A Lightweight Bioinspired SMA-Based Grasping Mechanism for Flapping Wing MAVs

Abstract

1. Introduction

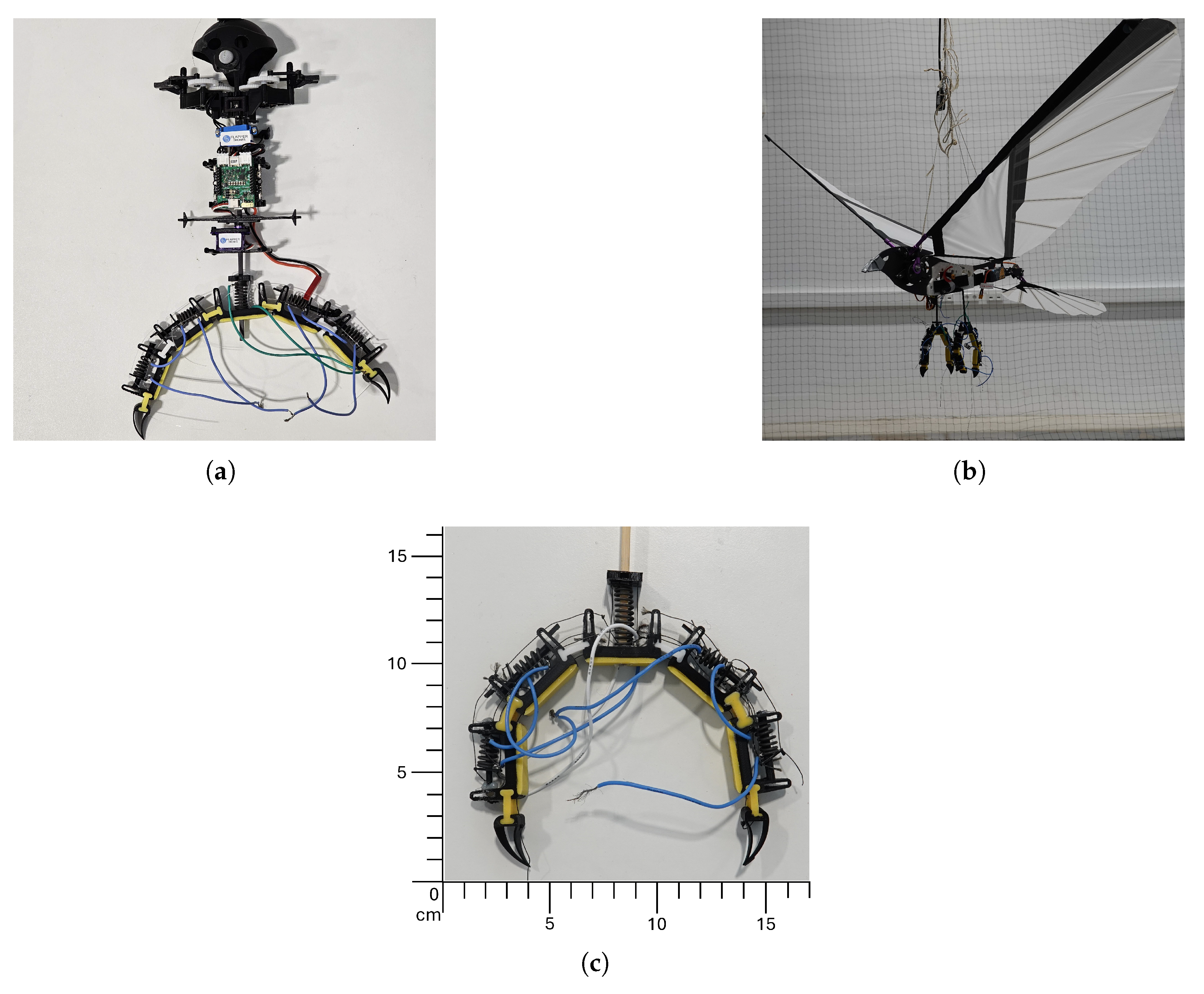

2. System Overview

2.1. Drone Platforms

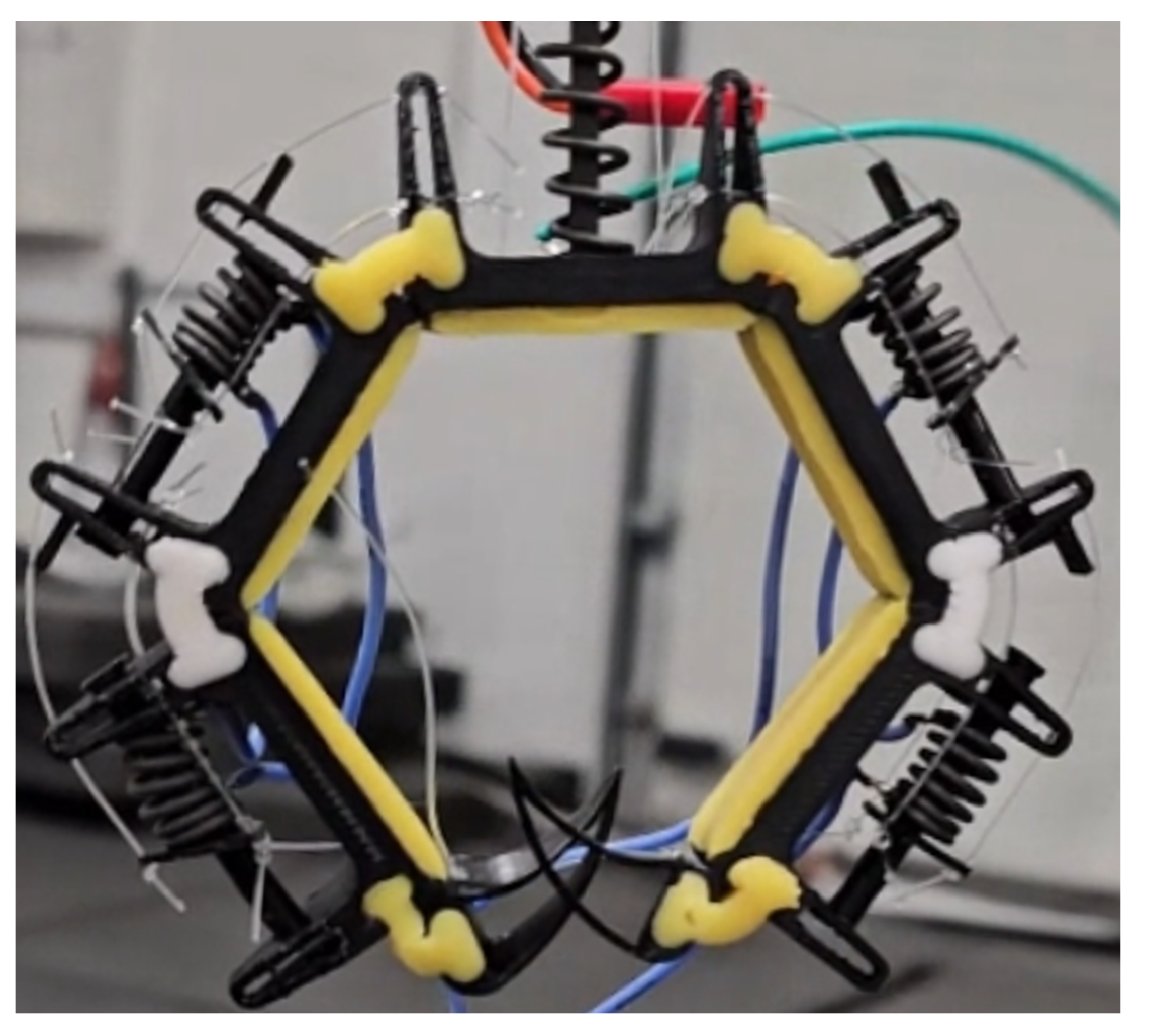

2.2. Gripper Design

2.3. Modeling & Optimization

- Phalanges mm and for Claw mm

- Thicknesses of Phalanges mm

- Joint radii mm

- Tendon entry(en) and exit(ex) points mm, mm, mm, mm, mm

3. Electronics and Control

3.1. Electronic Components

3.2. Control System

4. Results and Discussion

4.1. Static Testing of the Gripper Mechanism

4.2. Flight Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haider, N.; Shahzad, A.; Mumtaz Qadri, M.N.; Ali Shah, S.I. Recent progress in flapping wings for micro aerial vehicle applications. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 245–264. [Google Scholar] [CrossRef]

- Meng, J.; Buzzatto, J.; Liu, Y.; Liarokapis, M. On aerial robots with grasping and perching capabilities: A comprehensive review. Front. Robot. AI 2021, 8, 739173. [Google Scholar] [CrossRef]

- Hammad, A.; Armanini, S.F. Landing and take-off capabilities of bioinspired aerial vehicles: A review. Bioinspir. Biomim. 2024, 19, 031001. [Google Scholar] [CrossRef]

- Broers, K.C.V.; Armanini, S.F. Design and testing of a bioinspired lightweight perching mechanism for flapping-wing MAVs using soft grippers. IEEE Robot. Autom. Lett. 2022, 7, 7526–7533. [Google Scholar] [CrossRef]

- Doyle, C.E.; Bird, J.J.; Isom, T.A.; Johnson, C.J.; Kallman, J.C.; Simpson, J.A.; King, R.J.; Abbott, J.J.; Minor, M.A. Avian-inspired passive perching mechanism for robotic rotorcraft. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar]

- Erbil, M.A.; Prior, S.D.; Keane, A.J. Design Optimisation of a Reconfigurable Perching Element for Vertical Take-Off and Landing Unmanned Aerial Vehicles. Int. J. Micro Air Veh. 2013, 5, 207–228. [Google Scholar] [CrossRef]

- McLaren, A.; Fitzgerald, Z.; Gao, G.; Liarokapis, M. A passive closing, tendon driven, adaptive robot hand for ultra-fast, aerial grasping and perching. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Pope, M.T.; Kimes, C.W.; Jiang, H.; Hawkes, E.W.; Estrada, M.A.; Kerst, C.F.; Roderick, W.R.T.; Han, A.K.; Christensen, D.L.; Cutkosky, M.R. A multimodal robot for perching and climbing on vertical outdoor surfaces. IEEE Trans. Robot. 2017, 33, 38–48. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Siddall, R.; Stephens, B.; Navarro-Rubio, A.; Kovac, M. A passively adaptive microspine grapple for robust, controllable perching. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Wopereis, H.W.; van der Molen, T.D.; Post, T.H.; Stramigioli, S.; Fumagalli, M. Mechanism for perching on smooth surfaces using aerial impacts. In Proceedings of the 2016 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Lausanne, Switzerland, 23–27 October 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar]

- Thomas, J.; Pope, M.; Loianno, G.; Hawkes, E.W.; Estrada, M.A.; Jiang, H.; Cutkosky, M.R.; Kumar, V. Aggressive flight with quadrotors for perching on inclined surfaces. J. Mech. Robot. 2016, 8, 051007. [Google Scholar] [CrossRef]

- Hammad, A.; Demir, M.; Armanini, S.F. Enhancing Perching Capabilities of Flapping Wing Robots with Silicone-based Electromagnetic Claws. In Proceedings of the 2024 International Conference on Micro Air Vehicle (IMAV), Bristol, UK, 16–20 September 2024. [Google Scholar]

- Zufferey, R.; Tormo-Barbero, J.; Feliu-Talegón, D.; Nekoo, S.R.; Acosta, J.Á.; Ollero, A. How ornithopters can perch autonomously on a branch. Nat. Commun. 2022, 13, 7713. [Google Scholar] [CrossRef]

- Zhao, Y.; Xiang, R.; Li, H.; Wang, C.; Zhang, J.; Liu, X.; Hao, Y. Design and Validation of a Biomimetic Leg-Claw Mechanism Capable of Perching and Grasping for Multirotor Drones. Biomimetics 2024, 10, 10. [Google Scholar] [CrossRef]

- Kalantari, A.; Mahajan, K.; Ruffatto, D.; Spenko, M. Autonomous perching and take-off on vertical walls for a quadrotor micro air vehicle. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 4669–4674. [Google Scholar]

- Kovač, M.; Germann, J.; Hürzeler, C.; Siegwart, R.Y.; Floreano, D. A perching mechanism for micro aerial vehicles. J. Micro-Nano Mechatron. 2009, 5, 77–91. [Google Scholar] [CrossRef]

- Senthil, P.; Vishanagra, O.; Sparkman, J.; Smith, P.; Manero, A. Design and assessment of bird-inspired 3D-printed models to evaluate grasp mechanics. Biomimetics 2024, 9, 195. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Liu, Y.; Pancheri, F.; Lueth, T.C. Larg: A lightweight robotic gripper with 3-d topology optimized adaptive fingers. IEEE/ASME Trans. Mechatron. 2022, 27, 2026–2034. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Z.; Wang, B.; Ma, Z.; Ma, D.; Deng, X. A versatile topology-optimized compliant actuator for soft robotic gripper and walking robot. Soft Robot. 2024, 11, 157–170. [Google Scholar] [CrossRef] [PubMed]

- AboZaid, Y.A.; Aboelrayat, M.T.; Fahim, I.S.; Radwan, A.G. Soft robotic grippers: A review on technologies, materials, and applications. Sens. Actuators A Phys. 2024, 372, 115380. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E.; Libertini, R. Effect of Temperature on the Mechanical Behaviour of Ni-Ti Shape Memory Sheets. In Proceedings of the TMS 2016: 145th Annual Meeting & Exhibition: Supplemental Proceedings: Supplemental Proceedings, Nashville, TN, USA, 14–18 February 2016; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 433–439. [Google Scholar]

- Perez-Sanchez, V.; Garcia-Rubiales, F.J.; Nekoo, S.R.; Arrue, B.; Ollero, A. Modeling and Application of an SMA-Actuated Lightweight Human-Inspired Gripper for Aerial Manipulation. Machines 2023, 11, 859. [Google Scholar] [CrossRef]

- Rao, A.; Srinivasa, A.R.; Reddy, J.N. Design of Shape Memory Alloy (SMA) Actuators; Springer Briefs in Applied Sciences and Technology; Part of: Springer Professional “Wirtschaft+Technik”, Springer Professional “Technik”; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Frenzel, J.; Zhang, Z.; Neuking, K.; Eggeler, G. High quality vacuum induction melting of small quantities of NiTi shape memory alloys in graphite crucibles. J. Alloys Compd. 2004, 385, 214–223. [Google Scholar] [CrossRef]

- Lagoudas, D.C.; Vandygriff, E.L. Processing and characterization of NiTi porous SMA by elevated pressure sintering. J. Intell. Mater. Syst. Struct. 2002, 13, 837–850. [Google Scholar] [CrossRef]

- Park, N.J.; Lee, S.J.; Lee, I.S.; Cho, K.S.; Kim, S.J. Manufacturing of Cu-15.0Zn-8.1Al shape memory alloy using spark plasma sintering. Mater. Sci. For. 2004, 449–452, 1109–1112. [Google Scholar]

- Otubo, J.; Rigo, O.D.; Moura Neto, C.; Kaufman, M.J.; Mei, P.R. Scale up of NiTi shape memory alloy production by EBM. J. Phys. IV 2003, 112, 873–876. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, H.N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Stoeckel, D. Shape memory actuators for automotive applications. Mater. Eng. 1990, 11, 302–307. [Google Scholar]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng. G J. Aerosp. Eng. 2007, 221, 535–552. [Google Scholar] [CrossRef]

- Loewy, R.G. Recent developments in smart structures with aeronautical applications. Smart Mater. Struct. 1997, 6, R11–R42. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E. Shape memory alloys for aerospace, recent developments, and new applications: A short review. Materials 2020, 13, 1856. [Google Scholar] [CrossRef]

- Gomez-Tamm, A.E.; Perez-Sanchez, V.; Arrue, B.C.; Ollero, A. SMA actuated low-weight bio-inspired claws for grasping and perching using flapping wing aerial systems. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Kwon, H.C.; Cho, D.H.; Kim, K.H. Underactuated three-finger robot hand with human-like flexion. Int. J. Precis. Eng. Manuf. 2021, 22, 791–798. [Google Scholar] [CrossRef]

- Dollar, A.M.; Howe, R.D. A robust compliant grasper via shape deposition manufacturing. IEEE ASME Trans. Mechatron. 2006, 11, 154–161. [Google Scholar] [CrossRef]

- Roderick, W.R.; Chin, D.D.; Cutkosky, M.R.; Lentink, D. Birds land reliably on complex surfaces by adapting their foot-surface interactions upon contact. Elife 2019, 8, e46415. [Google Scholar] [CrossRef] [PubMed]

- Kruse, L.; Bradley, J. A hybrid, actively compliant manipulator/gripper for aerial manipulation with a multicopter. In Proceedings of the 2018 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Philadelphia, PA, USA, 6–8 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–8. [Google Scholar]

- Fiaz, U.A.; Abdelkader, M.; Shamma, J.S. An intelligent gripper design for autonomous aerial transport with passive magnetic grasping and dual-impulsive release. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1027–1032. [Google Scholar]

- Zhang, H.; Sun, J.; Zhao, J. Compliant bistable gripper for aerial perching and grasping. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1248–1253. [Google Scholar]

- Zhang, H.; Lerner, E.; Cheng, B.; Zhao, J. Compliant bistable grippers enable passive perching for micro aerial vehicles. IEEE/ASME Trans. Mechatron. 2020, 26, 2316–2326. [Google Scholar] [CrossRef]

- Hsiao, H.; Sun, J.; Zhang, H.; Zhao, J. A mechanically intelligent and passive gripper for aerial perching and grasping. IEEE/ASME Trans. Mechatron. 2022, 27, 5243–5253. [Google Scholar] [CrossRef]

- Drones, F. Flapper Drones—Bioinspired Flying Robots. Available online: https://flapper-drones.com/wp/nimbleplus/ (accessed on 26 April 2024).

- Karásek, M.; Muijres, F.T.; De Wagter, C.; Remes, B.D.; De Croon, G.C. A tailless aerial robotic flapper reveals that flies use torque coupling in rapid banked turns. Science 2018, 361, 1089–1094. [Google Scholar] [CrossRef]

- Ornihobby. Ornihobby—CarbonSail Ornithipter. Available online: https://www.ornihobby.com/ (accessed on 26 April 2024).

- Slavkina, V.; Lopatina, Y. Study of tribotechnical characteristics of 3D printed abs plastic samples. IOP Conf. Ser. Mater. Sci. Eng. 2020, 963, 012032. [Google Scholar] [CrossRef]

- Şirin, Ş.; Aslan, E.; Akincioğlu, G. Effects of 3D-printed PLA material with different filling densities on coefficient of friction performance. Rapid Prototyp. J. 2023, 29, 157–165. [Google Scholar] [CrossRef]

- Sato, S.; Yamaguchi, T.; Shibata, K.; Nishi, T.; Moriyasu, K.; Harano, K.; Hokkirigawa, K. Dry sliding friction and Wear behavior of thermoplastic polyurethane against abrasive paper. Biotribology 2020, 23, 100130. [Google Scholar] [CrossRef]

- Dong, H.; Asadi, E.; Qiu, C.; Dai, J.; Chen, I.M. Geometric design optimization of an under-actuated tendon-driven robotic gripper. Robot. Comput.-Integr. Manuf. 2018, 50, 80–89. [Google Scholar] [CrossRef]

- Bai, L.; Wang, H.; Chen, X.; Zheng, J.; Xin, L.; Deng, Y.; Sun, Y. Design and experiment of a deformable bird-inspired UAV perching mechanism. J. Bionic Eng. 2021, 18, 1304–1316. [Google Scholar] [CrossRef]

| Gripper Model | Fingers | Gripper Weight (N) | Force/ Weight | Mass Ratio | Maximum Grasped Object Size (cm) |

|---|---|---|---|---|---|

| Robot Hand [7] | 3 | 5.41 | 10.36 | 66% | 15 |

| Adaptive [37] | 2 | 2.91 | 0.20 | - | 12 |

| Magnetic [38] | - | 2.89 | 8.80 | 38% | 21 |

| Compliant [39] | 3 | 0.09 | 6.80 | 25% | - |

| Bi-stable [40] | 2 | 0.13 | 4.7 | 33% | 3.3 |

| Passive [41] | 2 | 0.28 | 22.13 | 5% | - |

| Soft Gripper [4] | 2 | 0.40 | 42.27 | 23% | 5 |

| SMA | 2 | 0.49 | 32.6 | 8% | 10 |

| Parameters | Values |

|---|---|

| Wingspan | 0.049 m |

| Weight | 102 g (min. take-off weight) |

| Payload Capacity | 25 g |

| Flight Time | 8 min (forward 3 m/s, min. weight) 5 min (hover, max. payload) |

| Parameters | Values |

|---|---|

| Mean chord length of each wing | 0.455 m |

| Aspect ratio of each wing | 1.42 |

| Mass of the ornithopter | 450 g |

| Flight speed of the ornithopter | 10–25 km/h |

| Range of wingbeat frequency | 3.5–4.5 Hz |

| Payload capacity | 450 g |

| Parameters | Values |

|---|---|

| Phalanges | 2.5–5 cm |

| Talons | 1.5–3 cm |

| Thicknesses of Phalanges | 3–10 mm |

| Joint radii | 3–10 mm |

| Tendon entry and exit points | 2–6 mm |

| Parameters | Values |

|---|---|

| Type | Pressure Spring |

| Wire Diameter | 1.26 mm |

| Number of Coils | 12 |

| Block length | 17 mm ± 2 mm |

| High Temperature | 50 mm ± 8 mm |

| 2S | 3S | 4S | |

|---|---|---|---|

| Mean Activation Time (s) | 0.6 | 0.4 | 0.3 |

| Activation Time Standard Deviation () | 8% | 8% | 9% |

| Voltage (V) | 8.32 | 11.54 | 16.01 |

| Current (A) | 16.64 | 23.08 | 32.02 |

| Power (W) | 138.44 | 266.34 | 512.64 |

| Activation Power (mAh) | 2.78 | 2.56 | 2.66 |

| Object | Success |

|---|---|

| Branch Ø30 mm | Unsuccessful |

| Branch Ø40 mm | Successful |

| Branch Ø60 mm | Successful |

| Branch Ø70 mm | Successful |

| Cardboard Cylinder Ø82 mm | Successful |

| Object | Mass (g) | Success |

|---|---|---|

| LDPE Ø50 mm | 17 | Successful |

| Cardboard □ 40 × 40 mm | 25 | Successful |

| Sponge □ 100 × 40 mm | 12 | Successful |

| Perch Angle | Perch Duration |

|---|---|

| 240 s | |

| 120 s | |

| 60 s | |

| 20 s | |

| (Hang) | 120 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammad, A.; Süer, M.; Armanini, S.F. A Lightweight Bioinspired SMA-Based Grasping Mechanism for Flapping Wing MAVs. Biomimetics 2025, 10, 364. https://doi.org/10.3390/biomimetics10060364

Hammad A, Süer M, Armanini SF. A Lightweight Bioinspired SMA-Based Grasping Mechanism for Flapping Wing MAVs. Biomimetics. 2025; 10(6):364. https://doi.org/10.3390/biomimetics10060364

Chicago/Turabian StyleHammad, Ahmad, Mehmet Süer, and Sophie F. Armanini. 2025. "A Lightweight Bioinspired SMA-Based Grasping Mechanism for Flapping Wing MAVs" Biomimetics 10, no. 6: 364. https://doi.org/10.3390/biomimetics10060364

APA StyleHammad, A., Süer, M., & Armanini, S. F. (2025). A Lightweight Bioinspired SMA-Based Grasping Mechanism for Flapping Wing MAVs. Biomimetics, 10(6), 364. https://doi.org/10.3390/biomimetics10060364