Abstract

Background: More effective and automated techniques for disinfecting elevator push-buttons currently need to be developed, especially given that they are frequently touched by hundreds of individuals. Methods: An automatic elevator push-button disinfection device equipped with four 265 nm ultraviolet-C (UVC) light-emitting diode (LED) packages has been developed for disinfection after each touch to reduce the risk of infection. In this paper, the UVC leakage test, UVC LED package reliability test, and bacteria disinfection efficiency test were performed. Results: The disinfection efficiency for Staphylococcus aureus and Escherichia coli can reach over 90% in 10 s, and end users can set multiple disinfection periods in light of their circumstances. The disinfection device is safe for the human body if the distance exceeds 120 mm. The accelerated aging test result demonstrates that the disinfection device is reliable under normal operation and end-users can increase the disinfection time by compensating for the irradiance drop. Conclusions: The automatic elevator push-button disinfection device provides a safe, highly efficient, and stable disinfection solution for elevator push-buttons.

1. Introduction

The pandemic of COVID-19 has raised the requirements for upgrading disinfection methods since 2019 [1]. The spread of bacteria and viruses in hospitals and public places is still a severe problem, causing a lot of losses every year [2,3,4,5,6]. The disinfection efficiency should be improved to cut down the potential routes of infection.

Ozone disinfection technology is an effective and environmentally friendly method that utilizes the strong oxidizing properties of ozone gas to eliminate bacteria and viruses [7]. This technology works by destroying the organic matter within these microorganisms, ultimately leading to their death [8]. Its benefits include thorough sterilization, the absence of harmful residues, and a wide range of antimicrobial activity, allowing it to effectively target bacterial cells, spores, viruses, fungi, and more [7,8]. Ozone disinfection is commonly employed in various fields such as water treatment, air purification, food processing, healthcare, pharmaceuticals, and aquaculture [9]. However, when it comes to disinfecting elevator push-buttons, the large size of ozone generators can make their use impractical in confined spaces like elevators. Moreover, ozone’s ability to diffuse and its distinctive odor may pose health risks to individuals using the elevator. As a result, ozone disinfection technology is not ideal for small, open areas where people are present.

Thermal disinfection is a process that raises the surrounding temperature to over 100 °C through physical heating [10]. This method leads to the oxidation and denaturation of proteins found in bacteria and viruses, effectively destroying them [10]. Its benefits include thorough sterilization, the absence of residue, and broad-spectrum effectiveness, making it widely applicable in medical settings, food processing, and biopharmaceutical industries [11]. However, when it comes to disinfecting elevator push-buttons, the high temperatures necessary for effective thermal disinfection can compromise the control circuit boards of elevator push-buttons, leading to potential reliability issues. This makes the implementation of this method in elevators particularly challenging. Moreover, the elevated temperatures may pose a burn risk to users. Consequently, thermal disinfection technology is not advisable for use on electronic products.

UVC (ultraviolet-C) technology offers several advantages for surface sterilization, including safety, speed, and the absence of secondary contamination [12]. The mechanism by which UVC inactivates microbes involves the damaging of their deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) through UVC radiation [12]. The primary mode of inactivation occurs when a photon is absorbed, leading to the formation of pyrimidine dimers between adjacent thymine bases. This process renders the microbe unable to replicate. In recent years, UVC disinfection technology has gained popularity in various sectors, especially in education, dining, and public transportation [12]. This innovative disinfection method is crucial for maintaining hygiene and ensuring public safety, particularly in response to recent global health challenges. In schools, many institutions have started installing UVC lights in classrooms [13]. These systems are activated after school hours to disinfect the environment, including desks and chairs, significantly lowering the risk of pathogen transmission among students. In the food service industry, UVC disinfection technology is being implemented in specialized preparation areas, such as salad bars and meal prep rooms [14]. This method ensures that surfaces are disinfected, minimizing the risk of foodborne illnesses. In the realm of public transportation, UVC disinfection lights were implemented to establish specialized disinfection workshops for buses [15]. This initiative guarantees the comprehensive disinfection of the city’s public buses. Furthermore, UVC disinfection robots have been introduced to effectively disinfect aircraft cabins [16].

One pathway of disease transmission is the surface of materials, such as elevator push-buttons, door handles, and railings [17]. Some researchers have even pointed out that elevator push-buttons are dirtier than toilet seats [18]. Therefore, surface disinfection should be implemented to reduce the risk of bacterial and viral transmission. Considering that the push-buttons of elevators are touched by hundreds of people frequently, push-buttons should be disinfected effectively to protect the health of users. Regarding elevator buttons’ disinfection, alcohol or other disinfectants are applied to spray disinfectant and kill microorganisms on the push-buttons [19]. Nonetheless, disinfection chemicals may harm the human body, and the solution may result in a short circuit or other circuit failure effects. Another method to prevent bacteria and viruses is using films and frequently changing the films to remove bacteria and viruses. The film is disinfected at a fixed frequency or replaced regularly. Although an indicator label is persistently stuck near the membrane to indicate the frequency of membrane replacement, there is still a high risk of infection during the replacement interval, and the plastic film is not environmentally friendly [20]. Currently, many other non-contact effective disinfection methods adopt UV radiation [21,22]. The disinfection efficiency of UV is related to energy density and wavelength. Regarding wavelength, researchers have indicated the highest germicidal efficiency of 265 nm UVC LEDs [23]. As for the power of UV, although mercury lamps have high power, they are fragile and need preheating [24], thus making them unsuitable for high-frequency sterilization. Therefore, 265 nm UVC LED is the preferred wavelength for developing elevator button disinfection devices, with the advantages of safety, rapidity, and no secondary pollution [25,26,27,28]. This paper reported a 265 nm UVC LED disinfection method for elevator push-buttons.

2. Materials and Methods

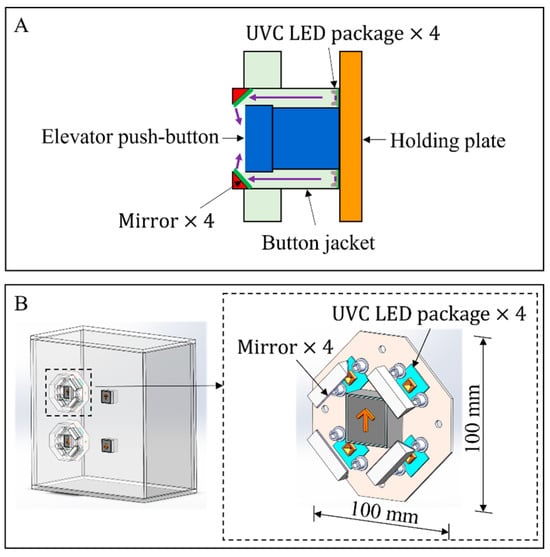

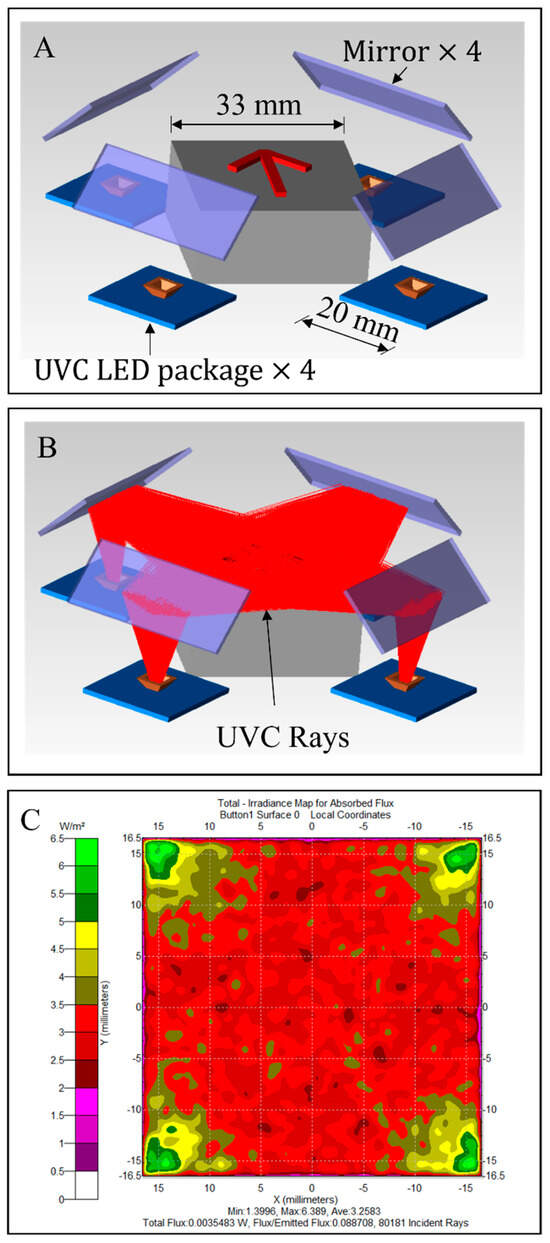

Our self-developed UVC LED package can be implemented in the front of elevator push-buttons (front-light structure) or at the back of elevator push-buttons (backlight structure). Regarding the front-light structure, an inappropriate design would introduce UVC energy waste since part of the UVC radiation would radiate out of the elevator push-button area, so the disinfection efficiency would be low. However, the backlight structure can make use of UVC radiation more efficiently. Thus, the backlight configuration has higher disinfection efficiency. A backlight UVC LED module with its own developed UVC LED packages was implemented, and the UVC LED packages were installed behind the button surface to save space. The developed UVC LED package featured a stacked silicon reflector with over 90% UVC reflectance to significantly improve UVC irradiance in the central region by converging UVC radiation [29,30,31]. As shown in Figure 1, the device includes four UVC LED packages, four mirrors, an elevator push-button, a holding plate, and a button jacket. The standard size of the elevator button was 33 mm × 33 mm, with the structure size of the UVC LED package being 20 mm × 20 mm. Four UVC LED packages with a peak wavelength of 265 nm were implemented to ensure disinfection efficiency and relatively uniform irradiation distribution in the central region of the push-button. Figure 2A,B illustrate that the 265 nm UVC rays reflected by the mirror were emitted from the UVC LED packages and ultimately reached the button surface to sterilize the push-button. Based on the irradiation simulation by Lambda Research TracePro (software version 7.3.4) of the button surface sketched in Figure 2C, the light could cover the entire button surface, and the average irradiance was 0.3 mW/cm2 and the irradiance in the central region was relatively uniform.

Figure 1.

(A) Schematic diagram of the push-button disinfection device for elevators, (B) structure design.

Figure 2.

(A) Optical model of the push-button disinfection device for elevators, (B) ray tracing result, (C) irradiance map of the push-button surface.

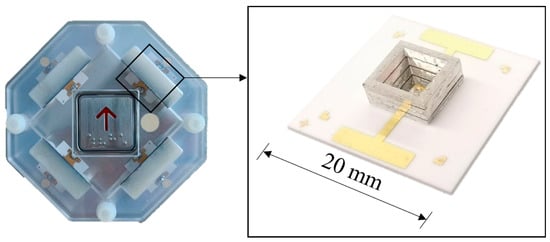

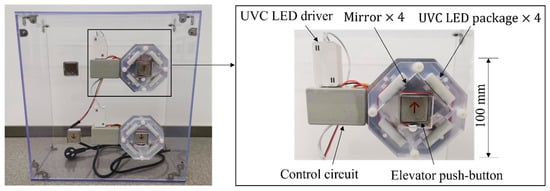

A mechanical design was conducted to fix the light path. The UVC LED packages were screwed to the holding plate with a size of 100 mm × 100 mm, and a button jacket was designed to fix the mirror. An acrylic box of 400 mm × 400 mm was designed to simulate the working environment. These four aforementioned UVC LED packages were assembled on the aluminum plate with screws to constitute the UVC LED module in the disinfection device, and the four mirrors were eventually mounted on the plastic plate. A control circuit was designed to control the response and the disinfection time of the UVC LED packages. The UVC LED module is presented in Figure 3, and the whole disinfection setup is presented in Figure 4.

Figure 3.

The UVC LED module with four UVC LED packages.

Figure 4.

The overall setup of the elevator push-button disinfection device.

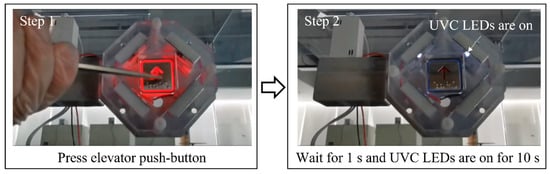

The disinfection time of the UVC LED module was set to 10 s, of which the response time was 1 s. In this setting, if a user touches the elevator, the UVC LED would wait for 1 s for the finger to retract, and afterward, the UVC LEDs would turn on for 10 s to sterilize the push-button. Figure 5 demonstrates the sterilization process of the device.

Figure 5.

Demonstration of the sterilization process of the elevator push-button disinfection device.

The prototype is composed of UVC LED chips, ceramic substrates, silicon reflectors, mirrors, a buttoned jacket, and a holding plate. A cost analysis based on the prototype, detailed in Table 1, indicates that the total cost is approximately HKD 200, making it affordable for most potential customers. The cost will further reduce during mass production. As UVC LED chip technology advances, we anticipate a significant increase in power, which will allow for a reduction in the quantity and cost of UVC LED chips, ceramic substrates, and silicon reflectors, ultimately lowering the overall cost even further. Given that the price of an elevator typically exceeds HKD one million, the cost of the current elevator push-button disinfection device is negligible in comparison. Furthermore, the disinfection function serves as an additional feature to enhance the elevator’s value.

Table 1.

Cost analysis.

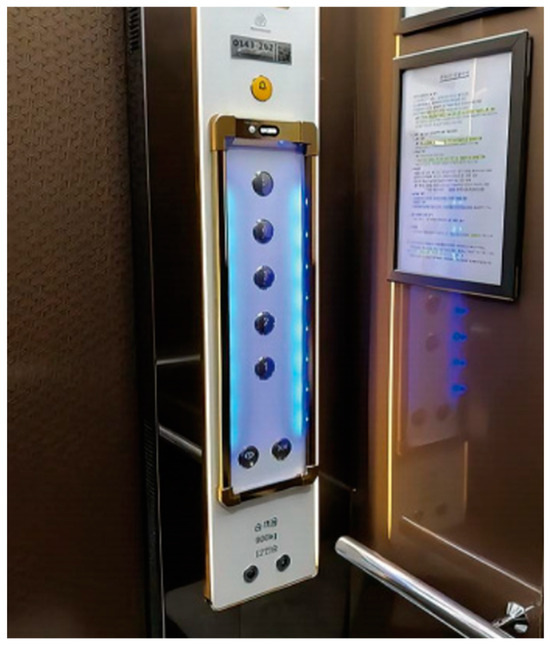

A comparable commercial UVC disinfection device designed for elevator push-buttons, produced by Ningbo Zixin Technology Co., Ltd., Ningbo, Zhejiang, China is illustrated in Figure 6 [32]. This device is strategically placed around elevator push-buttons, with a sensing range of 40 to 50 cm for users. If a user touches the elevator push-buttons and then steps outside the sensing range for 10 s, the device activates. In an unattended setting, it performs disinfection for 30 s every hour. The commercial UVC disinfection device operates within a wavelength range of 260 nm to 280 nm. However, it utilizes traditional commercial UVC LEDs paired with a flat quartz plate, resulting in a wide UVC radiation angle. This design means that only a small portion of the UVC rays effectively reach the push-buttons, potentially diminishing the disinfection effectiveness. Additionally, the broad radiation angle can lead to UVC leakage during operation, creating a safety risk for individuals in the elevator.

Figure 6.

UVC disinfection device for elevator push-buttons manufactured by Ningbo Zixin Technology Co., Ltd. [32].

Our device stands out from commercial UVC disinfection products due to its advanced optical design and our proprietary UVC LED packages, which feature a narrow radiation angle. This innovative approach effectively addresses the common issues of inadequate disinfection and UVC leakage found in existing products, significantly enhancing both performance and safety.

Regarding cost, the retail price of the commercial product is CNY 310 per unit. However, once we enter mass production, the price of our device will be competitive and comparable to that of the commercial alternatives.

3. Results

3.1. Disinfection Efficiency Test

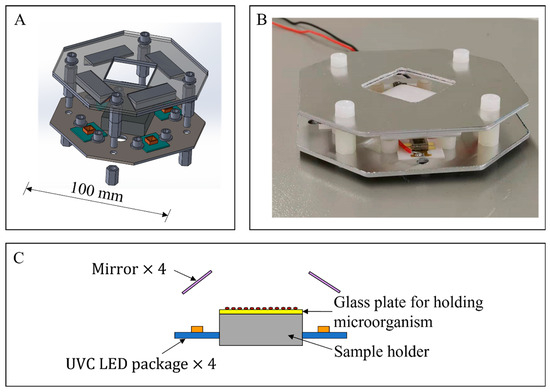

The disinfection test was carried out with Staphylococcus aureus and Escherichia coli by Société Générale de Surveillance (SGS) Guangzhou Branch, in accordance with the Technical Standard for Disinfection (2002 Ministry of Health, P.R. China)—2.1.5.4 [33]. In this procedure, a glass sheet coated with bacteria by spraying served as the carrier. The carrier was strategically placed at the center of the push-button within the testing device. Each test was performed for a duration of 10 s and was repeated three times to ensure reliability. To simulate the actual situation, the size of the disinfection test device was the same as the above-mentioned prototype. The mechanical design and the prototype of the disinfection test setup are shown in Figure 7A,B, respectively, while Figure 7C illustrates a schematic diagram of the disinfection test.

Figure 7.

(A) The mechanical design for the disinfection test, (B) disinfection test setup, (C) the schematic diagram of the disinfection test.

Table 2 presents the results of the disinfection test. Escherichia coli and Staphylococcus aureus are the most common bacterial species [34]. The disinfection efficiency of Staphylococcus aureus and Escherichia coli could reach more than 90% within 10 s of disinfection time. End users could choose different disinfection times according to the environment to cope with the standard. The self-developed UVC LED module can complete the sterilization process within 10 s, which is suitable for high-frequency sterilization.

Table 2.

Disinfection test results.

3.2. UVC Leakage Test

To ensure the elevator push-button disinfection device can work properly, safely, and efficiently, the device must be tested to restrict the UVC radiation leakage level and ensure reliability and disinfection efficiency before operation.

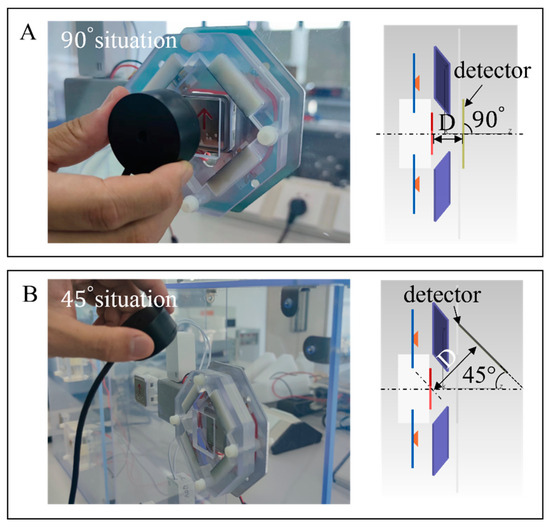

Metals can reflect UV lights, which are harmful to human eyes and skin, especially high-power deep UV light sources [35,36,37]. The leakage test was conducted to ensure that the energy levels of UVC LEDs were within the control range and safe. A UV detector (ILT560A, Mini-Spectroradiometer, International Light Technologies, Peabody, MA, USA) was placed in two positions, which were a 90° position and a 45° position, with different distances, D, to characterize UVC radiation leakage, as shown in Figure 8. The characterization results are summarized in Table 3, and D illustrates the distance between the detector and the surface of the push-button. The reason why the irradiance at 40 mm to 60 mm is stronger than that at 3 mm for the 90° situation is that the reflected UVC will produce an effect of intensity overlap in a certain area away from the button, and this distance is related to the angle between the UVC reflective mirror and the button.

Figure 8.

(A) A 90° situation to measure the UVC leakage level, (B) 45° situation to measure the UVC leakage level.

Table 3.

UVC leakage test results.

In regard to the American Conference of Governmental Industrial Hygienists (ACGIH) standards, the threshold limit for UVC radiation at 265 nm is 3.7 mJ/cm2 per day for the human eyes and 10 mJ/cm2 per day for the skin [38]. As far as the 90° situation is concerned, the maximum measured irradiance value was 75 μW/cm2 and the exposure should have been limited to a maximum of 49 s. Regarding the safety issue, a human body sensor will be adopted to prevent UVC exposure when someone stays close to the device. If the distance exceeded 120 mm, almost no UVC rays were radiated into the eyes or skin under the 90° situation. In the case of 45°, the measured maximum irradiance was 9 μW/cm2. Compared with the 90° case, the leakage level of 45° was negligible. It can be concluded that it is safe for a person to stand at a distance of 120 mm away from a push-button when using the UVC LED module to sterilize the surface of the push-button.

3.3. Reliability Test of UVC LED Package

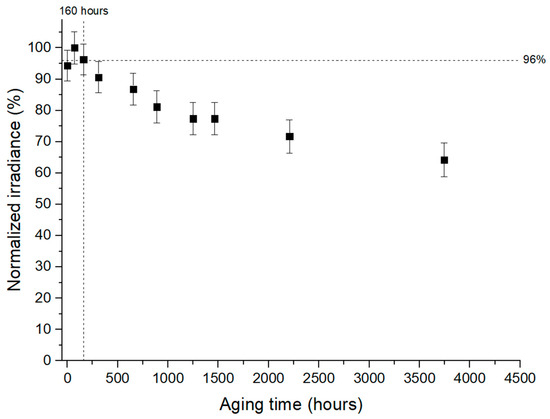

The long lifetime of the UVC LED module is essential. The module will be useless if the UVC intensity drops too much after a few days. An accelerated aging test was adopted to predict the lifetime of the UVC LED package based on the JESD22 Method A108-C standard [39]. Considering that the epitaxial layer was the most likely location for failure due to charge injection of the UVC LED package [40,41], the acceleration coefficient of the accelerated aging test could be achieved by calculating the Arrhenius equation [42]. Under normal working conditions, the current on the LED was 100 mA, while the current on the LED was 150 mA during the accelerated aging test, so the acceleration coefficient of 7.4 could be calculated. This means that the radiation drop of LED in the accelerated aging test was 7.4 times faster than in a standard working condition. The relationship between the normalized average irradiance of the UVC LED package and time in the accelerated aging test is plotted in Figure 9. Figure 9 shows that when the irradiance of the UVC LED package is attenuated by 4%, the aging time is 160 h, so the predicted lifetime of the LED is more than 1100 h. End-users can also increase the disinfection time by compensating for the irradiance drop based on the accelerated aging test result. It can be concluded that the elevator push-button disinfection device was reliable for long-time operation under the assumed working conditions in this paper.

Figure 9.

Lifetime of UVC LED package under high-current aging conditions.

4. Conclusions

A high-efficiency elevator push-button disinfection device in backlight mode with a new type of UVC LED package structure was developed and tested to reduce the risk of infection. According to the results of the disinfection test, UVC leakage test, and reliability test results, it could be confirmed that (1) a 10 s working period of the disinfection device could disinfect more than 90% of E. coli and S. aureus bacteria; (2) the disinfection device was safe for the human body if the distance exceeded 120 mm. The users could select different disinfection times as well as response times according to different applications; and (3) the packaging structure of UVC LED was reliable for long-time operation, and end-users could increase the disinfection time by compensating for the irradiance drop. In conclusion, the self-developed elevator push-button disinfection device represents a user-friendly solution that effectively and safely eliminates bacteria from elevator push-button surfaces. According to the American Conference of Governmental Industrial Hygienists (ACGIH), the human body can safely tolerate a daily ultraviolet radiation dose of 3.7 mJ/cm2 at a wavelength of 265 nm. Our experiments on ultraviolet radiation leakage at various distances indicate that exposure should be limited to a maximum of 49 s. Additionally, we recommend maintaining a safe distance of 120 mm to mitigate any risk of ultraviolet radiation damage. It is also advisable to integrate this sterilization device with other protective measures to further safeguard individuals from potential diseases.

5. Discussion

The ultraviolet disinfection method for elevator push-buttons poses several challenges. Firstly, the plastic jacket of the prototype may deteriorate when exposed to ultraviolet light. To address this concern, a transition to mass-producing the jacket in metal is planned. Secondly, the installation of an ultraviolet device might compromise the esthetic appeal of the elevator’s interior. To counter this issue, the design of the product will be prioritized to ensure it integrates seamlessly with the overall elevator esthetics. Lastly, there is a risk of skin and eye exposure to ultraviolet light, particularly for children who may be curious about the device. To mitigate this risk, the product design will incorporate safety features, including prominently displayed warning labels that inform users of the hazards associated with ultraviolet light.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/inventions10010004/s1, SGS Test Report, Report No.: GZES2205010042, Issue Date: 21 June 2021. Report S1: Test report.

Author Contributions

Conceptualization, X.Q.; Methodology, J.C.C.L. and Y.C.; Supervision, S.W.R.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported in part by the Project of Hong Kong University of Science and Technology Bridge Gap Fund (BGF.071.2021), the project of Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone (HZQB-KCZYB-2020083), the Project of IER Foundation 2021 (Project No. IERF202101), the Project of National Natural Science Foundation of China (Grant No. 62204213), and the Project of Guangzhou Municipal Science and Technology Program (Grant No. 2023A04J0405).

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Karim, S.S.A.; Karim, Q.A. Omicron SARS-CoV-2 variant: A new chapter in the COVID-19 pandemic. Lancet 2021, 398, 2126–2128. [Google Scholar] [CrossRef] [PubMed]

- Giske, C.G.; Monnet, D.L.; Cars, O.; Carmeli, Y. Clinical and economic impact of common multidrug-resistant gram-negative bacilli. Antimicrob. Agents Chemother. 2008, 52, 813–821. [Google Scholar] [CrossRef] [PubMed]

- Barber, L.M.; Schleier, J.J.; Peterson, R. Economic cost analysis of West Nile virus outbreak, Sacramento county, California, USA, 2005. Emerg. Infect. Dis. 2010, 16, 480. [Google Scholar] [CrossRef] [PubMed]

- Fiorillo, L.; Cervino, G.; Matarese, M.; Amico, C.; Surace, G.; Paduano, V.; Fiorillo, M.T.A.; Moschella, A.L.; Bruna, G.L.; Romano, R.; et al. COVID-19 surface persistence: A recent data summary and its importance for medical and dental settings. Int. J. Environ. Res. Public Health 2020, 17, 3132. [Google Scholar] [CrossRef] [PubMed]

- Doremalen, N.; Bushmaker, T.; Morris, D.H.; Holbrook, M.G.; Gamble, A.; Williamson, B.N.; Tamin, A.; Harcourt, J.L.; Thornburg, N.J.; Gerber, S.I.; et al. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef]

- Johnson, D.L.; Mead, K.R.; Lynch, R.A.; Hirst, D.V.L. Lifting the lid on toilet plume aerosol: A literature review with suggestions for future research. Am. J. Infect. Control. 2013, 41, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Zhao, Y.; Yadav, A.K.; Ji, B.; Kang, P.; Wei, T. Ozone based inactivation and disinfection in the pandemic time and beyond: Taking forward what has been learned and best practice. Sci. Total Environ. 2023, 862, 160711. [Google Scholar] [CrossRef]

- Epelle, E.; Macfarlane, A.; Cusack, M.; Burns, A.; Okolie, J.; Mackay, W.; Rateb, M.; Yaseen, M. Bacterial and fungal disinfection via ozonation in air. J. Microbiol. Methods 2022, 194, 106431. [Google Scholar] [CrossRef]

- Epelle, E.; Macfarlane, A.; Cusack, M.; Burns, A.; Thissera, B.; Mackay, W.; Rateb, M.; Yaseen, M. Ozone application in different industries: A review of recent developments. Chem. Eng. J. 2023, 454, 140188. [Google Scholar] [CrossRef]

- Bharti, B.; Li, H.; Ren, Z.; Zhu, R.; Zhu, Z. Recent advances in sterilization and disinfection technology: A review. Chemosphere 2022, 308, 136404. [Google Scholar] [CrossRef]

- Śmiech, K.M.; Kovács, T.; Wildschut, R.F.; Monleon, A.J.C.; de Vries-Onclin, B.; Bowen, J.G.; Agostinho, L.L.F. Thermal disinfection of hospital wastewater in a pilot-scale continuous-flow system. Appl. Water Sci. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Rauch, K.; Macisaac, S.; Reid, B.; Mullin, T.; Atikinson, A.; Pimentel, A.; Stoddart, A.; Linden, K.; Gagnon, G. A critical review of ultra-violet light emitting diodes as a one water disinfection technology. Water Res. X 2024, 25, 100271. [Google Scholar] [CrossRef] [PubMed]

- Messina, G.; Bosco, R.; Amodeo, D.; Nante, N.; De Palma, I.; Petri, C.; Cevenini, G. Safer school with near-UV technology: Novel applications for environmental hygiene. J. Environ. Health Sci. Eng. 2023, 21, 157–165. [Google Scholar] [CrossRef] [PubMed]

- Singh, H.; Bhardwaj, S.; Khatri, M.; Kim, K.; Bhardwaj, N. UVC radiation for food safety: An emerging technology for the microbial disinfection of food products. Chem. Eng. J. 2021, 417, 128084. [Google Scholar] [CrossRef]

- Available online: https://izakscientific.com/disinfect-buses-stations-and-other-public-transportation-systems-with-uv-light/ (accessed on 30 December 2024).

- Dejohn, C.; Beiland, K.; Garcia, D. Methods of Aircraft Disinfection to Reduce Airborne Infectious Disease Transmission. Aerosp. Med. Hum. Perform. 2024, 95, 930–936. [Google Scholar] [CrossRef] [PubMed]

- Ryu, B.H.; Cho, Y.; Cho, O.H.; Hong, S.I.; Kim, S.; Lee, S. Environmental contamination of SARS-CoV-2 during the COVID-19 outbreak in South Korea. Am. J. Infect. Control 2022, 48, 875–879. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Dong, Z.; Fan, W.; Xu, K.; Tang, S.; Wang, Y.; Wu, F. A narrative review on the role of temperature and humidity in COVID-19: Transmission, persistence, and epidemiological evidence. Eco-Environ. Health 2022, 1, 73–85. [Google Scholar] [CrossRef]

- García de Abajo, F.J.; Herna, R.J.; Kaminer, I.; Meyerhans, A.; Rosell-Llompart, J.; Sanchez-Elsner, T. Back to normal: An old physics route to reduce SARS-CoV-2 transmission in indoor spaces. ACS Nano 2020, 14, 7704–7713. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Azadi, E.; Hussain, C.M. Protection, disinfection, and immunization for healthcare during the COVID-19 pandemic: Role of natural and synthetic macromolecules. Sci. Total Environ. 2021, 776, 145989. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, V.; Kapoor, D.; Dhanjal, D.S.; Bhatia, D.; Jan, S.; Singh, N.; Romero, R.; Ramamurthy, P.; Singh, J. Detection and disinfection of COVID-19 virus in wastewater. Environ. Chem. Lett. 2021, 19, 1917–1933. [Google Scholar] [CrossRef]

- Heilingloh, C.S.; Aufderhorst, U.W.; Schipper, L.; Dittmer, U.; Witzke, O.; Yang, D.; Zheng, X.; Sutter, K.; Trilling, M.; Alt, M.; et al. Susceptibility of SARS-CoV-2 to UV irradiation. Am. J. Infect. Control 2020, 48, 1273–1275. [Google Scholar] [CrossRef]

- Kowalski, W. UVGI disinfection theory. In Ultraviolet Germicidal Irradiation Handbook; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Kim, D.K.; Kang, D.H. UVC LED irradiation effectively inactivates aerosolized viruses, bacteria, and fungi in a chamber-type air disinfection system. Appl. Environ. Microbiol. 2018, 84, e00944-18. [Google Scholar] [CrossRef]

- Shimoda, H.; Matsuda, J.; Iwasaki, T.; Hayasaka, D. Efficacy of 265-nm ultraviolet light in inactivating infectious SARS-CoV-2. J. Photochem. Photobiol. 2021, 7, 100050. [Google Scholar] [CrossRef] [PubMed]

- Messina, G.; Burgassi, S.; Messina, D.; Montagnani, V.; Cevenini, G. A new UV-LED device for automatic disinfection of stethoscope membranes. Am. J. Infect. Control 2015, 43, 61–66. [Google Scholar] [CrossRef] [PubMed]

- McGinn, C.; Scott, R.; Ryan, C.; Donnelly, N.; Cullinan, M.F.; Beckett, M. Rapid disinfection of radiology treatment rooms using an autonomous ultraviolet germicidal irradiation robot. Am. J. Infect. Control 2022, 50, 947–953. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhang, Y.; Yan, J.C.; Xie, H.Z.; Liu, L.; Chen, X.; Hou, M.J.; Qin, Z.X.; Wang, J.X.; Li, J.M. Light extraction enhancement of AlGaN-based ultraviolet light-emitting diodes by substrate sidewall roughening. Appl. Phys. Lett. 2017, 111, 11102. [Google Scholar] [CrossRef]

- Qiu, X.; Lo, J.C.C.; Lee, S.W.R. Packaging of UV LED with a stacked silicon reflector for converged UV emission. In Proceedings of the 2017 International Conference on Electronics Packaging, Yamagata, Japan, 19–22 April 2017. [Google Scholar]

- Qiu, X.; Lo, J.C.C.; Lee, S.W.R.; Tseng, Y.J.; Yi, H.K.; Chiu, P. UV LED assisted printing platform for fabrication of micro-scale polymer pillars. J. Microelectromech. Syst. 2020, 29, 1523–1530. [Google Scholar] [CrossRef]

- Qiu, X.; Lo, J.C.C.; Cheng, Y.J.; Xu, H.; Xu, Q.W.; Lee, S.W.R. Implementation and characterization of a sterilization module consisting of novel 265 nm UVC LED packages. HKIE Trans. 2021, 28, 213–220. [Google Scholar] [CrossRef]

- Available online: https://nb-uvtek.com/Products/elevatorbuttonsterilizationmodules.html (accessed on 30 December 2024).

- Technical Standard for Disinfection 2.1.5.4; Ministry of Health of the People’s Republic of China: Beijing, China, 2002.

- Bhatta, D.R.; Hamal, D.; Shrestha, R.; Subramanya, S.H.; Baral, N.; Singh, R.K.; Nayak, N.; Gokhale, S. Bacterial contamination of frequently touched objects in a tertiary care hospital of Pokhara, Nepal: How safe are our hands? Antimicrob. Resist. Infect. Control 2018, 7, 97. [Google Scholar] [CrossRef]

- Kitagawa, H.; Nomura, T.; Nazmul, T.; Omori, K.; Shigemoto, N.; Sakaguchi, T.; Ohge, H. Effectiveness of 222-nm ultraviolet light on disinfecting SARS-CoV-2 surface contamination. Am. J. Infect. Control 2021, 49, 299–301. [Google Scholar] [CrossRef] [PubMed]

- Skobowiat, C.; Brożyna, A.A.; Zorica, J.; Jeayeng, S.; Oak, A.S.; Kim, T.K.; Panich, U.; Reiter, R.J.; Slominski, A.T. Melatonin and its derivatives counteract the ultraviolet B radiation-induced damage in human and porcine skin ex vivo. J. Pineal Res. 2018, 65, e12501. [Google Scholar] [CrossRef] [PubMed]

- Duchaine, C. Assessing microbial decontamination of indoor air with particular focus on human pathogenic viruses. Am. J. Infect. Control 2016, 44, 121–126. [Google Scholar] [CrossRef]

- International Commission on Non-Ionizing Radiation Protection. Guidelines on limits of exposure to ultraviolet radiation of wavelengths between 180 nm and 400 nm (incoherent optical radiation). Health Phys. 2004, 87, 171–186. [Google Scholar] [CrossRef]

- Tsai, M.; Tang, C.; Wang, C.H.; Tsai, Y.Y.; Chen, C. Investigation on some parameters affecting optical degradation of LED packages during high-temperature aging. IEEE Trans. Device Mater. Reliab. 2015, 15, 335–341. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, L.; Qi, P. Progress of reliability and failure mechanisms for GaN-based light-emitting diodes. Phys. Status Solidi (A) 2022, 219, 2100425. [Google Scholar] [CrossRef]

- Hsu, T.; Teng, Y.; Yeh, Y.; Fan, X.; Chu, K.; Lin, S.; Yeh, K.; Lee, P.T.; Lin, Y.; Chen, Z.; et al. Perspectives on UVC LED: Its progress and application. Photonics 2021, 8, 196. [Google Scholar] [CrossRef]

- Chang, M.H.; Das, D.; Varde, P.V.; Pecht, M. Light emitting diodes reliability review. Microelectron. Reliab. 2012, 52, 762–782. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).