Mother–Daughter Vessel Operation and Maintenance Routing Optimization for Offshore Wind Farms Using Restructuring Particle Swarm Optimization

Abstract

1. Introduction

2. Mathematical Models

2.1. Problem Description

2.2. Mathematical Model

2.2.1. Mathematical Variables

2.2.2. Objective Function

2.2.3. Problem Formulation

- As the vessels depart from the port, Constraints (2)–(4) stipulate that the SOV, carrying the DV, sets out from the port to initiate service at the first turbine. It is imperative that the DV does not embark directly from the port. Constraint (5) specifies that the cumulative time is initialized to zero at the SOV’s departure from the port, with the elapsed time to the first turbine being determined by the transit time from the port to the turbine’s location.

- In this work, we establish a protocol where dispatch tasks must be executed before retrieval tasks begin. It is assumed that I− represents the set of WTs requiring service during the dispatch phase, while represents those requiring service during the retrieval phase. When the vessels complete the dispatch phase, the SOV docks at the last-serviced turbine until the DV returns. Then, the retrieval phase begins, and the SOV travels to the first-serviced turbine, carrying the DV. Thus, only the SOV travels from one of the turbines in to one in set , while the DV does not. Neither vessel can travel from any turbine in to any turbine in . Constraint (6) indicates that the SOV will proceed directly from the last-serviced turbine in the dispatch phase to the first turbine in the retrieval phase without deviation. Constraint (7) delineates that the DV is restricted from traversing between the dispatch and retrieval phases. Constraint (8) dictates that neither the SOV nor the DV is allowed to revisit the turbines from the dispatch phase once the retrieval phase has begun.

- Upon the completion of all tasks and the vessels’ return to port, Constraints (9)–(11) dictate that the SOV, after servicing the final turbine, must return to the port with all DVs embarked. This regulation precludes the DVs from making any independent return journeys, ensuring a coordinated and unified operation for the return lag of the mission.

- In this work, the DVs must both detach from and reconnect with the SOV at designated turbine sites, precluding the possibility of mid-route reconnections. The turbines identified for separation inherently become the responsibility of the SOV, thus imposing specific operational constraints for the processes of detachment and reconnection. Constraints (12) and (13) indicate that when the SOV is docked at a serviced turbine, it is permitted to execute the operations of separation and reconnection with the DV. Constraints (14) and (15) define the criteria for determining the reconnection and separation points along each leg of the DV’s itinerary. Constraint (16) specifies that the SOV will remain in wait for the DV’s return at the subsequent turbine designated for service. Constraint (17) mandates that the DV must service at least one turbine before its return following detachment. Constraints (18)–(21) stipulate that each voyage of the DV includes only one reconnection and one separation point, and these points must not overlap within the same phase for successive voyages, ensuring a seamless and efficient operational flow.

- Considering the operational constraints of the DV, which include the maximum load capacity and a stipulated travel distance, it is imperative to regulate the cumulative load and journey distance for DVs at each turbine. Constraints (22) and (23) address the capacity limitations of the DVs, while Constraints (24) and (25) govern the travel distances.

- In the maintenance operations at each turbine node, a single vessel is sufficient to fulfill the tasks. Thus, it is critical to maintain a balance between the arrival and departure of vessels at these nodes. Constraint (26) specifies that each turbine can be serviced by only one vessel within any given phase, thereby preventing any overlap in service assignments. Furthermore, Constraints (27) and (28) ensure that the servicing of each turbine by any vessel maintains a balance between vessel arrivals and departures.

- Given the additional waiting times incurred by servicing turbines, transferring equipment, and vessels arriving early at rendezvous points, detailed constraints for these intervals are also necessary. Equations (33) and (34) stipulate that the docking durations at turbines serviced by the DV and SOV must at least cover the time required to transfer equipment at those turbines. Equations (35) and (36) specify that at separation points, the docking times for the DV and SOV must satisfy the requirements for completing equipment transfers between them, including the time for DV refueling. Equation (37) dictates that the docking time for the DV at rendezvous points must include the time waiting for the SOV to arrive and the time to transfer equipment to the SOV. Equation (38) indicates that at rendezvous points, the SOV’s docking time, while engaging in turbine equipment transfer and DV equipment transfer operations, must also encompass the additional time potentially required due to waiting for the DV’s arrival. Equation (39) accounts for the scenario where the DV immediately commences a new voyage after completing a previous segment, considering two successive equipment transfers between the DV and SOV based on Equation (38). Equations (40) and (41) state that during the retrieval phase, the SOV or DV, upon arriving at a turbine, may need to wait for the completion of maintenance/repair works on that turbine before beginning loading or unloading operations, thus adding extra waiting time.

3. The Proposed Algorithm

3.1. Restructuring Particle Swarm Optimization

3.2. Encoding and Decoding Strategies

3.2.1. Encoding Strategy

- represent the indices of turbines during the dispatch phases, .

- represent the indices of turbines during the retrieval phases, .

- correspond to the transportation vehicles assigned to each turbine during the dispatch phases, with denoting the vehicle, where 0 represents the SOV, and 1 represents the DV.

- correspond to the transportation vehicles assigned to each turbine during the retrieval phases, with denoting the vehicle, where 0 represents the SOV, and 1 represents the DV.

3.2.2. Decoding Strategy

3.3. Algorithm Flow

4. Experiment and Analysis

4.1. Experimental Cases and Simulation Environment

4.2. Experimental Results and Analysis

4.2.1. Experiment 1: Comparison of Model

4.2.2. Experiment 2: Comparison of Algorithms

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weng, T.; Zhang, G.; Wang, H.; Qi, M.; Qvist, S.; Zhang, Y. The impact of coal to nuclear on regional energy system. Energy 2024, 302, 131765. [Google Scholar] [CrossRef]

- Erickson, P.; Lazarus, M.; Piggot, G. Limiting fossil fuel production as the next big step in climate policy. Nat. Clim. Chang. 2018, 8, 1037–1043. [Google Scholar] [CrossRef]

- Higgins, P.; Foley, A. The evolution of offshore wind power in the United Kingdom. Renew. Sustain. Energy Rev. 2014, 37, 599–612. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Díaz, H.; Guedes Soares, C. Review of the current status, technology and future trends of offshore wind farms. Ocean Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Rowell, D.; McMillan, D.; Carroll, J. Offshore wind H&S: A review and analysis. Renew. Sustain. Energy Rev. 2024, 189, 113928. [Google Scholar] [CrossRef]

- Global Wind Energy Council. Global Offshore Wind Report 2020; GWEC: Brussels, Belgium, 2020; Volume 19, pp. 10–12. [Google Scholar]

- de Matos Sá, M.; Correia da Fonseca, F.X.; Amaral, L.; Castro, R. Optimising O&M scheduling in offshore wind farms considering weather forecast uncertainty and wake losses. Ocean Eng. 2024, 301, 117518. [Google Scholar] [CrossRef]

- Astariz, S.; Iglesias, G. Accessibility for operation and maintenance tasks in co-located wind and wave energy farms with non-uniformly distributed arrays. Energy Convers. Manag. 2015, 106, 1219–1229. [Google Scholar] [CrossRef]

- Costa, Á.M.; Orosa, J.A.; Vergara, D.; Fernández-Arias, P. New Tendencies in Wind Energy Operation and Maintenance. Appl. Sci. 2021, 11, 1386. [Google Scholar] [CrossRef]

- Ren, Z.; Verma, A.S.; Li, Y.; Teuwen, J.J.E.; Jiang, Z. Offshore wind turbine operations and maintenance: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 144, 110886. [Google Scholar] [CrossRef]

- McMorland, J.; Flannigan, C.; Carroll, J.; Collu, M.; McMillan, D.; Leithead, W.; Coraddu, A. A review of operations and maintenance modelling with considerations for novel wind turbine concepts. Renew. Sustain. Energy Rev. 2022, 165, 112581. [Google Scholar] [CrossRef]

- Tusar, M.I.H.; Sarker, B.R. Developing the optimal vessel fleet size and mix model to minimize the transportation cost of offshore wind farms. Ocean Eng. 2023, 274, 114041. [Google Scholar] [CrossRef]

- Li, M.-W.; Lei, Y.-Z.; Yang, Z.-Y.; Huang, H.-P.; Hong, W.-C. An optimization method for maintenance routing and scheduling in offshore wind farms based on chaotic quantum Harris hawks optimization. Ocean Eng. 2024, 308, 118306. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Bai, X.; Guo, Y.; Yang, Z.; Wang, L.; Tao, T.; Zhang, L. DivideMerge: A multi-vessel optimization approach for cooperative operation and maintenance scheduling in offshore wind farm. Renew. Energy 2024, 229, 120758. [Google Scholar] [CrossRef]

- Feng, Q.; Bi, W.; Chen, Y.; Ren, Y.; Yang, D. Cooperative game approach based on agent learning for fleet maintenance oriented to mission reliability. Comput. Ind. Eng. 2017, 112, 221–230. [Google Scholar] [CrossRef]

- Karyotakis, A.; Bucknall, R. Planned intervention as a maintenance and repair strategy for offshore wind turbines. J. Mar. Eng. Technol. 2010, 9, 27–35. [Google Scholar] [CrossRef]

- Lazakis, I.; Khan, S. An optimization framework for daily route planning and scheduling of maintenance vessel activities in offshore wind farms. Ocean Eng. 2021, 225, 108752. [Google Scholar] [CrossRef]

- Liu, L.; Fu, Y.; Ma, S.; Huang, L.; Wei, S.; Pang, L. Optimal scheduling strategy of O&M task for OWF. Iet Renew. Power Gener. 2019, 13, 2580–2586. [Google Scholar] [CrossRef]

- O’Neil, R.; Khatab, A.; Diallo, C.; Venkatadri, U. Optimal joint maintenance and orienteering strategy for complex mission-oriented systems: A case study in offshore wind energy. Comput. Oper. Res. 2023, 149, 106020. [Google Scholar] [CrossRef]

- Dai, L.; Stålhane, M.; Utne, I.B. Routing and Scheduling of Maintenance Fleet for Offshore Wind Farms. Wind Eng. 2015, 39, 15–30. [Google Scholar] [CrossRef]

- Irawan, C.A.; Ouelhadj, D.; Jones, D.; Stålhane, M.; Sperstad, I.B. Optimisation of maintenance routing and scheduling for offshore wind farms. Eur. J. Oper. Res. 2017, 256, 76–89. [Google Scholar] [CrossRef]

- Feng, J.; Jia, X.; Zhu, F.; Yang, Q.; Pan, Y.; Lee, J. An intelligent system for offshore wind farm maintenance scheduling optimization considering turbine production loss. J. Intell. Fuzzy Syst. 2019, 37, 6911–6923. [Google Scholar] [CrossRef]

- Hadjoudj, Y.; Pandit, R.K. Improving O&M decision tools for offshore wind farm vessel routing by incorporating weather uncertainty. Iet Renew. Power Gener. 2023, 17, 1488–1499. [Google Scholar] [CrossRef]

- Irawan, C.A.; Ouelhadj, D.; Bakken Sperstad, I.; Jones, D. A combined tactical and operational framework for maintenance scheduling and routing in offshore wind farms. J. Oper. Res. Soc. 2023, 74, 2241–2260. [Google Scholar] [CrossRef]

- Irawan, C.A.; Salhi, S.; Chan, H.K. A continuous location and maintenance routing problem for offshore wind farms: Mathematical models and hybrid methods. Comput. Oper. Res. 2022, 144, 105825. [Google Scholar] [CrossRef]

- Ade Irawan, C.; Starita, S.; Chan, H.K.; Eskandarpour, M.; Reihaneh, M. Routing in offshore wind farms: A multi-period location and maintenance problem with joint use of a service operation vessel and a safe transfer boat. Eur. J. Oper. Res. 2023, 307, 328–350. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Q. Optimization of maintenance scheme for offshore wind turbines considering time windows based on hybrid ant colony algorithm. Ocean Eng. 2022, 263, 112357. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, J. A simple and scalable particle swarm optimization structure based on linear system theory. Memetic Comput. 2024, 16, 219–231. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the MHS’95: Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Fischetti, M.; Pisinger, D. Optimizing wind farm cable routing considering power losses. Eur. J. Oper. Res. 2018, 270, 917–930. [Google Scholar] [CrossRef]

- Fan, D.; Ren, Y.; Feng, Q.; Zhu, B.; Liu, Y.; Wang, Z. A hybrid heuristic optimization of maintenance routing and scheduling for offshore wind farms. J. Loss Prev. Process Ind. 2019, 62, 103949. [Google Scholar] [CrossRef]

- Royal IHC. IHC Offshore Energy Service Operation Vessel. Available online: https://www.royalihc.com/sites/default/files/documents/factsheet%20SOV%20T60-18.pdf (accessed on 1 August 2024).

- Zhan, Z.H.; Zhang, J.; Li, Y.; Chung, H.S.H. Adaptive Particle Swarm Optimization. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2009, 39, 1362–1381. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Coordinate magnification factor | 100.0 | Docking cost per unit for DV (CNY) | 200 |

| Turbine electricity loss cost (CNY) | 1400 | Maximum load capacity of DV (kg) | 3600 |

| SOV cruising speed () [34] | 20 | Endurance of DV (km) | 300 |

| Cost per unit of travel for SOV (CNY) | 24,000 | DV resupply time (h) | 0.25 |

| Docking cost per unit for SOV (CNY) | 2400 | Maximum equipment transfer time (h) | 0.25 |

| DV cruising speed () [34] | 35 | Maximum equipment weight required at site (kg) | 900 |

| Cost per unit of travel for DV (CNY) | 2000 |

| Simulation Index | MDVOMR | |||||

|---|---|---|---|---|---|---|

| Total Cost /CNY | Cost of SOV /CNY | Cost of DV /CNY | EGL Cost /CNY | Downtime /h | Running Time /s | |

| 1 | 59,753.4 | 40,614.8 | 3117.9 | 16,020.7 | 11.443355 | 9.854 |

| 2 | 59,036.7 | 39,812.2 | 3203.8 | 16,020.7 | 11.443355 | 9.670 |

| 3 | 57,473.3 | 38,515.7 | 2979.7 | 15,977.9 | 11.128020 | 9.811 |

| 4 | 55,887.4 | 36,670.9 | 3142.7 | 16,073.8 | 11.481299 | 9.748 |

| 5 | 57,847.8 | 38,090.5 | 3142.1 | 16,615.2 | 11.867977 | 9.720 |

| 6 | 53,174.9 | 34,102.7 | 2847.7 | 16,224.5 | 11.588952 | 9.784 |

| 7 | 56,810.2 | 37,585.4 | 3204.1 | 16,020.7 | 11.443355 | 9.615 |

| 8 | 55,169.7 | 36,031.1 | 3117.9 | 16,020.7 | 11.443355 | 9.766 |

| 9 | 56,519.7 | 37,407.4 | 3091.6 | 16,020.7 | 11.443355 | 9.755 |

| 10 | 58,944.3 | 39,699.0 | 3224.6 | 16,020.7 | 11.443355 | 9.785 |

| Average solution | 57,061.8 | 37,853.0 | 3107.2 | 16,101.6 | 11.472638 | 9.751 |

| Simulation Index | MDVOMR_B | ||||

|---|---|---|---|---|---|

| Total Cost /CNY | Cost of SOV /CNY | Electricity Loss Cost /CNY | Downtime /h | Running Time /s | |

| 1 | 80,509.8 | 63,285.1 | 17,224.7 | 12.303359 | 9.170 |

| 2 | 79,648.2 | 62,423.5 | 17,224.7 | 12.303359 | 9.144 |

| 3 | 84,507.8 | 67,283.1 | 17,224.7 | 12.303359 | 9.288 |

| 4 | 79,648.2 | 62,423.5 | 17,224.7 | 12.303359 | 9.146 |

| 5 | 79,584.1 | 62,359.4 | 17,224.7 | 12.303359 | 9.200 |

| 6 | 79,162.3 | 61,989.0 | 17,173.3 | 12.266668 | 9.240 |

| 7 | 79,532.7 | 62,359.4 | 17,173.3 | 12.266668 | 9.194 |

| 8 | 79,584.1 | 62,359.4 | 17,224.7 | 12.303359 | 9.325 |

| 9 | 79,820.3 | 62,647.0 | 17,173.3 | 12.266668 | 9.218 |

| 10 | 79,954.5 | 62,729.8 | 17,224.7 | 12.303359 | 9.176 |

| Average solution | 80,195.2 | 62,985.9 | 17,209.3 | 12.296021 | 9.210 |

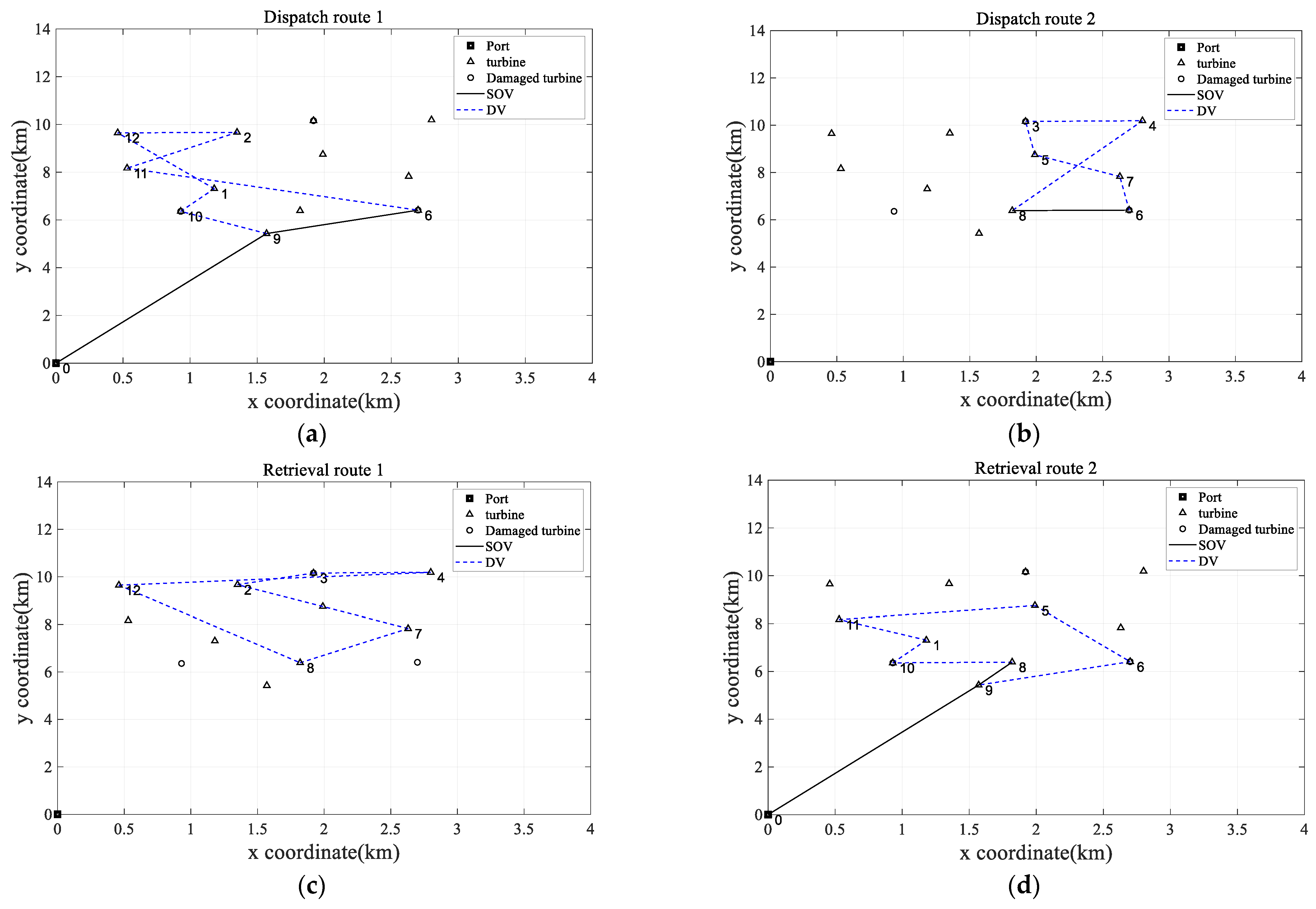

| Total Cost (CNY) | Route Number | Specific Service Information | Load Capacity (kg) | Travel Distance (km) | ||

|---|---|---|---|---|---|---|

| 65,808.5 | Dispatch Route | 1 | SOV Route | 0-> 9 (0.282621, 0.532621, 3.53262) | 400 | 5.6524 |

| 2 | DV Route | 9 -> 10 (0.564876, 0.731543, 5.73154) -> 1 (0.75961, 0.954054, 4.95405) -> 12 (1.024, 1.21845, 5.21845) -> 2 (1.24388, 1.43833, 4.43833) -> 11 (1.48717, 1.70939, 5.70939) -> 6 | 3500 | 9.7620 | ||

| SOV Route | 9 -> 6 (0.607409, 0.857409, 5.85741) | 900 | 1.4958 | |||

| 3 | DV Route | 6 -> 7 (2.07984, 2.32984, 4.32984) -> 5 (2.36186, 2.52853, 6.52853) -> 3 (2.56887, 2.6522, 4.6522) -> 4 (2.67736, 2.92736, 4.92736) -> 8 | 2700 | 8.7589 | ||

| SOV Route | 6-> 8 (2.08323, 2.33323, 4.33323) | 500 | 0.8802 | |||

| Retrieval Route | 1 | DV Route | 8 -> 7 (3.33669, 4.57984) -> 2 (4.64388, 4.83833) -> 3 (4.8598, 4.94314) -> 4 (4.9683, 5.2183) -> 12 (5.28691, 5.48135) -> 8 | 3600 | 11.4596 | |

| SOV Route | 8 -> 8 (4.10522, 6.04276) | 500 | 0 | |||

| 2 | DV Route | 8 -> 10 (5.85772, 6.02439) -> 1 (6.05245, 6.2469) -> 11 (6.2777, 6.49992) -> 5 (6.54481, 6.71147) -> 6 (6.78134, 7.03134) -> 9 | 3600 | 8.4630 | ||

| SOV Route | 8 -> 9 (5.88188, 7.32408) | 400 | 0.9920 | |||

| 3 | SOV Route | 9 -> 0 | 5.6524 | |||

| Solution Type | Algorithm | Total Cost/CNY | Cost for SOV/CNY | Cost for DV/CNY | EGL Cost/CNY | Downtime /h | Running Time/s |

|---|---|---|---|---|---|---|---|

| Best Solution | PSO | 57,728.2 | 38,395.1 | 3312.4 | 16,020.7 | 11.443355 | 9.048 |

| APSO | 54,956.2 | 35,825.5 | 2906.2 | 16,224.5 | 11.588952 | 14.310 | |

| RPSO | 53,174.9 | 34,102.7 | 2847.7 | 16,224.5 | 11.588952 | 9.784 | |

| Average Solution | PSO | 59,155.7 | 39,983.0 | 3098.7 | 16,074.0 | 11.481458 | 9.018 |

| APSO | 57,812.1 | 38,680.6 | 3053.1 | 16,078.4 | 11.484555 | 14.178 | |

| RPSO | 57,061.8 | 37,853.0 | 3107.2 | 16,101.6 | 11.472638 | 9.751 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Y.; Luo, H.; Huang, G.; Hou, P.; Jin, R.; Luo, Y. Mother–Daughter Vessel Operation and Maintenance Routing Optimization for Offshore Wind Farms Using Restructuring Particle Swarm Optimization. Biomimetics 2024, 9, 536. https://doi.org/10.3390/biomimetics9090536

Qi Y, Luo H, Huang G, Hou P, Jin R, Luo Y. Mother–Daughter Vessel Operation and Maintenance Routing Optimization for Offshore Wind Farms Using Restructuring Particle Swarm Optimization. Biomimetics. 2024; 9(9):536. https://doi.org/10.3390/biomimetics9090536

Chicago/Turabian StyleQi, Yuanhang, Haoyu Luo, Gewen Huang, Peng Hou, Rongsen Jin, and Yuhui Luo. 2024. "Mother–Daughter Vessel Operation and Maintenance Routing Optimization for Offshore Wind Farms Using Restructuring Particle Swarm Optimization" Biomimetics 9, no. 9: 536. https://doi.org/10.3390/biomimetics9090536

APA StyleQi, Y., Luo, H., Huang, G., Hou, P., Jin, R., & Luo, Y. (2024). Mother–Daughter Vessel Operation and Maintenance Routing Optimization for Offshore Wind Farms Using Restructuring Particle Swarm Optimization. Biomimetics, 9(9), 536. https://doi.org/10.3390/biomimetics9090536