Assessing the Technical and Economic Viability of Galvanizing Snow Crab (Chionoecetes opilio) Traps

Abstract

1. Introduction

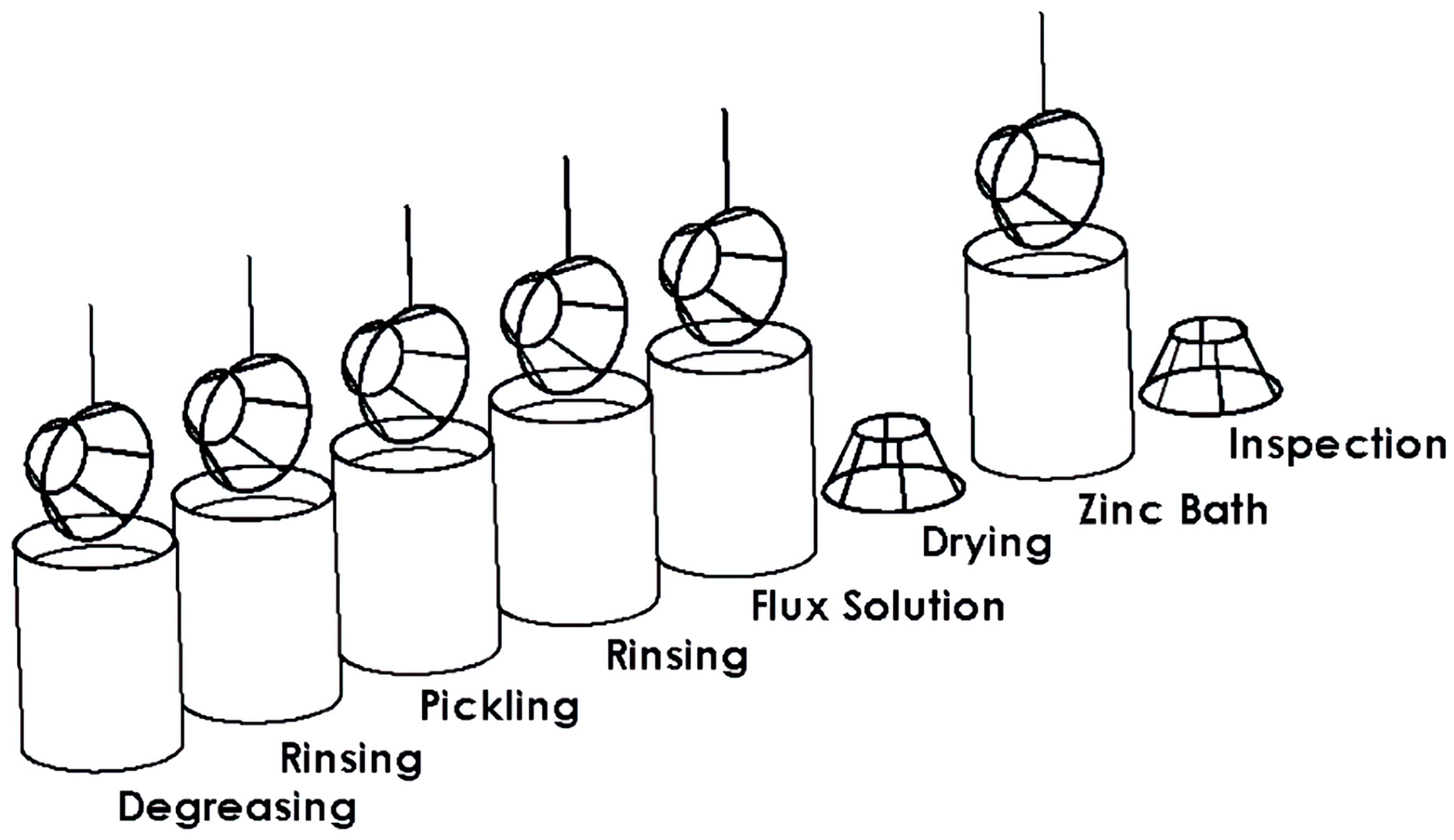

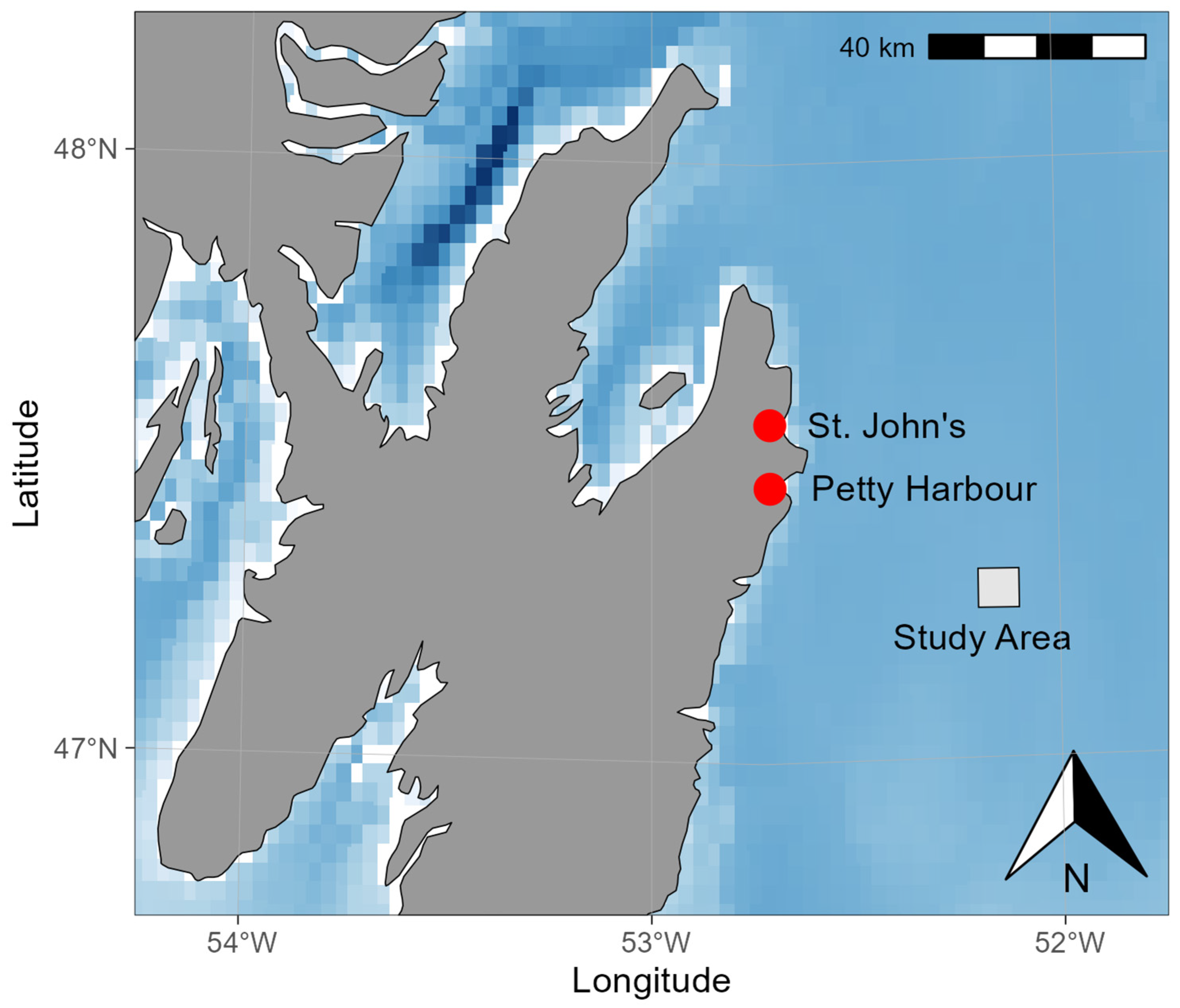

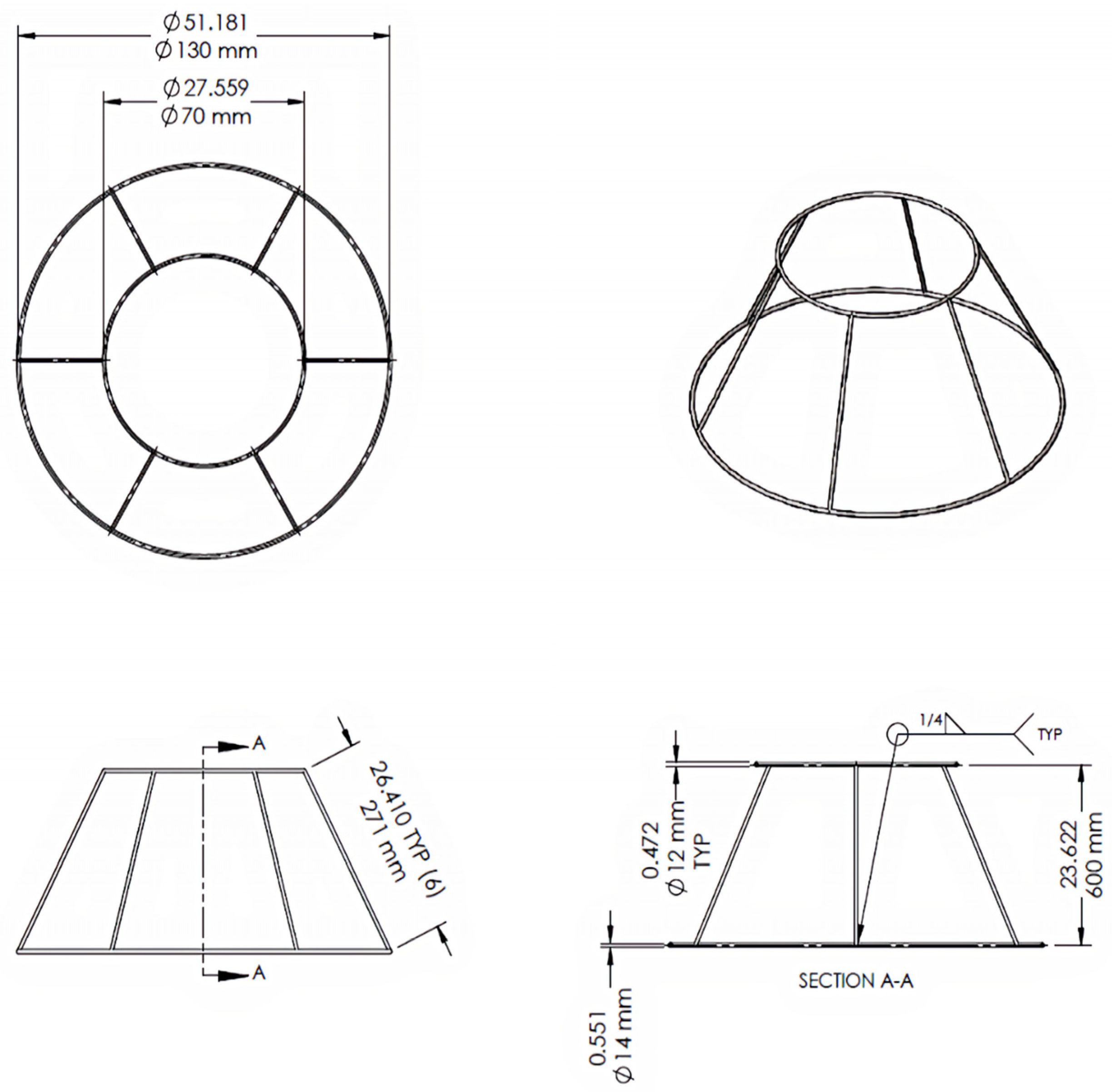

2. Materials and Methods

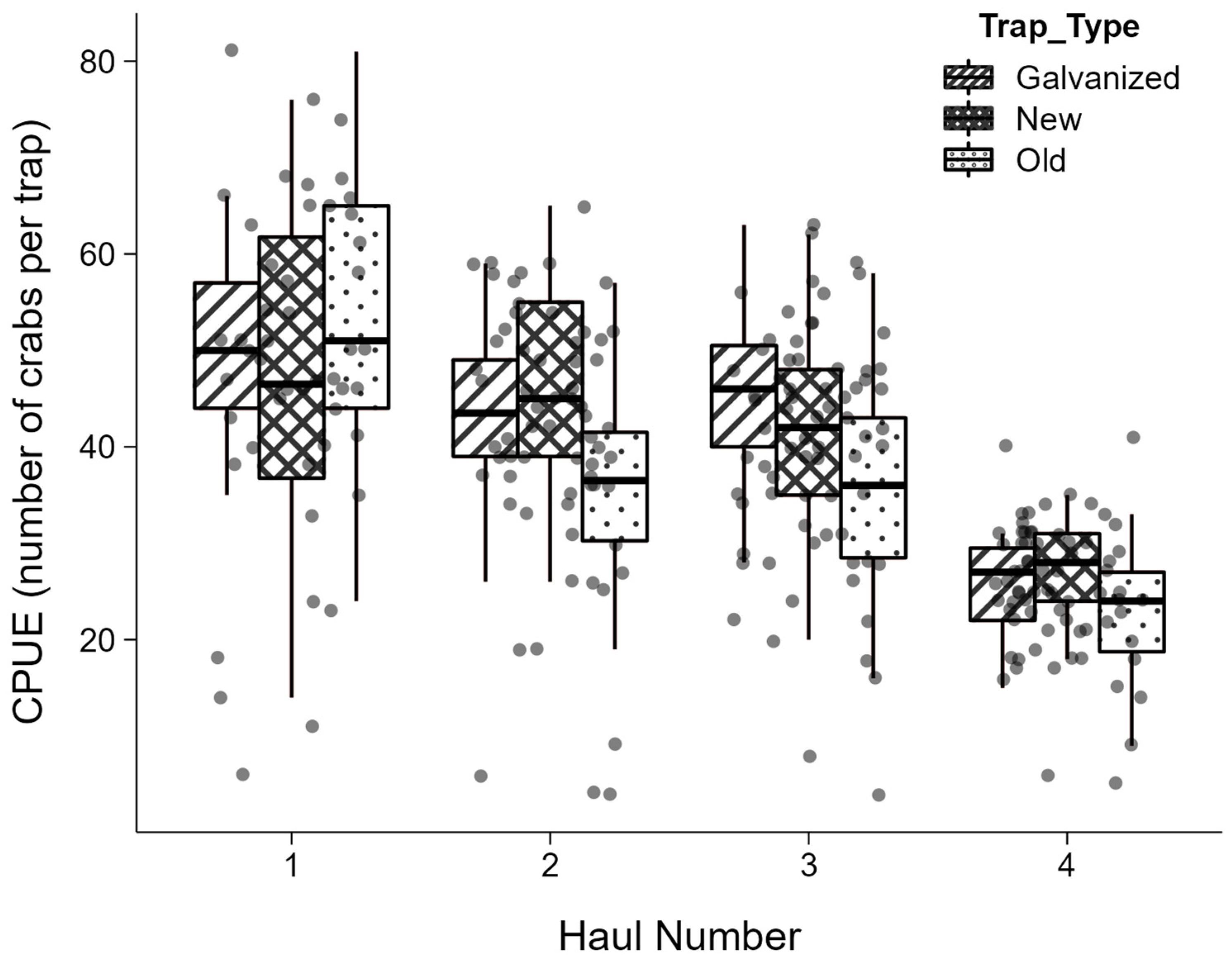

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Department of Fisheries Forestry and Agriculture. Seafood Industry Year in Review. 2022. Available online: https://www.gov.nl.ca/ffa/files/Seafood-Industry-Year-in-Review-2022.pdf (accessed on 2 December 2023).

- Mullowney, D.R.; Dawe, E.G. Development of performance indices for the Newfoundland and Labrador snow crab (Chionoecetes opilio) fishery using data from a vessel monitoring system. Fish. Res. 2009, 100, 248–254. [Google Scholar] [CrossRef]

- Fisheries and Oceans Canada. Landings and Landed Value by Species. Available online: https://www.inter.dfo-mpo.gc.ca/publications/reports_rapports/Land_All_Vessels_Debarquer_Tous_Les_Navires_2023_eng.htm (accessed on 12 March 2024).

- Atlantic Fishery Regulations. Part VI: Shellfish (SOR/86-21). Available online: https://laws-lois.justice.gc.ca/eng/regulations/sor-86-21/page-5.html#h-892053 (accessed on 20 January 2024).

- McGannon, H.E. Iron and steel. In Marks’ Standard Handbook for Mechanical Engineers, 9th ed.; Avallone, E.A., Baumeister, T., III, Eds.; McGraw-Hill Inc.: New York, NY, USA, 1987; pp. 6.12–6.46. [Google Scholar]

- Alcántara, J.; de la Fuente, D.; Chico, B.; Simancas, J.; Díaz, I.; Morcillo, M. Marine Atmospheric Corrosion of Carbon Steel: A Review. Materials 2017, 10, 406. [Google Scholar] [CrossRef]

- Phull, B.; Abdullahi, A.A. Marine Corrosion. In Reference Module in Materials Science and Materials Engineering; Hashmi, S., Ed.; Elsevier: Oxford, UK, 2017; pp. 1–39. [Google Scholar]

- Hipkins, F.W. Dungeness Crab Pots; Fisheries Leaflet 419; United States Fish and Wildlife Service: Washington, DC, USA, 1956. [Google Scholar]

- Kolbe, E. Understanding and Controlling Crevice Corrosion in Stainless Steel: A Troublesome Problem with Marine Gear and Equipment; SG 78; Oregon State University Extension Service: Corvallis, OR, USA, 1984. [Google Scholar]

- Richard, J.D. Delayed release device for use in trap fisheries. ICES J. Mar. Sci. 1971, 33, 492–505. [Google Scholar] [CrossRef]

- Fisheries and Oceans Canada. Snow Crab—Newfoundland and Labrador Region. Available online: https://www.dfo-mpo.gc.ca/fisheries-peches/ifmp-gmp/snow-crab-neige/2019/index-eng.html (accessed on 3 December 2023).

- Araya-Schmidt, T.; Winger, P.D.; Peck, G. Chocolate squid (Todarodes pacificus) bait reduces snow crab catch rates. Aquac. Fish. 2023, in press. [CrossRef]

- Chafe, B.; (Independent Harvester, Petty Harbour, NL, Canada). Lifespan of Crab Traps. Personal Communication, 2015. [Google Scholar]

- Winger, P.D.; Walsh, P. The feasibility of escape mechanisms in conical snow crab traps. ICES J. Mar. Sci. 2007, 64, 1587–1591. [Google Scholar] [CrossRef]

- Meenakumari, B.; Mohan-Rajan, K.V. Studies on materials for traps for spiny lobsters. Fish. Res. 1985, 3, 309–321. [Google Scholar] [CrossRef]

- Murray, C. Evaluation of Fish Pots as a Feasible Fishing Method in Irish Waters, with Specific Reference to the Physiological Effects of Common and Alternate Pots on the Lesser Spotted Dogfish (Scyliorhinus canicula). Master’s Thesis, Galway-Mayo Institute of Technology, Galway, Ireland, 2009. [Google Scholar]

- Merilä, J.; Lakka, H.K.; Eloranta, A. Large differences in catch per unit of effort between two minnow trap models. BMC Res. Notes 2013, 6, 151. [Google Scholar] [CrossRef]

- Power, A.; Mitchell, M.; Walker, R.; Posey, M.; Alphin, T.; Blecher, C. Baseline Port Surveys for Introduced Marine Molluskan, Crustacean and Polychaete Species in the South Atlantic Bight; 35155; NOAA Institutional Repository: Narragansett, RI, USA, 2006. [Google Scholar]

- American Galvanizers Association. Hot-Dip Galvanizing (HDG). Available online: https://galvanizeit.org/hot-dip-galvanizing (accessed on 20 January 2024).

- Kaleva, A.; Tassaing, T.; Saarimaa, V.; Le Bourdon, G.; Väisänen, P.; Markkula, A.; Levänen, E. Formation of corrosion products on zinc in wet supercritical and subcritical CO2: In-situ spectroscopic study. Corros. Sci. 2020, 174, 108850. [Google Scholar] [CrossRef]

- Strutzenberger, J.; Faderl, J. Solidification and spangle formation of hot-dip-galvanized zinc coatings. Metall. Mater. Trans. A 1998, 29, 631–646. [Google Scholar] [CrossRef]

- Prifiharni, S.; Nuraini, L.; Priyotomo, G.; Sundjono; Gunawan, H.; Purawiardi, I. Corrosion performance of steel and galvanized steel in Karangsong and Limbangan sea water environment. AIP Conf. Proc. 2018, 1964, 020038. [Google Scholar]

- Vihtakari, M. ggOceanMaps: Plot Data on Oceanographic Maps Using ‘ggplot2′. Available online: https://CRAN.R-project.org/package=ggOceanMaps (accessed on 31 December 2023).

- Zuur, A.F.; Ieno, E.N.; Elphick, C.S. A protocol for data exploration to avoid common statistical problems. Methods Ecol. Evol. 2010, 1, 3–14. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2023. [Google Scholar]

- O’Hara, R.B.; Kotze, D.J. Do not log-transform count data. Methods Ecol. Evol. 2010, 1, 118–122. [Google Scholar] [CrossRef]

- Brooks, M.E.; Kristensen, K.; van Benthem, K.J.; Magnusson, A.; Berg, C.W.; Nielsen, A.; Skaug, H.J.; Maechler, M.; Bolker, B.M. glmmTMB Balances Speed and Flexibility Among Packages for Zero-inflated Generalized Linear Mixed Modeling. R J. 2017, 9, 378–400. [Google Scholar] [CrossRef]

- Hartig, F. DHARMa: Residual Diagnostics for Hierarchical (Multi-Level/Mixed) Regression Models. Available online: https://CRAN.R-project.org/package=DHARMa (accessed on 29 December 2023).

- Lenth, R.V. emmeans: Estimated Marginal Means, aka Least-Squares Means. Available online: https://CRAN.R-project.org/package=emmeans (accessed on 29 December 2023).

- Asiedu, Y.; Gu, P. Product life cycle cost analysis: State of the art review. Int. J. Prod. Res. 1998, 36, 883–908. [Google Scholar] [CrossRef]

- Helsel, J.L.; Lanterman, R. Expected service life and cost considerations for maintenance and new construction protective coating work. In Proceedings of the Association for Materials Protection and Performance Annual Conference, San Antonio, TX, USA, 6–10 March 2022. [Google Scholar]

- Mearig, T.; Morris, L.; Morgan, M.; Coffee, N. Life Cycle Cost Analysis Handbook, 2nd ed.; State of Alaska—Department of Education & Early Development: Juneau, AK, USA, 2018. [Google Scholar]

- Anaesthesia, E.; Wijaya, S.S.; Frida, P. Technical and financial analysis of blue swimming crab (Portunus pelagicus) fishing business in Rembang district, Indonesia. Russ. J. Agric. Socio-Econ. Sci. 2019, 89, 18–26. [Google Scholar] [CrossRef]

- Acheson, J.M. Factors Influencing Productivity of Metal and Wooden Lobster Traps; 37936; National Oceanic and Atmospheric Administration: Narragansett, RI, USA, 1980. [Google Scholar]

- Bartlett, D.; (Vónin Canada Ltd., Port de Grave, NL, Canada). Crab Trap and Jacket Pricing. Personal Communication, 2023. [Google Scholar]

- Faccin, N.; (Island Manufacturing and Galvanizing Inc., Wabana, Bell Island, NL, Canada). Galvanizing Costs for Crab Traps. Personal Communication, 2023. [Google Scholar]

- Joe, H.; Zhu, R. Generalized Poisson Distribution: The Property of Mixture of Poisson and Comparison with Negative Binomial Distribution. Biom. J. 2005, 47, 219–229. [Google Scholar] [CrossRef]

- Huang, A. Mean-parametrized Conway–Maxwell–Poisson regression models for dispersed counts. Stat. Model. 2017, 17, 359–380. [Google Scholar] [CrossRef]

- Wickham, H. ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016. [Google Scholar]

- Olsen, L.; Herrmann, B.; Grimaldo, E.; Sistiaga, M. Effect of pot design on the catch efficiency of snow crabs (Chionoecetes opilio) in the Barents Sea fishery. PLoS ONE 2019, 14, e0219858. [Google Scholar] [CrossRef]

- Nguyen, K.Q.; Winger, P.D.; Morris, C.; Grant, S.M. Artificial lights improve the catchability of snow crab (Chionoecetes opilio) traps. Aquac. Fish. 2017, 2, 124–133. [Google Scholar] [CrossRef]

- Cerbule, K.; Herrmann, B.; Grimaldo, E.; Grimsmo, L.; Vollstad, J. The effect of white and green LED-lights on the catch efficiency of the Barents Sea snow crab (Chionoecetes opilio) pot fishery. PLoS ONE 2021, 16, e0258272. [Google Scholar] [CrossRef]

- Frank, C.C.H.; Bayse, S.M. The effect of variable light intensity in luminescent-netting pots on the catch of snow crab (Chionoecetes opilio). Aquac. Fish. 2023, in press. [Google Scholar] [CrossRef]

- Paradis, Y.; Dupuch, A.; Magnan, P. Comparison of catch efficiencies between black and galvanized minnow traps. North Am. J. Fish. Manag. 2012, 32, 539–543. [Google Scholar] [CrossRef]

| Treatment | Frame | Netting Jacket | Notes |

|---|---|---|---|

| 1 | New Galvanized | New | |

| 2 | New Ungalvanized | New | |

| 3 | Older Ungalvanized | Existing | Existing traps were assessed for fitness prior to use |

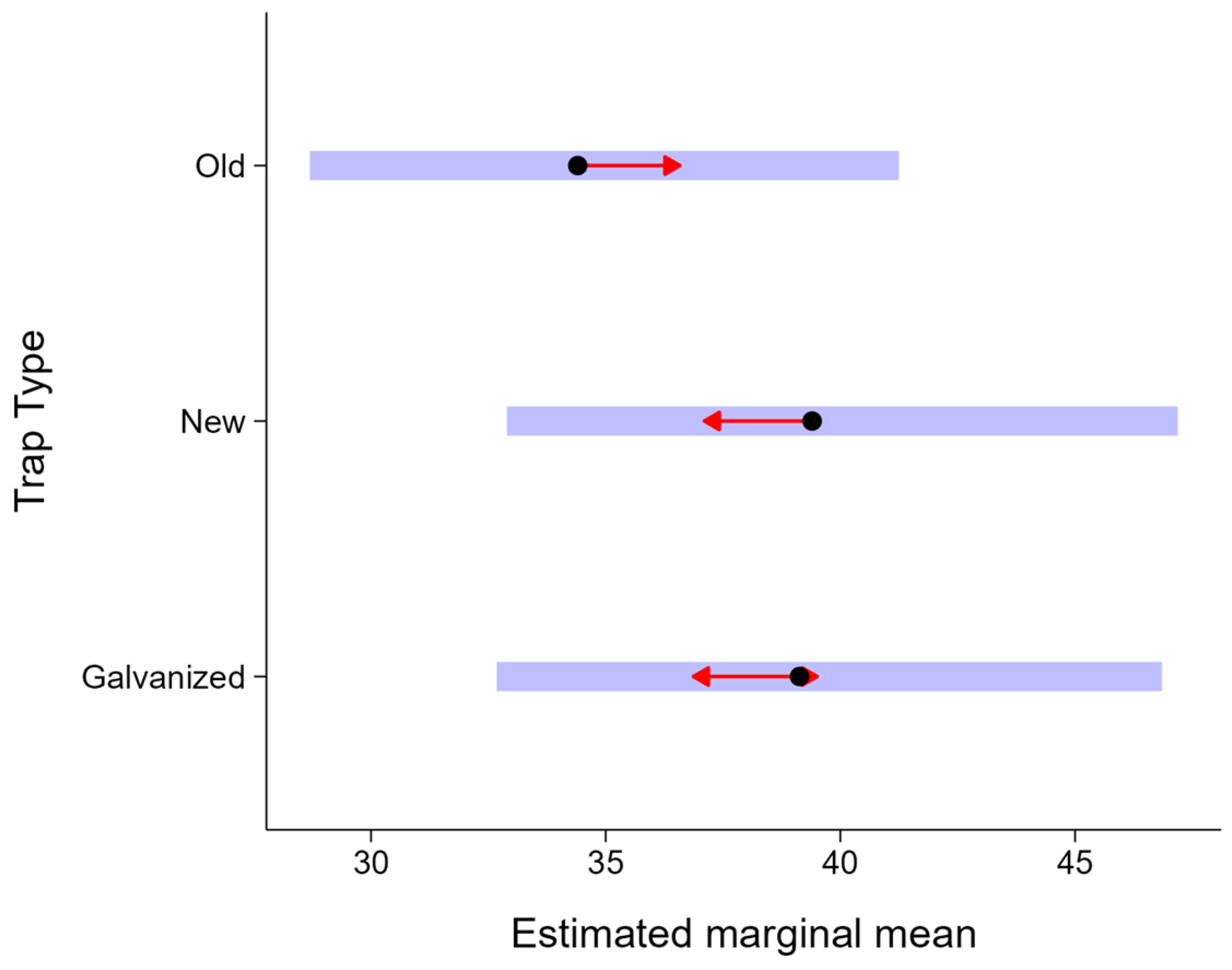

| CPUE Model | Estimate | Standard Error | z-Value | p-Value |

|---|---|---|---|---|

| Intercept | 3.50041 | 0.12703 | 27.555 | <2 × 10−16 |

| Trap_Type (New) | 0.00685 | 0.05062 | 0.135 | 0.8924 |

| Trap_Type (Old) | −0.12871 | 0.05158 | −2.496 | 0.0126 |

| Soak (Long) | 0.33294 | 0.17456 | 1.907 | 0.0565 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brown, P.; Araya-Schmidt, T.; Bungay, T.; Winger, P.D. Assessing the Technical and Economic Viability of Galvanizing Snow Crab (Chionoecetes opilio) Traps. Fishes 2024, 9, 109. https://doi.org/10.3390/fishes9030109

Brown P, Araya-Schmidt T, Bungay T, Winger PD. Assessing the Technical and Economic Viability of Galvanizing Snow Crab (Chionoecetes opilio) Traps. Fishes. 2024; 9(3):109. https://doi.org/10.3390/fishes9030109

Chicago/Turabian StyleBrown, Pete, Tomas Araya-Schmidt, Terry Bungay, and Paul D. Winger. 2024. "Assessing the Technical and Economic Viability of Galvanizing Snow Crab (Chionoecetes opilio) Traps" Fishes 9, no. 3: 109. https://doi.org/10.3390/fishes9030109

APA StyleBrown, P., Araya-Schmidt, T., Bungay, T., & Winger, P. D. (2024). Assessing the Technical and Economic Viability of Galvanizing Snow Crab (Chionoecetes opilio) Traps. Fishes, 9(3), 109. https://doi.org/10.3390/fishes9030109