Bio-Inspired Fault Diagnosis for Aircraft Fuel Pumps Using a Cloud-Edge System

Abstract

:1. Introduction

- Divide the different tasks on the sensor side, the edge side, and the cloud side to achieve collaborative monitoring;

- The anomaly judgment method and fault diagnosis algorithm are designed for edge-side state detection and cloud fault classification;

- The feasibility and effectiveness of the proposed method are verified by fuel pump simulation experiments.

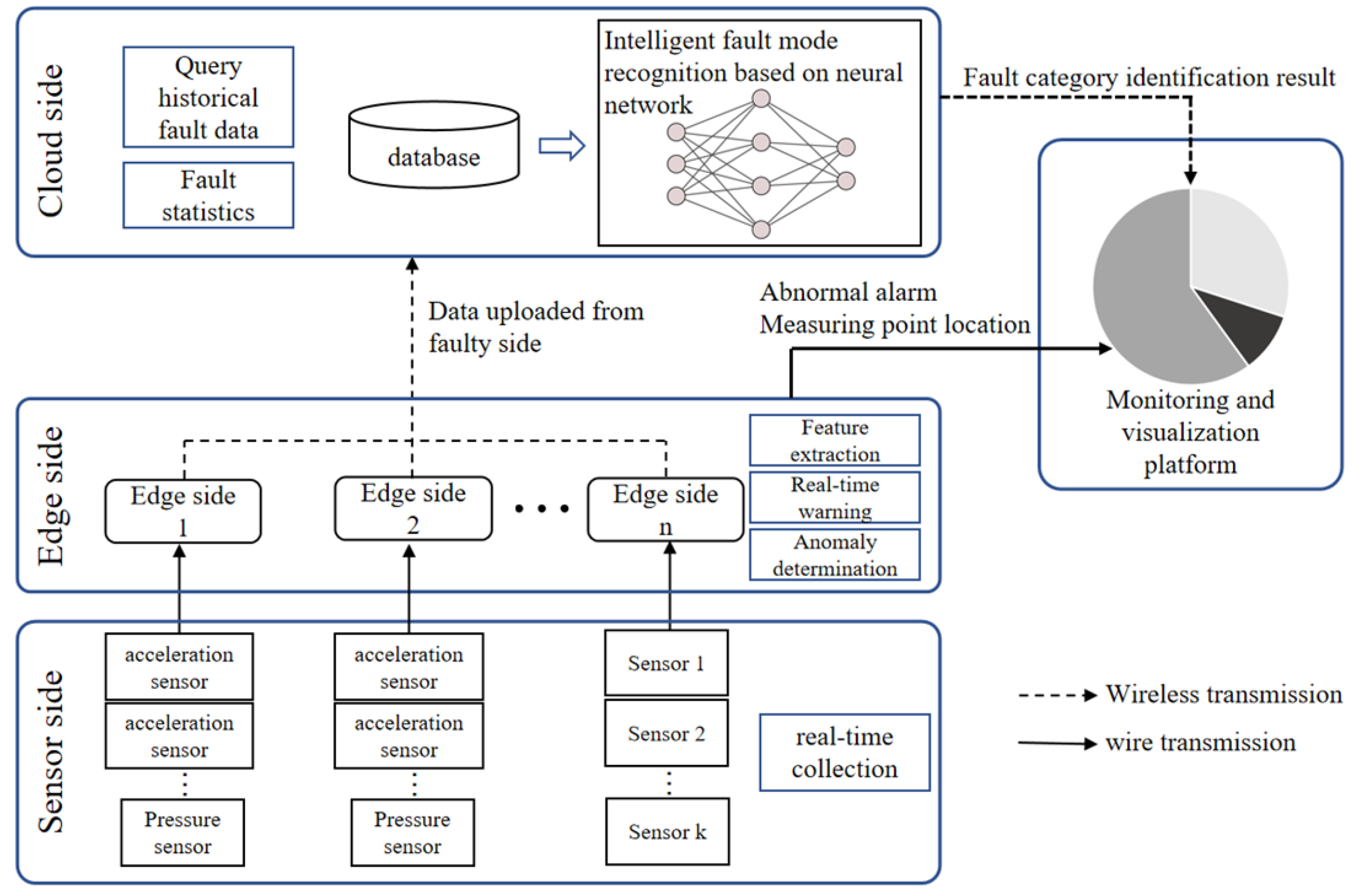

2. Fault Diagnosis Framework for Fuel Pumps Based on Cloud Edge Collaboration

2.1. General Framework

- Sensor side: At critical measurement locations of the fuel pump, multiple sensors (e.g., vibration, pressure, etc.) are strategically positioned to capture real-time operating data. These sensors facilitate the collection of comprehensive information regarding the fuel pump’s performance. The acquired real-time data are subsequently transmitted via wired connections to the edge side for further processing and analysis.

- Edge side: Upon receiving the uploaded data from each sensor, the location information of the corresponding measurement points is recorded, and the characteristic values are extracted simultaneously. Subsequently, the threshold method is employed to identify anomalies within the dataset. Segments of data that meet the abnormal condition are wirelessly transmitted to the cloud for further analysis. In the ground and airborne visual interfaces, both the abnormal alarm information and the respective positions of the measurement points are presented, providing a comprehensive overview of the detected anomalies.

- Cloud side: The fault segment information transmitted by each edge is stored in the historical database, which facilitates subsequent fault history tracing. An intelligent classification model is employed to identify the types of fault data detected by the system. Additionally, uploading more fault data are used to update and train the model parameters, thus enhancing its migration ability. Ultimately, the classification and diagnosis results are presented through the ground and airborne visual interfaces.

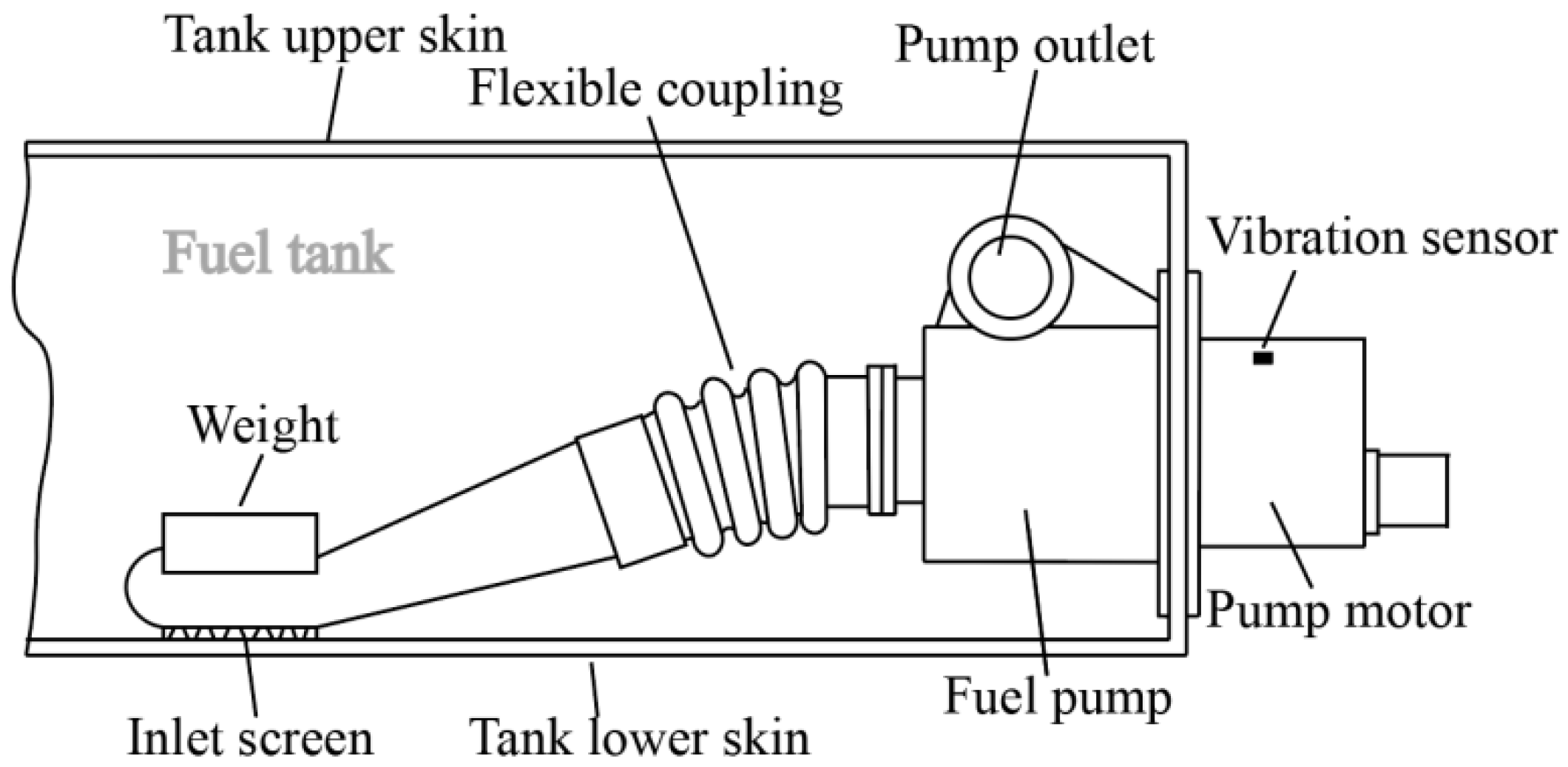

2.2. Data Acquisition on Sensor Side

2.3. Anomaly Detection on Edge Side

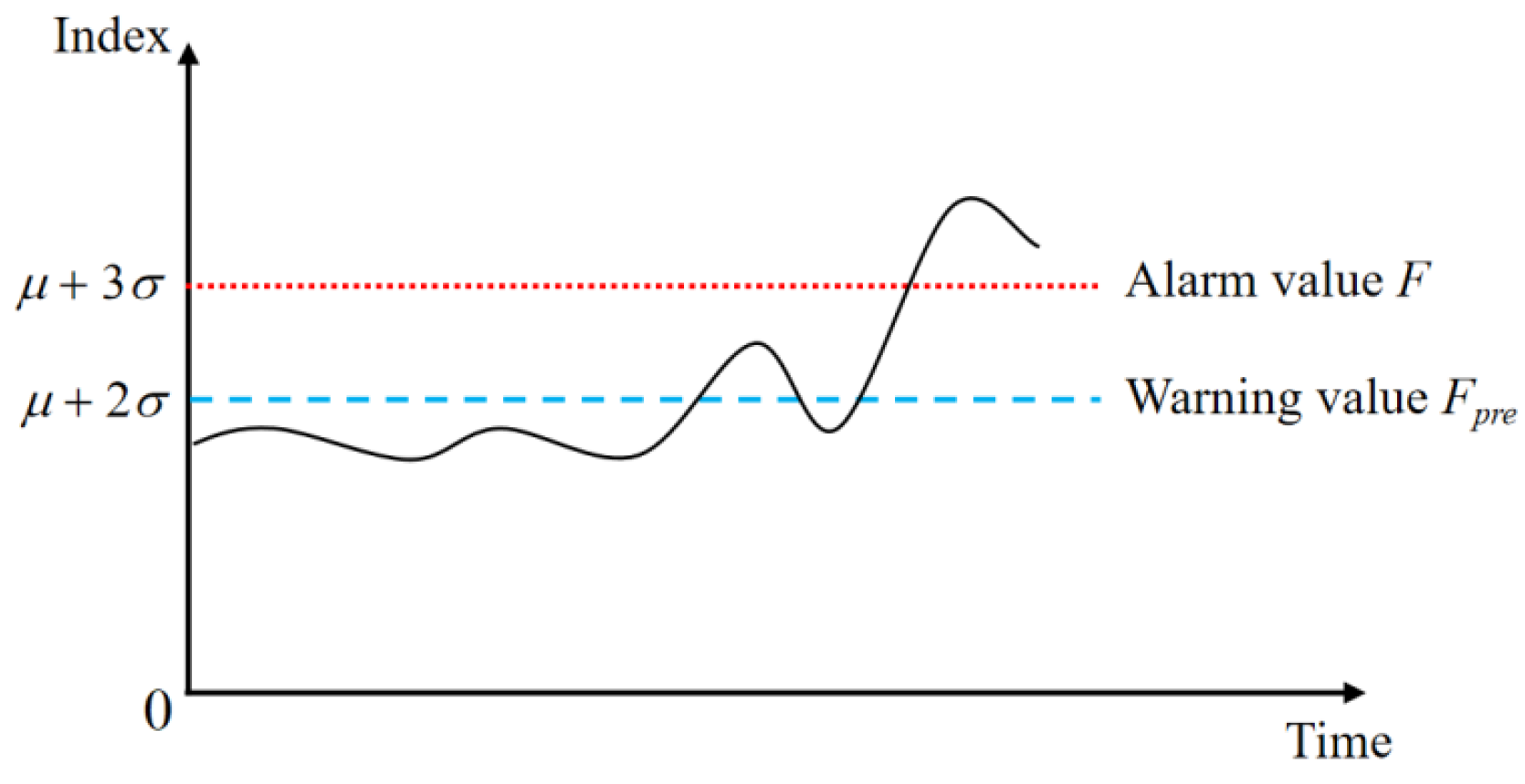

2.3.1. Detection Index

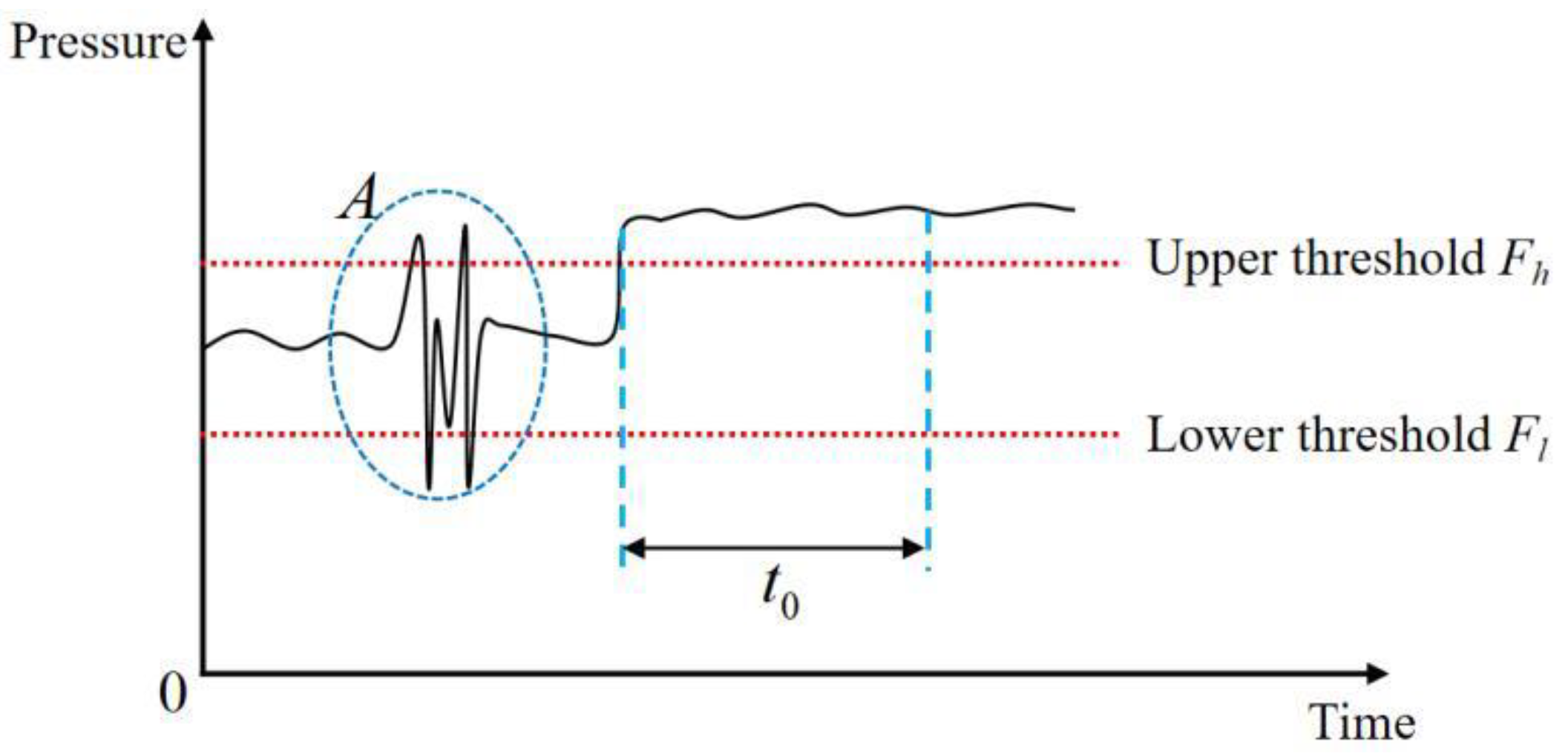

2.3.2. Threshold Detection

2.3.3. 3/5 Strategy

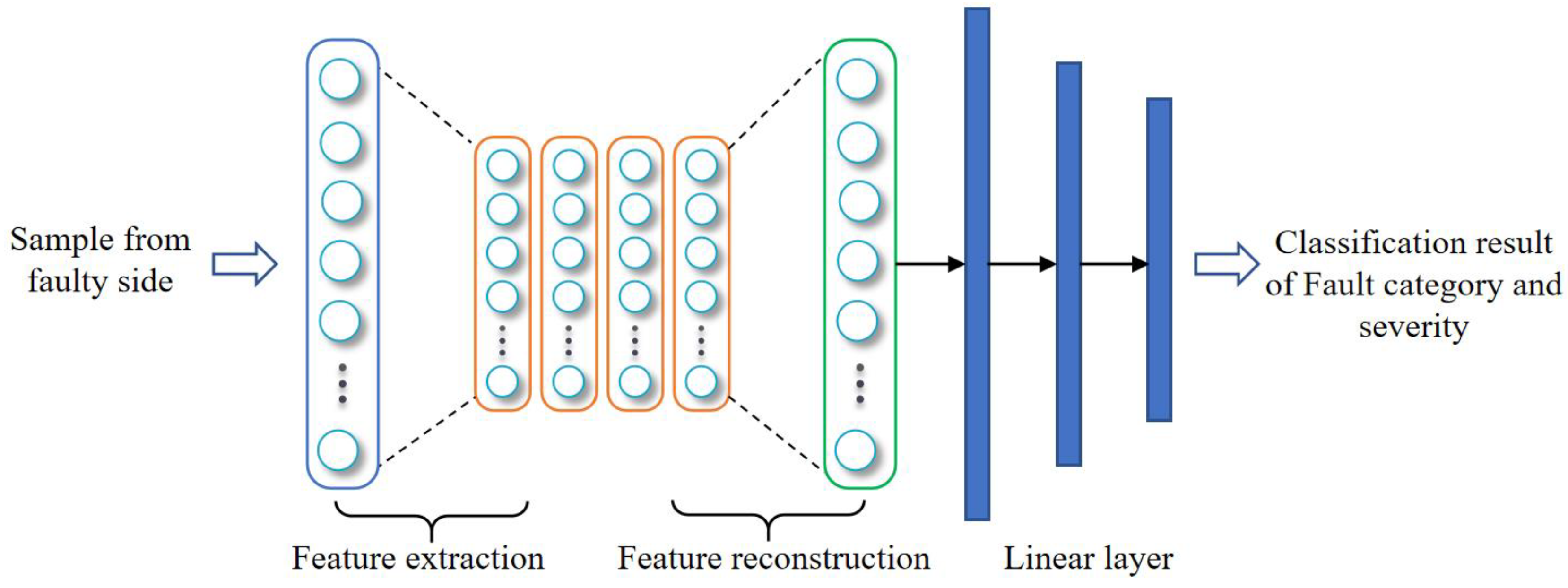

2.4. Cloud Fault Pattern Recognition Algorithm Based on Convolutional Auto-Encoder

- Feature extraction process

- 2.

- Feature reconstruction process

- 3.

- Classifier

3. Experiment and Result Analysis

3.1. Experimental Setup

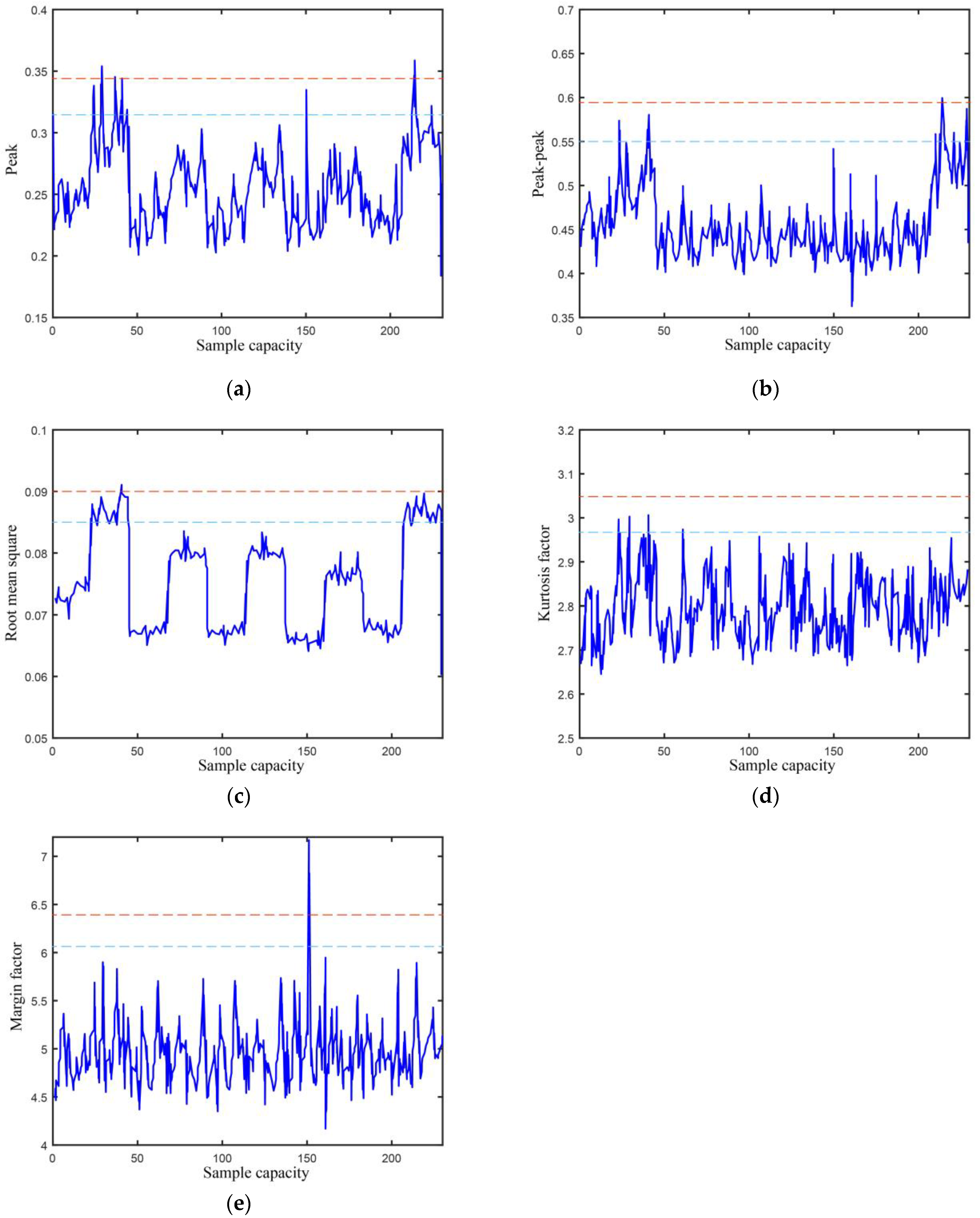

3.2. Result of Edge Side Detection

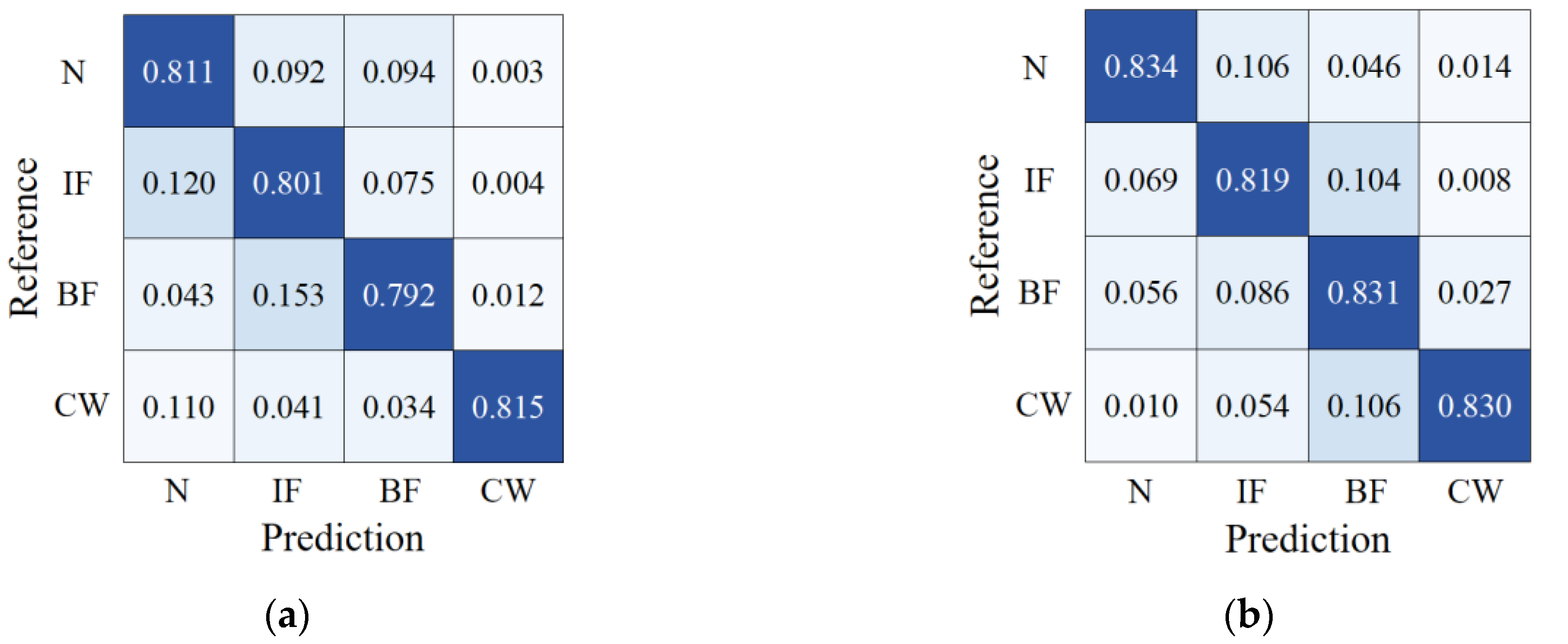

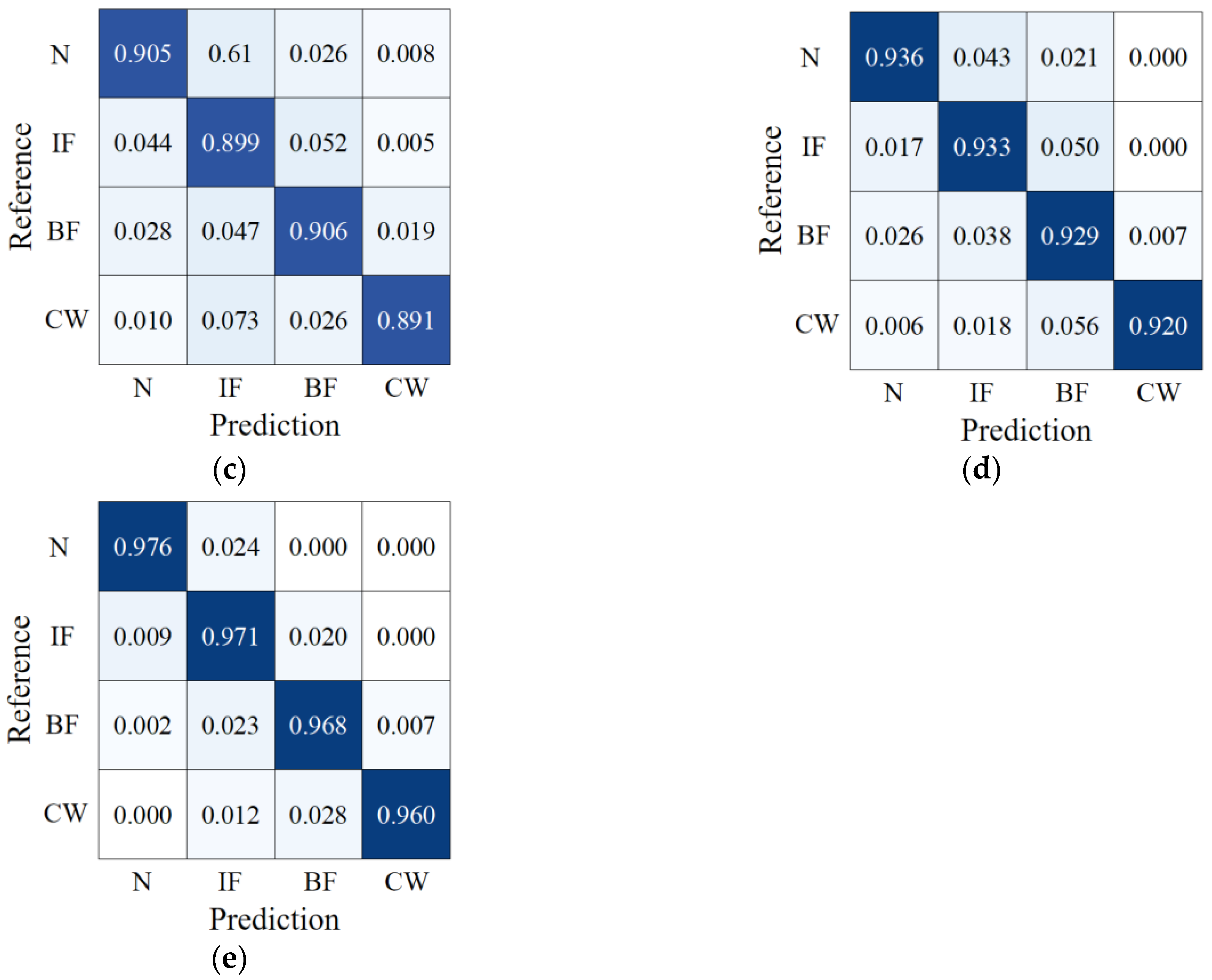

3.3. Performance Comparison of Different Fault Diagnosis Algorithms for Fuel Pumps

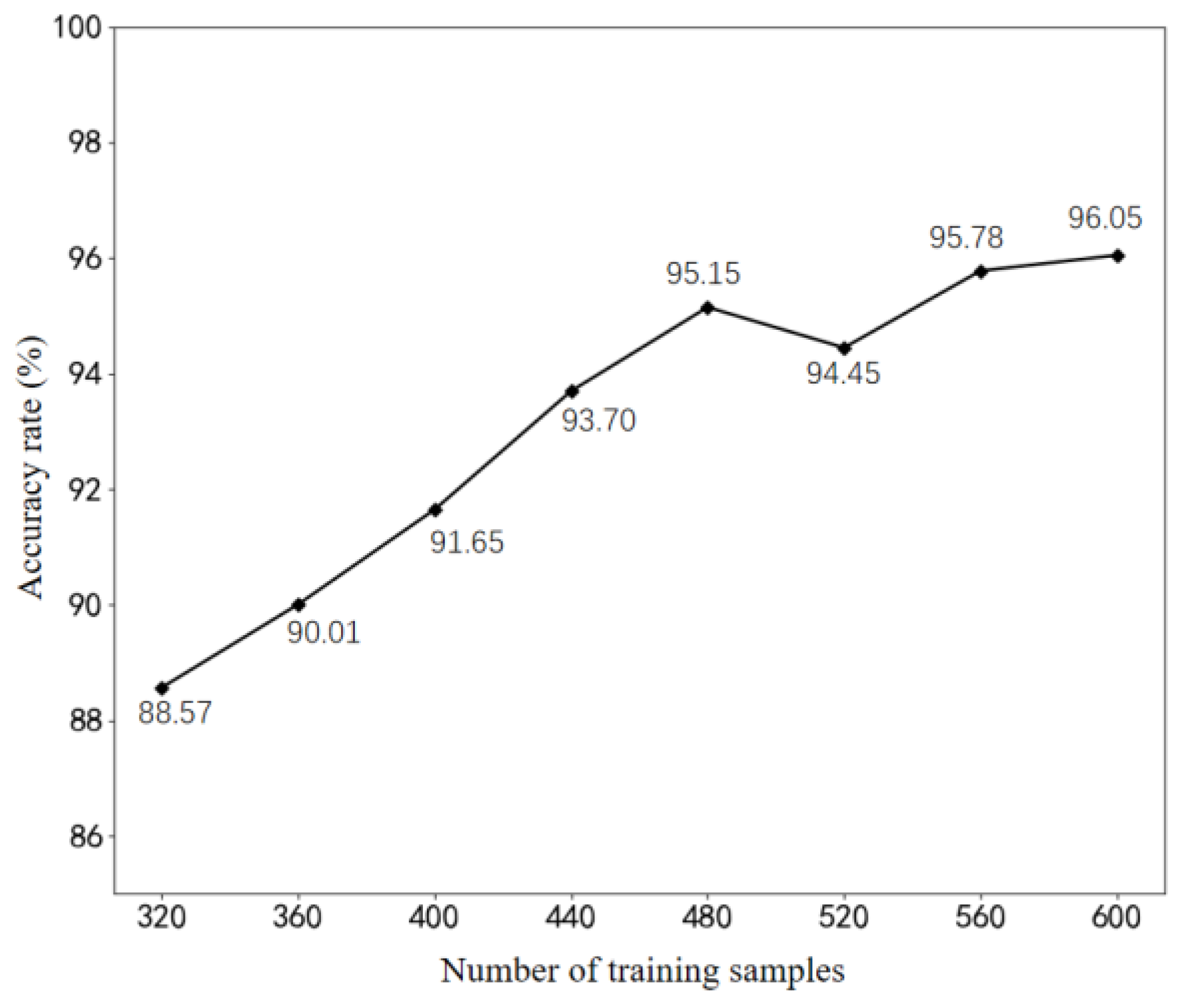

3.4. Analysis of the Influence of Sample Number on Cloud Diagnosis Algorithm

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Du, X.; Sun, X.M.; Peng, K. Fault simulation and diagnosis of the aero-engine fuel regulator. IEEE. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 5783–5789. [Google Scholar]

- Radle, M.; Shome, B. Cavitaion prediction in liquid ring pump for aircraft fuel systems by CFD approach. SAE Tech. Pap. 2013, 2013-01-2238. [Google Scholar]

- Yanjun, Z.; Youchao, S.; Fengchan, W.; Haijun, Z. Method of aircraft fuel tank system ignition source fail-safe feature analysis. Procedia Eng. 2011, 17, 638–644. [Google Scholar] [CrossRef]

- Yan, Z.; Xu, Y.; Wang, L.; Hu, A. Feature extraction by enhanced time-frequency analysis method based on Vold-Kalman filter. Measurement 2023, 207, 112383. [Google Scholar] [CrossRef]

- Cui, L.; Yang, M.; Liu, D.; Wang, H. The diagnosis of gear and bearing compound faults via adapted dictionary-free orthogonal matching pursuit and spectral negentroph. Measurement 2023, 206, 112134. [Google Scholar] [CrossRef]

- Liu, Z.; Jia, Z.; Vong, C.M.; Han, J.; Yan, C.; Pecht, M. A patent analysis of prognostics and health management (PHM) innovations for electrical systems. IEEE Access 2018, 6, 18088–18107. [Google Scholar] [CrossRef]

- Cui, L.; Sun, Y.; Wang, X.; Wang, H. Spectrum- based, full-band preprocessing, and two-dimensional separation of bearing and gear compound faults diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 1–16. [Google Scholar] [CrossRef]

- Wang, X.; Cui, L.; Wang, H.; Jiang, H. A generalized health indicator for performance degradation assessment of rolling element bearings based on graph spectrum reconstruction and spectrum characterization. Measurement 2021, 176, 109165. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, C.; Yang, X.; Zhang, N.; Liu, F.; Zhang, B. Time Series Multi-Step Forecasting Based on Memory Network for the Prognostics and Health Management in Freight Train Braking Systme. IEEE Trans. Intell. Transp. Syst. 2023, 24, 8149–8162. [Google Scholar] [CrossRef]

- Zio, E. Prognostics and Health Management of Industrial Equipment. In Diagnostics and Prognostics of Engineering Systems: Methods and Techniques; Kadry, S., Ed.; IGI Global: Hershey, PA, USA, 2013; pp. 333–356. [Google Scholar]

- Biggio, L.; Kastanis, I. Prognostics and health management of industrial assets: Current progress and road ahead. Front. Artif. Intell. 2020, 3, 578613. [Google Scholar] [CrossRef]

- Miao, Y.; Jiang, Y.; Huang, J.; Zhang, X.; Han, L. Application of fault diagnosis of seawater hydraulic pump based on transfer learning. Shock. Vib. 2020, 1–8. [Google Scholar] [CrossRef]

- Baur, M.; Albertelli, P.; Monno, M. A review of prognostics and health management of machine tools. Int. J. Adv. Manuf. Technol. 2020, 107, 2843–2863. [Google Scholar] [CrossRef]

- Verhulst, T.; Judt, D.; Lawson, C.; Chung, Y.; Al-Tayawe, O.; Ward, G. Review for State-of-the-Art Health Monitoring Technologies on Airframe Fuel Pumps. Int. J. Progn. Health Manag. 2022, 13, 1–20. [Google Scholar] [CrossRef]

- Che, C.; Wang, H.; Fu, Q.; Ni, X. Combining multiple deep learning algorithms for prognostic and health management of aircraft. Aerosp. Sci. Technol. 2019, 94, 105423. [Google Scholar] [CrossRef]

- Hsu, T.H.; Chang, Y.J.; Hsu, H.K.; Chen, T.T.; Hwang, P.W. Predicting the remaining useful life of landing gear with prognostics and health management (PHM). Aerospace 2022, 9, 462. [Google Scholar] [CrossRef]

- Yan, H.; Zuo, H.; Tang, J.; Wang, R.; Ma, X. Predictive maintenance framework of the aircraft system based on PHM information. In Proceedings of the 2020 Asia-Pacific international symposium on advanced reliability and maintenance modeling (APARM), Vancouver, BC, Canada, 20–23 August 2020; pp. 1–6. [Google Scholar]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 8, 679–698. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Yang, Q.; Hu, X.; Yan, W. Deep learning-based linear defects detection system for large-scale photovoltaic plants based on an edge-cloud computing infrastructure. Sol. Energy 2022, 231, 527–535. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, T.; Yang, C.; Li, Q.; Peng, B.; Cheng, Q. Cloud-edge collaborative data processing architecture for state assessment of transmission equipments. In Proceedings of the 2022 7th International Conference on Intelligent Computing and Signal Processing (ICSP), Virtual, 15–17 April 2022; pp. 458–461. [Google Scholar]

- Erbao, X.; Yan, L.I.; Mingshun, Y.; Xi, C. Design of intelligent monitoring system for power distribution equipment based on cloud edge collaborative computing. In Proceedings of the 2019 International Conference on Precision Machining, Non-Traditional Machining and Intelligent Manufacturing (PNTIM 2019), Xi’an, China, 22–24 November 2019; Atlantis Press: Dordrecht, The Netherlands, 2019; pp. 10–13. [Google Scholar]

- Qiu, T.; Chi, J.; Zhou, X.; Ning, Z.; Atiquzzaman, M.; Wu, D.O. Edge computing in industrial internet of things: Architecture, advances and challenges. IEEE Commun. Surv. Tutor. 2020, 22, 2462–2488. [Google Scholar] [CrossRef]

- Li, D.; Yuan, D.; Zhang, H.; Zheng, A.; Di zijun, L.D. Research on intelligent tool fault diagnosis system of machine tools with cloud-edge-device collaboration. China Mech. Eng. 2023, 34, 584. [Google Scholar]

- Namigtle-Jiménez, A.; Escobar-Jiménez, R.F.; Gómez-Aguilar, J.F.; García-Beltrán, C.D.; Téllez-Anguiano, A.C. Online ANN-based fault diagnosis implementation using an FPGA: Application in the EFI system of a vehicle. ISA Trans. 2020, 100, 358–372. [Google Scholar] [CrossRef]

- Pecho, P.; Bugaj, M. Vibration fault detection of fuel pump using recurrence quantification analysis. Transp. Res. Procedia 2018, 35, 287–294. [Google Scholar] [CrossRef]

- Jiang, Y.; Miao, Y.; Qiu, Z.; Wang, Z.; Pan, J.; Yang, C. Intermittent fault detection and diagnosis for aircraft fuel system based on SVM. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2020), Online, 18–21 September 2020; pp. 1255–1258. [Google Scholar]

- Qiu, Z.; Miao, Y.; Hong, W.; Jiang, Y.; Liu, Y.; Pan, J.; Li, X. Fault diagnosis of aircraft fuel pump based on transfer learning. In Proceedings of the 2021 7th International Conference on Condition Monitoring of Machinery in Non-Stationary Operations (CMMNO), Guangzhou, China, 11–13 June 2021; pp. 171–175. [Google Scholar]

- Liu, Z.; Zhang, X.; Pan, J.; Zhang, X.; Hong, W.; Wang, Z.; Wang, Z.; Miao, Y. Similar or unknown fault mode detection of aircraft fuel pump using transfer learning with subdomain adaption. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Shi, L.; Yuan, Y.; Jiao, H.; Tang, F.; Cheng, L.; Yang, F.; Jin, Y.; Zhu, J. Numerical investigation and experiment on pressure pulsation characteristics in a full tubular pump. Renew. Energy 2021, 163, 987–1000. [Google Scholar] [CrossRef]

- Qian, Q.; Qin, Y.; Wang, Y.; Liu, F. A new deep transfer learning network based on convolutional auto-encoder for mechanical fault diagnosis. Measurement 2021, 178, 109352. [Google Scholar] [CrossRef]

| Time Domain Index | Sensitivity | Stability |

|---|---|---|

| Peak | Preferably | Common |

| Peak-to-peak | Common | Common |

| Mean | Worse | Preferably |

| Root-mean-square | Preferably | Preferably |

| Kurtosis factor | Well | Common |

| Waveform factor | Bad | Well |

| Margin factor | Well | Common |

| Skewness | Common | Worse |

| Pulse factor | Common | Common |

| Peak factor | Common | Common |

| Model | Accuracy | Precision | Recall | F1-Score |

|---|---|---|---|---|

| SVM | 76.70 ± 1.67 | 80.12 ± 1.39 | 76.70 ± 1.28 | 76.40 ± 1.20 |

| ELM | 78.40 ± 0.97 | 82.35 ± 0.71 | 78.40 ± 1.32 | 77.63 ± 1.25 |

| CNN | 89.65 ± 0.77 | 89.99 ± 0.96 | 89.65 ± 1.02 | 89.75 ± 0.86 |

| LSTM | 91.70 ± 1.04 | 92.69 ± 0.87 | 91.70 ± 2.06 | 91.45 ± 1.65 |

| CAE (proposed) | 96.05 ± 0.62 | 96.46 ± 0.63 | 96.05 ± 0.99 | 96.03 ± 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Y.; Li, Y.; Pan, J.; Liu, Z.; Liu, L.; Wang, Z.; Wang, Z. Bio-Inspired Fault Diagnosis for Aircraft Fuel Pumps Using a Cloud-Edge System. Biomimetics 2023, 8, 601. https://doi.org/10.3390/biomimetics8080601

Miao Y, Li Y, Pan J, Liu Z, Liu L, Wang Z, Wang Z. Bio-Inspired Fault Diagnosis for Aircraft Fuel Pumps Using a Cloud-Edge System. Biomimetics. 2023; 8(8):601. https://doi.org/10.3390/biomimetics8080601

Chicago/Turabian StyleMiao, Yang, Yantang Li, Jun Pan, Zhen Liu, Lei Liu, Zeng Wang, and Zijing Wang. 2023. "Bio-Inspired Fault Diagnosis for Aircraft Fuel Pumps Using a Cloud-Edge System" Biomimetics 8, no. 8: 601. https://doi.org/10.3390/biomimetics8080601

APA StyleMiao, Y., Li, Y., Pan, J., Liu, Z., Liu, L., Wang, Z., & Wang, Z. (2023). Bio-Inspired Fault Diagnosis for Aircraft Fuel Pumps Using a Cloud-Edge System. Biomimetics, 8(8), 601. https://doi.org/10.3390/biomimetics8080601