Vole Foraging-Inspired Dynamic Path Planning of Wheeled Humanoid Robots Under Workshop Slippery Road Conditions

Abstract

1. Introduction

2. Problem Formulation

2.1. Grid-Based Environment Modeling

2.2. Problem Formulation

3. Slip Risk Assessment

4. Vole Foraging-Inspired Dynamic Path Planning

4.1. Dynamic Path-Planning Model

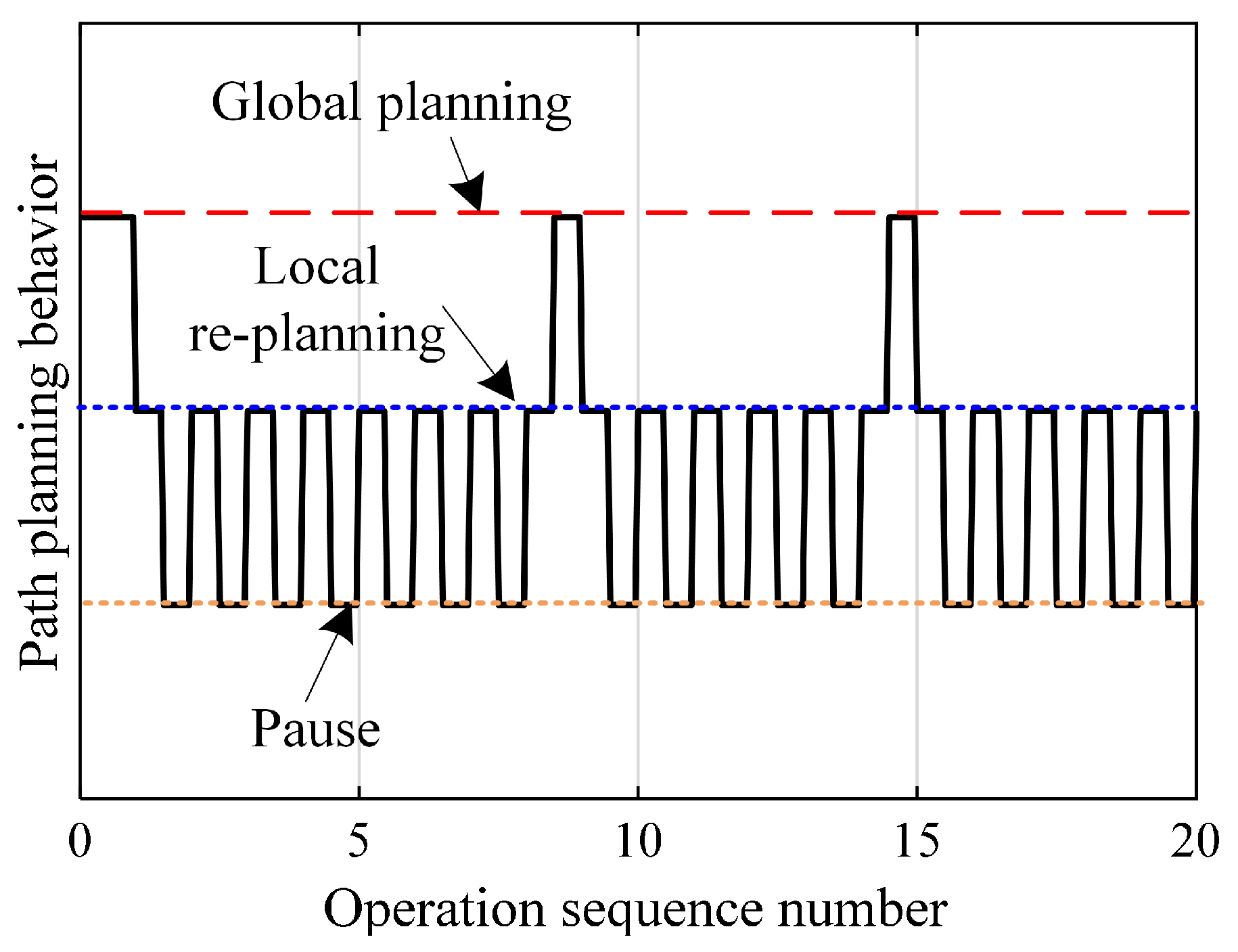

4.2. Two-Level Non-Periodic Cyclical Dynamic Planning

| Algorithm 1: Two-level non-periodic cyclical dynamic planning |

1 Main loop 2 While the WHR has not reached the target point 3 Detect the operating environment and the state of the WHR; 4 Refresh the operating environment model by (1)–(6); 5 If the trigger condition is met 6 Plan the global path by (7)–(15); 7 Re-plan the local path by (16)–(18); 8 Else 9 Re-plan the local path by (16)–(18); 10 End if 11 End while 12 End loop |

5. Results and Discussion

5.1. Results

5.2. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WHR | Wheeled humanoid robots |

References

- Liu, L.; Wang, X.; Yang, X.; Liu, H.; Li, J.; Wang, P. Path planning techniques for mobile robots: Review and prospect. Expert Syst. Appl. 2023, 227, 120254. [Google Scholar] [CrossRef]

- Heiden, E.; Palmieri, L.; Bruns, L.; Arras, K.O.; Sukhatme, G.S.; Koenig, S. Bench-MR: A Motion Planning Benchmark for Wheeled Mobile Robots. IEEE Robot. Automat. Lett. 2021, 6, 4536–4543. [Google Scholar] [CrossRef]

- Zhao, W.; Lin, R.; Dong, S.; Cheng, Y. A Study of the Global Topological Map Construction Algorithm Based on Grid Map Representation for Multirobot. IEEE Trans. Autom. Sci. Eng. 2023, 20, 2822–2835. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, J.; Chi, W.; Chen, G.; Sun, L. A Gaussian Mixture Model Based Fast Motion Planning Method Through Online Environmental Feature Learning. IEEE Trans. Ind. Electron. 2023, 70, 3955–3965. [Google Scholar] [CrossRef]

- Guo, B.; Guo, N.; Cen, Z. Obstacle Avoidance with Dynamic Avoidance Risk Region for Mobile Robots in Dynamic Environments. IEEE Robot. Automat. Lett. 2022, 7, 5850–5857. [Google Scholar] [CrossRef]

- Cheon, H.; Kim, T.; Kim, B.K.; Moon, J.; Kim, H. Online Waypoint Path Refinement for Mobile Robots Using Spatial Definition and Classification Based on Collision Probability. IEEE Trans. Ind. Electron. 2023, 70, 7004–7013. [Google Scholar] [CrossRef]

- Duan, P.; Yu, Z.; Gao, K.; Meng, L.; Han, Y.; Ye, F. Solving the multi-objective path planning problem for mobile robot using an improved NSGA-II algorithm. Swarm Evol. Comput. 2024, 87, 101576. [Google Scholar] [CrossRef]

- Jian, Z.; Zhang, S.; Chen, S.; Nan, Z.; Zheng, N. A Global-Local Coupling Two-Stage Path Planning Method for Mobile Robots. IEEE Robot. Automat. Lett. 2021, 6, 5349–5356. [Google Scholar] [CrossRef]

- Wen, J.; Zhang, X.; Gao, H.; Yuan, J.; Fang, Y. E3MoP:Efficient Motion Planning Based on Heuristic-Guided Motion Primitives Pruning and Path Optimization with Sparse-Banded Structure. IEEE Trans. Autom. Sci. Eng. 2022, 19, 2762–2775. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Y.; Liang, J.; He, B.; Wang, Y. ST-FMT*: A Fast Optimal Global Motion Planning for Mobile Robot. IEEE Trans. Ind. Electron. 2022, 69, 3854–3864. [Google Scholar] [CrossRef]

- Lee, C.C.; Song, K.T. Path Re-Planning Design of a Cobot in a Dynamic Environment Based on Current Obstacle Configuration. IEEE Robot. Automat. Lett. 2023, 8, 1183–1190. [Google Scholar] [CrossRef]

- Li, D.; Wang, L.; Cai, J.; Ma, K.; Tan, T. Research on Terminal Distance Index-Based Multi-Step Ant Colony Optimization for Mobile Robot Path Planning. IEEE Trans. Autom. Sci. Eng. 2023, 20, 2321–2337. [Google Scholar] [CrossRef]

- Xu, L.; Cao, M.; Song, B. A new approach to smooth path planning of mobile robot based on quartic Bezier transition curve and improved PSO algorithm. Neurocomputing 2022, 473, 98–106. [Google Scholar] [CrossRef]

- Chi, W.; Ding, Z.; Wang, J.; Chen, G.; Sun, L. A Generalized Voronoi Diagram-Based Efficient Heuristic Path Planning Method for RRTs in Mobile Robots. IEEE Trans. Ind. Electron. 2022, 69, 4926–4937. [Google Scholar] [CrossRef]

- Hu, B.; Cao, Z.; Zhou, M. An Efficient RRT-Based Framework for Planning Short and Smooth Wheeled Robot Motion Under Kinodynamic Constraints. IEEE Trans. Ind. Electron. 2021, 68, 3292–3302. [Google Scholar] [CrossRef]

- Pei, M.; An, H.; Liu, B.; Wang, C. An Improved Dyna-Q Algorithm for Mobile Robot Path Planning in Unknown Dynamic Environment. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 4415–4425. [Google Scholar] [CrossRef]

- Yao, M.; Deng, H.; Feng, X.; Li, P.; Li, Y.; Liu, H. Improved dynamic windows approach based on energy consumption management and fuzzy logic control for local path planning of mobile robots. Comput. Ind. Eng. 2024, 187, 109767. [Google Scholar] [CrossRef]

- Szczepanski, R. Safe Artificial Potential Field—Novel Local Path Planning Algorithm Maintaining Safe Distance From Obstacles. IEEE Robot. Automat. Lett. 2023, 8, 4823–4830. [Google Scholar] [CrossRef]

- Guo, N.; Li, C.; Wang, D.; Song, Y.; Liu, G.; Gao, T. Local path planning of mobile robot based on long short-term memory neural network. Autom. Control Comp. Sci. 2021, 55, 53–65. [Google Scholar] [CrossRef]

- Low, E.S.; Ong, P.; Low, C.Y.; Omar, R. Modified Q-learning with distance metric and virtual target on path planning of mobile robot. Expert Syst. Appl. 2022, 199, 117191. [Google Scholar] [CrossRef]

- Md Hafizur, R.; Muhammad Majid, G.; Tansu Sila, H.; Salman, H.; Adnan, S.; Ali Faisal, M. Trajectory planning and tracking control in autonomous driving system: Leveraging machine learning and advanced control algorithms. Eng. Sci. Technol. 2025, 64, 101950. [Google Scholar] [CrossRef]

- Reda, M.; Onsy, A.; Haikal, A.Y.; Ghanbari, A. Path planning algorithms in the autonomous driving system: A comprehensive review. Robot. Auton. Syst. 2024, 174, 104630. [Google Scholar] [CrossRef]

- Loganathan, A.; Ahmad, N.S. A Hybrid HHO-AVOA for Path Planning of a Differential Wheeled Mobile Robot in Static and Dynamic Environments. IEEE Access 2024, 12, 25967–25979. [Google Scholar] [CrossRef]

- Inotsume, H.; Kubota, T.; Wettergreen, D. Robust Path Planning for Slope Traversing Under Uncertainty in Slip Prediction. IEEE Robot. Automat. Lett. 2020, 5, 3390–3397. [Google Scholar] [CrossRef]

- Kim, J.; Kim, B.K. Cornering Trajectory Planning Avoiding Slip for Differential-Wheeled Mobile Robots. IEEE Trans. Ind. Electron. 2020, 67, 6698–6708. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, D.; Ye, W.; Fan, J.; Liu, S.; Su, C.Y. Targeting Posture Control with Dynamic Obstacle Avoidance of Constrained Uncertain Wheeled Mobile Robots Including Unknown Skidding and Slipping. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 6650–6659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, Y.; Guo, Y.; Duan, J. Vole Foraging-Inspired Dynamic Path Planning of Wheeled Humanoid Robots Under Workshop Slippery Road Conditions. Biomimetics 2025, 10, 277. https://doi.org/10.3390/biomimetics10050277

Li H, Wang Y, Guo Y, Duan J. Vole Foraging-Inspired Dynamic Path Planning of Wheeled Humanoid Robots Under Workshop Slippery Road Conditions. Biomimetics. 2025; 10(5):277. https://doi.org/10.3390/biomimetics10050277

Chicago/Turabian StyleLi, Hu, Yan Wang, Yixuan Guo, and Jiawang Duan. 2025. "Vole Foraging-Inspired Dynamic Path Planning of Wheeled Humanoid Robots Under Workshop Slippery Road Conditions" Biomimetics 10, no. 5: 277. https://doi.org/10.3390/biomimetics10050277

APA StyleLi, H., Wang, Y., Guo, Y., & Duan, J. (2025). Vole Foraging-Inspired Dynamic Path Planning of Wheeled Humanoid Robots Under Workshop Slippery Road Conditions. Biomimetics, 10(5), 277. https://doi.org/10.3390/biomimetics10050277