Simple Microcontact Printing Technique to Obtain Cell Patterns by Lithography Using Grayscale, Photopolymer Flexographic Mold, and PDMS

Abstract

1. Introduction

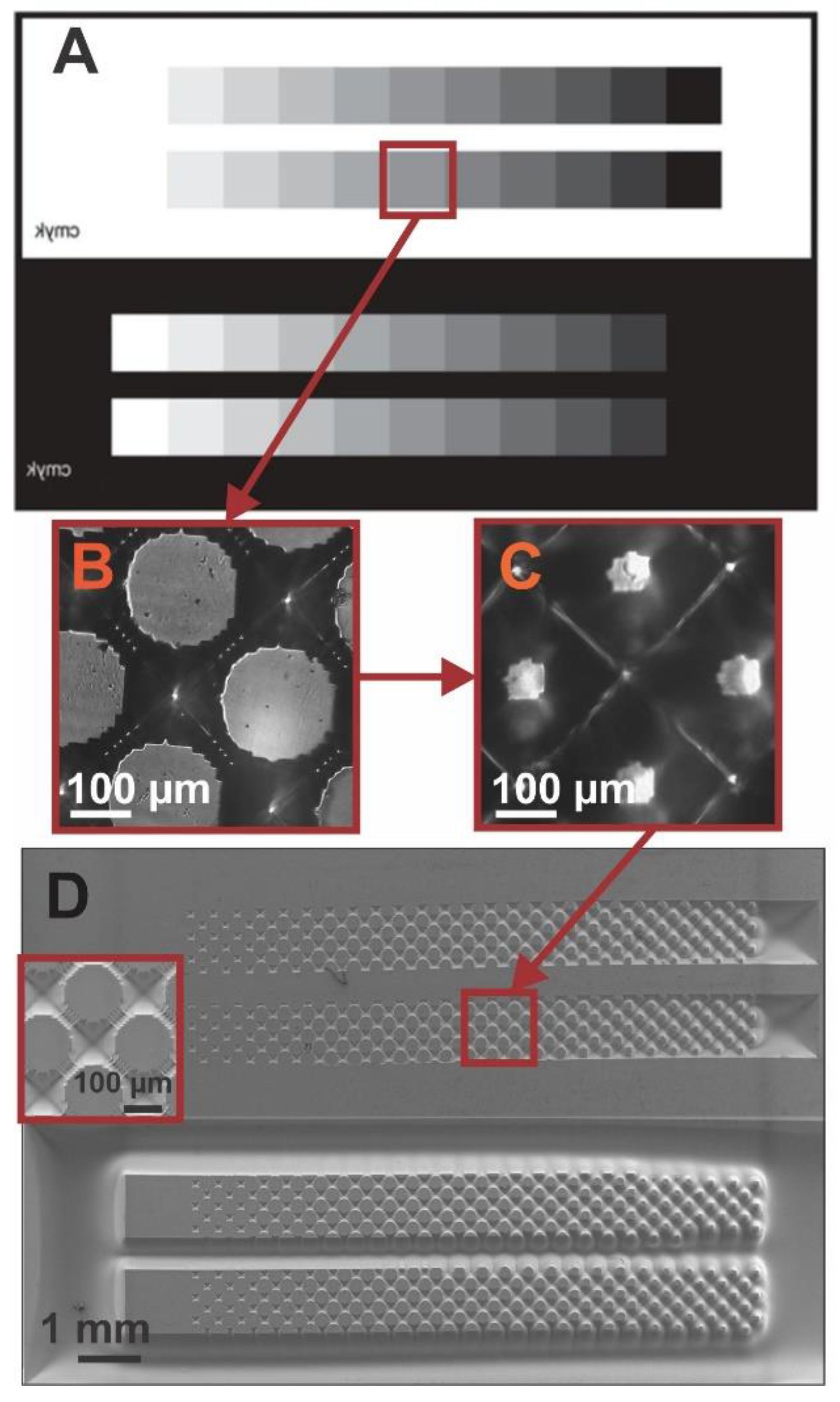

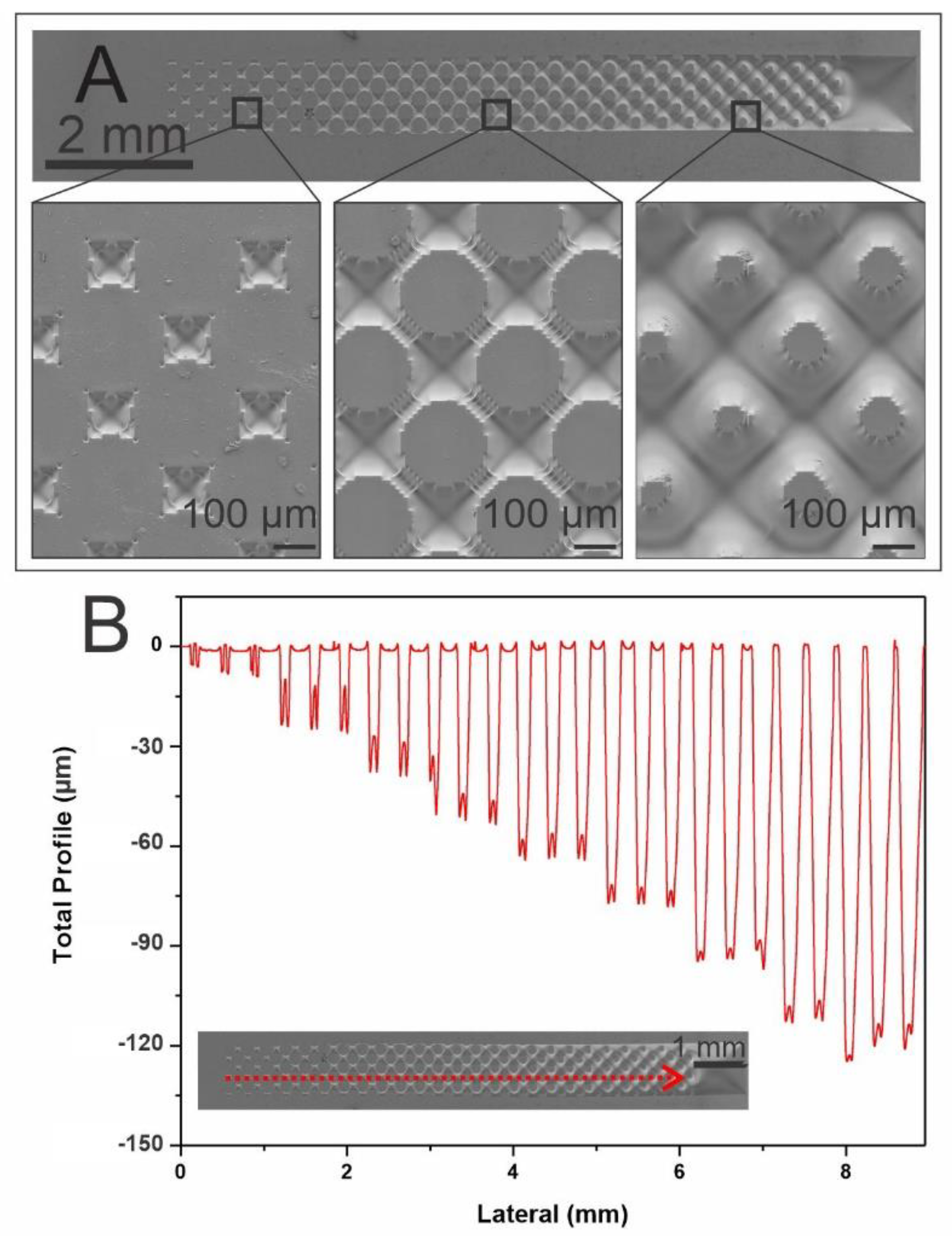

2. Materials and Methods

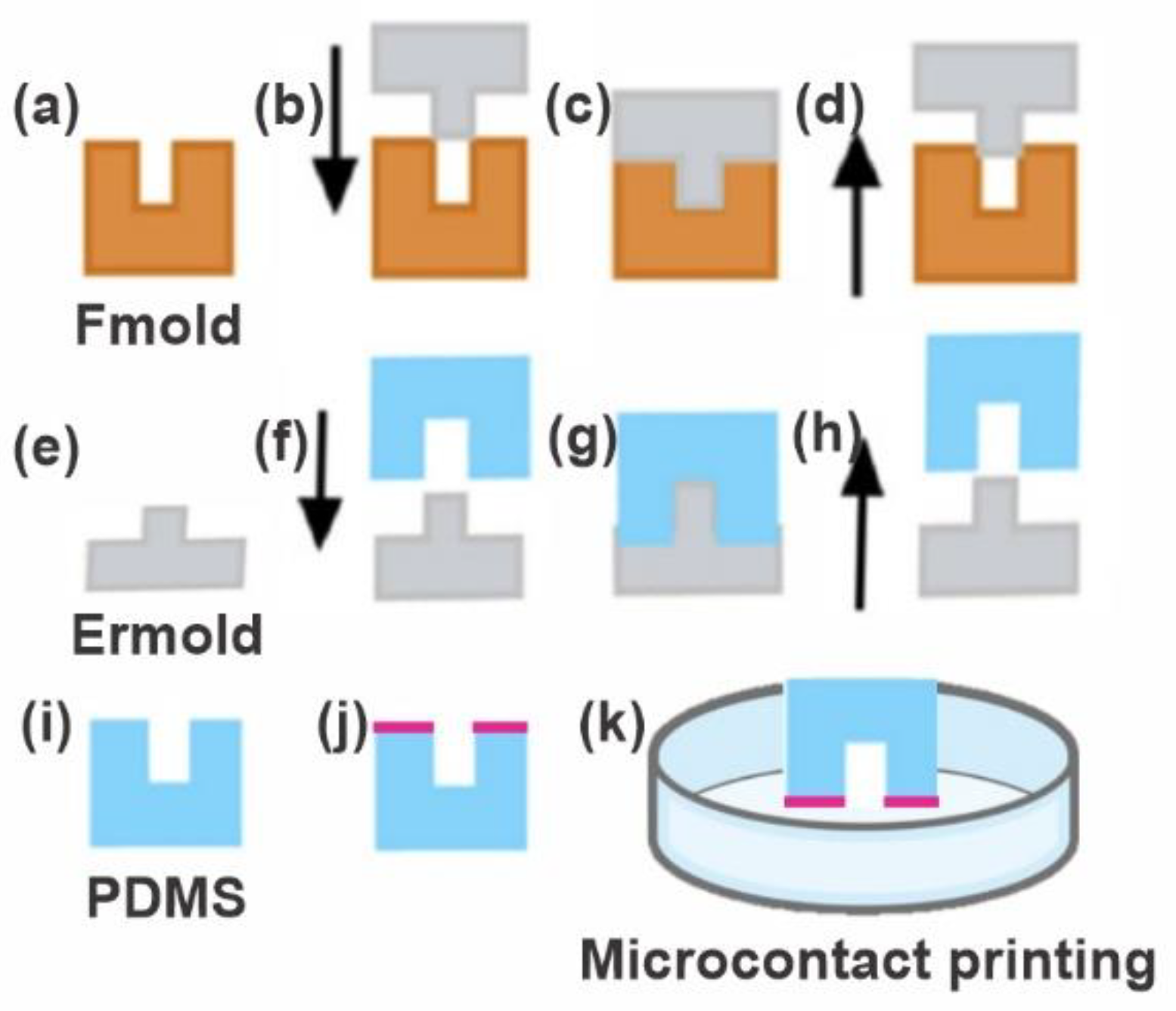

2.1. Fabrication of PDMS Stamp

2.1.1. Photopolymer Flexographic Mold (Fmold)

2.1.2. Epoxy Resin Mold (ERmold)

2.1.3. PDMS Stamp

2.2. Characterization

2.3. Cell Culture

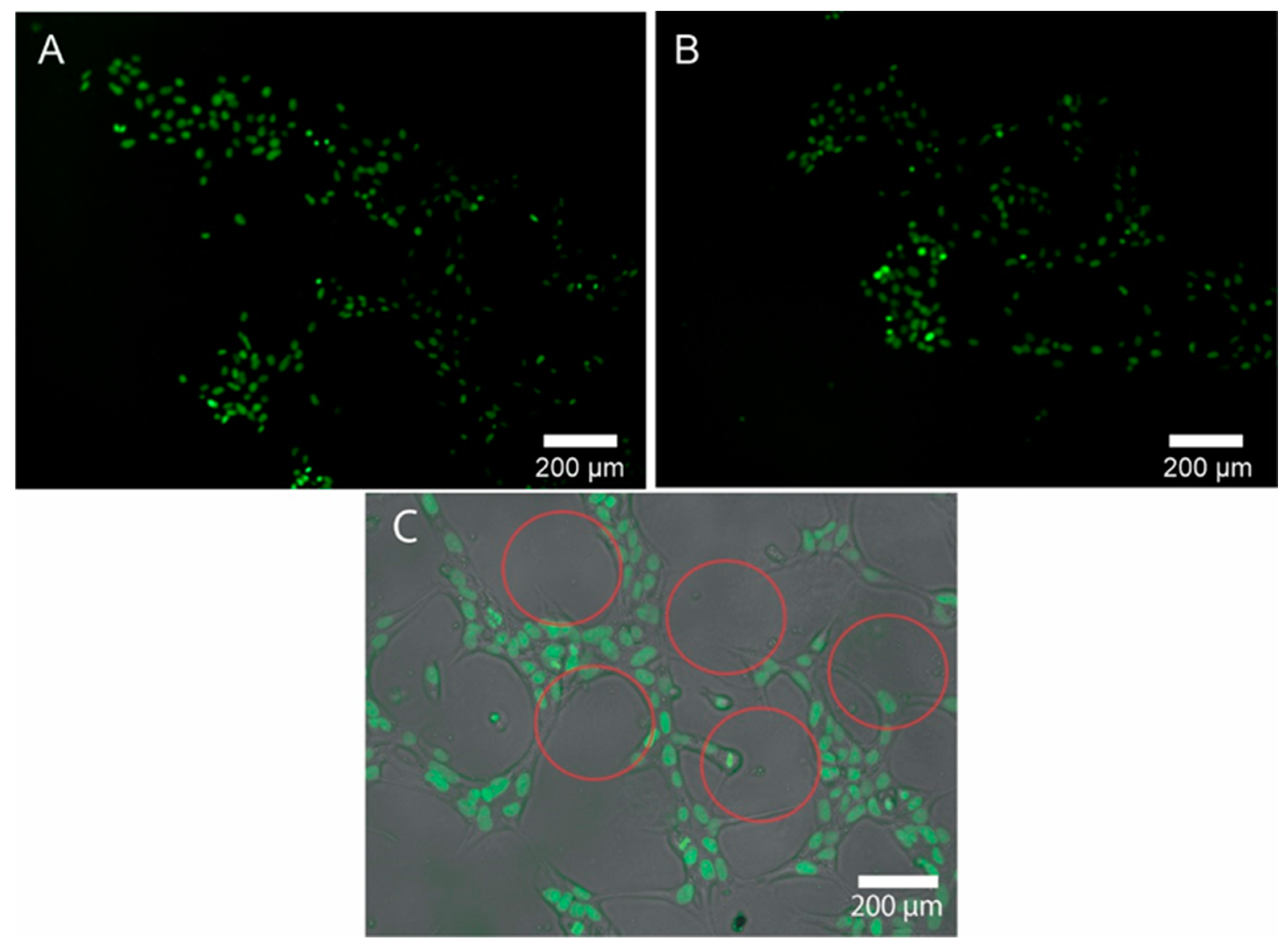

2.4. Contact Printing on Cell Culture Plates

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Derby, B. Printing and prototyping of tissues and scaffolds. Science 2012, 338, 921–926. [Google Scholar] [CrossRef]

- Lee, H.; Jeon, T.Y.; Lee, S.Y.; Lee, S.Y.; Kim, S.-H. Designing Multicolor Micropatterns of Inverse Opals with Photonic Bandgap and Surface Plasmon Resonance. Adv. Funct. Mater. 2018, 28, 1706664. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Voisiat, B.; Kunze, T.; Lasagni, A.F. The Role of the Surface Nano-Roughness on the Wettability Performance of Microstructured Metallic Surface Using Direct Laser Interference Patterning. Materials 2019, 12, 2737. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Dai, S.; John, J.; Carter, K.R. Superhydrophobic surfaces from hierarchically structured wrinkled polymers. ACS Appl. Mater. Interfaces 2013, 5, 11066–11073. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, B.; Liu, Y.; Suo, X.; Li, H. Influence of surface topography on bacterial adhesion: A review. Biointerphases 2018, 13, 060801. [Google Scholar] [CrossRef]

- Geim, A.K.; Dubonos, S.V.; Grigorieva, I.V.; Novoselov, K.S.; Zhukov, A.A.; Shapoval, S.Y. Microfabricated adhesive mimicking gecko foot-hair. Nat. Mater. 2003, 2, 461–463. [Google Scholar] [CrossRef]

- Martines, E.; Seunarine, K.; Morgan, H.; Gadegaard, N.; Wilkinson, C.D.W.; Riehle, M.O. Superhydrophobicity and superhydrophilicity of regular nanopatterns. Nano Lett. 2005, 5, 2097–2103. [Google Scholar] [CrossRef]

- Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G.M.; Yin, X.; Xiao, J. Harnessing Surface Wrinkling-Cracking Patterns for Tunable Optical Transmittance. Adv. Opt. Mater. 2017, 5, 1700425. [Google Scholar] [CrossRef]

- Kim, D.; Ko, Y.; Kwon, G.; Kim, U.J.; You, J. Micropatterning Silver Nanowire Networks on Cellulose Nanopaper for Transparent Paper Electronics. ACS Appl. Mater. Interfaces 2018, 10, 38517–38525. [Google Scholar] [CrossRef]

- Raghavan, S.; Chen, C.S. Micropatterned Environments in Cell Biology. Adv. Mater. 2004, 16, 1303–1313. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. 3D printed microfluidic devices: Enablers and barriers. Lab Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef] [PubMed]

- Lima, F.; Khazi, I.; Mescheder, U.; Tungal, A.C.; Muthiah, U. Fabrication of 3D microstructures using grayscale lithography. Adv. Opt. Technol. 2019, 8, 181–193. [Google Scholar] [CrossRef]

- Chen, C.; Hirdes, D.; Folch, A. Gray-scale photolithography using microfluidic photomasks. Proc. Natl. Acad. Sci. USA 2003, 100, 1499–1504. [Google Scholar] [CrossRef] [PubMed]

- Pang, Y.; Shu, Y.; Shavezipur, M.; Wang, X.; Mohammad, M.A.; Yang, Y.; Zhao, H.; Deng, N.; Maboudian, R.; Ren, T.L. 3D Stretchable Arch Ribbon Array Fabricated via Grayscale Lithography. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Stavis, S.M.; Strychalski, E.A.; Gaitan, M. Nanofluidic structures with complex three-dimensional surfaces. Nanotechnology 2009, 20, 165302. [Google Scholar] [CrossRef]

- Loomis, J.; Ratnayake, D.; McKenna, C.; Walsh, K.M. Grayscale lithography—automated mask generation for complex three-dimensional topography. J. Micro/Nanolithography MEMS MOEMS 2016, 15, 013511. [Google Scholar] [CrossRef]

- Grushina, A. Direct-write grayscale lithography. Adv. Opt. Technol. 2019, 8, 163–169. [Google Scholar] [CrossRef]

- Mortelmans, T.; Kazazis, D.; Guzenko, V.A.; Padeste, C.; Braun, T.; Stahlberg, H.; Li, X.; Ekinci, Y. Grayscale e-beam lithography: Effects of a delayed development for well-controlled 3D patterning. Microelectron. Eng. 2020, 225, 111272. [Google Scholar] [CrossRef]

- Erdmanis, M.; Tittonen, I. Focused ion beam high resolution grayscale lithography for silicon-based nanostructures. Appl. Phys. Lett. 2014, 104, 073118. [Google Scholar] [CrossRef]

- Schleunitz, A.; Schift, H. Fabrication of 3D patterns with vertical and sloped sidewalls by grayscale electron-beam lithography and thermal annealing. Microelectron. Eng. 2011, 88, 2736–2739. [Google Scholar] [CrossRef]

- Gale, M.T. Fabrication of continuous-relief micro-optical elements by direct laser writing in photoresists. Opt. Eng. 1994, 33, 3556. [Google Scholar] [CrossRef]

- Mosher, L.; Waits, C.M.; Morgan, B.; Ghodssi, R. Double-exposure grayscale photolithography. J. Microelectromech. Syst. 2009, 18, 308–315. [Google Scholar] [CrossRef]

- Abdul Hamid, I.S.L.; Khim, B.K.; Sal Hamid, S.; Abd Rahman, M.F.; Abd Manaf, A. Implementation of a single emulsion mask for three-dimensional (3D) microstructure fabrication of micromixers using the grayscale photolithography technique. Micromachines 2020, 11, 548. [Google Scholar] [CrossRef] [PubMed]

- Mekaru, H. Fabrication and evaluation of a grayscale mask for x-ray lithography using MEMS technology. J. Micro/Nanolithography MEMS MOEMS 2008, 7, 013009. [Google Scholar] [CrossRef]

- Shrauger, V.E.; Erwin, L.L.; Ahn, J.L.; Warde, C. Computer-generated multiple-phase-level holograms by use of color-printer techniques. Appl. Opt. 1994, 33, 5318. [Google Scholar] [CrossRef] [PubMed]

- Kaufmann, T.; Ravoo, B.J. Stamps, inks and substrates: Polymers in microcontact printing. Polym. Chem. 2010, 1, 371–387. [Google Scholar] [CrossRef]

- Santhanam, V.; Andres, R.P. Microcontact Printing of Uniform Nanoparticle Arrays. Nano Lett. 2004, 4, 41–44. [Google Scholar] [CrossRef]

- Bernard, A.; Renault, J.P.; Michel, B.; Bosshard, H.R.; Delamarche, E. Microcontact printing of proteins. Adv. Mater. 2000, 12, 1067–1070. [Google Scholar] [CrossRef]

- Xu, L.; Robert, L.; Ouyang, Q.; Taddei, F.; Chen, Y.; Lindner, A.B.; Baigl, D. Microcontact printing of living bacteria arrays with cellular resolution. Nano Lett. 2007, 7, 2068–2072. [Google Scholar] [CrossRef]

- Lange, S.A.; Benes, V.; Kern, D.P.; Hörber, J.K.H.; Bernard, A. Microcontact Printing of DNA Molecules. Anal. Chem. 2004, 76, 1641–1647. [Google Scholar] [CrossRef]

- Bourguignon, N.; Olmos, C.M.; Sierra-Rodero, M.; Peñaherrera, A.; Rosero, G.; Pineda, P.; Vizuete, K.; Arroyo, C.R.; Cumbal, L.; Lasorsa, C.; et al. Accessible and Cost-Effective Method of PDMS Microdevices Fabrication Using a Reusable Photopolymer Mold. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1433–1442. [Google Scholar] [CrossRef]

- Bhansali, S.; Perez, M.S.; Lerner, B.; Bourguignon, N. Large Microfluidic Bioreactor And Manufacturing Method Thereof. U.S. Patent 11,135,589, 5 October 2021. [Google Scholar]

- Olmos, C.M.; Vaca, A.; Rosero, G.; Peñaherrera, A.; Perez, C.; de Sá Carneiro, I.; Vizuete, K.; Arroyo, C.R.; Debut, A.; Pérez, M.S.; et al. Epoxy resin mold and PDMS microfluidic devices through photopolymer flexographic printing plate. Sens. Actuators B Chem. 2019, 288, 742–748. [Google Scholar] [CrossRef]

- Olmos, C.M.; Penãherrera, A.; Rosero, G.; Vizuete, K.; Ruarte, D.; Follo, M.; Vaca, A.; Arroyo, C.R.; Debut, A.; Cumbal, L.; et al. Cost-effective fabrication of photopolymer molds with multi-level microstructures for pdms microfluidic device manufacture. RSC Adv. 2020, 10, 4071–4079. [Google Scholar] [CrossRef]

- KODAK FLEXCEL NX. The Revolutionary Technology at the Heart of KODAK FLEXCEL NX Solutions is the Result of Many Years of Expertise in Print and Materials Science—Distilled into a Decade of Dedicated Flexo R&D. Available online: https://www.miraclon.com/products-technology/our-technology/ (accessed on 1 September 2022).

- Layout Editor. Available online: https://layouteditor.com/ (accessed on 1 September 2022).

- Pérez-Sosa, C.; Pazmiño Peñaherrera, A.B.; Rosero, G.; Bourguignon, N.; Aravelli, A.; Bhansali, S.; Pérez, M.S.; Lerner, B. Novel Reproducible Manufacturing and Reversible Sealing Method for Microfluidic Devices. Micromachines 2022, 13, 650. [Google Scholar] [CrossRef]

- Peñaherrera, A.; Payés, C.; Sierra-Rodero, M.; Vega, M.; Rosero, G.; Lerner, B.; Helguera, G.; Pérez, M.S.S. Evaluation of cell culture in microfluidic chips for application in monoclonal antibody production. Microelectron. Eng. 2016, 158, 126–129. [Google Scholar] [CrossRef]

- Hoang, P.; Wang, J.; Conklin, B.R.; Healy, K.E.; Ma, Z. Generation of spatial-patterned early-developing cardiac organoids using human pluripotent stem cells. Nat. Protoc. 2018, 13, 723–737. [Google Scholar] [CrossRef] [PubMed]

- Waits, C.M.; Morgan, B.; Kastantin, M.; Ghodssi, R. Microfabrication of 3D silicon MEMS structures using gray-scale lithography and deep reactive ion etching. Sens. Actuators A Phys. 2005, 119, 245–253. [Google Scholar] [CrossRef]

- Hamid, I.S.L.A.; Khim, B.K.; Omar, M.F.M.; Zain, K.A.M.; Rhaffor, N.A.; Hamid, S.S.; Manaf, A.A. Three-Dimensional Soft Material Micropatterning via Grayscale Photolithography for Improved Hydrophobicity of Polydimethylsiloxane (PDMS). Micromachines 2022, 13, 78. [Google Scholar] [CrossRef]

- Bietsch, A.; Michel, B. Conformal contact and pattern stability of stamps used for soft lithography. J. Appl. Phys. 2000, 88, 4310–4318. [Google Scholar] [CrossRef]

- Alom Ruiz, S.; Chen, C.S. Microcontact printing: A tool to pattern. Soft Matter 2007, 3, 168–177. [Google Scholar] [CrossRef]

- Qiu, S.; Ji, J.; Sun, W.; Pei, J.; He, J.; Li, Y.; Li, J.J.; Wang, G. Recent advances in surface manipulation using micro-contact printing for biomedical applications. Smart Mater. Med. 2021, 2, 65–73. [Google Scholar] [CrossRef]

- Chen, L.; Yan, C.; Zheng, Z. Functional polymer surfaces for controlling cell behaviors. Mater. Today 2018, 21, 38–59. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gimenez, R.; Pérez-Sosa, C.; Bourguignon, N.; Miriuka, S.; Bhansali, S.; Arroyo, C.R.; Debut, A.; Lerner, B.; Pérez, M.S. Simple Microcontact Printing Technique to Obtain Cell Patterns by Lithography Using Grayscale, Photopolymer Flexographic Mold, and PDMS. Biomimetics 2022, 7, 155. https://doi.org/10.3390/biomimetics7040155

Gimenez R, Pérez-Sosa C, Bourguignon N, Miriuka S, Bhansali S, Arroyo CR, Debut A, Lerner B, Pérez MS. Simple Microcontact Printing Technique to Obtain Cell Patterns by Lithography Using Grayscale, Photopolymer Flexographic Mold, and PDMS. Biomimetics. 2022; 7(4):155. https://doi.org/10.3390/biomimetics7040155

Chicago/Turabian StyleGimenez, Rocio, Camilo Pérez-Sosa, Natalia Bourguignon, Santiago Miriuka, Shekhar Bhansali, Carlos R. Arroyo, Alexis Debut, Betiana Lerner, and Maximiliano S. Pérez. 2022. "Simple Microcontact Printing Technique to Obtain Cell Patterns by Lithography Using Grayscale, Photopolymer Flexographic Mold, and PDMS" Biomimetics 7, no. 4: 155. https://doi.org/10.3390/biomimetics7040155

APA StyleGimenez, R., Pérez-Sosa, C., Bourguignon, N., Miriuka, S., Bhansali, S., Arroyo, C. R., Debut, A., Lerner, B., & Pérez, M. S. (2022). Simple Microcontact Printing Technique to Obtain Cell Patterns by Lithography Using Grayscale, Photopolymer Flexographic Mold, and PDMS. Biomimetics, 7(4), 155. https://doi.org/10.3390/biomimetics7040155