameters are reported in

Table 1, where

θi represents the joint angle variable of each UR5e joint,

di is the offset of the link, a

i denotes the length of the link,

αi indicates the joint torsion angle, where

i = 1, …, 6 is the joint number.

Thus, the homogeneous transformation matrix between the D-H reference frames that are associated to the joints

i − 1 and

i, takes the form

2.1. Direct Kinematics

The DK problem for a serial kinematic chain consists of finding the position and orientation of the end-effector moving reference frame, when all the joint angles

θi (

i = 1, …, 6) are given. Referring to

Table 1 and Equation (1), the D-H homogeneous transformation matrices are obtained as follows

where c

i and s

i (

i = 1, …, 6) stand for

and

, respectively.

Consequently, the direct kinematics solution is obtained by multiplying in sequence and among them, the six homogeneous transform matrices of the Equation (2), by giving the following

resultant matrix

This can be considered equal to the following 4 × 4 matrix

that includes the noa rotation matrix, whose entries are the Cartesian components of the corresponding unit vectors

n,

o, and

a, respectively, while (

px,

py,

pz) are those of the tool position vector

p.

Thus, equating the corresponding entries of the matrices of Equation (4), one has

where s and c stand for sine and cosine, respectively, and one has

,

,

and

.

2.2. Inverse Kinematics

The IK problem for a serial kinematic chain consists of finding the joint angles

θi (

i = 1, …6) of the serial kinematic chain, when the position and orientation of the end-effector is given in terms of the [

n o a p] homogeneous transformation matrix. The required end-effector pose is given by the Equation (4) and thus, multiplying each side of it by the inverse matrix

, it obtains the following matrix equation

where

is given by

and one has

Similarly, developing the right side of Equation (6), one has

The joint angles

θi for

i = 1, …, 6 are obtained by equating the right sides of the Equations (7) and (8), excluding the fourth row, and thus obtaining a system of 12 non-linear equations, which are coupled two by two, in order to obtain six subsystems of two equations for each. In particular, developing the first subsystem, which is obtained by equating the two entries of the third row with the columns three and four,

θ1 is given by

Likewise, the joint angles

θ5 and

θ6 are obtained by equating the two entries of the third row with the columns one and two. One has

The joint angle

θ234 is obtained by equating the two entries of the first and second rows with the column three and after a suitable development, one has

Similarly, the joint angles

θ2 and

θ23 are obtained by equating the first and second rows with the fourth column and thus, one has

where the coefficients A and B are expressed as follows

Finally, referring to Equations (12)–(14), the joint angles

θ3 and

θ4 are given by

2.3. Experimental Validation for One Pose

The proposed algorithms for solving the inverse and direct kinematics of the UR5e Cobot have been experimentally validated by referring to an arbitrary Cobot reference pose, which is given by the teach pendant in terms of the tool position vector

p and the rotation vector

r, along with the joint angles

θi for

i = 1, …, 6, respectively. Vectors

p and

r have Cartesian components with respect to the base frame of (

px,

py,

pz) and (

rx,

ry,

rz), respectively. In particular, the rotation vector

r of magnitude

ϕ, define the rotation axis of the tool end-effector, along with the corresponding rotation angle

ϕ, which is not a joint angle, since referred to the axis of unit vector

u. In fact, one has

where

rx,

ry and

rz are the Cartesian components of

r with respect to base frame.

Consequently, the homogeneous transformation matrix

, which includes the noa rotation matrix that corresponds to a given rotation vector

r of magnitude

ϕ and unit vector

u, along with the tool position vector

p, can be expressed as follows

Therefore, referring to

Table 2 that contains the experimental Cartesian components of vectors

p and

r for the assigned UR5e Cobot pose, applying Equations (18) and (19) to determine the rotation angle

ϕ = 3.111 rad and the unit vector

, and finally substituting in Equation (20), one has

According to the proposed IK algorithm, the assigned experimental Cartesian components of

p and

r of

Table 2, the corresponding joint angles

θi for

i = 1, …6 are reported in

Table 3, as follows

Likewise, the DK is solved by using as input data, the joint angles

θi for

i = 1, …6 of

Table 3, which are substituted into the Equation (2) in order to obtain the whole homogeneous transformation matrix

of Equation (3), as follows

However, the teach pendant of the UR5e Cobot gives the tool end-effector pose in terms of

p and

r components, for which, the following matrix is introduced

where the first three numbers of the fourth column of Equation (22) correspond to the Cartesian components of vector

p, respectively.

Developing Equation (23), one has

and thus, the rotation vector

r is given by

which numerical results, along with

p, are reported in

Table 4, as follows

This experimental validation procedure of the proposed algorithm for the UR5e Cobot direct and inverse kinematics is extensively applied in the next session by referring to the robotized assembling of a multi-cylinder IC engine. Particular attention will be devoted to the first Operation of the whole automatic cycle and then all Cobot poses will be also considered for the validation purposes of the proposed kinematic model.