Using BioFloc Technology to Improve Aquaculture Efficiency

Abstract

1. Introduction

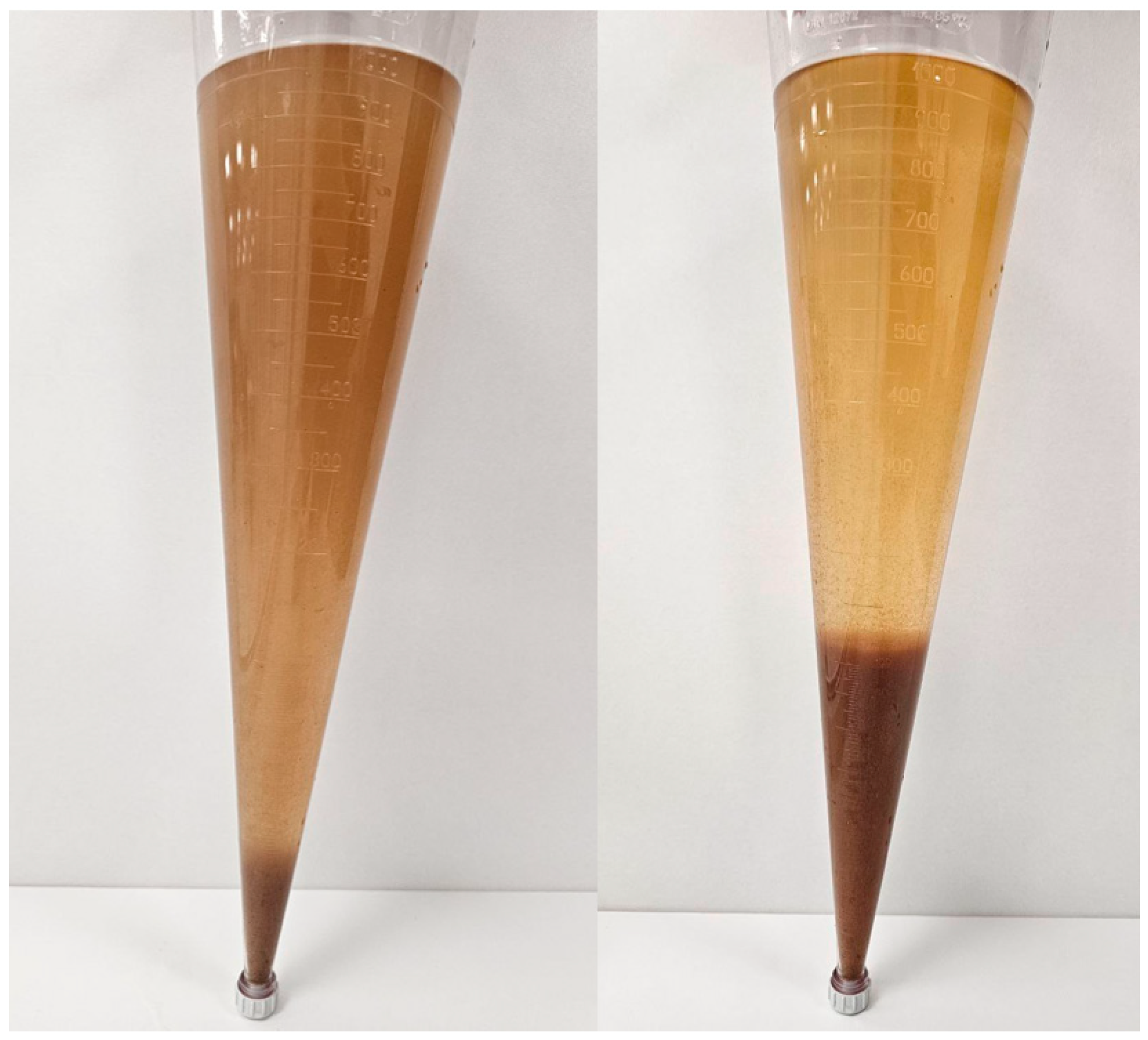

2. BFT Components

3. Impact of BFT on Aquaculture Productivity

4. Condition of Hydrobionts Under Cultivation in BFT

5. Water Quality Using BFT Technology

6. Disadvantages of Biofloc Technology

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AHPND | acute hepatopancreatic necrosis disease |

| BFT | biofloc technology |

| C/N | organic carbon to total nitrogen ratio |

| DE | duration of the experiment |

| DHC | differential hemocyte number |

| EC | experimental conditions |

| FBW | final body weight |

| FCR | feed conversion ratio |

| GIFT | genetically improved farmed tilapia |

| IBW | initial body weight |

| Ig | immunoglobulin |

| IL-1 | interleukin-1 |

| LPS | lipopolysaccharides |

| LZM | lysozyme |

| MPO | myeloperoxidase |

| NBT | nitroblue tetrazolium |

| PHB | poly-β-hydroxybutyrate |

| PO | phenoloxidase |

| RAS | recirculating aquaculture system |

| S | survival |

| SCFAs | short-chain fatty acids |

| SGR | specific growth rate |

| TAN | total ammonia nitrogen |

| THC | total number of hemocytes |

| TLR | toll-like receptors |

| TNF | tumor necrosis factor |

| TSS | total suspended solids |

References

- Sharifinia, M.; Afshari Bahmanbeigloo, Z.; Smith, W.O., Jr.; Yap, C.K.; Keshavarzifard, M. Prevention is better than cure: Persian Gulf biodiversity vulnerability to the impacts of desalination plants. Glob. Chang. Biol. 2019, 25, 4022–4033. [Google Scholar] [CrossRef] [PubMed]

- Asche, F.; Roll, K.H.; Tveterås, S. Future trends in aquaculture: Productivity growth and increased production. Aquac. Ecosyst. 2008, 271–292. [Google Scholar] [CrossRef]

- Crab, R.; Defoirdt, T.; Bossier, P.; Verstraete, W. Biofloc technology in aquaculture: Beneficial effects and future challenges. Aquaculture 2012, 356, 351–356. [Google Scholar] [CrossRef]

- Food and Agriculture Organization FAO and the SDGs. Indicators: Measuring up to the 2030 Agenda for Sustainable Development; FAO: Rome, Italy, 2017; p. 39. Available online: https://openknowledge.fao.org/handle/20.500.14283/i6919en (accessed on 5 January 2025).

- Ogello, E.O.; Outa, N.O.; Obiero, K.O.; Kyule, D.N.; Munguti, J.M. The prospects of biofloc technology (BFT) for sustainable aquaculture development. Sci. Afr. 2021, 14, e01053. [Google Scholar] [CrossRef]

- De Schryver, P.; Crab, R.; Defoirdt, T.; Boon, N.; Verstraete, W. The basics of bio-flocs technology: The added value for aquaculture. Aquaculture 2008, 277, 125–137. [Google Scholar] [CrossRef]

- David, L.H.; Pinho, S.M.; Keesman, K.J.; Garcia, F. Assessing the sustainability of tilapia farming in biofloc-based culture using emergy synthesis. Ecol. Indic. 2021, 131, 108186. [Google Scholar] [CrossRef]

- Hargreaves, J.A. Photosynthetic suspended-growth systems in aquaculture. Aquac. Eng. 2006, 34, 344–363. [Google Scholar] [CrossRef]

- Bossier, P.; Ekasari, J. Biofloc technology application in aquaculture to support sustainable development goals. Microb. Biotechnol. 2017, 10, 1012–1016. [Google Scholar] [CrossRef]

- Luo, G.; Xu, J.; Meng, H. Nitrate accumulation in biofloc aquaculture systems. Aquaculture 2020, 520, 734675. [Google Scholar] [CrossRef]

- Sandoval-Vargas, L.Y.; Jiménez-Amaya, M.N.; Rodríguez-Pulido, J.; Guaje-Ramírez, D.N.; Ramírez-Merlano, J.A.; Medina-Robles, V.M. Applying biofloc technology in the culture of juvenile of Piaractus brachypomus (Cuvier, 1818): Effects on zootechnical performance and water quality. Aquac. Res. 2020, 51, 3865–3878. [Google Scholar] [CrossRef]

- El-Sayed, A.F.M. Use of biofloc technology in shrimp aquaculture: A comprehensive review, with emphasis on the last decade. Rev. Aquac. 2021, 13, 676–705. [Google Scholar] [CrossRef]

- Day, S.B.; Salie, K.; Stander, H.B. A growth comparison among three commercial tilapia species in a biofloc system. Aquac. Int. 2016, 24, 1309–1322. [Google Scholar] [CrossRef]

- Kuhn, D.D.; Lawrence, A.L.; Crockett, J.; Taylor, D. Evaluation of bioflocs derived from confectionary food effluent water as a replacement feed ingredient for fishmeal or soy meal for shrimp. Aquaculture 2016, 454, 66–71. [Google Scholar] [CrossRef]

- Avnimelech, Y. Feeding with microbial flocs by tilapia in minimal discharge bio-flocs technology ponds. Aquaculture 2007, 264, 140–147. [Google Scholar] [CrossRef]

- Ahmad, I.; Babitha Rani, A.; Verma, A.; Maqsood, M. Biofloc technology: An emerging avenue in aquatic animal healthcare and nutrition. Aquac. Int 2017, 25, 1215–1226. [Google Scholar] [CrossRef]

- Raza, B.; Zheng, Z.; Yang, W. A Review on Biofloc System Technology, History, Types, and Future Economical Perceptions in Aquaculture. Animals 2024, 14, 1489. [Google Scholar] [CrossRef]

- Qiao, G.; Zhang, M.; Li, Y.; Xu, C.; Xu, D.H.; Zhao, Z. Biofloc technology (BFT): An alternative aquaculture system for prevention of Cyprinid herpesvirus 2 infection in gibel carp (Carassius auratus gibelio). Fish Shellfish Immunol. 2018, 83, 140–147. [Google Scholar] [CrossRef]

- Wei, Y.; Liao, S.A.; Wang, A.L. The effect of different carbon sources on the nutritional composition, microbial community and structure of bioflocs. Aquaculture 2016, 465, 88–93. [Google Scholar] [CrossRef]

- Jiang, W.; Rena, W.; Li, L.; Dong, S.; Tian, X. Light and carbon sources addition alter microbial community in biofloc-based Litopenaeus vannamei culture systems. Aquaculture 2020, 515, 734572. [Google Scholar] [CrossRef]

- Panigrahi, A.; Sundaram, M.; Saranya, C.; Swain, S.; Dash, R.R.; Dayal, J.S. Carbohydrate sources deferentially influence growth performances, microbial dynamics and immunomodulation in Pacific white shrimp (Litopenaeus vannamei) under biofloc system. Fish Shellfish Immunol. 2019, 86, 1207–1216. [Google Scholar] [CrossRef]

- Emerenciano, M.G.C.; Martínez-Córdova, L.R.; Martínez-Porchas, M.; Miranda-Baeza, A. Biofloc technology (BFT): A tool for water quality management in aquaculture. Water Qual. 2017, 5, 92–109. [Google Scholar] [CrossRef]

- McCusker, S.; Warberg, M.B.; Davies, S.J.; de Souza, V.C.; Johnson, M.P.; Cooney, R.; Wan, A.H.L. Biofloc technology as part of a sustainable aquaculture system: A review on the status and innovations for its expansion. Aquacultire Fish Fish. 2023, 3, 331–352. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Mohammadi, A.; Emerenciano, M.G.C. Microorganisms in biofloc aquaculture system. Aquac. Rep. 2022, 26, 101300. [Google Scholar] [CrossRef]

- Daniel, N.; Nageswari, P. Exogenous Probiotics on Biofloc Based Aquaculture: A Review. Curr. Agric. Res. J. 2017, 5, 88–107. [Google Scholar] [CrossRef]

- Choi, J.Y.; Park, J.S.; Kim, H.; Hwang, J.; Lee, D.; Lee, J.H. Assessment of water quality parameters during a course of applying biofloc technology (BFT). J. Fishries Mar. Sci. Educ. 2020, 32, 1632–1638. [Google Scholar] [CrossRef]

- Panigrahi, A.; Esakkiraj, P.; Jayashree, S.; Saranya, C.; Das, R.R.; Sundaram, M. Colonization of enzymatic bacterial flora in biofloc grown shrimp Penaeus vannamei and evaluation of their beneficial effect. Aquac. Int. 2019, 27, 1835–1846. [Google Scholar] [CrossRef]

- El-Dahhar, A.A.; Elhetawy, A.I.; Shawky, W.A.; El-Zaeem, S.Y.; Abdel-Rahim, M.M. Diverse carbon sources impact the biofloc system in brackish groundwater altering water quality, fish performance, immune status, antioxidants, plasma biochemistry, pathogenic bacterial load and organ histomorphology in Florida red tilapia. Aquac. Int. 2024, 32, 9225–9252. [Google Scholar] [CrossRef]

- In-Kwon, J. Biofloc as disease control. In Proceedings of the International Water Congres, Busan, Republic of Korea, 17–20 September 2012. [Google Scholar]

- Tepaamorndech, S.; Nookaew, I.; Higdon, S.M.; Santiyanont, P.; Phromson, M.; Chantarasakha, K.; Mhuantonga, W.; Plengvidhya, V.; Visessanguan, W. Metagenomics in bioflocs and their effects on gut microbiome and immune responses in Pacific white shrimp. Fish Shellfish Immunol. 2020, 106, 733–741. [Google Scholar] [CrossRef]

- Nootong, K.; Pavasant, P.; Powtongsook, S. Effects of organic carbon addition in controlling inorganic nitrogen concentrations in a biofloc system. J. World Aquac. Soc. 2011, 42, 339–346. [Google Scholar] [CrossRef]

- Ferreira, G.S.; Bolívar, N.C.; Pereira, S.A.; Guertler, C.; do Nascimento Vieira, F.; Mouriño, J.L.P.; Seiffert, W.Q. Microbial biofloc as source of probiotic bacteria for the culture of Litopenaeus vannamei. Aquaculture 2015, 448, 273–279. [Google Scholar] [CrossRef]

- Abakari, G.; Wu, X.; He, X.; Fan, L.; Luo, G. Bacteria in biofloc technology aquaculture systems: Roles and mediating factors. Rev. Aquac. 2022, 14, 1260–1284. [Google Scholar] [CrossRef]

- Hostins, B.; Wasielesky, W.; Decamp, O.; Bossier, P.; De Schryver, P. Managing input C/N ratio to reduce the risk of Acute Hepatopancreatic Necrosis Disease (AHPND) outbreaks in biofloc systems—A laboratory study. Aquaculture 2019, 508, 60–65. [Google Scholar] [CrossRef]

- Domınguez-May, R.; Poot-Lopez, G.R.; Hernandez, J.; Gasca-Leyva, E. Dynamic optimal ration size in tilapia culture: Economic and environmental considerations. Ecol. Model 2020, 420, 108930. [Google Scholar] [CrossRef]

- El-Hawarry, W.N.; Shourbela, R.M.; Haraz, Y.G.; Khatab, S.A.; Dawood, M.A. The influence of carbon source on growth, feed efficiency, and growth-related genes in Nile tilapia (Oreochromis niloticus) reared under biofloc conditions and high stocking density. Aquaculture 2021, 542, 736919. [Google Scholar] [CrossRef]

- Wei, Y.F.; Wang, A.L.; Liao, S.A. Effect of different carbon sources on microbial community structure and composition of ex-situ biofloc formation. Aquaculture 2020, 515, 734492. [Google Scholar] [CrossRef]

- Browdy, C.L.; Ray, A.J.; Leffler, J.W.; Avnimelech, Y. Biofloc-based aquaculture systems. Aquac. Prod. Syst. 2012, 278–307. [Google Scholar] [CrossRef]

- Lara, G.; Krummenauer, D.; Abreu, P.C.; Poersch, L.H.; Wasielesky, W. The use of different aerators on Litopenaeus vannamei biofloc culture system: Effects on water quality, shrimp growth and biofloc composition. Aquac. Int. 2017, 25, 147–162. [Google Scholar] [CrossRef]

- Ekasari, J.; Nugroho, U.A.; Fatimah, N.; Angela, D.; Hastuti, Y.P.; Pande, G.S.J.; Natrah, F.M.I. Improvement of biofloc quality and growth of Macrobrachium rosenbergii in biofloc systems by Chlorella addition. Aquac. Int. 2021, 29, 2305–2317. [Google Scholar] [CrossRef]

- Brito, L.O.; dos Santos, I.G.S.; de Abreu, J.L.; de Araújo, M.T.; Severi, W.; Gàlvez, A.O. Effect of the addition of diatoms (Navicula spp.) and rotifers (Brachionus plicatilis) on water quality and growth of the Litopenaeus vannamei postlarvae reared in a biofloc system. Aquac. Res. 2016, 47, 3990–3997. [Google Scholar] [CrossRef]

- Ju, Z.Y.; Forster, I.; Conquest, L.; Dominy, W.; Kuo, W.C.; David Horgen, F. Determination of microbial community structures of shrimp floc cultures by biomarkers and analysis of floc amino acid profiles. Aquac. Res. 2008, 39, 118–133. [Google Scholar] [CrossRef]

- Kasan, N.A.; Ghazali, N.A.; Hashim, N.F.C.; Jauhari, I.; Jusoh, A.; Ikhwanuddi, M. 18s rDNA sequence analysis of microfungi from biofloc-based system in Pacific whiteleg shrimp, Litopenaeus vannamei culture. Biotechnology 2018, 17, 135–141. [Google Scholar] [CrossRef]

- Ballester, E.L.C.; Marzarotto, S.A.; Silva de Castro, C.; Frozza, A.; Pastore, I.; Abreu, P.C. Productive performance of juvenile freshwater prawns Macrobrachium rosenbergii in biofloc system. Aquac. Res. 2017, 48, 4748–4755. [Google Scholar] [CrossRef]

- Brol, J.; Pinho, S.M.; Sgnaulin, T.; Pereira, K.D.R.; Thomas, M.C.; De Mello, G.L.; Emerenciano, M.G.C. Tecnologia de bioflocos (BFT) no desempenho zootécnico de tilápias: Efeito da linhagem e densidades de estocagem. Arch. De Zootec. 2017, 66, 229–235. [Google Scholar]

- Pinho, S.M.; Lima, J.P.; David, L.H.; Oliveira, M.S.; Goddek, S.; Carneiro, D.J.; Keesman, K.J.; Portella, M.C. Decoupled FLOCponics systems as an alternative approach to reduce the protein level of tilapia juveniles’ diet in integrated agri-aquaculture production. Aquaculture 2021, 543, 736932. [Google Scholar] [CrossRef]

- Kishawy, A.T.; Sewid, A.H.; Nada, H.S.; Kamel, M.A.; El-Mandrawy, S.A.; Abdelhakim, T.M.; El Nahhas, N.; Hozzein, W.N.; Ibrahim, D. Mannanoligosaccharides as a carbon source in Biofloc boost dietary plant protein and water quality, growth, immunity and Aeromonas hydrophila resistance in Nile tilapia (Oreochromis niloticus). Animals 2020, 10, 1724. [Google Scholar] [CrossRef] [PubMed]

- De Souza, R.L.; De Lima, E.C.R.; De Melo, F.P.; Ferreira, M.G.P.; De Souza Correia, E. The culture of Nile tilapia at different salinities using a biofloc system. Fish Eng. 2019, 50, 267–275. [Google Scholar] [CrossRef]

- Farahmandi, V.; Tukmechi, A.; Ahmadifard, N.; Moghanlooi, K.S.; Vayaieh, R.M. Reduce the environmental impacts of rainbow trout ponds effluent by Biofloc technology running title: Biofloc and the reduced impacts of effluent. J. Nat. Environ. 2015, 68, 247–255. [Google Scholar] [CrossRef]

- Poli, M.A.; Schveitzer, R.; de Oliveira Nuñer, A.P. The use of biofloc technology in a South American catfish (Rhamdia quelen) hatchery: Effect of suspended solids in the performance of larvae. Aquac. Eng. 2015, 66, 17–21. [Google Scholar] [CrossRef]

- Battisti, E.; Rabaioli, A.; Uczay, J.; Sutili, F.; Lazzari, R. Effect of stocking density on growth, hematological and biochemical parameters and antioxidant status of silver catfish (Rhamdia quelen) cultured in a biofloc system. Aquaculture 2020, 524, 735213. [Google Scholar] [CrossRef]

- Battisti, E.K.; Rabaioli, A.; Uczay, J.; Peixoto, N.C.; Sutili, F.J.; Lazzari, R. Effects of dietary protein and feeding regimes on growth and biochemical parameters of Rhamdia quelen cultured in biofloc technology. Aquac. Int. 2024, 32, 5199–5213. [Google Scholar] [CrossRef]

- Ekasari, J.; Suprayudi, M.A.; Wiyoto, W.; Hazanah, R.F.; Lenggara, G.S.; Sulistiani, R.; Zairin, M., Jr. Biofloc technology application in African catfish fingerling production: The effects on the reproductive performance of broodstock and the quality of eggs and larvae. Aquaculture 2016, 464, 349–356. [Google Scholar] [CrossRef]

- Green, B.W.; McEntire, M.E. Comparative water quality and channel catfish production in earthen ponds and a biofloc technology production system. J. Appl. Aquac. 2017, 29, 1–15. [Google Scholar] [CrossRef]

- Aghabarari, M.; Abdali, S.; Yousefi Jourdehi, A. The effect of Biofloc system on water quality, growth and hematological indices of Juvenile great sturgeon (Huso huso). Iran. J. Fish. Sci. 2021, 20, 1467–1482. [Google Scholar]

- Berber, S.; Özcelep, T. Effects of different carbon sources on growth and some innate immune responses of Russian sturgeon (Acipenser gueldenstaedtii) in biofloc systems. Mar. Sci. Technol. Bull. 2023, 12, 162–171. [Google Scholar] [CrossRef]

- Azimi, A.; Shekarabi, S.P.H.; Paknejad, H.; Harsij, M.; Khorshidi, Z.; Zolfaghari, M.; Zakariaee, H. Various carbon/nitrogen ratios in a biofloc-based rearing system of common carp (Cyprinus carpio) fingerlings: Effect on growth performance, immune response, and serum biochemistry. Aquaculture 2022, 548, 737622. [Google Scholar] [CrossRef]

- Deng, M.; Chen, J.; Gou, J.; Hou, J.; Li, D.; He, X. The effect of different carbon sources on water quality, microbial community and structure of biofloc systems. Aquaculture 2018, 482, 103–110. [Google Scholar] [CrossRef]

- Zhu, Z.M.; Lin, X.T.; Pan, J.X.; Xu, Z.N. Effect of cyclical feeding on compensatory growth, nitrogen and phosphorus budgets in juvenile Litopenaeus vannamei. Aquac. Res. 2016, 47, 283–289. [Google Scholar] [CrossRef]

- Esparza-Leal, H.M.; Ponce-Palafox, J.T.; Álvarez-Ruiz, P.; López-Álvarez, E.S.; Vázquez-Montoya, N.; López-Espinoza, M.; Mejia, M.M.; Gómez-Peraza, R.L.; Nava-Perez, E. Effect of stocking density and water exchange on performance and stress tolerance to low and high salinity by Litopenaeus vannamei postlarvae reared with biofloc in intensive nursery phase. Aquac. Int. 2020, 28, 1473–1483. [Google Scholar] [CrossRef]

- Luo, G.; Gao, Q.; Wang, C.; Liu, W.; Sun, D.; Li, L.; Tan, H. Growth, digestive activity, welfare, and partial cost-effectiveness of genetically improved farmed tilapia (Oreochromis niloticus) cultured in a recirculating aquaculture system and an indoor biofloc system. Aquaculture 2014, 422, 1–7. [Google Scholar] [CrossRef]

- Azim, M.E.; Little, D.C. The biofloc technology (BFT) in indoor tanks: Water quality, biofloc composition, and growth and welfare of Nile tilapia (Oreochromis niloticus). Aquaculture 2008, 283, 29–35. [Google Scholar] [CrossRef]

- Dauda, A.B.; Romano, N.; Ebrahimi, M.; Karim, M.; Natrah, I.; Kamarudin, M.S.; Ekasari, J. Different carbon sources affects biofloc volume, water quality and the survival and physiology of African catfish Clarias gariepinus fingerlings reared in an intensive biofloc technology system. Fish. Sci. 2017, 83, 1037–1048. [Google Scholar] [CrossRef]

- Krummenauer, D.; Peixoto, S.; Cavalli, R.O.; Poersch, L.H.; Wasielesky, W. Superintensive culture of white shrimp, Litopenaeus vannamei, in a biofloc technology system in southern Brazil at different stocking densities. J. World Aquac. Soc. 2011, 42, 726–733. [Google Scholar] [CrossRef]

- Ray, A.J.; Dillon, K.S.; Lotz, J.M. Water quality dynamics and shrimp (Litopenaeus vannamei) production in intensive, mesohaline culture systems with two levels of biofloc management. Aquac. Eng. 2011, 45, 127–136. [Google Scholar] [CrossRef]

- Miao, S.; Hu, J.; Wan, W.; Han, B.; Zhou, Y.; Xin, Z.; Sun, L. Biofloc technology with addition of different carbon sources altered the antibacterial and antioxidant response in Macrobrachium rosenbergii to acute stress. Aquaculture 2020, 525, 735280. [Google Scholar] [CrossRef]

- Long, L.; Yang, J.; Li, Y.; Guan, C.; Wu, F. Effect of biofloc technology on growth, digestive enzyme activity, hematology, and immune response of genetically improved farmed tilapia (Oreochromis niloticus). Aquaculture 2015, 448, 135–141. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Sharifinia, M.; Emerenciano, M.G.C. A detailed look at the impacts of biofloc on immunological and hematological parameters and improving resistance to diseases. Fish Shellfish Immunol. 2023, 137, 108796. [Google Scholar] [CrossRef] [PubMed]

- Samocha, T.M. Sustainable Biofloc Systems for Marine Shrimp; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128180402. [Google Scholar]

- Kim, S.; Pang, Z.; Seo, H.; Cho, Y.; Samocha, T.; Jang, I. Effect of bioflocs on growth and immune activity of Pacific white shrimp, Litopenaeus vannamei postlarvae. Aquac. Res. 2014, 45, 362–371. [Google Scholar] [CrossRef]

- Kim, S.; Guo, Q.; Jang, I. Effect of Biofloc on the survival and growth of the postlarvae of three Penaeids (Litopenaeus vannamei, Fenneropenaeus chinensis, and Marsupenaeus japonicus) and their biofloc feeding efficiencies, as related to the morphological structure of the third maxilliped. J. Crustac. Biol 2015, 35, 41–50. [Google Scholar] [CrossRef]

- Vinatea, L.; Galvez, A.O.; Browdy, C.L.; Stokes, A.; Venero, J.; Haveman, J. Photosynthesis, water respiration and growth performance of Litopenaeus vannamei in a super-intensive raceway culture with zero water exchange: Interaction of water quality variables. Aquac. Eng. 2010, 42, 17–24. [Google Scholar] [CrossRef]

- Qiao, G.; Chen, P.; Sun, Q.; Zhang, M.; Zhang, J.; Li, Z.; Li, Q. Poly-βhydroxybutyrate (PHB) in bioflocs alters intestinal microbial community structure, immune related gene expression and early Cyprinid herpesvirus 2 replication in gibel carp (Carassius auratus gibelio). Fish Shellfish Immunol. 2020, 97, 72–82. [Google Scholar] [CrossRef]

- Mansour, A.T.; Esteban, M.A. Effects of carbon sources and plant protein levels in a biofloc system on growth performance, and the immune and antioxidant status of Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol. 2017, 64, 202–209. [Google Scholar] [CrossRef]

- Panigrahi, A.; Sundaram, M.; Saranya, C.; Satish Kumar, R.; Syama Dayal, J.; Saraswathy, R.; Otta, S.K.; Shyne Anand, P.S.; Nila Rekha, P.; Gopal, C. Influence of differential protein levels of feed on production performance and immune response of pacific white leg shrimp in a biofloc–based system. Aquaculture 2019, 503, 118–127. [Google Scholar] [CrossRef]

- Kaya, D.; Genc, E.; Genc, M.A.; Aktas, M.; Eroldogan, O.T.; Guroy, D. Biofloc technology in recirculating aquaculture system as a culture model for green tiger shrimp, Penaeus semisulcatus: Effects of different feeding rates and stocking densities. Aquaculture 2020, 528, 735526. [Google Scholar] [CrossRef]

- Kumar, V.; Roy, S.; Behera, B.K.; Swain, H.S.; Das, B.K. Biofloc Microbiome With Bioremediation and Health Benefits. Front. Microbiol. 2021, 12, 741164. [Google Scholar] [CrossRef]

- Panigrahi, A.; Das, R.R.; Sivakumar, M.R.; Saravanan, A.; Saranya, C.; Sudheer, N.S.; Kumaraguru Vasagam, K.P.; Mahalakshmi, P.; Kannappan, S.; Gopikrishna, G. Bio augmentation of heterotrophic bacteria in biofloc system improves growth, survival, and immunity of Indian white shrimp Penaeus Indicus. Fish Shellfish Immunol. 2020, 98, 477–487. [Google Scholar] [CrossRef] [PubMed]

- Chethurajupalli, L.; Tambireddy, N. Rearing of white leg shrimp Litopenaeus vannamei (Boone, 1931) in biofloc and substrate systems: Microbial community of water, growth and immune response of shrimp. Turk. J. Fish. Aquat. Sci. 2022, 22, 3. [Google Scholar] [CrossRef]

- Gao, L.; Shan, H.W.; Zhang, T.W.; Bao, W.Y.; Ma, S. Effects of carbohydrate addition on Litopenaeus vannamei intensive culture in a zero-water exchange system. Aquaculture 2012, 342–343, 89–96. [Google Scholar] [CrossRef]

- Zhao, D.; Pan, L.; Huang, F.; Wang, C.; Xu, W. Effects of different carbon sources on bioactive compound production of biofloc, immune response, antioxidant level, and growth performance of Litopenaeus vannamei in zero- water exchange culture tanks. J. World Aquacult. Soc. 2016, 47, 566–576. [Google Scholar] [CrossRef]

- Ekasari, J.; Azhar, M.H.; Enang, H.; Sri Nuryati, S.; De Schryver, P.; Bossier, P. Immune response and disease resistance of shrimp fed biofloc grown on different carbon sources. Fish Shellfish Immunol. 2014, 41, 332–339. [Google Scholar] [CrossRef]

- Khanjani, M.H.; da Silva, L.O.B.; Foes, G.K.; Vieira, F.D.; Poli, M.; Santos MEmerenciano, M.G.C. Synbiotics and aquamimicry as alternative microbial-based approaches in intensive shrimp farming and biofloc: Novel disruptive techniques or complementary management tools? A scientific-based overview. Aquaculture 2023, 567, 739273. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Torfi Mozanzade, M.; Sharifinia, M.; Emerenciano, M.G.C. Biofloc: A sustainable dietary supplement, nutritional value and functional properties. Aquaculture 2023, 562, 738757. [Google Scholar] [CrossRef]

- Kaya, D.; Genc, M.A.; Aktas, M.; Yavuzcan, H.; Ozmen, O.; Genc, E. Effect of biofloc technology on growth of speckled shrimp, Metapenaeus monoceros (Fabricus) in different feeding regimes. Aquac. Res. 2019, 50, 2760–2768. [Google Scholar] [CrossRef]

- Ahmad, H.; Verma, A.; Babitha Rani, A.; Rathore, G.; Saharan, N.; Gora, A. Growth, non-specific immunity and disease resistance of Labeo rohita against Aeromonas hydrophila in biofloc systems using different carbon sources. Aquaculture 2016, 457, 61–67. [Google Scholar] [CrossRef]

- Menaga, M.; Felix, S.; Charulatha, M.; Gopalakannan, A.; Panigrahi, A. Effect of in-situ and ex-situ biofloc on immune response of genetically improved farmed tilapia. Fish Shellfish Immunol. 2019, 92, 698–705. [Google Scholar] [CrossRef] [PubMed]

- Crab, R.; Chielens, B.; Wille, M.; Bossier, P.; Verstraete, W. The effect of different carbon sources on the nutritional value of bioflocs, a feed for (Macrobrachium rosenbergii) postlarvae. Aquac. Res. 2010, 41, 559–567. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Akrami, R.; Najdegerami, E.H.; Ghiasvand, Z.; Koohsari, H. Effects of different protein levels and carbon sources on water quality, antioxidant status and performance of common carp (Cyprinus carpio) juveniles raised in biofloc based system. Aquaculture 2020, 516, 639–734. [Google Scholar] [CrossRef]

- Liu, G.; Ye, Z.; Liu, D.; Zhao, J.; Sivaramasamy, E.; Deng, Y.; Zhu, S. Influence of stocking density on growth, digestive enzyme activities, immune responses, antioxidant of Oreochromis niloticus fingerlings in biofloc systems. Fish Shellfish Immunol. 2018, 81, 416–422. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, Y.Y.; Jiang, N.; Zhang, A.Z.; Li, M.Y. Bioflocs attenuates lipopolysaccharide-induced inflammation, immunosuppression and oxidative stress in Channa argus. Fish Shellfish Immunol. 2021, 114, 218–228. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.K.; Hur, Y.B. Hematological parameters and antioxidant responses in olive flounder Paralichthys olivaceus in biofloc depend on water temperature. J. Therm. Biol. 2019, 82, 206–212. [Google Scholar] [CrossRef]

- Haridas, H.; Chadha, N.K.; Sawant, P.B.; Deo, A.D.; Ande, M.P.; Syamala, K.; Sontakke, R.; Lingam, S.S. Growth performance, digestive enzyme activity, non specific immune response and stress enzyme status in early stages of grey mullet reared in a biofloc system. Aquac. Res. 2021, 52, 4923–4933. [Google Scholar] [CrossRef]

- Nageswari, P.; Verma, A.K.; Gupta, S.; Jeyakumari, A.; Hittinahalli, C.M. Effects of different stocking densities on haematological, non-specific immune, and antioxidant defence parameters of striped catfish (Pangasianodon hypophthalmus) fingerlings reared in finger millet-based biofloc system. Aquacult. Int 2022, 30, 3229–3245. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, J.C. Acute toxicity of ammonia on Litopenaeus vannamei Boone juveniles at different salinity levels. J. Exp. Mar. Biol. Ecol. 2001, 259, 109–119. [Google Scholar] [CrossRef]

- Kuhn, D.D.; Lawrence, A. Ex-situ biofloc technology. In Biofloc Technology—A Practical Guide Book, 3rd ed.; Avnimelech, Y., Ed.; The World Aquaculture Society: Baton Rouge, LO, USA, 2015; pp. 87–99. [Google Scholar]

- Avnimelech, Y. Tilapia production using biofloc technology: Saving water, waste recycling improves economics. Glob. Aquac. Advocate 2011. Available online: https://www.globalseafood.org/advocate/tilapia-production-using-biofloc-technology/ (accessed on 6 January 2025).

- Hargreaves, J.A. Biofloc Production Systems for Aquaculture; Southern Regional Aquaculture Center (SRAC): Stoneville, MS, USA, 2013; p. 4503. [Google Scholar]

- Martins, G.B.; Tarouco, F.; Rosa, C.E.; Robaldo, R.B. The utilization of sodium bicarbonate, calcium carbonate or hydroxide in biofloc system: Water quality, growth performance and oxidative stress of Nile tilapia (Oreochromis niloticus). Aquaculture 2017, 468, 10–17. [Google Scholar] [CrossRef]

- Kroupova, H.; Machova, J.; Svobodova, Z. Nitrite influence on fish: A review. Veterinární Med. 2012, 50, 461–471. [Google Scholar] [CrossRef]

- Learmonth, C.; Carvalho, A.P. Acute and chronic toxicity of nitrate to early life stages of zebrafish—Setting nitrate safety levels for zebrafish rearing. Zebrafish 2015, 12, 305–311. [Google Scholar] [CrossRef]

- Su, Y.; Mennerich, A.; Urban, B. Municipal wastewater treatment and biomass accumulation with a wastewater-born and settleable algal-bacterial culture. Water Res. 2011, 45, 3351–3358. [Google Scholar] [CrossRef]

- Harun, A.A.C.; Mohammad, N.A.H.; Ikhwanuddin, M.; Jauhari, I.; Sohaili, J.; Kasan, N.A. Effect of different aeration units, N types and inoculum on biofloc formation for improvement of Pacific whiteleg shrimp production. Egypt. J. Aquat. Res. 2019, 45, 287–292. [Google Scholar] [CrossRef]

- Gaona, C.A.P.; de Almeida, M.S.; Viau, V.; Poersch, L.H.; Wasielesky, W.J. Effect of different total suspended solids levels on a Litopenaeus vannamei (Boone, 1931) BFT culture system during biofloc formation. Aquac. Res. 2015, 48, 1070–1079. [Google Scholar] [CrossRef]

- Hosain, M.E.; Amin, S.M.N.; Kamarudin, M.S.; Arshad, A.; Karim, M.; Romano, N. Effect of salinity on growth, survival, and proximate composition of Macrobrachium rosenbergii post larvae as well as zooplankton composition reared in a maize starch based biofloc system. Aquaculture 2021, 533, 736235. [Google Scholar] [CrossRef]

- Kumar, V.S.; Pandey, P.K.; Anand, T.; Bhuvaneswari, G.R.; Dhinakaran, A.; Kumar, S. Biofloc improves water, effluent quality and growth parameters of Penaeus vannamei in an intensive culture system. J. Environ. Manag. 2018, 215, 206–215. [Google Scholar] [CrossRef]

- Pérez-Fuentes, J.A.; Pérez-Rostro, C.I.; Hernández-Vergara, M.P.; Monroy-Dosta, M.D.C. Variation of the bacterial composition of biofloc and the intestine of Nile tilapia Oreochromis niloticus, cultivated using biofloc technology, supplied different feed rations. Aquac. Res. 2018, 49, 3658–3668. [Google Scholar] [CrossRef]

- Ray, A.J.; Lewis, B.L.; Browdy, C.L.; Leffler, J.W. Suspended solids removal to improve shrimp (Litopenaeus vannamei) production and an evaluation of a plant-based feed in minimal-exchange, superintensive culture systems. Aquaculture 2010, 299, 89–98. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Sharifinia, M.; Emerenciano, M.G.C. Biofloc Technology (BFT) in Aquaculture: What Goes Right, What Goes Wrong? A Scientific-Based Snapshot. Aquac. Nutr. 2024, 2024, 7496572. [Google Scholar] [CrossRef] [PubMed]

- Srimadhuri, S.; Dumpala, S.; Viswasanthi, N.; Ramaneswari, K. Biofloc technology in aquaculture: A comprehensive review. In Sustainable Innovations in Life Sciences: Integrating Ecology, Nanotechnology, and Toxicology; Pasumarthi, B., Dumpala, S., Perli, M.D., Chintada, V., Eds.; Deep Science Publishing: San Francisco, CA, USA, 2024; pp. 31–35. [Google Scholar] [CrossRef]

- Saeedi, K.H.; Maheen, N.; Sharafat, A. The Future of Biofloc Development Techniques for Aquaculture: A Comprehensive Review of Current Scenarios and Potential Improvements. Egypt. J. Aquat. Biol. Fish. 2024, 28, 769–791. [Google Scholar] [CrossRef]

- Minaz, M.; Yazıcı, İ.S.; Sevgili, H.; Aydın, İ. Biofloc technology in aquaculture: Advantages and disadvantages from social and applicability perspectives—A review. Ann. Anim. Sci. 2024, 24, 307–319. [Google Scholar] [CrossRef]

- Veershetty Jagadeesh, M.S.; i Anil, C.; Ragini, S.; Thanuja, K.; Abhishek, G.J. Economic Viability and Operational Efficiency: A Comparative Study of Biofloc and Traditional Aquaculture with Special Reference to Bengaluru, India. J. Sci. Res. Rep. 2024, 30, 191–198. [Google Scholar] [CrossRef]

- Mauladani, S.; Rahmawati, A.I.; Absirin, M.F.; Saputra, R.N. Economic feasibility study of Litopenaeus vannamei shrimp farming: Nanobubble investment in increasing harvest productivity. J. Akuakultur Indones. 2020, 19, 30–38. [Google Scholar] [CrossRef]

- Mugwanya, M.; Dawood, M.A.O.; Kimera, F.; Sewilam, H. Biofloc Systems for Sustainable Production of Economically Important Aquatic Species: A Review. Sustainability 2021, 13, 7255. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Sharifinia, M. Biofloc technology as a promising tool to improve aquaculture production. Rev. Aquac. 2020, 12, 1836–1850. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.; Chen, Y.; Zhang, S.; Dai, L.; Zhu, W.; Chen, Y. Optimized Utilization of Organic Carbon in Aquaculture Biofloc Systems: A Review. Fishes 2023, 8, 465. [Google Scholar] [CrossRef]

- Tasleem, S.; Alotaibi, B.; Masud, S.; Habib, S.; Acar, Ü.; Cecchini, S.; Ullah, M.; Khan, K.; Fazio, F.; Khayyam, K. Biofloc System with Different Carbon Sources Improved Growth, Haematology, Nonspecific Immunity, and Resistivity against the Aeromonas hydrophila in Common Carp, Cyprinus carpio. Aquac. Res. 2024, 2024, 1–11. [Google Scholar] [CrossRef]

- El-Husseiny, O.; Goda, A.; Mabroke, R.; Soaudy, M. Complexity of carbon sources and the impact on biofloc integrity and quality in tilapia (Oreochromis niloticus) tanks. AACL Bioflux 2018, 11, 846–855. [Google Scholar]

- Khanjani, M.H.; Mohammadi, A.; Emerenciano, M. Water quality in biofloc technology (BFT): An applied review for an evolving aquaculture. Aquac. Int. 2024, 32, 9321–9374. [Google Scholar] [CrossRef]

- Crockett, J.; Lawrence, A. Two organic carbon application rates to control inorganic nitrogen in minimal water exchange, bio oc, shallow water, shrimp nursery systems. Int. J. Recirc. Aquac. 2017, 14, 1–7. [Google Scholar] [CrossRef]

- Bakhit, A.A.; Jamlos, M.F.; Nordin MA, H.; Jamlos, M.A.; Mamat, R.; Nawi, M.A.M.; Nugroho, A. Design of a Low-cost IoT-based Biofloc Water Quality Monitoring System. J. Adv. Res. Appl. Mech. 2024, 114, 153–162. [Google Scholar] [CrossRef]

- Abid, M.; Amjad, M.; Munir, K.; Sidd, H.; Siddique, R.; Jurcut, A.; Anca, D.; Jurcut, M. IoT-Based Smart Biofloc Monitoring System for Fish Farming Using Machine Learning. IEEE Access 2024, 12, 86333–86345. [Google Scholar] [CrossRef]

- Lindholm-Lehto, P. Water quality monitoring in recirculating aquaculture systems. Aquac. Fish Fish. 2023, 3, 113–131. [Google Scholar] [CrossRef]

| Species | DE | EC | IBW | FBW | S | SGR | FCR | Reference |

|---|---|---|---|---|---|---|---|---|

| Carp Cyprinus carpio | 8 weeks | C/N-10 | 6.91 ± 0.13 a | 11.32 ± 0.34 b | 93.33 ± 2.89 b | 0.88 ± 0.08 b | 2.51 ± 0.63 a | [57] |

| C/N-15 | 6.88 ± 0.08 a | 11.40 ± 0.48 b | 100 a | 0.90 ± 0.07 b | 1.67 ± 0.45 ab | |||

| C/N-20 | 6.91 ± 0.09 a | 13.58 ± 0.21 a | 100 a | 1.21 ± 0.02 a | 1.27 ± 0.08 b | |||

| Nile tilapia Oreochromis niloticus | 84 days | 35% CP without BFT | 99.61 ± 13.74 | 127.51 ± 28.17 b | 100 | - | 4.97 ± 0.12 a | [62] |

| 35% CP with BFT | 100.69 ± 13.61 | 140.72 ± 27.26 a | 100 | - | 3.51 ± 0.44 b | |||

| 24% CP with BFT | 98.45 ± 12.71 | 138.58 ± 24.99 a | 100 | - | 3.44 ± 0.45 b | |||

| African catfish Clarias gariepinus | 122 days | Control | - | 956 ± 28 a | 98 ± 2 a | - | - | [53] |

| BFT | - | 1077 ± 77 a | 100 a | - | - | |||

| South American catfish Rhamdia quelen | 21 days | T-HET | - | 0.066 ± 0.0125 ab | 44.0 ± 10.1 a | - | - | [50] |

| T200 | - | 0.0886 ± 0.0084 a | 38.1 ± 3.4 a | - | - | |||

| T400–600 | - | 0.0457 ± 0.0063 b | 54.4 ± 2.4 a | - | - | |||

| T800–1000 | - | 0.0445 ± 0.0044 b | 51.1 ± 2.7 a | - | - | |||

| Control | - | 0.0649 ± 0.022 ab | 10.2 ± 4.5 b | - | - | |||

| African catfish Clarias gariepinus | 6 weeks | Control | 5.13 ± 0.13 | 22.60 ± 1.58 | 60.0 ± 2.3 ** | 3.52 ± 0.20 | - | [63] |

| Sucrose BFT | 5.07 ± 0.07 | 24.13 ± 1.86 | 76.3 ± 4.9 ** | 3.70 ± 0.22 | - | |||

| Glycerin BFT | 5.07 ± 0.18 | 22.63 ± 1.62 | 90.6 ± 2.4 *** | 3.55 ± 0.09 | - | |||

| rice bran BFT | 5.00 ± 0.11 | 23.46 | 22.6 ± 22.6 * | 3.68 | - | |||

| Shrimp Penaeus vannamei | 120 days | 150 Shrimp/m2 | 0.96 ± 0.28 a | 15.6 ± 1.70 a | 92.0 ± 2.55 a | - | 1.40 ± 0.09 a | [64] |

| 300 Shrimp/m2 | 0.96 ± 0.28 a | 16.8 ± 0.93 a | 81.2 ± 3.09 b | - | 1.29 ± 0.05 a | |||

| 450 Shrimp/m2 | 0.96 ± 0.28 a | 9.0 ± 1.20 b | 75.0 ± 3.74 c | - | 2.41 ± 0.55 b | |||

| Shrimp Penaeus vannamei | 33 days | Blower | 4.30 ± 0.93 | 12.96 ± 2.63 a | 86.0 ± 3.0 a | - | 1.71 ± 0.15 ab | [39] |

| Vertical pump | 4.30 ± 0.93 | 10.93 ± 2.66 b | 92.3 ± 5.68 a | - | 1.56 ± 0.17 a | |||

| Propeller | 4.30 ± 0.93 | 12.81 ± 2.21 a | 55.0 ± 18.3 b | - | 1.99 ± 0.21 b | |||

| Shrimp Penaeus vannamei | 42 days # | Control | 3.03 ± 0.12 | 10.42 ± 0.03 | 99.2 ± 1.66 | 2.93 ± 0.18 | 1.96 ± 0.15 | [32] |

| Probiotic | 3.03 ± 0.12 | 10.8 ± 0.18 | 95.8 ± 3.19 | 2.97 ± 0.11 | 2.18 ± 0.21 | |||

| Shrimp Penaeus vannamei | 13 weeks | low solids content | - | 22.1 ± 0.3 (21.7–22.7) a | 49.7 ± 3.1 (43.9–54.5) | - | 2.5 ± 0.1 (2.3–2.7) | [65] |

| High solids content | - | 17.8 ± 0.2 (15.3–19.7) b | 49.4 ± 5.9 (41.7–66.5) | - | 3.3 ± 0.4 (2.0–4.0) | |||

| Freshwater shrimp Macrobrachium rosenbergii | 45 days # | Control | 0.25 ± 0.01 | 2.91 ± 0.07 | 88.72 ± 1.78 | - | - | [66] |

| Glucose | 0.25 ± 0.01 | 3.15 ± 0.13 | 93.85 ± 3.08 | - | - | |||

| Sucrose | 0.25 ± 0.01 | 3.09 ± 0.16 | 91.79 ± 4.95 | - | - | |||

| Molasses | 0.25 ± 0.01 | 2.97 ± 0.10 | 92.82 ± 3.20 | - | - | |||

| Tilapia Oreochromis niloticus | 8 weeks | Control | 50.25 ± 0.78 a | 146.66 ± 0.85 b | 100 a | 1.92 ± 0.02 b | 0.97 ± 0.01 a | [67] |

| BFT | 50.61 ± 0.91 a | 160.54 ± 3.06 a | 100 a | 2.04 ± 0.01 a | 0.83 ± 0.03 b |

| Parameter | Optimal Range | Main Information | Reference |

|---|---|---|---|

| Temperature | 28–30 °C | Temperatures below 20 °C can significantly slow down the development of the microbial community, which in turn will affect the species being grown. | [22] |

| Dissolved oxygen | >4 mg L−1 ≥ 60% saturated | Aeration needs to be adjusted according to the biomass of the organisms being grown. Respiration rates as high as 6 mg L−1 (CO2) per hour have been observed in some intensive operations, so ensuring good aeration and water mixing is essential. | [97,98] |

| pH | 6.8–8.0 (freshwater) 7.8–8.4 (brackish and marine) | Deviation from the optimum range can cause various biological reactions such as blood acidosis and alkalosis, resulting in animal stress and reduced growth. Chemical effects can also occur, including ammonia toxicity and the toxicity and solubility of metallic compounds. | [22] |

| Alkalinity | 100–150 mg L−1 | Autotrophic and heterotrophic bacteria utilize carbonates as a source of inorganic carbon in the BFT. Therefore, it is important to monitor the buffer capacity and adjust it if necessary. | [98,99] |

| Total ammonia nitrogen | <1 mg L−1 | As pH increases, ammonium loses the H⁺ ion and is converted to ammonia, which is much more toxic to aquatic organisms. Therefore, the pH should remain close to neutral values. If the pH rises, it may be necessary to add additional carbohydrates to stimulate microbial growth. | [6] |

| Nitrite | 0 | Studies have shown that nitrite causes a variety of physiological problems in aquatic organisms, including ion imbalances in cellular metabolism, oxidation of hemoglobin to methemoglobin, increased heart rate, and increased water retention in the kidneys. | [100] |

| Nitrate | <20 mg L−1 | Nitrate levels below 20 mg L−1 are considered safe for most aquatic organisms. However, some fish species, such as Danio rerio, can also tolerate concentrations up to 200 mg L−1. However, at levels above 400 mg/l, morphological abnormalities and a significant reduction in growth and survival are observed. | [22,101] |

| Orthophosphate | <20 mg L−1 | Phosphate itself is not toxic to the aquatic ecosystem or farm animals, but high concentrations can promote the growth of harmful cyanobacteria. Phosphorus removal from water bodies can occur through microbial back uptake, although this process is slower than nitrogen removal. | [102] |

| Settling solids and total suspended solids (TSSs) | 5–15 mL L−1 100–300 mg L−1 (TSS) | Lack of slurry and agitation in a BFT can lead to the formation of an anaerobic zone in the tank. This in turn will cause a rapid consumption of dissolved oxygen and may result in the release of dangerous gases such as ammonia, hydrogen sulfide, and methane, which are lethally toxic to the fish and shrimp that are reared there. | [22,98,103,104] |

| Salinity | Variable (depends on the needs of the animal being reared) | Studies have shown that some species, such as the giant freshwater shrimp (Macrobrachium rosenbergii), thrive in brackish water biofloc systems at salinities of 15 ppt. In contrast, other species such as Nile tilapia (Oreochromis niloticus) show little change in salinity conditions from 0 to 12 ppt. However, in the same study, signs of stress were recorded in tilapia at salinities of 16 ppt and above. | [48,105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matishov, G.; Meskhi, B.; Rudoy, D.; Olshevskaya, A.; Shevchenko, V.; Golovko, L.; Maltseva, T.; Odabashyan, M.; Teplyakova, S. Using BioFloc Technology to Improve Aquaculture Efficiency. Fishes 2025, 10, 144. https://doi.org/10.3390/fishes10040144

Matishov G, Meskhi B, Rudoy D, Olshevskaya A, Shevchenko V, Golovko L, Maltseva T, Odabashyan M, Teplyakova S. Using BioFloc Technology to Improve Aquaculture Efficiency. Fishes. 2025; 10(4):144. https://doi.org/10.3390/fishes10040144

Chicago/Turabian StyleMatishov, Gennady, Besarion Meskhi, Dmitry Rudoy, Anastasiya Olshevskaya, Victoria Shevchenko, Liliya Golovko, Tatyana Maltseva, Mary Odabashyan, and Svetlana Teplyakova. 2025. "Using BioFloc Technology to Improve Aquaculture Efficiency" Fishes 10, no. 4: 144. https://doi.org/10.3390/fishes10040144

APA StyleMatishov, G., Meskhi, B., Rudoy, D., Olshevskaya, A., Shevchenko, V., Golovko, L., Maltseva, T., Odabashyan, M., & Teplyakova, S. (2025). Using BioFloc Technology to Improve Aquaculture Efficiency. Fishes, 10(4), 144. https://doi.org/10.3390/fishes10040144