Oxygen-Plasma-Treated Al/TaOX/Al Resistive Memory for Enhanced Synaptic Characteristics

Abstract

1. Introduction

2. Materials and Methods

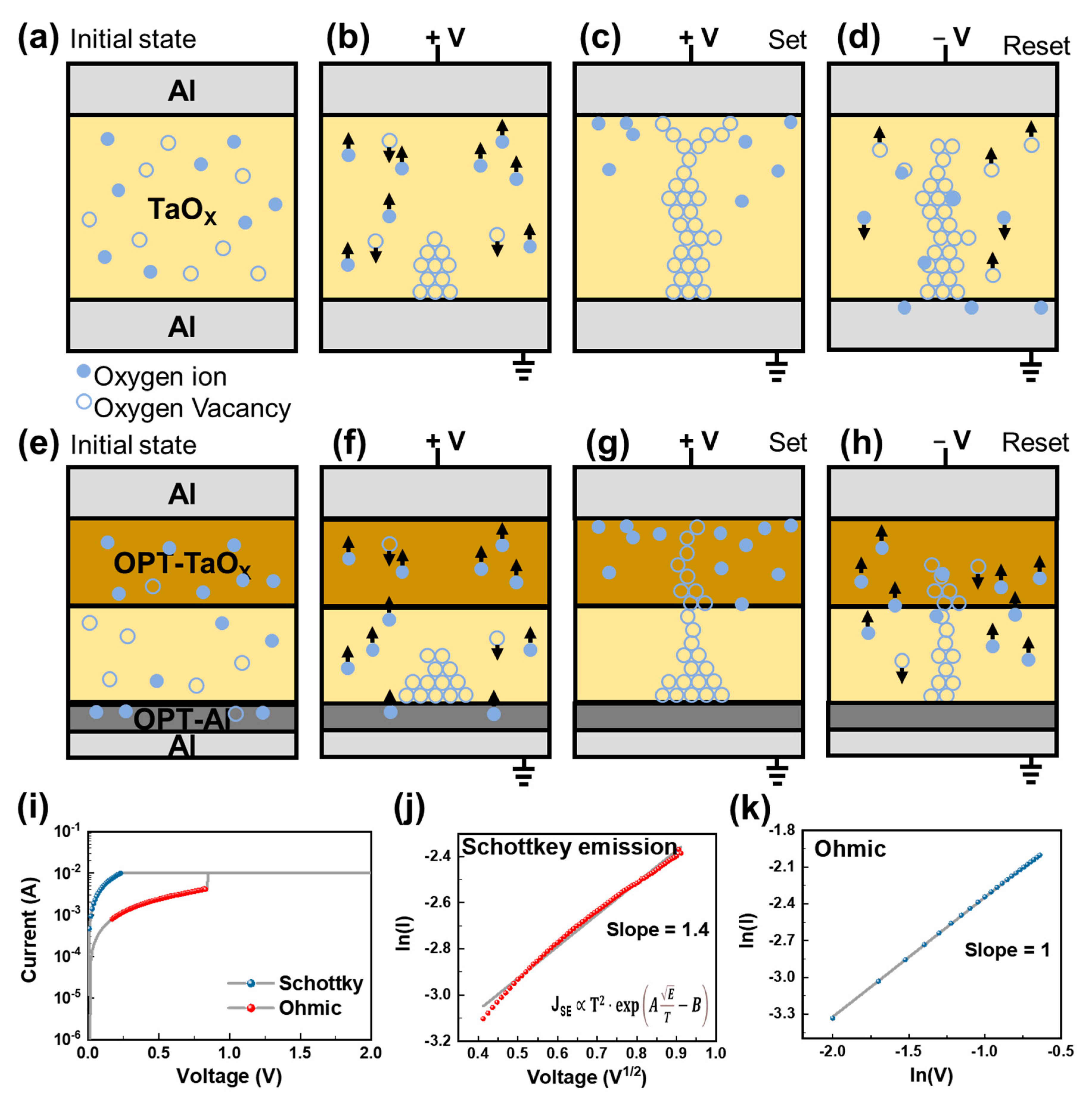

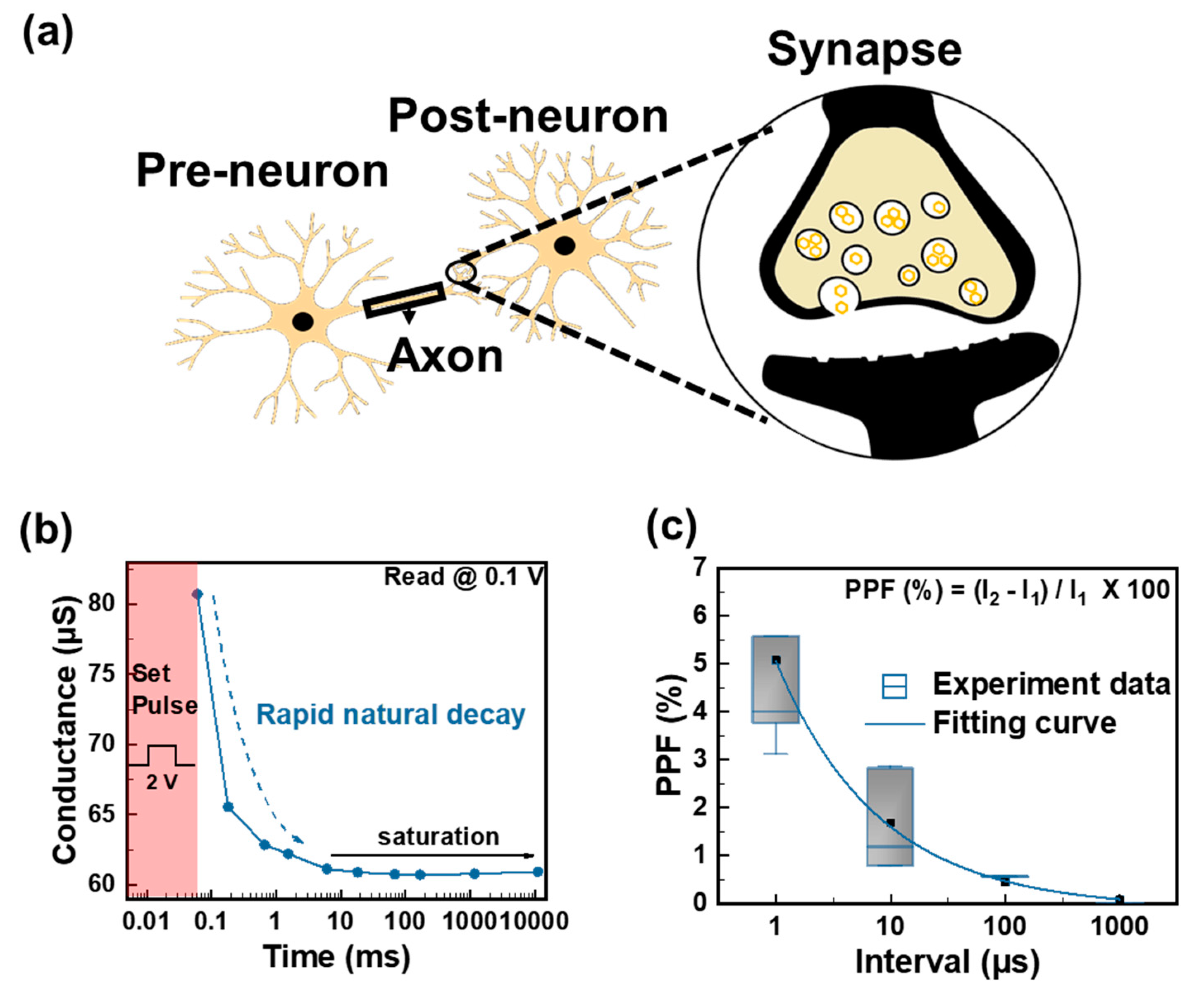

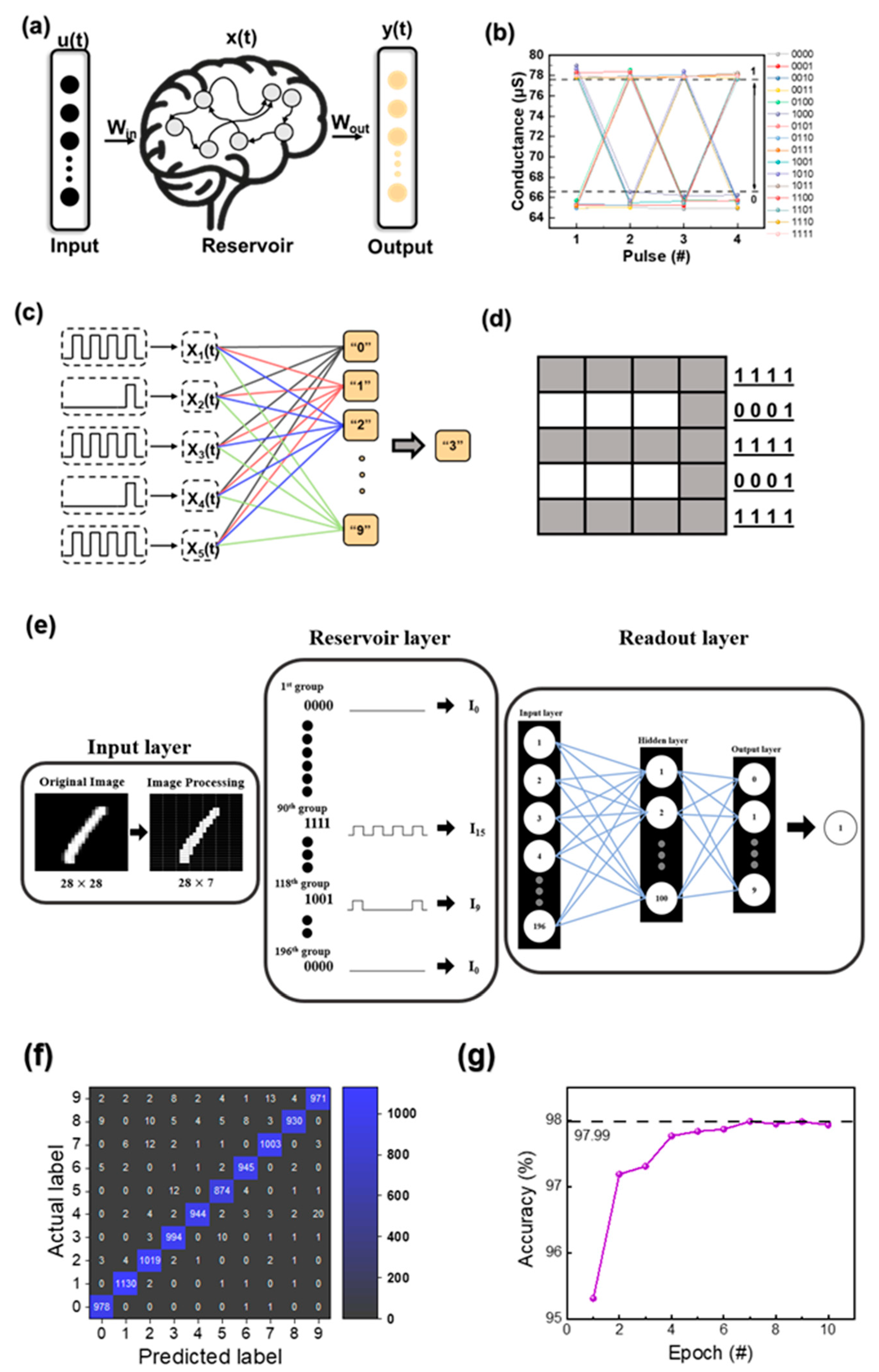

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zahoor, F.; Azni Zulkifli, T.Z.; Khanday, F.A. Resistive Random Access Memory (RRAM): An Overview of Materials, Switching Mechanism, Performance, Multilevel Cell (Mlc) Storage, Modeling, and Applications. Nanoscale Res. Lett. 2020, 15, 90. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.H.; Choi, H.S.; Kim, J.N.; Park, B.G.; Kim, S.; Lee, J.; Kim, Y. On-Chip Adaptive Matching Learning with Charge-Trap Synapse Device and ReLU Activation Circuit. Solid State Electron. 2021, 186, 108177. [Google Scholar] [CrossRef]

- Yang, R.; Huang, H.M.; Guo, X. Memristive Synapses and Neurons for Bioinspired Computing. Adv. Electron. Mater. 2019, 5, 1900287. [Google Scholar] [CrossRef]

- Yang, J.J.; Strukov, D.B.; Stewart, D.R. Memristive Devices for Computing. Nat. Nanotechnol. 2013, 8, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Jang, J.T.; Park, S.; Ansari, M.H.R.; Bae, J.H.; Choi, S.J.; Kim, D.M.; Kim, C.; Cho, S.; Kim, D.H. Threshold-Variation-Tolerant Coupling-Gate α-IGZO Synaptic Transistor for More Reliably Controllable Hardware Neuromorphic System. IEEE Access 2021, 9, 59345–59352. [Google Scholar] [CrossRef]

- IEEE Staff. IEEE Staff 2012 IEEE International Electron Devices Meeting; IEEE Staff: Piscataway, NJ, USA, 2012; ISBN 9781467348713. [Google Scholar]

- IEEE Staff. 2019 IEEE International Electron Devices Meeting (IEDM); IEEE: Piscataway, NJ, USA, 2019; ISBN 9781728140322. [Google Scholar]

- Kim, K.; Lee, S. Integration of Lead Zirconium Titanate Thin Films for High Density Ferroelectric Random Access Memory. J Appl Phys 2006, 100, 051604. [Google Scholar] [CrossRef]

- Fong, S.W.; Neumann, C.M.; Wong, H.S.P. Phase-Change Memory—Towards a Storage-Class Memory. IEEE Trans. Electron. Devices 2017, 64, 4374–4385. [Google Scholar] [CrossRef]

- Zhao, W.S.; Devolder, T.; Lakys, Y.; Klein, J.O.; Chappert, C.; Mazoyer, P. Design Considerations and Strategies for High-Reliable STT-MRAM. Microelectron. Reliab. 2011, 51, 1454–1458. [Google Scholar] [CrossRef]

- Pan, F.; Gao, S.; Chen, C.; Song, C.; Zeng, F. Recent Progress in Resistive Random Access Memories: Materials, Switching Mechanisms, and Performance. Mater. Sci. Eng. R Rep. 2014, 83, 1–59. [Google Scholar] [CrossRef]

- Mu, B.; Hsu, H.H.; Kuo, C.C.; Han, S.T.; Zhou, Y. Organic Small Molecule-Based RRAM for Data Storage and Neuromorphic Computing. J. Mater. Chem. C Mater 2020, 8, 12714–12738. [Google Scholar] [CrossRef]

- Liu, X.; Ren, S.; Li, Z.; Guo, J.; Yi, S.; Yang, Z.; Hao, W.; Li, R.; Zhao, J. Flexible Transparent High-Efficiency Photoelectric Perovskite Resistive Switching Memory. Adv. Funct. Mater. 2022, 32, 2202951. [Google Scholar] [CrossRef]

- Kim, H.; Choi, M.J.; Suh, J.M.; Han, J.S.; Kim, S.G.; Van Le, Q.; Kim, S.Y.; Jang, H.W. Quasi-2D Halide Perovskites for Resistive Switching Devices with ON/OFF Ratios above 109. NPG Asia Mater. 2020, 12, 21. [Google Scholar] [CrossRef]

- Park, J.; Kim, T.H.; Kwon, O.; Ismail, M.; Mahata, C.; Kim, Y.; Kim, S.; Kim, S. Implementation of Convolutional Neural Network and 8-Bit Reservoir Computing in CMOS Compatible VRRAM. Nano Energy 2022, 104, 107886. [Google Scholar] [CrossRef]

- Ju, D.; Kim, J.H.; Kim, S. Highly Uniform Resistive Switching Characteristics of Ti/TaOX/ITO Memristor Devices for Neuromorphic System. J. Alloys Compd. 2023, 961, 170920. [Google Scholar] [CrossRef]

- Kim, S.; Ju, D.; Kim, S. Implementation of Artificial Synapse Using IGZO-Based Resistive Switching Device. Materials 2024, 17, 481. [Google Scholar] [CrossRef]

- Yoon, J.-G. A New Approach to the Fabrication of Memristive Neuromorphic Devices: Compositionally Graded Films. Materials 2020, 13, 3680. [Google Scholar] [CrossRef]

- Gong, R.; Wang, J.; Liu, S.; Dong, Z.; Yu, M.; Wen, C.P.; Cai, Y.; Zhang, B. Analysis of Surface Roughness in Ti/Al/Ni/Au Ohmic Contact to AlGaN/GaN High Electron Mobility Transistors. Appl. Phys. Lett. 2010, 97, 062115. [Google Scholar] [CrossRef]

- Kindsmüller, A.; Meledin, A.; Mayer, J.; Waser, R.; Wouters, D.J. On the Role of the Metal Oxide/Reactive Electrode Interface during the Forming Procedure of Valence Change ReRAM Devices. Nanoscale 2019, 11, 18201–18208. [Google Scholar] [CrossRef]

- Rana, A.M.; Ismail, M.; Akber, T.; Younus Nadeem, M.; Kim, S. Transition from Unipolar to Bipolar, Multilevel Switching, Abrupt and Gradual Reset Phenomena in a TaN/CeO2/Ti: /Pt Memory Devices. Mater. Res. Bull. 2019, 117, 41–47. [Google Scholar] [CrossRef]

- Rana, A.M.; Akbar, T.; Ismail, M.; Ahmad, E.; Hussain, F.; Talib, I.; Imran, M.; Mehmood, K.; Iqbal, K.; Nadeem, M.Y. Endurance and Cycle-to-Cycle Uniformity Improvement in Tri-Layered CeO2/Ti/CeO2 Resistive Switching Devices by Changing Top Electrode Material. Sci. Rep. 2017, 7, 39539. [Google Scholar] [CrossRef]

- Ismail, M.; Ahmed, E.; Rana, A.M.; Hussain, F.; Talib, I.; Nadeem, M.Y.; Panda, D.; Shah, N.A. Improved Endurance and Resistive Switching Stability in Ceria Thin Films Due to Charge Transfer Ability of Al Dopant. ACS Appl. Mater. Interfaces 2016, 8, 6127–6136. [Google Scholar] [CrossRef] [PubMed]

- Hao, A.; Ismail, M.; He, S.; Qin, N.; Huang, W.; Wu, J.; Bao, D. Ag-NPs Doping Enhanced Resistive Switching Performance and Induced Changes in Magnetic Properties of NiFe2O4 Thin Films. RSC Adv. 2017, 7, 46665–46677. [Google Scholar] [CrossRef]

- Wang, R.; Shi, T.; Zhang, X.; Wang, W.; Wei, J.; Lu, J.; Zhao, X.; Wu, Z.; Cao, R.; Long, S.; et al. Bipolar Analog Memristors as Artificial Synapses for Neuromorphic Computing. Materials 2018, 11, 2102. [Google Scholar] [CrossRef]

- Lin, C.L.; Chang, W.Y.; Huang, Y.L.; Juan, P.C.; Wang, T.W.; Hung, K.Y.; Hsieh, C.Y.; Kang, T.K.; Shi, J. Bin Resistance Switching Behavior of ZnO Resistive Random Access Memory with a Reduced Graphene Oxide Capping Layer. Jpn. J. Appl. Phys. 2015, 54, 04DJ08. [Google Scholar] [CrossRef]

- Kim, M.C.; Lim, K.Y.; Kim, C.O.; Choi, S.H. Effect of Doping Concentration on Resistive Switching Behaviors of Cu-Doped ZnO Films. J. Korean Phys. Soc. 2011, 59, 304–307. [Google Scholar] [CrossRef]

- Xu, D.L.; Xiong, Y.; Tang, M.H.; Zeng, B.W.; Li, J.Q.; Liu, L.; Li, L.Q.; Yan, S.A.; Tang, Z.H. Bipolar Resistive Switching Behaviors in Cr-Doped ZnO Films. Microelectron. Eng. 2014, 116, 22–25. [Google Scholar] [CrossRef]

- Hao, C.; Xie, B.; Li, M.; Wang, H.; Jiang, Y.; Song, Y. The Influences of High Energetic Oxygen Negative Ions and Active Oxygen on the Microstructure and Electrical Properties of ZnO:Al Films by MF Magnetron Sputtering. Appl. Surf. Sci. 2012, 258, 8234–8240. [Google Scholar] [CrossRef]

- Hsu, C.C.; Chuang, H.; Jiang, W.-C. Annealing effect on forming-free bipolar resistive switching characteristics of sol-gel WOx resistive memories with Al conductive bridges. J. Alloys Compd. 2021, 882, 16078. [Google Scholar] [CrossRef]

- Wang, D.; Yan, S.; Chen, Q.; He, Q.; Xiao, Y.; Tang, M.; Zheng, X. Direct Observation of Structural Deformation Immunity for Understanding Oxygen Plasma Treatment-Enhanced Resistive Switching in Hfox-Based Memristive Devices. Nanomaterials 2019, 9, 1355. [Google Scholar] [CrossRef]

- Yin, C.; Gong, C.; Tian, S.; Cui, Y.; Wang, X.; Wang, Y.; Hu, Z.; Huang, J.; Wu, C.; Chen, B.; et al. Low-Energy Oxygen Plasma Injection of 2D Bi2Se3 Realizes Highly Controllable Resistive Random Access Memory. Adv. Funct. Mater. 2022, 32, 2108455. [Google Scholar] [CrossRef]

- Chen, P.H.; Chang, T.C.; Chang, K.C.; Tsai, T.M.; Pan, C.H.; Chen, M.C.; Su, Y.T.; Lin, C.Y.; Tseng, Y.T.; Huang, H.C.; et al. Resistance Switching Characteristics Induced by O2 Plasma Treatment of an Indium Tin Oxide Film for Use as an Insulator in Resistive Random Access Memory. ACS Appl. Mater. Interfaces 2017, 9, 3149–3155. [Google Scholar] [CrossRef]

- Chand, U.; Huang, C.Y.; Jieng, J.H.; Jang, W.Y.; Lin, C.H.; Tseng, T.Y. Suppression of Endurance Degradation by Utilizing Oxygen Plasma Treatment in HfO2 Resistive Switching Memory. Appl. Phys. Lett. 2015, 106, 153502. [Google Scholar] [CrossRef]

- Chen, X.; Feng, J.; Bae, D. Drastic Reduction of RRAM Reset Current via Plasma Oxidization of TaOX Film. Appl. Surf. Sci. 2015, 324, 275–279. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, Z.; Zhang, H.; Liu, J.; Yang, H.; Sun, Y.; Tan, D.; Li, W.; Xu, L.; Chen, K.; et al. Forming-Free Performance of a-SiNX:H-Based Resistive Switching Memory Obtained by Oxygen Plasma Treatment. Nanotechnology 2018, 29, 245701. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.C.; Liu, P.T.; Gan, K.J.; Ruan, D.B.; Chiu, Y.C.; Sze, S.M. Impact of O2 Plasma Treatment on Novel Amorphous Oxide InWZnO on Conductive Bridge Random Access Memory. Surf. Coat. Technol. 2021, 422, 127539. [Google Scholar] [CrossRef]

- Moo, J.G.S.; Awaludin, Z.; Okajima, T.; Ohsaka, T. An XPS depth-profile study on electrochemically deposited TaOX. J. Solid State Electrochem. 2013, 17, 3115–3123. [Google Scholar] [CrossRef]

- Prakash, A.; Maikap, S.; Lai, C.S.; Tien, T.C.; Chen, W.S.; Lee, H.Y.; Chen, F.T.; Kao, M.J.; Tsai, M.J. Bipolar Resistive Switching Memory Using Bilayer TaOX/WO × Films. Solid State Electron. 2012, 77, 35–40. [Google Scholar] [CrossRef]

- Lee, C.B.; Lee, D.S.; Benayad, A.; Lee, S.R.; Chang, M.; Lee, M.J.; Hur, J.; Kim, Y.B.; Kim, C.J.; Chung, U.I. Highly Uniform Switching of Tantalum Embedded Amorphous Oxide Using Self-Compliance Bipolar Resistive Switching. IEEE Electron Device Lett. 2011, 32, 399–401. [Google Scholar] [CrossRef]

- Chen, Y.C.; Chung, Y.L.; Chen, B.T.; Chen, W.C.; Chen, J.S. Revelation on the Interrelated Mechanism of Polarity-Dependent and Multilevel Resistive Switching in TaOX-Based Memory Devices. J. Phys. Chem. C 2013, 117, 5758–5764. [Google Scholar] [CrossRef]

- Ge, J.; Chaker, M. Oxygen Vacancies Control Transition of Resistive Switching Mode in Single-Crystal TiO2 Memory Device. ACS Appl. Mater Interfaces 2017, 9, 16327–16334. [Google Scholar] [CrossRef]

- Li, Y.T.; Long, S.B.; Liu, Q.; Lü, H.B.; Liu, S.; Liu, M. An Overview of Resistive Random Access Memory Devices. Chin. Sci. Bull. 2011, 56, 3072–3078. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, H.W.; Yu, S.; Sun, B.; Liu, L.F.; Liu, X.Y.; Wang, Y.; Han, R.Q.; Kang, J.F.; Yb, B.; et al. Oxide-based RRAM: Uniformity improvement using a new material-oriented methodology. In Proceedings of the 2009 Symposium on VLSI Technology, Kyoto, Japan, 15–17 June 2009; pp. 30–31. [Google Scholar]

- Jeong, H.; Shin, J.; Kim, S.; Pak, J.J. Improved Resistive Switching Characteristics by O2 Plasma Treatment in Bi-Layer Ti/ZnO/OPT-ZnO/ITO RRAM. Curr. Appl. Phys. 2023, 49, 120–126. [Google Scholar] [CrossRef]

- Kumar, D.; Chand, U.; Siang, L.W.; Tseng, T.Y. High-Performance TiN/Al2O3/ZnO/Al2O3/TiN Flexible RRAM Device with High Bending Condition. IEEE Trans. Electron. Devices 2020, 67, 493–498. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.; Chung, D.; Kim, S. Transformed Filaments by Oxygen Plasma Treatment and Improved Resistance State. Nanomaterials 2022, 12, 2716. [Google Scholar] [CrossRef] [PubMed]

- Lim, E.W.; Ismail, R. Conduction Mechanism of Valence Change Resistive Switching Memory: A Survey. Electronics 2015, 4, 586–613. [Google Scholar] [CrossRef]

- Najem, J.S.; Taylor, G.J.; Weiss, R.J.; Hasan, M.S.; Rose, G.; Schuman, C.D.; Belianinov, A.; Collier, C.P.; Sarles, S.A. Memristive Ion Channel-Doped Biomembranes as Synaptic Mimics. ACS Nano 2018, 12, 4702–4711. [Google Scholar] [CrossRef]

- Ismail, M.; Mahata, C.; Kim, S. Forming-Free Pt/Al2O3/HfO2/HfAlOx/TiN Memristor with Controllable Multilevel Resistive Switching and Neuromorphic Characteristics for Artificial Synapse. J. Alloys Compd. 2022, 892, 162141. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, S.; Zhao, X.; Wu, F.; Wu, Q.; Wang, W.; Cao, R.; Fang, Y.; Lv, H.; Long, S.; et al. Emulating Short-Term and Long-Term Plasticity of Bio-Synapse Based on Cu/a-Si/Pt Memristor. IEEE Electron Device Lett. 2017, 38, 1208–1211. [Google Scholar] [CrossRef]

- Kim, G.; Cho, Y.; Kim, S. Short-Term Memory Characteristics of TiN/WOX/FTO-Based Transparent Memory Device. Chin. J. Phys. 2024, 88, 1044–1052. [Google Scholar] [CrossRef]

- Kim, H.; Hwang, S.; Park, J.; Yun, S.; Lee, J.H.; Park, B.G. Spiking Neural Network Using Synaptic Transistors and Neuron Circuits for Pattern Recognition with Noisy Images. IEEE Electron Device Lett. 2018, 39, 630–633. [Google Scholar] [CrossRef]

- Guan, X.; Yu, S.; Wong, H.S.P. On the Switching Parameter Variation of Metal-Oxide RRAM—Part I: Physical Modeling and Simulation Methodology. IEEE Trans Electron Devices 2012, 59, 1172–1182. [Google Scholar] [CrossRef]

- Ju, D.; Kim, S.; Park, K.; Lee, J.; Koo, M.; Kim, S. Realization of Multiple Synapse Plasticity by Coexistence of Volatile and Nonvolatile Characteristics of Interface Type Memristor. ACS Appl. Mater. Interfaces 2024, 16, 24929–24942. [Google Scholar] [CrossRef] [PubMed]

- Lukoševičius, M.; Jaeger, H. Reservoir Computing Approaches to Recurrent Neural Network Training. Comput. Sci. Rev. 2009, 3, 127–149. [Google Scholar] [CrossRef]

| Device Structure | VSET | VRESET | On/Off Ratio | Retention Time | Endurance | LRS CV | HRS CV |

|---|---|---|---|---|---|---|---|

| Al/TaOX/Al | 0.57 V | −0.59 V | 2 | 3 × 102 s | 45 | 67% | 45% |

| Al/TaOX(OPT)/Al(OPT) | 0.97 V | −0.5 V | 10 | 103 s | 60 | 19% | 22% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.; Park, S.; Koo, M.; Kim, S. Oxygen-Plasma-Treated Al/TaOX/Al Resistive Memory for Enhanced Synaptic Characteristics. Biomimetics 2024, 9, 578. https://doi.org/10.3390/biomimetics9090578

Kim G, Park S, Koo M, Kim S. Oxygen-Plasma-Treated Al/TaOX/Al Resistive Memory for Enhanced Synaptic Characteristics. Biomimetics. 2024; 9(9):578. https://doi.org/10.3390/biomimetics9090578

Chicago/Turabian StyleKim, Gyeongpyo, Seoyoung Park, Minsuk Koo, and Sungjun Kim. 2024. "Oxygen-Plasma-Treated Al/TaOX/Al Resistive Memory for Enhanced Synaptic Characteristics" Biomimetics 9, no. 9: 578. https://doi.org/10.3390/biomimetics9090578

APA StyleKim, G., Park, S., Koo, M., & Kim, S. (2024). Oxygen-Plasma-Treated Al/TaOX/Al Resistive Memory for Enhanced Synaptic Characteristics. Biomimetics, 9(9), 578. https://doi.org/10.3390/biomimetics9090578