Molybdenum Sinter-Cladding of Solid Radioisotope Targets

Abstract

1. Introduction

- Target preparation time and the cost of each target

- Equipment cost

- Reliability and reproducibility of the process

- Build-up of the required thickness

- Coating material losses

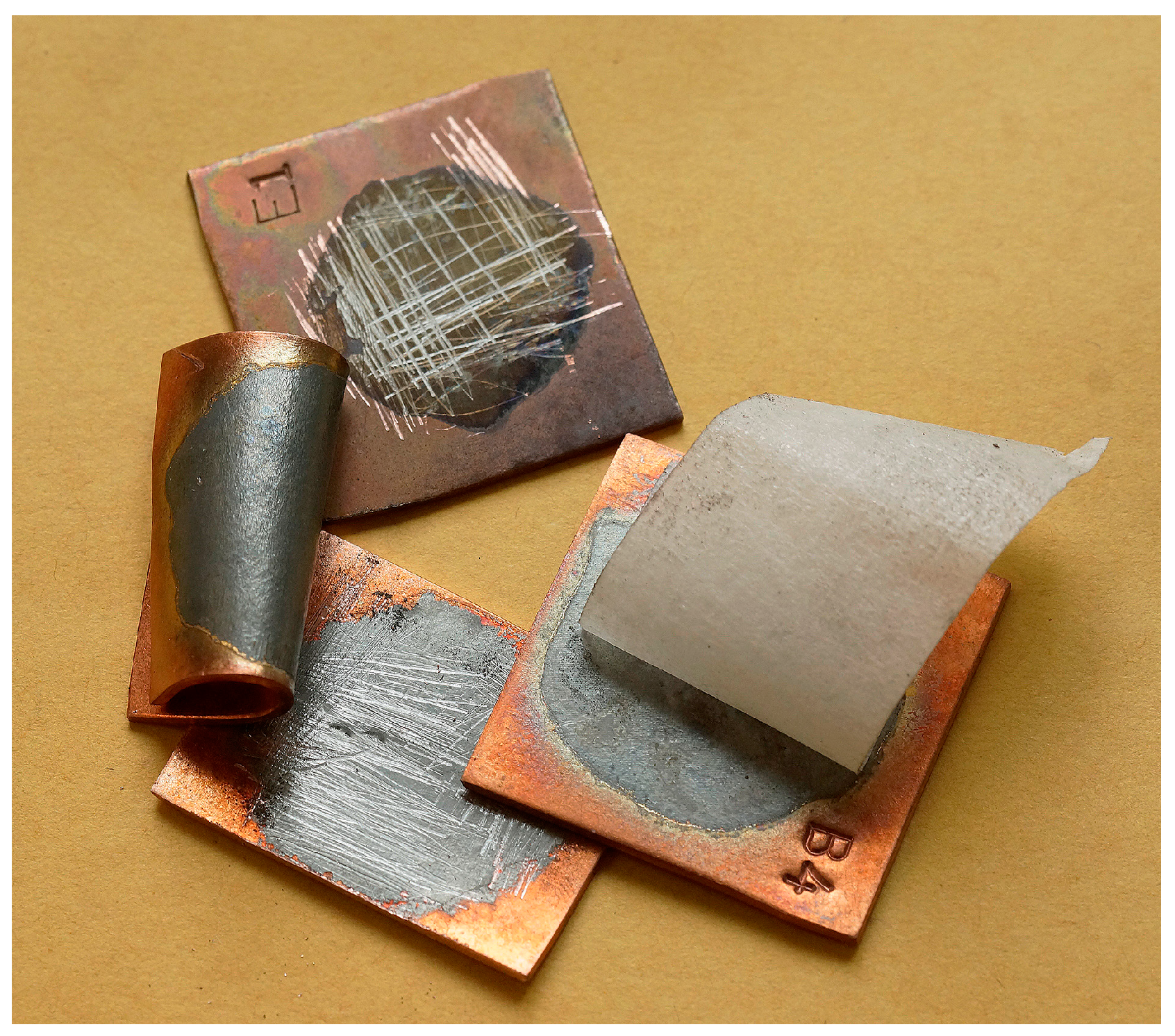

- Coating adhesion, especially at a high operating temperature

- Density of the coating

2. Materials and Methods

- Mo powder, <150 μm, 99.99% trace metals basis, Sigma Aldrich 203823

- Polyvinyl alcohol, Mw 89,000–98,000, 99+% hydrolyzed, Sigma Aldrich 341584

- C10100 oxygen free copper, OnlineMetals, www.onlinemetals.com

- 3M 250 Flatback Masking Tape, 3M Company

- 3M 720 Film Fiber Tape, 3M Company

- Hydrogen sintering oven system, Rapidia Inc., Vancouver, BC, Canada

- The substrates samples, approximately 40 mm × 40 mm, were sheared from a 2 mm thick, C10100, oxygen-free, copper sheet and lightly wet-sanded with #400 silicon carbide paper, followed by a wash with hot water and detergent.

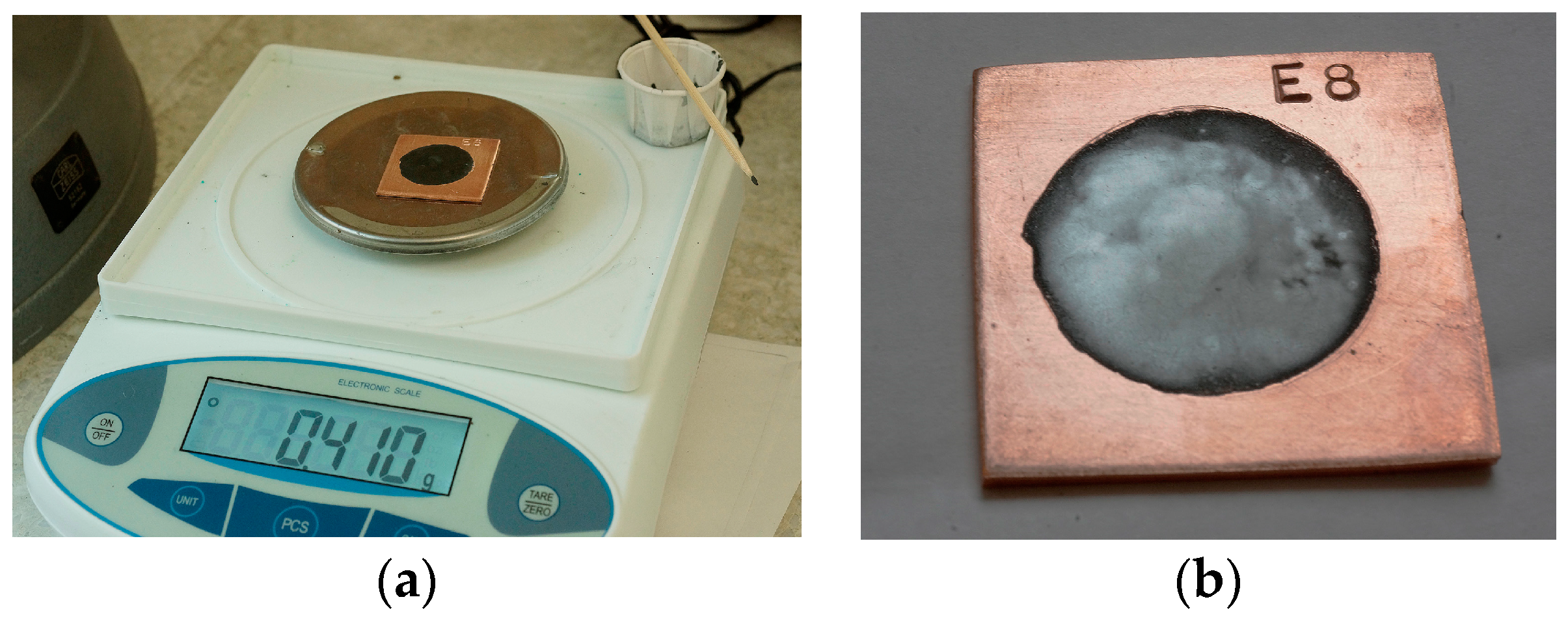

- The metal slurry was deposited on the substrate. This was done with the substrate on a scale and the weight of slurry deposited and evenly spread over an area of a 25 mm diameter circle that corresponded to final molybdenum thicknesses of 3–5 gm/cm2. Figure 1a.

- The sample was dried on a hot plate for one hour at 50 °C.

- The surfaces of the first ten samples were rolled with a silicon carbide ball-bearing (mounted on a handle) using hand pressure. Small rolling mills with steel rollers were used for later samples. The rolling was to consolidate the dry coat and to flatten any small voids that were left as a result of air bubbles. Figure 1b.

- The sample was placed in a hydrogen oven (Figure 2), the temperature was raised to 980 °C with a ramping rate of 8 °C per minute, and it was kept at 980 °C for a number of hours. Various times were employed from 4 to 8 h. There seemed to be no difference in the results after 4 h.

- The hydrogen was at atmospheric pressure, and a flow of 0.3 L/min was maintained throughout the process. Since the temperature was close to the melting point of copper and to avoid any deformation, the samples were place on a flat sheet of 99.8% alumina.

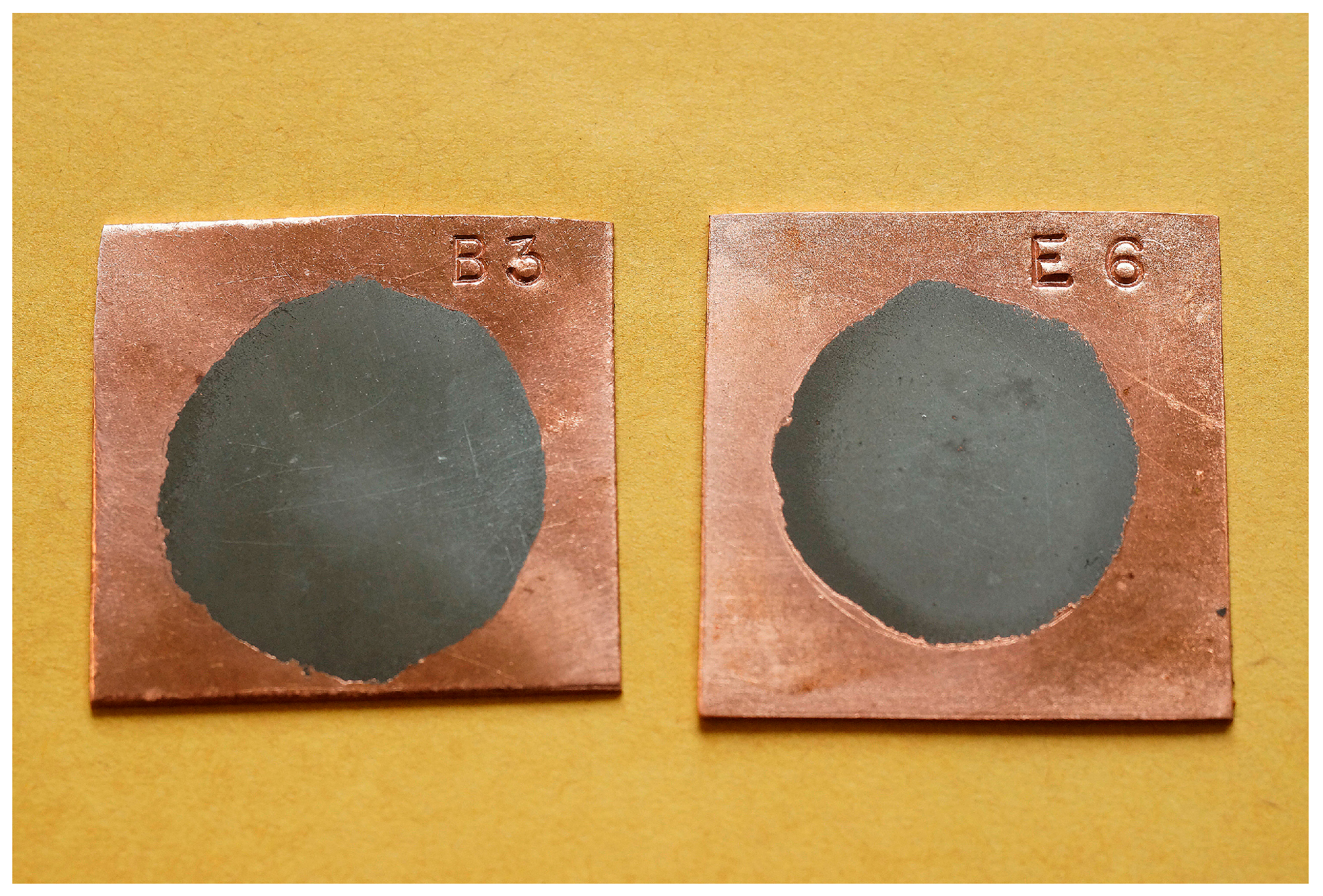

- At the end of the process, samples were allowed to cool while still in the oven (and still under hydrogen atmosphere) to below 100 °C and removed (Figure 3). The cooling time of the oven to this temperature was 12 h, and the cooling was done overnight.

3. Results

4. Discussion

5. Patents

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Stolarz, A.; Kowalska, J.A.; Jasinski, P.; Janiak, T.; Samorajczyk, J. Molybdenum targets produced by mechanical reshaping. JRNC 2015, 305, 947–952. [Google Scholar] [CrossRef] [PubMed]

- Gelbart, W.; Johnson, R.R.; Abeysekera, B. Solid Target Irradiation and Transfer System. In Proceedings of the 14th International Workshop on Targetry and Target Chemistry, Playa del Carmen, Mexico, 26–29 August 2012. [Google Scholar]

- Stolarz, A. Target preparation for research with charged projectiles. JRNC 2014, 299, 913–931. [Google Scholar] [CrossRef] [PubMed]

- Bénard, F.; Buckley, K.R.; Ruth, T.J.; Zeisler, S.K.; Klug, J.; Hanemaayer, V.; Vuckovic, M.; Hou, X.; Celler, A.; Appiah, J.P.; et al. Implementation of Multi-Curie Production of 99mTc by Conventional Medical Cyclotrons. J. Nucl. Med. 2014, 55, 1017–1022. [Google Scholar] [CrossRef] [PubMed]

- Gelbart, W.Z.; Johnson, R.R. Irradiation Targets for Accelerator Production of 99mTc. In Proceedings of the 14th International Workshop on Targetry and Target Chemistry, Playa del Carmen, Mexico, 26–29 August 2012. [Google Scholar]

- Target and Apparatus for Cyclotron Production Of Technetium-99m. EP Patent EP3197246(A1), 26 July 2017.

- Hanemaayer, V.; Zeisler, S.K.; Buckley, K.R.; Klug, J.; Kovacs, M.; Bérnard, F.; Ruth, T.J.; Schaffer, P. Solid Targets for Tc-99m Production on Medical Cyclotrons. In Proceedings of the 14th International Workshop on Targetry and Target Chemistry, Playa del Carmen, Mexico, 26–29 August 2012. [Google Scholar]

- Surette, G.J. Molybdenum 100 Targets for Cyclotron Production of Technetium 99m. Master’s Thesis, Department of Mechanical and Aerospace Engineering, Carleton University, Ottawa, ON, Canada, 2015. [Google Scholar]

- Thomas, B.A.; Wilson, J.S.; Gagnon, K. Solid 100Mo target preparation using cold rolling and diffusion bonding. In Proceedings of the 15th International Workshop on Targetry and Target Chemistry, Prague, Czech Republic, 18–21 August 2014. [Google Scholar]

- Sklairova, H.; Cisterno, S.; Cicoria, G.; Marengo, M.; Palmieri, V. Innovative Target for Production of Technetium-99m by Biomedical Cyclotron. Molecules 2019, 24, 25. [Google Scholar] [CrossRef] [PubMed]

- Matei, L.; McRae, G.; Galea, R.; Niculae, D.; Craciun, L.; Leonte, R.; Surette, G.; Langille, S.; St. Louis, C.; Gelbart, W.; et al. A new approach for manufacturing and processing targets used to produce 99mTc with cyclotrons. Mod. Phys. Lett. A 2017, 32, 1740011. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gelbart, W.Z.; Johnson, R.R. Molybdenum Sinter-Cladding of Solid Radioisotope Targets. Instruments 2019, 3, 11. https://doi.org/10.3390/instruments3010011

Gelbart WZ, Johnson RR. Molybdenum Sinter-Cladding of Solid Radioisotope Targets. Instruments. 2019; 3(1):11. https://doi.org/10.3390/instruments3010011

Chicago/Turabian StyleGelbart, William Z., and Richard R. Johnson. 2019. "Molybdenum Sinter-Cladding of Solid Radioisotope Targets" Instruments 3, no. 1: 11. https://doi.org/10.3390/instruments3010011

APA StyleGelbart, W. Z., & Johnson, R. R. (2019). Molybdenum Sinter-Cladding of Solid Radioisotope Targets. Instruments, 3(1), 11. https://doi.org/10.3390/instruments3010011