Aerodynamic Noise Simulation of a Super-High-Rise Building Facade with Shark-Like Grooved Skin

Abstract

:1. Introduction

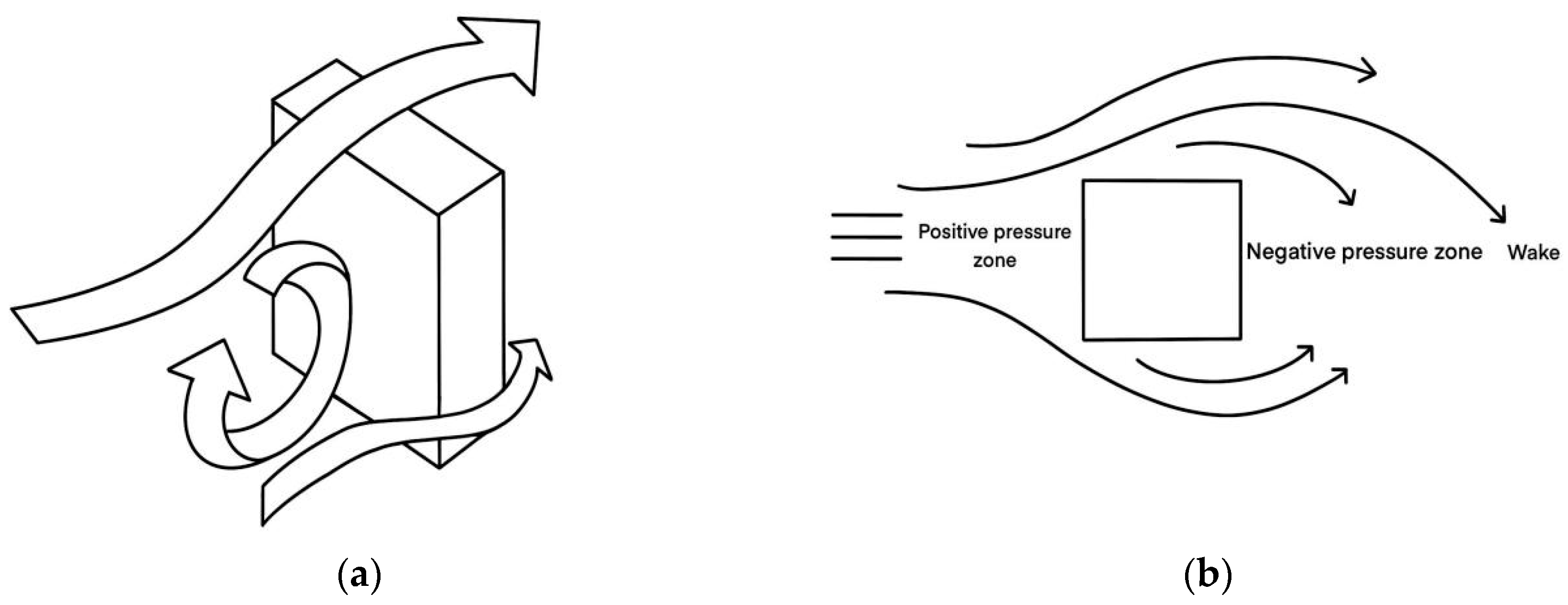

1.1. Aerodynamic Noise Issues and Research in Super-High-Rise Buildings

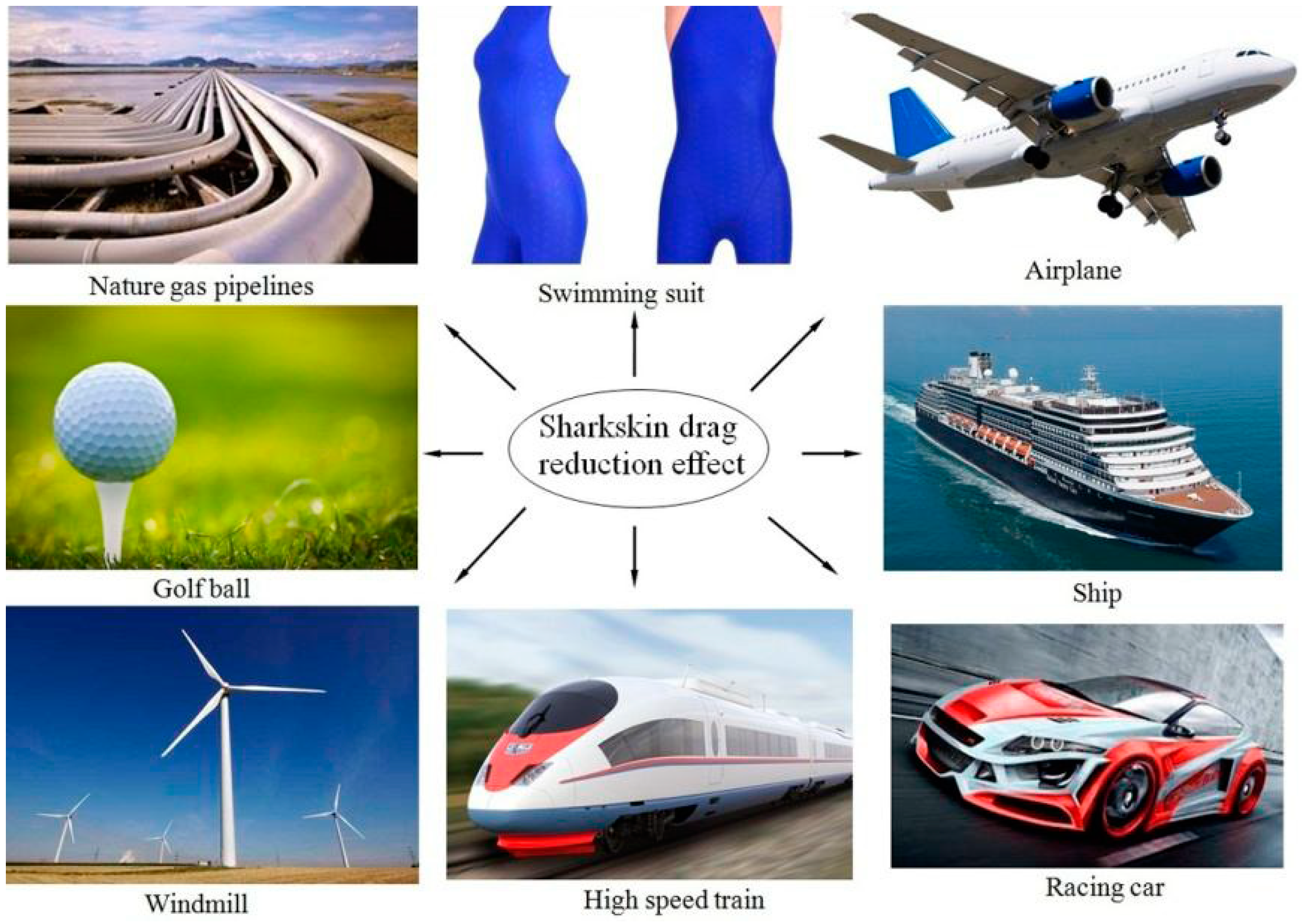

1.2. Theoretical and Technological Research on Shark-Like Grooved Epidermis

1.3. Purpose and Significance of the Study

2. Materials and Methods

2.1. Objects of Study

2.1.1. Super-High-Rise Building Modeling

2.1.2. Bionic Shark Groove Modeling

2.2. Experimental Procedure

2.3. Modeling

2.3.1. Flow Field Calculation Model

2.3.2. Sound Field Calculation Model

2.4. Experimental Process

2.4.1. Simulation Methods and Simulation Process

2.4.2. Computational Flow Field Modeling

2.4.3. Solving the Sound Field Model

3. Results

3.1. Outflow Field Results for the Smooth Skin Building Model and Bionic Groove Skin Building Model

3.2. Outer Sound Field Results for the Smooth Skin Building Model and Bionic Groove Skin Building Model

4. Discussion

4.1. Outflow Field Analysis of the Smooth Skin Building Model and Bionic Groove Skin Building Model

4.2. External Sound Field Analysis of the Smooth Skin Building Model and Bionic Groove Skin Building Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GB 50352-2019; Code for Design of Civil Buildings. Ministry of Housing and Urban-Rural Development: Beijing, China, 2019.

- CTBUH Staff. CTBUH Year in Review: Tall Trends of 2019 Tall Buildings in 2019: Another Record Year for Supertall Completions. CTBUH J. 2020, 1, 42–49. [Google Scholar]

- Yang, M.; Zhou, P.; Wang, J. Overview of design status of air conditioning system for super high rise buildings over 200 m. Refrig. Air-Cond. 2023, 23, 1–6. (In Chinese) [Google Scholar] [CrossRef]

- Tian, H. Research on the Environmental Aerodynamic Noise of Super High-Rise Buildings with Computational Method of CFD. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2018. [Google Scholar]

- Liu, B.; Guo, J.; Zhang, X. Research on the Environmental Aerodynamic Noise of Super High-Rise Buildings with Computational Method of CFD. Archit. Tech. 2011, 3, 164–166. (In Chinese) [Google Scholar] [CrossRef]

- GB 50118-2010; Code for Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Blocken, B. 50 years of Computational Wind Engineering: Past, present and future. J. Wind. Eng. Ind. Aerodyn. 2014, 129, 69–102. [Google Scholar] [CrossRef]

- Toparlar, Y.; Blocken, B.; Maiheu, B.; van Heijst, G.J.F. A review on the CFD analysis of urban microclimate. Renew. Sustain. Energy Rev. 2017, 80, 1613–1640. [Google Scholar] [CrossRef]

- Kaijima, S.; Bouffanais, R.; Willcox, K.; Naidu, S. Computational fluid dynamics for architectural design. Archit. Des. 2013, 83, 118–123. [Google Scholar]

- Hu, Y.; Xu, F.; Gao, Z. A comparative study of the simulation accuracy and efficiency for the urban wind environment based on CFD plug-ins integrated into architectural design platforms. Buildings 2022, 12, 1487. [Google Scholar] [CrossRef]

- Zhang, J.H.L.; Li, W.; Yue, Y. Numerical simulation research on wind-induced noise of Nanjing Financial City II. Build. Struct. 2019, 49, 373–376. [Google Scholar] [CrossRef]

- Tao, Y.; Xiao, Y.; Xinhong, X.; Siqing, W.; Peng, L. Investigation on aerodynamic noise around close-distance asymmetry twin-tower connected structure by CFD numerical simulation. Build. Struct. 2022, 52, 89–94. [Google Scholar] [CrossRef]

- Raschi, W.; Tabit, C. Functional aspects of placoid scales: A review and update. Mar. Freshw. Res. 1992, 43, 123–147. [Google Scholar] [CrossRef]

- Guo, P.; Zhang, K.; Yasuda, Y.; Yang, W.; Galipon, J.; Rival, D.E. On the influence of biomimetic shark skin in dynamic flow separation. Bioinspiration Biomim. 2021, 16, 034001. [Google Scholar] [CrossRef]

- Ball, P. Engineering shark skin and other solutions. Nature 1999, 400, 507–509. [Google Scholar] [CrossRef]

- Bechert, D.; Bruse, M.; Hage, W. Experiments with three-dimensional riblets as an idealized model of shark skin. Exp. Fluids 2000, 28, 403–412. [Google Scholar] [CrossRef]

- Walsh, M. Turbulent boundary layer drag reduction using riblets. In Proceedings of the 20th Aerospace Sciences Meeting, Orlando, FL, USA, 11–14 January 1982; p. 169. [Google Scholar]

- Luo, Y.; Yuan, L.; Li, J.; Wang, J. Boundary layer drag reduction research hypotheses derived from bio-inspired surface and recent advanced applications. Micron 2015, 79, 59–73. [Google Scholar] [CrossRef]

- Chen, S. Bionic Surface Textures and Their Effects on Frictional Noise of High Speed Train. Master’s Thesis, Zhejiang University, Zhejiang, China, 2014. [Google Scholar]

- Hou, Z. Study on Structural Design and Noise Reduction Characteristics of Tractor Muffler Exhaust Pipe. Ph.D. Thesis, Jilin University, Jilin, China, 2023. [Google Scholar]

- Bechert, D.; Bartenwerfer, M. The viscous flow on surfaces with longitudinal ribs. J. Fluid Mech. 1989, 206, 105–129. [Google Scholar] [CrossRef]

- Bechert, D.W.; Bruse, M.; Hage, W.v.; Van der Hoeven, J.T.; Hoppe, G. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry. J. Fluid Mech. 1997, 338, 59–87. [Google Scholar] [CrossRef]

- Bacher, E.v.; Smith, C. A combined visualization-anemometry study of the turbulent drag reducing mechanisms of triangular micro-groove surface modifications. In Proceedings of the Shear Flow Control Conference, Boulder, CO, USA, 12–14 March 1985; p. 548. [Google Scholar]

- Choi, K.-S. Near-wall structure of a turbulent boundary layer with riblets. J. Fluid Mech. 1989, 208, 417–458. [Google Scholar] [CrossRef]

- Linde, P.; Hegenbart, M. Riblet film for reducing the air resistance of aircraft. U.S. Patent No. 10,994,832. 4 May 2021. U.S. Patent and Trademark Office, Washington, DC, USA. 2021. [Google Scholar]

- Yang, X. Study on Large Area Molding Technology and Drag Reduction Performance of Bionic Shark Skin. Master’s Thesis, Dalian University of Technology, Dalian, China, 2018. [Google Scholar]

- Han, M. The First “Sharkskin” Airliner Takes Off; China Petrochemical Industry Observer; China National Center for Chemical Economy and Technology Development: Beijing, China, 2022; p. 1. [Google Scholar]

- Shuai, T. Research on the Building Facade Design Strategy Based on Noise Insulation Performance and Natural Ventilation. Master’s Thesis, South China University of Technology, Guangzhou, China, 2020. [Google Scholar]

- Corticos, N.D. Improving residential building efficiency with membranes over facades: The Mediterranean context. J. Build. Eng. 2020, 32, 101421. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Bio-Based Building Skin; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- Ferreira, C.; Barrelas, J.; Silva, A.; de Brito, J.; Dias, I.S.; Flores-Colen, I. Impact of environmental exposure conditions on the maintenance of facades’ claddings. Buildings 2021, 11, 138. [Google Scholar] [CrossRef]

- Liang, S.; Li, Q.; Liu, S.; Zhang, L.; Gu, M. Torsional dynamic wind loads on rectangular tall buildings. Eng. Struct. 2004, 26, 129–137. [Google Scholar] [CrossRef]

- Zhewei, G. Research on Residential area Planning Based on CFD Wind Environment Simulation: A Case Study of Fengyuan Chunhe Community in Nanchang City. Master’s Thesis, Jiangxi Normal University, Nanchang, China, 2023. [Google Scholar]

- Chen, M. Analysis of the relationship between wind shear and wind speed in a low hilly region—Based on LiDAR measurements. In Proceedings of the Wind Energy Industry, Beijing, China, 1 January 2018; p. 3. [Google Scholar]

- Hao, G.; Guoqiang, K.; Qiangzhong, H.; Peiqing, L. Numerical study on noise reduction by blowing around a square cylinder. Civ. Aircr. Des. Res. 2022, 24–37. [Google Scholar] [CrossRef]

- Wang, J. Influence of Bionic Fence Structure on Noise Around a Circular Cylinder. Ph.D. Thesis, Hunan University of Science and Technology, Changsha, China, 2021. [Google Scholar] [CrossRef]

- Giret, J.-C.; Sengissen, A.; Moreau, S.; Sanjosé, M.; Jouhaud, J.-C. Prediction of the sound generated by a rod-airfoil configuration using a compressible unstructured LES solver and a FW-H analogy. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference (33rd AIAA Aeroacoustics Conference), Colorado Springs, CO, USA, 4–6 June 2012; p. 2058. [Google Scholar]

- Chen, W. Experimental and Numerical Study on Blade Aerodynamic Noise Control by Bio-inspired Treatments. Ph.D. Thesis, Northwestern Polytechnical University, Shanxi, China, 2018. [Google Scholar]

- Peet, Y.; Sagaut, P.; Charron, Y. Pressure loss reduction in hydrogen pipelines by surface restructuring. Int. J. Hydrog. Energy 2009, 34, 8964–8973. [Google Scholar] [CrossRef]

- Peet, Y.; Sagaut, P.; Charron, Y. Turbulent drag reduction using sinusoidal riblets with triangular cross-section. In Proceedings of the 38th Fluid Dynamics Conference and Exhibit, Seattle, WA, USA, 23–26 June 2008; p. 3745. [Google Scholar]

- Bai, X.; Zhang, X.; Yuan, C. Numerical analysis of drag reduction performance of different shaped riblet surfaces. Mar. Technol. Soc. J. 2016, 50, 62–72. [Google Scholar] [CrossRef]

- Cong, Q.; Feng, Y.; Ren, L. Affecting of riblets shape of nonsmooth surface on drag reduction. J. Hydrodyn. Ser. A 2006, 21, 232–238. [Google Scholar]

- Walsh, M.; Lindemann, A. Optimization and application of riblets for turbulent drag reduction. In Proceedings of the 22nd Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1984; p. 347. [Google Scholar]

- Gao, M. The Study of the Turbulent Drag Reduction on Biomimetic Surface Based on the Microstructural Characteristics of Sharkskin. Ph.D. Thesis, Jilin University, Jilin, China, 2023. [Google Scholar] [CrossRef]

- Hui, H.; Zi-xian, C.; Tao, Z. Research on acoustic performance of bionic cylinder based on acoustic analogue. Ship Sci. Technol. 2021, 43, 76–82. [Google Scholar] [CrossRef]

- Smagorinsky, J. General circulation experiments with the primitive equations: I. The basic experiment. Mon. Weather Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Ffowcs Williams, J.E.; Hawkings, D.L. Sound generation by turbulence and surfaces in arbitrary motion. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1969, 264, 321–342. [Google Scholar]

- Fayemi, P.-E.; Maranzana, N.; Aoussat, A.; Bersano, G. Bio-inspired design characterisation and its links with problem solving tools. In Proceedings of the DS 77: DESIGN 2014 13th International Design Conference, Dubrovnik, Croatia, 16–19 May 2014; pp. 173–182. [Google Scholar]

- Kruiper, R.; Vincent, J.F.; Abraham, E.; Soar, R.C.; Konstas, I.; Chen-Burger, J.; Desmulliez, M.P. Towards a design process for computer-aided biomimetics. Biomimetics 2018, 3, 14. [Google Scholar] [CrossRef]

| Topographic Classification | Height h | The Coefficient α |

|---|---|---|

| Offshore sea, islands, coasts, lakeshores and desert areas | 300 | 0.12 |

| Fields, countryside, jungles, hills and sparsely housed townships | 350 | 0.16 |

| Urban areas with dense built-up areas | 400 | 0.22 |

| Urban areas with densely built-up urban areas and taller houses | 450 | 0.3 |

| B1/dB | B2/dB | B3/dB | Average Value | Noise Reduction | Noise Reduction Percentage | |

|---|---|---|---|---|---|---|

| smoothness | 18.6 | 26.6 | 18.6 | 21.3 | -- | -- |

| ∩-shape | 19.0 | 26.9 | 19.1 | 21.7 | 0.4 | 1.9% |

| V-shaped | 18.2 | 26.5 | 18.2 | 21.0 | 0.3 | 1.4% |

| U-shaped | 16.4 | 24.4 | 16.4 | 19.1 | 1.2 | 5.6% |

| I-shaped | 15.3 | 23.6 | 15.3 | 18.1 | 2.2 | 10.3% |

| 0° | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | 100° | 110° | 120° | 130° | 140° | 150° | 160° | 170° | 180° | Average Value | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| smoothness | 66.6 | 66.5 | 67.3 | 68.6 | 70.1 | 71.4 | 72.4 | 73.3 | 73.9 | 74.4 | 74.6 | 74.5 | 74.3 | 73.7 | 72.9 | 71.7 | 70.3 | 68.7 | 67.4 | 71.2 |

| ∩-shape | 66.2 | 66.6 | 67.8 | 69.1 | 70.3 | 71.4 | 72.3 | 73.0 | 73.5 | 73.7 | 73.8 | 73.6 | 73.2 | 72.6 | 71.6 | 70.4 | 68.9 | 67.6 | 67.0 | 70.7 |

| V-shaped | 63.6 | 64.5 | 66.3 | 68.1 | 69.7 | 70.9 | 71.9 | 72.7 | 73.2 | 73.5 | 73.5 | 73.3 | 72.8 | 72.0 | 70.9 | 69.4 | 67.5 | 65.5 | 64.5 | 69.7 |

| U-shaped | 64.6 | 64.4 | 64.9 | 66.1 | 67.4 | 68.6 | 69.7 | 70.5 | 71.1 | 71.6 | 71.8 | 71.8 | 71.6 | 71.1 | 70.3 | 69.2 | 67.9 | 66.5 | 65.4 | 68.7 |

| I-shaped | 64.3 | 64.5 | 65.3 | 66.4 | 67.5 | 68.5 | 69.4 | 70.1 | 70.6 | 70.9 | 71.0 | 70.9 | 70.6 | 70.0 | 69.1 | 68.1 | 66.8 | 65.6 | 65.0 | 68.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wen, G.; Wei, Y. Aerodynamic Noise Simulation of a Super-High-Rise Building Facade with Shark-Like Grooved Skin. Biomimetics 2024, 9, 570. https://doi.org/10.3390/biomimetics9090570

Wang X, Wen G, Wei Y. Aerodynamic Noise Simulation of a Super-High-Rise Building Facade with Shark-Like Grooved Skin. Biomimetics. 2024; 9(9):570. https://doi.org/10.3390/biomimetics9090570

Chicago/Turabian StyleWang, Xueqiang, Guangcai Wen, and Yangyang Wei. 2024. "Aerodynamic Noise Simulation of a Super-High-Rise Building Facade with Shark-Like Grooved Skin" Biomimetics 9, no. 9: 570. https://doi.org/10.3390/biomimetics9090570

APA StyleWang, X., Wen, G., & Wei, Y. (2024). Aerodynamic Noise Simulation of a Super-High-Rise Building Facade with Shark-Like Grooved Skin. Biomimetics, 9(9), 570. https://doi.org/10.3390/biomimetics9090570