Performance Evaluation of a Cicada-Inspired Subsoiling Tool Using DEM Simulations

Abstract

1. Introduction

2. Methodology

2.1. Biomimetic Design of the Cutting Share of the Subsoiling Tool

2.2. Lab Soil Bin Tests

2.3. DEM Simulations

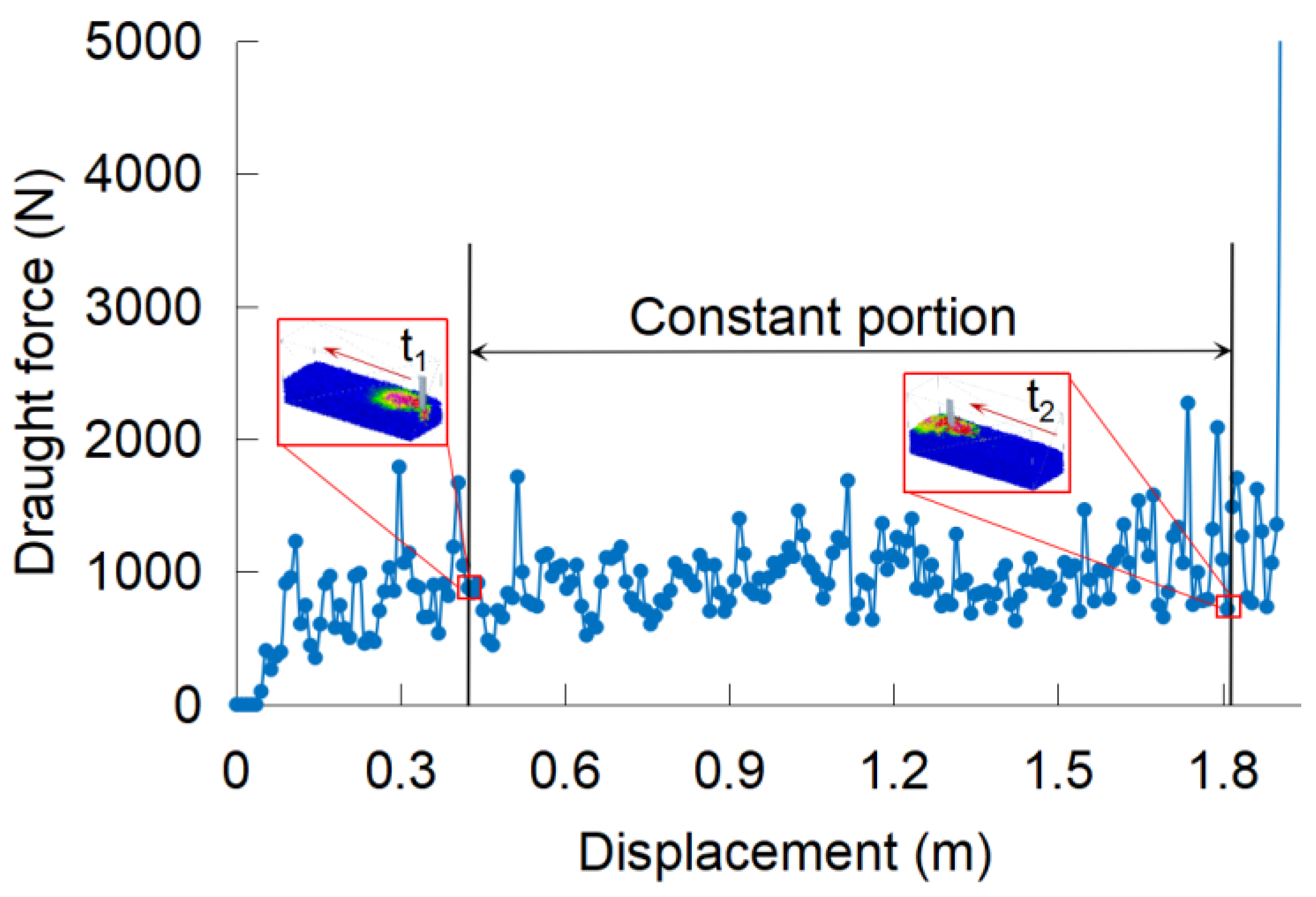

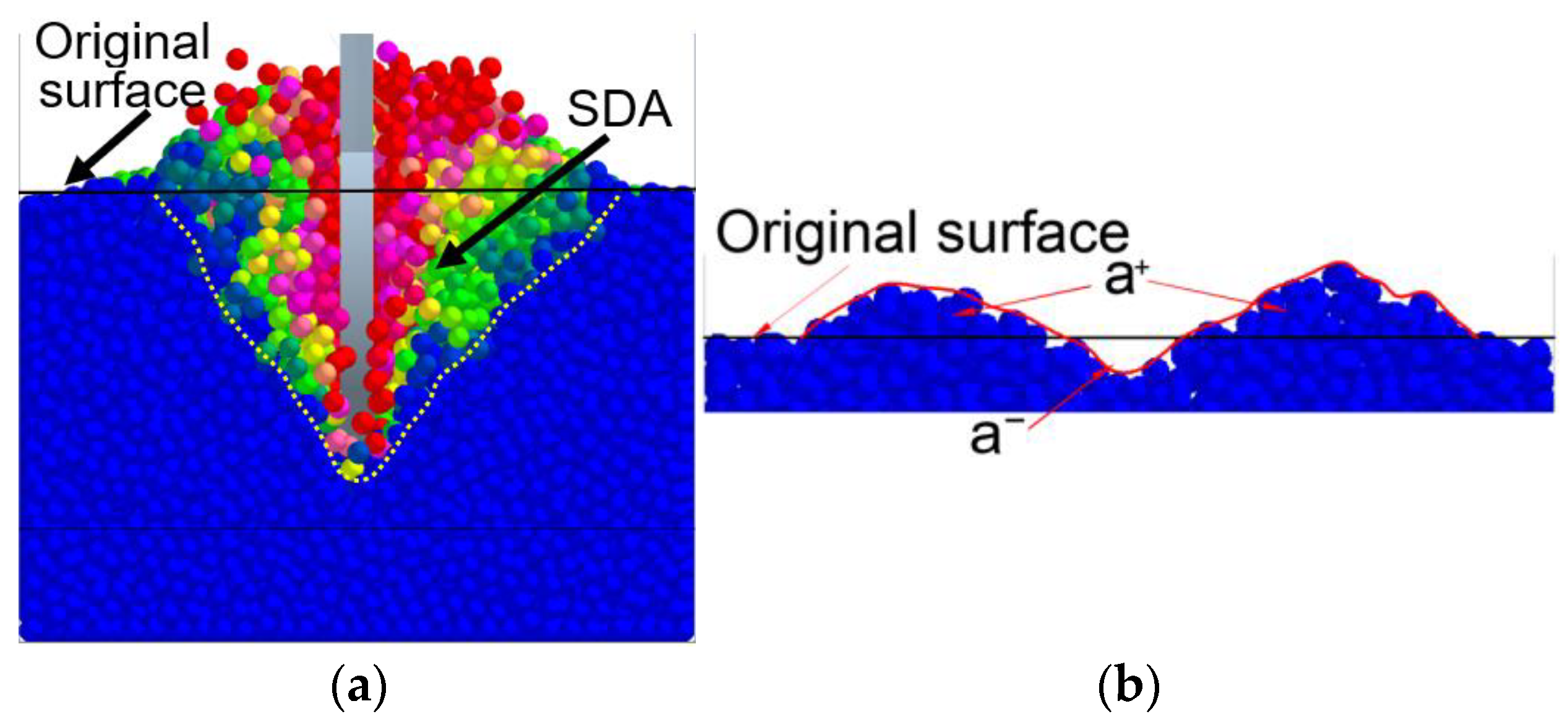

2.4. Monitoring of Draught Forces and Soil Disturbance in the DEM

3. Results and Discussion

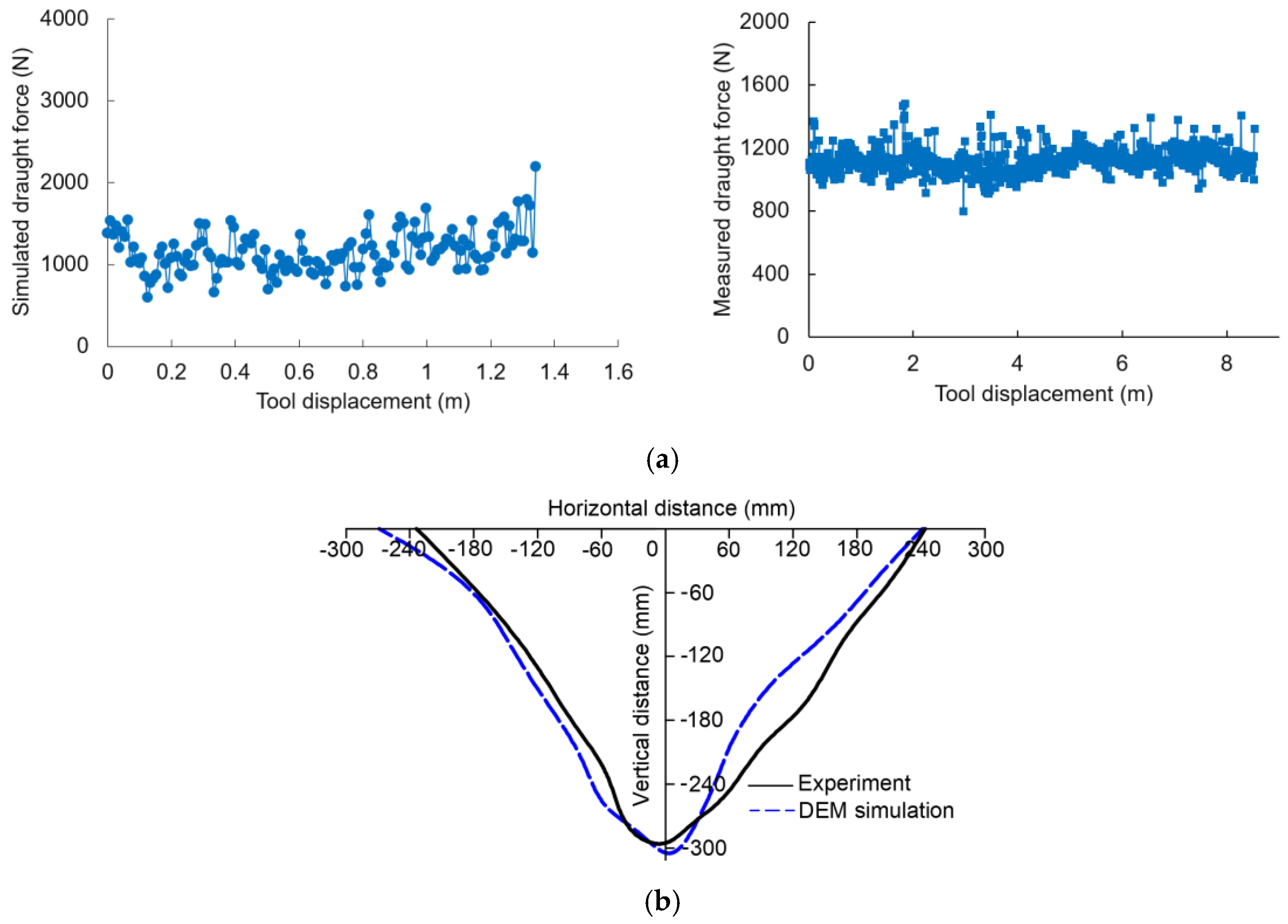

3.1. Model Validation

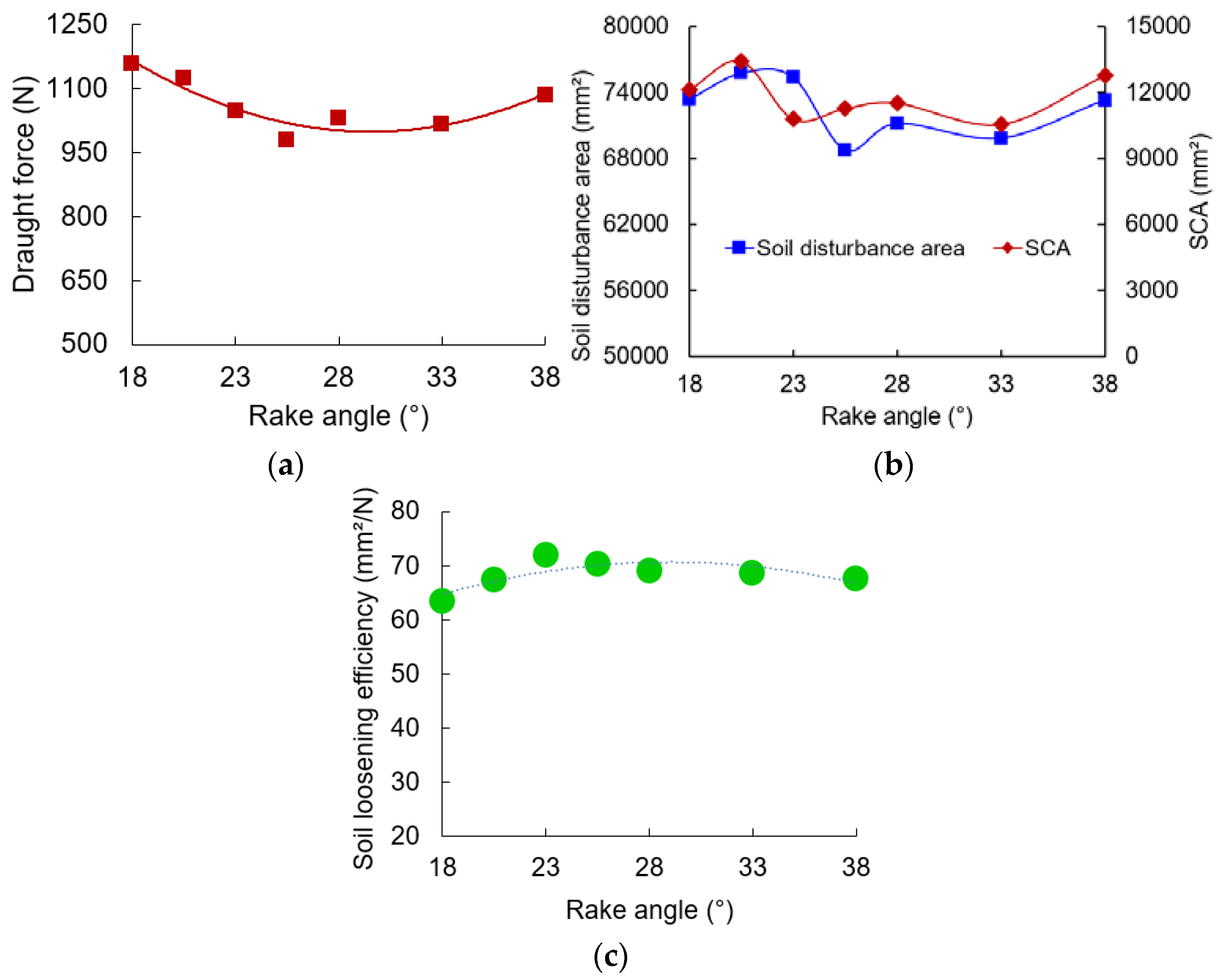

3.2. Biomimetic Subsoiling Tool Performance Affected by Rake Angle

3.3. Comparisons between Biomimetic and Conventional Subsoiling Tools

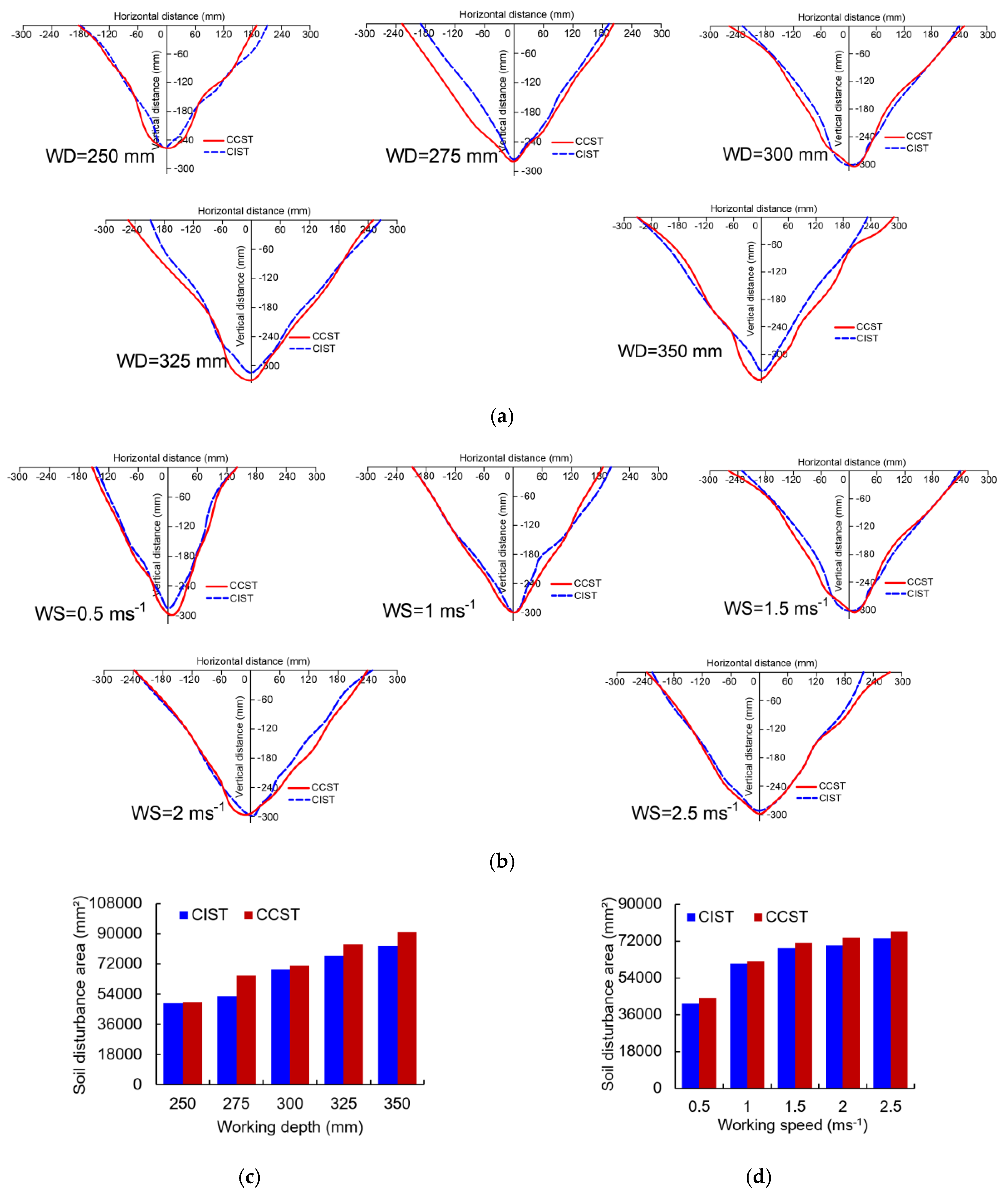

3.3.1. Soil Disturbance Profile and Soil Disturbance Area

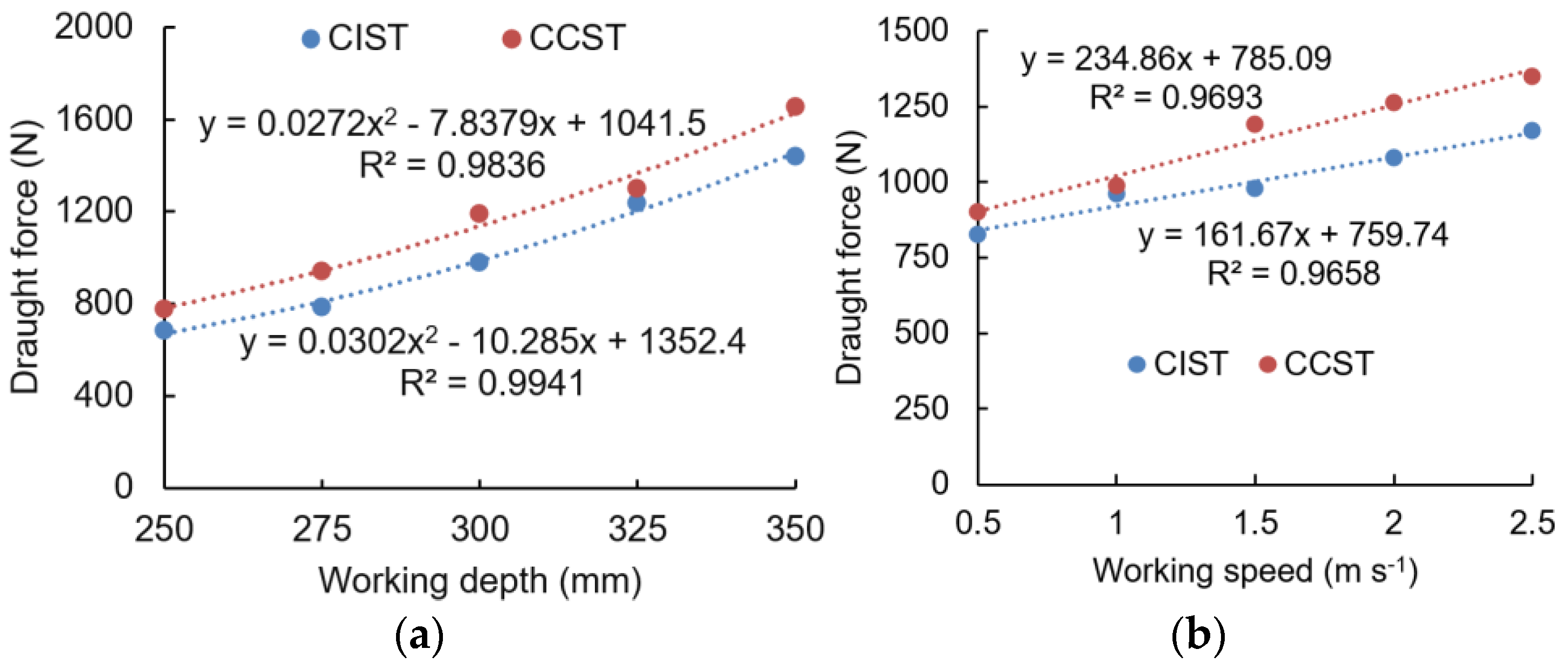

3.3.2. Draught Force

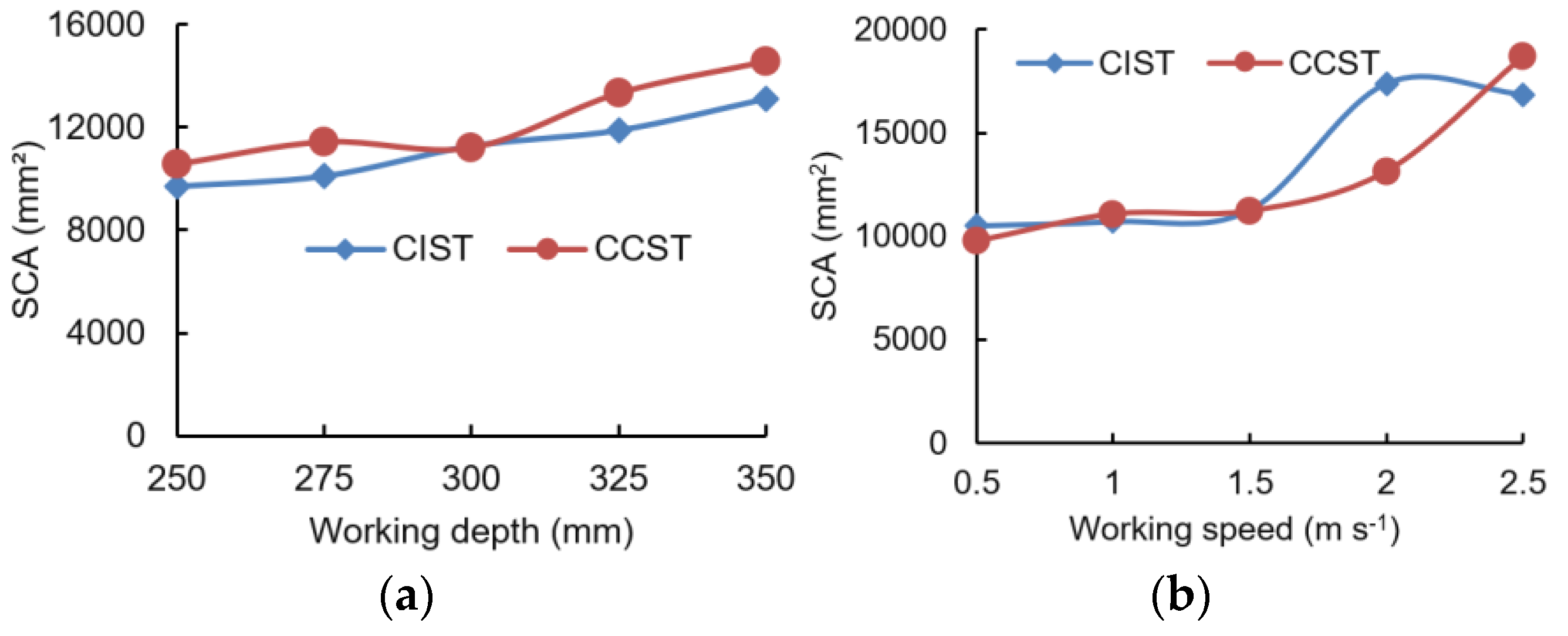

3.3.3. Surface Cross-Sectional Area (SCA)

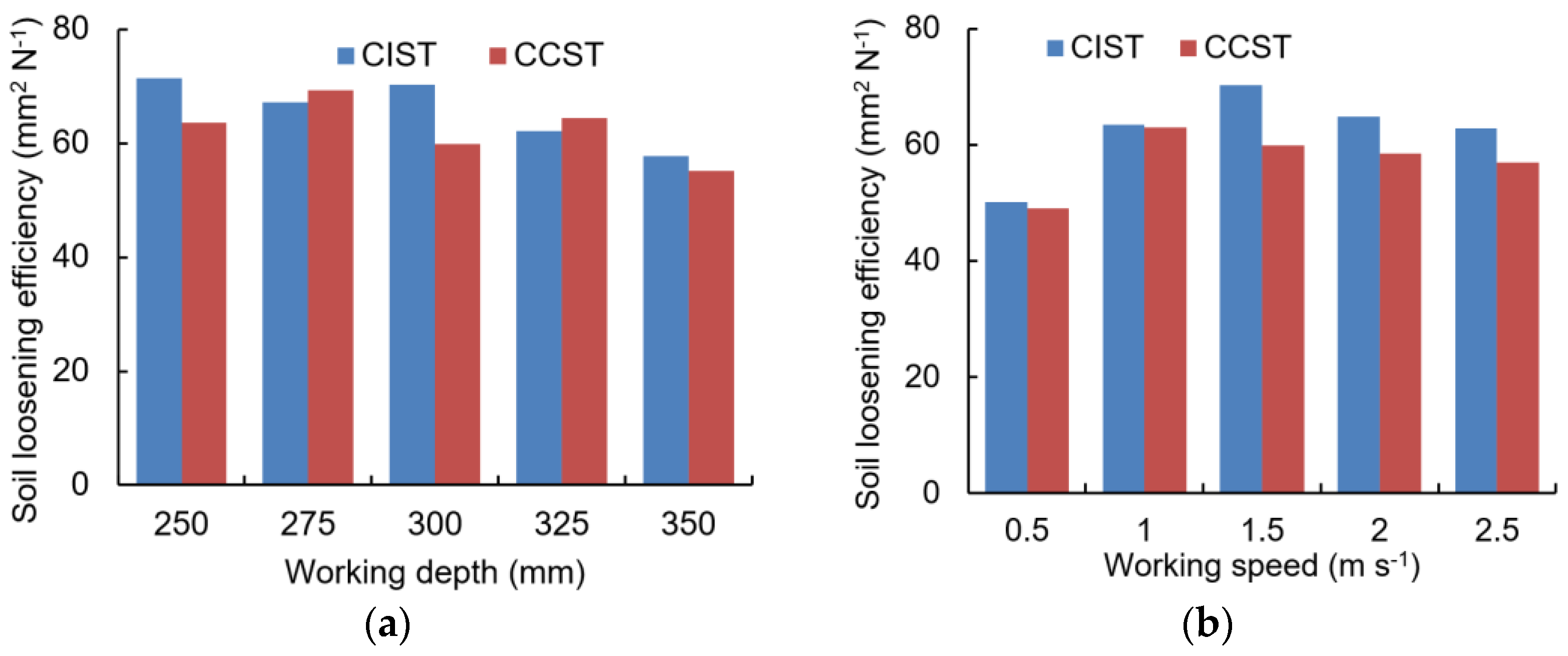

3.3.4. Soil Loosening Efficiency

4. Conclusions

- (1)

- The developed DEM model could be used to simulate soil–subsoiling tool interactions with good accuracy, as indicated by relative errors of <6.1% between simulated and measured draught forces and soil disturbance areas;

- (2)

- Compared with the CCST, the draught forces of the CIST can be reduced by 17.7% at a working depth of 300 mm and working speed of 1.5 m s−1; this CIST design obviously outperforms the biomimetic designs by Bai et al. [23], Guo [19], and Li [20], which have largest draught force reductions of 7.29–12.8%. Therefore, the CIST has a good potential to further reduce the draught forces and energy requirements of subsoiling operations;

- (3)

- Soil surface flatness after subsoiling using the CIST was smoother at various depths than the CCST. Soil loosening efficiencies of the CIST were 0.81–17.37% higher than the CCST at various working speeds.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, L.; Li, B.F. Experiment study on the self-excited virbration subsoiler for reducing draft force. Trans. CSAE 2000, 16, 72–76. [Google Scholar]

- Chen, Y.; Caversb, C.; Tessierc, S.; Moneroa, F.; Lobb, D. Short-term tillage effects on soil cone index and plant development in a poorly drained, heavy clay soil. Soil Tillage Res. 2005, 82, 161–171. [Google Scholar] [CrossRef]

- Song, W.; Jiang, X.H.; Li, L.K.; Ren, L.L.; Tong, J. Increasing the width of disturbance of plough pan with bionic inspired subsoilers. Soil Tillage Res. 2022, 220, 105356. [Google Scholar] [CrossRef]

- Wang, Y.; Li, N.; Ma, Y.; Tong, J.; Pfleging, W.; Sun, J. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction. Soil Tillage Res. 2020, 196, 104432. [Google Scholar] [CrossRef]

- Wang, X.Z.; Zhou, H.; Wang, S.S.; Zhou, H.M.; Ji, J.T. Methods for reducing the tillage force of subsoiling tools: A review. Soil Tillage Res. 2023, 229, 105676. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

- Li, B.; Liu, F.; Mu, J.; Chen, J.; Han, W. Distinct element method analysis and field experiment of soil resistance applied on the subsoiler. Int. J. Agric. Biol. Eng. 2014, 7, 54–59. [Google Scholar] [CrossRef]

- Raper, R.L. Force requirements and soil disruption of straight and bentleg subsoilers for conservation tillage systems. Appl. Eng. Agric. 2005, 21, 787–794. [Google Scholar] [CrossRef]

- Spoor, G.; Tijink, F.G.J.; Weisskopf, P. Subsoil compaction: Risk, avoidance, identification and alleviation. Soil Tillage Res. 2003, 73, 175–182. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.Q. Analysis on operational process of self-excited vibrating subsoiler based on DEM-MBD coupling algorithm. Trans. CSAM 2020, 51, 17–24. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Wang, S.; Wang, H.; Xu, Z.; Jia, G.; Wang, X.; Li, J. Effects of different sub-soiling frequencies incorporated into no-tillage systems on soil properties and crop yield in dryland wheat-maize rotation system. Field Crops Res. 2017, 209, 151–158. [Google Scholar] [CrossRef]

- Zheng, K.; Mchugh, A.D.; Li, H.; Wang, Q.; He, J. Design and experiment of anti-vibrating and anti-wrapping rotary components for subsoiler cum rotary tiller. Int. J. Agric. Biol. Eng. 2019, 12, 47–55. [Google Scholar] [CrossRef]

- Wang, X.Z.; Fu, Z.L.; Zhang, Q.K.; Huang, Y.X. Short-term subsoiling effects with different wing mounting heights before winter wheat on soil properties and wheat growth in Northwest China. Soil Tillage Res. 2021, 213, 105151. [Google Scholar] [CrossRef]

- Wang, X.Z.; Li, P.; He, J.P.; Wei, W.Q.; Huang, Y.X. Discrete element simulations and experiments of soil-winged subsoiler interaction. Int. J. Agric. Biol. Eng. 2021, 14, 50–62. [Google Scholar] [CrossRef]

- Li, X.; Fu, J.; Zhang, D.; Cui, T.; Tang, M. Experiment analysis on traction resistance of vibration subsoiler. Trans. CSAM 2012, 28, 32–36. [Google Scholar] [CrossRef]

- Ren, L.Q. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines. Sci. China Technol. Sci. 2009, 52, 273–284. [Google Scholar] [CrossRef]

- Song, Y.M.; Xie, Y.Z.; Malyarchuk, V.; Xiao, J.L.; Jung, I.; Choi, K.J.; Liu, Z.J.; Park, H.; Lu, C.F.; Kim, R.H.; et al. Digital cameras with designs inspired by the arthropod eye. Nature 2013, 497, 95–99. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Ma, Y.; Tong, J.; Zhang, Z. DEM simulation of bionic subsoilers (tillage depth > 40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Guo, M.Z. Design and Key Technology Research of Stubble Breaking and Subsoiling Combined Machine Based on Dynamic Bionics. Ph.D. Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- Li, B. Reduction Force and Tillage Performance of a Subsoiler Based on the Discrete Element Method (DEM). Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2016. [Google Scholar]

- Guo, Z.; Zhou, Z.; Zhang, Y.; Li, Z. Study on bionic optimization design of soil tillage components. Sci. China Technol. Sci. 2009, 4, 720–728. [Google Scholar]

- Zhang, L.; Zhai, Y.; Chen, J.; Zhang, Z.; Huang, S. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Tillage Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

- Bai, J.F.; Li, B.; Lv, X.T.; Chen, J.; Dang, G.R.; Shi, J.T. Structure design and test of the badger claws bionic subsoiler. J. Agric. Eng. Res. 2016, 4, 175–179. [Google Scholar] [CrossRef]

- Mak, J.; Chen, Y.; Sadek, M.A. Determining parameters of a discrete element model for soil–tool interaction. Soil Tillage Res. 2012, 118, 117–122. [Google Scholar] [CrossRef]

- Sadek, M.A.; Chen, Y. Feasibility of using PFC3D to simulate soil flow resulting from a simple soil-engaging tool. Trans. ASABE 2014, 58, 987–996. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Tong, J.; Ma, Y. Study on the interaction between soil and the five-claw combination of a mole using the discrete element method. Appl. Bionics Biomech. 2018, 2018, 7854052. [Google Scholar] [CrossRef]

- Chen, Y.; Munkholm, L.J.; Nyord, T. A discrete element model for soil-sweep interaction in three different soils. Soil Tillage Res. 2013, 126, 34–41. [Google Scholar] [CrossRef]

- Milkevychet, V.; Lars, J.M.; Chen, Y.; Nyord, T. Modelling approach for soil displacement in tillage using discrete element method. Soil Tillage Res. 2018, 183, 60–71. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielk, J.M.; Saunders, C. 3D DEM tillage simulation: Validation of a hysteretic spring (plastic) contact model for a sweep tool operating in a cohesionless soil. Soil Tillage Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Wang, J.W.; Li, X.; Gao, P.X.; Na, M.J.; Wang, Q.; Zhou, W.Q. Design and experiment of high efficiency drag reducing shovel for carrot combine harvester. Trans. CSAM 2020, 51, 93–103. [Google Scholar] [CrossRef]

- Wang, Y.C. Study on Mining Mechanism of Panax Notoginseng Based on Discrete Element Method. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2021. [Google Scholar]

- Hang, C.G. Soil Disturbance Behavior of Subsoiling Based on Discrete Element Method. Master’s Thesis, Northwest A&F University, Xianyang, China, 2017. [Google Scholar]

- Zheng, K.; He, J.; Li, H.; Diao, P.; Wang, Q.; Zhao, H. Research on polyline soil-breaking blade subsoiler based on subsoiling soil model using discrete element method. Trans. CSAM 2016, 47, 62–72. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Gan, S.; Zuo, G.; Tong, J. Bionic design and performance experiment of sandfish head inspired subsoiler tine. Trans. CSAM 2021, 52, 33–42. [Google Scholar] [CrossRef]

- Wang, X.Z.; Zhang, Q.K.; Huang, Y.X.; Ji, J.T. An efficient method for determining DEM parameters of a loose cohesive soil modelled using hysteretic spring and linear cohesion contact models. Biosyst. Eng. 2022, 215, 283–294. [Google Scholar] [CrossRef]

- Zheng, K. Study on Subsoiling and Rotary Tillage Operation Adjustable Combine Machine. Ph.D. Thesis, China Agricultural University, Beijing, China, 2018. [Google Scholar]

- Shi, L.R.; Zhao, W.Y.; Sun, W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method. Trans. CSAE 2017, 33, 181–187. [Google Scholar] [CrossRef]

- Hu, H. Design and Research of Targeted Hole-Pricking and Deep-Application Fertilizer Applicator between Maize Rows. Ph.D. Thesis, China Agricultural University, Beijing, China, 2017. [Google Scholar]

- Li, J.W.; Tong, J.; Hu, B.; Wang, H.B.; Mao, C.Y.; Ma, Y.H. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China. Trans. CSAE 2019, 35, 130–140. [Google Scholar] [CrossRef]

- Xiang, W.; Wu, M.L.; Lü, J.N.; Quan, W.; Ma, L.; Liu, J.J. Calibration of simulation physical parameters of clay loam based on soil accumulation test. Trans. CSAE 2019, 35, 116–123. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielk, J.M.; Saunders, C. Three-dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosyst. Eng. 2014, 121, 105–117. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; John, M.F. Discrete element modelling of top soil burial using a full scale mouldboard plough under field conditions. Biosyst. Eng. 2017, 160, 140–153. [Google Scholar] [CrossRef]

- Xia, L. Optimum Parameter and Experimental Study of Shovel Wing Based on Discrete Element Method. Master’s Thesis, Northwest A&F University, Xianyang, China, 2018. [Google Scholar]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Comparison of two subsoiler designs using the discrete element method (DEM). Trans. ASABE 2018, 61, 1529–1537. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, X.; Lin, Z.; Zhu, R. Design and experiment of self-exciting vibration deep-loosening and sub-soiling machine. Trans. CSAM 2016, 47, 44–49. [Google Scholar] [CrossRef]

- Hang, C.G.; Huang, Y.X.; Li, W.; Zhu, R.X. Influencing factors and reduction strategies of subsoiling tillage resistance. J. Northwest AF Univ. 2016, 44, 202–208. [Google Scholar] [CrossRef]

- Liu, J.A. Study on Subsoiler Parameters Optimization and Comprehensive Effect of Subsoiling Based on the Discrete Element Method. Ph.D. Thesis, China Agricultural University, Beijing, China, 2018. [Google Scholar]

- McKyes, E. Soil Cutting and Tillage; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1985. [Google Scholar]

- Godwin, R.J. A review of the effect of implement geometry on soil failure and implement forces. Soil Tillage Res. 2007, 97, 331–340. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | Source |

|---|---|---|---|

| Poisson’s ratio of soil | Dimensionless | 0.3 | [42] |

| Shear modulus of soil | Pa | 5 × 107 | [42] |

| Density of steel | kg m−3 | 7865 | [33] |

| Poisson’s ratio of steel | Dimensionless | 0.3 | [33] |

| Shear modulus of steel | Pa | 7.9 × 1010 | [33] |

| Coefficient of static friction of soil–soil | Dimensionless | 0.7 | Calibrated |

| Coefficient of rolling friction of soil–soil | Dimensionless | 0.225 | Calibrated |

| Coefficient of restitution between materials | Dimensionless | 0.6 | [14,33] |

| Coefficient of static friction of steel–soil | Dimensionless | 0.49 | Measured |

| Coefficient of rolling friction of steel–soil | Dimensionless | 0.06 | Calibrated |

| Surface energy | J m−3 | 6 | [38] |

| Rayleigh time step | s | 2.2802 × 10−4 | Calculated |

| Particle radii | mm | 9.5–10.5 | [41] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Du, R.; Geng, L.; Zhou, H.; Ji, J. Performance Evaluation of a Cicada-Inspired Subsoiling Tool Using DEM Simulations. Biomimetics 2024, 9, 25. https://doi.org/10.3390/biomimetics9010025

Wang X, Du R, Geng L, Zhou H, Ji J. Performance Evaluation of a Cicada-Inspired Subsoiling Tool Using DEM Simulations. Biomimetics. 2024; 9(1):25. https://doi.org/10.3390/biomimetics9010025

Chicago/Turabian StyleWang, Xuezhen, Ruizhi Du, Lingxin Geng, Hanmi Zhou, and Jiangtao Ji. 2024. "Performance Evaluation of a Cicada-Inspired Subsoiling Tool Using DEM Simulations" Biomimetics 9, no. 1: 25. https://doi.org/10.3390/biomimetics9010025

APA StyleWang, X., Du, R., Geng, L., Zhou, H., & Ji, J. (2024). Performance Evaluation of a Cicada-Inspired Subsoiling Tool Using DEM Simulations. Biomimetics, 9(1), 25. https://doi.org/10.3390/biomimetics9010025