3.1. Evaluation of the Range of Motion

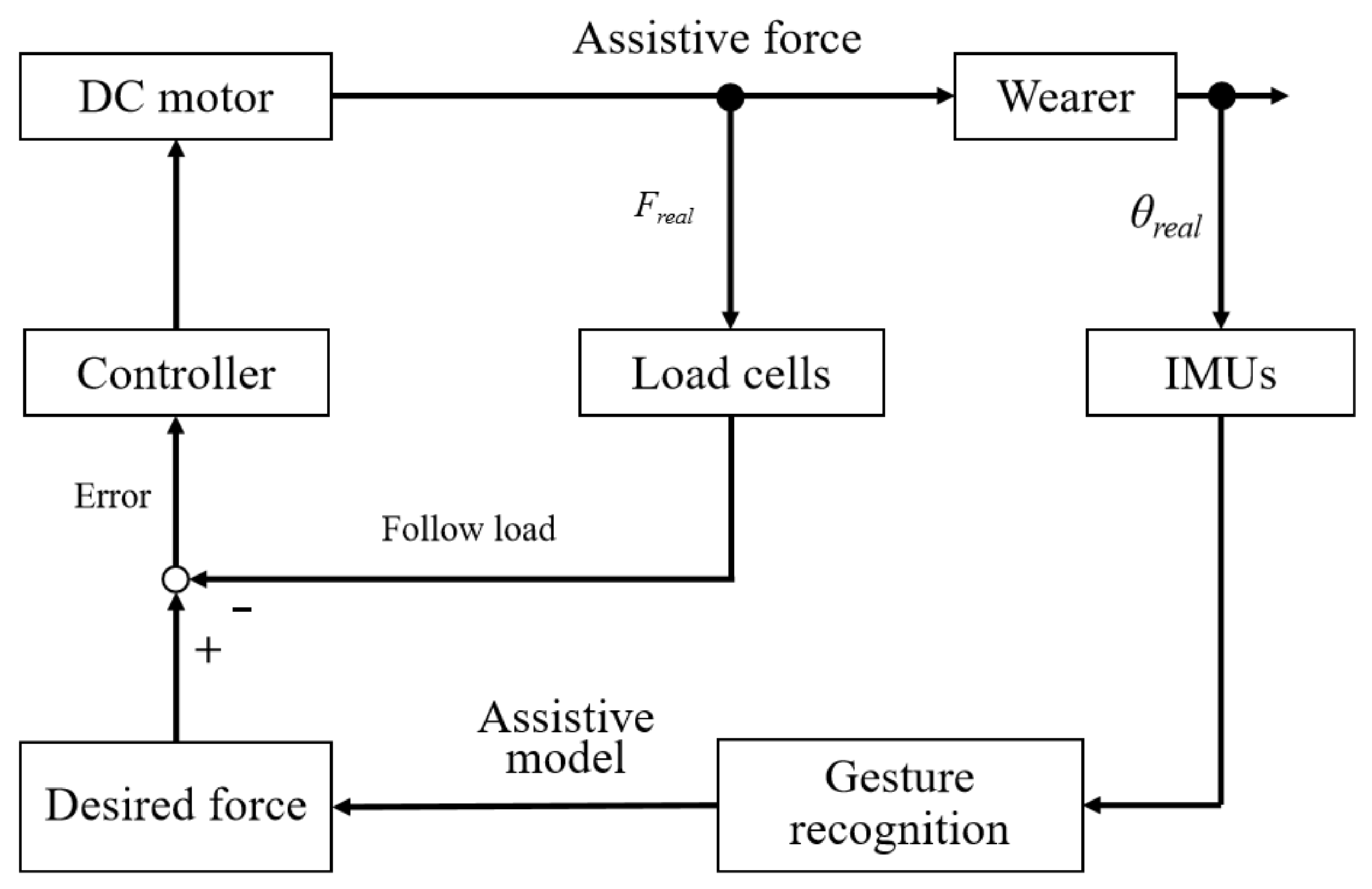

The flexible transmission mode shows good adaptability, aiming at the human upper limb’s complex movement, effectively improving the power without interfering with the wearer’s normal working movement.

If the exoskeleton motion range is consistent with the human upper limb motion range, it can provide comfortable wearability to the wearer and reduce the interference of upper limb motion. Previous studies [

29,

30] evaluated the effect of wearing exoskeletons on the normal range of motion of the human body, which includes the finger part. However, in this study, the study of the finger is removed because the wearable exoskeleton proposed in this paper does not involve the assistance of the finger.

The wearer repeats five handling movements before and after wearing, mainly related to the arm and waist, and uses the three-dimensional motion capture system to achieve motion testing, analysis, and comparison.The upper limbs of the subjects were attached to 10 sampling points. The optical sensor collected upper limb and lumbar motion data at a sampling frequency of 180 Hz. When sampling while wearing the exoskeleton, the same equipment and settings were used for data collection. At this time, the exoskeleton is not in a powered state.

Table 1 shows the comparison results of the wearer in the two states. Similar results of the wearer’s front and back arm movements can be obtained. The main reason for the test results is that the flexible rotation method does not interfere with the wearer’s upper limb movement. These results show that the flexible transmission mode is light and dexterous and has little interference with the upper limb movement. In shoulder horizontal extension and flexion, the limit is relatively large compared to other movement parts. The main reason for the decrease from 89.6° to 83.2° is a slight motion interference between the flexible ropes fixed on the shoulder. Nevertheless, the impact is acceptable in the actual handling work.

3.2. Evaluation of Assistive Force

The auxiliary performance of the proposed exoskeleton is based on five healthy adults, consisting of three males and two females, wearing the proposed ULE and performing all the handling actions. All wearers wear the same exoskeleton because the ULE can be adjusted to fit the body shape and shape of five different wearers. The participant information is shown in

Table 2.

In this experiment, the wearer activates the ULE by pressing the power switch to provide assistive power when they need it. The muscle activity data of the wearer in the case of wearing the exoskeleton are compared with those in the case of not wearing the ULE, and the assist performance of the ULE is analyzed.

The experiment was approved by the Medical Ethics Committee of Shenzhen Institute of Advanced Technology ((SIAT)-IRB-221215-H0632), and the content of the experiment and its possible impact were explained to all the participants before experimenting. None of the subjects reported any history of medical illness. The subjects are guaranteed to be in healthy physical condition.

During this evaluation, selecting the electromyography (EMG) muscle position most conducive to reflecting the upper limb movement and connecting the electrodes is necessary [

31,

32,

33]. The surface EMG sensor was attached to the muscle of the wearer’s right arm. Based on the process of carrying heavy objects, the three muscles are highly correlated, the EMG signal intensity is significant, and the acquisition quality is high. The EMG signals of three muscles were collected in the brachioradialis muscle (BM), triceps brachii (TB), and biceps brachii (BB).

Each wearer is tested according to the handling process, including lifting, holding, and squatting. The lifting action refers to lifting the weight after bending and squatting. The EMG information of the arm was collected from the low position to the high position. In contrast, the holding action refers to lifting the weight at a certain height and holding it for 5 s. The EMG information of the arm-related muscle groups was collected under the state of continuous force. The other movements of the arm were prohibited during the experiment; the squatting action refers to placing the weight on the ground after maintaining the action, collecting the arm EMG signal in the process. The EMG signal was collected during handling under the three weight levels of 5 kg, 10 kg, and 15 kg. After each level test was completed, the wearer was fully rested, and the independence of each test’s data was maintained as much as possible.

According to the standard steps of EMG signal acquisition before the test, EMG signal inspection during data acquisition, band-pass filtering, and rectification is performed using a fourth-order zero-lag Butterworth filter of 20–450 Hz. Eliminate interference from other devices or external environments and filter 20–150 Hz data. Next, the data is low-pass filtered to create a linear envelope. The 400 ms moving window was used to determine the average EMG amplitude in the MVC, and the EMG amplitude was normalized when the highest average was used for evaluation. The wearer’s EMG signals were collected under 5 kg, 10 kg, and 15 kg, respectively, in the lifting, holding, and squatting actions, and the data were normalized. The values after processing are shown in the following figure.

As shown in

Figure 7, the normalized EMG linear envelope diagram represents BM, TB, and BB muscle activity in the three stages of the handling process under different weights of 5 kg, 10 kg, and 15 kg. In summary, muscle activity decreased under the condition of ULE assistance compared with that under the condition of without ULE assistance. However, BM, TB, and BB muscles showed relatively strong muscle activity in the non-assisted mode during the lifting and squatting stages. The possible reason is the lag of sensor data collection. During the assist delay of the ULE, in the rising and squatting stages, the muscle compensates for the lack of assist or the existence of flexible line friction, and the auxiliary force transmitted to the user is reduced, which ultimately leads to insufficient auxiliary force, and BM, TB, BB muscle activity increases. This fact is positive; the ULE can effectively reduce fatigue, as is proved, but also provides a further basis for friction.

Table 3,

Table 4 and

Table 5 show the assist efficiency of the ULE under regular work. Under different weights of 5 kg, 10 kg, and 15 kg, the assist efficiency of BM, TB, and BB muscle activities is shown in the three stages of the handling process.

The handling efficiency is based on the ratio of the average value of the normalized EMG signal under the condition of ULE and without ULE. The

Table 3,

Table 4 and

Table 5 show the handling efficiency of lifting, holding, and squatting stages under 5 kg, 10 kg, and 15 kg load conditions. All handling efficiency is between 9% and 38%.

Table 6 data show the average efficiency of the entire handling process. Under 5 kg, 10 kg, and 15 kg load conditions, the average work efficiency of BM, TB, and BB is between 19% and 38%. This data shows that the ULE reduces muscle activity during handling and reduces the risk of physical loss during the wearer’s long-term continuous operation.

RMS is one of the key indicators used to evaluate muscle fatigue [

34,

35]. The RMS of the normalized EMG in the three stages is shown in

Figure 8. The figure shows that the value without ULE assistance is still the highest, and the EMG signals are reduced when wearing ULE, indicating that the ULE provides practical assistance. All adjacent pairs of histograms were also subjected to a

t-test, which revealed that all comparisons were statistically significant (

p < 0.05).