Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory

Abstract

1. Introduction

2. Materials and Methods

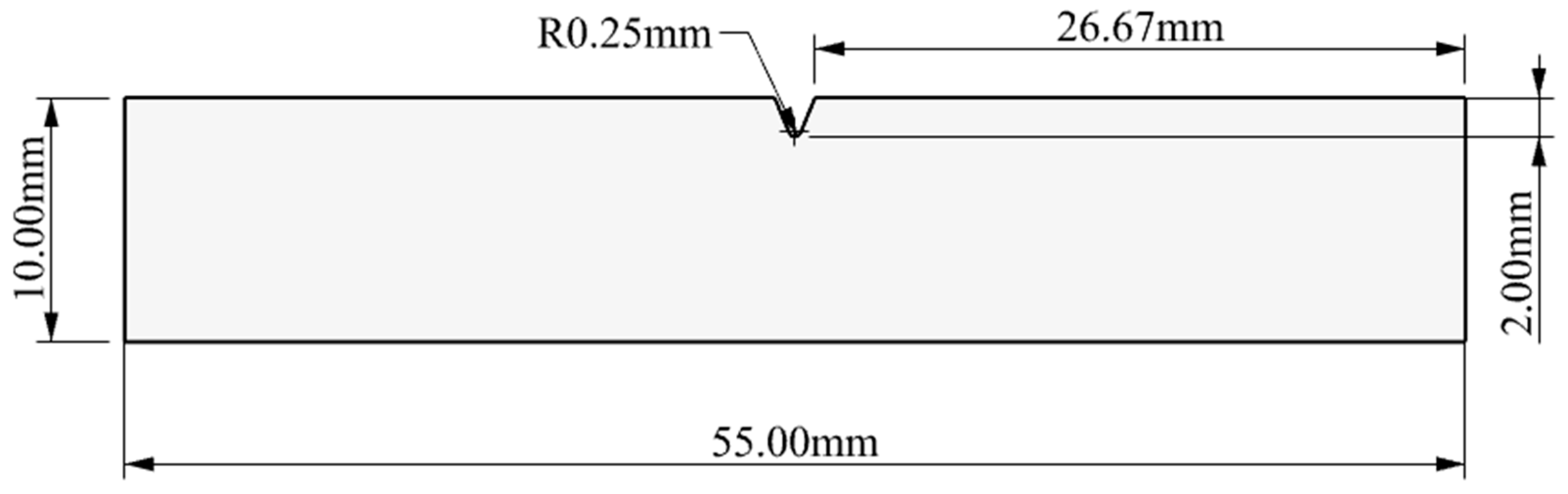

2.1. Design Methods

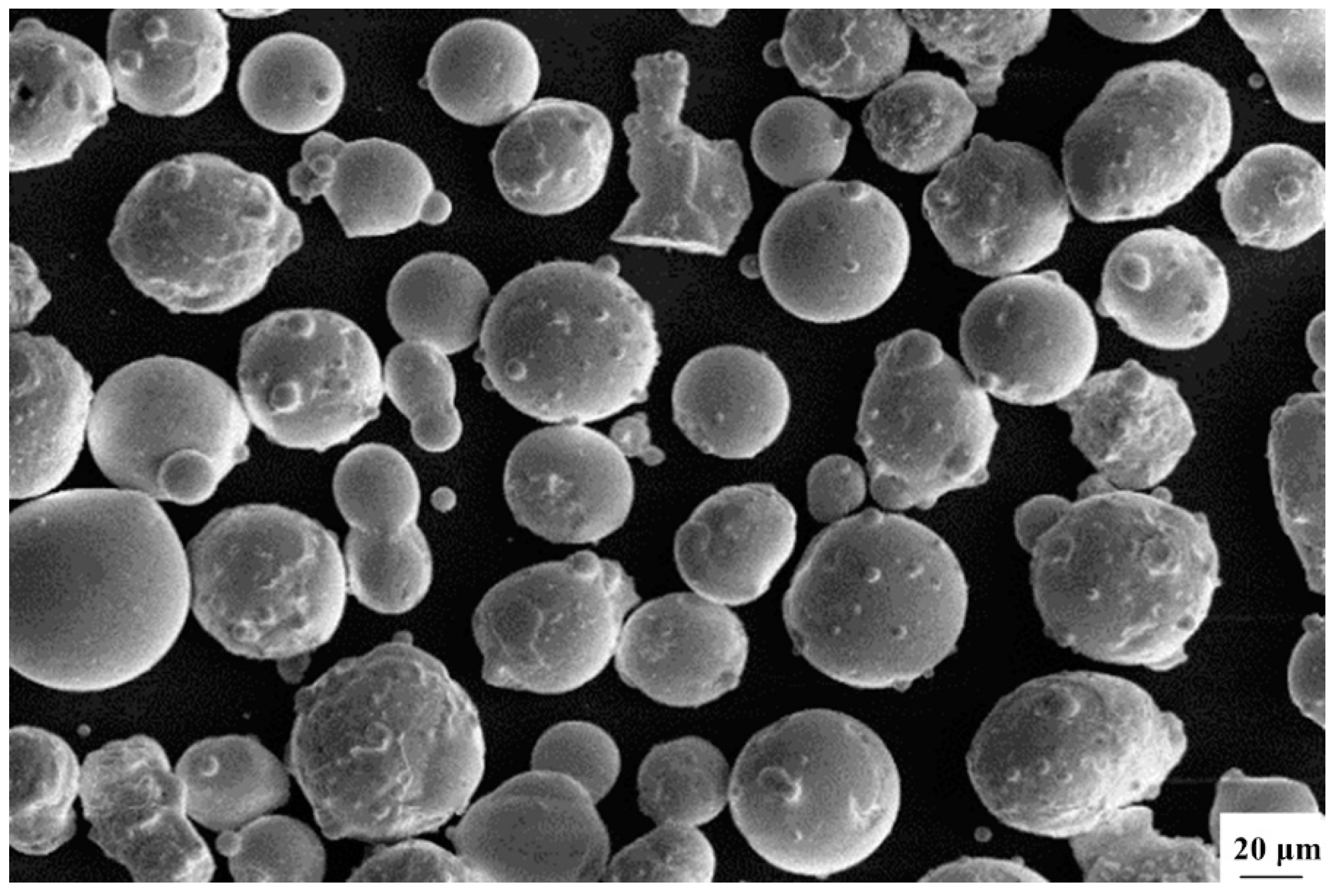

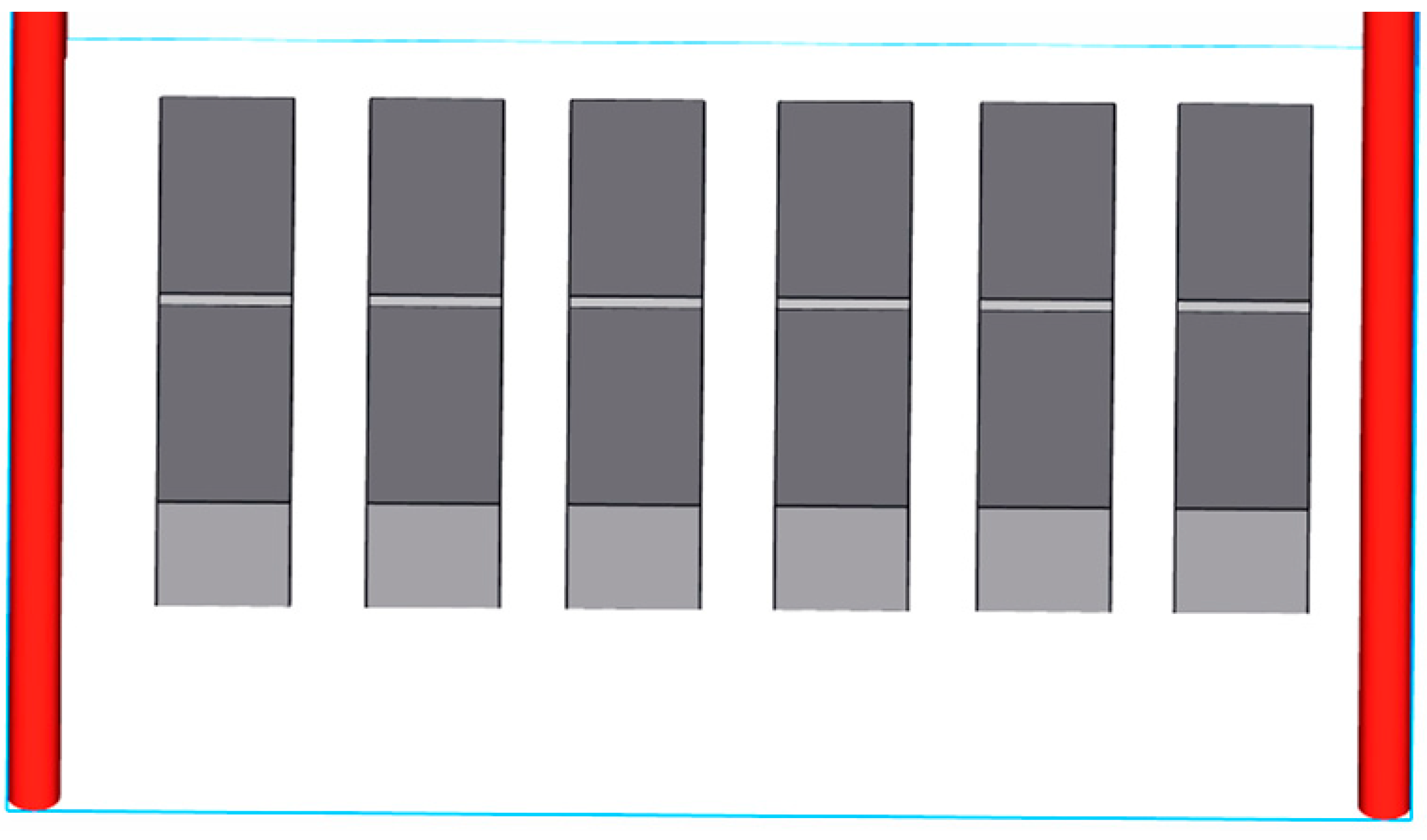

2.2. Materials and Manufacturing Methods

2.3. Analysis Methods

3. Results and Discussion

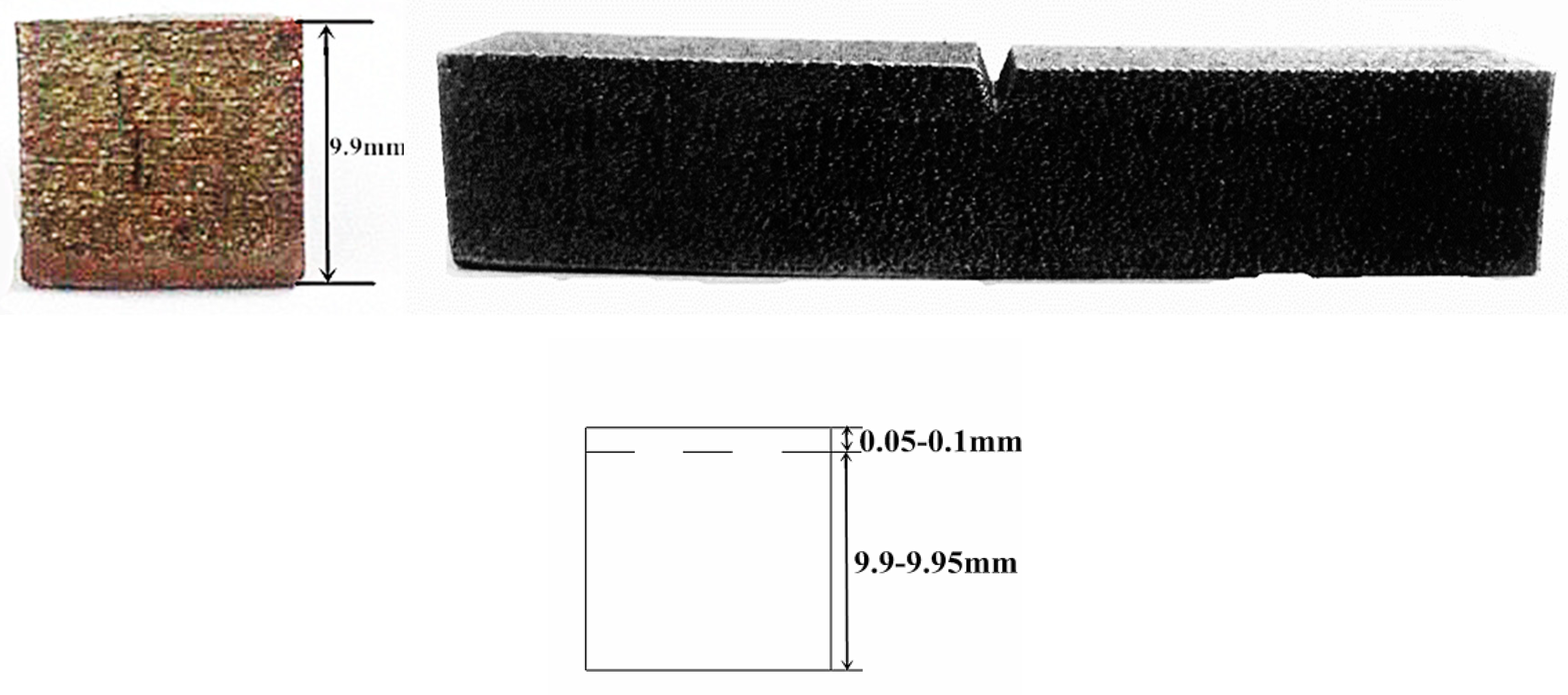

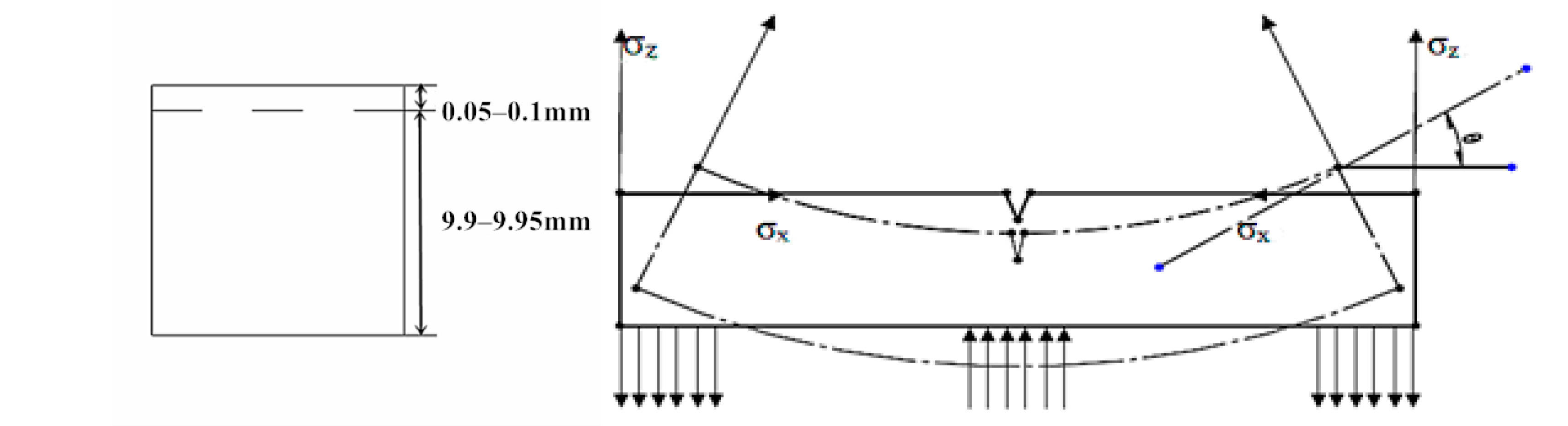

3.1. Data Processing for the 3D-Printed Impact Sample

3.2. Analysis of the Effectiveness of 3D-Printed Parts

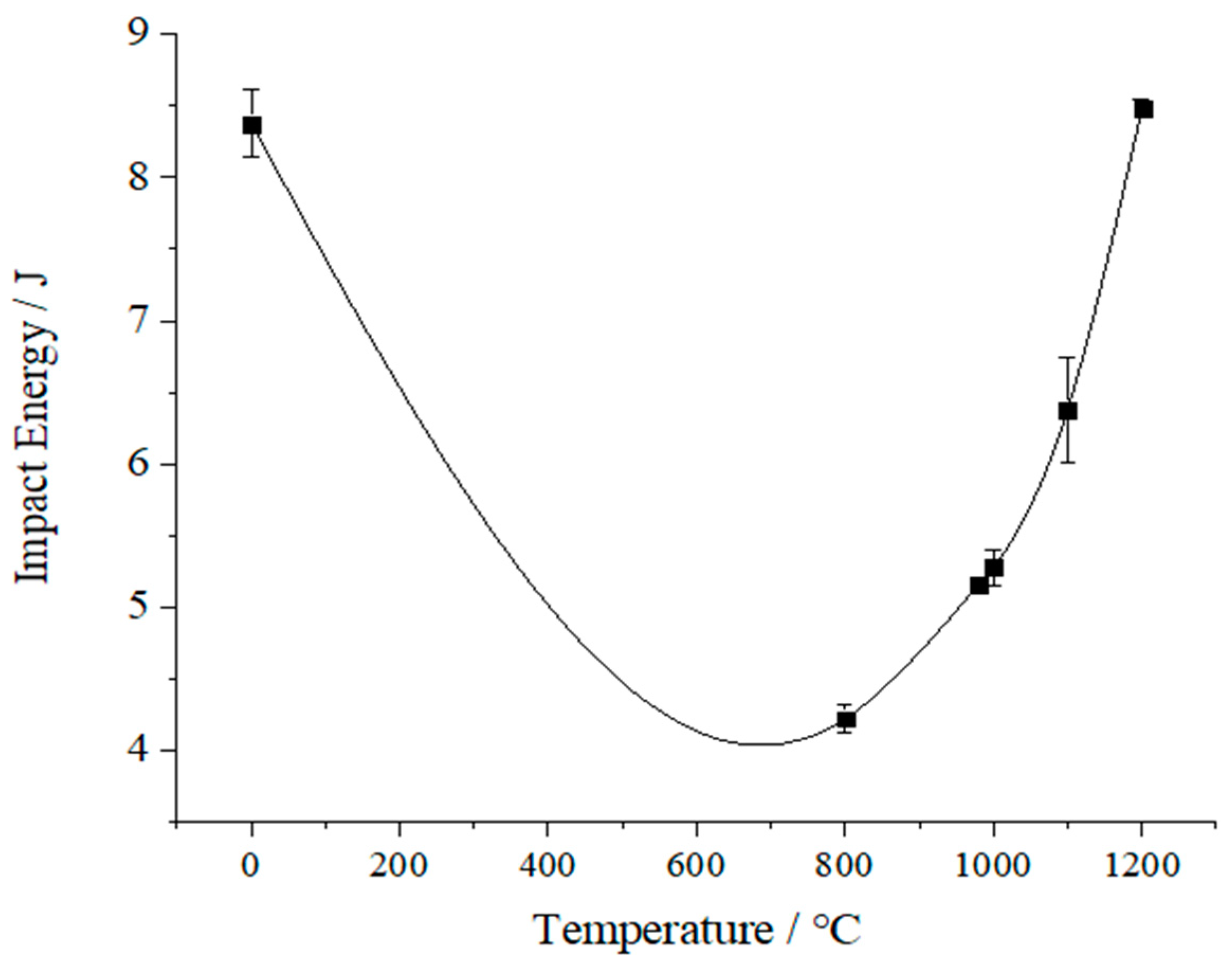

3.3. Analysis of the Impact Performance of 3D-Printed Parts

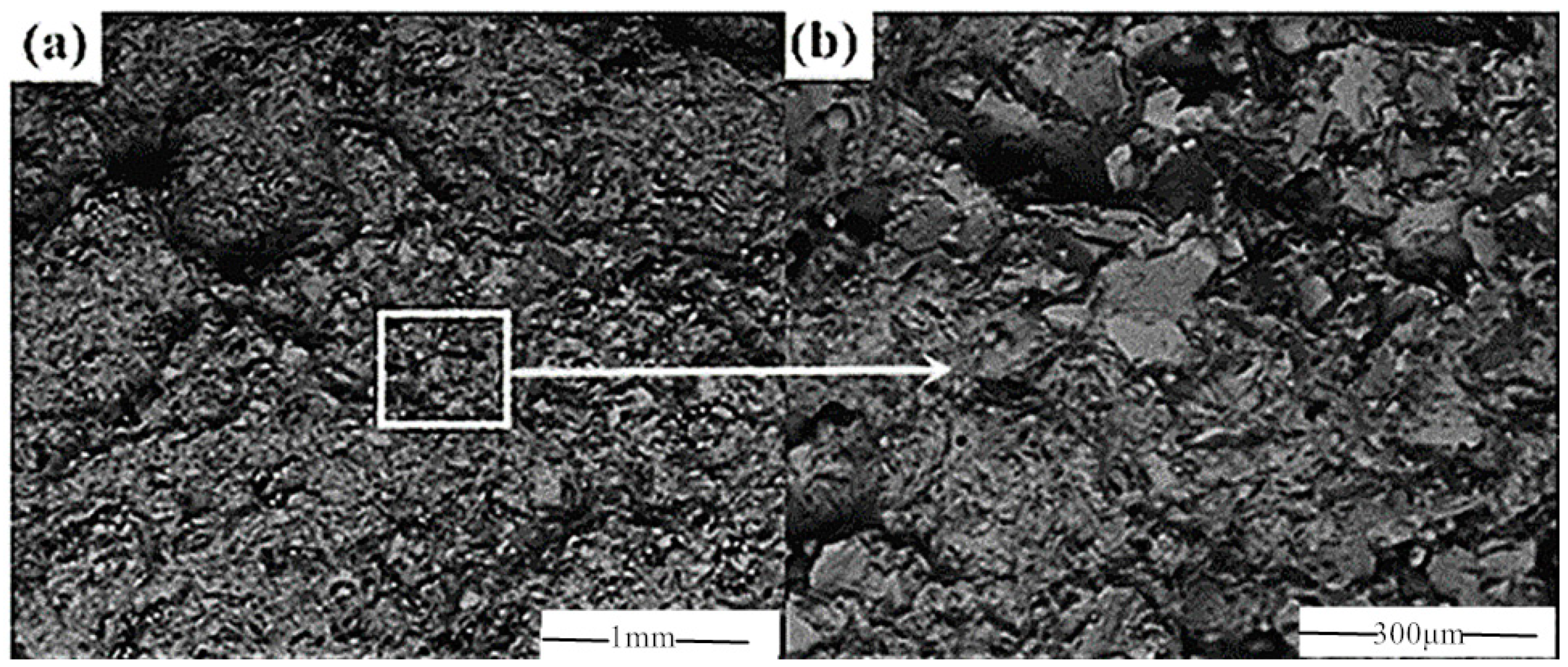

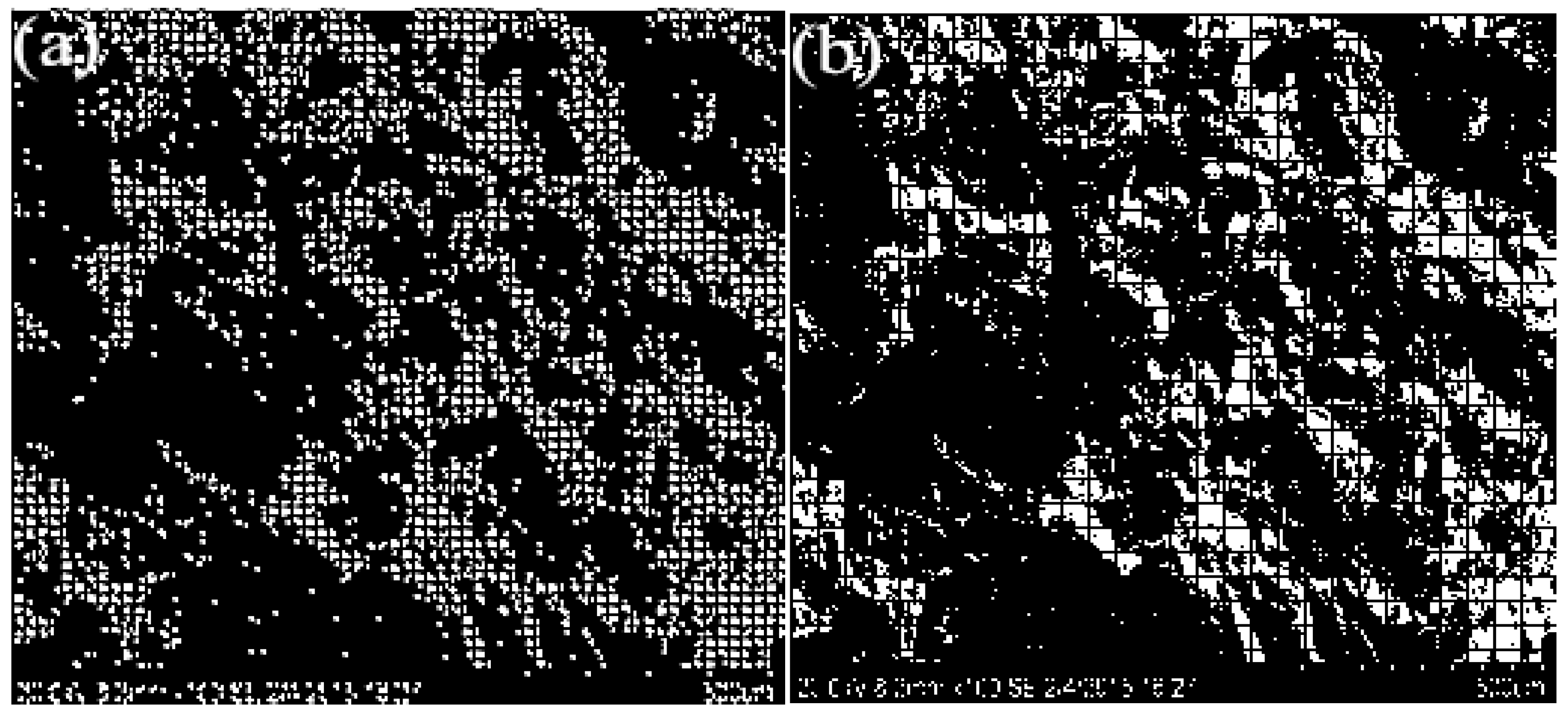

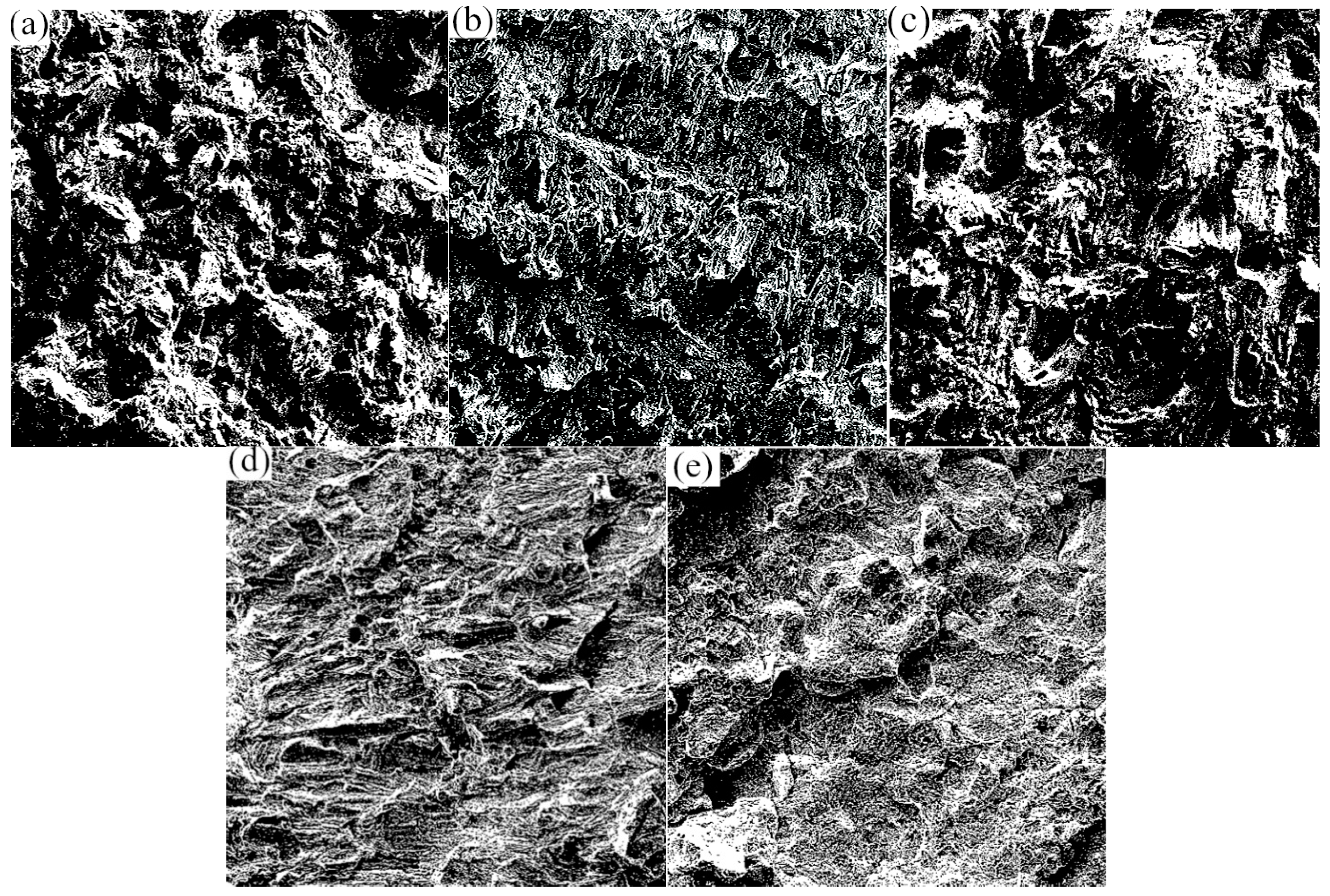

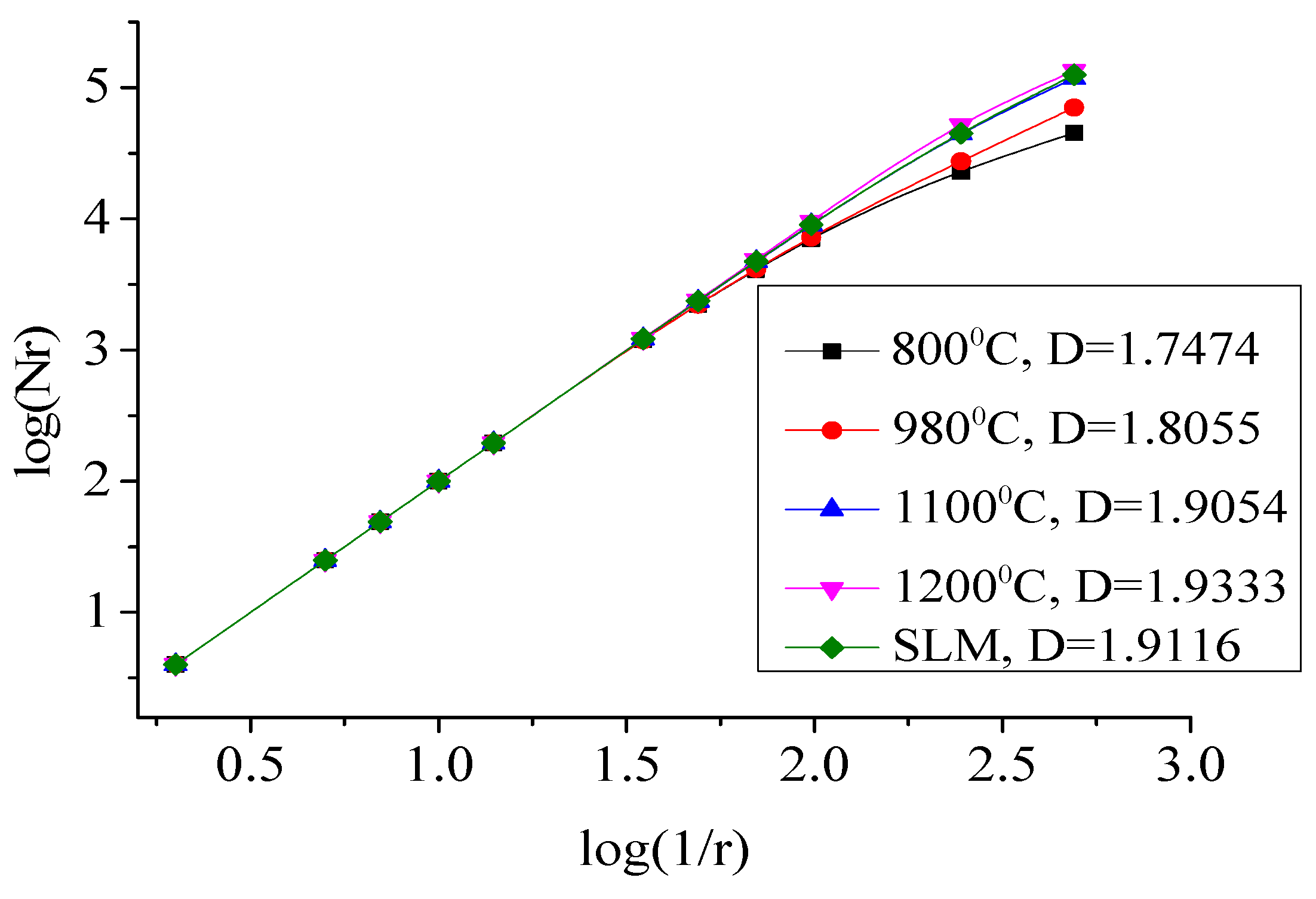

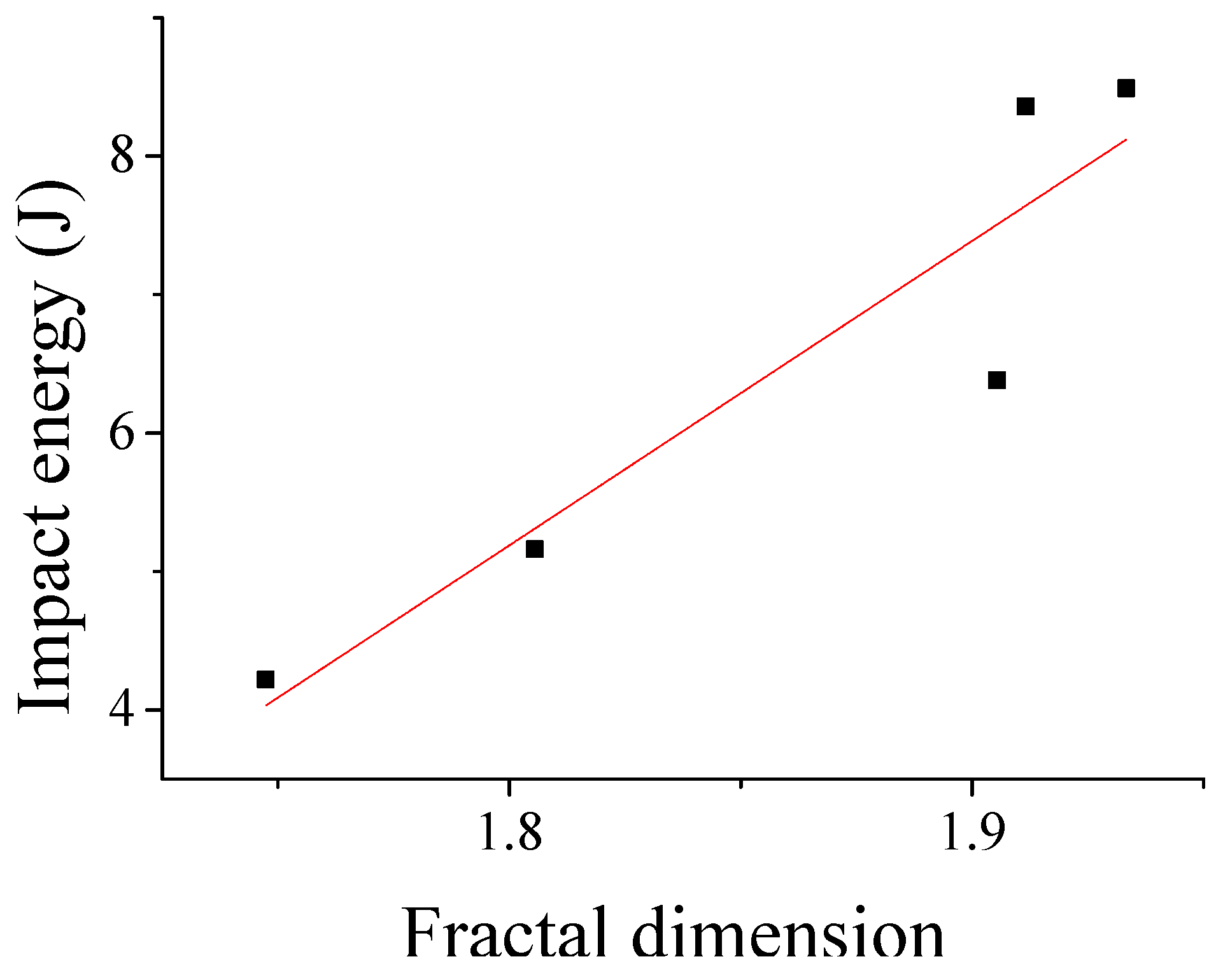

3.4. Analysis of the Fractal Behavior of Impact Fracture

| Algorithm 1 Basic structure of box algorithm code. |

| Start Read SEM image % input the image level = graythresh(I); BW = im2bw(I,level); % image binaryzation I2 = imcrop(BW,[181 181 489 489]); % image clipping Step (2) for j = 1:x for k = 1:y fprintf(fid,‘%d’,I(j,k)); % image data preservation end fprintf(fid,‘\n\n’); end Step (3) nn = length(im); thresh = 120; im = (im > thresh); % read the sizes of the image [M,N] = size(im); Step (4) Ngcd = gcd(M,N); Nmin = min([M,N]); if Ngcd == Nmin % greatest common factor Sgcd = Nmin; else Sgcd = Ngcd; for a = 1:Sgcd for(i = 1:k:M) nr = nr + nj; % count the total number Step (5) xd = get(h,‘XData’); yd = get(h,‘YData’); % least square fitting a = [yd(1) − yd(2)]./[xd(1) − xd(2)] % fractal dimension b = yd(1) − a*xd(1) |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, G.; Wang, M.; Gu, Q.; Bao, H.; Wang, Y.; Feng, M.; Chi, Y.; Zhang, Q.; Yao, J. The effect of WC particle size ratio on the wear/impact resistance of 316L laser cladding layer. Surf. Technol. 2024, 54, 205–217. [Google Scholar]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar]

- Zhang, T.; Li, H.; Zhang, C.; Zhang, A. Effects of beam mode on hole properties in laser processing. Coatings 2024, 14, 594. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Zhou, X.; Zhou, Y.; Bai, Y. The design and processing of a 3D-printed high-performance biological fixation plate. Int. J. Bioprint. 2022, 9, 658. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, T.; Chen, H.; Li, Z.; Li, S.; Wang, D.; Wang, Y.; Kosiba, K. Impact behaviors of additively manufactured metals and structures: A review. Int. J. Impact Eng. 2024, 191, 104992. [Google Scholar] [CrossRef]

- Zhong, Z. Research on Laser Selective Melting Forming and Mechanical Properties of Magnesium Alloy Lattice Structure; Guizhou University: Guizhou, China, 2021. [Google Scholar]

- Liu, P.; Li, H.; Zhang, R.; Xiao, M.; Qu, Y.; Wei, X.; Yin, Y. Comparative analysis of performance of Ti6Al4V parts melted by selective laser under different mirror accuracies. J. Weld. 2024, 45, 52–61. [Google Scholar] [CrossRef]

- Yan, C.; Lv, X.; Jia, Z. Process and mechanical properties of pure tantalum shaped parts prepared by laser selective melting. Weapon Mater. Sci. Eng. 2024, 47, 22–27. [Google Scholar]

- Xiang, C.; Zhang, T.; Wu, W.; Zou, Z.; Sun, Y.; Liu, J.; Xu, X.; Han, E. Effect of heat treatment on the microstructure and mechanical properties of laser selective melting 18Ni300 martensitic aging steel. Chin. Laser 2024, 51, 176–185. [Google Scholar]

- Zhao, H.; Fang, L.; Liu, H.; Dou, K. Heat treatment eliminates the anisotropy of microstructure and high-temperature tensile properties of GH4169 high-temperature alloy melted by laser selective melting. Mater. Eng. 2024, 53, 54–62. [Google Scholar]

- Wang, Y.; Sun, M.; Chen, J.; Qin, Y.; Shen, X.; Wang, G.; Huang, S. The effect of heat treatment temperature on the impact toughness and anisotropy of 316L stainless steel formed by selective laser melting. China Laser 2024, 51, 147–155. [Google Scholar]

- Li, Y.; Wu, D.; Chen, C.; Men, Z.; Zhang, H. The influence of laser selective melting forming process on the impact toughness of 304L stainless steel. Precis. Form. Eng. 2022, 14, 126–132. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Zhou, X.; Li, J.; Wang, A. Effect of heat treatment on the properties of CoCrMo alloy manufactured by selective laser melting. J. Mater. Eng. Perform. 2018, 27, 2281–2287. [Google Scholar]

- Ghayoor, M.; Lee, K.; He, Y.; Chang, C.H.; Paul, B.K.; Pasebani, S. Selective laser melting of 304L stainless steel: Role of volumetric energy density on the microstructure, texture and mechanical properties. Addit. Manuf. 2020, 32, 101011. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Bogahawaththa, M.; Mohotti, D.; Hazell, P.J.; Wang, H.; Wijesooriya, K.; Lee, C.K. Energy absorption and mechanical performance of 3D printed Menger fractal structures. Eng. Struct. 2024, 305, 14. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Podulka, P.; Nejad, R.M.; Costa, J.; Ferreira, J.; Capela, C. The correlation of fractal dimension to fracture surface slope for fatigue crack initiation analysis under bending-torsion loading in high-strength steels. Measurement 2023, 218, 21. [Google Scholar] [CrossRef]

- Macek, W. Correlation between fractal dimension and areal surface parameters for fracture analysis after bending-torsion fatigue. Metals 2021, 11, 1790. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Song, C.; Wang, Y.; Yu, J. Design and performance study of laser selective melting forming CoCrMo porous structure. Chin. Laser 2015, 42, 59–68. [Google Scholar]

- GB/T 229—2020; Metallic Materials—Charpy Pendulum Impact Test Method. National Standardization Administration: Beijing, China, 2020.

- Sun, H. Fractal Geometry and Fractal Interpolation; Science Press: Beijing, China, 2010; pp. 1–5. [Google Scholar]

- Zhang, G.; Yang, Y.; Zhang, Z.; Song, C.; Wang, A.; Yu, J. Optimization design of support structure for laser selective melting forming parts. China Laser 2016, 43, 59–66. [Google Scholar]

- Diao, M.; Tian, Q. Study of impact energy and fractal behavior of stainless steel 1Cr18Ni9Ti. Foundry Technol. 2014, 35, 911–913. [Google Scholar]

- Xiao, L.; Gu, H. Fractal features of high temperature fatigue fracture of a 4 alloy two electron scan method. Rare Met. Mater. Eng. 1995, 24, 22–26. [Google Scholar]

- Mecholsky, J.J.; Passoja, D.E.; Feinberg-Ringel, K.S. Quantitative analysis of brittle fracture surfaces using fractal geometry. J. Am. Ceram. Soc. 1989, 72, 60–65. [Google Scholar] [CrossRef]

| Element | CoCrMo Powder | ASTM F75 Standard | Element | CoCrMo Powder | ASTM F75 Standard |

|---|---|---|---|---|---|

| Cr | 29.4% | 27–30% | C | 0.15% | <0.35% |

| Mo | 6% | 5–7% | Ni | 0.09% | <0.5% |

| Si | 0.8% | <1% | Al | <0.010% | <0.1% |

| Mn | 0.75% | <1% | Ti | <0.010% | <0.1% |

| Fe | 0.26% | <0.75% | W | <0.010% | <0.2% |

| N | 0.19% | <0.25% | Co | Balance | Balance |

| Sample | Impact Energy (J) | Impact Energy Average (J) | Impact Toughness (J/cm2) | ||

|---|---|---|---|---|---|

| Untreatments | 8.13 | 8.6 | 8.4 | 8.36 | 11.91 × 10−3 |

| Annealing (800 °C) | 4.12 | 4.31 | 4.23 | 4.22 | 6.03 × 10−3 |

| Annealing (980 °C) | 5.14 | 5.16 | 5.17 | 5.16 | 7.83 × 10−3 |

| Furnace cooling (1000 °C) | 5.41 | 5.16 | 5.27 | 5.23 | 7.83 × 10−3 |

| Furnace cooling (1100 °C) | 6.01 | 6.39 | 6.74 | 6.38 | 9.11 × 10−3 |

| Furnace cooling (1200 °C) | 8.42 | 8.53 | 8.51 | 8.49 | 12.13 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Li, J.; Wang, H.; Shangguan, C.; Xie, J.; Zhou, Y. Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics 2025, 10, 292. https://doi.org/10.3390/biomimetics10050292

Zhang G, Li J, Wang H, Shangguan C, Xie J, Zhou Y. Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics. 2025; 10(5):292. https://doi.org/10.3390/biomimetics10050292

Chicago/Turabian StyleZhang, Guoqing, Junxin Li, Han Wang, Congcong Shangguan, Juanjuan Xie, and Yongsheng Zhou. 2025. "Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory" Biomimetics 10, no. 5: 292. https://doi.org/10.3390/biomimetics10050292

APA StyleZhang, G., Li, J., Wang, H., Shangguan, C., Xie, J., & Zhou, Y. (2025). Research on the Impact Toughness of 3D-Printed CoCrMo Alloy Components Based on Fractal Theory. Biomimetics, 10(5), 292. https://doi.org/10.3390/biomimetics10050292