Microstructural Analysis of Terbium Doped Zirconia and Its Biological Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Zirconia

2.2. Synthesis of Terbium Doped Zirconia

2.3. Characterization

2.4. Biocompatibility

3. Results and Discussion

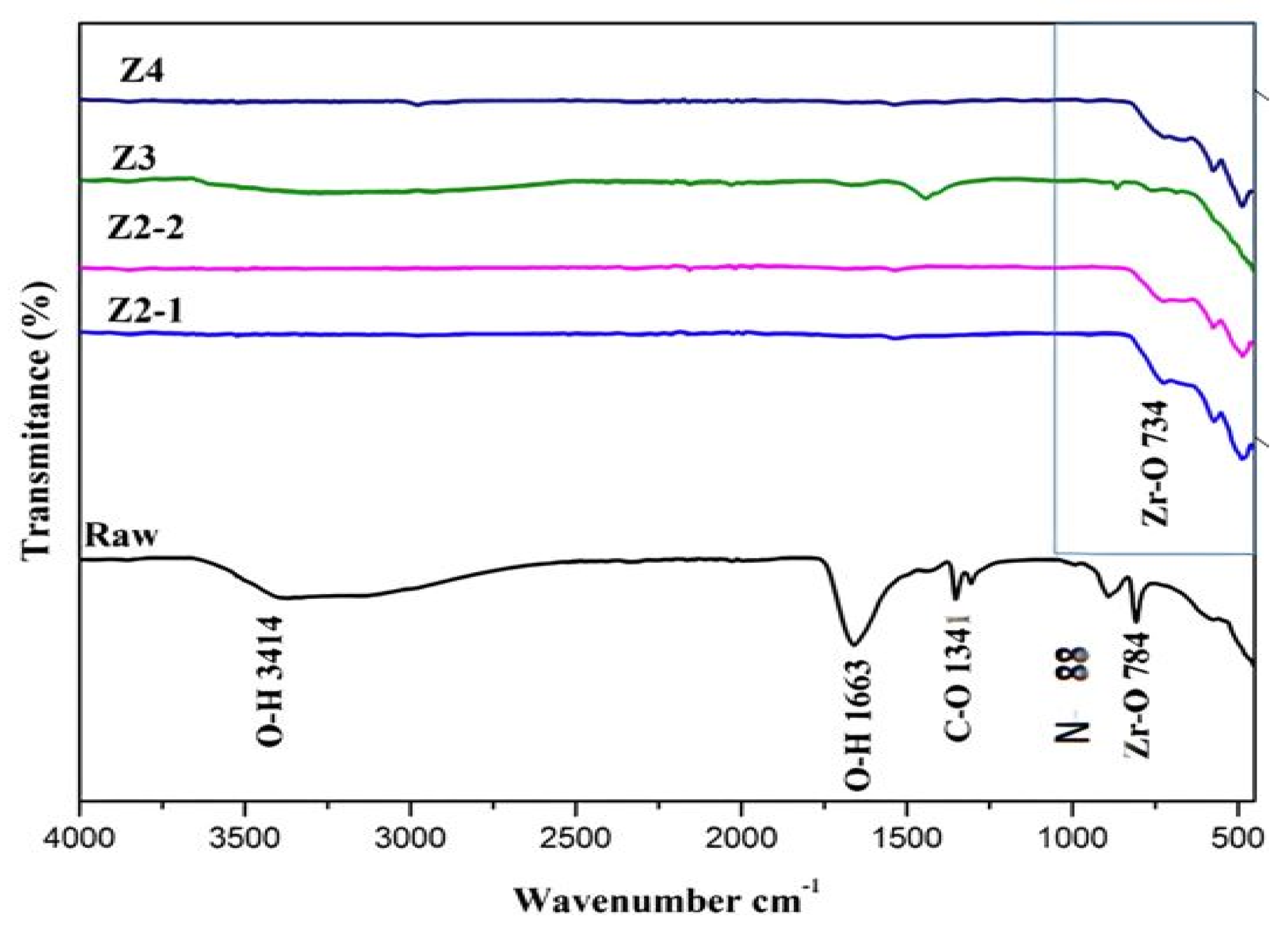

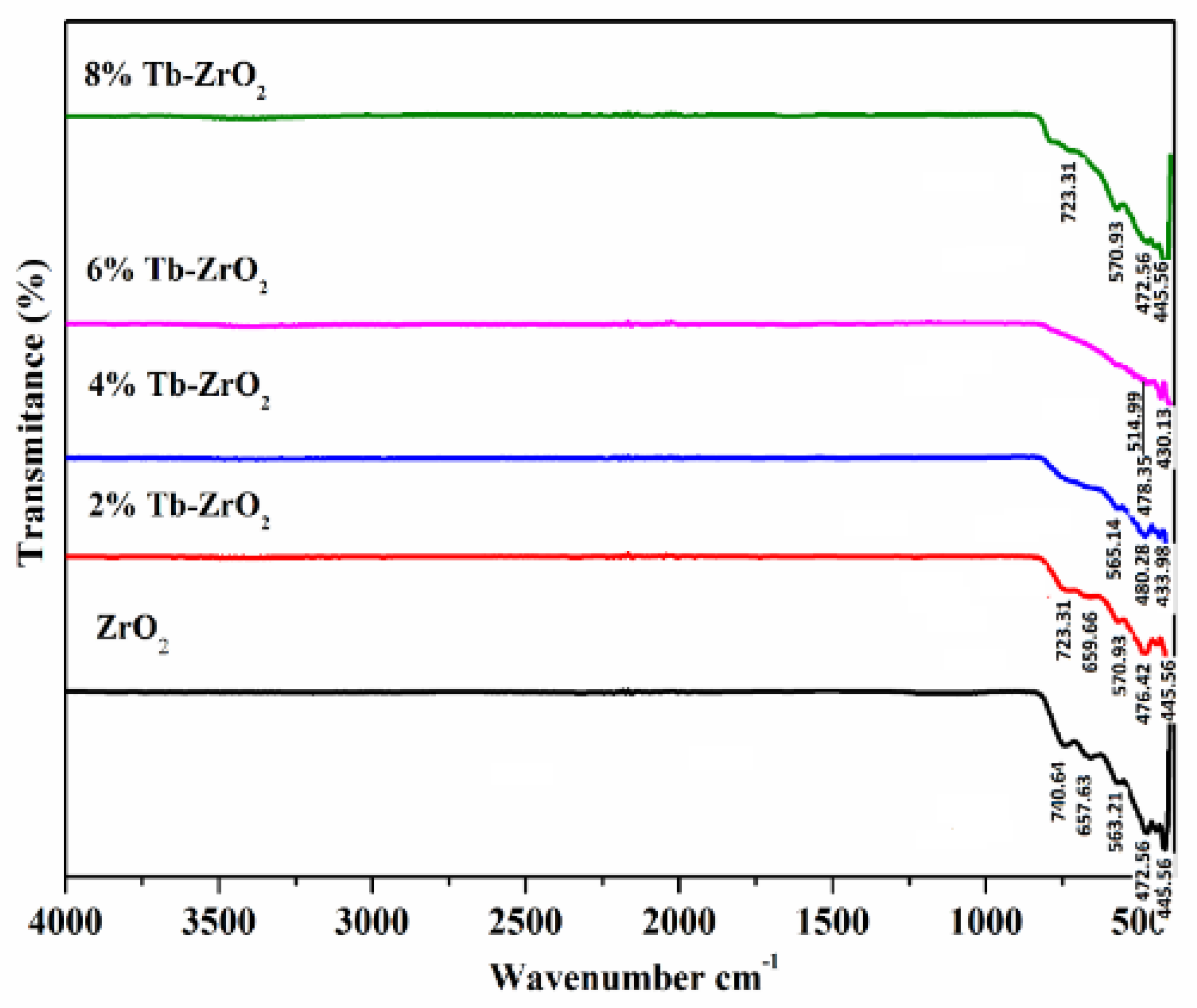

3.1. FTIR

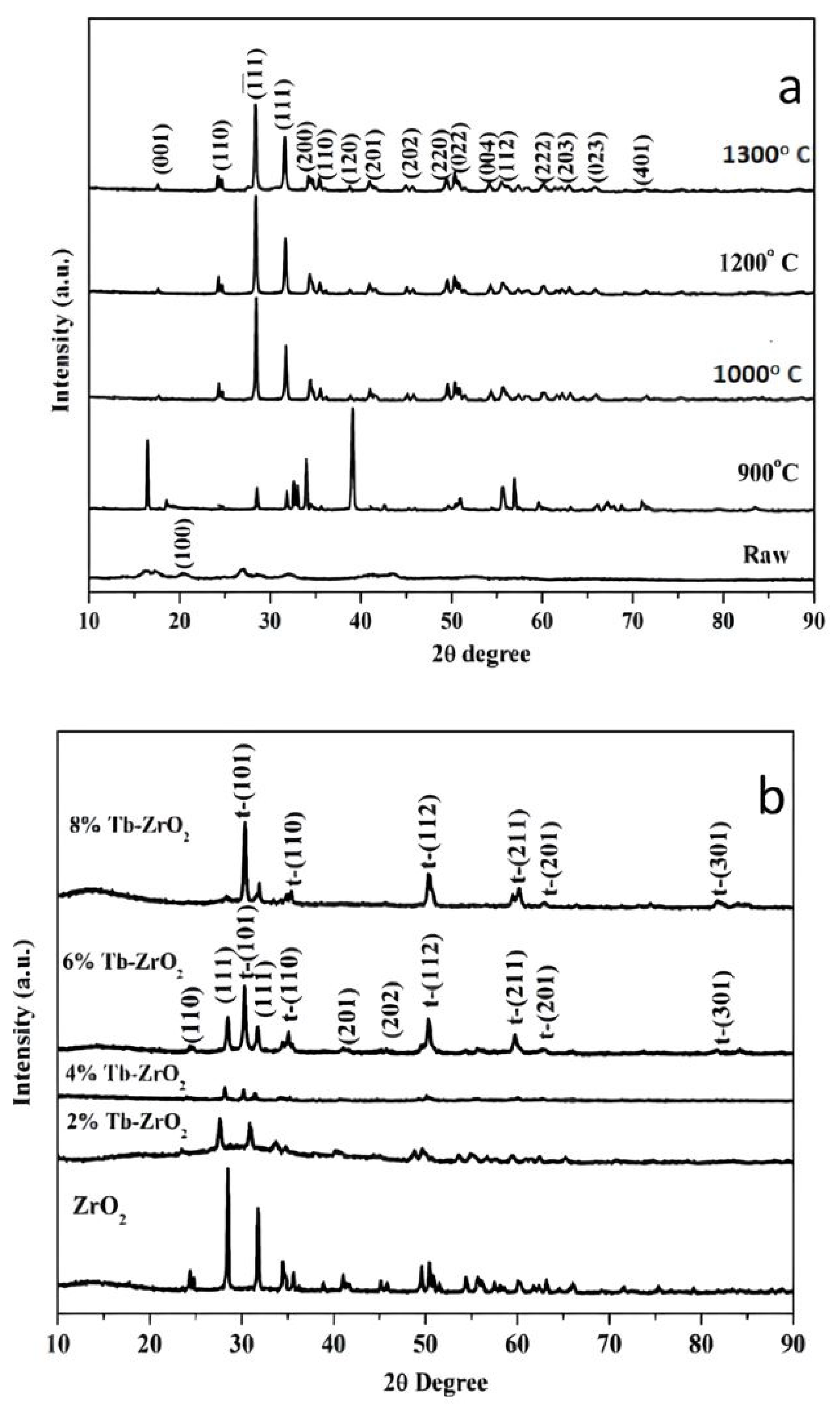

3.2. XRD Analysis

3.3. FE-SEM

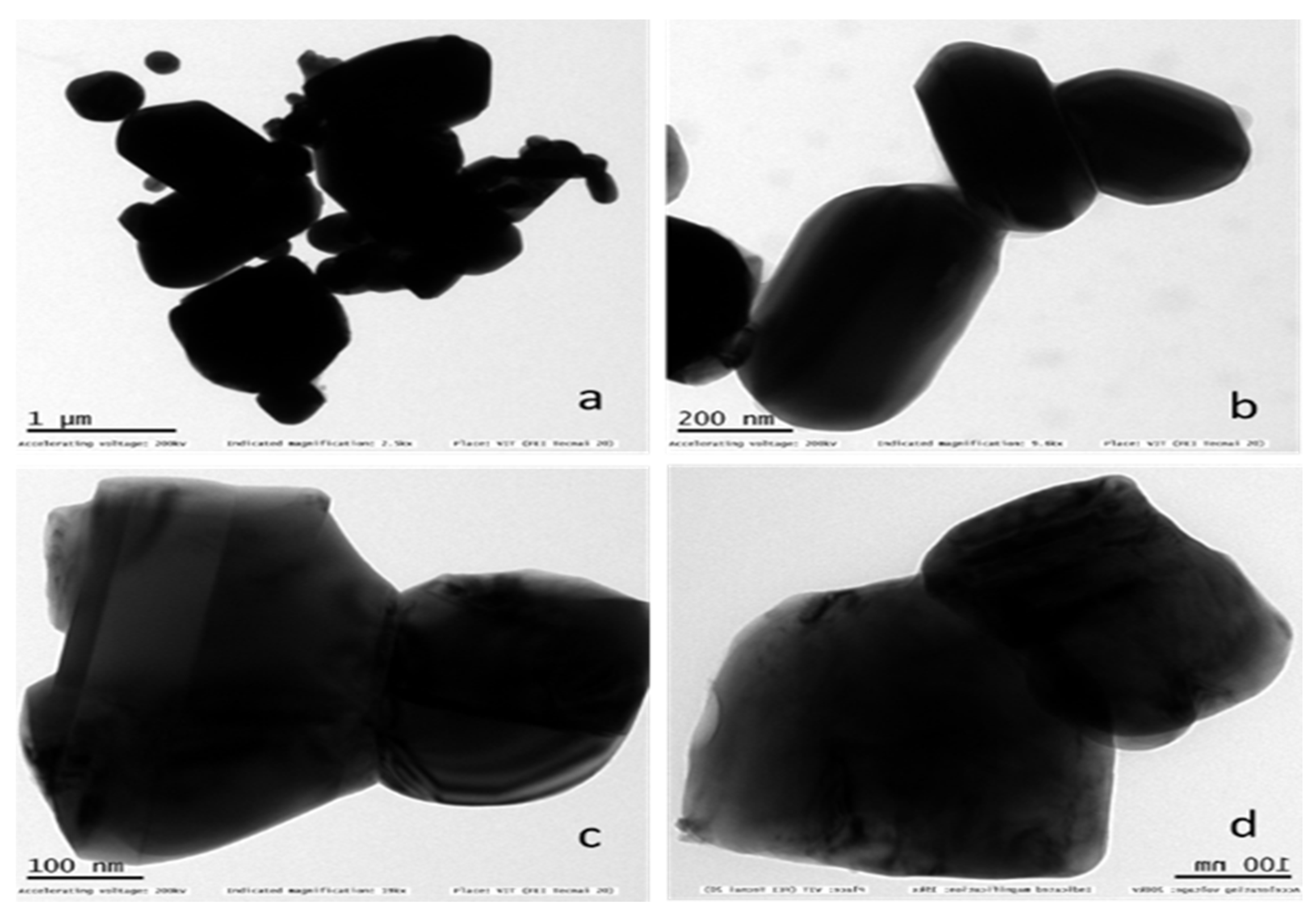

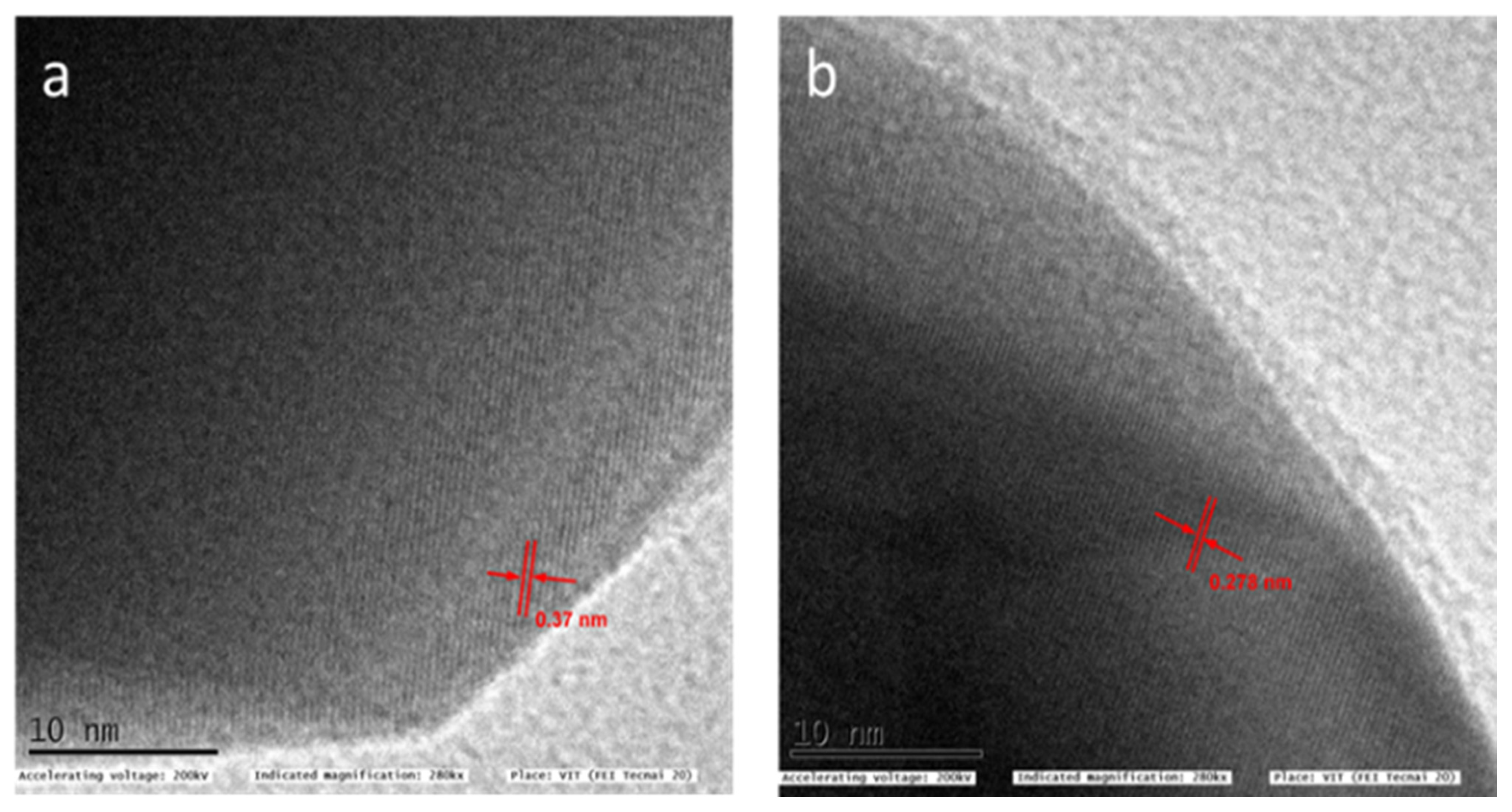

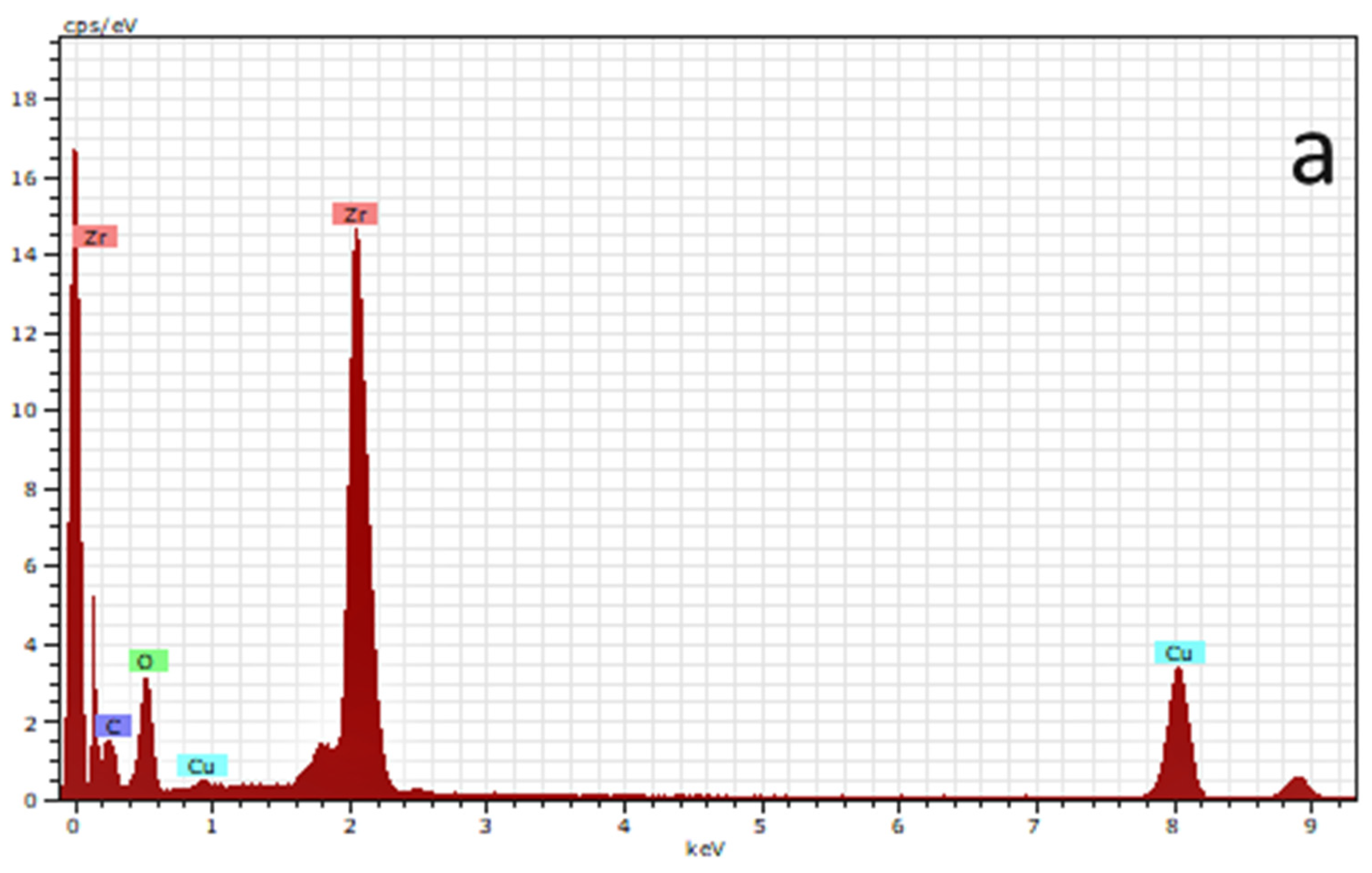

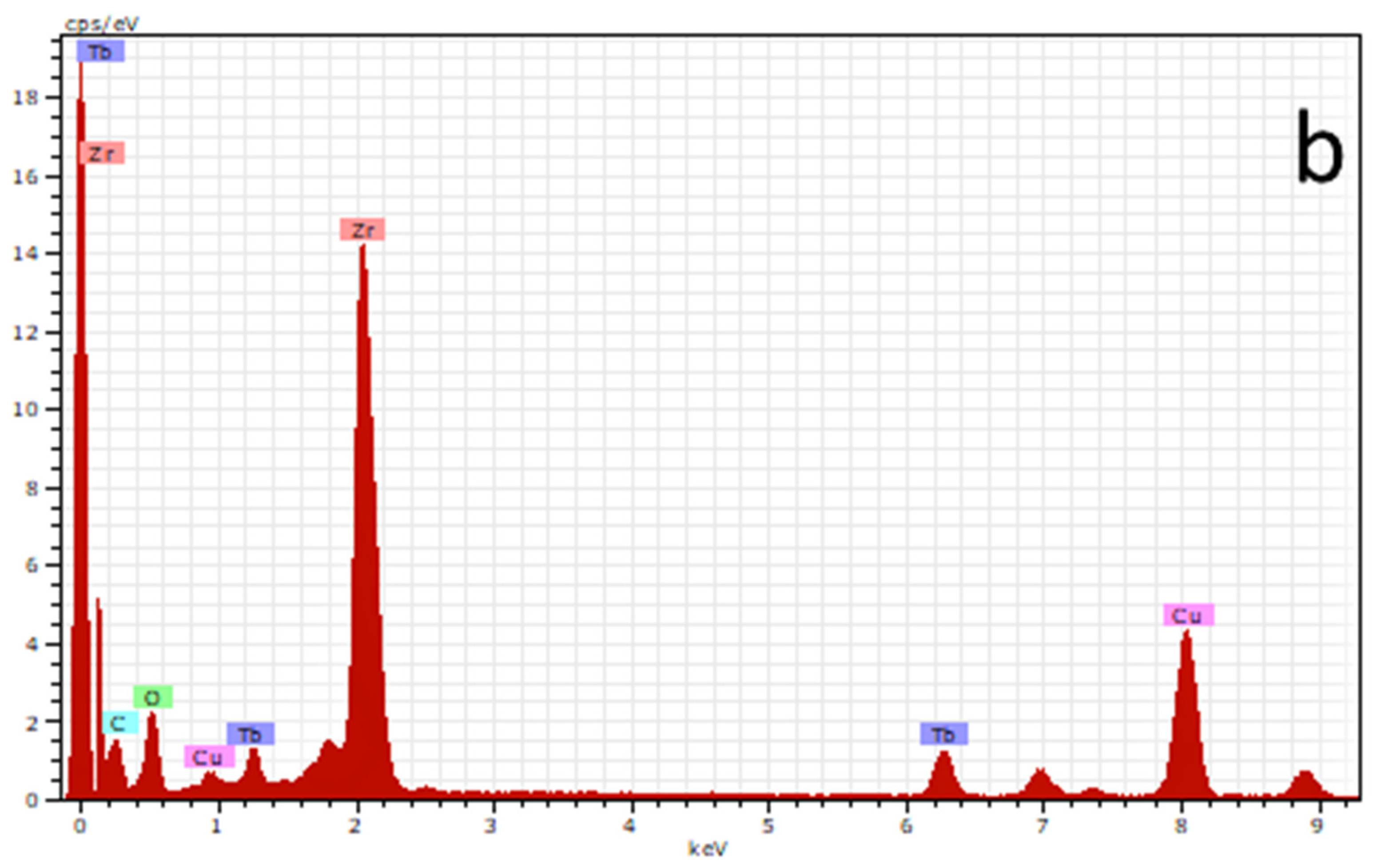

3.4. TEM

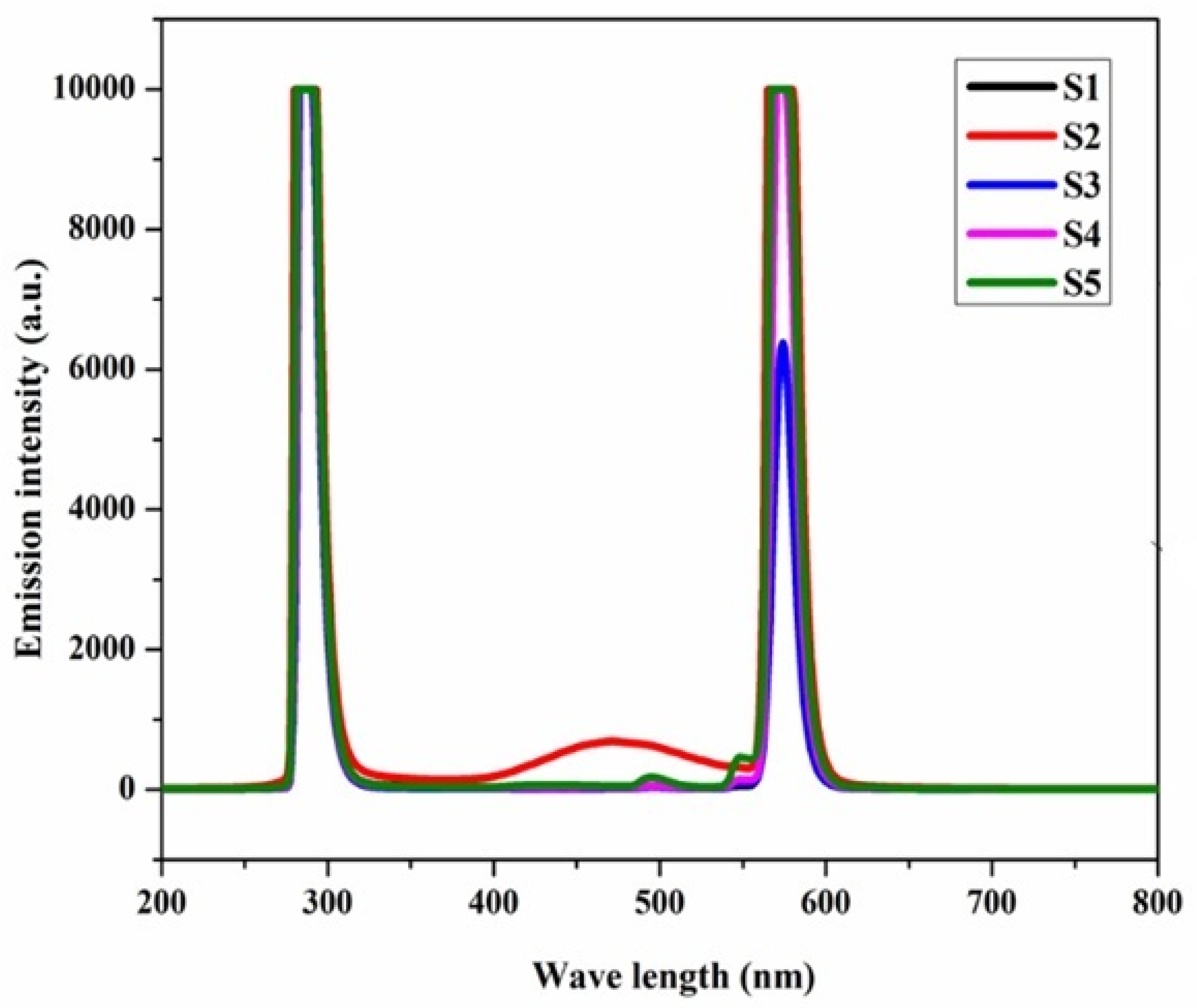

3.5. Photoluminescence Property

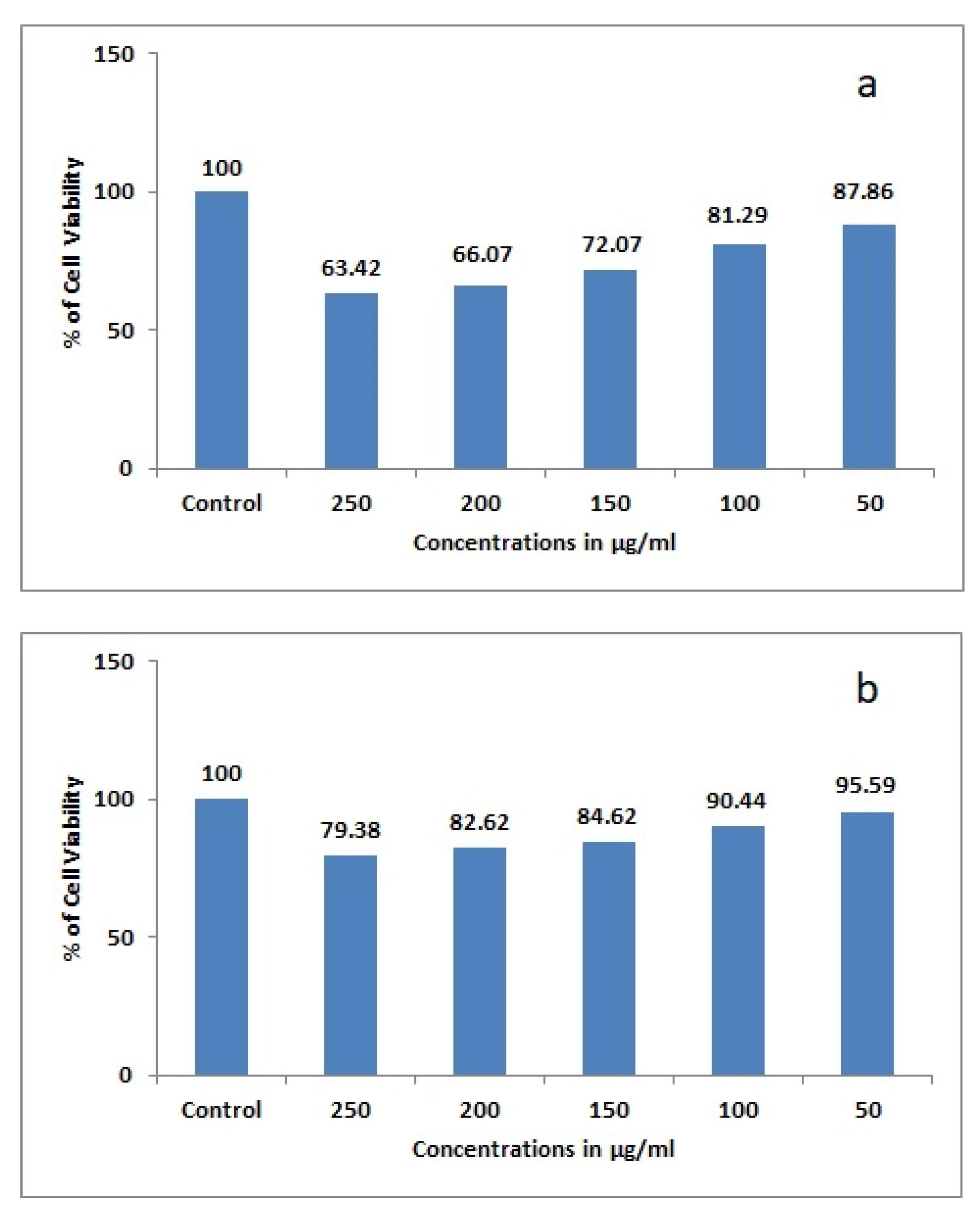

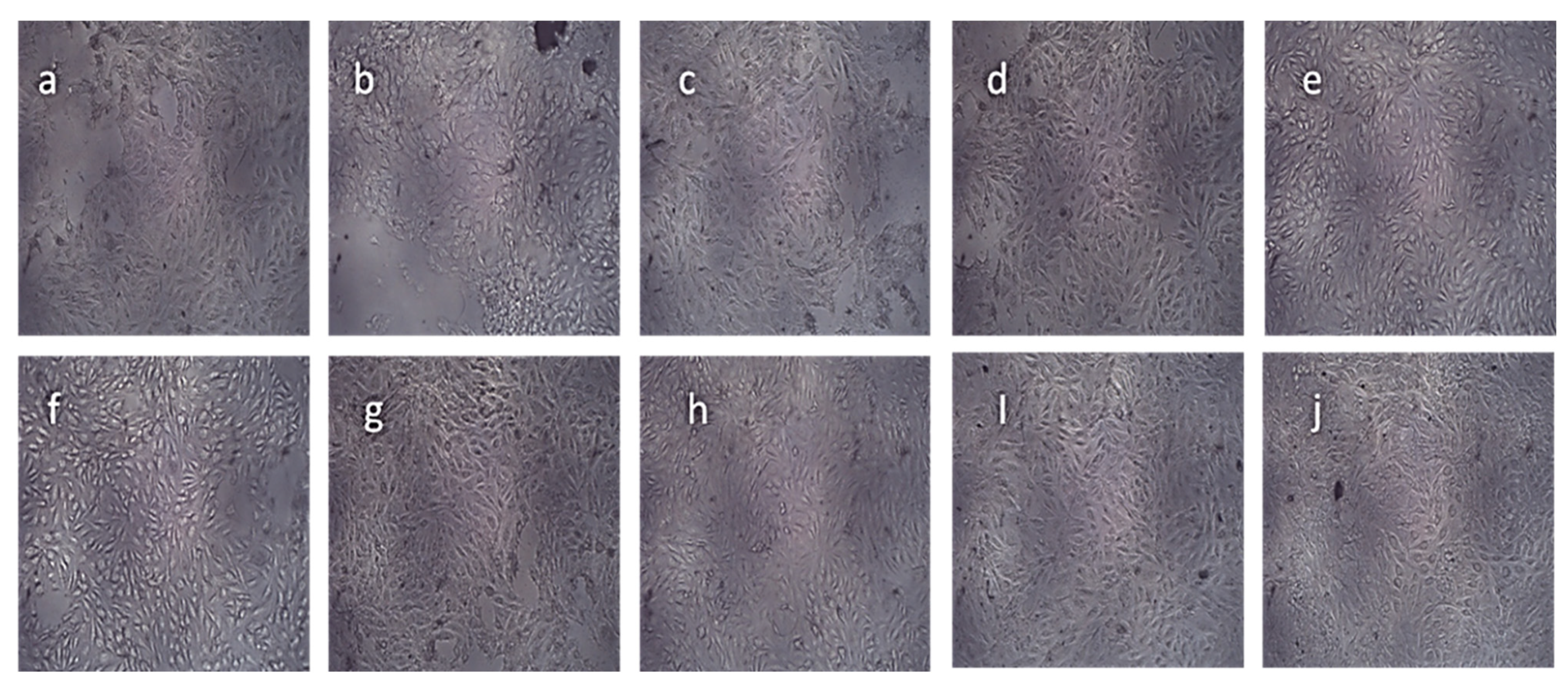

3.6. Biocompatibility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Eichler, A. Tetragonal Y-doped zirconia: Structure and ion conductivity. Phys. Rev. B 2001, 64, 174103. [Google Scholar] [CrossRef]

- Shukla, S.; Seal, S. Mechanisms of room temperature metastable tetragonal phase stabilization in zirconia. Int. Mater. Rev. 2005, 50, 45–64. [Google Scholar] [CrossRef]

- Shanmugam, K.; Sahadevan, R. Bioceramics—An Introductory Overview, Fundamental Biomaterials: Ceramics; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Emrullahoglu Abi, C.B. Toughening Mechanisms in Dental Composites, Toughening Mechanisms in Composite Materials; Woodhead Publishing: Philadelphia, PA, USA, 2015. [Google Scholar]

- Matinlinna, J.P. Processing and Bonding of Dental Ceramics, Non-Metallic, Biomaterials for Tooth Repair and Replacement; Woodhead Publishing: Philadelphia, PA, USA, 2013. [Google Scholar]

- Manicone, P.F.; Iommetti, P.R.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Sollazzo, V.; Pezzetti, F.; Scarano, A.; Piattelli, A.; Bignozzi, C.A.; Massari, L.; Brunelli, G.; Carinci, F. Zirconium oxide coating improves implant osseointegration in vivo. Dent. Mater. 2008, 24, 357–361. [Google Scholar] [CrossRef]

- Özkurt, Z.; Kazazoğlu, E. Zirconia Dental Implants: A Literature Review. J. Oral Implantol. 2011, 37, 367–376. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S. A Recent Updates on Zirconia Implants: A Literature Review. J. Dent. Sci. Med. 2016, 1, 18–26. [Google Scholar]

- Chai, J.; Chu, F.C.S.; Chow, T.W.; Liang, B.M.H. Chemical solubility and flexural strength of zirconia-based ceramics. Int. J. Prosthodont. 2007, 20, 587–595. [Google Scholar]

- Kvam, K.; Karlsson, S. Solubility and strength of zirconia-based dental materials after artificial aging. J. Prosthet. Dent. 2013, 110, 281–287. [Google Scholar] [CrossRef]

- Thompson, J.Y.; Stoner, B.R.; Piascik, J.R.; Smith, R. Adhesion/cementation to zirconia and other non-silicate ceramics: Where are we now? Dent. Mater. 2011, 27, 71–82. [Google Scholar] [CrossRef] [Green Version]

- Mulinti, P.; Lervick, B.; Pullan, J.E.; Brooks, A.E. Strategies to improve the hemocompatibility of biodegradable biomaterials. In Hemocompatibility of Biomaterials for Clinical Applications; Woodhead Publishing: Philadelphia, PA, USA, 2018. [Google Scholar]

- Khang, G.; Kim, S.H.; Kim, M.S.; Lee, H.B. Hybrid, Composite, and Complex Biomaterials for Scaffolds; Hybrid, Composite, and Complex Biomaterials for Scaffolds, Principles of Regenerative Medicine; Academic Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Zafar, M.S.; Khurshid, Z.; Najeeb, S.; Zohaib, S.; Rehman, I.U. Therapeutic Applications of Nanotechnology in Dentistry, Nanostructures for Oral Medicine; Elsevier: Amsterdam, The Netherlands, 2017; pp. 833–862. [Google Scholar]

- Al-Amleh, B.; Lyons, K.; Swain, M. Clinical trials in zirconia: A systematic review. J. Oral Rehabil. 2010, 37, 641–652. [Google Scholar] [CrossRef]

- Wong, M.S.; Ying, J.Y. Amphiphilic Templating of Mesostructured Zirconium Oxide. Chem. Mater. 1998, 10, 2067–2077. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Ding, C. Phase composition and in-vitro bioactivity of plasma sprayed calcia stabilized zirconia coatings. Surf. Coat. Technol. 2008, 202, 5824–5831. [Google Scholar] [CrossRef]

- Kelly, J.R.; Denry, I. Stabilized zirconia as a structural ceramic: An overview. Dent. Mater. 2008, 24, 289–298. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.-W.; Yang, K.-H.; Chang, K.-M.; Yeh, S.-W.; Wang, M.-C. Synthesis and crystallization behavior of 3mol% yttria stabilized tetragonal zirconia polycrystals (3Y-TZP) nanosized powders prepared using a simple co-precipitation process. J. Alloys Compd. 2011, 509, 6864–6870. [Google Scholar] [CrossRef]

- Benzaid, R.; Chevalier, J.; Saâdaoui, M.; Fantozzi, G.; Nawa, M.; Diaz, L.A.; Torrecillas, R. Fracture toughness, strength and slow crack growth in a ceria stabilized zirconia–alumina nanocomposite for medical applications. Biomaterials 2008, 29, 3636–3641. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Huang, A.; Ding, C.; Chu, P.K. Bioactivity and cytocompatibility of zirconia (ZrO2) films fabricated by cathodic arc deposition. Biomaterials 2006, 27, 3904–3911. [Google Scholar] [CrossRef] [PubMed]

- Ebnesajjad, S.; Ebnesajjad, C. Surface Treatment and Bonding of CeramicsSurface Treatment of Materials for Adhesive Bonding, 2nd ed.; Elsivier: Singapore, 2013. [Google Scholar]

- Huang, H.-L.; Chang, Y.-Y.; Chen, Y.-C.; Lai, C.-H.; Chen, M.Y. Cytocompatibility and antibacterial properties of zirconia coatings with different silver contents on titanium. Thin Solid Films 2013, 549, 108–116. [Google Scholar] [CrossRef]

- Han, Y.; Yan, Y.; Lu, C. Ultraviolet-enhanced bioactivity of ZrO2 films prepared by micro-arc oxidation. Thin Solid Films 2009, 517, 1577–1581. [Google Scholar] [CrossRef]

- Afzal, A. Implantable zirconia bioceramics for bone repair and replacement: A chronological review. Mater. Express 2014, 4, 1–12. [Google Scholar] [CrossRef]

- Cho, Y.; Hong, J.; Ryoo, H.; Kim, D.; Park, J.; Han, J. Osteogenic Responses to Zirconia with Hydroxyapatite Coating by Aerosol Deposition. J. Dent. Res. 2015, 94, 491–499. [Google Scholar] [CrossRef] [Green Version]

- Vijayalakshmi, U.; Prabakaran, K.; Rajeswari, S. Preparation and characterization of sol-gel hydroxyapatite and its electrochemical evaluation for biomedical applications. J. Biomed. Mater. Res. Part A 2008, 87A, 739–749. [Google Scholar] [CrossRef]

- Natarajan, U.V.; Rajeswari, S. Influence of calcium precursors on the morphology and crystallinity of sol–gel-derived hydroxyapatite nanoparticles. J. Cryst. Growth 2008, 310, 4601–4611. [Google Scholar] [CrossRef]

- Kaszewski, J.; Borgstrom, E.; Witkowski, B.; Wachnicki, Ł.; Kiełbik, P.; Slonska, A.; Domino, M.; Narkiewicz, U.; Gajewski, Z.; Hochepied, J.-F. Terbium content affects the luminescence properties of ZrO2:Tb nanoparticles for mammary cancer imaging in mice. Opt. Mater. 2017, 74, 16–26. [Google Scholar] [CrossRef]

- Navarro, M.; Michiardi, A.; Castano, O.; Planell, J. Biomaterials in orthopedics. J. R. Soc. Interface 2008, 5, 1137–1158. [Google Scholar] [CrossRef] [Green Version]

- Chambers, M.; Clarke, D. Terbium as an alternative for luminescence sensing of temperature of thermal barrier coating materials. Surf. Coatings Technol. 2007, 202, 688–692. [Google Scholar] [CrossRef]

- James, M. Anderson, Biocompatibility and Bioresponse to Biomaterials, Principles of Regenerative Medicine; Academic Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Ahmed, M.H.; Byrne, J.A.; Keyes, T.E.; Ahmed, W.; Elhissi, A.; Jackson, M.J.; Ahmed, E. Characteristics and applications of titanium oxide as a biomaterial for medical implants. In The Design and Manufacture of Medical Devices; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Sawston, UK, 2012. [Google Scholar]

- Zawadzki, M.; Hreniak, D.; Wrzyszcz, J.; Mista, W.; Grabowska, H.; Malta, O.; Stręk, W. Photoluminescence and cathodoluminescence of Tb-doped Al2O3–ZrO2 nanostructures obtained by sol–gel method. Chem. Phys. 2003, 291, 275–285. [Google Scholar] [CrossRef]

- Ponnilavan, V.; Khan, M.I.K.; Dhayalan, A.; Kannan, S. Structure, luminescence, mechanical and in vitro behavior of zirconia toughened alumina due to Terbium substitutions. Mater. Sci. Eng. C 2019, 102, 810–819. [Google Scholar] [CrossRef] [PubMed]

- Hardin, C.L.; Kodera, Y.; Basun, S.A.; Evans, D.R.; Garay, J.E. Transparent, luminescent Terbium doped zirconia: Development of optical-structural ceramics with integrated temperature measurement functionalities. Opt. Mater. Express 2013, 3, 893–903. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veerachamy, S.; Rajagopal, S. Microstructural Analysis of Terbium Doped Zirconia and Its Biological Studies. Condens. Matter 2022, 7, 20. https://doi.org/10.3390/condmat7010020

Veerachamy S, Rajagopal S. Microstructural Analysis of Terbium Doped Zirconia and Its Biological Studies. Condensed Matter. 2022; 7(1):20. https://doi.org/10.3390/condmat7010020

Chicago/Turabian StyleVeerachamy, Suganthan, and Sivakumar Rajagopal. 2022. "Microstructural Analysis of Terbium Doped Zirconia and Its Biological Studies" Condensed Matter 7, no. 1: 20. https://doi.org/10.3390/condmat7010020

APA StyleVeerachamy, S., & Rajagopal, S. (2022). Microstructural Analysis of Terbium Doped Zirconia and Its Biological Studies. Condensed Matter, 7(1), 20. https://doi.org/10.3390/condmat7010020