Research on Impact Resistance of Aluminum Alloy New Rotating Thin-Walled Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Theoretical Analysis

2.1.1. Young’s Modulus

2.1.2. Critical Speed

2.2. Experiments

Quasi-Static Compression Experiment

2.3. Numerical Modelling

2.3.1. Establishment of Finite Element Modelling

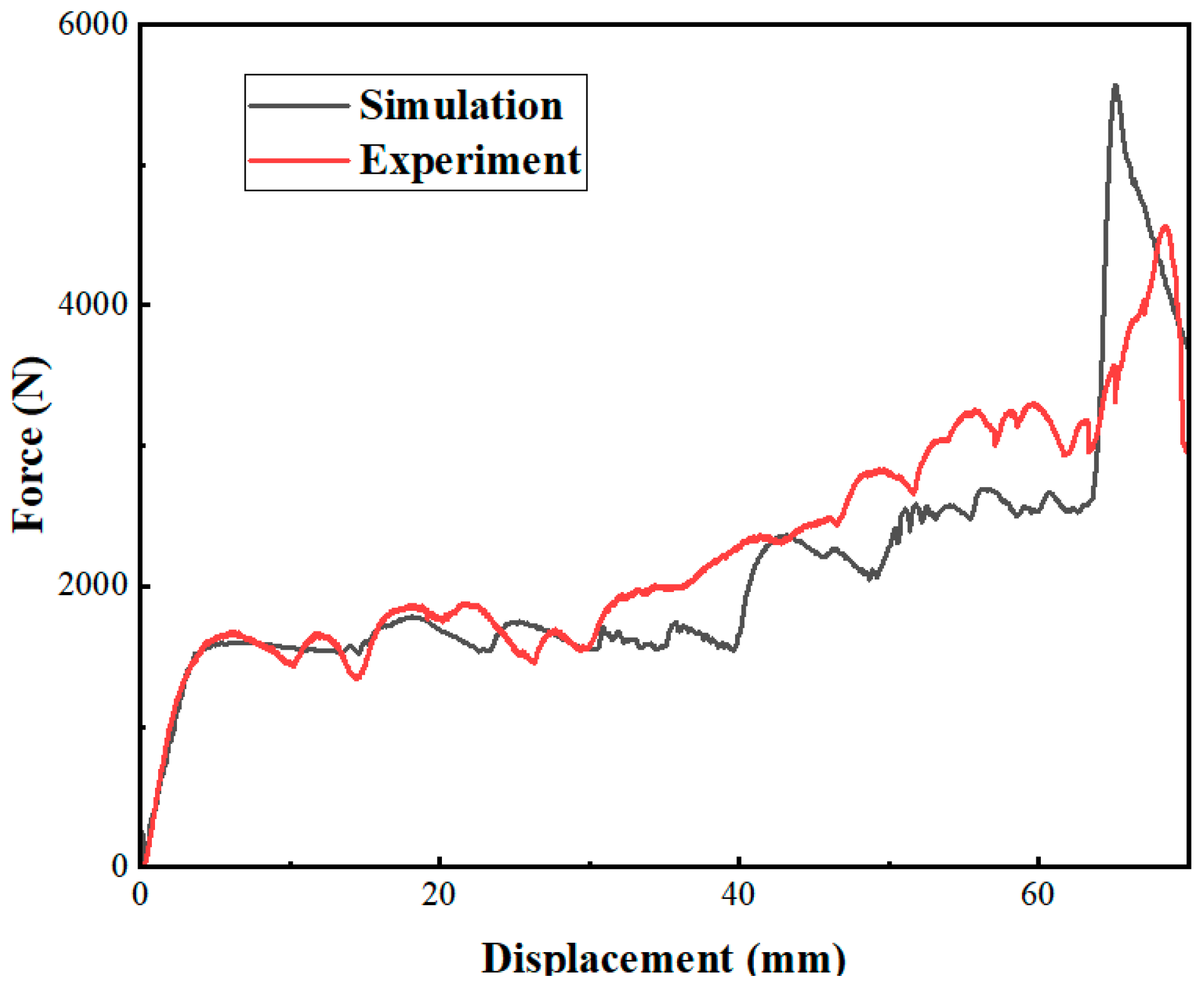

2.3.2. Validation of the Finite Element Model

3. Results and Discussion

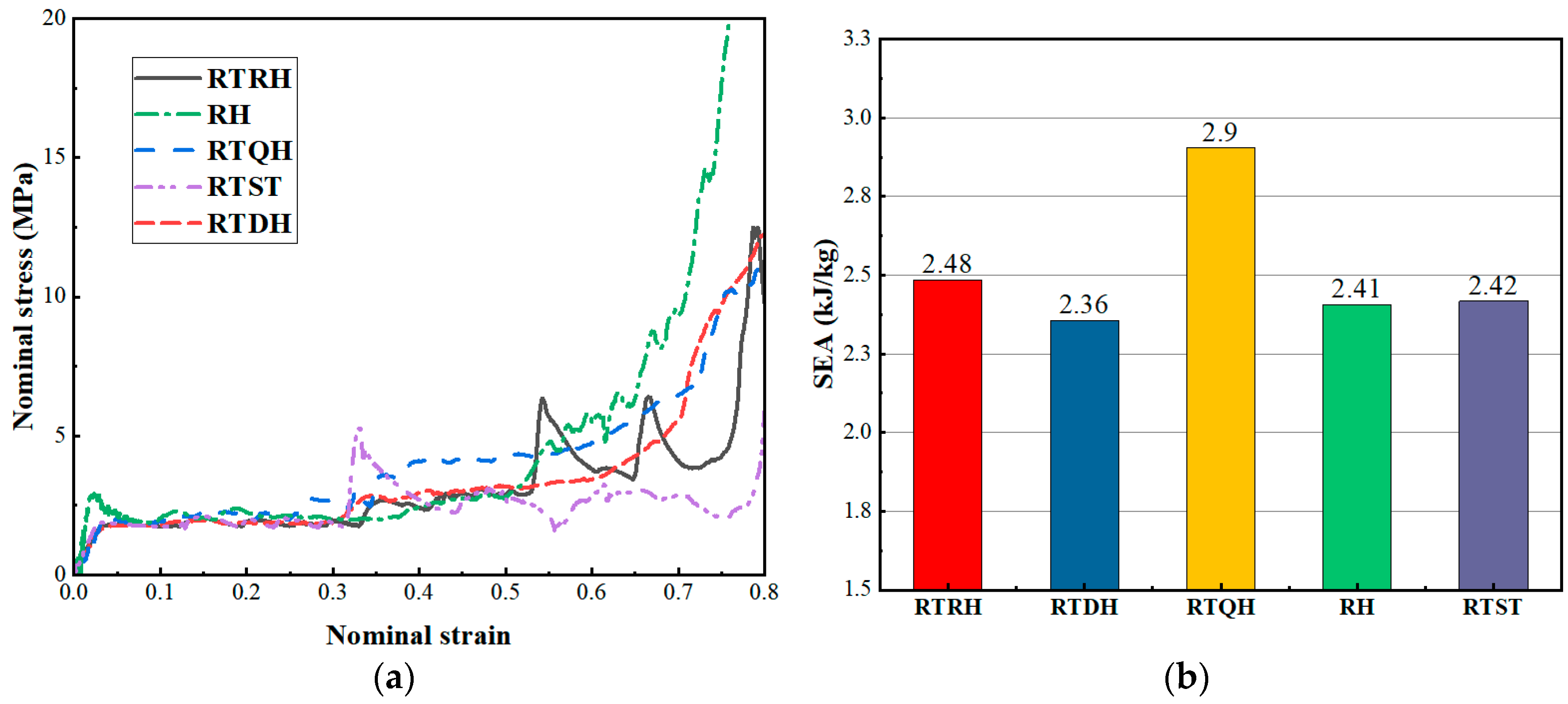

3.1. Energy Absorption Properties of Honeycomb Structures

3.2. Deformation Patterns of Honeycomb Structures at Different Velocities

3.3. Impact of Parametric Analysis and Gradient Optimisation

3.3.1. Effect of Different Rotation Angles

3.3.2. Cell Gradient Optimisation

3.3.3. Thickness Gradient Optimisation

4. Conclusions

- In this paper, finite element models of three NRTS structures were designed. Then, samples of RTRH were fabricated through 3D printing. In this study, the stress-strain curves of RTRH in quasi-static compression experiment and finite element simulation were compared. The error between the experimental and finite element simulation results was found to be 6.6%. This proves that the finite element model developed in this paper can effectively simulate real working conditions. These findings provide a reference for the design of honeycomb structures.

- Compared to the RH and RTST structures, the NRTS structure was shown to have a good energy absorption capacity. In low-velocity impact, the RTQH and RTRH structures demonstrate higher plateau stresses. Compared to the RH structure, the RTQH and RTRH increased by 78% and 124%, respectively. When compared to the RTST structure, the increases are 20% and 51%, respectively. Compared to the RH and RTST structures, the RTQH structure shows an increase in energy absorption by 21% and 20%, respectively. The RTDH structure exhibits an excellent CEF, which is 54% and 57% higher compared to the RH and RTST structures, respectively. The RTQH and RTRH structures have the highest plateau stresses at medium-speed and high-speed impacts, respectively.

- For the RTRH structure, different rotation angles have a significant effect on the deformation pattern and energy absorption capacity. The RTRH structure has excellent energy absorption at a rotation angle of 20° for low- and medium-speed impacts, and even better energy absorption at a rotation angle of 40° for high-speed impacts. In the case of the RTDH and RTQH structures, the rotation angle does not affect the deformation pattern. The effect of different rotation angles on the energy absorption performance is less significant at low- and medium-impact speeds, whereas for high speed impacts, the RTDH-40°and RTQH-30° have better energy absorption.

- At low-impact velocities, the gradient structures are not significantly different from each other, but the specific absorption energies are all slightly higher than those of the uniform gradient structures. As the impact speed increases, the differences between the gradients gradually appear and expand. Among them, the B-A-C structure, the positive mixed thickness gradient (0.8 mm–1.2 mm–1 mm), the negative thickness gradient (1.2 mm–1 mm–0.8 mm), and the negative mixed thickness gradient (1.2 mm–0.8 mm–1 mm) all further increase the energy absorption capacity of the NTRS structure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, Y.C.; Zhou, G.M.; Cai, D.A. In-plane compression properties of 3D printed circular reinforced honeycombs with continuous carbon fibers. Acta Mater. Compos. Sin. 2023, 1–13. [Google Scholar]

- Yang, Y.; Liu, H.; Zhang, Q.; Ma, J.; Yang, X.; Yang, J. Energy absorption characteristics of a super hexagonal honeycomb under out-of-plane crushing. Thin-Walled Struct. 2023, 189, 110914. [Google Scholar] [CrossRef]

- Yin, Q.F.; Zhang, Y.Q.; Zhang, L.; Chen, J.; Zhang, J. Analysis of heat transfer and thermal ablation of honeycomb sandwich composite structure under laser irradiation. High Power Laser Part. Beams 2023, 35, 081005-1–081005-8. [Google Scholar]

- Chen, Y.Q.; Chou, K.; Li, X. Acoustic-vibration characteristics of quasi-square honeycomb sandwich structure. J. Wuhan Univ. Sci. Technol. 2023, 46, 311–320. [Google Scholar]

- Wang, W.J.; Zhang, W.M.; Guo, M.F.; Yang, J.S.; Ma, L. Energy absorption characteristics of a lightweight auxetic honeycomb under low-velocity impact loading. Thin-Walled Struct. 2023, 185, 110577. [Google Scholar] [CrossRef]

- Morin-Martinez, A.A.; Arcudia, J.; Zarate, X.; Cifuentes-Quintal, M.E.; Merino, G. The quest for a bidirectional auxetic, elastic, and enhanced fracture toughness material: Revisiting the mechanical properties of the BeH2 monolayers. J. Comput. Chem. 2023, 44, 248–255. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, B.L.; Wang, K.F.; Zheng, L. Improving thermomechanical properties of cracked brittle honeycombs by negative Poisson’s ratio effect. Compos. Struct. 2021, 266, 113825. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Ma, D.W.; Ren, J. Ballistic performance of double—Arrow negative Poisson’s ratio structure. J. Natl. Univ. Def. Technol. 2023, 45, 197–207. [Google Scholar]

- Du, Y.; Li, H.; Luo, Z.; Tian, Q. Topological design optimization of lattice structures to maximize shear stiffness. Adv. Eng. Softw. 2017, 112, 211–221. [Google Scholar] [CrossRef]

- Zhong, R.; Ren, X.; Zhang, X.Y.; Luo, C.; Zhang, Y.; Xie, Y.M. Mechanical properties of concrete composites with auxetic single and layered honeycomb structures. Constr. Build. Mater. 2022, 322, 126453. [Google Scholar] [CrossRef]

- Sun, P.; Guo, H.; Jin, F.; Zhang, Z.; Liu, N.; Yuan, T.; Ma, L.; Wang, Y. Mechanics and extreme low-frequency band gaps of auxetic hexachiral acoustic metamaterial with internal resonant unit. Appl. Acoust. 2022, 200, 109046. [Google Scholar] [CrossRef]

- Pan, K.; Zhang, W.; Ding, J. Negative Poisson’s Ratio Re-Entrant Base Modeling and Vibration Isolation Performance Analysis. Symmetry 2022, 14, 1356. [Google Scholar] [CrossRef]

- Evans, E.K.; Alderson, A. Auxetic materials: Functional materials and structures from lateral thinking. Adv. Mater. 2000, 9, 617–628. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Auxetic materials and their potential applications in textiles. Text. Res. J. 2014, 84, 1600–1611. [Google Scholar] [CrossRef]

- Liu, J.Y.; Liu, H.T.; An, M.R. Crushing behaviors of novel Diabolo shaped honeycombs with enhanced energy absorption performance. Int. J. Mech. Sci. 2022, 229, 107492. [Google Scholar] [CrossRef]

- Ma, F.W.; Wang, Q.; Liang, H.Y.; Pu, Y. Multi-objective Optimization of Crash Box Filled with Gradient Negative Poisson’s Ratio Structure under Multiple Conditions. Automot. Eng. 2021, 43, 754–761+769. [Google Scholar]

- Gao, Y.K. Auxetic metamaterials and structures. J. Mater. Eng. 2021, 49, 38–47. [Google Scholar]

- Gomes, R.A.; de Oliveira, L.A.; Francisco, M.B.; Gomes, G.F. Tubular auxetic structures: A review. Thin-Walled Struct. 2023, 188, 110850. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Z.; Cao, X.; Liu, J.; Huang, W.; Wang, Y. The compressive responses and failure behaviors of composite graded auxetic re-entrant honeycomb structure. Thin-Walled Struct. 2023, 187, 110721. [Google Scholar] [CrossRef]

- Wang, T.; Li, M.; Qin, D.; Chen, J.; Wu, H. In-plane impact performance of concave I-shaped honeycomb structure. J. Plast. Eng. 2022, 29, 183–192. [Google Scholar]

- Luo, H.W.; He, W.Q.; Wu, W.J.; Li, S.Q.; Wang, Z.J. Deformation behavior of curved structures with negative Poisson’s ratio at diverse velocities. Explos. Shock Waves 2023, 1–15. [Google Scholar]

- Grima, J.N.; Evans, K.E. Auxetic behavior from rotating squares. J. Mater. Sci. Lett. 2000, 19, 1563–1565. [Google Scholar] [CrossRef]

- Meena, K.; Singamneni, S. A new auxetic structure with significantly reduced stress concentration effects. Mater. Des. 2019, 173, 107779. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, G.P.; Hui, X.L.; He, H. Mechanical performance of negative poisson’s ratio structures based on rotating concave hexagon. J. Mech. Strength 2023, 45, 124–130. [Google Scholar]

- Lulu, W.E.; Qiang, Y.U.; Xuan, Z.H. In-plane dynamic crushing characteristics of re-entrant anti-trichiral honeycomb. J. Vib. Shock 2021, 40, 261–269. [Google Scholar]

- Li, K.; Zhang, Y.; Hou, Y.; Su, L.; Zeng, G.; Xu, X. Mechanical properties of re-entrant anti-chiral auxetic metamaterial under the in-plane compression. Thin-Walled Struct. 2023, 184, 110465. [Google Scholar] [CrossRef]

- Shen, W.J.; Ye, L.H.; Tian, F.W. Design of a new negative Poisson’s ratio energy-absorbing dot structure. In Proceedings of the 29th Annual Conference of the Beijing Mechanics Society, Beijing, China, 8 April 2023; Volume 2. [Google Scholar]

- Sun, F.; Liu, M.; Wang, B.; Yang, N.; Wang, J.; Cai, K.; Liu, Z. Properties of 3D Double-Arrow Negative Poisson’sRatio Lattice Structure under Quasi-Static Compression and Low-Speed Impact. Adv. Mater. Sci. Eng. 2022, 2022, 3726964. [Google Scholar] [CrossRef]

- Guo, R.Z.; Xue, B.; Xie, L.; Liang, Y. Oxygen-free Ageing Mechanism of 3D Printed Nylon 1212. China Plast. Ind. 2023, 51, 115–121. [Google Scholar]

- Mizzi, L.; Grasselli, L.; Spaggiari, A.; Gatt, R.; Farrugia, P.S.; Grima, J.N. Design of isotropic 2D chiral metamaterials based on monohedral pentagonal tessellations. Thin-Walled Struct. 2023, 187, 110739. [Google Scholar] [CrossRef]

- Luo, G.; Chai, C.; Chen, Y.; Li, L.; Xue, P. Investigations on the quasi-static/dynamic mechanical properties of 3D printed random honeycombs under in-plane compression. Thin-Walled Struct. 2023, 190, 110931. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Rama Sreekanth, P.S. Evaluation of Cell Parameter Variation on Energy Absorption Characteristic of Thermoplastic Honeycomb Sandwich Structure. Arab. J. Sci. Eng. 2021, 46, 12487–12507. [Google Scholar] [CrossRef]

- Yan, C.M.; Xue, C.P.; Tian, G.Y.; Yang, Z.H.; Liu, X.G.; Wang, J.S. Review of the stereolithographic 3D printing of metals. Chin. J. Eng. 2023, 1–13. [Google Scholar]

- Kumar, S.S.; Rama, S.P.S.; Kota, V.S.R. A Brief Review on Advanced Sandwich Structures with Customized Design Core and Composite Face Sheet. Polymers 2022, 14, 4267. [Google Scholar]

- Liu, B.; Xu, X.G. Experimental and numerical study on crashworthiness of bionic hedgehog spine thin-walled structures. Thin-Walled Struct. 2023, 189, 110892. [Google Scholar] [CrossRef]

- Jerzy, B.; Tomasz, K.; Jarosław, Z. The Mechanical Properties of Direct Metal Laser Sintered Thin-Walled Maraging Steel (MS1) Elements. Materials 2023, 16, 4699. [Google Scholar]

- Wang, Y.; Xu, S.; Yang, X.; Huang, B.; Song, J.; Li, S. Design and numerical study of bionic sandwich panel based on a shrimp chela structure. J. Jilin Univ. 2023, 1–9. [Google Scholar]

- Zhu, C.X.; Xu, S.X.; Chen, W.; Li, X.B.; Yue, J.X. Researchon Impact Energy Absorption Characteristics of Negative Poisson’s Ration Concentric Honeycomb Structures with Curved Concaves Sides. J. Wuhan Univ. Technol. 2023, 47, 90–95. [Google Scholar]

- You, Z.H.; Xiao, J.H. Numerical Study on In-plane Impact Dynamics of Concave Honeycomb Structure with Negative Poisson’s Ratio. Eng. Mech. 2022, 39, 248–256. [Google Scholar]

- Hönig, A.; Stronge, W. In-plane dynamic crushing of honeycomb. Part I: Crush band initiation and wave trapping. Int. J. Mech. Sci. 2002, 44, 1696. [Google Scholar] [CrossRef]

- Zou, Z.; Reid, S.R.; Tan, P.J.; Li, S.; Harrigan, J.J. Dynamic crushing of honeycombs and features of shock fronts. Int. J. Impact Eng. 2007, 36, 165–176. [Google Scholar] [CrossRef]

- Qiu, X.M.; Zhang, J.; Yu, T.X. Collapse of periodic planar lattices under uniaxial compression, part II: Dynamic crushing based on finite element simulation. Int. J. Impact Eng. 2009, 36, 1231–1241. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, F.Z. Research Progress of 3D Printing Materials. Ind. Technol. 2023, 10, 55–63. [Google Scholar]

- Zhao, L.; Liu, P.; Zheng, J.C.; Du, Y.; Zhao, Y.N.; Ke, F.X. Exploration of Metal 3D Printing Technologies and Applications. Automob. Technol. Mater. 2023, 1–8+15. [Google Scholar]

- Sun, G.; Huo, X.; Chen, D.; Li, Q. Experimental and numerical study on honeycomb sandwich panels under bending and in-panel compression. Mater. Des. 2017, 133, 154–168. [Google Scholar] [CrossRef]

- Amaro, A.M.; Neto, M.A.; Cirne, J.S.; Reis, P.N. Mechanical Characterization of Different Aluminium Foams at High Strain Rates. Materials 2019, 12, 1428. [Google Scholar] [CrossRef]

- Amaro, M.A.; Neto, A.M.; Reis, N.B.P. Mechanical characterization of AlSi12 foams at high strain rates. Mater. Des. Process. Commun. 2019, 1, e55. [Google Scholar] [CrossRef]

- Su, B.Y.; Huang, C.M.; Sheng, H.; Jang, W.Y. The effect of cell-size dispersity on the mechanical properties of closed-cell aluminum foam. Mater. Charact. 2017, 135, 203–213. [Google Scholar] [CrossRef]

- Warminski, J.; Jaroslaw, L. Saturation control for a rotating thin-walled composite beam structure. Procedia Eng. 2016, 144, 713–720. [Google Scholar] [CrossRef]

- Najafi, M.; Reza, E.F. Design and characterization of a multilayered hybrid cored-sandwich panel stiffened by thin-walled lattice structure. Thin-Walled Struct. 2021, 161, 107514. [Google Scholar] [CrossRef]

- Maher, R.; Mohammad, R.K.; Reza, E.F. Experimental analysis of corrugated core sandwich panel with smart composite face-sheets under high-velocity impact. J. Compos. Mater. 2022, 56, 1495–1511. [Google Scholar] [CrossRef]

- Ding, C.; Zhou, X.D.; Qi, C.; Zheng, C.; Jiang, F.; Yang, S. Neural Network Prediction Method for Dynamic Crushing Plateau Stress of Circular Double Arrowed Honeycomb. Eng. Mech. 2023, 40, 1–10. [Google Scholar]

- Gong, C.; Bai, Z.; Lv, J.; Zhang, L. Crashworthiness analysis of bionic thin-walled tubes inspired by the evolution laws of plant stems. Thin-Walled Struct. 2020, 157, 107081. [Google Scholar] [CrossRef]

- Manes, A.N.; Peroni, L.; Scapin, M.; Giglio, M.A. Analysis of strain rate behavior of an Al 6061 T6 alloy. Procedia Eng. 2011, 10, 3477–3482. [Google Scholar] [CrossRef]

- An, M.R. Research on Design and Energy Absorption Characteristic of New Multilayer Gradient Structure with Negative Poisson’s Ratio; Hebei University of Technology: Tianjin, China, 2022. [Google Scholar]

- Li, C.B.; Zhang, J.T.; Ye, Q.; Li, R.; Li, R.F.; Yang, L.Y. Impact response characteristics of composite honeycomb structures. J. Plast. Eng. 2023, 30, 195–203. [Google Scholar]

- Xu, F.X.; Jian, Y.J.; Zou, Z.; Liu, Y.X.; Wu, L.; Tu, F. Research on in-plane impact performance for negative Poisson’s ratio honeycomb structure with square function curved edge. Forg. Stamp. Technol. 2022, 47, 212–220. [Google Scholar]

- Jin, Z.H.; Liu, Q.Y.; Ma, W.C.; Meng, J.H. Design of Anti-Impact Structure with Novel star-Shaped Negative Poisson’s Ratio and Research on Water Impact. Acta Armamentarii 2023, 1–18. [Google Scholar]

- Zhang, X.C.; Liu, Y. Research on the dynamic crushing of honeycombs with density gradient. Eng. Mech. 2012, 29, 372–377. [Google Scholar]

| Honeycomb Structure Name | |

|---|---|

| RTRH | |

| RTDH | |

| RTQH | |

| RH | |

| RTST |

| Honeycomb Structure Name | l (mm) | h (mm) | a (mm) | θ1 (°) | m (kg) | θ2 (°) | t (mm) | d (mm) |

|---|---|---|---|---|---|---|---|---|

| RTRH | 14.61 | 14.61 | 4.23 | 60 | 0.124 | 30 | 1 | 20 |

| RTDH | 14.61 | 14.61 | 4.23 | 0.127 | 30 | 1 | 20 | |

| RTQH | 3.03 | 0.128 | 30 | 1 | 20 | |||

| RH | 15.77 | 20 | 60 | 0.170 | 1 | 20 | ||

| RTST | 14.61 | 14.61 | 0.115 | 30 | 1 | 20 |

| Honeycomb Structure Name | |||||

|---|---|---|---|---|---|

| RTRH | 0.03 | 0.33 | 0.356 | 0.72 | 5.52 |

| RTDH | 0.04 | 0.3 | 0.344 | 0.6 | 4.94 |

| RTQH | 0.045 | 0.34 | 0.3575 | 0.72 | 6.95 |

| RH | 0.018 | 0.68 | 3.1 | ||

| RTST | 0.035 | 0.31 | 0.33 | 0.78 | 4.6 |

| Structure | RTDH-20° | RTDH-30° | RTDH-40° | |

|---|---|---|---|---|

| Velocity | ||||

| 1 m/s | 2.95 | 3.08 | 2.97 | |

| 30 m/s | 3.49 | 3.48 | 3.37 | |

| 100 m/s | 10.62 | 11.22 | 11.56 | |

| Structure | RTQH-20° | RTQH-30° | RTQH-40° | |

|---|---|---|---|---|

| Velocity | ||||

| 1 m/s | 3.69 | 3.82 | 3.69 | |

| 30 m/s | 4.22 | 4.33 | 4.21 | |

| 100 m/s | 10.96 | 11.88 | 11.10 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.-C.; Chen, N.; Qin, H.-Y.; Wang, R.-X.; Yang, X.; Song, J.-F. Research on Impact Resistance of Aluminum Alloy New Rotating Thin-Walled Structures. Biomimetics 2023, 8, 590. https://doi.org/10.3390/biomimetics8080590

Xu S-C, Chen N, Qin H-Y, Wang R-X, Yang X, Song J-F. Research on Impact Resistance of Aluminum Alloy New Rotating Thin-Walled Structures. Biomimetics. 2023; 8(8):590. https://doi.org/10.3390/biomimetics8080590

Chicago/Turabian StyleXu, Shu-Cai, Nuo Chen, Hao-Yi Qin, Rui-Xiang Wang, Xin Yang, and Jia-Feng Song. 2023. "Research on Impact Resistance of Aluminum Alloy New Rotating Thin-Walled Structures" Biomimetics 8, no. 8: 590. https://doi.org/10.3390/biomimetics8080590

APA StyleXu, S.-C., Chen, N., Qin, H.-Y., Wang, R.-X., Yang, X., & Song, J.-F. (2023). Research on Impact Resistance of Aluminum Alloy New Rotating Thin-Walled Structures. Biomimetics, 8(8), 590. https://doi.org/10.3390/biomimetics8080590