Design and Experiment of a Hard-Shell Clam Harvester

Abstract

1. Introduction

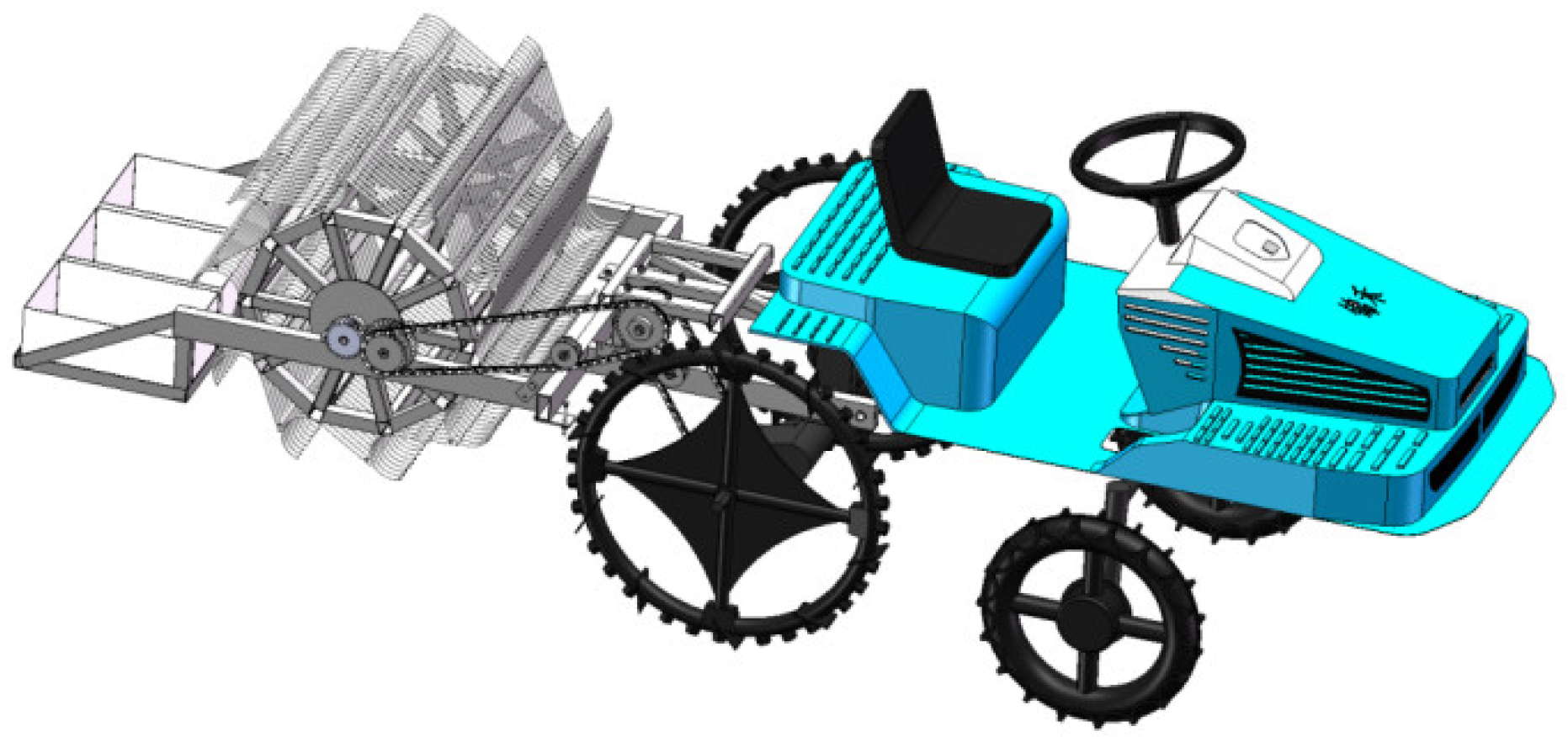

2. Overall Structure and Operating Principle of the Clam Harvesting Machine

2.1. Overall Structure

2.2. Operating Principle

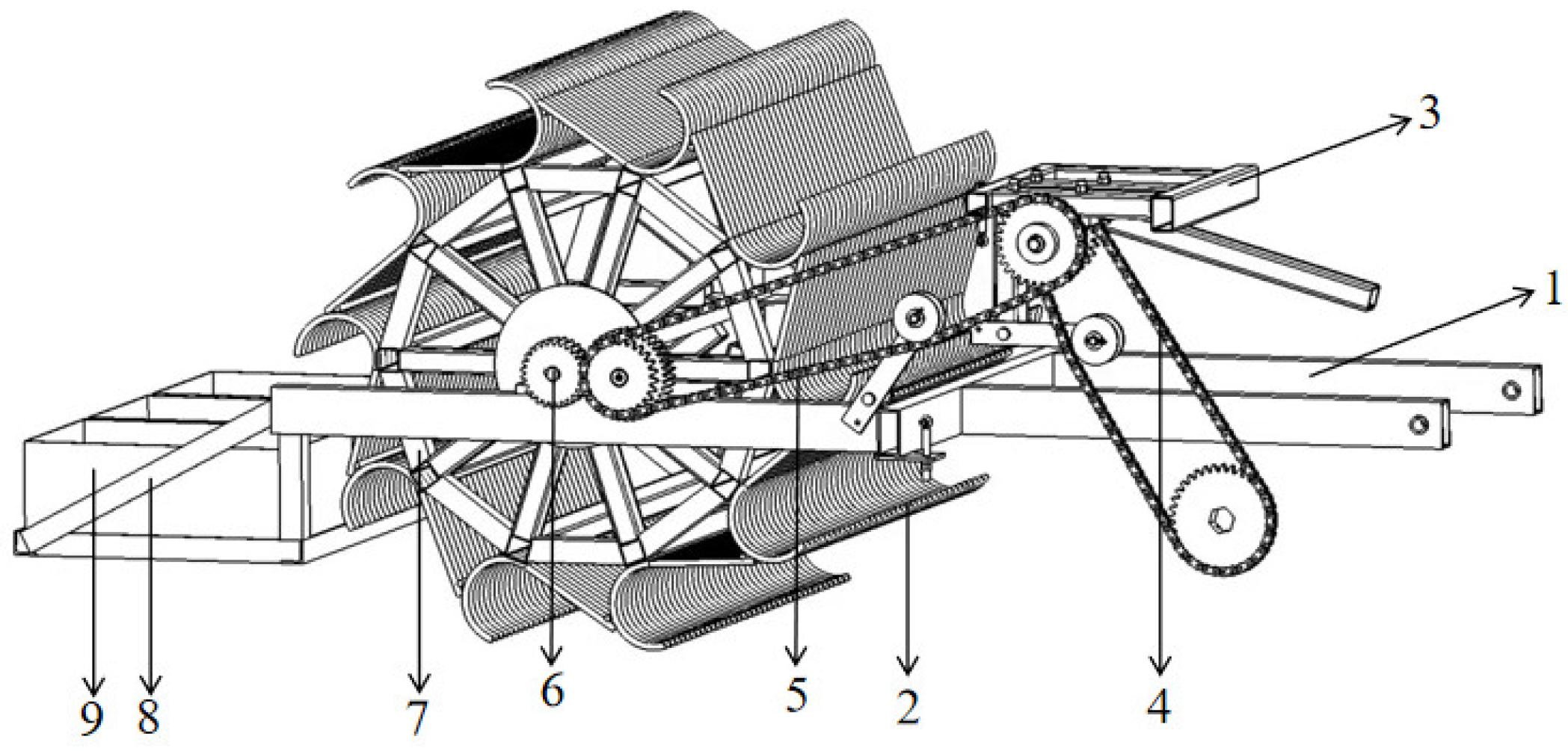

3. Composition and Key Components Design of the Digging Mechanism

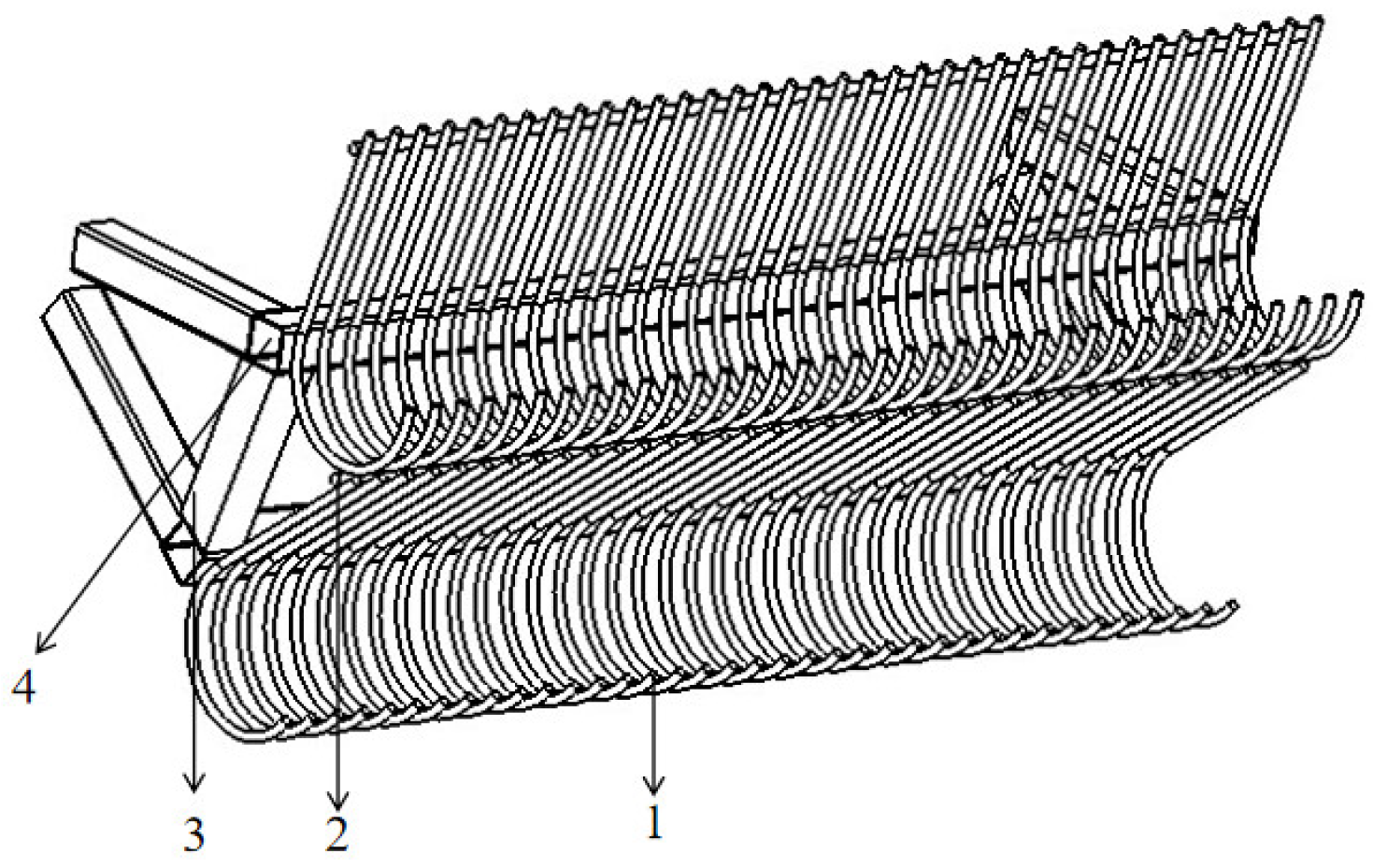

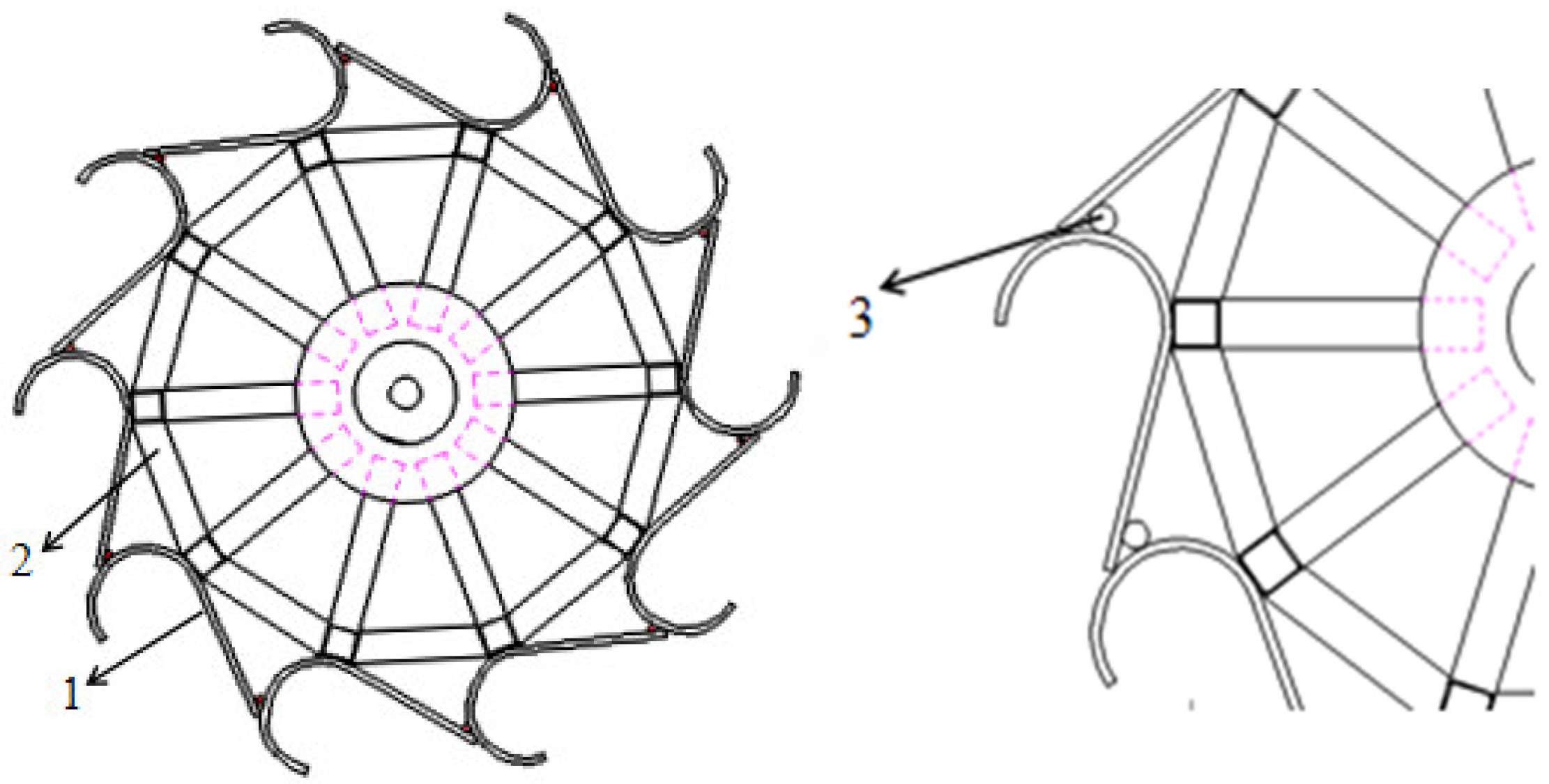

3.1. Composition of the Tines’ Assembly

3.2. Design of the Tines

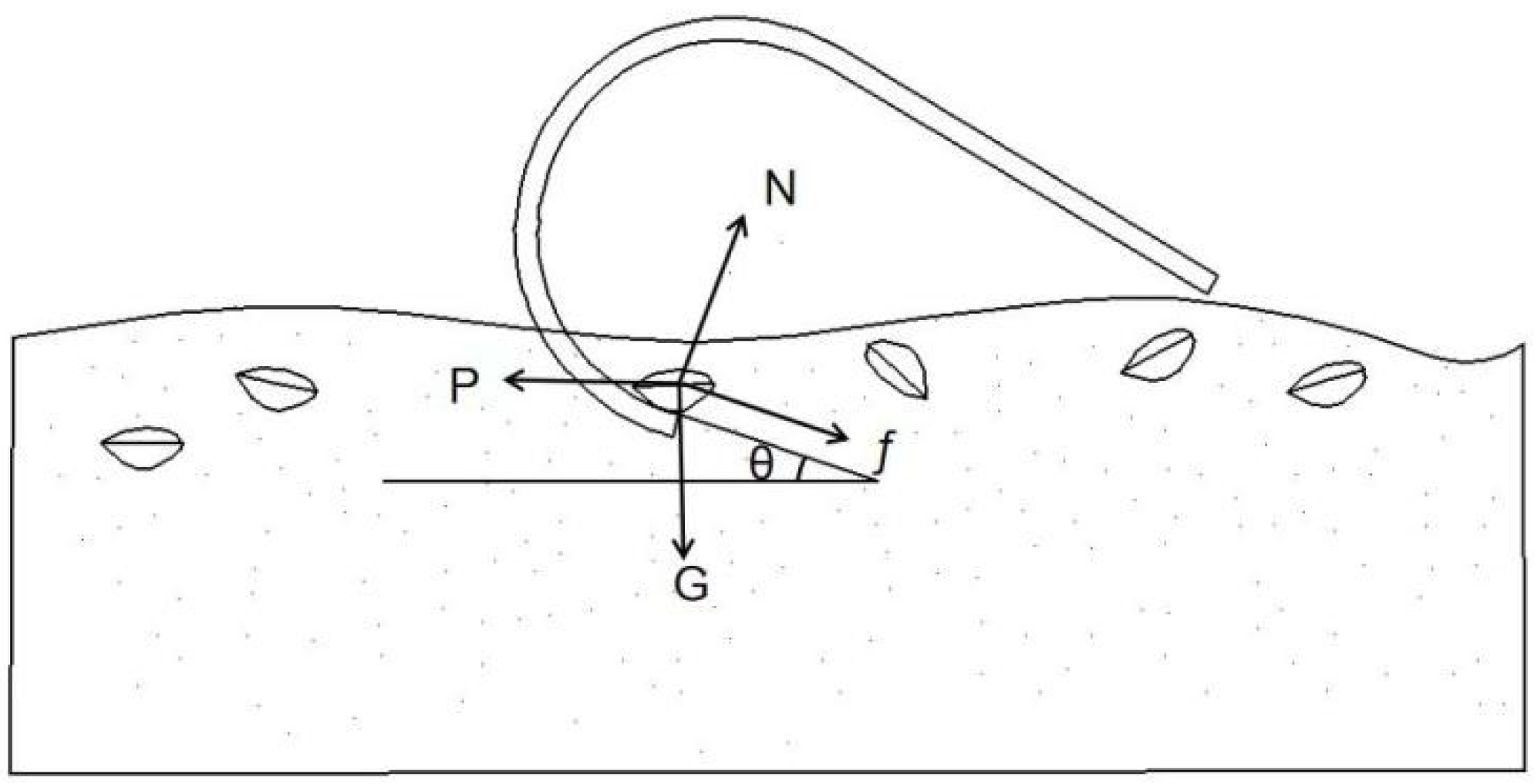

3.2.1. Design of the Excavation Depth

3.2.2. Design of the Penetration Angle for the Tines

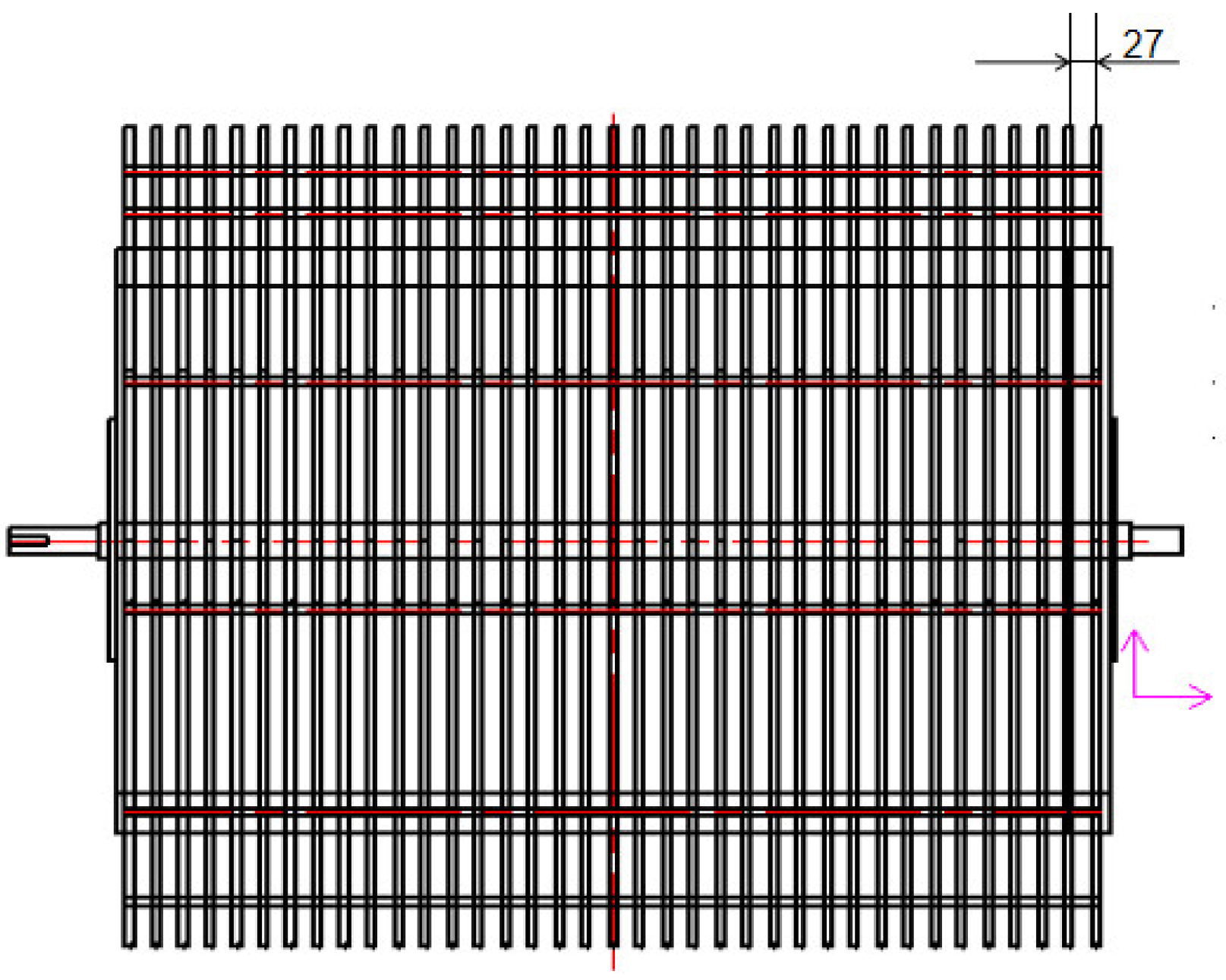

3.2.3. Design of Tines Arrangement Width

4. Model Construction and Simulation Analysis

4.1. Construction of Discrete Element Model

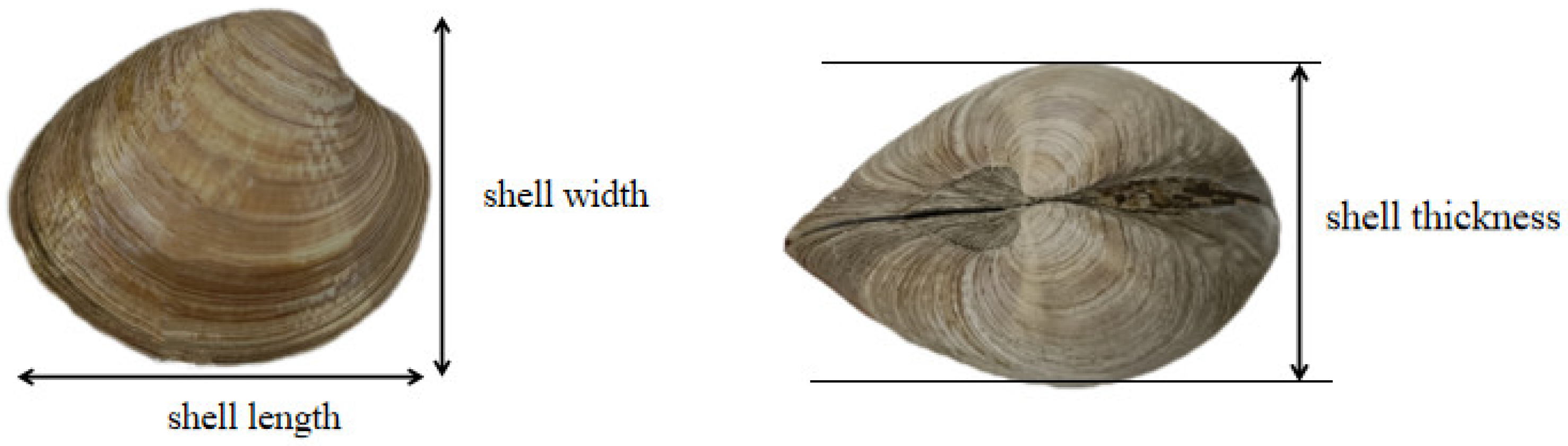

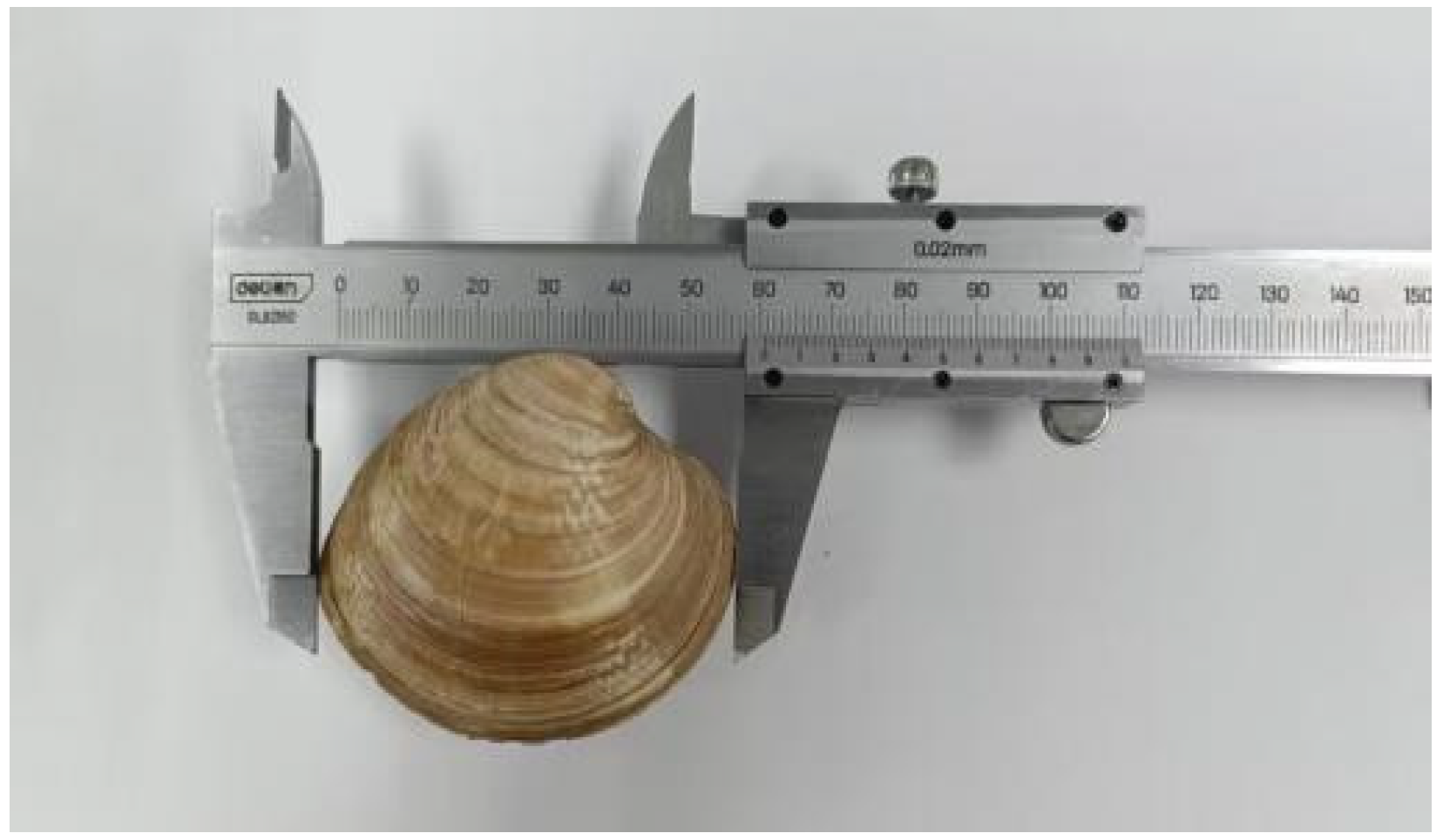

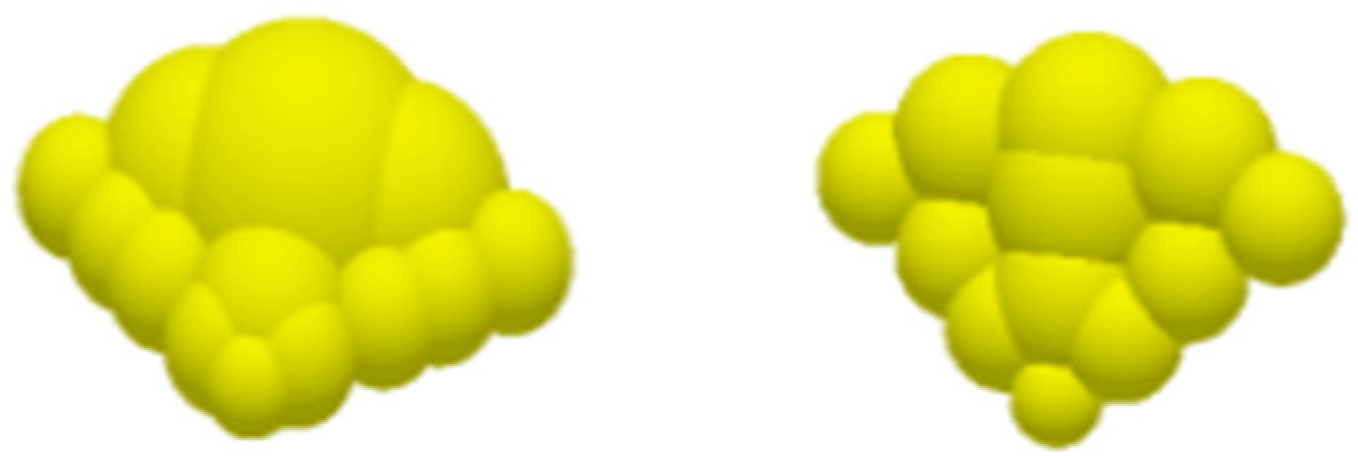

4.1.1. Creation of the Hard-Shell Clam Model

4.1.2. Soil Model Construction and Contact Model Selection

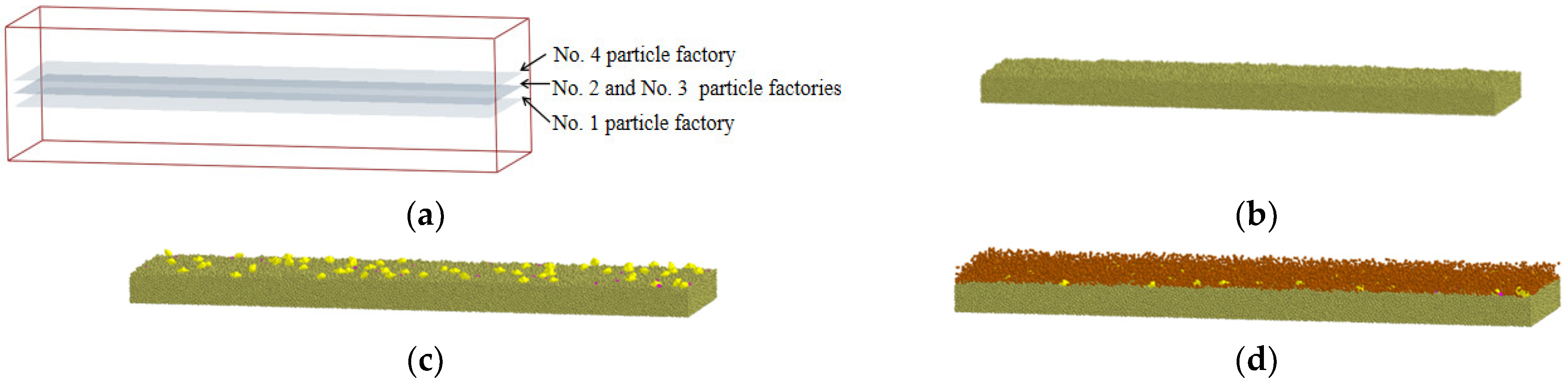

4.1.3. The Construction of the Soil–Hard-Shell Clam Discrete Element Model

4.2. Simulation Experiment Design and Result Analysis

4.2.1. Experiment Objectives

4.2.2. Experiment Scheme Design

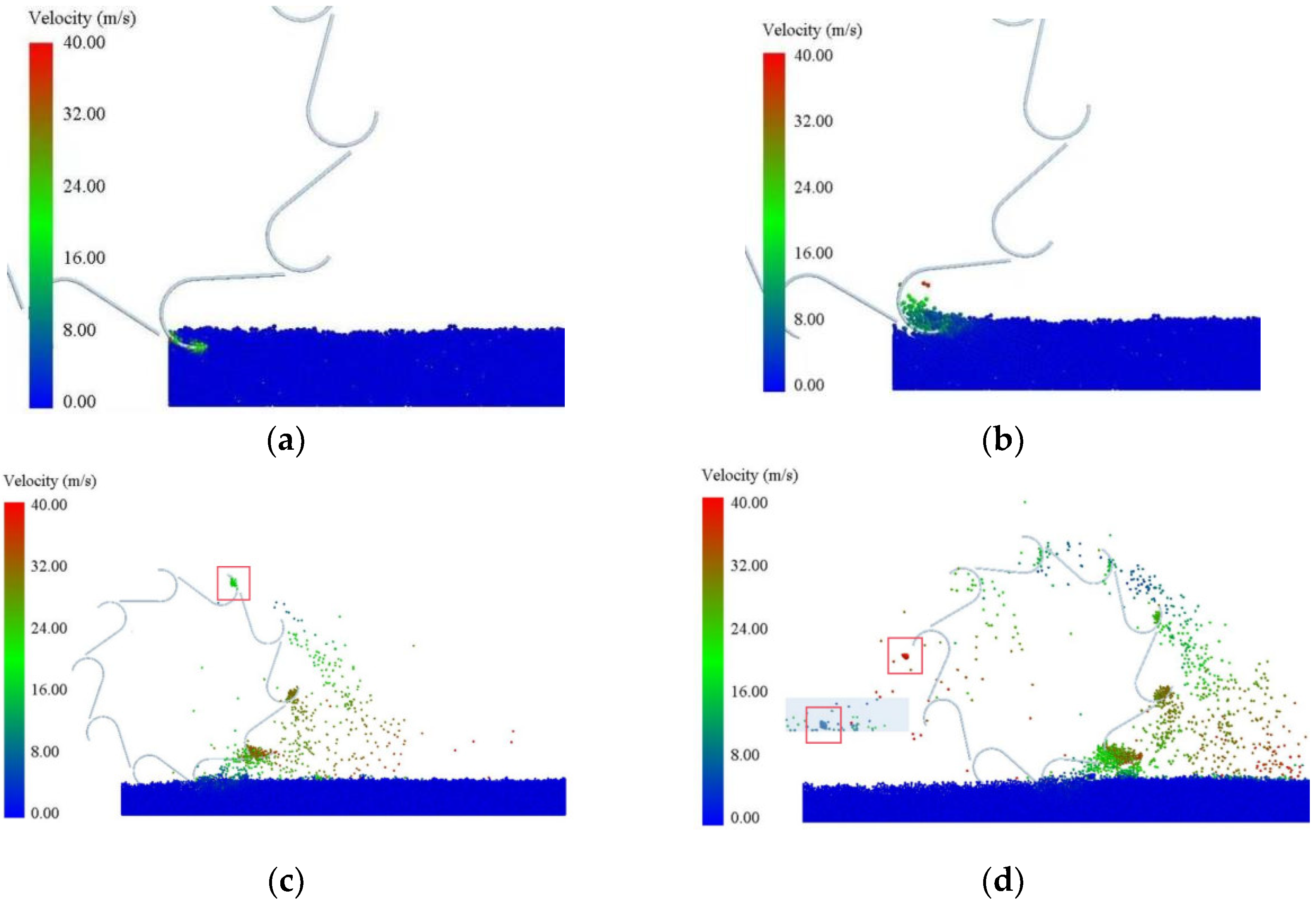

4.2.3. Operation Process Analysis

4.3. Parameter Analysis

4.3.1. Analysis of Variance

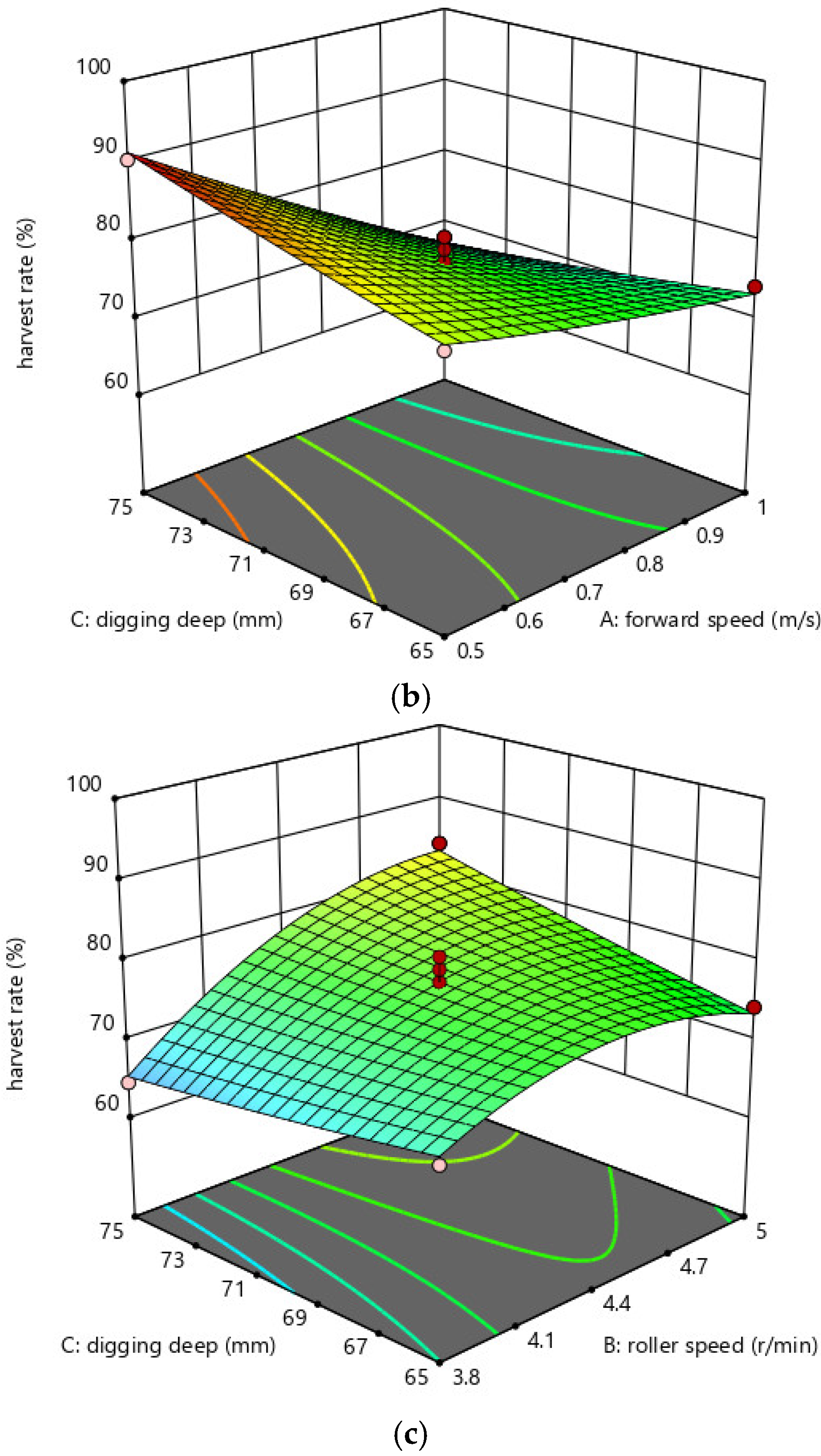

4.3.2. Effect of Interaction Among Parameters

4.3.3. Parameters Optimization

5. Prototype Design and Field Testing

5.1. Prototype Production

5.2. Field Testing

5.2.1. Testing Purpose and Design

5.2.2. Test Results

6. Conclusions

- (1)

- Through the investigation of the condition of hard-shell clam cultivation and the physical parameters measurement results of hard-shell clams and soil, the key components of the hard-shell clam harvesting mechanism were designed, which can effectively harvest the mature clams and collect them into the collection box, solving the low efficiency problem in the manual harvesting process.

- (2)

- By establishing a discrete element model of hard-shell clams and cultivation sediment in EDEM software and importing the simplified model of the harvest machine into EDEM for simulation analysis, the soil disturbance and harvesting conditions during the operation of the machine were studied. Factors affecting the harvesting rate were found to be the forward speed, roller speed, and digging depth in decreasing order of influence by simulating harvesters operating at different forward speeds. The parameters were then optimized to achieve the optimal work parameters of forward speed of 0.526 m/s, roller speed of 4.772 r/min, and digging depth of 73.067 mm, which were validated by field testing, corroborating their feasibility level that was consistent with a comparative analysis of simulations and practical experiments.

- (3)

- This shellfish harvesting machine is designed for the problems of low efficiency and high cost of manual harvesting of shellfish in tidal flats. The harvesting machine has the advantages of improving efficiency and reducing labor intensity, which is of positive significance to the development of shellfish aquaculture industry in tidal flats, but there are also shortcomings that can be improved. For example, the crushing rate of clams has not been studied in depth, and the damage rate and the factors affecting the damage rate can be further studied to optimize the structure of the harvesting machine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mu, G.; Duan, F.; Yang, J. Research Progress on Benthic Bivalve Capture Machines. J. Dalian Ocean. Univ. 2020, 35, 19–30. [Google Scholar]

- Song, J.; Chang, Y. Introduction, Artificial Breeding and Developmental Technology of Hard-shell Clam in Northern China. China Fish. 2009, 9, 50–51. [Google Scholar]

- Zhang, H.; Li, P.; Zhang, H.; Huang, W.; Zhang, G.; Mu, G.; Li, X. Design and Experiment of Cone Disk Centrifugal Shellfish Seeding Device. Front. Mar. Sci. 2023, 10, 1136844. [Google Scholar] [CrossRef]

- Shentu, L.; Gong, Z.; Sun, X.; Zhao, Q.; Sun, C. Design of the Self-propelled Clam Harvester. J. Chin. Agric. Mech. 2015, 36, 192–195. [Google Scholar]

- Lepofsky, D.; Smith, N.F.; Cardinal, N.; Harper, J.; Morris, M.; Gitla, E.W.; Bouchard, R.; Kennedy, D.I.D.; Salomon, A.K.; Puckett, M. Ancient shellfish mariculture on the northwest coast of north America. Am. Antiq. 2015, 80, 236–259. [Google Scholar] [CrossRef]

- Dimitrijevi, M.; Zuber Bogdanovi, I.; Grkovi, N.; Aksentijevi, K.; Nikoli, M.; Pavievi, Z.; Lauevi, D. Sustainability of Shellfish Aquaculture in Montenegro-perspectives. Vet. Glas. 2022, 76, 125. [Google Scholar]

- Bargione, G.; Barone, G.; Virgili, M.; Lucchetti, A. Evaluation and quantification of shell damage and survival of the striped venus clam (Chamelea gallina) harvested by hydraulic dredges. Mar. Environ. Res. 2023, 187, 105954. [Google Scholar] [CrossRef]

- Stewart, N.L.; Brenda, K. Kelp Forests Versus Urchin Barrens: Alternate Stable States and Their Effect on Sea Otter Prey Quality in the Aleutian Islands. J. Mar. Biol. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Stevick, B.C.; Carson, H.S.; Working, O. The Pace of Harvest and Recovery in Geoduck Clam Stocks Fifty Years into the Fishery. Fish. Res. 2021, 42, 106018. [Google Scholar] [CrossRef]

- Weng, Z.; He, H. YXF-4 Type Snail and Shellfish Suction Machine. Agric. Mach. 1982, 242, 27–28. [Google Scholar]

- Hauton, C.; Hall-Spencer, J.M.; Moore, P.G. An Experimental Study of the Ecological Impacts of Hydraulic Bivalve Dredging on Maerl. ICES J. Mar. Sci. 2003, 60, 381–392. [Google Scholar] [CrossRef]

- Gilkinson, K.D.; Fader, G.B.J.; Gordon, D.C., Jr.; Charron, R.; McKeown, D.; Roddick, D.; Kenchington, E.L.R.; MacIsaac, K.; Bourbonnais, C.; Vass, P. Immediate and Longer-term Impacts of Hydraulic Clam Dredging on an Offshore Sandy Seabed: Effects on Physical Habitat and Processes of Recovery. Cont. Shelf Res. 2003, 23, 1315–1336. [Google Scholar] [CrossRef]

- Goldberg, R.; Mercaldo-Allen, R.; Rose, J.M.; Clark, P.; Kuropat, C.; Meseck, S.; Pereira, J. Effects of Hydraulic Shellfish Dredging on the ecology of a Cultivated Clam Bed. Aquac. Environ. Interact. 2012, 3, 11–21. [Google Scholar] [CrossRef]

- Tuck, I.D.; Bailey, N.; Harding, M.; Sangster, G.; Breen, M. The Impact of Water Jet Dredging for Razor Clams, Ensis spp., in a Shallow Sandy Subtidal Environment. J. Sea Res. 2000, 43, 65–81. [Google Scholar] [CrossRef]

- Yamazaki, S.; Hiyonno, J.; Toshihiro, W. Damage to the Foot of Chosen Surf Clam by the Use of a Trap Net. Bull. Jpn. Soc. Sci. Fish. 2002, 68, 368–373. [Google Scholar]

- Zhang, W. The Design and Research of Sinonovacula Constricta Harvester. Master’s Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2018. [Google Scholar]

- Lu, J.; Zhou, Y.; Shen, C.; Lu, S.; Tu, L.; Xue, A. Design and Experiment of Self-propelled Shellfish Harvester. Fish. Mod. 2021, 48, 85–90. [Google Scholar]

- Zhang, Y.; Xie, F.; Fu, Z.; Zheng, P.; Liu, D.; Wang, X. Research Status and Prospect of Intelligent Side-deep Fertilization Device for Synchronous Rice Planting by Machine. Agric. Equip. Veh. Eng. 2023, 61, 51–55. [Google Scholar]

- Ji, L.; Jiang, X.; Ma, Y.; Tong, J.; Hu, B. Bionic Design of a Potato Digging Shovel with Drag Reduction Based on the Discrete Element Method (DEM) in Clay Soil. Appl. Sci. 2020, 10, 7096. [Google Scholar] [CrossRef]

- Liu, S.; Weng, S.; Liao, Y.; Zhu, D. Structural Bionic Design for Digging Shovel of Cassava Harvester Considering Soil Mechanics. Appl. Bionics Biomech. 2014, 11, 1–11. [Google Scholar] [CrossRef]

- Fu, W.; Chen, H.; Kan, Z. Optimization of Parameters for Vibrating Soil-loosening Shovel of Carrot Harvester. Trans. Chin. Soc. Agric. Eng. 2011, 27, 46–50. [Google Scholar]

- Deng, W.; Wang, C.; Sun, H.; Hou, Z.; Wang, F. The Mechanical Model Building of the Potato Excavator Digger Shove. J. Agric. Mech. Res. 2014, 36, 84–86. [Google Scholar]

- Fakayode, A.O. Size-based Physical Properties of Hard-shell Clam (Mercenaria mercenaria) Shell Relevant to the Design of Mechanical Processing Equipment. Aquac. Eng. 2020, 89, 102056. [Google Scholar] [CrossRef]

- Boikov, A.V.; Savelev, R.V.; Payor, V.A. DEM Calibration Approach: Orthogonal Experiment. J. Phys. Conf. Ser. 2019, 1210, 012025. [Google Scholar] [CrossRef]

- Wang, C.; Ding, L.; Dou, F.; Kang, Z.; Li, F.; Li, J. Design and Experiment of Comb Type Picking Device of Ground Jujube. J. Shihezi Univ. (Nat. Sci.) 2021, 39, 409–414. [Google Scholar]

- Huang, B.; Pan, H.; Wang, X.; Li, Y.; Zhang, T.; Li, S.; Jiang, Y.; Wang, F. Parameter Calibration of Discrete Element Simulation for the Interaction Between Heavy Soil and Soil-engaging Components in Shellfish Culture. Can. J. Soil Sci. 2023, 104, 38–53. [Google Scholar] [CrossRef]

- Li, Y.; Li, F.; Xu, X.; Shen, C.; Meng, K.; Chen, J.; Chang, D. Parameter Calibration of Wheat Flour in Discrete Elements Based on Particle Scaling. Trans. Chin. Soc. Agric. Eng. 2019, 35, 320–327. [Google Scholar]

- Acquah, K.; Chen, Y. Discrete Element Modelling of Soil Compaction of a Press-wheel. AgriEngineering 2021, 3, 278–293. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, D.; Yang, L.; Cui, T.; Song, W.; He, X.; Wu, H.; Dong, J. Optimal Design and Experiment of Critical Components of Hand-pushing Corn Plot Precision Planter. Agriculture 2013, 12, 2103. [Google Scholar] [CrossRef]

- Zhao, H.; Deng, W.; Xie, S.; Zhao, Z. Performance Optimization and Experimental Study of Small-scale Potato-grading Device. Agriculture 2024, 14, 822. [Google Scholar] [CrossRef]

- Xu, X.; Chen, S.; Hu, L. Design and Analysis of Excavation Mechanism for Pseudo-ginseng Harvester. J. Chin. Agric. Mech. 2022, 43, 32–39. [Google Scholar]

| Parameters | Values |

|---|---|

| Dimensions/mm | 2480 × 1130 × 950 |

| Operating width/mm | 980 |

| Digging depth/mm | 0~130 |

| Engine power/kw | 18.5 |

| Traveling speed/km/h | 0~5 |

| Mature Shell | Juvenile Shell | |

|---|---|---|

| Lenth/cm | 4~6 | 1~3 |

| Width/cm | 3~5 | 0.8~2 |

| Thickness/cm | 2~4 | 0.2~1 |

| Parameters | Values |

|---|---|

| Mature clams trilateral dimensions (length × width × height)/(mm) | 44 × 34 × 24 |

| Juvenile clams trilateral dimensions (length × width × height)/(mm) | 18 × 12 × 6 |

| Poisson’s ratio | 0.25 |

| Density/(g/cm3) | 1.745 |

| Shear Modulus (MPa) | 11 |

| Parameters | Values |

|---|---|

| Soil Density/(g/cm3) | 1.04 |

| Soil Poisson’s Ratio | 0.45 |

| Soil Shear Modulus/(MPa) | 1 |

| Soil-Soil Recovery Coefficient | 0.3 |

| Soil-Soil Static Friction Coefficient | 0.3 |

| Soil-Soil Rolling Friction Coefficient | 0.5 |

| Poisson’s Ratio of Digging Instrument’s Material | 0.29 |

| Density of Excavation Instrument’s Material/(g/cm3) | 7.86 |

| Shear Modulus of Excavation Instrument’s Material/(MPa) | 7.9 × 104 |

| Soil–Surface energy between Soil/(J/m2) | 8.05 |

| Level | Forward Velocity (m/s) | Digging Depth (mm) | Revolving Speed (r/min) |

|---|---|---|---|

| 1 | 0.5 | 65 | 3.8 |

| 2 | 0.75 | 70 | 4.4 |

| 3 | 1 | 75 | 5.0 |

| Experiment Plan | Forward Velocity (m/s) | Digging Depth (mm) | Revolving Speed (r/min) | Harvesting Rate R (%) |

|---|---|---|---|---|

| 1 | 1 | 65 | 4.4 | 74.2 |

| 2 | 0.75 | 65 | 3.8 | 70.1 |

| 3 | 0.5 | 65 | 4.4 | 80.6 |

| 4 | 0.75 | 65 | 5.0 | 74.2 |

| 5 | 0.5 | 70 | 5.0 | 87.1 |

| 6 | 0.75 | 70 | 4.4 | 74.2 |

| 7 | 1 | 70 | 3.8 | 61.3 |

| 8 | 1 | 70 | 5.0 | 67.8 |

| 9 | 0.75 | 70 | 4.4 | 75.8 |

| 10 | 0.75 | 70 | 4.4 | 77.4 |

| 11 | 0.75 | 70 | 4.4 | 79 |

| 12 | 0.5 | 70 | 3.8 | 77.4 |

| 13 | 0.75 | 70 | 4.4 | 80.6 |

| 14 | 0.5 | 75 | 4.4 | 90.3 |

| 15 | 0.75 | 75 | 3.8 | 64.5 |

| 16 | 0.75 | 75 | 5.0 | 83.9 |

| 17 | 1 | 75 | 4.4 | 67.8 |

| Simulation Item | Sum of Squares | Degrees of Freedom | Mean Square | F | p | Significance |

|---|---|---|---|---|---|---|

| Model | 933.14 | 9 | 103.68 | 19.29 | 0.0004 | ** |

| A | 516.81 | 1 | 516.81 | 96.16 | <0.0001 | ** |

| B | 197.01 | 1 | 197.01 | 36.66 | 0.0005 | ** |

| C | 6.85 | 1 | 6.85 | 1.27 | 0.2963 | × |

| AB | 2.56 | 1 | 2.56 | 0.4763 | 0.5123 | × |

| AC | 64.80 | 1 | 64.80 | 12.06 | 0.0104 | * |

| BC | 58.52 | 1 | 58.52 | 10.89 | 0.0131 | * |

| A2 | 1.16 | 1 | 1.16 | 0.2159 | 0.6563 | × |

| B2 | 86.21 | 1 | 86.21 | 16.04 | 0.0052 | ** |

| C2 | 0.3789 | 1 | 0.3789 | 0.0705 | 0.7983 | × |

| Residual | 37.62 | 7 | 5.37 | |||

| Lack of Fit | 12.02 | 3 | 4.01 | 0.6262 | 0.6350 | × |

| Error | 25.60 | 4 | 6.40 | |||

| Total | 970.76 | 16 |

| Test Group | Numbers of Layout (Pieces) | Harvested Hard-Shell Clams (Pieces) | Field Harvesting Rate (%) | Simulation Harvest Rate (%) |

|---|---|---|---|---|

| 1 | 88 | 80 | 91 | 91.173 |

| 2 | 88 | 81 | 92 | |

| 3 | 88 | 80 | 91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Wang, X.; Huang, B.; Li, S.; Hu, J.; Fu, S.; Yang, L.; Cui, M.; Chen, Z.; Zeng, Y.; et al. Design and Experiment of a Hard-Shell Clam Harvester. Fishes 2025, 10, 217. https://doi.org/10.3390/fishes10050217

Wu H, Wang X, Huang B, Li S, Hu J, Fu S, Yang L, Cui M, Chen Z, Zeng Y, et al. Design and Experiment of a Hard-Shell Clam Harvester. Fishes. 2025; 10(5):217. https://doi.org/10.3390/fishes10050217

Chicago/Turabian StyleWu, Haiyun, Xiaomeng Wang, Bing Huang, Shide Li, Jincheng Hu, Shancan Fu, Lei Yang, Mengxiang Cui, Zhenwei Chen, Yanan Zeng, and et al. 2025. "Design and Experiment of a Hard-Shell Clam Harvester" Fishes 10, no. 5: 217. https://doi.org/10.3390/fishes10050217

APA StyleWu, H., Wang, X., Huang, B., Li, S., Hu, J., Fu, S., Yang, L., Cui, M., Chen, Z., Zeng, Y., Jiang, Y., & Zhang, T. (2025). Design and Experiment of a Hard-Shell Clam Harvester. Fishes, 10(5), 217. https://doi.org/10.3390/fishes10050217