Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory

Abstract

:1. Introduction

2. Materials and Methods

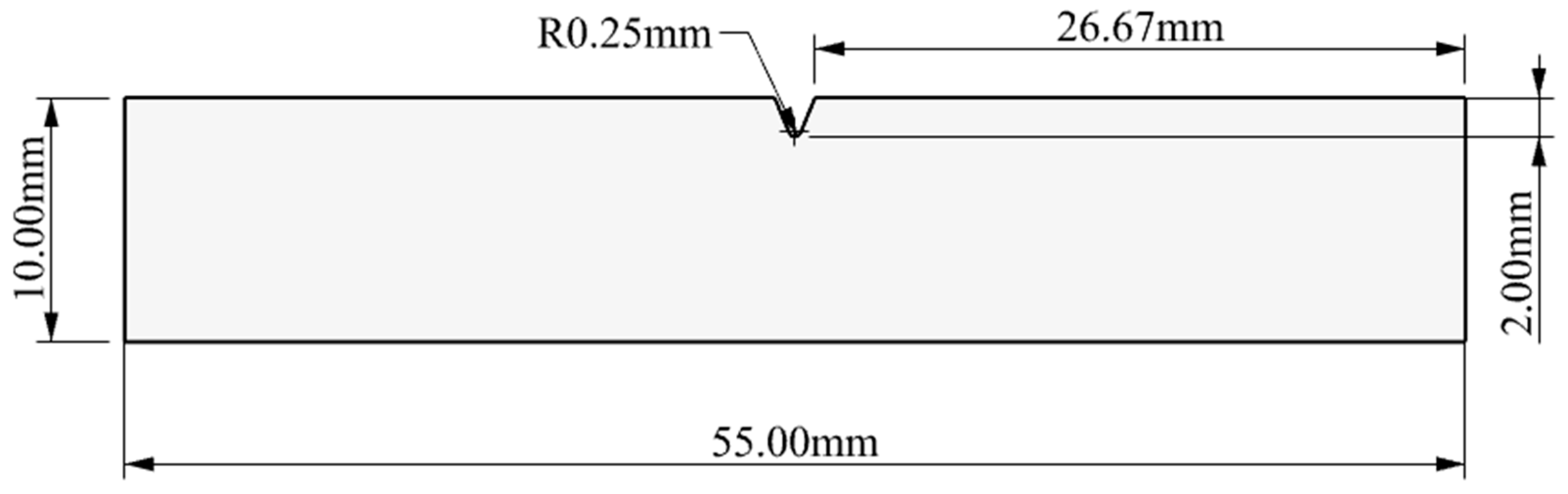

2.1. Design Methods

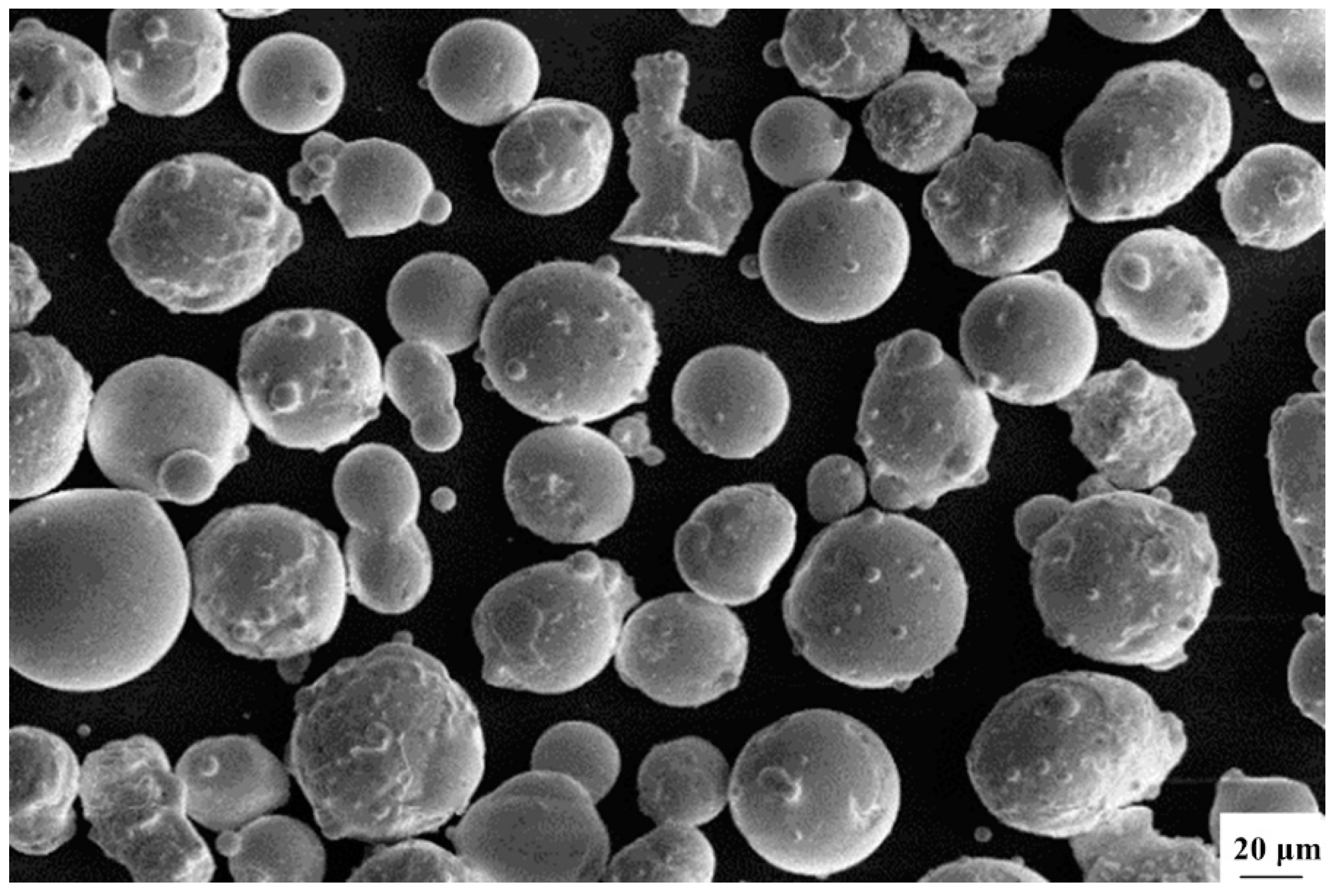

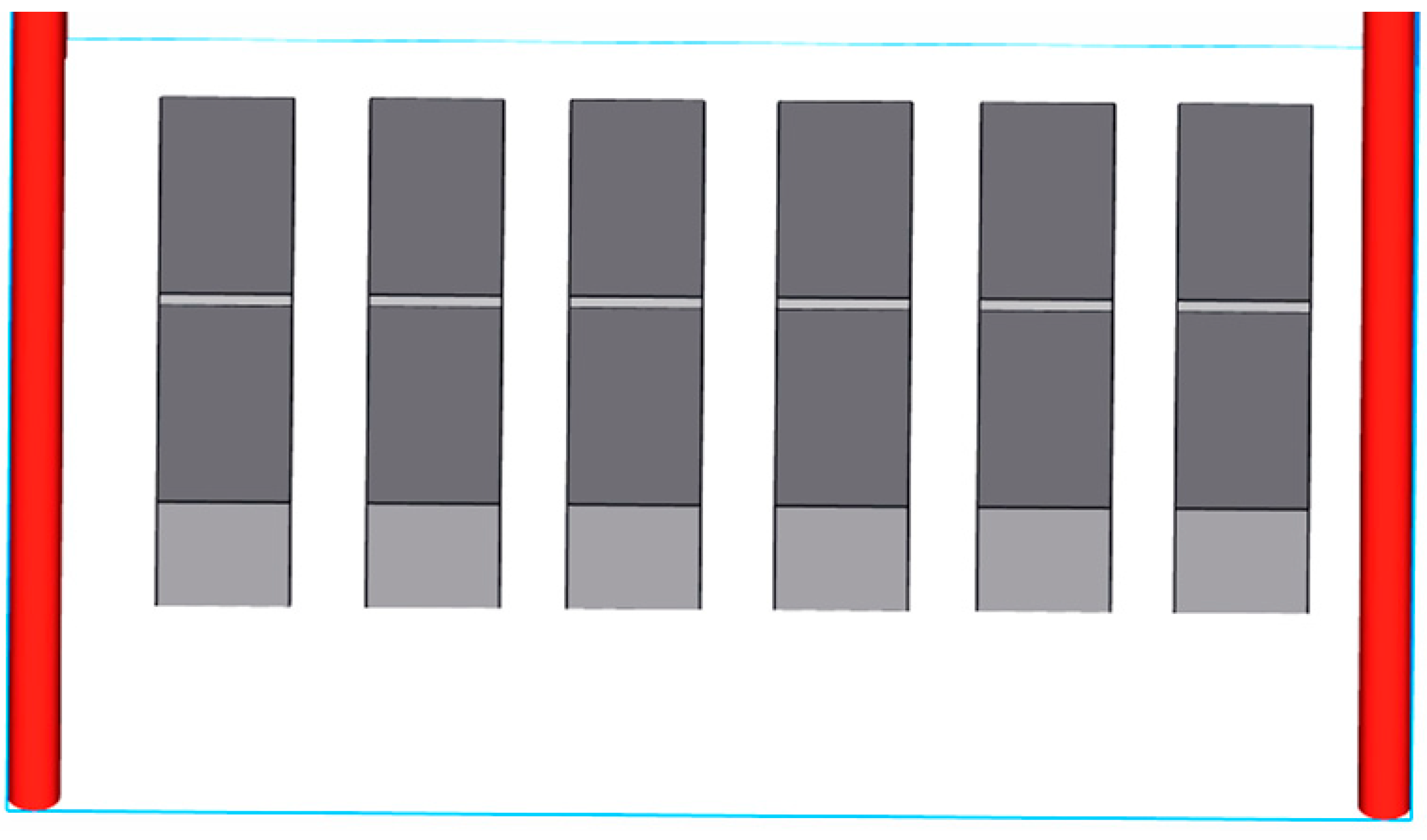

2.2. Materials and Manufacturing Methods

2.3. Analysis Methods

3. Results and Discussion

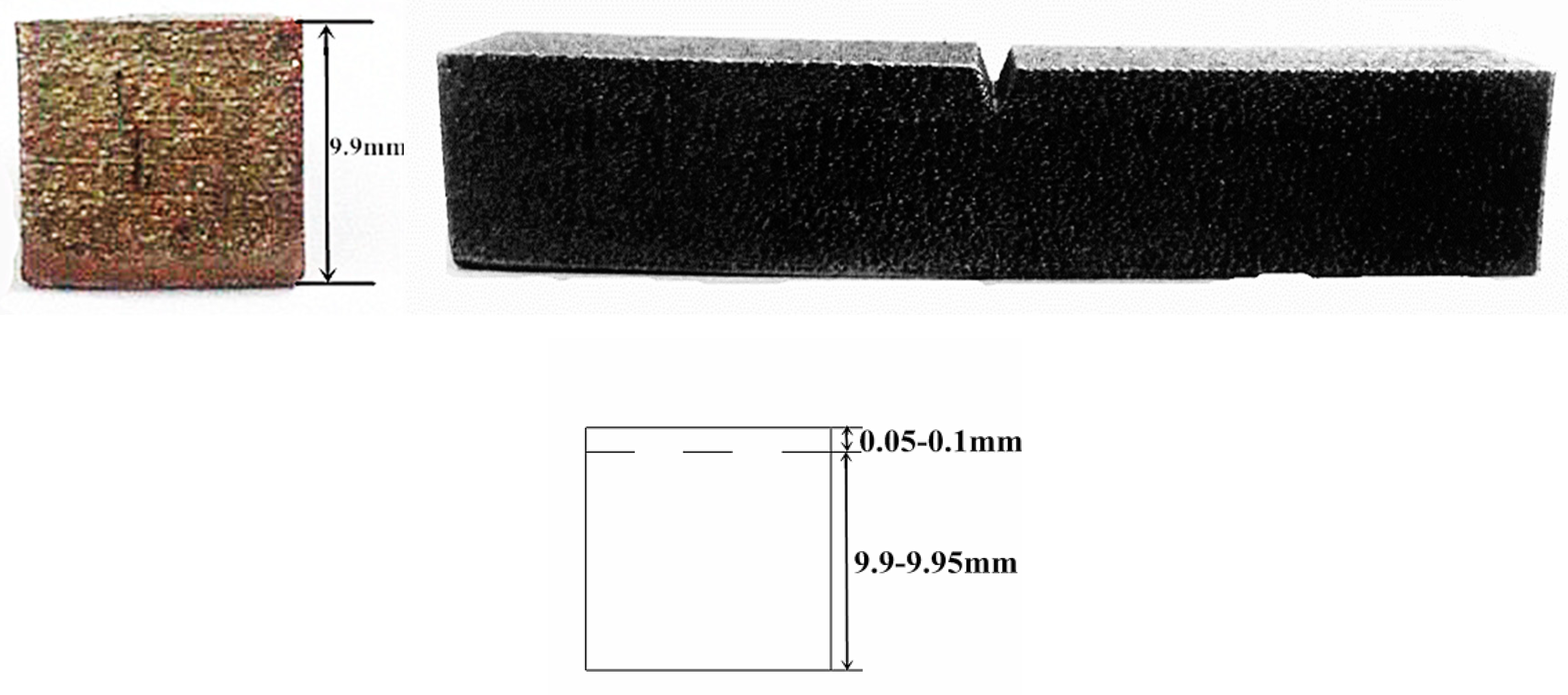

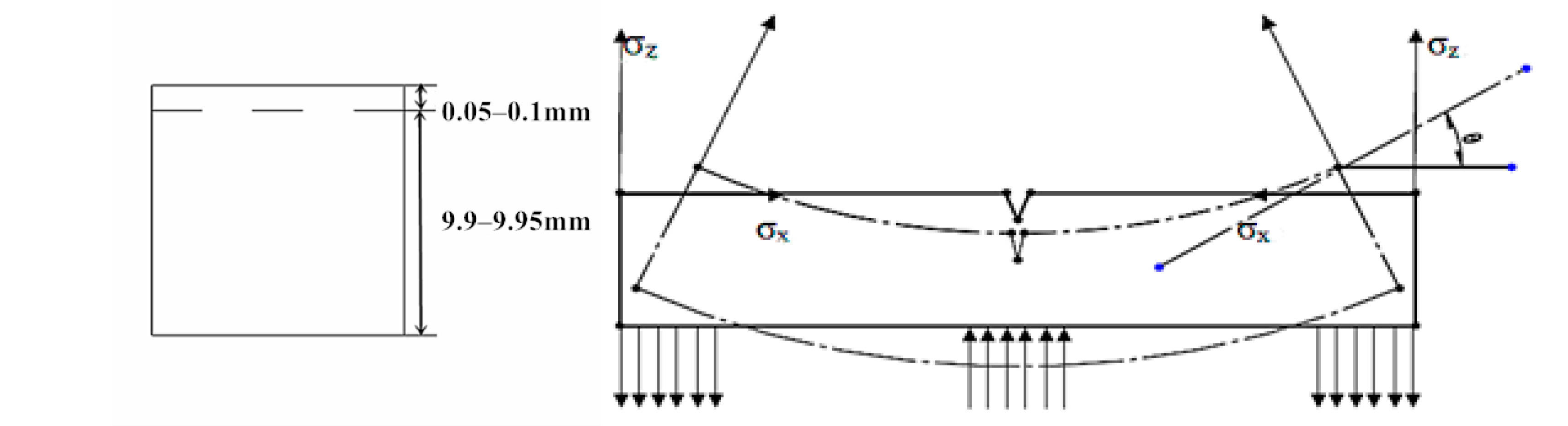

3.1. Data Processing for the 3D-Printed Impact Sample

3.2. Analysis of the Effectiveness of 3D-Printed Parts

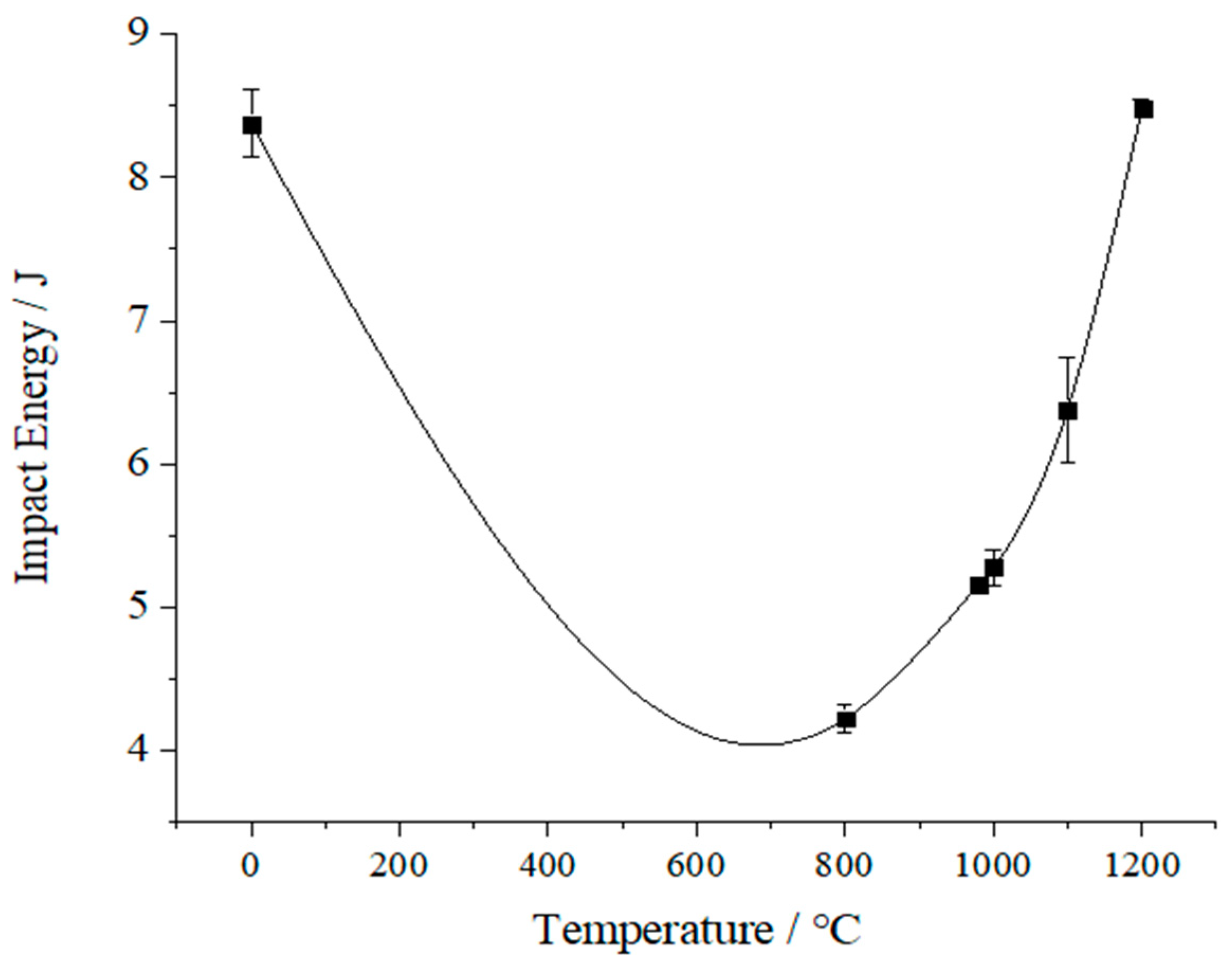

3.3. Analysis of the Impact Performance of 3D-Printed Parts

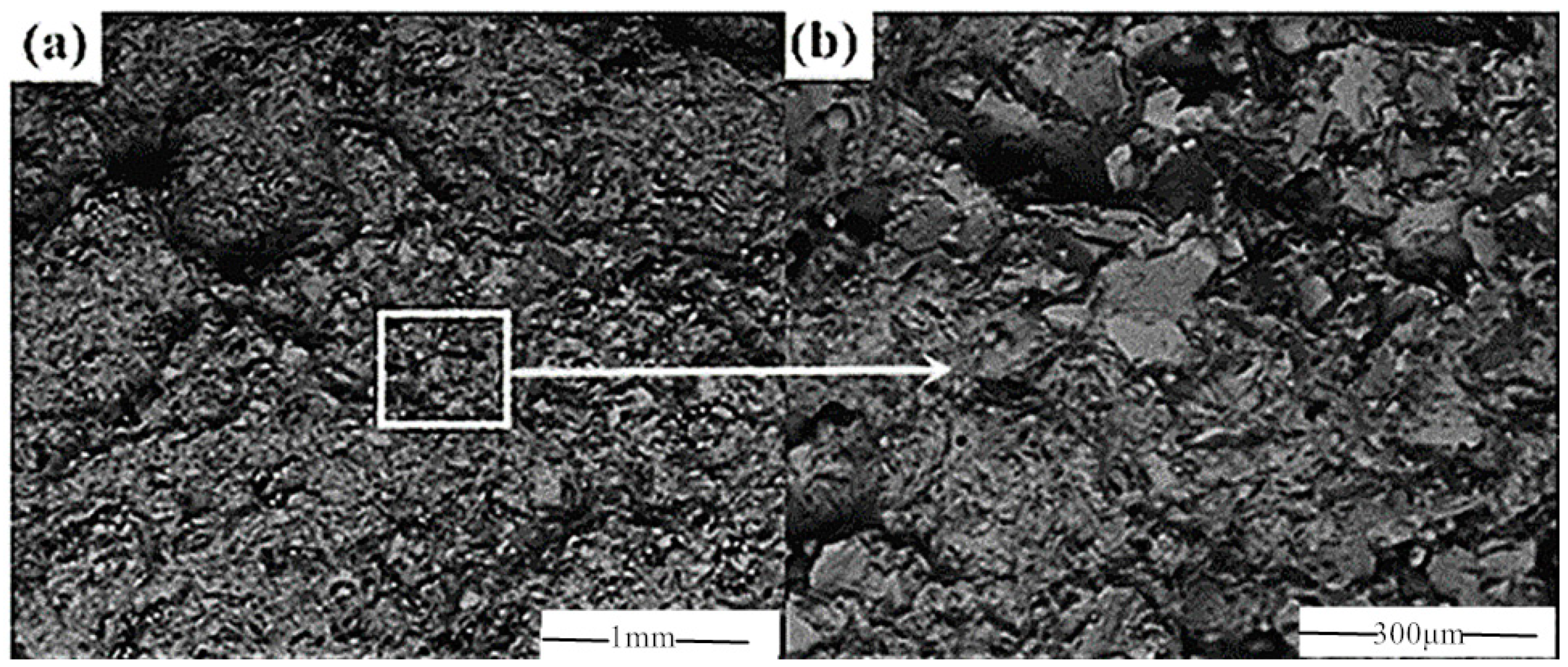

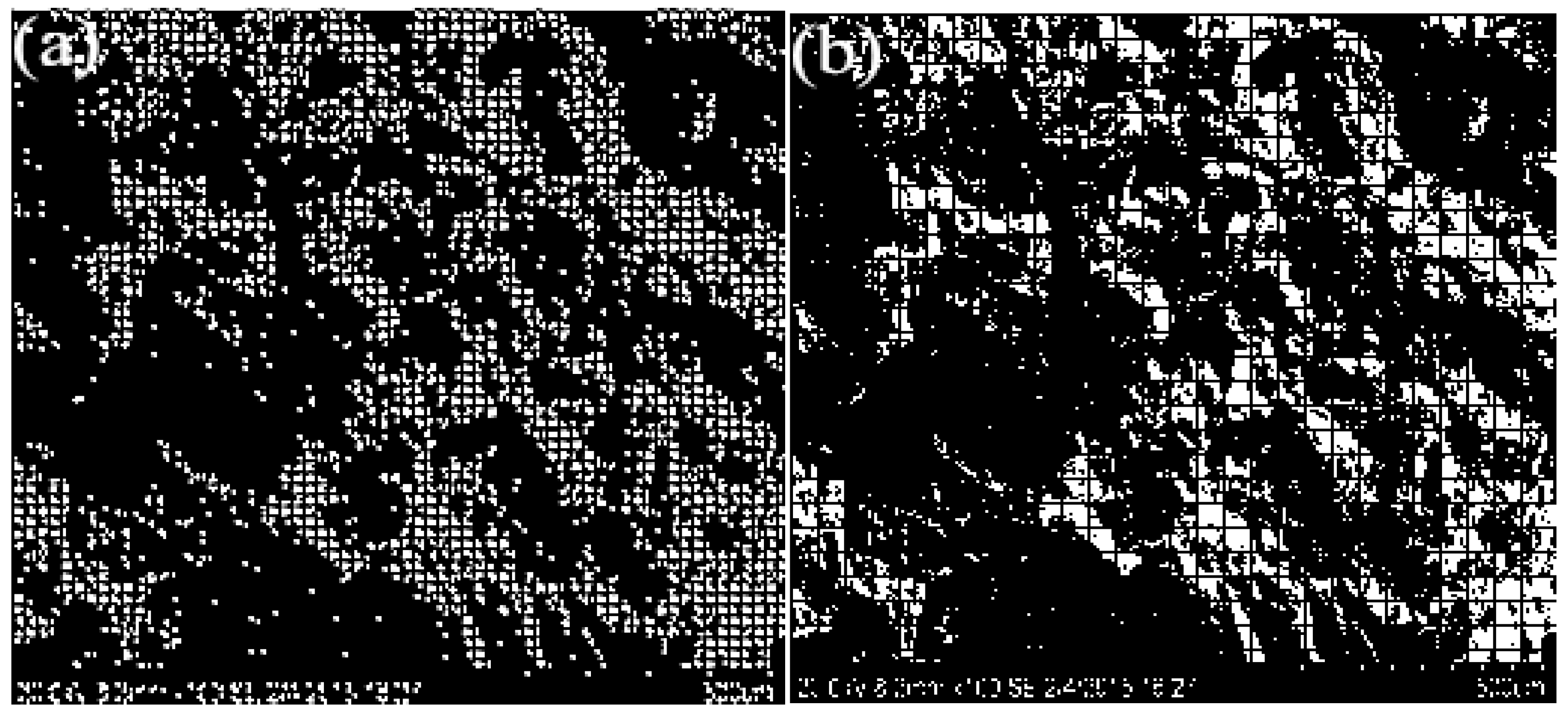

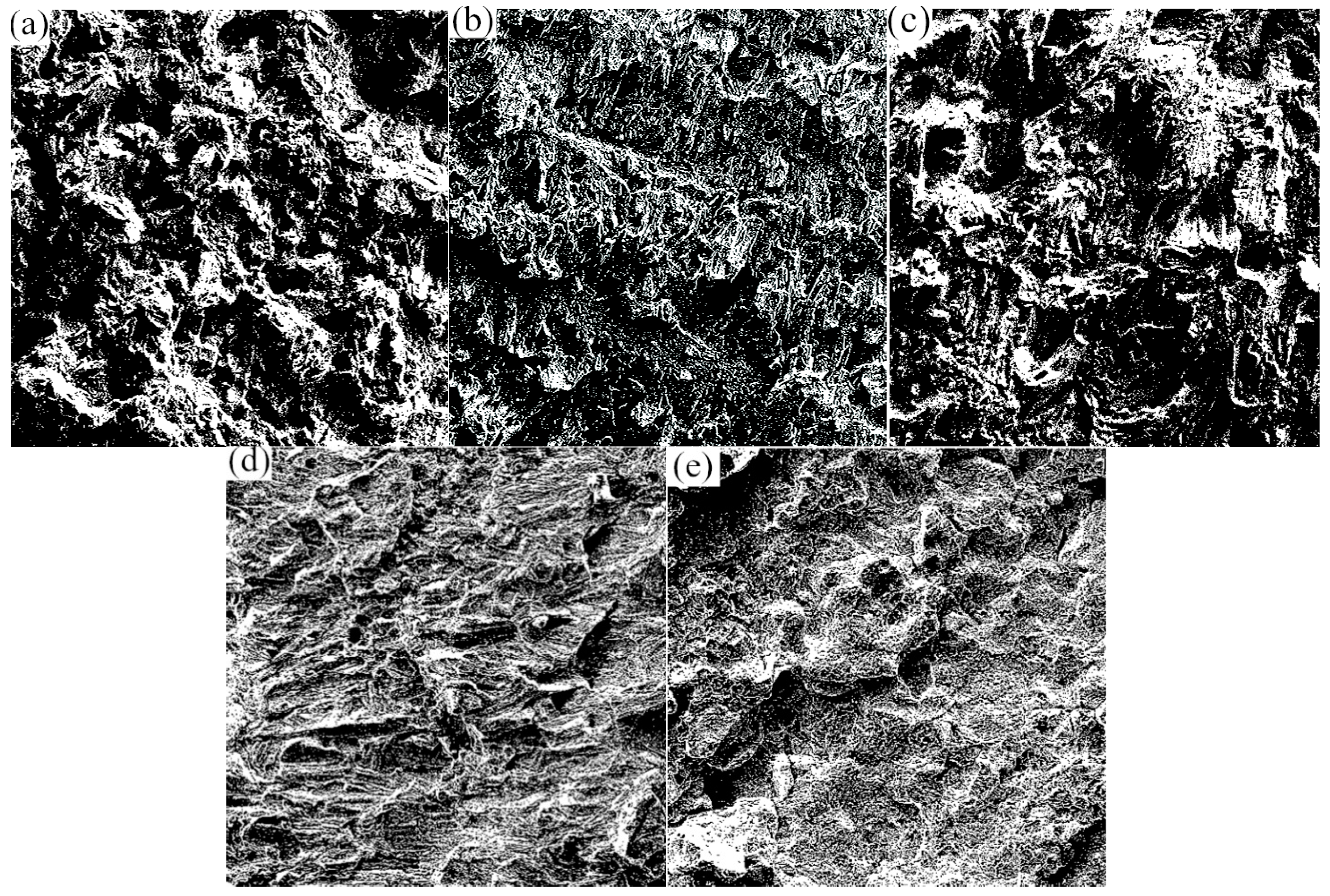

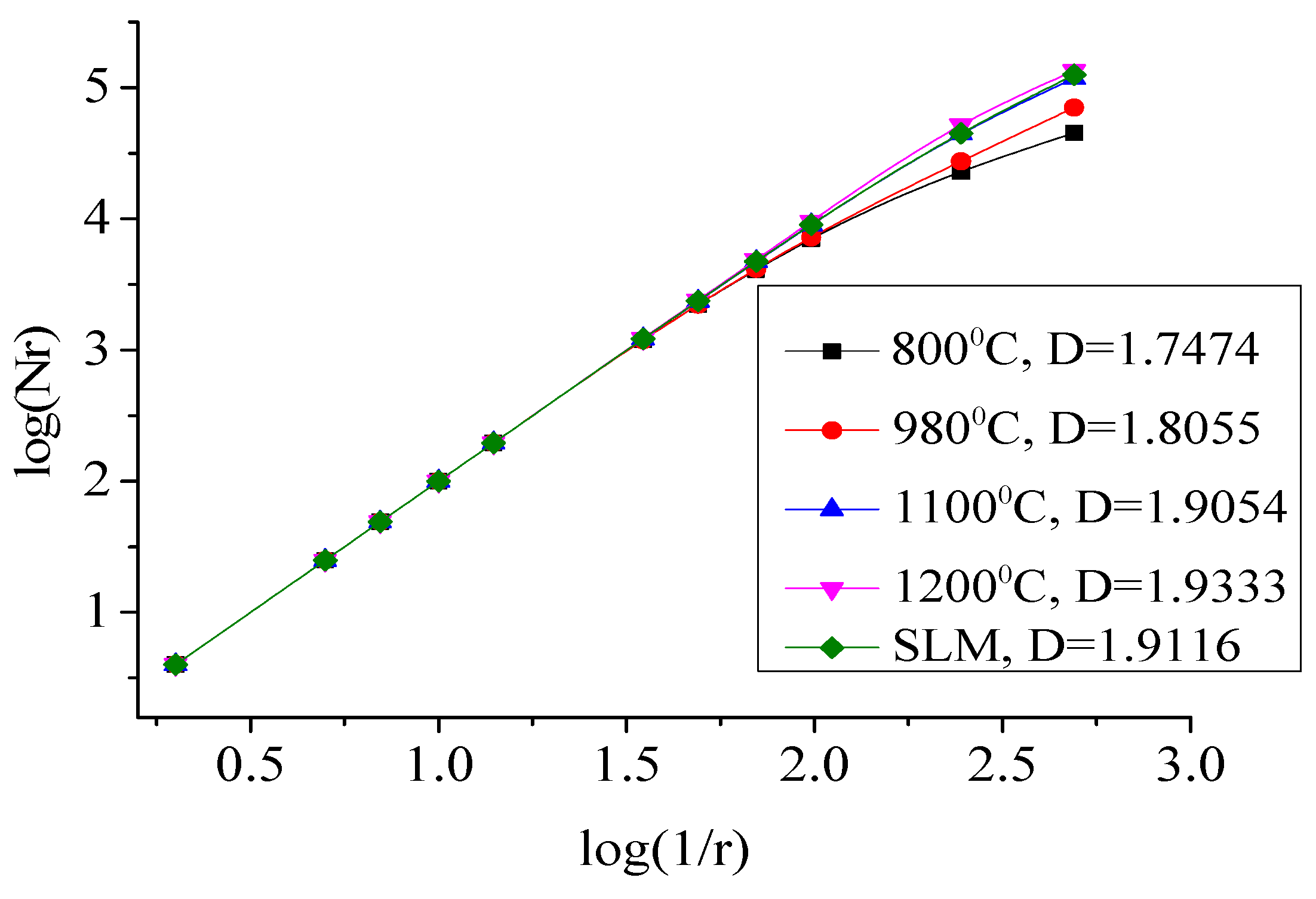

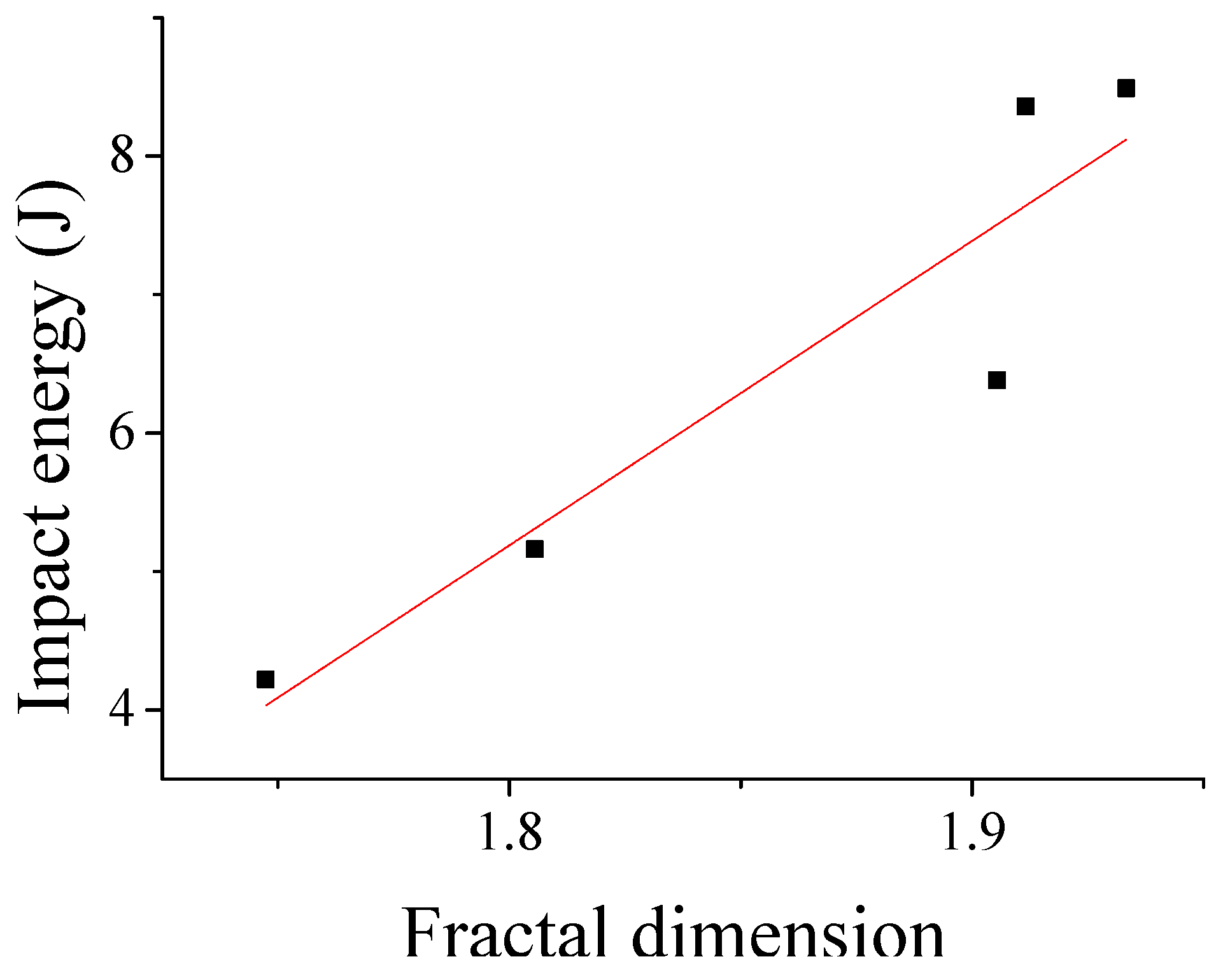

3.4. Analysis of the Fractal Behavior of Impact Fracture

| Algorithm 1 Basic structure of box algorithm code. |

| Start Read SEM image % input the image level = graythresh(I); BW = im2bw(I,level); % image binaryzation I2 = imcrop(BW,[181 181 489 489]); % image clipping Step (2) for j = 1:x for k = 1:y fprintf(fid,‘%d’,I(j,k)); % image data preservation end fprintf(fid,‘\n\n’); end Step (3) nn = length(im); thresh = 120; im = (im > thresh); % read the sizes of the image [M,N] = size(im); Step (4) Ngcd = gcd(M,N); Nmin = min([M,N]); if Ngcd == Nmin % greatest common factor Sgcd = Nmin; else Sgcd = Ngcd; for a = 1:Sgcd for(i = 1:k:M) nr = nr + nj; % count the total number Step (5) xd = get(h,‘XData’); yd = get(h,‘YData’); % least square fitting a = [yd(1) − yd(2)]./[xd(1) − xd(2)] % fractal dimension b = yd(1) − a*xd(1) |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, G.; Wang, M.; Gu, Q.; Bao, H.; Wang, Y.; Feng, M.; Chi, Y.; Zhang, Q.; Yao, J. The effect of WC particle size ratio on the wear/impact resistance of 316L laser cladding layer. Surf. Technol. 2024, 54, 205–217. [Google Scholar]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar]

- Zhang, T.; Li, H.; Zhang, C.; Zhang, A. Effects of beam mode on hole properties in laser processing. Coatings 2024, 14, 594. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Zhou, X.; Zhou, Y.; Bai, Y. The design and processing of a 3D-printed high-performance biological fixation plate. Int. J. Bioprint. 2022, 9, 658. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, T.; Chen, H.; Li, Z.; Li, S.; Wang, D.; Wang, Y.; Kosiba, K. Impact behaviors of additively manufactured metals and structures: A review. Int. J. Impact Eng. 2024, 191, 104992. [Google Scholar] [CrossRef]

- Zhong, Z. Research on Laser Selective Melting Forming and Mechanical Properties of Magnesium Alloy Lattice Structure; Guizhou University: Guizhou, China, 2021. [Google Scholar]

- Liu, P.; Li, H.; Zhang, R.; Xiao, M.; Qu, Y.; Wei, X.; Yin, Y. Comparative analysis of performance of Ti6Al4V parts melted by selective laser under different mirror accuracies. J. Weld. 2024, 45, 52–61. [Google Scholar] [CrossRef]

- Yan, C.; Lv, X.; Jia, Z. Process and mechanical properties of pure tantalum shaped parts prepared by laser selective melting. Weapon Mater. Sci. Eng. 2024, 47, 22–27. [Google Scholar]

- Xiang, C.; Zhang, T.; Wu, W.; Zou, Z.; Sun, Y.; Liu, J.; Xu, X.; Han, E. Effect of heat treatment on the microstructure and mechanical properties of laser selective melting 18Ni300 martensitic aging steel. Chin. Laser 2024, 51, 176–185. [Google Scholar]

- Zhao, H.; Fang, L.; Liu, H.; Dou, K. Heat treatment eliminates the anisotropy of microstructure and high-temperature tensile properties of GH4169 high-temperature alloy melted by laser selective melting. Mater. Eng. 2024, 53, 54–62. [Google Scholar]

- Wang, Y.; Sun, M.; Chen, J.; Qin, Y.; Shen, X.; Wang, G.; Huang, S. The effect of heat treatment temperature on the impact toughness and anisotropy of 316L stainless steel formed by selective laser melting. China Laser 2024, 51, 147–155. [Google Scholar]

- Li, Y.; Wu, D.; Chen, C.; Men, Z.; Zhang, H. The influence of laser selective melting forming process on the impact toughness of 304L stainless steel. Precis. Form. Eng. 2022, 14, 126–132. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Zhou, X.; Li, J.; Wang, A. Effect of heat treatment on the properties of CoCrMo alloy manufactured by selective laser melting. J. Mater. Eng. Perform. 2018, 27, 2281–2287. [Google Scholar]

- Ghayoor, M.; Lee, K.; He, Y.; Chang, C.H.; Paul, B.K.; Pasebani, S. Selective laser melting of 304L stainless steel: Role of volumetric energy density on the microstructure, texture and mechanical properties. Addit. Manuf. 2020, 32, 101011. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Bogahawaththa, M.; Mohotti, D.; Hazell, P.J.; Wang, H.; Wijesooriya, K.; Lee, C.K. Energy absorption and mechanical performance of 3D printed Menger fractal structures. Eng. Struct. 2024, 305, 14. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Podulka, P.; Nejad, R.M.; Costa, J.; Ferreira, J.; Capela, C. The correlation of fractal dimension to fracture surface slope for fatigue crack initiation analysis under bending-torsion loading in high-strength steels. Measurement 2023, 218, 21. [Google Scholar] [CrossRef]

- Macek, W. Correlation between fractal dimension and areal surface parameters for fracture analysis after bending-torsion fatigue. Metals 2021, 11, 1790. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Song, C.; Wang, Y.; Yu, J. Design and performance study of laser selective melting forming CoCrMo porous structure. Chin. Laser 2015, 42, 59–68. [Google Scholar]

- GB/T 229—2020; Metallic Materials—Charpy Pendulum Impact Test Method. National Standardization Administration: Beijing, China, 2020.

- Sun, H. Fractal Geometry and Fractal Interpolation; Science Press: Beijing, China, 2010; pp. 1–5. [Google Scholar]

- Zhang, G.; Yang, Y.; Zhang, Z.; Song, C.; Wang, A.; Yu, J. Optimization design of support structure for laser selective melting forming parts. China Laser 2016, 43, 59–66. [Google Scholar]

- Diao, M.; Tian, Q. Study of impact energy and fractal behavior of stainless steel 1Cr18Ni9Ti. Foundry Technol. 2014, 35, 911–913. [Google Scholar]

- Xiao, L.; Gu, H. Fractal features of high temperature fatigue fracture of a 4 alloy two electron scan method. Rare Met. Mater. Eng. 1995, 24, 22–26. [Google Scholar]

- Mecholsky, J.J.; Passoja, D.E.; Feinberg-Ringel, K.S. Quantitative analysis of brittle fracture surfaces using fractal geometry. J. Am. Ceram. Soc. 1989, 72, 60–65. [Google Scholar] [CrossRef]

| Element | CoCrMo Powder | ASTM F75 Standard | Element | CoCrMo Powder | ASTM F75 Standard |

|---|---|---|---|---|---|

| Cr | 29.4% | 27–30% | C | 0.15% | <0.35% |

| Mo | 6% | 5–7% | Ni | 0.09% | <0.5% |

| Si | 0.8% | <1% | Al | <0.010% | <0.1% |

| Mn | 0.75% | <1% | Ti | <0.010% | <0.1% |

| Fe | 0.26% | <0.75% | W | <0.010% | <0.2% |

| N | 0.19% | <0.25% | Co | Balance | Balance |

| Sample | Impact Energy (J) | Impact Energy Average (J) | Impact Toughness (J/cm2) | ||

|---|---|---|---|---|---|

| Untreatments | 8.13 | 8.6 | 8.4 | 8.36 | 11.91 × 10−3 |

| Annealing (800 °C) | 4.12 | 4.31 | 4.23 | 4.22 | 6.03 × 10−3 |

| Annealing (980 °C) | 5.14 | 5.16 | 5.17 | 5.16 | 7.83 × 10−3 |

| Furnace cooling (1000 °C) | 5.41 | 5.16 | 5.27 | 5.23 | 7.83 × 10−3 |

| Furnace cooling (1100 °C) | 6.01 | 6.39 | 6.74 | 6.38 | 9.11 × 10−3 |

| Furnace cooling (1200 °C) | 8.42 | 8.53 | 8.51 | 8.49 | 12.13 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Li, J.; Wang, H.; Shangguan, C.; Xie, J.; Zhou, Y. Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics 2025, 10, 292. https://doi.org/10.3390/biomimetics10050292

Zhang G, Li J, Wang H, Shangguan C, Xie J, Zhou Y. Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics. 2025; 10(5):292. https://doi.org/10.3390/biomimetics10050292

Chicago/Turabian StyleZhang, Guoqing, Junxin Li, Han Wang, Congcong Shangguan, Juanjuan Xie, and Yongsheng Zhou. 2025. "Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory" Biomimetics 10, no. 5: 292. https://doi.org/10.3390/biomimetics10050292

APA StyleZhang, G., Li, J., Wang, H., Shangguan, C., Xie, J., & Zhou, Y. (2025). Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics, 10(5), 292. https://doi.org/10.3390/biomimetics10050292