Development of Mixed Flow Fans with Bio-Inspired Grooves

Abstract

:1. Introduction

2. Materials and Methods

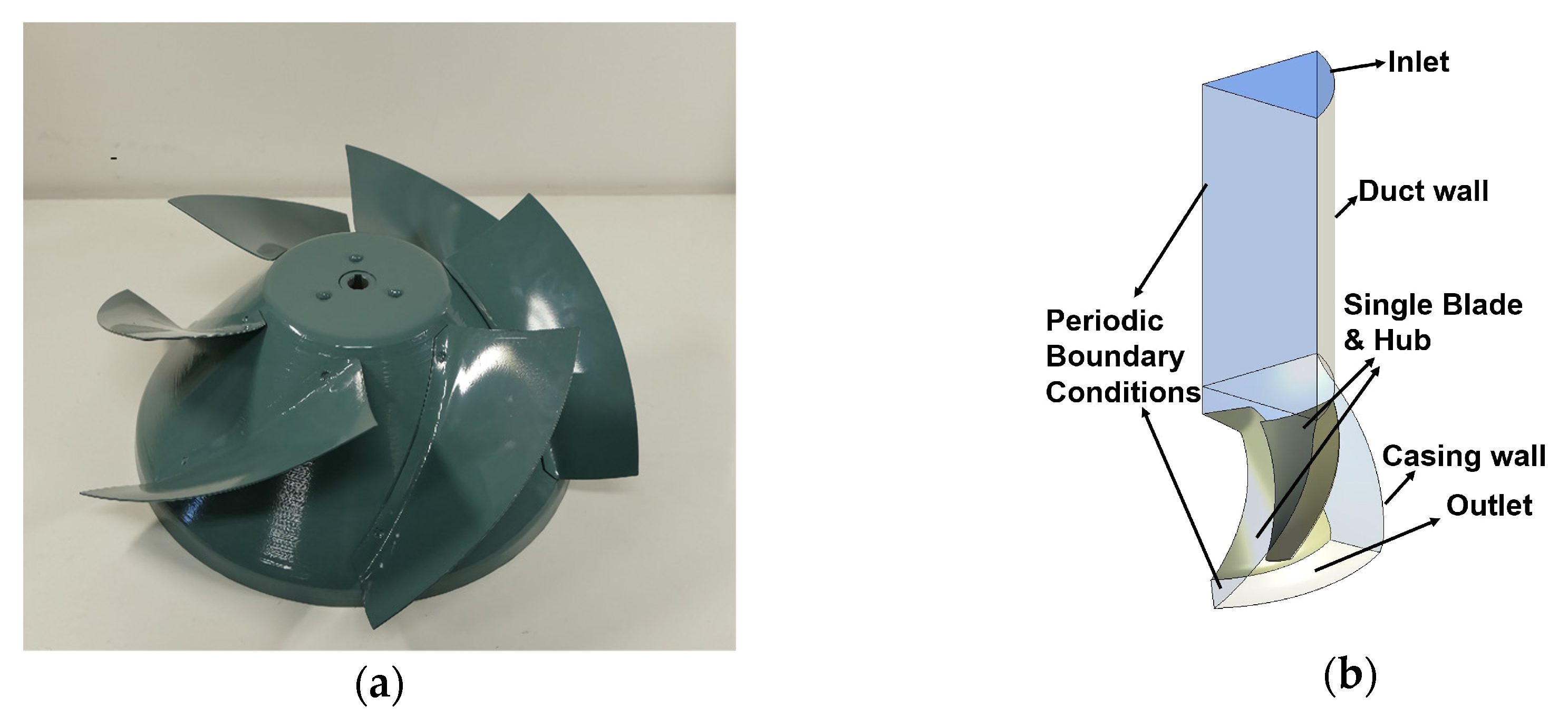

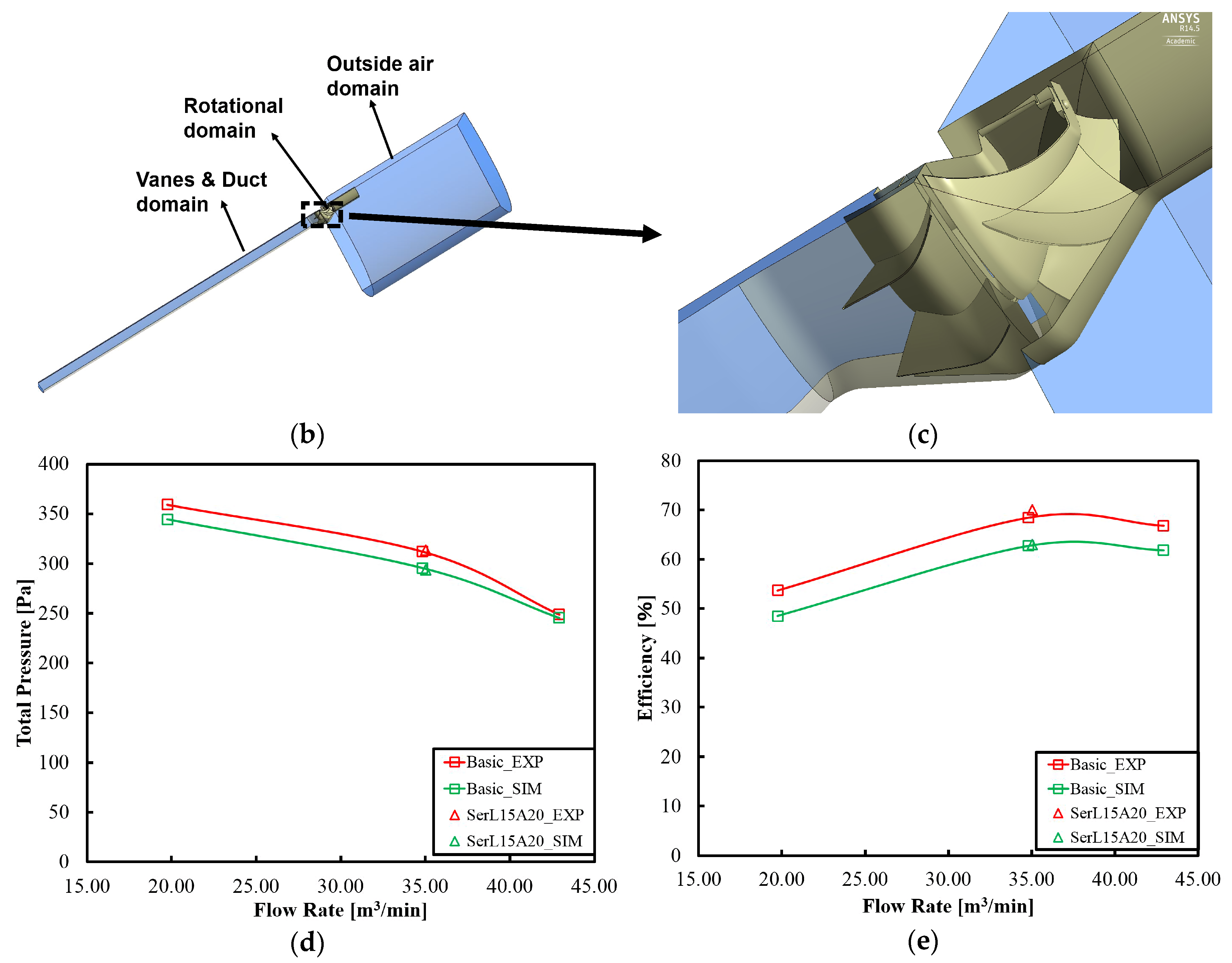

2.1. The Original Impeller and the Computational Fluid Dynamic (CFD) Modelling

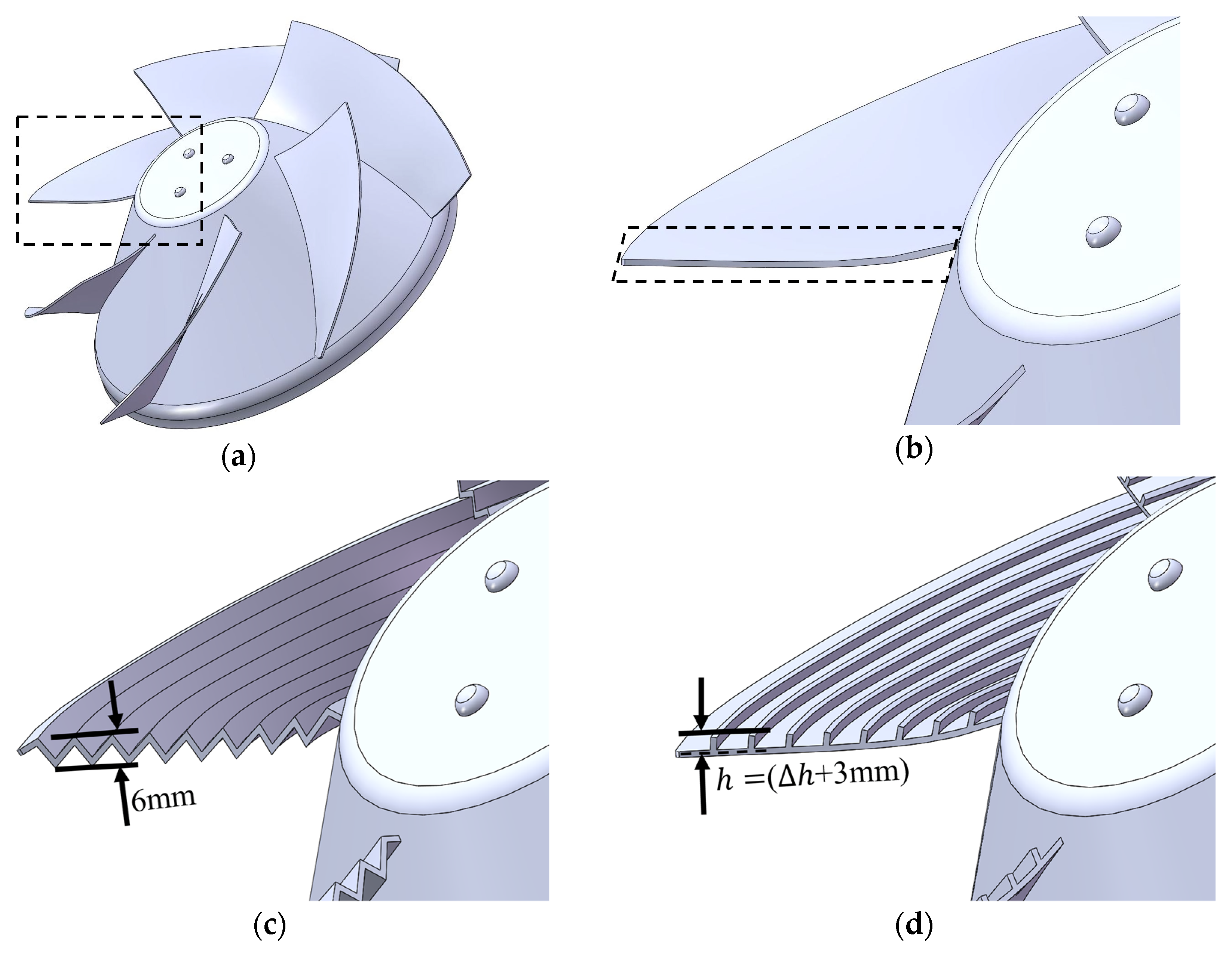

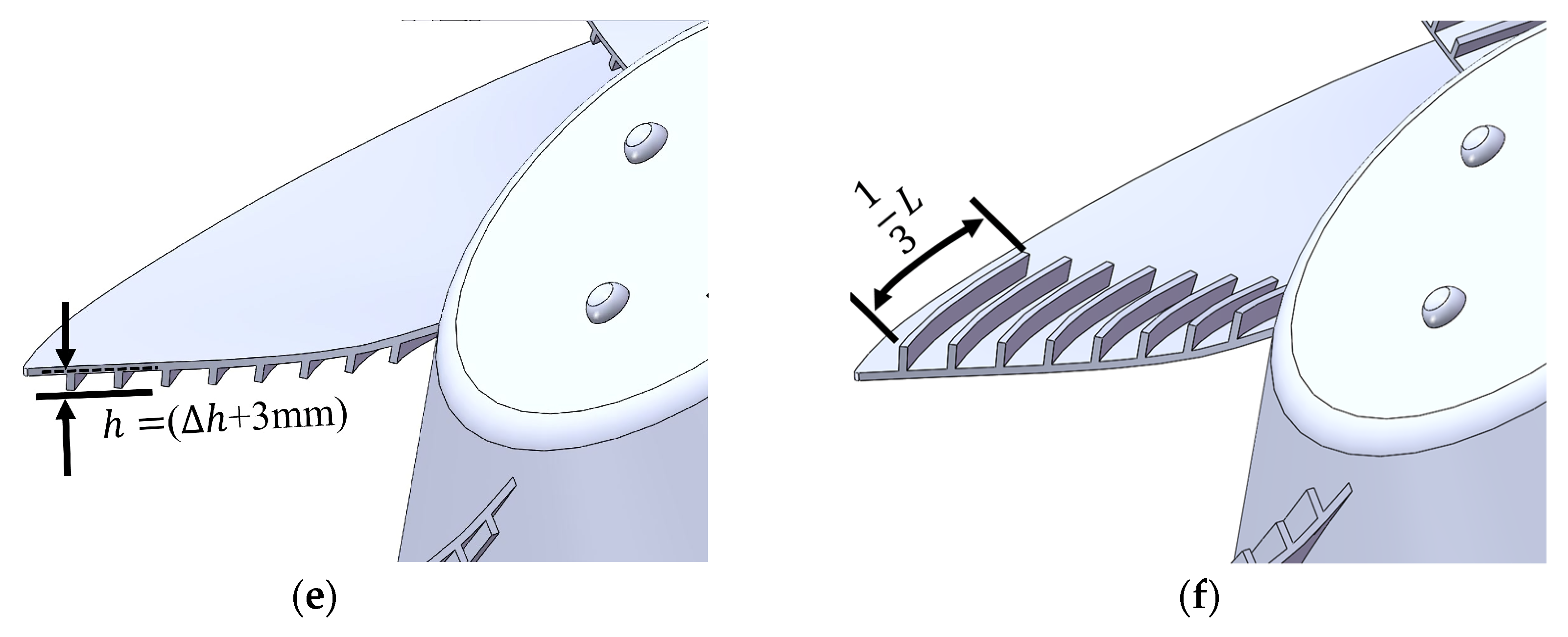

2.2. Biomimetic Designs and the Design Method

2.3. Evaluation Method of Aerodynamic and Aeroacoustic Performance

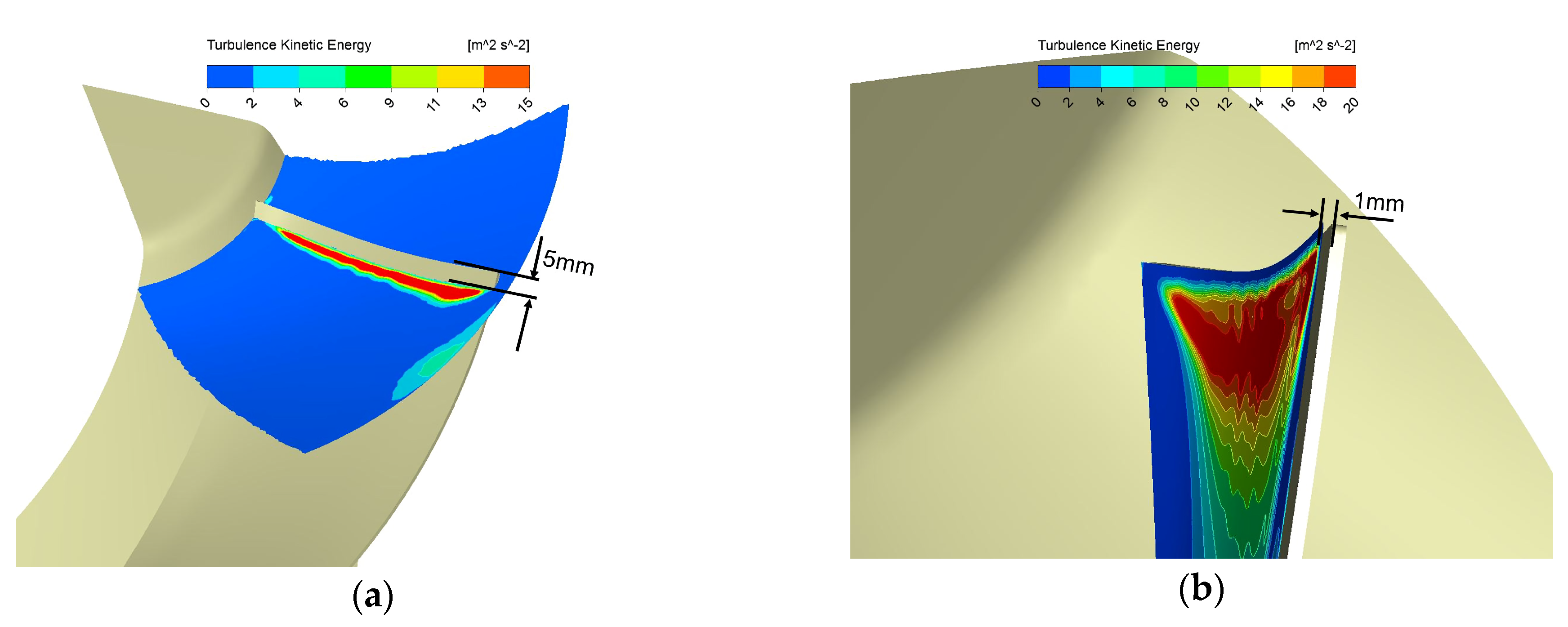

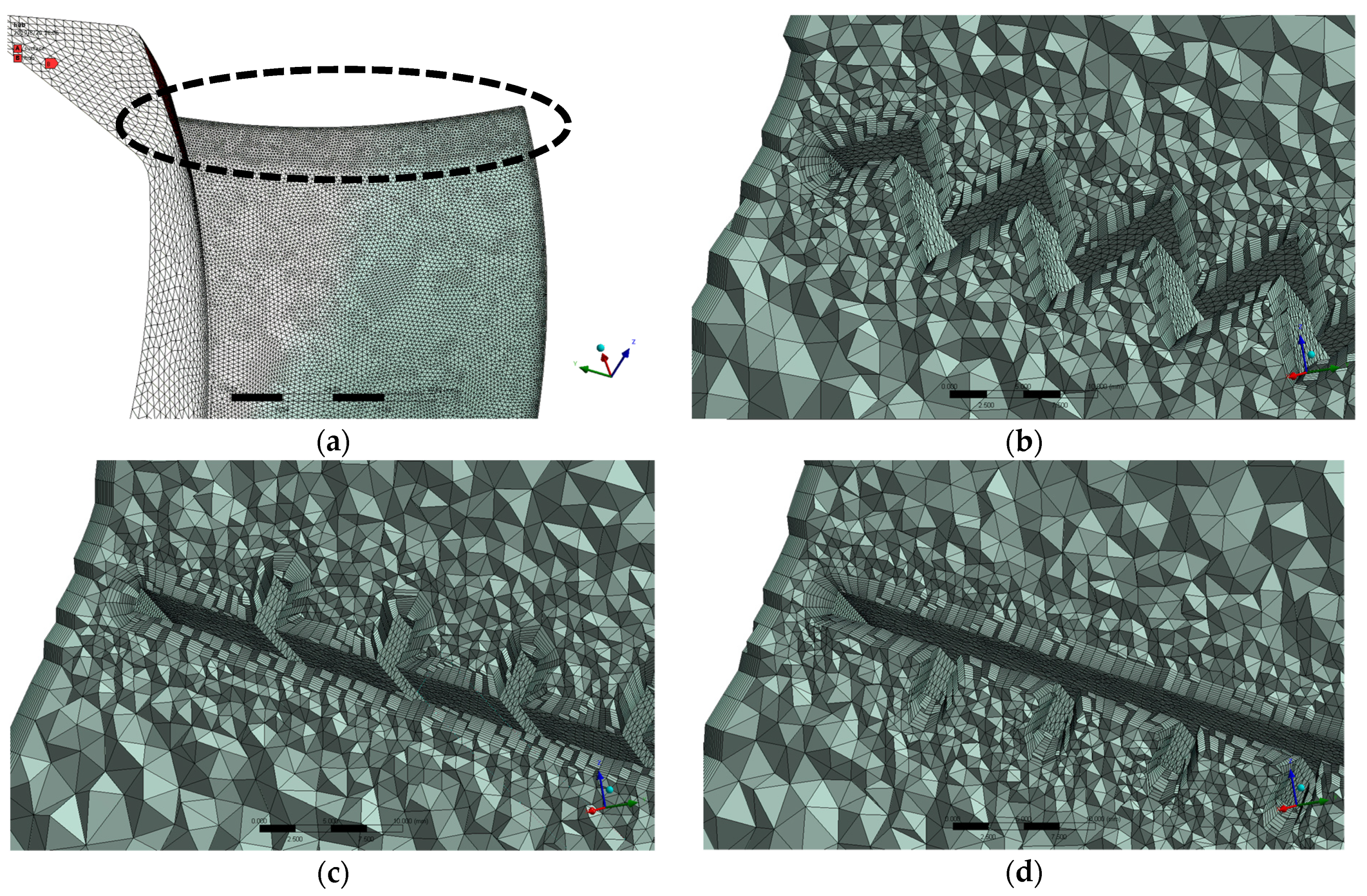

2.4. Numerical Grid

3. Results

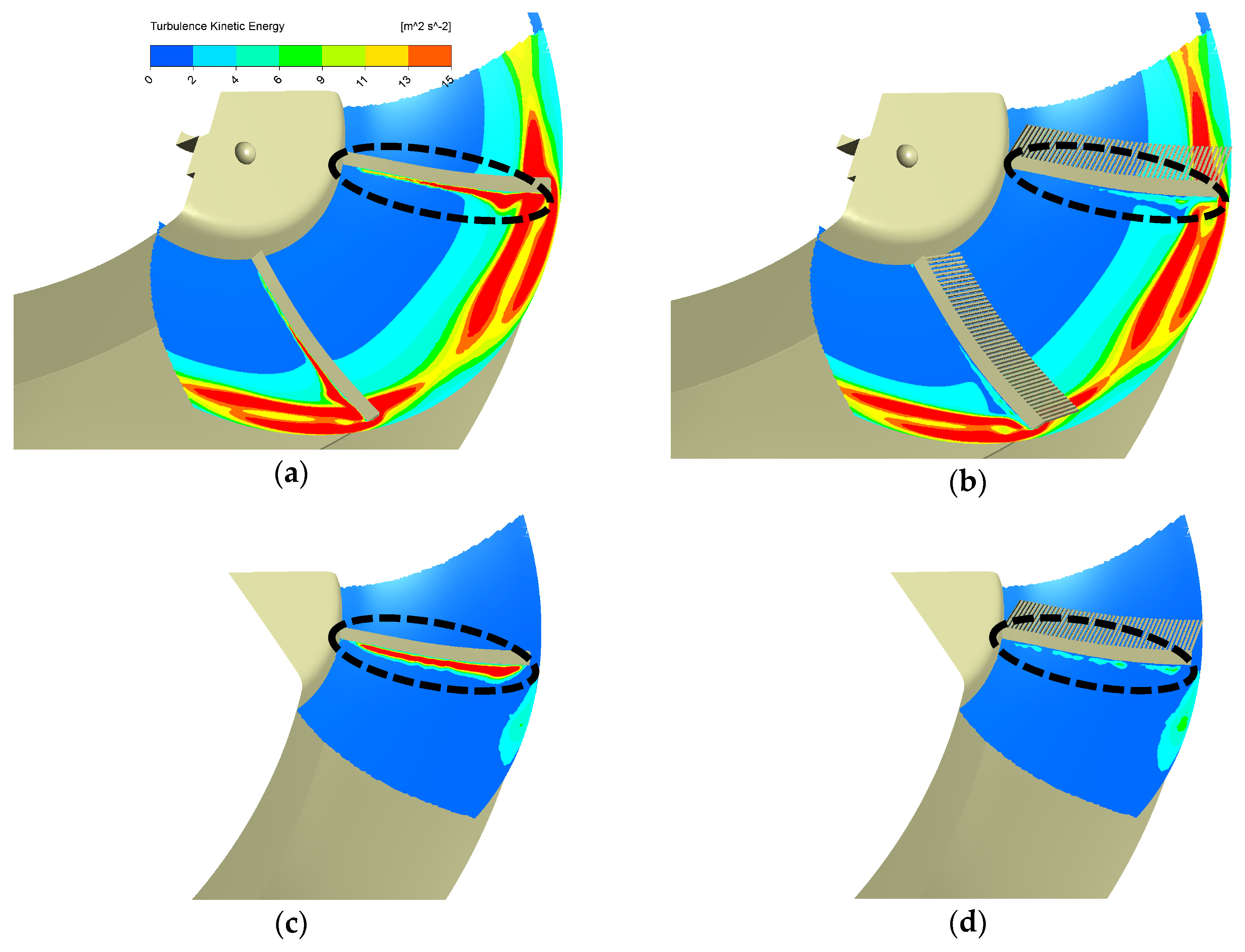

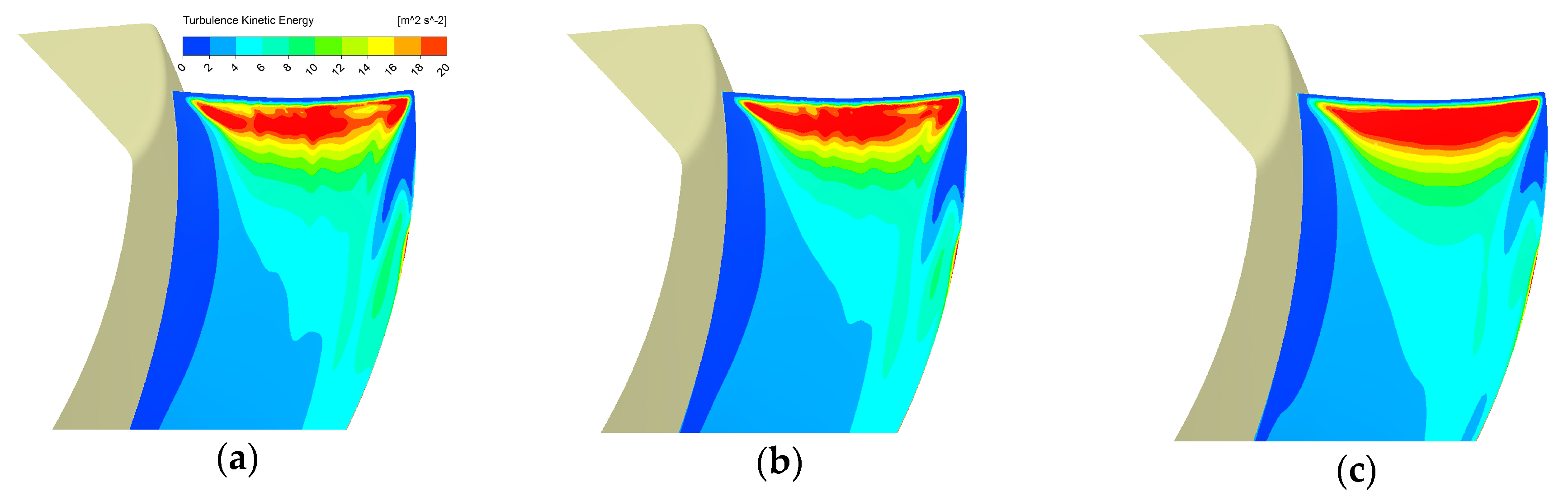

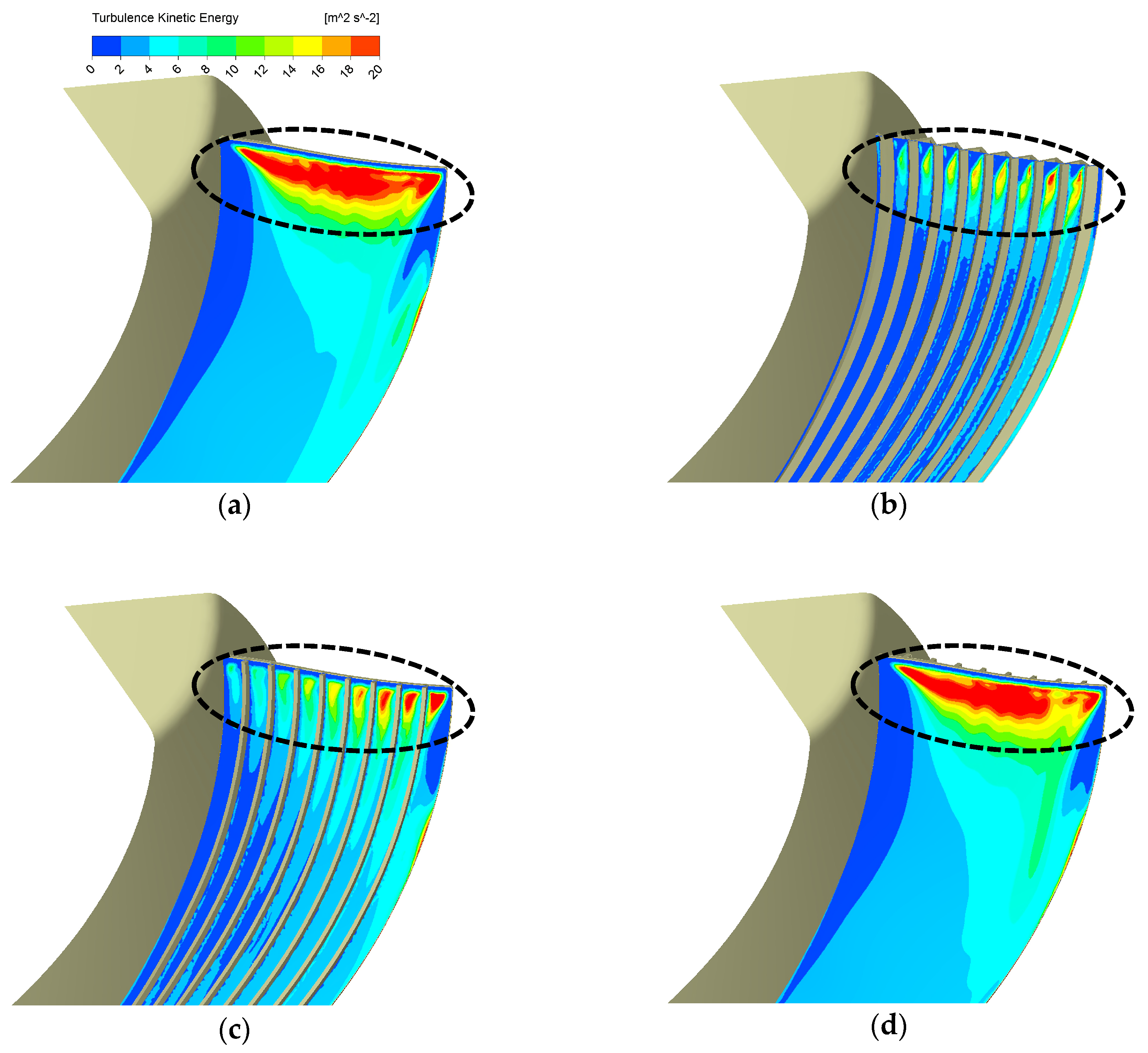

3.1. Groove Form Effects

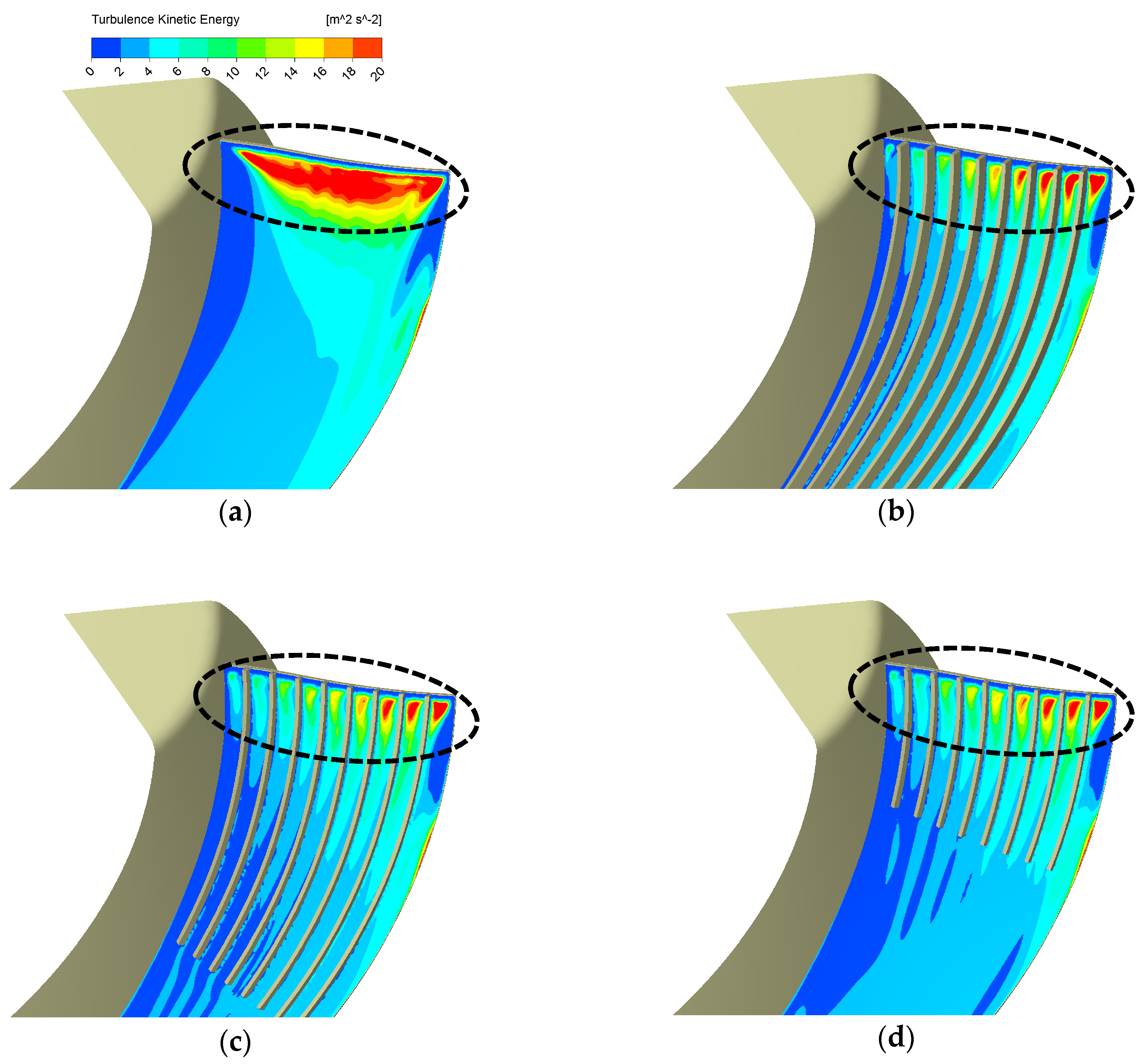

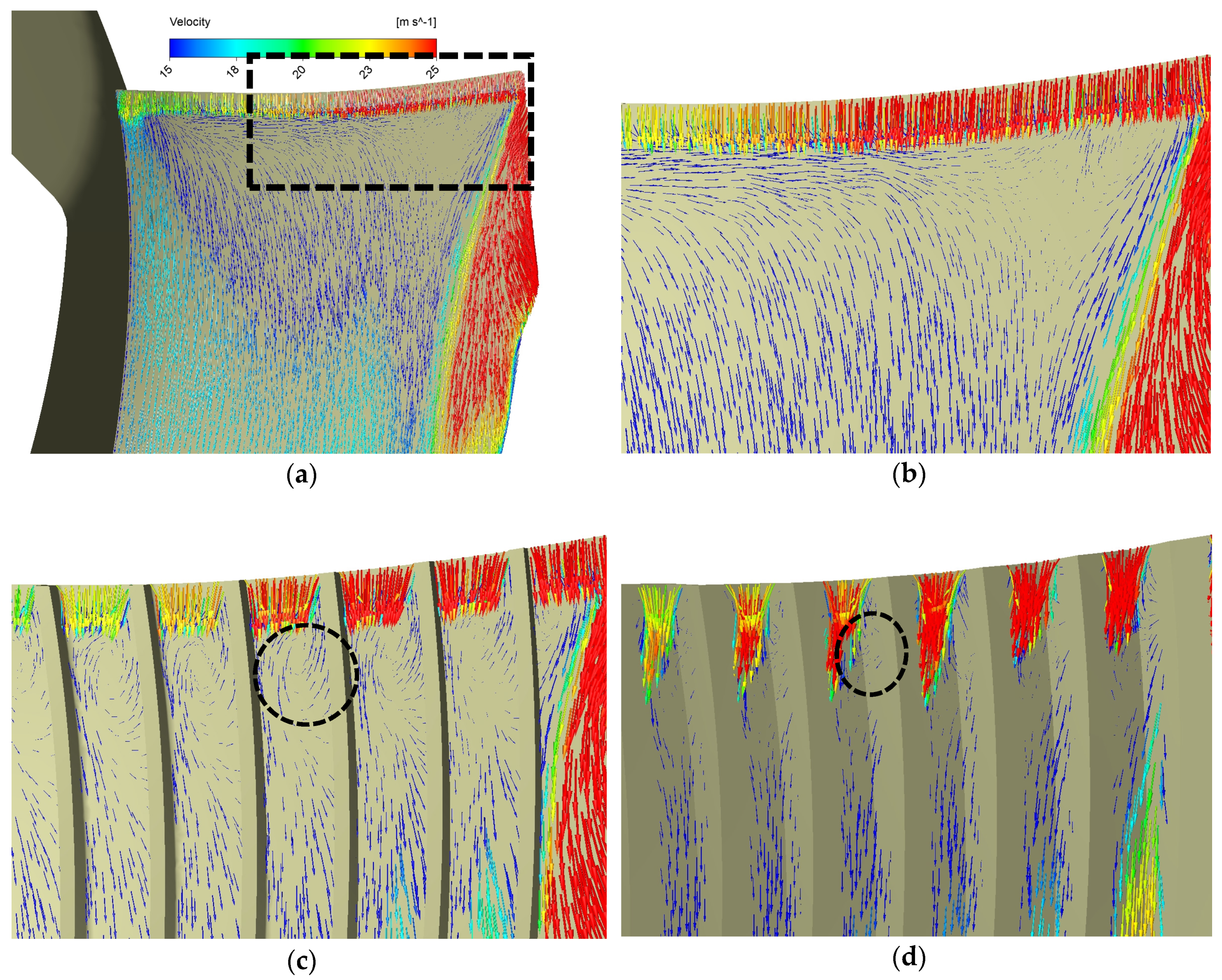

3.2. Groove Parameter Effects

4. Discussion

5. Conclusions

- The wavy shape form is better at reducing the TKE associated with the broadband noise than the riblet ones with the same groove cross-section area. However, the riblets on the suction face form outperforms others by excellently solving the tradeoff problem between aerodynamic loss and TKE reduction. Our best design can suppress the turbulence kinetic energy by approximately 38% at the blade leading edge, while its aerodynamic efficiency loss is merely 0.3 percentage points.

- More grooves can result in more TKE reduction at the leading-edge region. Large groove height may harm grooves’ TKE reduction ability. For the riblet design, the riblets’ length does not play a critical role in both aerodynamics and aeroacoustics as long as the length is enough to cover the leading-edge region.

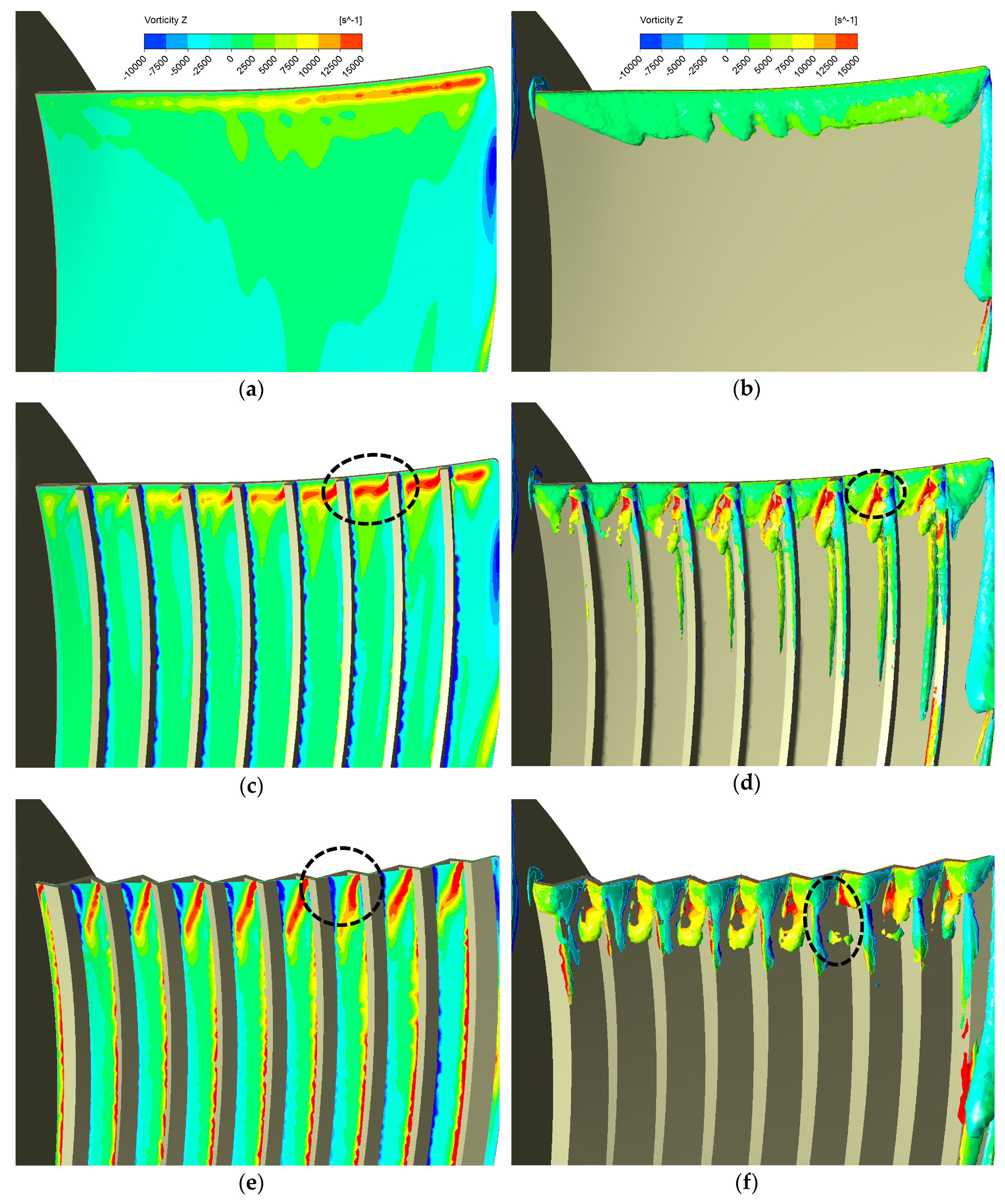

- Bio-inspired grooves can break the leading-edge vortex up into smaller vortices or eddies and result in higher vorticity concentrated at this region. This passive flow control near the leading edge probably suppresses the TKE associated with the broadband noise successfully.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yannopoulos, S.I.; Lyberatos, G.; Theodossiou, N.; Li, W.; Valipour, M.; Tamburrino, A.; Angelakis, A.N. Evolution of water lifting devices (Pumps) over the centuries worldwide. Water (Switzerland) 2015, 7, 5031–5060. [Google Scholar] [CrossRef]

- Guan, X.F. Modern pumps theory and design. China Astronaut. Beijing China 2011, 35–37, 265–266. [Google Scholar]

- Feng, J.; Luo, X.; Guo, P.; Wu, G. Influence of tip clearance on pressure fluctuations in an axial flow pump. J. Mech. Sci. Technol. 2016, 30, 1603–1610. [Google Scholar] [CrossRef]

- Jung, U.H.; Kim, J.H.; Kim, S.; Kim, J.H.; Choi, Y.S. Analyzing the shape parameter effects on the performance of the mixed-flow fan using CFD & Factorial design. J. Mech. Sci. Technol. 2016, 30, 1149–1161. [Google Scholar]

- Lei, T.; Zhiyi, Y.; Yun, X.; Yabin, L.; Shuliang, C. Role of blade rotational angle on energy performance and pressure fluctuation of a mixed-flow pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 227–238. [Google Scholar] [CrossRef]

- Hao, Y.; Tan, L. Symmetrical and unsymmetrical tip clearances on cavitation performance and radial force of a mixed flow pump as turbine at pump mode. Renew. Energy 2018, 127, 368–376. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L. Tip clearance on pressure fluctuation intensity and vortex characteristic of a mixed flow pump as turbine at pump mode. Renew. Energy 2018, 129, 606–615. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, W.; Zhu, B.; Li, Y. Numerical analysis for the effect of tip clearance in a low specific speed mixed-flow pump. Adv. Mech. Eng. 2019, 11, 168781401983222. [Google Scholar] [CrossRef]

- Gad-el-Hak, M. Flow control. MEMS Appl. 1989, 42, 13–51. [Google Scholar] [CrossRef]

- Gad-El-Hak, M. Modern developments in flow control. Appl. Mech. Rev. 1996, 49, 365–469. [Google Scholar] [CrossRef]

- Yousefi, K.; Saleh, R. Three-dimensional suction flow control and suction jet length optimization of NACA 0012 wing. Meccanica 2015, 50, 1481–1494. [Google Scholar] [CrossRef]

- Yousefi, K.; Saleh, R.; Zahedi, P. Numerical study of blowing and suction slot geometry optimization on NACA 0012 airfoil. J. Mech. Sci. Technol. 2014, 28, 1297–1310. [Google Scholar] [CrossRef] [Green Version]

- Volino, R.J. Passive flow control on low-pressure turbine airfoils. J. Turbomach. 2003, 125, 754–764. [Google Scholar] [CrossRef]

- Bohl, D.G.; Volino, R.J. Experiments with three-dimensional passive flow control devices on low-pressure turbine airfoils. J. Turbomach. 2006, 128, 251–260. [Google Scholar] [CrossRef]

- McAuliffe, B.R.; Yaras, M.I. Passive manipulation of separation-bubble transition using surface modifications. J. Fluids Eng. Trans. ASME 2009, 131, 0212011–02120116. [Google Scholar] [CrossRef]

- Fish, F.E.; Lauder, G.V. Passive and Active Flow Control by Swimming Fishes and Mammals. Annu. Rev. Fluid Mech. 2006, 38, 193–224. [Google Scholar] [CrossRef]

- Rao, C.; Ikeda, T.; Nakata, T.; Liu, H. Owl-inspired leading-edge serrations play a crucial role in aerodynamic force production and sound suppression. Bioinspiration Biomim. 2017, 12, aa7013. [Google Scholar] [CrossRef]

- Ikeda, T.; Ueda, T.; Nakata, T.; Noda, R.; Tanaka, H.; Fujii, T.; Liu, H. Morphology Effects of Leading-edge Serrations on Aerodynamic Force Production: An Integrated Study Using PIV and Force Measurements. J. Bionic. Eng. 2018, 15, 661–672. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Choi, H. Flow structure modifications by leading-edge tubercles on a 3D wing. Bioinspiration Biomim. 2018, 13, 066011. [Google Scholar] [CrossRef]

- Zhang, M.M.; Wang, G.F.; Xu, J.Z. Aerodynamic control of low-reynolds-number airfoil with leading-edge protuberances. AIAA J. 2013, 51, 1960–1971. [Google Scholar] [CrossRef]

- Feinerman, J.A.; Schmitz, F.H. Effect of Leading-Edge Serrations on Helicopter Blade–Vortex. J. Am. Helicopter Soc. 2017, 62, 1–11. [Google Scholar] [CrossRef]

- Shanmukha Srinivas, K.; Datta, A.; Bhattacharyya, A.; Kumar, S. Free-stream characteristics of bio-inspired marine rudders with different leading-edge configurations. Ocean. Eng. 2018, 170, 148–159. [Google Scholar] [CrossRef]

- Shi, W.; Atlar, M.; Rosli, R.; Aktas, B.; Norman, R. Cavitation observations and noise measurements of horizontal axis tidal turbines with biomimetic blade leading-edge designs. Ocean. Eng. 2016, 121, 143–155. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, T.; Tanaka, H.; Yoshimura, R.; Noda, R.; Fujii, T.; Liu, H. A robust biomimetic blade design for micro wind turbines. Renew. Energy 2018, 125, 155–165. [Google Scholar] [CrossRef]

- Miyazaki, M.; Hirai, Y.; Moriya, H.; Shimomura, M.; Miyauchi, A.; Liu, H. Biomimetic design inspired Sharkskin denticles and modeling of diffuser for fluid control. J. Photopolym. Sci. Technol. 2018, 31, 133–138. [Google Scholar] [CrossRef]

- Lauder, G.V.; Wainwright, D.K.; Domel, A.G.; Weaver, J.C.; Wen, L.; Bertoldi, K. Structure, biomimetics, and fluid dynamics of fish skin surfaces. Phys. Rev. Fluids 2016, 1, 060502. [Google Scholar] [CrossRef]

- Chen, H.; Rao, F.; Shang, X.; Zhang, D.; Hagiwara, I. Biomimetic drag reduction study on herringbone riblets of bird feather. J. Bionic Eng. 2013, 10, 341–349. [Google Scholar] [CrossRef]

- Miyazaki, M.; Hirai, Y.; Moriya, H.; Shimomura, M.; Miyauchi, A.; Liu, H. Biomimetic Riblets Inspired by Sharkskin Denticles: Digitizing, Modeling and Flow Simulation. J. Bionic. Eng. 2018, 15, 999–1011. [Google Scholar] [CrossRef]

- Dean, B.; Bhushan, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4775–4806. [Google Scholar] [CrossRef]

- Skrzypacz, J.; Bieganowski, M. The influence of micro grooves on the parameters of the centrifugal pump impeller. Int. J. Mech. Sci. 2018, 144, 827–835. [Google Scholar] [CrossRef]

- ZIEHL-ABEGG. Available online: https://www.ziehl-abegg.com/gb/en/product-range/ventilation-systems/centrifugal-fans/zabluefin/ (accessed on 30 August 2019).

- Ishibashi, K.; Naka, T.; Ikeda, T.; Fujii, T.; Liu, H. フクロウ規範型微細構造を用いた高効率・低騒音型斜流送風機の創製 (Development of efficient and silent mixed flow fan inspired by microstructure of owl wing). In Proceedings of the JSME Bioengineering Conference, Koriyama, Japan, 24–25 October 2018. [Google Scholar]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- ANSYS CFX. ANSYS CFX-Solver Theory Guide; ANSYS CFX Release: Canonsburg, PA, USA, 2013; p. 100. [Google Scholar]

- ANSYS CFX. ANSYS CFX Solver Modeling Guide, Release 15.0; ANSYS CFX Release: Canonsburg, PA, USA, 2013; Volume 455, pp. 162–168. [Google Scholar]

- Bechert, D.W.; Bruse, M.; Hage, W.; Van Der Hoeven, J.G.T.; Hoppe, G. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry. J. Fluid Mech. 1997, 338, 59–87. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson education: London, UK, 2007. [Google Scholar]

- Glegg, S.; Morin, B.; Atassi, O.; Reba, R. Using RANS calculations of turbulent kinetic energy to provide predictions of trailing edge noise. In Proceedings of the 14th AIAA/CEAS Aeroacoustics Conference (29th AIAA Aeroacoustics Conf, Vancouver, BC, Canada, 5–7 May 2008; pp. 5–7. [Google Scholar]

- Remmler, S.; Christophe, J.; Anthoine, J.; Moreau, S. Computation of wall-pressure spectra from steady flow data for noise prediction. AIAA J. 2010, 48, 1997–2007. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Herrig, A.; Lutz, T.; Würz, W.; Krämer, E.; Wagner, S. Comprehensive evaluation and assessment of trailing edge noise prediction based on dedicated measurements. Noise Control. Eng. J. 2011, 59, 54–67. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Lutz, T.; Herrig, A.; Krämer, E. Semi-empirical modeling of turbulent anisotropy for airfoil self-noise predictions. AIAA J. 2012, 50, 46–60. [Google Scholar] [CrossRef]

- McMasters, J.H.; Henderson, M.L. Low-Speed Single-Element Airfoil Synthesis; NASA: Washington DC, USA, 1979.

- Yousefi, K.; Razeghi, A. Determination of the critical reynolds number for flow over symmetric NACA airfoils. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; pp. 1–11. [Google Scholar]

| Parameters | Values |

|---|---|

| Maximum Diameter of impeller/mm | 426 |

| Number of blades | 6 |

| Duct length/mm | 412 |

| Flow rate/m3/min | 35.7 |

| Rotational speed/rpm | 1450 |

| Parameters | Values |

|---|---|

| Groove number N | 5, 7, 9 |

| Wavy shape groove height H/mm | 3 |

| Riblet height H/mm (for the ones on the suction face) | 3.8 (N = 5) 4.0 (N = 7) 4.2, 5.9, 7.6 (N = 9) |

| Riblets length proportion (for N = 9 and H = 4.2mm) |

| Parameters and Results | Mesh Set 1 | Mesh Set 2 | Mesh Set 3 |

|---|---|---|---|

| Blade surface grid size/mm | 0.7 | 0.7 (only leading-edge region)/1 | 1.5 |

| Rotational domain body size/mm | 3 | 4 | 5 |

| Element number () | 6.40 | 2.63 | 1.26 |

| y+ on blade (based on Re = 446,000) | 5 | 10 | 25 |

| Growth rate of prism layer (blade) | 1.1 | 1.06 | 1.2 |

| Prism layer number (blade) | 15 | 11 | 5 |

| Outlet total pressure/Pa | 366 | 368 (+0.5%)1 | 374 (+2.2%) |

| Efficiency () | 81.9 | 81.8 (−0.1 pp) | 81.9 (0 pp) |

| 1000 TKE Integrated on SF_5 mm/ m4/s2 | 9.77 | 9.74 (−0.3%) | 11.30 (+15.7%) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Nakata, T.; Liu, H. Development of Mixed Flow Fans with Bio-Inspired Grooves. Biomimetics 2019, 4, 72. https://doi.org/10.3390/biomimetics4040072

Wang J, Nakata T, Liu H. Development of Mixed Flow Fans with Bio-Inspired Grooves. Biomimetics. 2019; 4(4):72. https://doi.org/10.3390/biomimetics4040072

Chicago/Turabian StyleWang, Jinxin, Toshiyuki Nakata, and Hao Liu. 2019. "Development of Mixed Flow Fans with Bio-Inspired Grooves" Biomimetics 4, no. 4: 72. https://doi.org/10.3390/biomimetics4040072

APA StyleWang, J., Nakata, T., & Liu, H. (2019). Development of Mixed Flow Fans with Bio-Inspired Grooves. Biomimetics, 4(4), 72. https://doi.org/10.3390/biomimetics4040072