1. Introduction

The rapid development of technology now allows the manufacture of thin, light-weight, eminently functional notebook computers, smart phones, players and very many other small electronic devices. The integrated circuit (IC) elements needed for all these advanced devices need to be multifunctional and consequently have a very high pin out numbers, in addition they need to be very compact. The packaging processes have become much more challenging. The technology of IC Packaging is complex and involved. The processes include wafer slitting, crystal sticking, lead soldering, packaging, cutting and forming, marking, and testing. In the packaging process, packing material (epoxy) is injected into a mold to enclose the IC chip as a package which is removed from the mold after forming. In general, a packaging mold assembly must be cleaned after 500 to 600 chips have been packaged. This cleaning takes 3 to 4 h and involves the removal of hardened plastic from the mold surface. This residual plastic adhering to the mold will result in reduced production efficiency [

1].

Most IC packaging material consists of Epoxy and non-organic Silica additives, generally divided into General-purpose Cresol Block and high-class Bis-phenol. However, most of the solid packaging materials used today are Epoxy Molding Compounds (EMCs). Epoxy resins are extremely complicated mixtures of resin, additives, hardener, promoter, catalyst, and other substances added for special purposes [

2]. Furthermore, since epoxy resins are cured at an elevated temperature, this also affects the service life of ports and plungers of the packaging molds, which are shortened by 30% or more at high-temperature. Since the ports and plungers are both in the top ten consumables of the process, it is very important to find a way to prolong working life or to find ways to recycle them.

In the early years, plastic cakes contained halogens and other materials that were harmful to the environment. Now, advanced counties such as the USA and the European Union have introduced laws that ban the import of products containing such hazardous material and manufacturers now use green EMCs free of harmful substances. However, these EMCs are much stickier than the older ones and they reduce production counts. In other words, molds have to be cleaned much more often. In fact, use of the new green EMCs shows a 37.5%–50% decrease in production count compared to the old processes under identical packaging conditions. This has increased the cost to the packaging companies. The main reason that ports and plungers are corroded is due to acidic and alkaline chemicals in the plastic cake and mold cleaning cake. Furthermore, plungers wear during use and accumulate residual plastic, this affects stability of the filling pressure and the number of defective (not good, NG) packages [

3]. Sticking of the packaging material in the mold is a persistent problem and urgently requires a solution. This is especially troubling in the ports and plungers using organic epoxy packaging. The sticky material forms hardened residues in the mold that can result in defective packaging such as breakage or short shot [

4,

5,

6].

A dirty mold can also affect the bonding, which causes packaging failure, with a significant decrease of IC yield [

7]. Excessive adhesion to the mold causes three major problems:

(1) Adhesion hinders ejection of the product and de-molding because a higher pushing force is needed to release the package from the mold. This can cause deformation or breakage of the product, as well as wear of the surface of the ports and plungers.

(2) Hardened packages tend to stick to the mold surface and affect production yield.

(3) A large force is needed for mold cleaning which has a serious effect on production efficiency.

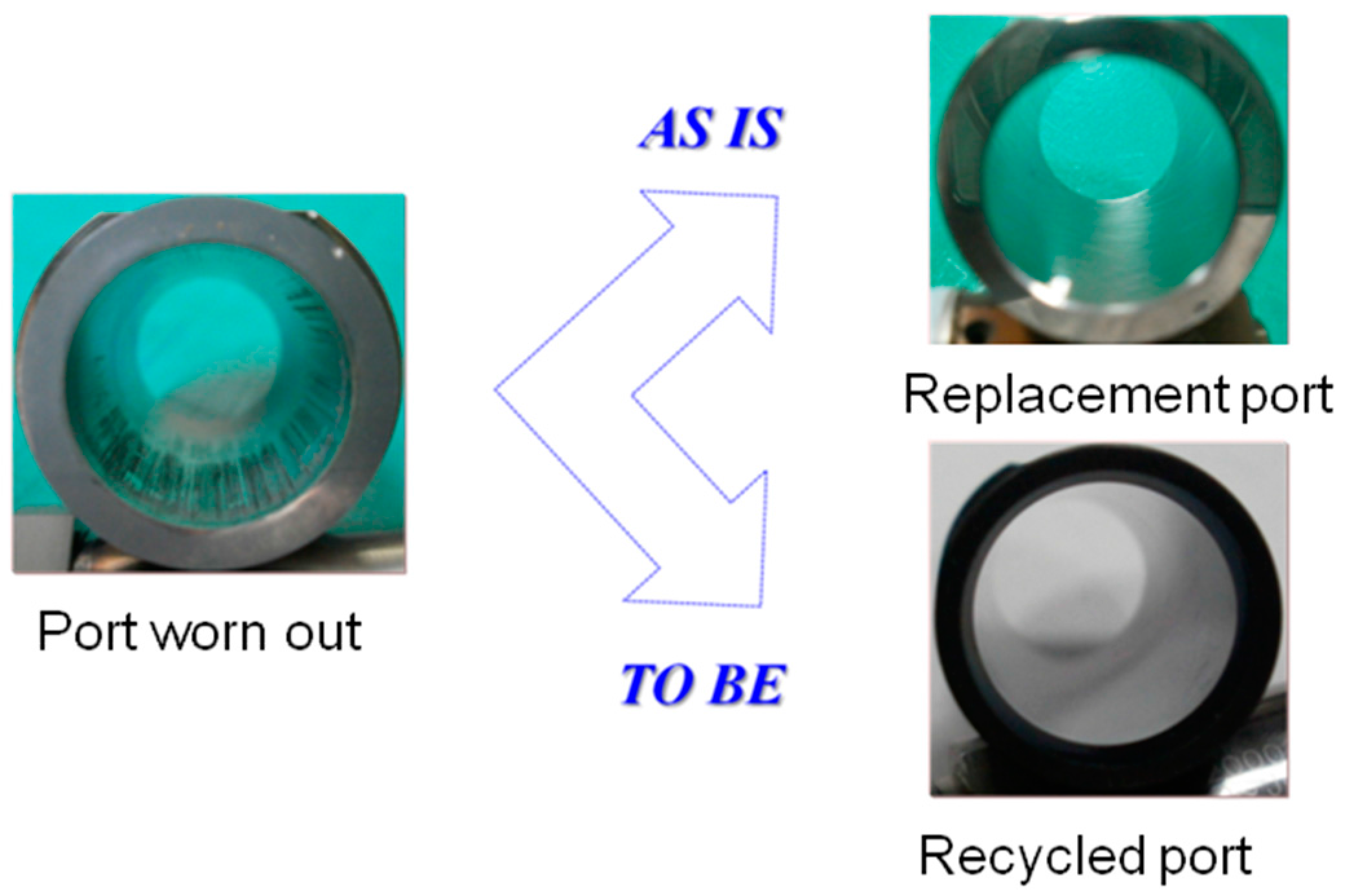

Therefore, packaging plants discard these parts after a certain amount of use. Increased wear of the ports and plungers or an increase in the number of NG packages constitutes a major cause of increased cost. A reduction of adhesion to the mold would be an important topic for IC packagers. However, it is even more worthwhile to study the recycling and refurbishment of mold ports and plungers and epoxy resin filling to lower cost as well as the NG ratio of the packaging process.

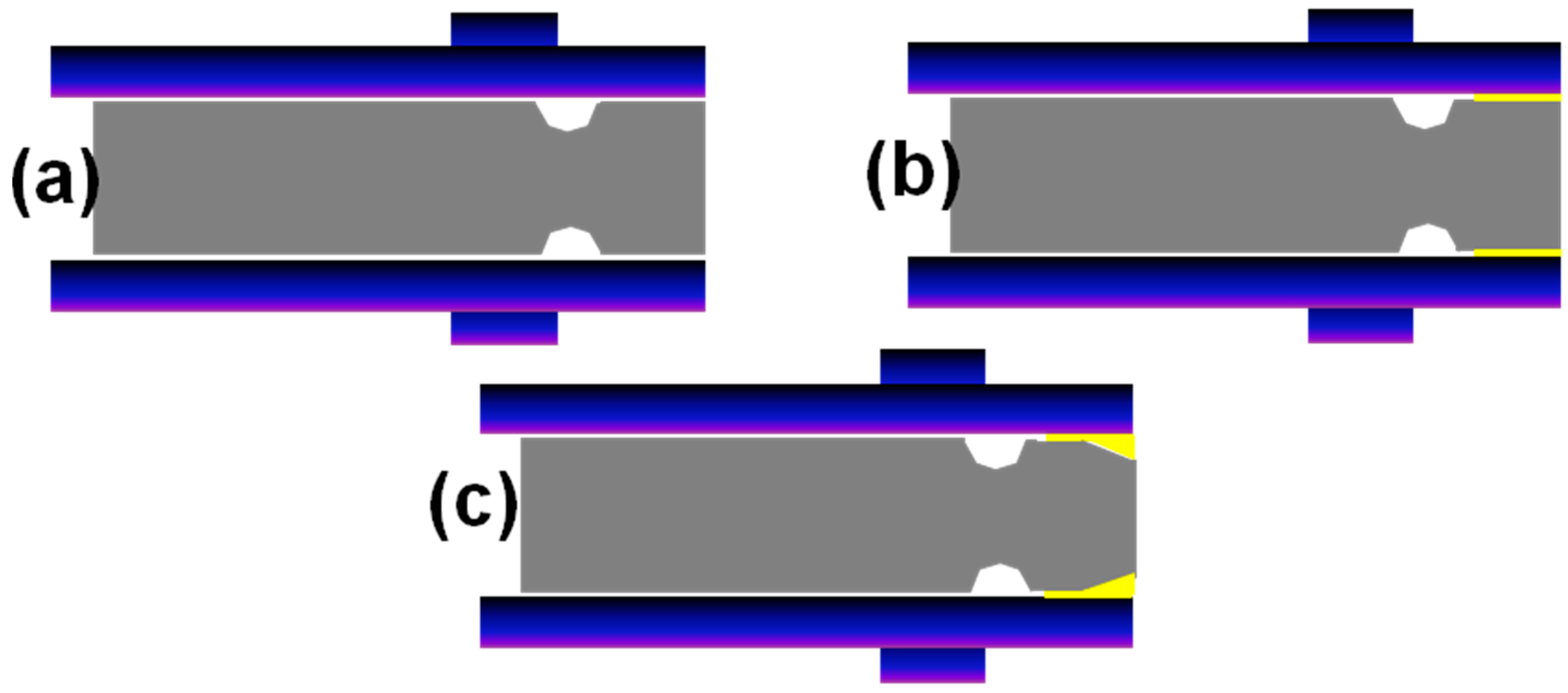

In this process IC packaging material known as plastic cake (epoxy resin) is injected into the molds to enclose the IC chip. Competition in the IC packaging industry dictates that transfer molding using Epoxy resin be used to accomplish this enclosing action. The process involves placing the semi-finished IC chip with all the bonding leads attached into the mold and then feeding the pre-heated epoxy in after the machine closes the two halves of the mold. The softened epoxy is injected into the cavity by way of the respective runners and gates and the packaged IC is removed after the setting reaction has completed, see

Figure 1. During the process several problems may arise: (1) The surfaces of the mold, ports and plungers may suffer damage and this will increase costs and the NG ratio; (2) The plungers tend to stick in the mold and this causes de-molding problems which also increase the opportunity for the mold and plunger surfaces to sustain damage. This makes a search for methods to improve the surface coating of these components an important part of this study.

2. Experimental Methods

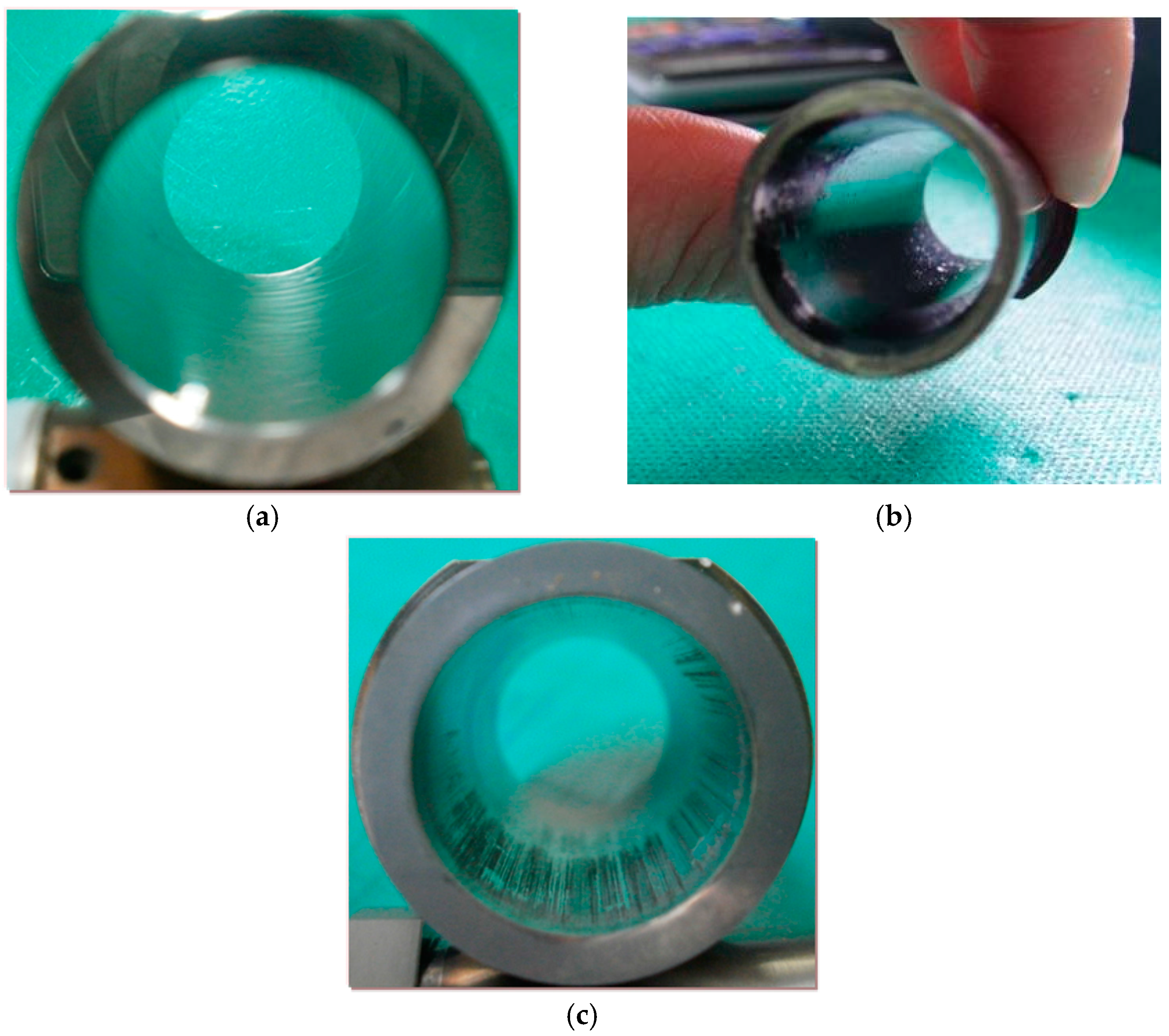

The problem of adhesion between the packaging material and the mold has been a problem from the start. Hardened organic packaging material (epoxy) adheres and accumulates in the mold over time. If left, this debris will eventually cause problems and result in defective packaging that may include broken packages or short shots. Another problem involves difficulties in de-molding. The IC package in the cavity needs to be released from the mold and adhesion will hinder this process. Furthermore, adhesion can also cause damage to the coatings on the surface of the ports and plungers, which will increase wear of these parts and also affect the product NG ratio. Consultation with the suppliers of the mold cleaning material confirmed that the amine ingredient could damage the mold ports. Significant surface damage is seen in molds after ~50,000 fillings. The same amount of damage occurs to filling plungers. Some discarded ports taken from a packaging plant are shown in

Figure 2.

Figure 3a shows an original Port and two Ports with visible adhesion and severe abrasion are shown in

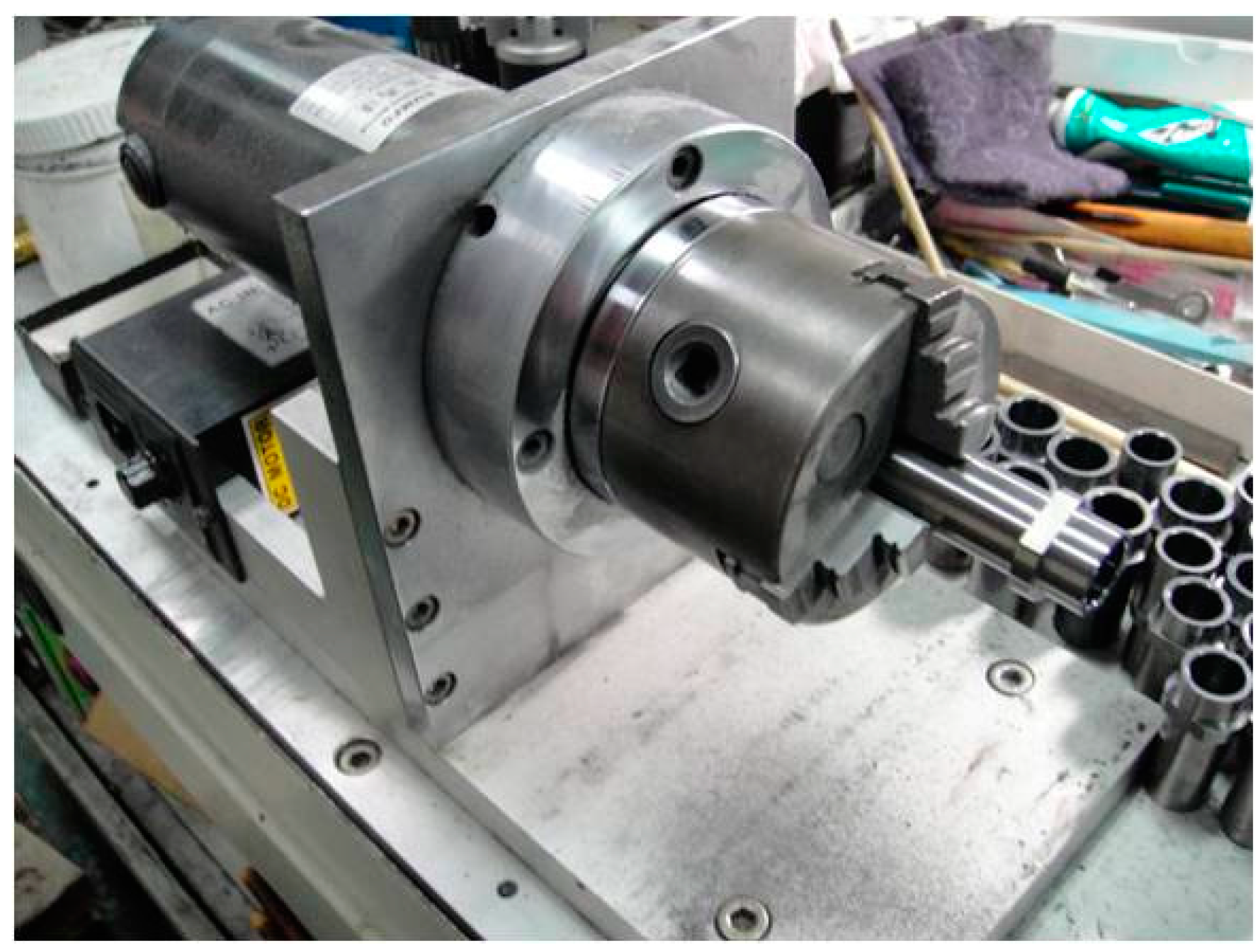

Figure 3b,c. These severely contaminated ports and plungers were cleaned by sonication and then polished using the publishing machine shown in

Figure 4. The picture for the published ports is shown in

Figure 5.

A Restriction of Hazardous Substances (RoHS) directive enforced by the Europa (EU) requires that international enterprises must completely cease the use of six chemicals containing heavy metals (such as lead and mercury) in all electronic products including IC packaging and plastic computer parts. Conventional coating processes can no longer tackle the problem of the significantly increased mold cleaning time. The use of environmentally friendly packaging material has resulted in more down time for mold cleaning and lower productivity. The plunger is made of tungsten carbide, with some added cobalt to ensure high strength and resistance to abrasion. There are two main causes of wear in ports and plungers:

1. Wear in the mold caused by vertical and horizontal deviation which results in friction and subsequent abrasion.

2. Corrosion caused by the acidic and alkaline ingredients in plastic cake and mold cleaning chemicals. The primary result being worn off cobalt metal and distortions of the circularity of the inner diameter of the ports.

To reduce corrosion, a protective layer, which can be deposited by physical deposition (PVD) process, is formed on the surface. In this study, the diamond-like coating is laid down by vacuum electron beam (E-gun) deposition and forms a very hard protective surface on the ports. The deposition time of diamond-like coating is used to control the thickness and the deposition temperature is used to control the hardness. Most of the sticking or wear of the epoxy filling plungers occurs within about 3 mm of the tip. Two methods can be used for a repair and improvement of the plungers: one is by machining a chamfer angle on the end of the plunger. The value of chamfer angle is an important factor to affect the sticking or wear of the epoxy filling plungers. The addition of chamfer angle not only reduces abrasion but also increases the space for the cleaning and removal of organic debris. The other method is to cut off the worn out tip and attach a high-strength end by silver welding to strengthen the tip of the plunger. The silver welding temperature is an important factor to affect the adhesive force of the new added metal. Both methods can be used to recycle plungers which would otherwise be discarded.

3. Results

The study can be divided into three parts to investigate the results: Part 1—How do we rectify the surface abrasion of ports and plungers to increase the service life of recycled ports and plungers. Plungers are made of tungsten carbide doping with little cobalt because they are required to have very high strength and abrasion resistance. The abrasions of both ports and plungers have two main causes:

(1) Wear in the mold caused by vertical and horizontal deviations which result in friction and abrasion.

(2) Corrosion caused by acidic and alkaline ingredients in both the plastic cakes and mold cleaning chemicals. This mainly results in the wearing off of the cobalt metal and unevenness in the circularity of the inner diameter of the port.

When we discussed with the suppliers of the mold cleaning materials, we had confirmed that an amine ingredient can damage the surfaces of ports in the mold.

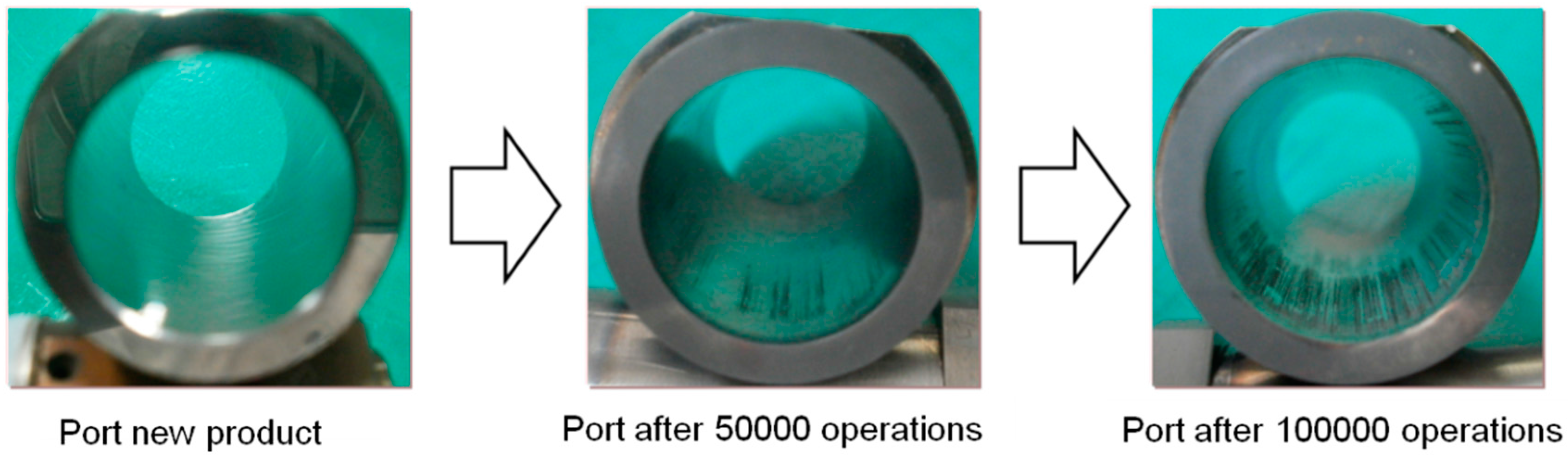

Figure 6 shows significant surface abrasion on a port surface after ~50,000 epoxy fillings, the damage is really observed. The abrasion in the port is even more severe after 100,000 fillings, this is also the case for the plunger, the more serious damage is also really observed.

Ductile metals are prone to produce adhesion when they are machined or ground, especially at high-temperature, this results in solidification of the metal or alloy which causes processing difficulty and shortens the service life of tools. Problems in such a metal or alloy can be resolved by applying a diamond-like coating to protect the metal from corrosion or scratching. Due to its compact nature the diamond-like coating can block moisture and oxygen and is eminently suitable for use in this application. The coating also facilitates heat dissipation. It is evenly applied to both the internal and external parts and increases abrasion resistance very well.

Figure 7 shows how we try to recycle and increase service lifespan of ports to overcome corrosion problems [

8,

9]. The solution for this was a diamond-like coating obtained by E-gun deposition [

10,

11,

12,

13,

14].

The diamond-like coating, which is very hard, is resistant to both acid and alkali and has a smooth surface with a low coefficient of friction. The diamond-like coating is also a material with the characteristics of abrasion resistant, has good heat conductivity, and a low processing temperature, and it can extend the working life of a mold from 2 to 10 times. Although graphite coating has been used to protect the ports of Epoxy filling molds, it is uneven and coverage is poor. The technique for coating the ports of molds with a diamond-like carbon film has been accomplished in this study and coatings have been thoroughly tested. We have found that the coating can increase the abrasion resistance of recycled ports and increase their service life. The coating is applied evenly to the inside and outside of the port and optical microscopy has been used to verify the quality of the surface. Hardness tests of the deposited diamond-like carbon films were also performed. The results of the study, which were included in specifications presented to Advanced Semiconductor Engineering Inc. (ASE Inc., Kaohsiung, Taiwan) and other companies, show the coatings to be 2 ± 0.2 μm in thickness. The coating is capable of resisting a friction of 150 kg, and it has a hardness up to Hv 3300.

Figure 8 shows the surface observation of a port coated with diamond-like carbon film. The performances of the originally normal and recycled ports and plungers are checked by ASE Inc. The service life of originally normal ports and plungers is about 4 months, and the service life of recycled ports and plungers with diamond-like carbon films is about 8 months. Those results really prove the diamond-like carbon films on the surfaces of ports and plungers can really increase their service life.

Part 2—The surfaces of the used plungers tend to wear out after a considerable number of operations. Also, the volume of accumulation plastic debris will increase after a considerable number of operations. The halogen-free green EMCs are now used for environmental reasons and they have the problem of much stickier than the old ones do. When the ports and plungers are used for production process, the time needed to clean the stickier halogen-free green EMCs becomes more necessary and much shorter. To address this issue, we developed a technique for chamfering the plunger tip, as shown in

Figure 9. Current chamfering and polishing methods are mostly performed manually on a milling machine, where the main problem is the achievement of even beveling of the edges. But an automated milling machine can easily carry out the necessary machining without trouble.

Figure 9a shows the pattern of a new product, where port and plunger are closely linked with merely a very small gap left for movement; since they are linked closely, wear as well as sticking issues will eventually occur.

Figure 9b shows surface wear issues in ports and plungers after a number of Epoxy resin filling actions. When the wear reaches a certain extent, a film of epoxy resin will be left on both the port and plunger of the packaging mold. This residue is the result of unused resin and adhesion. Since the residue is small and difficult to remove, cleaning takes a long time and this reduces the time available for production. To solve this problem, we developed a plunger tip with a chamfered end formed by milling, as shown in

Figure 9c. This technology can increase the volume of the remaining resin and this actually facilitates cleaning and reduces the time taken for the process to be completed. After much trial and error, we have found the optimal chamfering angle to be about 15 degrees.

Part 3—The recycling and re-use of plungers with worn out tips. Although the service lifespan of plungers generally used for the epoxy resin filling operation can be prolonged using the two methods described earlier, the plungers will eventually become unusable. Also, as compared with the ports the plungers always have a shorter service life time as compared that of ports. Existing plungers, which are made in one piece, undergo great torsion and strain during the push-pull action of the filling operation. In addition to surface roughening caused by the excessive friction, the threaded holes also tend to break. Because of this, we investigated a new welding technique to increase the service life of the plungers.

Most of the abrasion takes place within 3 mm of the tip of the plungers. To recycle worn plungers for reuse we developed a seam-less silver welding technique to attach a new tip onto the plungers. The worn tip is cut off and replaced by one new tip made of DC53 + F10 steel with super-fine grain tungsten carbide, the processes are revealed in

Figure 10. As the

Figure 10 shows, this material stands up very well to the forces involved in the operation and transfers and absorbs the torque very well. We have found that the use of DC53 + F10 steel as the tip of the plungers can substitute the original metal of the plungers. The DC53 + F10 steel can really increase the service life of the plungers. When we combine the three techniques investigated in this study, we can reuse the ports and plungers. Also, we could realistically save more than 50% of the production fee of ICs’ packages because we investigated the reused techniques of the ports and plungers.