1. Introduction

Robotic hands are essential end effectors in robotic systems and have been widely used in the manufacturing, service, and rehabilitation industries. Humanoid robotic hands are usually developed to imitate the dexterity and versatility of human hands [

1,

2], which have high dexterity and can perform different grasping actions on target objects according to their shape, size, and relative position [

3,

4].

Some scholars have statistically classified the grasping action types of human hands, such as Feix et al. [

5] and Liu et al. [

6], who focused on the static and stable grasping of a single hand and, according to (1) opposition type, (2) the virtual finger assignments, (3) type in terms of power, precision, or intermediate grasp, and (4) the position of the thumb, divided the hand’s grasping actions into 33 types. Stival et al. [

7], based on the previous classification methods, collected electromyography and kinematic data during human grasping actions to establish the kinematic classification and muscle classification methods for human hand actions. In summary, the grasping ability of the human hand is diverse to adapt to objects of various sizes and shapes. All of this has put higher demand on humanoid robotic hands’ dexterity and grasping mode diversity.

In recent years, to achieve a better imitation of human hands, scholars have developed numerous dexterous humanoid robotic hands [

8]. For example, Cheng et al. [

1] proposed an adaptive humanoid finger with a nine-bar mechanism; the I-limb robotic hand [

9] by Touch Bionics; the Hannes hand [

10] by M. Laffranchi et al.; the BeBionic Hand by Ottobock, etc. However, the above robotic hands all use coupled-adaptive underactuated mechanisms, in which two or three finger joints of a finger bend or extend simultaneously with a fixed coupling ratio under the drive of a single motor. Although the underactuation simplifies the mechanism and reduces the weight to a certain extent, it sacrifices the robotic hand’s dexterity and grasping mode diversity, making the robotic hand’s phalanges unable to move independently or in a coupled manner like the human hand. Moreover, the robotic hand’s interphalangeal coupling ratio is fixed and cannot be changed with the object’s characteristics, resulting in limited grasping modes of the robotic hand.

In terms of the interphalangeal coupling ratio, researchers have carried out a lot of exploration. The ILDA hand [

11] by Kim et al. consists of a linkage mechanism, three motors, and three ball screw nuts for each finger, which can achieve the independent and combined grasping of the three finger joints of the robotic hand through the linear displacement of the ball screw nut pairs. However, the complex linkage mechanism and large quantity of parts are not conducive to installation and maintenance in the later stage; furthermore, the interphalangeal coupling ratio is fixed and unchanged. Quintero et al. [

12] captured and analyzed a tennis ball spinning on top of a flat surface by the subject’s right hand using a Vicon optical motion capture system, and they found that the human hand’s interphalangeal coupling ratio was changing dynamically rather than being fixed during the process. Therefore, making the robotic hand’s phalanges able to move independently or changing the coupling ratio dynamically can improve robotic hands’ dexterity and grasping mode diversity.

In addition, the linkage transmission and tendon transmission mechanisms are currently the most widely used in robotic hands. For example, linkage transmission mechanisms have been adopted by the Harbin Institute of Technology [

1], the German Aerospace Center DIL [

13], the German Schunk Hand, and Ottobock’s BeBionic Hand [

14]. However, the linkage transmission mechanism has weaknesses, such as complex structure and limited flexibility. Meanwhile, tendon transmission mechanisms have been adopted by the Huazhong University of Science and Technology’s X-hand [

15], the UK’s Shadow Hand, the I-Limb Hand, and the American Washington Hand. However, the tendon transmission mechanism has a defect of insufficient rigidity, as its tendons are easy to break and require the application of pre-tightening force [

8]. Some researchers [

16] have tried to integrate the linkage and tendon mechanisms in recent years. Inspired by the above work, we attempted to design a new transmission mechanism that combines the advantages of solid rigidity, stability, and high transmission efficiency of linkage transmission with the benefits of the flexible, lightweight, and simple structure of tendon transmission.

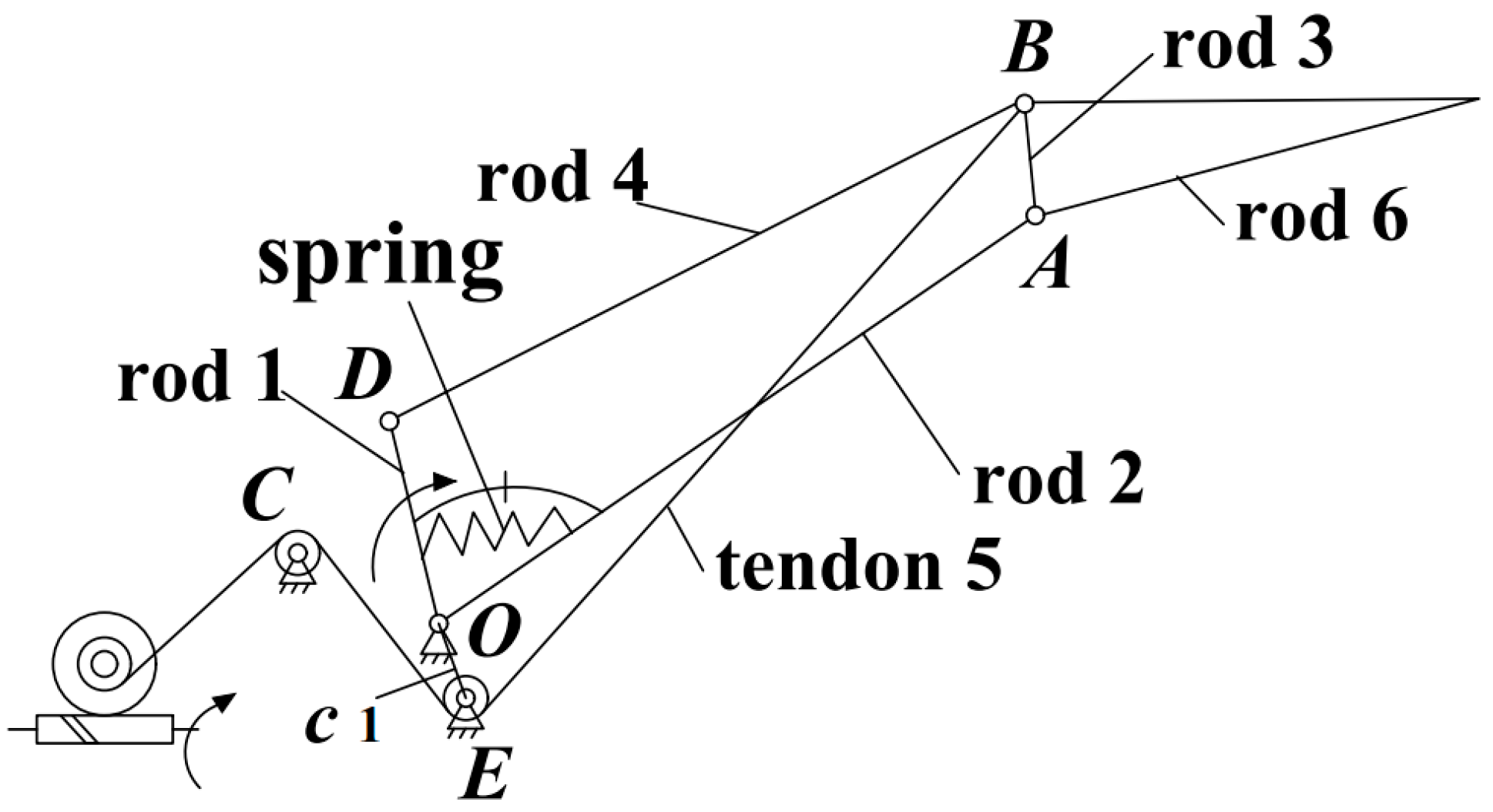

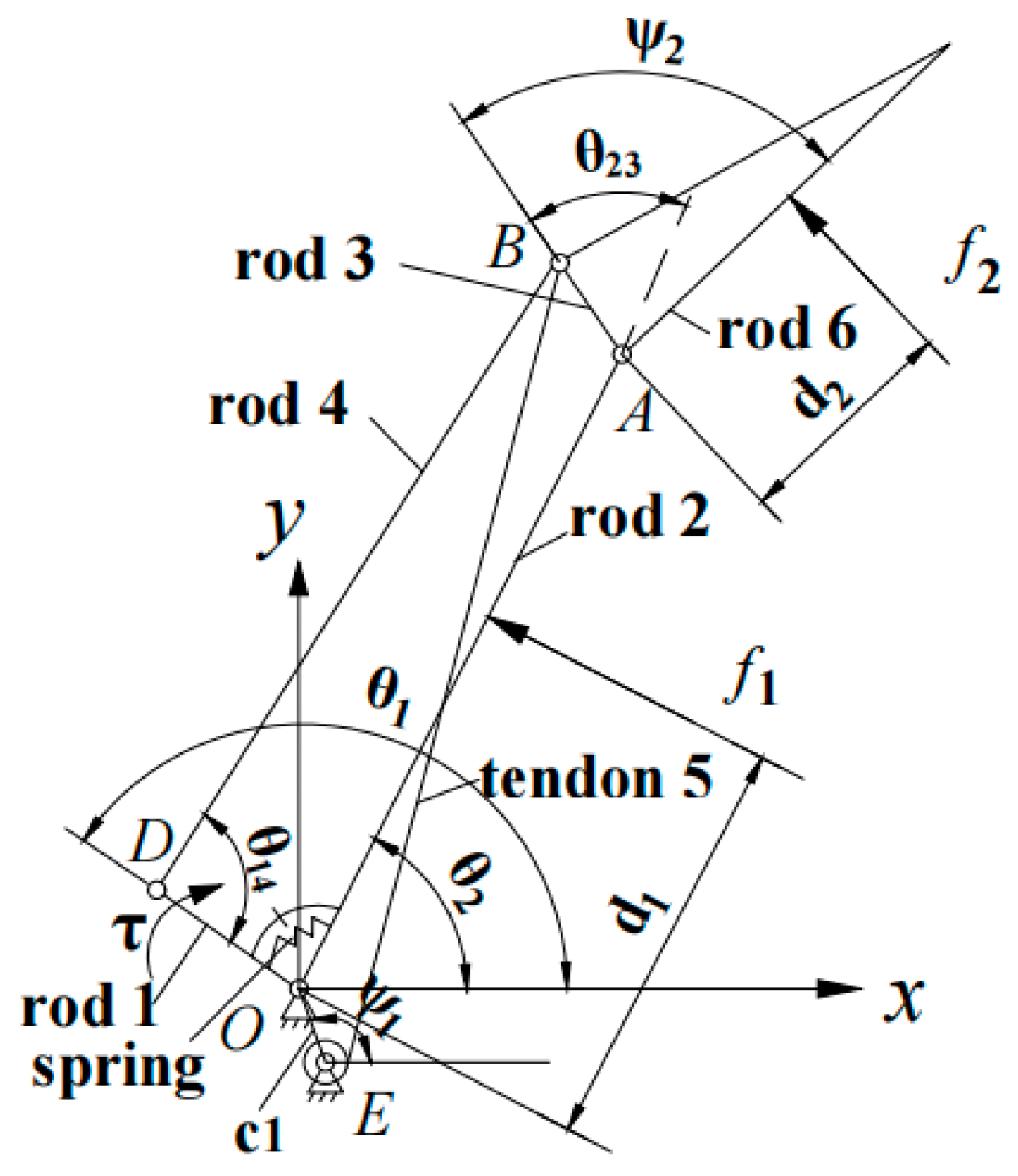

This paper proposes a multi-mode humanoid mechanical finger based on linkage and tendon fusion transmission. The finger comprises two motors. The linkage mechanism is driven by the main motor as the finger’s power input; the tendon mechanism mainly acts as a coupling mechanism to make the finger achieve humanoid coupling motion. Moreover, the finger’s interphalangeal coupling ratio can be dynamically changed based on a minor motor to adjust the tendon’s length and tension. Therefore, the finger can realize shape-adaptive, coupled-adaptive, and variable coupling-adaptive grasping modes simultaneously.

The rest of this paper is organized as follows:

Section 2 introduces the mechanical design of the finger.

Section 3 analyzes the kinematics and statics of the finger.

Section 4 explains the control strategy of the three modes. The performance of the finger is evaluated in

Section 5, and the conclusions are discussed in

Section 6.

4. Multi-Mode Grasping Control Strategy

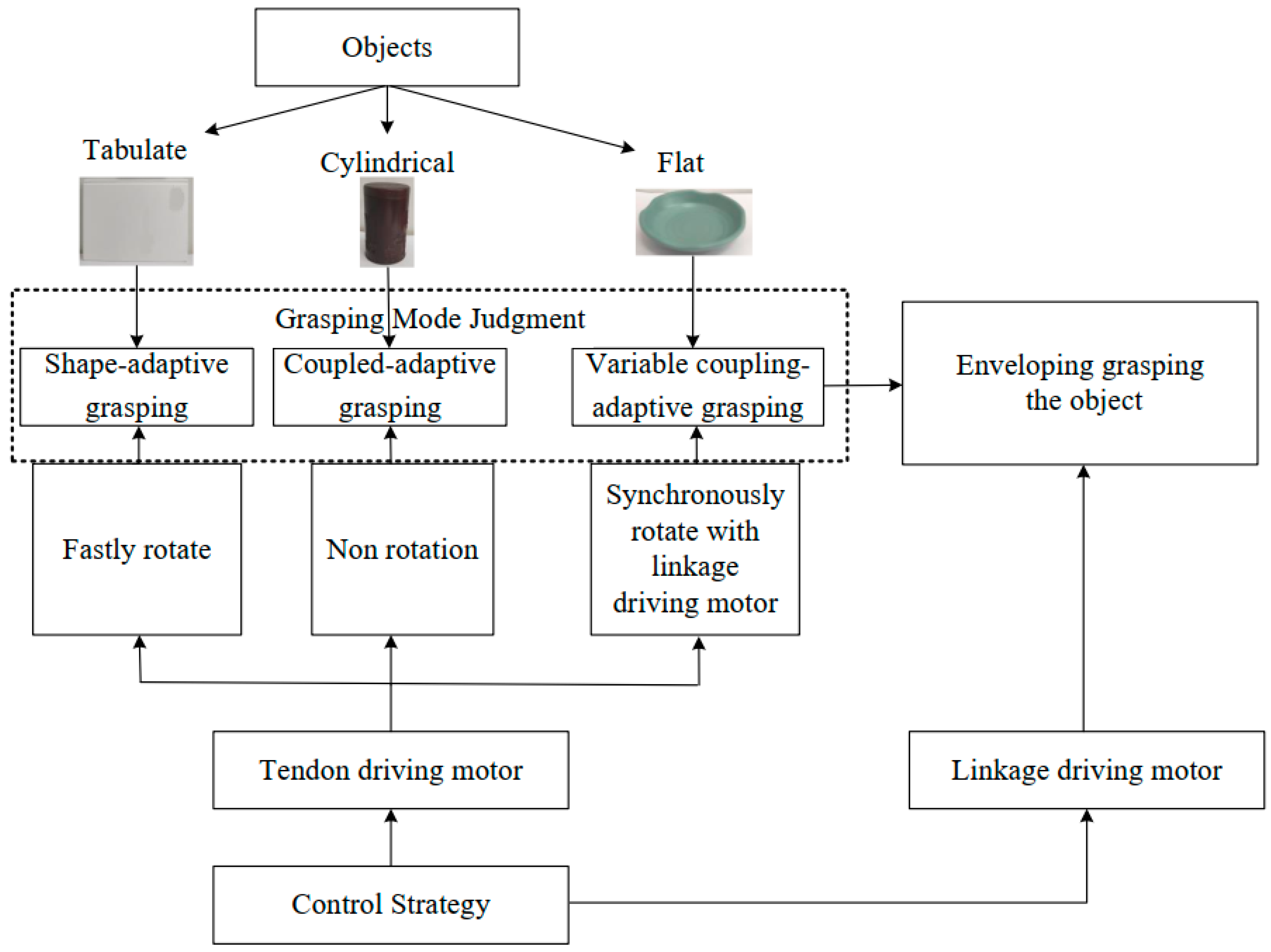

The finger presented in this paper can realize three grasping modes: shape-adaptive, coupled-adaptive, and variable coupling-adaptive grasping modes. As shown in

Figure 4, by controlling the speed relationship between the linkage driving motor and the tendon driving motor to adjust the tendon’s length and tension, the finger can switch between the three grasping modes. In addition, by controlling the different speed change rules of the tendon driving motor, the finger can realize different grasping trajectories.

4.1. Shape-Adaptive Grasping Mode

In the shape-adaptive grasping mode, there is no coupling relationship between the proximal phalanx and distal phalanx. The proximal phalanx and distal phalanx will bend as a whole before contacting objects, so it is beneficial to grasp the tabulate objects. In this mode, tendon 5 needs to remain relaxed. Therefore, before the linkage driving motor drives the finger to grasp, the tendon driving motor rotates quickly to release the tendon from the wheel, leading to the tendon becoming relaxed and losing its coupling effect.

4.2. Coupled-Adaptive Grasping Mode

At present, mainstream humanoid robotic hands adopt the coupled-adaptive grasping mode, in which the proximal phalanx and distal phalanx bend simultaneously with a fixed coupling ratio before contacting the object. This mode is suitable for enveloping grasping cylindrical or spherical objects. In this mode, the tendon driving motor reverse rotates to tighten the tendon, then maintains the tendon at the initial length without further rotation. The tendon is equivalent to a rigid linkage, and the entire mechanism becomes a coupled-adaptive mechanism.

4.3. Variable Coupling-Adaptive Grasping Mode

The finger’s distal phalanx touches the object directly and approximately vertically in the variable coupling-adaptive grasping mode, which is convenient for pinching with the thumb. Therefore, this mode is beneficial for grasping flat objects, such as bowls and plates. When the tendon motor rotates synchronously with the linkage driving motor with a specific rule, the coupling ratio between the proximal phalanx and distal phalanx dynamically changes with the tendon BE’s length.

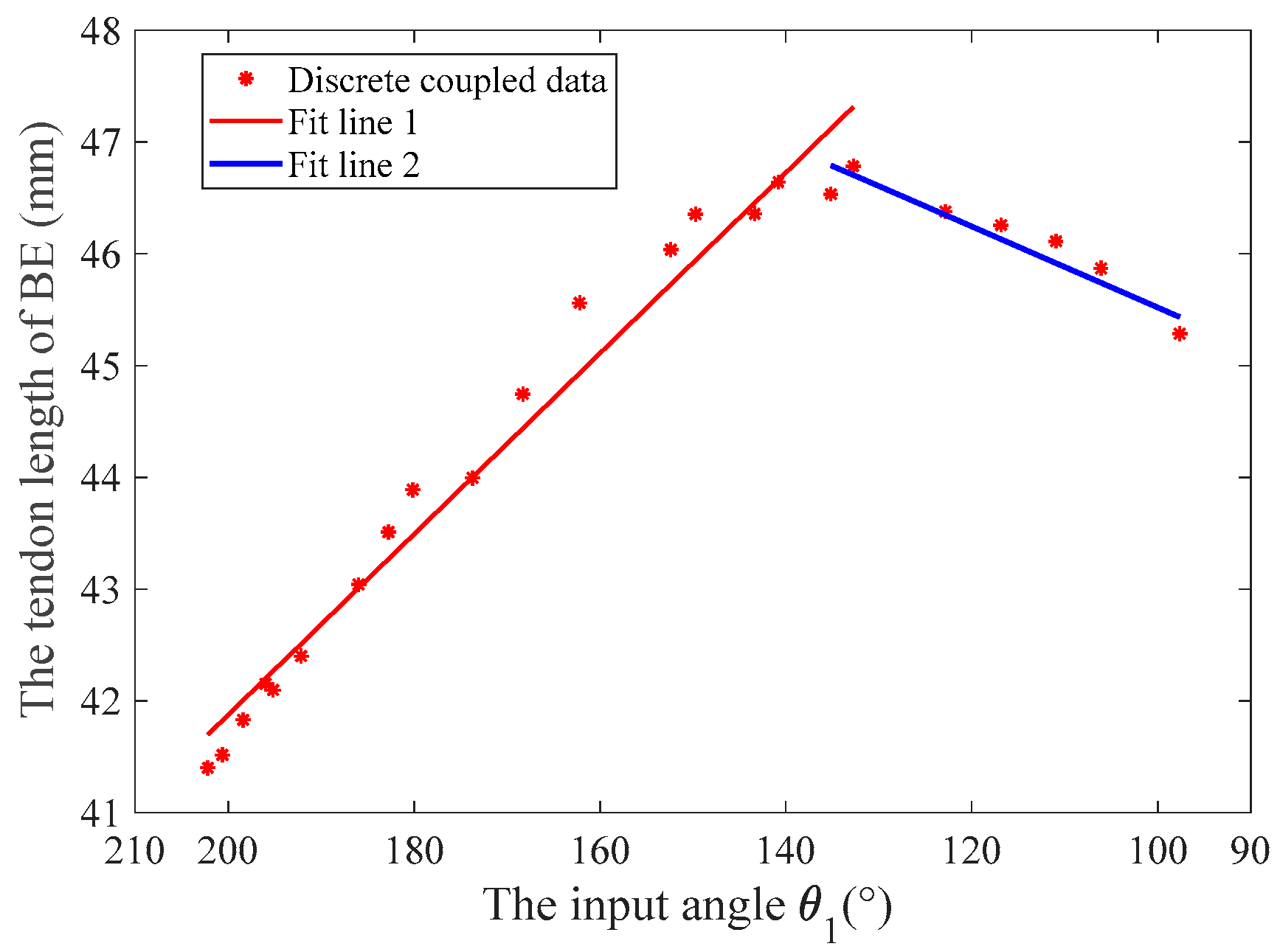

The variable coupling-adaptive grasping mode can achieve the motion of the input trajectory. In this mode, the length change law of tendon

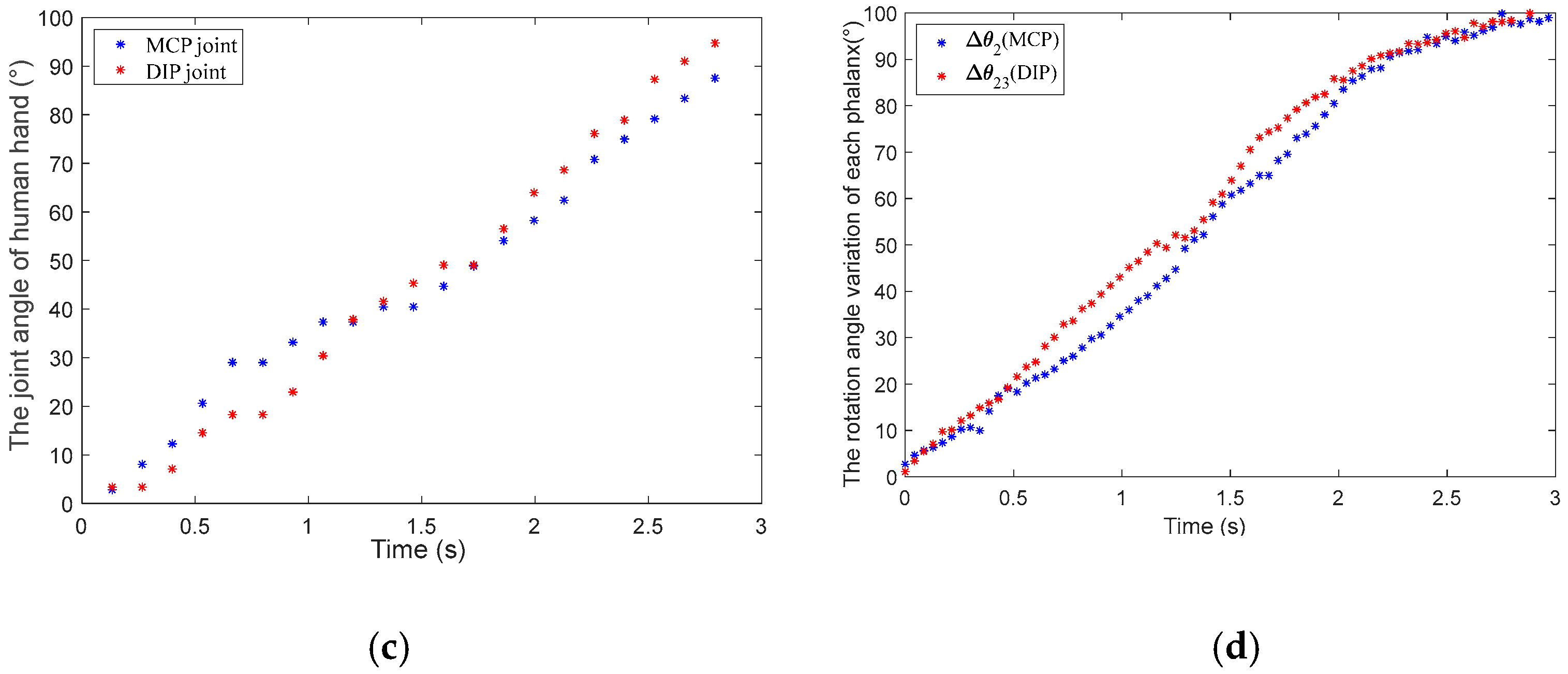

BE can be obtained through kinematic analysis and conversion to reproduce the grasping trajectory of the human hand. As shown in

Figure 5, we take grasping a flat saucer as an example for analysis. Firstly, we collect the angle data of the human hand’s metacarpophalangeal (MCP) joint and proximal interphalangeal (PIP) joint from the CyberGloveII, as shown in

Figure 6. Secondly, the coupling relationship between the proximal phalanx and distal phalanx is obtained from the collected data. Thirdly, we combine the result of kinematic analysis Equations (3) and (4) in

Section 3. Finally, the relationship between the driving rod’s input angle

and tendon 5’s length can be derived, as shown in

Figure 7. The obtained discrete data are fitted with a polynomial curve, and a linear fitting of the first order is used in this example:

Then, differentiating to time yields:

We combine the drive shaft’s radius, the worm gear, and the gears’ reduction ratio to convert the speed. The speed relationship between the linkage driving motor and the tendon driving motor is obtained as follows:

5. Experimental Verification

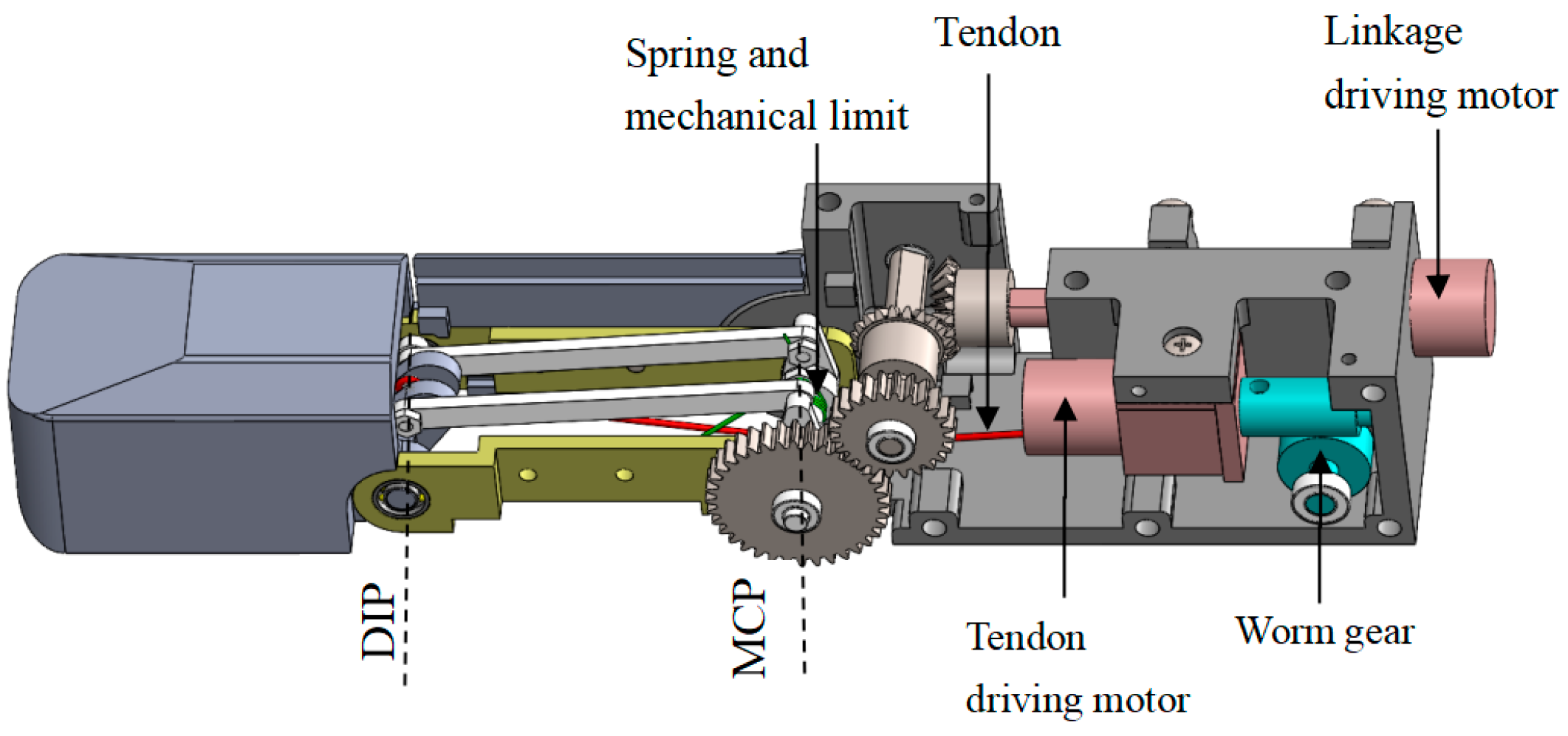

The three-dimensional internal structure of the finger proposed in this paper is shown in

Figure 8. The linkage driving motor and the tendon driving motor are placed parallel and opposite to make the structure more compact. The tendon is arranged at the symmetrical center of the finger. The proximal phalanx adopts two sets of linkage mechanisms with the center symmetrical to distribute the load evenly, reduce the risk of jamming, and increase the strength of the mechanism. A worm gear mechanism is connected at the output shaft of the tendon driving motor, which has a self-locking function to ensure the tendon cannot be stretched in the coupled-adaptive mode.

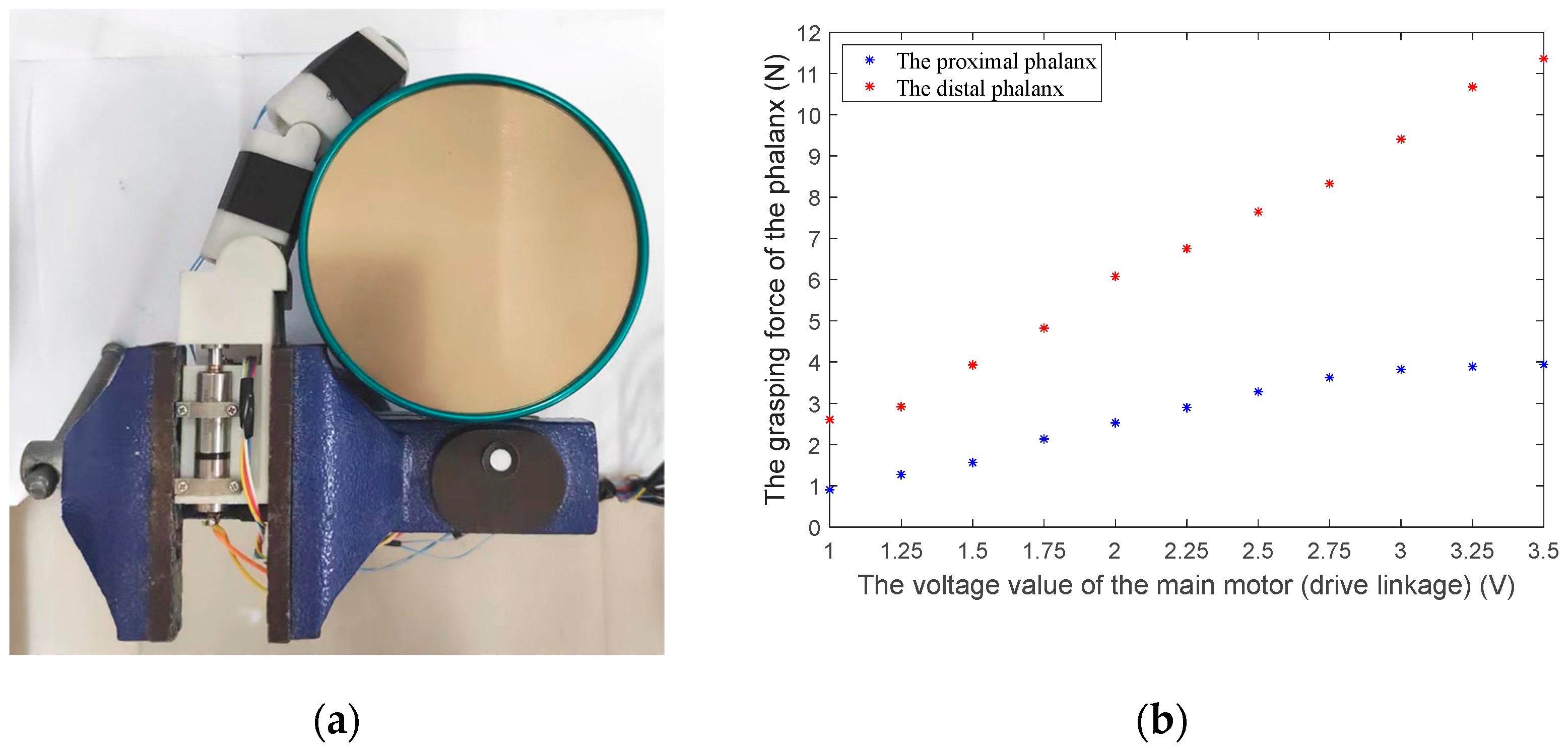

The prototype finger is shown in

Figure 9. Considering the mechanical strength and lightweight structure requirements, the finger shell is made of glass-fiber-reinforced nylon from 3D printing, and the internal linkage mechanism is made of high-strength aluminum alloy. The finger’s overall length (including the palm part) is about 15 cm, and the phalanx length is 9 cm, which is similar to human hands. The Faulhaber micro-high-speed motor (1016K006SR) and 1024 reduction ratio reducer are used to ensure the finger‘s grasping force output. As shown in

Figure 10a, we install the finger on a fixed platform. Then, we arrange two force-sensing resistors (FSRs) at the finger’s proximal phalanx and distal phalanx, respectively, to measure the finger’s grasping force when grasping a cylindrical tin can. According to

Figure 10b, when the motor’s torque is approximately 0.5 N·mm with a voltage of 3.5 V, the force of the proximal phalanx and distal phalanx is approximately 4 N and 11.4 N, respectively.

To verify the proposed multi-mode finger’s grasping performance, the finger’s shape-adaptive, coupled-adaptive, and variable coupling-adaptive grasping modes are tested and analyzed in this paper. We collect the finger’s MCP and distal interphalangeal (DIP) joints’ angle data using two bending sensors. Then, we compare and analyze the movement characteristics between the human hand and mechanical finger, as shown in

Figure 11,

Figure 12 and

Figure 13.

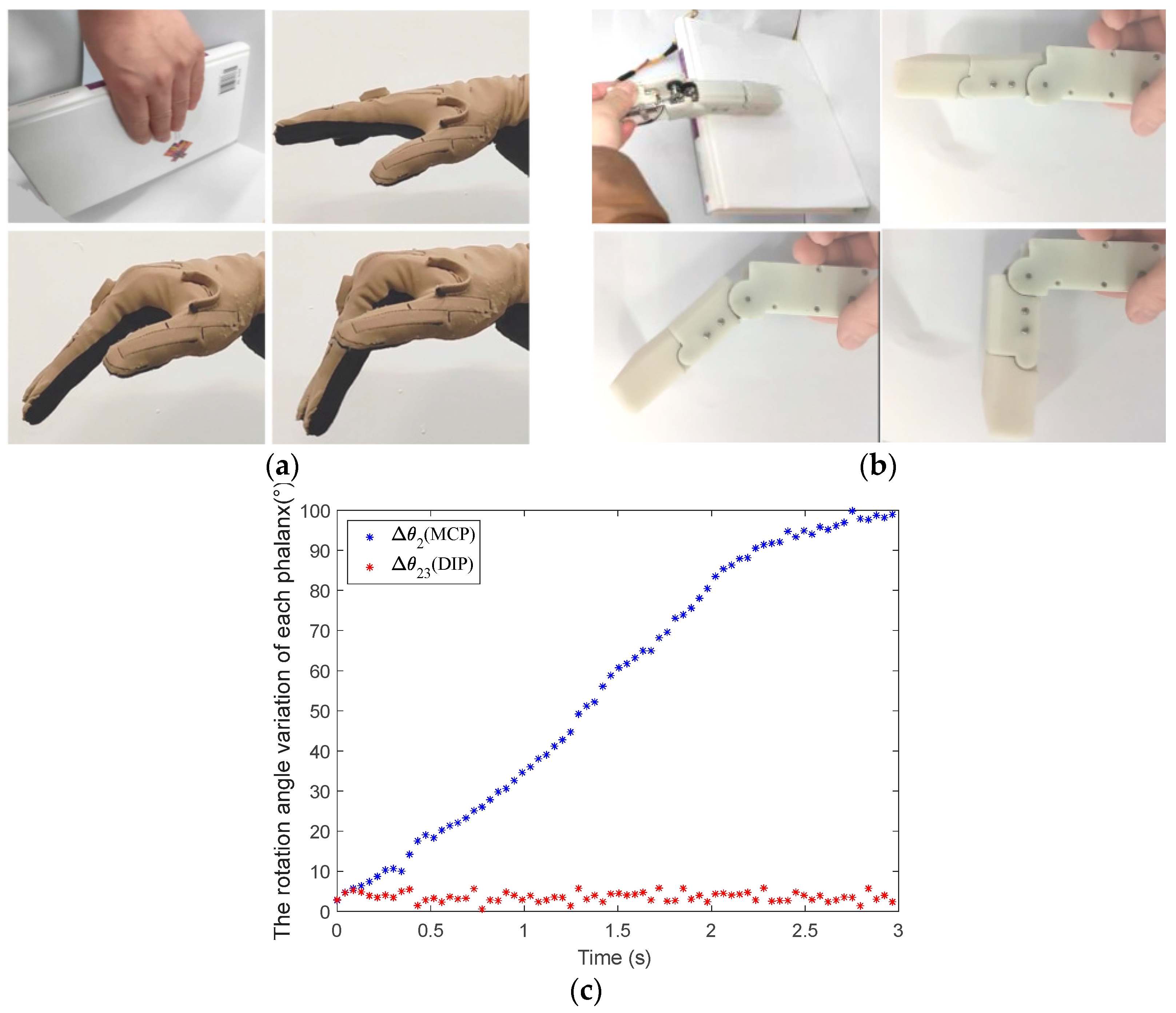

As shown in

Figure 11a, the human hand is straight when grasping a large tabulate book. There is no relative movement between the proximal phalanx and distal phalanx; they bend downward as a whole. When the tendon driving motor rotates quickly at the beginning of the finger grasp, the tendon is released from the wheel; then, the mechanical finger is in the shape-adaptive mode. The action of the finger grasping a book is shown in

Figure 11b at this time. It can be seen that the grasping motion trajectory of the finger is similar to the human hand. In addition, according to the angle data collected using the bending sensor in

Figure 11c, only the MCP joint of the finger rotates under the drive of the linkage driving motor, which is consistent with the human hand. Therefore, the proposed finger can grasp the large tabulate object well in shape-adaptive mode.

As shown in

Figure 12a, when the human hand grasps a cylindrical tin can, it is in an enveloping grasping state. Each phalanx of the human hand is bending simultaneously and with a similar angle. If the tendon driving motor does not rotate and the tendon is initially in a tension state, the mechanical finger is in coupled-adaptive mode. Using the finger to grasp the cylindrical tin can in coupled-adaptive mode is shown in

Figure 12b. It can be seen that both the finger’s MCP joint and PIP joint rotate simultaneously by comparing with

Figure 12a,b. Their rotation angles are also similar according to the angle data in

Figure 12d, in line with the human hand’s motion characteristics collected using CyberGloveII in

Figure 12c. Therefore, the proposed finger can grasp the cylindrical or spherical object well in coupled-adaptive mode.

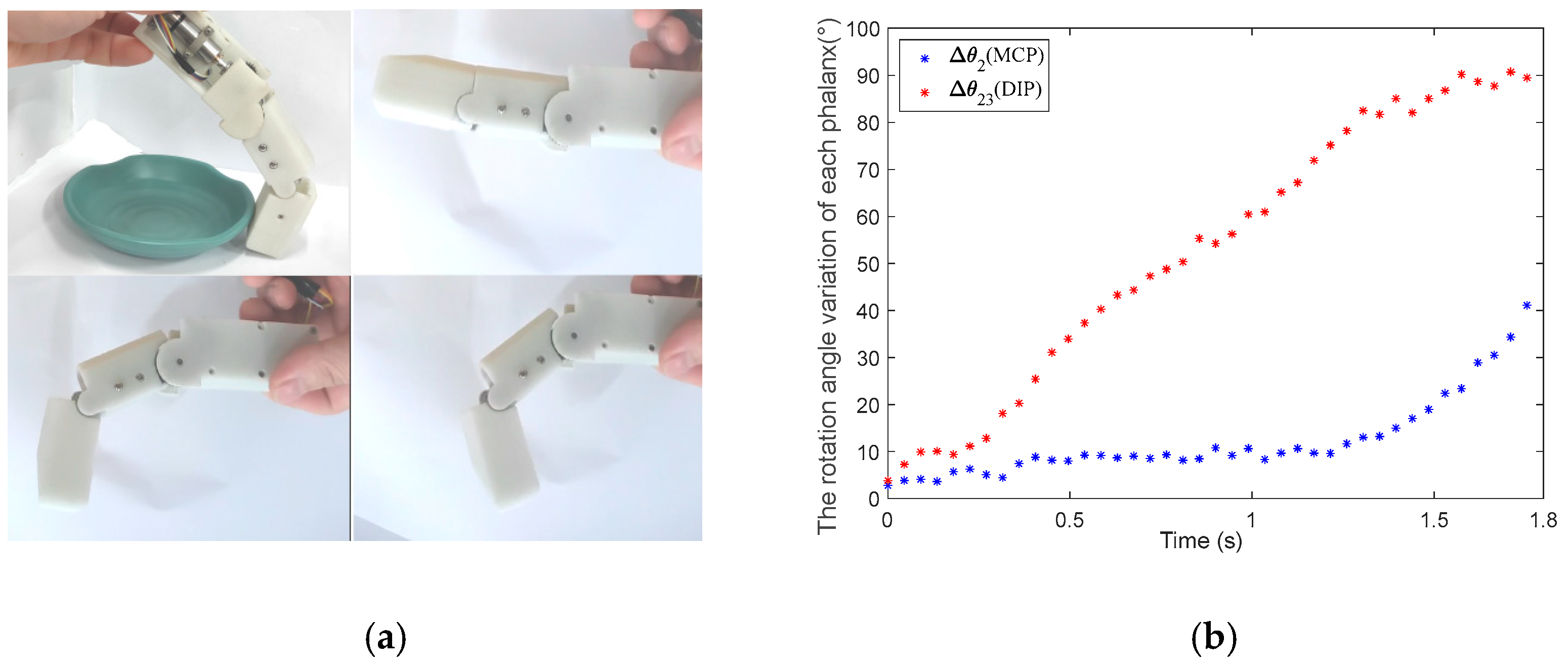

The human hand grasping the flat saucer is shown in

Figure 5 in

Section 4. The mechanical finger switches to the variable coupling-adaptive mode to grasp a flat saucer, as shown in

Figure 13a. In this mode, the tendon driving motor and linkage driving motor rotate synchronously according to the speed rule obtained in

Section 4. It can be seen that the distal phalanx’s grasp speed is faster than the proximal phalanx, according to

Figure 13b. This motion characteristic is consistent with the human hand shown in

Figure 6. Therefore, the finger has a good grasping effect under variable coupling-adaptive grasping mode.

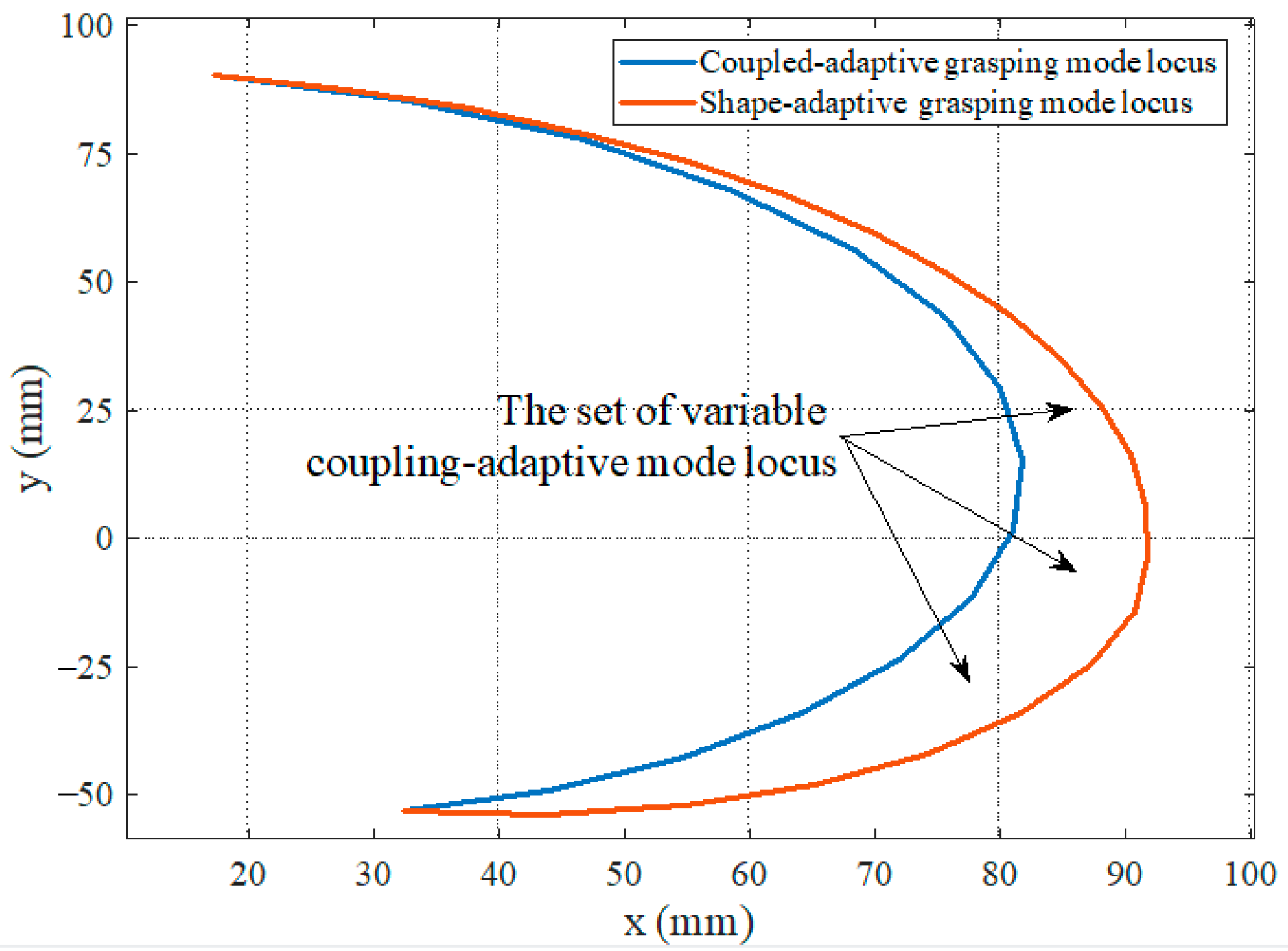

Based on the above grasping experiments, the finger presented in this paper can achieve the three grasping modes. The fingertip locus of the finger in the shape-adaptive and coupled-adaptive modes is drawn through kinematics, as shown in

Figure 14. It can be seen that the grasping space of the shape-adaptive grasping mode is the largest, and the coupled-adaptive grasping mode is the smallest. In addition, the grasping space of the variable coupling-adaptive grasping mode is in the middle part between them. By controlling different speed change rules of the tendon driving motor, various variable coupling-adaptive grasping modes can be realized. The finger’s grasping space and motion trajectory can be dynamically adjusted to adapt to different grasping scenes and targets, which improves the finger’s dexterity and grasping mode diversity. The grasping evaluation experiments show that the prototype finger performed well in its shape-adaptive capability and can effectively envelop various cylinders, spheres, rectangular objects, flat plates, and small parts of different diameters, as shown in

Figure 15.

6. Conclusions

This paper presented a novel design for a multi-mode mechanical finger based on linkage and tendon fusion transmission. The finger can realize shape-adaptive, coupled-adaptive, and variable coupling-adaptive grasping. Firstly, the mechanical structure of the proposed finger was introduced. The finger’s structural parameters were optimized. Furthermore, we discussed controlling the tendon’s length and tension to switch three different modes. Subsequently, the finger’s grasping performance was verified through grasping experiments using a prototype finger.

The research demonstrates that the finger can achieve three grasping modes by controlling the relationship between the linkage driving motor and the tendon driving motor. In addition, the finger’s grasping space and motion trajectory can be dynamically adjusted by the drive speed of the tendon driving motor, which can adapt to different objects. Hence, the proposed fingers can improve the flexibility of the robotic hand and achieve grasping operations similar to humans.

In the future, we will design a multi-finger robotic hand to perform more grasping tasks. Furthermore, we will combine with the vision to identify the grasping object’s contour, then design the corresponding grasping control strategy to realize efficient multi-mode grasping operation.