Soft Fillets in a Sustainable Seafood Era: Assessing Texture, Yield Loss and Valorization Potential of ‘Mushy’ Greenland Halibut Fillets

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.1.1. Capture and Processing

2.1.2. Fillet Categorization

2.2. Drip Loss and Yield Analysis

2.2.1. Thaw Drip Loss (TDL)

2.2.2. Cooked Drip Loss (CDL)

2.2.3. Cooked Yield

2.3. Tissue Compressibility and Elasticity

2.3.1. Tissue Compressibility

2.3.2. Tissue Elasticity

2.4. Histology

2.5. Statistical Analysis

3. Results

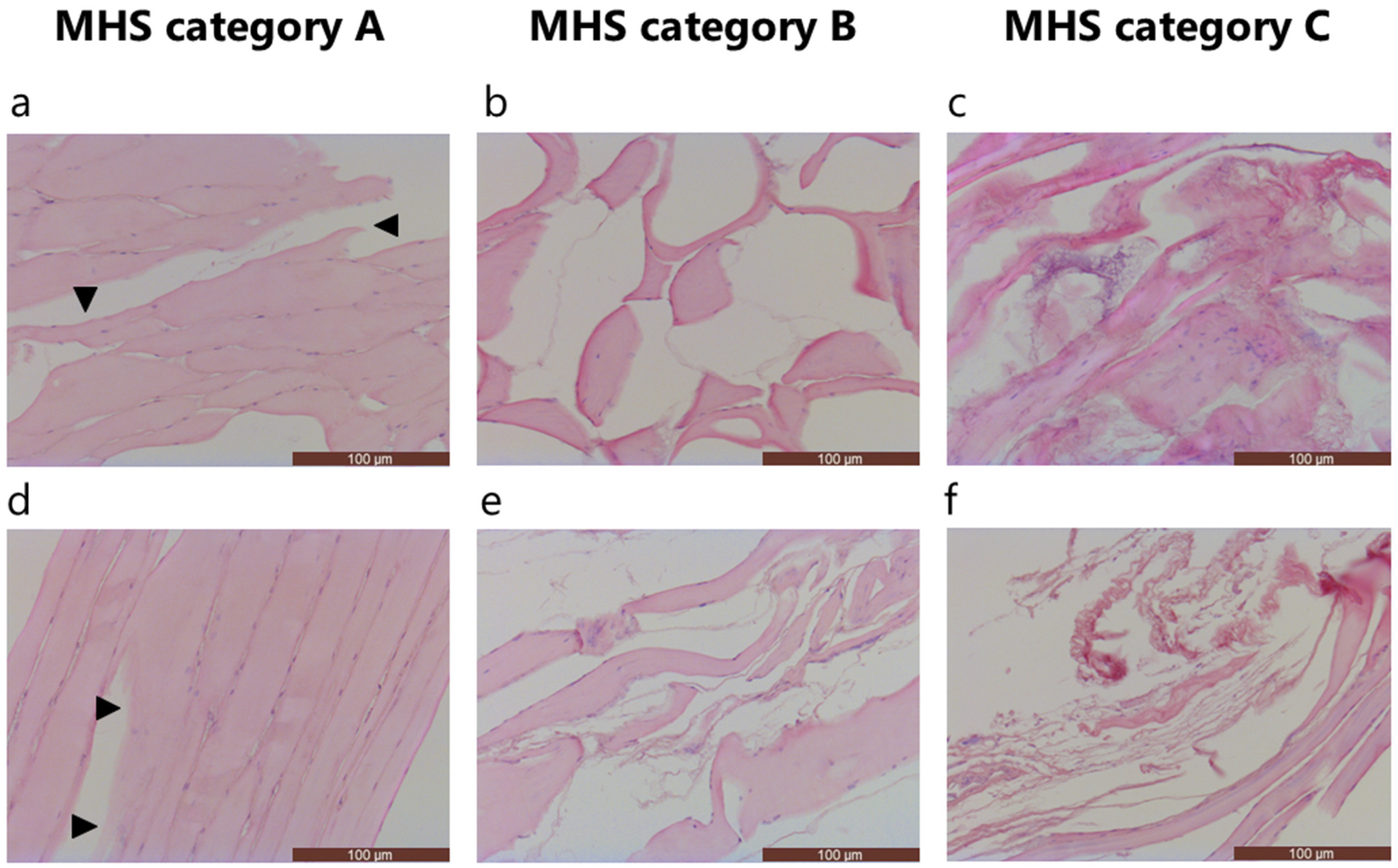

3.1. Histology

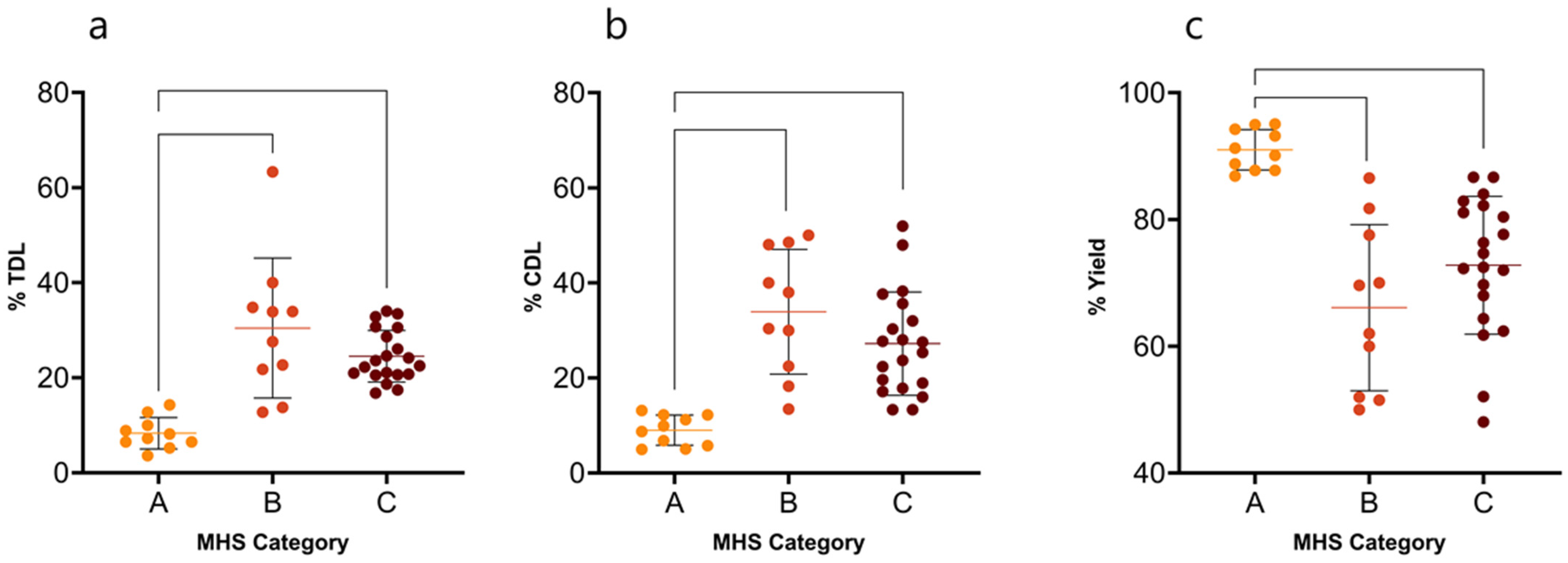

3.2. Thaw Drip Loss, Cooked Drip Loss, and Cooked Yield

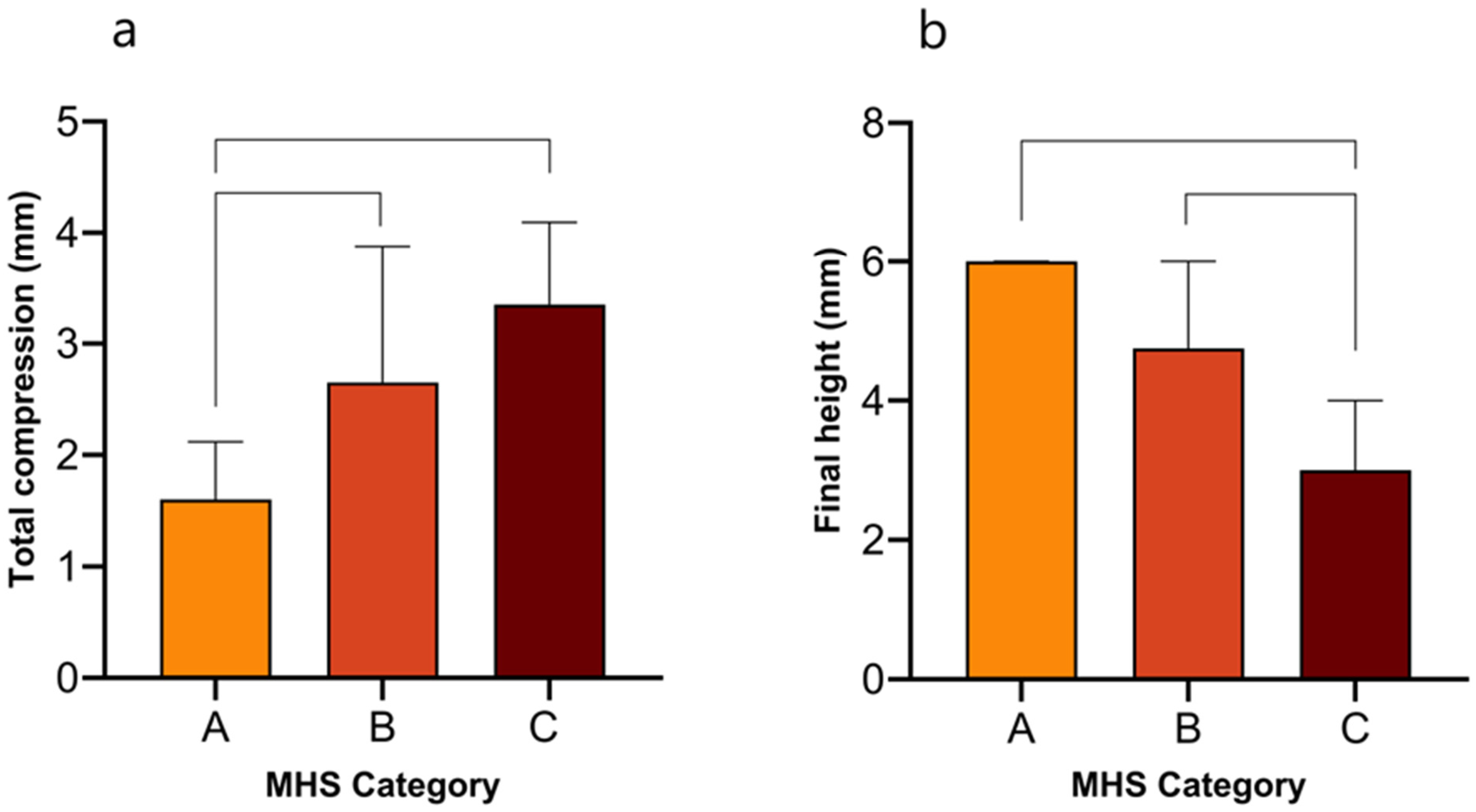

3.3. Tissue Compressibility and Elasticity

3.4. Correlations

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MHS | Mushy halibut syndrome |

| TDL | Thaw drip loss |

| CDL | Cooked drip loss |

| WHC | Water holding capacity |

References

- Naatsorsueqqissaartarfik. Greenland in Figures 2024; Statistics Greenland: Nuuk, Greenland, 2024. [Google Scholar]

- Ortega, S.; Lindberg, S.-K.; Olsen, S.H.; Anderssen, K.E.; Heia, K. Early identification of mushy Halibut syndrome with hyperspectral image analysis. LWT 2023, 176, 114559. [Google Scholar] [CrossRef]

- Ortega, S.; Ofstad, R.; Syed, S.; Kranz, M.; Heia, K.; Anderssen, K.E. Characterization of vasskveite (water halibut) syndrome for automated detection. Appl. Food Res. 2023, 3, 100250. [Google Scholar] [CrossRef]

- Severin, N.L.; Buchmann, K. The ‘jellied’ or ‘mushy’ condition of fish in the North Atlantic and North Pacific fisheries: Characteristics, causes and consequences. Heliyon 2024, 10, e27130. [Google Scholar] [CrossRef] [PubMed]

- Templeman, W.; Andrews, G.L. Jellied Condition in the American Plaice Hippoglossoides platessoides (Fabricius). J. Biol. Board Can. 1956, 13, 147–182. [Google Scholar] [CrossRef]

- FAO. The State of the World Fisheries and Aquaculture 2020. Sustainability in Action; FAO: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture 2022—Towards Blue Transformation; The State of the World Series; Food and Agriculture Organization of the United States: Rome, Italy, 2022. [Google Scholar]

- Olsen, R.L.; Toppe, J.; Karunasagar, I. Challenges and realistic opportunities in the use of by-products from processing of fish and shellfish. Trends Food Sci. Technol. 2014, 36, 144–151. [Google Scholar] [CrossRef]

- Nawaz, A.; Li, E.; Irshad, S.; Xiong, Z.; Xiong, H.; Shahbaz, H.M.; Siddique, F. Valorization of fisheries by-products: Challenges and technical concerns to food industry. Trends Food Sci. Technol. 2020, 99, 34–43. [Google Scholar] [CrossRef]

- Rideout, S.G.; Snow, G.W. A Study into the Possible Utilization of “Jellied” Flounder of the Species Hippoglossoides platessoides by Commuting the Fillets; Fisheries and Oceans Canada: Ottawa, ON, Canda, 1974. [Google Scholar]

- Severin, N.L.; Ortega, S.; Romeyn, R.; Olsen, S.H.; Heia, K.; Jacobsen, C.; Boeknaes, N.; Hauptmann, A.L.; Boje, J.; Kania, P.W.; et al. An Interdisciplinary Approach to Detect and Grade ‘Mushy Halibut Syndrome’ in fillets of Greenland halibut (Reinhardtius hippoglossoides). J. Food Meas. Charact. 2025, 19, 3444–3461. [Google Scholar] [CrossRef]

- Bigelow, W.; Lee, C.M. Evaluation of Various Infused Cryoprotective Ingredients for Their Freeze–Thaw Stabilizing and Texture Improving Properties in Frozen Red Hake Muscle. J. Food Sci. 2007, 72, C056–C064. [Google Scholar] [CrossRef]

- Karinen, J.F.; Barnett, H.J.; Masuda, M. Soft flesh in sablefish, Anoplopoma fimbria, of southeastern Alaska: Relationships with depth, season, and biochemistry. Mar. Fish. Rev. 2010, 72, 26–35. [Google Scholar]

- Murmu, P.; Chowdhury, S.; Sarkar, S.; Dora, K.C.; Nath, S.; Pal, D. Utilisation of filleting wastes in improving yield of Asian Sea Bass fillet. J. Ecol. Environ. 2016, 34, 2404–2408. [Google Scholar]

- Cheng, J.-H.; Sun, D.-W.; Han, Z.; Zeng, X.-A. Texture and Structure Measurements and Analyses for Evaluation of Fish and Fillet Freshness Quality: A Review. Compr. Rev. Food Sci. Food Saf. 2014, 13, 52–61. [Google Scholar] [CrossRef]

- Montgomery, J.L. Compression Measurements. In Handbook of Meat, Poultry and Seafood Quality; Nollet, L.M.L., Ed.; Blackwell Publishing: Oxford, UK, 2007; pp. 71–88. [Google Scholar]

- Buchmann, K.; Skovgaard, A.; Kania, P. Myxobolus groenlandicus n. sp. (Myxozoa) distorting skeletal structures and musculature of Greenland halibut Reinhardtius hippoglossoides (Teleostei: Pleuronectidae). Dis. Aquat. Org. 2012, 98, 133–141. [Google Scholar] [CrossRef]

- Love, R.M. Variability in Atlantic Cod (Gadus morhua) from the Northeast Atlantic: A Review of Seasonal and Environmental Influences on Various Attributes of the Flesh. J. Biol. Board Can. 1975, 32, 2333–2342. [Google Scholar] [CrossRef]

- Olsson, G.B.; Olsen, R.L.; Ofstad, R. Post-mortem structural characteristics and water-holding capacity in Atlantic halibut muscle. LWT Food Sci. Technol. 2003, 36, 125–133. [Google Scholar] [CrossRef]

- Hughes, J.M.; Oiseth, S.K.; Purslow, P.P.; Warner, R.D. A structural approach to understanding the interactions between colour, water-holding capacity and tenderness. Meat Sci. 2014, 98, 520–532. [Google Scholar] [CrossRef]

- Chan, S.S.; Roth, B.; Jessen, F.; Jakobsen, A.N.; Lerfall, J. Water holding properties of Atlantic salmon. Compr. Rev. Food Sci. Food Saf. 2022, 21, 477–498. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Q.; Pan, Y.; Wei, S.; Xia, Q.; Liu, S.; Ji, H.; Deng, C.; Hao, J. Investigation on the correlation between changes in water and texture properties during the processing of surimi from golden pompano (Trachinotus ovatus). J. Food Sci. 2021, 86, 376–384. [Google Scholar] [CrossRef] [PubMed]

- Havforskningsinstituttet. Ønsker Blåkveiteprøver fra Fiskere og Importører. Available online: https://www.hi.no/hi/nyheter/2019/mars/onsker-blakveiteprover-fra-fiskere-og-importorer (accessed on 10 October 2024).

- Karl, H.; Numata, J.; Lahrssen-Wiederholt, M. Variability of fat, water and protein content in the flesh of beaked redfish (Sebastes mentella) and Greenland halibut (Reinhardtius hippoglossoides) from artic fishing grounds. J. Consum. Prot. Food Saf. 2018, 13, 383–389. [Google Scholar] [CrossRef]

- Severin, N.L. (University of Copenhagen, Frederiksberg, Denmark). Unpublished work and personal communication, 2023.

- Bashir, K.M.I.; Kim, J.-S.; An, J.H.; Sohn, J.H.; Choi, J.-S. Natural Food Additives and Preservatives for Fish-Paste Products: A Review of the Past, Present, and Future States of Research. J. Food Qual. 2017, 2017, 9675469. [Google Scholar] [CrossRef]

- Erikson, U.; Uglem, S.; Greiff, K. Freeze-Chilling of Whitefish: Effects of Capture, On-Board Processing, Freezing, Frozen Storage, Thawing, and Subsequent Chilled Storage—A Review. Foods 2021, 10, 2661. [Google Scholar] [CrossRef]

- Cropotova, J.; Mozuraityte, R.; Standal, I.B.; Grøvlen, M.S.; Rustad, T. Superchilled, chilled and frozen storage of Atlantic mackerel (Scomber scombrus) fillets—Changes in texture, drip loss, protein solubility and oxidation. Int. J. Food Sci. Technol. 2019, 54, 2228–2235. [Google Scholar] [CrossRef]

- Gonçalves, A.; Souza, M.; Regis, R. Effects of different levels of food additives on weight gain, cook-related yield loss, physicochemical and sensorial quality of Nile tilapia fillets (Oreochromis niloticus). Int. Food Res. J. 2018, 25, 2068–2080. [Google Scholar]

- Ghosh, P.R.; Fawcett, D.; Sharma, S.B.; Poinern, G.E.J. Progress towards Sustainable Utilisation and Management of Food Wastes in the Global Economy. Int. J. Food Sci. 2016, 2016, 3563478. [Google Scholar] [CrossRef] [PubMed]

- Hyldig, G.; Nielsen, D. A Review of Sensory and Instrumental Methods used to Evaluate the Texture of Fish Muscle. J. Texture Stud. 2001, 32, 219–242. [Google Scholar] [CrossRef]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations Publishing: New York, NY, USA, 2015. [Google Scholar]

- Jiang, Q.; Nakazawa, N.; Hu, Y.; Osako, K.; Okazaki, E. Microstructural modification and its effect on the quality attributes of frozen-thawed bigeye tuna (Thunnus obesus) meat during salting. LWT 2019, 100, 213–219. [Google Scholar] [CrossRef]

| American Plaice | Greenland Halibut | ||||

|---|---|---|---|---|---|

| Templeman & Andrews (1956) [5] a | % Moisture [Min–Max] | Rideout & Snow (1974) [10] b | % Moisture [Min–Max] | Severin et al. (2025) [11] | % Moisture [Min–Max] |

| Normal | 82.39–83.36% | Normal | 80.5–83.13% | Normal | 69.5–77.3% |

| Intermediate | 84.31–85.40% | Semi-jellied | 83.26–86.13% | Mild-moderate MHS c | 71–84.6% |

| Jellied | 86.14–87.45% | Heavy jellied | 84.6–93.7% | Severe MHS d | 80.0–87.35% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Severin, N.L.; Buchmann, K. Soft Fillets in a Sustainable Seafood Era: Assessing Texture, Yield Loss and Valorization Potential of ‘Mushy’ Greenland Halibut Fillets. Fishes 2025, 10, 367. https://doi.org/10.3390/fishes10080367

Severin NL, Buchmann K. Soft Fillets in a Sustainable Seafood Era: Assessing Texture, Yield Loss and Valorization Potential of ‘Mushy’ Greenland Halibut Fillets. Fishes. 2025; 10(8):367. https://doi.org/10.3390/fishes10080367

Chicago/Turabian StyleSeverin, Natacha L., and Kurt Buchmann. 2025. "Soft Fillets in a Sustainable Seafood Era: Assessing Texture, Yield Loss and Valorization Potential of ‘Mushy’ Greenland Halibut Fillets" Fishes 10, no. 8: 367. https://doi.org/10.3390/fishes10080367

APA StyleSeverin, N. L., & Buchmann, K. (2025). Soft Fillets in a Sustainable Seafood Era: Assessing Texture, Yield Loss and Valorization Potential of ‘Mushy’ Greenland Halibut Fillets. Fishes, 10(8), 367. https://doi.org/10.3390/fishes10080367