Abstract

The permutation flow shop scheduling problem (PFSP) stands as a classic conundrum within the realm of combinatorial optimization, serving as a prevalent organizational structure in authentic production settings. Given that conventional scheduling approaches fall short of effectively addressing the intricate and ever-shifting production landscape of PFSP, this study proposes an end-to-end deep reinforcement learning methodology with the objective of minimizing the maximum completion time. To tackle PFSP, we initially model it as a Markov decision process, delineating pertinent states, actions, and reward functions. A notably innovative facet of our approach involves leveraging disjunctive graphs to represent PFSP state information. To glean the intrinsic topological data embedded within the disjunctive graph’s underpinning, we architect a policy network based on a graph isomorphism network, subsequently trained through proximal policy optimization. Our devised methodology is compared with six baseline methods on randomly generated instances and the Taillard benchmark, respectively. The experimental results unequivocally underscore the superiority of our proposed approach in terms of and computation time. Notably, the can save up to 183.2 h in randomly generated instances and 188.4 h in the Taillard benchmark. The calculation time can be reduced by up to 18.70 s for randomly generated instances and up to 18.16 s for the Taillard benchmark.

1. Introduction

The Job-Shop Scheduling Problem (JSSP) stands as a renowned combinatorial optimization challenge within the realms of computer science and operations research, finding widespread application across industries such as manufacturing and transportation [1,2]. Workshop scheduling, through judicious allocation of pending tasks within a designated timeframe, facilitates optimal resource utilization, thereby aiding enterprises in mitigating excessive investments in raw materials, energy, and productivity. Moreover, the application of various algorithms has led to a reduction in the practical application costs associated with workshop scheduling, garnering substantial attention from scholars [3], engineering professionals [4], and manufacturers [5]. Notably, permutation flow shop workshops, emblematic of a prototypical workshop configuration, find extensive prevalence in manufacturing and large-scale product fabrication. [6,7,8]. In PFSP, there are jobs , each of which consists of a sequence of processes. There are machines , is the ith process of Job , and each process can only be performed by . Moreover, the execution of any process cannot be interrupted nor preempted, and job delivery is not allowed. That is, the jobs must be executed in the same order on each machine. Furthermore, the PFSP has been established as an NP-hard conundrum [9], implying its intractability in yielding optimal solutions within polynomial time. Hence, the pursuit of judicious algorithmic design, generating high-quality solutions within acceptable timeframes for practical scenarios, assumes significant research import. Presently, the dominant methodologies for addressing this domain encompass exact algorithms [10], heuristic algorithms [11], metaheuristic algorithms [12,13], and deep reinforcement learning (DRL) algorithms [14]. Nevertheless, the existing mainstream approaches fall short of striking an optimal balance between solution quality and computational time. In light of this, we proffer an innovative end-to-end model based on DRL to effectively tackle this intricate predicament.

The PFSP, renowned as a challenging NP-hard endeavor, has yielded prolific research outcomes [15,16,17]. However, as production scales expand, exact algorithms such as integer programming models and branch-and-bound techniques struggle to provide timely resolutions for large-scale manufacturing quandaries. Over the past decades of inquiry, endeavors have been directed towards expeditiously deriving scheduling solutions through heuristic approaches. In the realm of heuristic methodologies targeting the optimization of maximum completion time for addressing PFSP, NEH has emerged as a paragon of efficiency [18,19], commanding the admiration of heuristic-minded scholars. In this context, Christos Koulamas [20] introduced a facile constructive heuristic algorithm aimed at the objective of maximum completion time, adeptly generating non-permutative schedules where advantageous, and demonstrating superior performance to the NEH algorithm in addressing the flow shop scheduling challenge. Zheng and Wang [21], in a fusion of the NEH heuristic with genetic algorithms, advanced an effective hybrid heuristic for the flow shop scheduling issue, substantiating its efficacy through empirical validation. Nagano et al. [22] introduced an N&M algorithm that penalizes the priority of NEH jobs based on the lower bound of job waiting times, thus reshuffling the initial sequence. Empirical findings underscore that the N&M algorithm secures superior outcomes to the NEH algorithm without escalating computational complexity. For the minimization of total tardiness in the context of flow shop scheduling, Fernandez-Viagas and Framinan [23] harnessed an NEH-based heuristic to unravel the quandary. Delving into decision problems contingent on job due dates, they delineated parallels with various associated decision challenges. Kalczynski et al. [24] propounded novel priority sequencing and coupled it with an uncomplicated disruption rule, resulting in a methodology that outperforms the NEH algorithm across all problem scales. In a bid to minimize total flow time in DPFSP, Pan et al. [25] extended the utility of NEH and LR through the introduction of three heuristic approaches, DNEH, DLR, and DLR-DNEH, effectively broadening the scope of the NEH application to alternative problem formulations and objectives.

Traditional heuristic methods are confined to addressing smaller-scale flow shop scheduling quandaries. Subsequently, to enhance computational efficiency and refine outcomes, numerous scholars have harnessed metaheuristic algorithms for tackling a diverse array of large-scale scheduling challenges. Leveraging their robust global search capabilities and relatively acceptable solution speeds, metaheuristic algorithms find application across both static and dynamic problem domains [26,27,28], emerging as the most prolific category in contemporary workshop scheduling research. In 2013, Ceberio et al. [29] proposed a hybrid approach consisting of a new estimation of the distribution algorithm and a variable neighborhood search. Conducted experiments demonstrate that the proposed hybrid approach obtains new best-known results in 152 cases. In 2015, Sayoti and Essaid Ri [30] introduced the Gold Ball Algorithm, a metaheuristic approach founded on football-inspired concepts for resolving flow shop scheduling problems. In 2016, Santucci et al. [31] proposed a new discrete Differential Evolution algorithm for the Permutation Flowshop Scheduling Problem with the total flowtime and criteria. The core of the algorithm is a distance-based differential mutation operator defined by means of a new randomized bubble sort algorithm. In 2017, Dubois-Lacoste et al. [32] proposed the utilization of local search techniques to enhance the partial solutions derived from iterated greedy algorithms, applying this framework to the PFSP while aiming to minimize the maximum completion time. Empirical findings substantiated the advantageous nature of reoptimizing partial solutions. In 2018, Baioletti et al. [33] introduced a decomposition-based algebraic evolutionary algorithm for multi-objective permutation-based problems (MOEA/DEP). In order to mitigate the diversity loss during the evolution, MOEA/DEP introduces some additional components and variants. In 2020, Kaya et al. [34] formulated and compared five distinct methods for generating initial populations, employing a hybrid firefly-particle swarm optimization algorithm to evaluate the effects of various initial populations in tackling intricate flow shop scheduling dilemmas. In 2022, Li et al. [35] introduced an improved simulated annealing algorithm grounded in solution space pruning to address large-scale PFSP, concurrently presenting a hybrid release strategy based on the Palmer algorithm.

Given the fixed structure of heuristic and metaheuristic algorithms, the search performance encounters certain limitations. Many researchers have endeavored to harness machine learning algorithms for solving scheduling predicaments, owing to their potent learning capabilities that autonomously seek optimal solutions. DRL, a subset of machine learning, showcases robustness by eschewing the need for prior knowledge or fixed models. It attains experiential knowledge through interactions with the environment, thereby autonomously acquiring adept solutions, rendering the pursuit of optimal solutions more intellectually adept. Scholars, commencing in 2018, have embarked on infusing DRL into the arena of workshop scheduling. Pan et al. [36] employed a DRL paradigm rooted in policy gradients (PG), utilizing classical pointer networks as actors and multi-head attention networks as critics, underpinned by immediate rewards corresponding to completion times. Ingimundardottir et al. [37] introduced an imitation learning algorithm to acquire scheduling rules. However, due to the elevated time complexity inherent in workshop scheduling dilemmas, obtaining a multitude of optimal solutions for training purposes on large-scale problems proves impractical, thus constraining the method’s applicability. Lin [38] proposed a Deep Q-Networks (DQN)-based algorithm for addressing workshop scheduling, with the action space represented as a set of priority dispatching rules. At each state, the agent selects a rule. Yang et al. [39] established a mathematical model for dynamic PFSP utilizing DRL, extracting five distinct features as the state space and deploying the A2C algorithm to train a network in selecting appropriate heuristic rules. This, in essence, achieves a metaheuristic approach. Han and Yang [40] delved into the extraction of processing state information using convolutional neural networks and employed D3QN to train Q-values for diverse heuristic rules across distinct states. Despite the substantial achievements attained through the application of DRL to workshop scheduling, research specifically addressing PFSP using DRL methodologies remains comparatively limited.

Following substantial interactions with the environment, DRL models achieve the capability for iterative decision-making, accompanied by commendable generalization prowess. In comparison with heuristic and metaheuristic algorithms, the beauty of DRL lies in its capacity to resolve problems of all magnitudes through a single training iteration, obviating the need for recurrent training necessitated by varying problem scales [41]. Presently, DRL algorithms have progressively ascended as the mainstream approach to tackling combinatorial optimization quandaries. Indicative of this shift, certain investigations applying DRL to combinatorial optimization underscore the surpassing of metaheuristic algorithmic outcomes in certain domains [42]. However, existing endeavors employing DRL for resolving the PFSP remain beset by certain concerns. Foremost, it is very important to define the permutation flow shop scheduling system as the state in the Markov decision process (MDP). Nonetheless, prevalent approaches predominantly adopt mathematical models for state representation, inadvertently omitting a comprehensive and rational encapsulation of the scheduling environment’s entirety. Furthermore, the efficacy of information extraction from current states directly influences the training process of learning algorithms. Regrettably, the conventional feedforward neural networks, extensively favored in extant research, prove inadequate in efficiently extracting state information. In addition, existing research largely relies on DQN to train policy networks [43]. However, it is noteworthy that DQN does not inherently optimize policies, thereby potentially introducing instability or protracted convergence periods into the training dynamics.

To address the aforementioned quandaries, we present an end-to-end DRL approach to solve the PFSP. In pursuit of a more comprehensive portrayal of PFSP scheduling states, we ingeniously employ disjunctive graphs to represent the intricate tapestry of the PFSP scheduling landscape. To harness the wealth of information implicit in the underlying topological structure of these disjunctive graphs, we craft a policy network based on graph isomorphism network (GIN) for embedding and training it using the proximal policy optimization (PPO). In this construct, the policy network initially leverages a graph encoder to embed the multifaceted information contained in the disjunctive graph. Thereafter, an action selection network furnishes the agent with the optimal action through a probability distribution over available actions. We subjected our methodology to rigorous comparison with six baseline methods. Empirical findings consistently underscore the superior performance of our model in terms of both completion time and computational efficiency. Furthermore, even when confronting larger-scale instances, our model elegantly demonstrates robust generalization capabilities. This endeavor yields a manifold contribution, encapsulated as follows:

- (1).

- A MDP model has been established for PFSP, elaborating in detail the construction of state space, action space, and reward scheme. Furthermore, an innovative application of disjunctive graphs encapsulates the state intricacies inherent in the scheduling domain.

- (2).

- To more effectively extract information embedded within the graphical state structures, a policy network grounded in GIN has been introduced. Internally, this policy network employs a graph encoder to articulate the state representation, subsequently guiding decision-making based on the encoded state. The efficacy of this network has been validated through the resolution of diverse-scale instances.

- (3).

- A novel end-to-end DRL paradigm has been advanced to address PFSP, surmounting the historical limitations in terms of generalization capacity. This model transcends prior constraints, enabling the resolution of problems of arbitrary dimensions after a single training iteration.

The remaining sections of the study are presented as follows: Section 2 provides a mathematical exposition of the PFSP and an introduction to the techniques employed. In Section 3, our research methodology is expounded, encompassing the establishment of the MDP model and the formulation of the policy network. Section 4 delineates the experimental protocol and engages in a comprehensive discourse on the findings. Lastly, Section 5 furnishes our conclusions, highlights the study’s limitations, and illuminates avenues for future exploration.

2. Problem Background

2.1. The Description of PFSP

This study delves into the PFSP, wherein a set of n jobs undergo processing across m machines through a sequence of processes . The essence of this study revolves around orchestrating an optimal arrangement where all jobs are processed on each machine in a uniform sequence. Assuming that the jobs are processed in the order of machines 1 to m, let the job processing sequence be denoted by . Our focus, in this discourse, centers on the minimization of the maximal processing time, serving as the bedrock of our scheduling objective. Within this context, the ensuing assumptions are set forth:

- (1).

- A job can be processed on only one machine at any given moment;

- (2).

- Jobs are independent and arrive at time zero without any disturbances during production;

- (3).

- Once a job is initiated on a machine, it proceeds without interruption;

- (4).

- Setup and transportation times between processes are encompassed within the processing duration;

- (5).

- Each job is processed exactly once on each machine;

- (6).

- The processing durations for all jobs on all machines are known in advance.

2.2. Disjunctive Graph

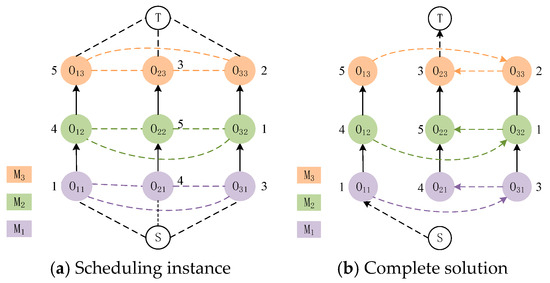

The disjunctive graph [44] consists of three components: vertices, connecting arcs, and disjunctive arcs. In order to provide a more comprehensive and coherent representation of the scheduling state for the permutation flow shop, we introduce the disjunctive graph to depict the scheduling process of the permutation flow shop. The disjunctive graph stores data in the form of a graph structure, where represents the set of nodes, with each node denoting a production process. is a set of directed edges represented by solid lines, referred to as connecting arcs. The direction of each edge signifies the sequential constraint between processes of the same job. represents a set of undirected edges depicted by dashed lines, known as disjunctive arcs, connecting nodes that need to be processed on the same machine. Once we establish the direction of each disjunctive arc, which indicates the processing order on each machine, we obtain a solution. S and T, respectively, denote the start and end of the schedule. Figure 1 illustrates an example of representing the scheduling state of the permutation flow shop using a disjunctive graph. In Figure 1a, we give the disjunctive graph representation for a workshop scheduling problem with three machines and three jobs. In Figure 1b, we depict a feasible solution for the disjunctive graph representation of the problem. Notably, in Figure 1a, undirected dashed lines connect processes of different jobs, while edges of different colors represent distinct machines. Among them, each column of the disjunctive graph represents different machining processes between the same job, and each row represents the same machine. In Figure 1b, a solution has been determined, resulting in directed edges throughout the graph.

Figure 1.

Disjunctive graph representation of 3 3 scheduling instance and its solution.

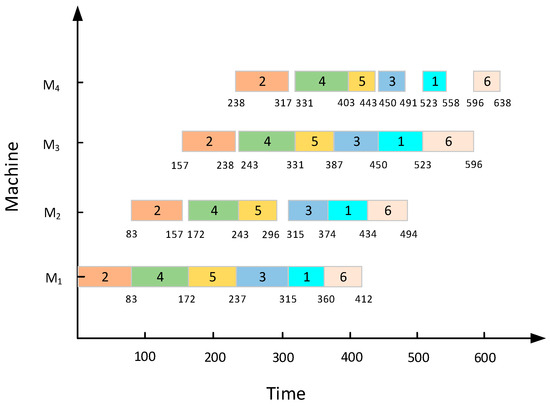

To elucidate the scheduling procedure of PFSP more lucidly, a permutation flow shop with six jobs and five machines is shown in Figure 2, for example, as can be seen from the Gantt chart, when the input jobs sequence , the makespan of this instance is the smallest, which is 638.

Figure 2.

The scheduling instance of 6 4.

3. Methods

In this section, we shall elucidate the fundamental principles of our approach. First, we establish an MDP model based on the PFSP, elaborating in detail the methods for defining states, actions, state transitions, rewards, and policy. Subsequently, we devise an innovative strategy representation technique founded upon graph neural networks, encompassing the construction of both a graph encoder and an action selection network. Last, we present the training framework for our algorithm and provide a detailed exposition of the specific training regimen.

3.1. MDP Model

State: the PFSP is characterized by uniform processing procedures for all jobs, ensuring a consistent order of job processing on each machine. Upon selecting a job, the system can ascertain its completion time on each machine. We define a state as the disjunctive graph representing the scheduling system at each moment. Specifically, the initial state of each solution, iteration is denoted as in Figure 1a from Section Two. This graph encompasses both directed and undirected edges, with distinct-color nodes in each column representing process steps for the same job. Directed edges between nodes denote sequential constraints between process steps, while dashed lines connecting nodes in the same row signify undirected edges. These undirected edges link process nodes of the same color, signifying the need for processing on a shared machine. As the agent makes sequential selections from the candidate set of jobs and as the processing of certain steps of the preceding job concludes, the direction of the disjunctive arc between the two job nodes can be determined. Through successive decisions by the agent, the disjunctive graph progressively evolves from a mixed graph into a directed acyclic graph, illustrated in Figure 1b. This transformation signifies that with changing scheduling dynamics at each decision step, the disjunctive graph can offer distinct state compositions for the scheduling environment of PFSP. In turn, shifts in the scheduling environment will consequently yield varying disjunctive graphs.

Action: the effectiveness of action design directly influences the algorithm’s efficiency. Each action yields optimization benefits within distinct production environments, necessitating multifaceted considerations to minimize idle time between machines and enhance machine utilization. is the action taken by the agent in step to select which job to enter the permutation flow shop. Due to priority constraints, only one job can be scheduled at a given moment. Hence, the agent’s action at step corresponds to the remaining number of jobs in the state . However, as job processing concludes, progressively diminishes until it reaches zero upon the completion of all jobs. Additionally, it is noteworthy that when selecting an action in the state , the PFSP state transitions from to , consequently generating a novel disjunctive graph.

State Transition: owing to the constant change in the PFSP environment, the scheduling environment advances from the state to the next decision step , wherein the job under consideration transitions from to . Designating the temporal inception of the initial state as , the initiation of a state transition transpires upon the completion of the initial machine task. In the event that the time of transition is in the state , the reward acquired upon the environment’s transition to state subsequent to the agent’s execution of action is denoted as .

Reward: the reward function is used to evaluate the agent’s behavior and guide the agent to choose the appropriate behavior for different states and optimize the policy. This article’s objective resides in the minimization of the PFSP . According to the characteristics of the problem constraint and scheduling model, the earlier the processing time of each job on the first machine, the more compact the arrangement of the jobs and the shorter the completion time. However, the reward function that only gives feedback at the end of each round of scheduling makes it difficult for agents to understand how each action affects the global results. To surmount this challenge, we have devised a reward function that mitigates such limitations, as shown in Equation (1). The function first calculates the difference between the partial solutions between two consecutive steps and .

characterizes the solution quality in terms of the . We define it as , where is the completion time until the machine finishes the job at step . Obviously, corresponds to the makespan of the terminal state , where is the state when the schedule is completed, and all disjunctive arcs have directions at this time. Through iterative calculations, the cumulative reward . Since remains constant, the maximization of cumulative reward is related to the minimization of the .

Policy: Upon completion of model training, the policy network yields a probability distribution for candidate jobs at each decision point. The agent selects the job with the highest probability at each decision step and feeds it into the network to derive the probability distribution for the next candidate job.

3.2. Policy Network Based on GIN

In the pursuit of solving PFSP using the MDP framework established in the preceding section, we employ the state representation method of disjunctive graphs as the input for the policy network. These disjunctive graphs encompass both the node features of the states and the structural information of the graphs. To more effectively extract structural features, a policy founded on graph networks is necessary to extract state information. This study introduces the recently proposed GIN [45] as an encoder, presenting a policy network rooted in GIN. The encoder first encodes the original disjunctive graph into an implicit vector containing state information, upon which the policy network bases its decision-making process.

3.2.1. Policy Network

Graph encoder: we employ an encoder based on GIN for encoding. When tackling PFSP, the disjunctive graph encapsulates pertinent information such as task precedence constraints and processing times for each job on various machines. The representation of the state within the disjunctive graph exhibits dynamic fluctuations. GIN, a variant of GNN, possesses robust isomorphism verification and inference capabilities, rendering it well-suited for dynamic graphs. Embedding these pertinent details through GIN facilitates efficient scheduling for PFSP. To enhance generalization capabilities and minimize the frequency of policy network training, we deploy a GIN to encode and express . GIN extracts the feature embedding of each node in a disjunctive graph in an iterative and nonlinear way. For a disjunctive graph representing the real scheduling state, at each time step t, each node undergoes encoding via L layers of GIN, denoted as , as defined in Equation (2). Here, corresponds to the l-th layer of a multi-layer perceptron (MLP), represents the layer’s parameters, is used to iterate and normalize the batch; denotes the learning parameters, which is an arbitrary parameter that can be learned, and signifies the neighborhood set of .

After undergoing iterations of update, obtain the global representation of the entire disjunctive graph using the mean pooling function, as illustrated by Equation (3). After coding by the encoder, we can parameterize the policy () into a graph neural network () with trainable parameters , which makes our model able to deal with unknown scale instances.

Action selection network: the encoder typically comprises neural networks. Considering model complexity, we employ an MLP as the action selection network. After encoding, the disjunctive graph yields a representation of the state. Subsequently, the action selection network maps the state representation to a probability distribution over actions, employing the softmax function for output. In each decision step, the agent sequentially selects the optimal action based on the order of probabilities.

3.2.2. Training Framework

Next, we elucidate the training framework for our algorithm. Due to the high variance exhibited by randomly generated training data, the training process becomes notably unstable. Furthermore, given the sensitivity of DRL to hyperparameter tuning, we employ the PPO algorithm [46] to mitigate the aforementioned challenges and train our model. Benefiting from the actor–critic (AC) architecture, PPO adeptly addresses continuous control problems. It stands as a typical same-track strategy algorithm, signifying that the policy improved in each round aligns with the policy utilized for sampling.

PPO is rooted in the AC framework, encompassing two networks: the actor, denoted by the policy network () than described above, and the critic, a value function network. Notably, both networks share a GIN. The agent selects actions from the policy network’s output, while the value function network evaluates actions. The actor component utilizes a policy function to delineate the relationship between states and actions. Meanwhile, the critic component employs the parameter ω within the action-state value function to guide the direction of policy updates, thereby crafting the function to appraise the execution of action given input state features . is mainly used to calculate the dominance function together with the state value function. The equation of is Equation (4).

where represents the long-term expected discount reward received after executing the action at state . represents the expected value and represents the future return value from step . The calculation equation of is Equation (5).

where is the discount factor .

The two networks undergo parameter updates via alternating gradient descent. A comprehensive account of the PPO algorithm’s intricate training process is provided in Algorithm 1.

| Algorithm 1 PPO-Based Training Algorithm |

| Input: discounting factor ; clipping ratio ; update epoch ; number of training steps ; critic network ; actor-network , behavior actor-network , where ; entropy loss coefficient ; value function loss coefficient ; policy loss coefficient . 1 Initialize , , and ; 2 for e = 1 to E 3 Pick N independent scheduling instances from distribution D; 4 for n = 1 to N 5 for t = 1 to … 6 sample based on ; 7 Receive reward and next state ; 8 Compute the advantage function and probability ratio . 9 = ; 10 = 11 while is terminal do 12 break; 13 end while 14 end for 15 Compute the policy loss , the value function loss and the entropy loss . 16 ; 17 ; 18 , where is entropy; 19 Total Losses: ; 20 end for 21 for l = 1 to L 22 Update , with cumulative loss by Adam optimizer: 23 , 24 end for 25 26 end for 27 Output: Trained parameter set of . |

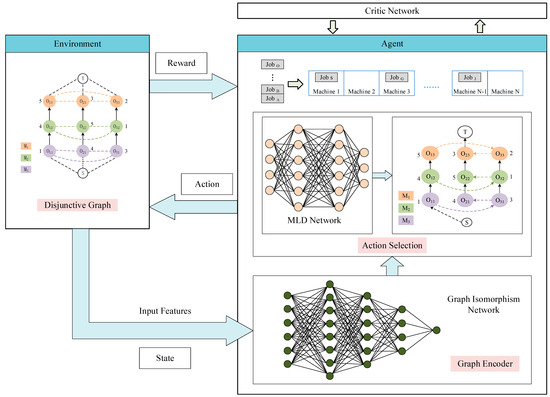

Figure 3 illustrates the training framework of our model, showcasing the process by which the DRL approach proposed in this study addresses the scheduling challenges of PFSP. This reinforcement learning paradigm consists of an agent responsible for determining the order of job inputs and an environment, which captures the current state of PFSP using disjunctive graphs. Initially, the environment feeds the disjunctive graph, encompassing the machining status of various machines, into the graph encoder. This encoder transforms the original disjunctive graph into an implicit vector carrying state information. Subsequently, an action selection network based on an MLP generates a probability distribution over potential actions. The agent’s decision-making process involves selecting the optimal action based on the probabilities. This determines the job to be inputted into the current pipeline state. The environment confers rewards to the agent based on the decisions made, iterating through this process until scheduling for all pending jobs is completed.

Figure 3.

The DRL framework based on PPO.

4. Numerical Experiment

These data samples employed for model training are randomly generated, with a total count of 10,000. Among these, the number of machines is set at five. The total job count for each individual sample adheres to a uniform distribution within the range of [5, 100], while the processing times follow a uniform distribution within the interval [0, 100]. To ascertain the efficacy of our proposed methodology, we conducted tests on both randomly generated instances and the Taillard benchmark dataset [47]. Comparative analyses were performed against heuristic algorithms SPT and NEH, along with metaheuristic algorithms Ant Colony Optimization (ACO) and Genetic Algorithms (GA). Additionally, we contrasted the experimental outcomes against DRL algorithms Dueling Double Deep Q Network (D3QN) and PPO, which do not employ disjunctive graph-based state representations. Among them, D3QN is a variant of the Dueling DQN algorithm, which incorporates the idea of the Double DQN algorithm on the basis of the Dueling DQN algorithm.

4.1. Experimental and Parameter Settings

We conducted an extensive series of experiments using the methodology we proposed to solve the PFSP in order to validate its efficiency and effectiveness. All experiments were implemented in Python 3.8, running on a computer equipped with an AMD Ryzen 7 5800 H CPU clocked at 3.20 GHz and an NVIDIA RTX 3050 Ti GPU. Appropriate parameter configurations are crucial for the successful training of the model. Each MLP within the GIN architecture comprises two hidden layers, with each layer having a dimension of 64. Similarly, the MLP within the action selection network contains two hidden layers, each with a dimension of 32. The remaining hyperparameters during the training process are detailed in Table 1.

Table 1.

Hyperparameter configuration.

4.2. Performance Metrics

For the optimization problem of the PFSP studied in this article, we employ two metrics to assess the quality of both baseline methods and our proposed approach. These metrics encompass and computational time. signifies the maximum completion time expended for resolving this scheduling quandary. In addition to comparing the magnitudes of across various algorithms, we also employ the Relative Percentage Deviation () [48] to gauge the algorithms’ performance in terms of , as denoted by Equation (6). Herein, represents the currently best for this problem, while corresponds to the computed by the current algorithm for this issue. It is worth noting that algorithms with lower values exhibit superior performance compared with those with higher values. In the practical realm of factory production, the time taken to obtain solutions for problems also assumes importance. Swift discovery of resolutions to production issues accelerates the process of restoring production to full capacity. This, in turn, aids in more effectively meeting production objectives and customer demands. Hence, we also consider the model’s computational time as one of the metrics for evaluating model performance.

4.3. Computational Results of Randomly Generated Instances

We commence by subjecting our model to testing on randomly generated instances, ranging in size from 6 × 6 to 100 × 20. Eight examples with different scales are tested, and the processing times of the jobs on a single machine adhere to a uniform distribution within the interval [0, 100]. We tested different algorithms on these same randomly generated data at the same scale and compared the performance of each algorithm. We compare the test outcomes against those of SPT, NEH, ACO, GA, D3QN, and PPO algorithms, the latter of which does not employ a disjunctive graph representation of states. The yielded by each algorithm is presented in Table 2, measured in hours (h). The bold typeface highlights the optimal results for each instance. As Table 2 elucidates, our model attains a lower compared to all baseline methods. For instance, when faced with a problem of dimensions 100 × 20, our proposed model reduces by 183.2 h, 59.7 h, 69.2 h, 58.3 h, 39.8 h, and 28.4 h, respectively, compared the six baseline methods. In a broader perspective, DRL algorithms D3QN and PPO outperform heuristic and metaheuristic approaches. The heuristic algorithm NEH holds a competitive stance against metaheuristic algorithms such as ACO and GA, while the performance of SPT, another heuristic algorithm, performs poorly.

Table 2.

The of each algorithm on randomly generated instances (h).

Furthermore, it is noteworthy that as the scale of the problem expands, the disparity between the baseline methods and the model presented in this study intensifies. For instance, in the case of the D3QN algorithm, the gap grows from 1.9 h to 39.8 h. This underscores the superior generalization prowess of our model when confronted with larger-scale instances in comparison to the baseline approaches.

In order to encompass the disparities in achieved by the model from multiple perspectives, we employ the in Table 3 to gauge the performance of each algorithm in terms of across various instance scales. Given that the approach proposed in this study yields a smaller than that of the baseline methods for every test instance, the of our model is uniformly zero across all instances, signifying that it consistently outperforms the baseline methods in this regard. For instance, in the case of an instance size of 100 × 5, the disparities in between the six baseline methods and our model are as follows: 2.8238, 1.0818, 1.0501, 1.0613, 0.7293, and 0.4476, respectively. Overall, the of DRL algorithms is comparatively lower than that of heuristic and metaheuristic algorithms. Among DRL algorithms, the PPO algorithm, which does not employ disjunctive graph representations for states, exhibits a marginal advantage over the D3QN algorithm. Metaheuristic algorithms, on the whole, surpass heuristic algorithms, with NEH closely approaching the values of metaheuristic algorithms.

Table 3.

The of each algorithm on randomly generated instances.

The performance of the scheduling model is not solely contingent upon the quality of solution generation; the swiftness of solution generation also stands as a significant metric. Table 4 presents the computational times for both baseline methods and the method proposed in this study, and the unit of data in the table is seconds (s). It is evident from the table that SPT achieves nearly instantaneous resolution for all problems. Apart from the SPT algorithm, the D3QN algorithm exhibits the fastest computational speed for problem sizes ranging from 10 × 10 to 50 × 5, surpassing our model in this regard. However, as the instance scales continue to escalate, our model demonstrates faster computational speed, further accentuated by the growing discrepancy in computational times between the baseline methods and our proposed approach. For instance, in the case of the PPO algorithm, which does not incorporate disjunctive graphs, the disparity in computational times increases from 0.04 s to 5.24 s. Benefiting from the characteristics of DRL algorithms, which can handle instances of all scales after a single training session, the computational time of DRL algorithms is superior to that of heuristic and metaheuristic algorithms. However, heuristic scheduling algorithms outpace metaheuristic algorithms in terms of computational efficiency.

Table 4.

The computation time of each algorithm on randomly generated instances (s).

4.4. Computational Results of Benchmark Instances

In this section, we juxtapose our model against six baseline methods, SPT, NEH, ACO, GA, D3QN, and PPO, without disjunctive graph state representation on the esteemed Taillard benchmark. We conduct comparative experiments on ten distinct instances from the Taillard benchmark, spanning dimensions of 20 × 5 to 200 × 10. To ensure the reliability of experimental outcomes, we employ the same trained model across these trials. Table 5 presents the experimental findings for our model and the six baseline methods.

Table 5.

The of each algorithm on Taillard benchmark (h).

While NEH, ACO, GA, D3QN, PPO, and our model exhibit identical results for an instance of size 20 × 5, the disparity between the baseline methods and our model becomes more pronounced as instance dimensions expand. For instance, in the case of the PPO algorithm without disjunctive graph usage, the discrepancy between it and our proposed model escalates from 0 to 33.3 h as the instance scale increases. When compared to heuristic and metaheuristic algorithms, DRL algorithms still demonstrate competitive performance, adept at adaptive problem-solving across varying scheduling contexts. Metaheuristic algorithms, on the whole, outperform heuristic algorithms, with NEH showcasing performance akin to metaheuristic counterparts.

Table 6 presents the values of our model and various baseline algorithms on different scale instances from the esteemed Taillard benchmark, with the optimal results highlighted in bold. For an instance size of 20 × 5, all algorithms except SPT exhibit an value of zero, signifying that, in this instance, all algorithms other than SPT achieve outcomes identical to the benchmark’s optimal results. As the instances grow larger, our model attains smaller values compared to the baseline methods. For instance, when faced with an instance size of 200 × 10, the disparities in between the six baseline methods and our model are as follows: 1.7563, 0.4456, 0.5631, 0.4904, 0.3803, and 0.3104, respectively. Across instances of the same scale, DRL algorithms consistently manifest lower values compared to the other two categories of algorithms. Among DRL algorithms, the value of the PPO algorithm without disjunctive graphs slightly surpasses that of D3QN. In contrast, the NEH value closely approximates those of the metaheuristic algorithms ACO and GA, with SPT exhibiting the least favorable performance.

Table 6.

The of each algorithm on the Taillard benchmark.

Similarly, we have also conducted a comparison of the computational times for each algorithm on the Taillard benchmark, as depicted in Table 7. The SPT algorithm continues to showcase near-instantaneous computational prowess. Apart from SPT, D3QN exhibits swifter computational abilities for smaller instances ranging from 20 × 5 to 50 × 5, as compared to the model proposed in this paper. However, as instance dimensions escalate from 50 × 10 to 200 × 10, our model demonstrates heightened computational speed. Furthermore, with an increase in instance size, the gap in computational time between D3QN and our model expands from 0.2 s to 4.96 s. DRL algorithms persist in manifesting quicker computational speeds than heuristic and metaheuristic methods, whereas the computational time of metaheuristic algorithms is longer than that of heuristic algorithms.

Table 7.

The computation time of each algorithm on Taillard benchmark (s).

4.5. Discussion

The SPT algorithm demonstrates instantaneous computational prowess both on randomly generated instances and the Taillard benchmark yet falls short in generating solutions of satisfactory quality. In contrast, the approach proposed in this study, while slightly slower in computation compared to SPT, proves quicker than other baseline methods. This trade-off remains acceptable in practical production contexts, further amplified by the superior solution quality generated by our proposed method in comparison to all baseline approaches. Furthermore, as the problem-solving dimensions expand, the disparity in and computational time between the baseline methods and our proposed model also grows, underscoring the heightened robustness of our method over baseline approaches in both test scenarios. These experiments verify the smoothness of our model in solving PFSF problems and further prove that the correlation between the MDP model and PFSF is effective. Consequently, a comprehensive evaluation indicates the superiority of our model over all heuristic scheduling rules, metaheuristic algorithms, and DRL algorithms.

Benefiting from the inherent self-learning capacity of DRL algorithms and their ability to handle instances of varying scales following a single training session, these algorithms outshine heuristic and metaheuristic methods. Notably, the model proposed in this paper exhibits superior performance in both and computational time compared to the PPO algorithm that abstains from disjunctive graph state representation. Our model’s prowess in addressing PFSP can be attributed to two factors: First, the disjunctive graph-based state representation method provides a more comprehensive depiction of scheduling states, proving efficacious even when dealing with intricate and sizable PFSP instances. Second, the strategy network founded on GIN more effectively absorbs the underlying information of graph structures. Additionally, the encoding process within the graph encoder primarily relies on matrix parallel computation, enhancing the computational efficiency of the model.

5. Conclusions and Future Work

In this study, we propose a novel end-to-end DRL framework to address the PFSP. Our initial step involves constructing an MDP model for PFSP, meticulously elaborating on the definitions of states, actions, and rewards. Notably, we innovatively portray the PFSP environment using disjunctive graphs. To capture the underlying topological structure of disjunctive graphs, we engineer a strategy network rooted in GIN. This network adeptly extracts rich representational information from node embeddings. Training of this network is executed via the PPO algorithm. In assessing the performance of the proposed model, we employ and computational time as evaluative benchmarks. Experimental validation takes place on both randomly generated instances and the Taillard public benchmark. Outcomes affirm our model’s superiority over heuristic, metaheuristic, and DRL-based baseline approaches. Moreover, the model’s seamless extensibility to larger problem instances without necessitating retraining underscores its commendable scalability. Given the rapid expansion of the manufacturing industry, characterized by heightened product complexity and demand, optimizing production line efficiency through advanced methods assumes paramount significance. Our model, empowered by its robust generalization capacity, can effectively confront this challenge, making it a formidable tool for enhancing production efficiency amid evolving industrial landscapes.

Although we have validated the efficacy of the method proposed in this study in outperforming baseline approaches, there remains some disparity between the obtained results and the standard outcomes for each instance in the Taillard benchmark test. Moving forward, we shall continue enhancing our model and subject it to testing on more and larger benchmark data sets. To strike a balance between computation time and result quality, we have employed a simple Multi-layer Perceptron (MLP) as the action selection network. However, the inclusion of more intricate modules within the action selection network will undoubtedly contribute to the amplification of the model’s performance. In the future, we will further delve into the exploration of the action selection network, aiming to advance result quality while maintaining an acceptable level of computational efficiency. Additionally, this study primarily delves into the realm of single-objective optimization, with the objective of minimizing . Yet, practical production scenarios often entail the consideration of multiple objectives, such as the energy consumption of equipment. In our subsequent endeavors, we will conduct a more profound analysis of the PFSP and undertake refinements to our model, thereby addressing the broader spectrum of multi-objective optimization challenges prevalent in real-world production settings.

Author Contributions

Conceptualization, T.Z. and L.L.; data curation, T.Z.; formal analysis, T.Z. and L.L.; funding acquisition, L.L.; investigation, T.Z.; methodology, T.Z. and L.L.; project administration, T.Z.; resources, T.Z.; software, T.Z.; supervision, T.Z. and L.L.; validation, T.Z. and L.L.; visualization, T.Z., L.L., S.J. and Y.H.; writing—original draft, T.Z., L.L., S.J. and Y.H.; writing—review and editing, T.Z., L.L., S.J. and Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities (2023-vb-016).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, C.; Wu, Y.; Ma, Y.; Song, W.; Le, Z.; Cao, Z.; Zhang, J. A review on learning to solve combinatorial optimisation problems in manufacturing. IET Collab. Intell. Manuf. 2023, 5, e12072. [Google Scholar] [CrossRef]

- Sun, X.; Vogel Heuser, B.; Bi, F.; Shen, W. A deep reinforcement learning based approach for dynamic distributed blocking flowshop scheduling with job insertions. IET Collab. Intell. Manuf. 2022, 4, 166–180. [Google Scholar] [CrossRef]

- Oliva, D.; Martins, M.S.R.; Hinojosa, S.; Elaziz, M.A.; Dos Santos, P.V.; Da Cruz, G.; Mousavirad, S.J. A hyper-heuristic guided by a probabilistic graphical model for single-objective real-parameter optimization. Int. J. Mach. Learn Cyb. 2022, 13, 3743–3772. [Google Scholar] [CrossRef]

- Xie, J.; Gao, L.; Peng, K.; Li, X.; Li, H. Review on flexible job shop scheduling. IET Collab. Intell. Manuf. 2019, 1, 67–77. [Google Scholar] [CrossRef]

- Chen, X.; Voigt, T. Implementation of the Manufacturing Execution System in the food and beverage industry. J. Food Eng. 2020, 278, 109932. [Google Scholar] [CrossRef]

- Singh, H.; Oberoi, J.S.; Singh, D. Simulation and modelling of hybrid heuristics distribution algorithm on flow shop scheduling problem to optimize makespan in an Indian manufacturing industry. J. Sci. Ind. Res. (JSIR) 2021, 80, 137–142. [Google Scholar]

- Khurshid, B.; Maqsood, S.; Omair, M.; Sarkar, B.; Saad, M.; Asad, U. Fast Evolutionary Algorithm for Flow Shop Scheduling Problems. IEEE Access 2021, 9, 44825–44839. [Google Scholar] [CrossRef]

- Molina-Sánchez, L.; González-Neira, E. GRASP to minimize total weighted tardiness in a permutation flow shop environment. Int. J. Ind. Eng. Comput. 2016, 7, 161–176. [Google Scholar] [CrossRef]

- Röck, H. The three-machine no-wait flow shop is NP-complete. J. ACM (JACM) 1984, 31, 336–345. [Google Scholar] [CrossRef]

- Tomazella, C.P.; Nagano, M.S. A comprehensive review of Branch-and-Bound algorithms: Guidelines and directions for further research on the flowshop scheduling problem. Expert Syst. Appl. 2020, 158, 113556. [Google Scholar] [CrossRef]

- Perez-Gonzalez, P.; Fernandez-Viagas, V.; Framinan, J.M. Permutation flowshop scheduling with periodic maintenance and makespan objective. Comput. Ind. Eng. 2020, 143, 106369. [Google Scholar] [CrossRef]

- Singh, H.; Oberoi, J.S.; Singh, D. Multi-objective permutation and non-permutation flow shop scheduling problems with no-wait: A systematic literature review. Rairo-Oper. Res. 2021, 55, 27–50. [Google Scholar] [CrossRef]

- Gao, K.; Huang, Y.; Sadollah, A.; Wang, L. A review of energy-efficient scheduling in intelligent production systems. Complex Intell. Syst. 2019, 6, 237–249. [Google Scholar] [CrossRef]

- Yan, Q.; Wu, W.; Wang, H. Deep Reinforcement Learning for Distributed Flow Shop Scheduling with Flexible Maintenance. Machines 2022, 10, 210. [Google Scholar] [CrossRef]

- Ying, K.; Lin, S. Reinforcement learning iterated greedy algorithm for distributed assembly permutation flowshop scheduling problems. J. Amb. Intel. Hum. Comp. 2023, 14, 11123–11138. [Google Scholar] [CrossRef]

- Grumbach, F.; Müller, A.; Reusch, P.; Trojahn, S. Robust-stable scheduling in dynamic flow shops based on deep reinforcement learning. J. Intell. Manuf. 2022. [Google Scholar] [CrossRef]

- Yang, S.L.; Wang, J.Y.; Xin, L.M.; Xu, Z.G. Verification of intelligent scheduling based on deep reinforcement learning for distributed workshops via discrete event simulation. Adv. Prod. Eng. Manag. 2022, 17, 401–412. [Google Scholar] [CrossRef]

- Babor, M.; Senge, J.; Rosell, C.M.; Rodrigo, D.; Hitzmann, B. Optimization of No-Wait Flowshop Scheduling Problem in Bakery Production with Modified PSO, NEH and SA. Processes 2021, 9, 2044. [Google Scholar] [CrossRef]

- Liang, Z.; Zhong, P.; Liu, M.; Zhang, C.; Zhang, Z. A computational efficient optimization of flow shop scheduling problems. Sci. Rep. 2022, 12, 845. [Google Scholar] [CrossRef]

- Koulamas, C. A new constructive heuristic for the flowshop scheduling problem. Eur. J. Oper Res. 1998, 105, 66–71. [Google Scholar] [CrossRef]

- Zheng, D.Z.; Wang, L. An effective hybrid heuristic for flow shop scheduling. Int. J. Adv. Manuf. Technol. 2003, 21, 38–44. [Google Scholar] [CrossRef]

- Nagano, M.S.; Moccellin, J.V. A high quality solution constructive heuristic for flow shop sequencing. J. Oper Res. Soc. 2002, 53, 1374–1379. [Google Scholar] [CrossRef]

- Fernandez-Viagas, V.; Framinan, J.M. NEH-based heuristics for the permutation flowshop scheduling problem to minimise total tardiness. Comput. Oper. Res. 2015, 60, 27–36. [Google Scholar] [CrossRef]

- Kalczynski, P.J.; Kamburowski, J. An improved NEH heuristic to minimize makespan in permutation flow shops. Comput. Oper. Res. 2008, 35, 3001–3008. [Google Scholar] [CrossRef]

- Pan, Q.; Gao, L.; Wang, L.; Liang, J.; Li, X.Y. Effective heuristics and metaheuristics to minimize total flowtime for the distributed permutation flowshop problem. Expert Syst. Appl. 2019, 124, 309–324. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Pan, Q.; Wang, Q. Energy-efficient permutation flow shop scheduling problem using a hybrid multi-objective backtracking search algorithm. J. Clean Prod. 2017, 144, 228–238. [Google Scholar] [CrossRef]

- Zhang, Z.; Qian, B.; Hu, R.; Jin, H.; Wang, L. A matrix-cube-based estimation of distribution algorithm for the distributed assembly permutation flow-shop scheduling problem. Swarm Evol. Comput. 2021, 60, 100785. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, Y.; Zhang, S.; Luo, Y.; Zhang, L. Ant colony optimization for Cuckoo Search algorithm for permutation flow shop scheduling problem. Syst. Sci. Control. Eng. 2019, 7, 20–27. [Google Scholar] [CrossRef]

- Ceberio, J.; Irurozki, E.; Mendiburu, A.; Lozano, J.A. A Distance-Based Ranking Model Estimation of Distribution Algorithm for the Flowshop Scheduling Problem. IEEE Trans. Evolut. Comput. 2014, 18, 286–300. [Google Scholar] [CrossRef]

- Sayoti, F.; Essaid, R.M. Golden ball algorithm for solving flow shop scheduling problem. Int. J. Interact. Multimed. Artif. Intell. 2016, 4, 15. [Google Scholar] [CrossRef]

- Santucci, V.; Baioletti, M.; Milani, A.; Mancini, T.; Maratea, M.; Ricca, F. Solving permutation flowshop scheduling problems with a discrete differential evolution algorithm. Ai Commun. 2016, 29, 269–286. [Google Scholar] [CrossRef]

- Dubois-Lacoste, J.; Pagnozzi, F.; Stützle, T. An iterated greedy algorithm with optimization of partial solutions for the makespan permutation flowshop problem. Comput. Oper. Res. 2017, 81, 160–166. [Google Scholar] [CrossRef]

- Baioletti, M.; Milani, A.; Santucci, V. MOEA/DEP: An Algebraic Decomposition-Based Evolutionary Algorithm for the Multiobjective Permutation Flowshop Scheduling Problem. In Proceedings of the Evolutionary Computation in Combinatorial Optimization: 18th European Conference, EvoCOP 2018, Parma, Italy, 4–6 April 2018; Springer International Publishing: Cham, Switzerland, 2018; pp. 132–145. [Google Scholar]

- Kaya, S.; Karazmel, Z.; Aydilek, I.B.; Tenekechi, M.E.; Gümüşçü, A. The effects of initial populations in the solution of flow shop scheduling problems by hybrid firefly and particle swarm optimization algorithms. Pamukkale Univ. J. Eng. Sci. 2020, 26, 140–149. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Gao, L. An Effective Solution Space Clipping-Based Algorithm for Large-Scale Permutation Flow Shop Scheduling Problem. IEEE Trans. Syst. Man Cybern. Syst. 2022, 53, 635–646. [Google Scholar] [CrossRef]

- Pan, R.; Dong, X.; Han, S. Solving permutation flowshop problem with deep reinforcement learning. In Proceedings of the Prognostics and System Health Management Conference (PHM-Besancon), Besancon, France, 4–7 May 2020; pp. 349–353. [Google Scholar]

- Ingimundardottir, H.; Runarsson, T.P. Discovering dispatching rules from data using imitation learning: A case study for the job-shop problem. J. Sched. 2018, 21, 413–428. [Google Scholar] [CrossRef]

- Lin, C.C.; Deng, D.J.; Chih, Y.L.; Chiu, H.T. Smart manufacturing scheduling with edge computing using multiclass deep Q network. IEEE Trans. Ind. Inform. 2019, 15, 4276–4284. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Z.; Wang, J. Intelligent Decision-Making of scheduling for dynamic permutation flowshop via deep reinforcement learning. Sensors 2021, 21, 1019. [Google Scholar] [CrossRef]

- Han, B.A.; Yang, J.J. Research on Adaptive Job Shop Scheduling Problems Based on Dueling Double DQN. IEEE Access 2020, 8, 186474–186495. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Z. Intelligent scheduling and reconfiguration via deep reinforcement learning in smart manufacturing. Int. J. Prod. Res. 2022, 60, 4936–4953. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, H. Application of Machine Learning and Rule Scheduling in a Job-Shop Production Control System. Int. J. Simul Model 2021, 20, 410–421. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Lin, T.; Zhao, C.; Wang, K.; Chen, Z. Solving job scheduling problems in a resource preemption environment with multi-agent reinforcement learning. Robot. Comput.-Integr. Manuf. 2022, 77, 102324. [Google Scholar] [CrossRef]

- Gebreyesus, G.; Fellek, G.; Farid, A.; Fujimura, S.; Yoshie, O. Gated-Attention Model with Reinforcement Learning for Solving Dynamic Job Shop Scheduling Problem. IEEJ Trans. Electron. Electron. Eng. 2023, 18, 932–944. [Google Scholar] [CrossRef]

- Lei, K.; Guo, P.; Zhao, W.; Wang, Y.; Qian, L.; Meng, X.; Tang, L. A multi-action deep reinforcement learning framework for flexible Job-shop scheduling problem. Expert Syst. Appl. 2022, 205, 117796. [Google Scholar] [CrossRef]

- Cho, Y.I.; Nam, S.H.; Cho, K.Y.; Yoon, H.C.; Woo, J.H. Minimize makespan of permutation flowshop using pointer network. J. Comput. Des. Eng. 2022, 9, 51–67. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, L.; Wang, J.; Lu, J. Deep Reinforcement Learning Based Optimization Algorithm for Permutation Flow-Shop Scheduling. IEEE Trans. Emerg. Top. Comput. Intell. 2021, 7, 983–994. [Google Scholar] [CrossRef]

- Ren, J.F.; Ye, C.M.; Li, Y. A new solution to distributed permutation flow shop scheduling problem based on NASH Q-Learning. Adv. Prod. Eng. Manag. 2021, 16, 269–284. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).