Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices

Abstract

1. Introduction

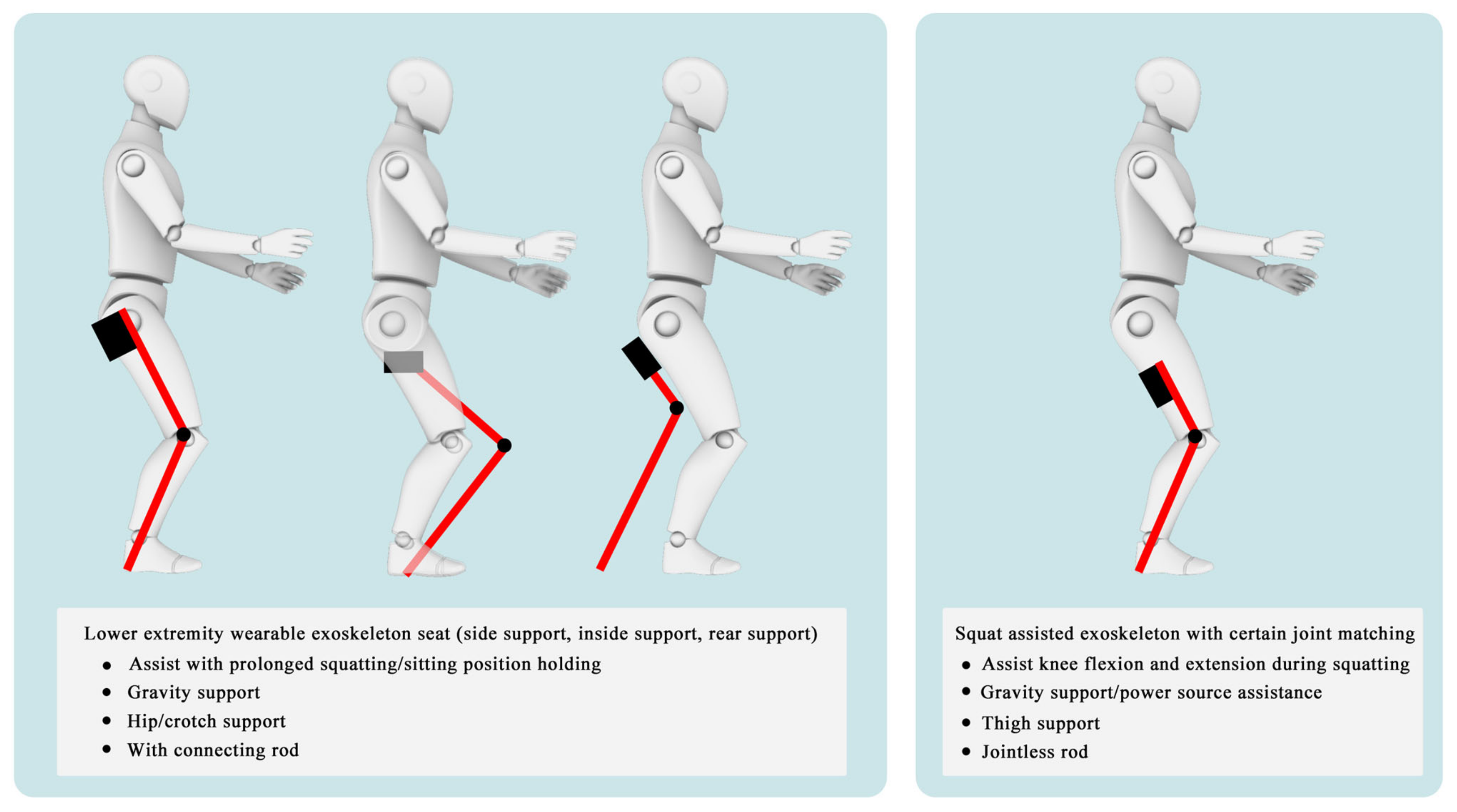

2. Lower-Limb Wearable Exoskeleton Seat

2.1. Side-Support Exoskeleton Seat

| Side-Support Exoskeleton Seat | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/ Source | Support and Power Parts | Driver | Locking Mechanism | Quality | Assisting Effect | Graphical Representation | Market Launch | Technology Commercialization Barriers |

| LegX from SuitX [16] | thigh/ knee | Compression spring | Manual; Three-stage locking | / | Muscle activity decreased by 56% | / | / | |

| Ritsumeikan University, Japan [19] | Buttoc/thigh/knee | Air pump | Auto; Stepless locking | 4 kg | Structural support reduces lower-limb loading |  | / |  SH SH(Noise and lack of fall protection devices) |

| Anhui University of Technology [20] | Hip/ knee | The hydraulic cylinder | / | / | Simulation results indicate hip joint range of up to 135° extension and 30° flexion |  | / |  EC EC SH SH(The hydraulic system carries a risk of high-pressure leakage)  ED ED(It may lead to motion lag or a sense of impact) |

| KARE Kwangwoon University [9] | Hip/ knee | Gas Strut | Singularity point of the linkage | 6 kg | General muscle activity reduction observed |  | / |  EC EC(Complex structure) |

| UMExoLEA, Universities in Malaysia [21] | Hip/ knee | Brushless DC motor | Auto; Stepless locking | / | Muscle activity in medial gastrocnemius and lateral gastrocnemius decreased by 40.8% and 45.3%, respectively |  | / |  ED ED(The prototype is relatively heavy) |

| J-Exo, Harbin Institute of Technology, China [22] | Hip | Electric machine | Auto; Stepless locking | 7.7 kg | Average EMG activation of VL, VM, BF, TA, and GAS muscles decreased by 62.02%, 53.36%, 70.04%, 67.50%, and 35.33%, respectively |  | / |  SH SH(Insufficient force balance)  EC EC(Relies on customized flexible insoles and IMUs) |

EC—Excessive Cos,

EC—Excessive Cos,  SH—Safety Hazards—SH,

SH—Safety Hazards—SH,  ED—Ergonomic Deficiencies.

ED—Ergonomic Deficiencies.2.2. Rear-Support Exoskeleton Seat

| Rear-Support Exoskeleton Seat | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/Source | Support and Power Parts | Driver | Locking Mechanism | Quality | Assisting Effect | Graphical Representation | Market Launch | Technology Commercialization Barriers |

| Chairless Chair, Noonee [28] | buttock | / | Manual; Fixed lock | 2 kg | / |  | √ | / |

| H-CEX [30] | buttock | / | Fixed multistage locking | 1.6 kg | Lower-limb muscle activity reduced by 30.59–84.08% |  | √ | / |

| Lex [31] | buttock | / | Fixed multistage locking | 2.2 kg | Effectively relieves gravitational load on the hip joint |  | √ | / |

| ExoChair Useful Robotics Russia [32] | buttock | Pneumatic power | / | 5 kg | / |  | √ | / |

| Ofrees Co., Ltd., Gyeonggi-do, Republic of Korea [33] | Buttock/knee | / | Rotary extreme position | 1.9 kg | / |  | √ | / |

| Flexible wearable Indian Institute of technology, Delhi [34] | / | / | Telescopic bar and lock pin | 3 kg | / |  | / |  SH SH(Absence of dynamic stability validation) |

| HUST-EC, Huazhong University of Science and Technology, China [35] | Buttock/knee | Motor + pneumatic spring | Fixed multistage locking | / | Significantly reduces muscle activation and plantar pressure by 54–67% |  | / |  TH TH  ED ED(Spring travel-limited posture adjustment) |

| SW-SiStA, University of Alabama [36] | Thigh/ knee | Pneumatic cylinder | Fixed multistage locking | / | Substantial reduction in knee joint loading; EMG activity of VL, VM, and RF muscles significantly decreased |  | / | / |

| Chairless chair-based on local component University Tarumanagara [37] | Buttock | / | Slider extreme position | 3.7 kg | / |  | / |  SH SH(Wearable-device donning predisposes to postural instability) |

| Beijing University of Aeronautics and Astronautics, China [38] | Buttock/knee | Pneumatic spring | Fixed multistage locking | No more than 5 kg | EMG signals across various muscles decreased by 41–87%, and plantar pressure reduced by 70–80% |  | / | / |

| Shenzhen Institute of Advanced Technology, China [39] | Buttock/hip/ knee | Electric machine | Auto; Stepless locking | / | Simulation analysis shows reduced muscle force demand at the hip and knee joints |  | / |  TC TC ED ED |

| ChairX, Moratuwa University, Sri Lanka [40] | thigh | / | Fixed multistage locking | 13.4 kg | Notable reduction in RF and VL muscle activity |  | / |  ED ED(Excessive mass) |

| E-LEG, Xi’an Jiaotong University, China [41] | buttock | / | Fixed stepless lock | / | Muscle activation reduced during squatting; gait pattern remains largely unaffected during walking |  | / |  ED EDPost-donning kinematic constraint of knee joint articulation |

| Nanjing University of Aeronautics and Astronautics, China [42] | buttock | / | Fixed multistage locking | 2 kg | No interference observed between exoskeleton and human limb movement; structural strength meets support requirements |  | / |  EC EC FR FR(Passive stabilization only, limiting adaptability to complex movements.) |

| Hunan Normal University, China [43] | buttock | / | Fixed stepless lock | / | Normal coupling maintained between human body and exoskeleton without mechanical interference |  | / |  EC EC FR FR |

EC—Excessive Cos,

EC—Excessive Cos,  TC—Technological Complexity,

TC—Technological Complexity,  SH—Safety Hazards—SH,

SH—Safety Hazards—SH,  ED—Ergonomic Deficiencies,

ED—Ergonomic Deficiencies,  FR—Functional Restriction.

FR—Functional Restriction.2.3. Medial-Support Exoskeleton Seats

3. Squat-Assist Exoskeletons with Certain Joint Matching

4. Key Technology Analysis

4.1. Kinematic and Dynamic Analysis

4.2. Human Motion Perception

4.2.1. Bioelectrical Signal-Based Interactive Control

4.2.2. Motion Signal-Based Interactive Control

4.3. Structural and Mechanism Innovation

4.4. Drive Mechanism Design

4.5. Exoskeleton Effectiveness Validation Methods

4.5.1. Numerical Simulation

4.5.2. Objective Experiments

4.5.3. Subjective Evaluation

5. Outlook

- (1)

- Multimodal Signal Sensing

- (2)

- Intelligent Control

- (3)

- Human–Machine Collaboration

- (4)

- Experimental Validation

- (5)

- Compliance with International Standards

Author Contributions

Funding

Conflicts of Interest

References

- Kuorinka, L.; Jonsson, B.; Kilbom, A.; Vinterberg, H.; Biering-Sørensen, F.; Andersson, G.; Jørgensen, K. Standardised Nordic questionnaires for theanalysis of musculoskeletal symptoms1. Appl. Ergon. 1987, 18, 233–237. [Google Scholar] [CrossRef]

- James, S.L.; Abate, D.; Abate, K.H.; Abay, S.M.; Abbafati, C.; Abbasi, N.; Abbastabar, H.; Abd-Allah, F.; Abdela, J.; Abdelalim, A.; et al. Global, regional, and national incidence. prevalence, and years lived with disability for 354 diseases and injuries for 195 countriesand territories, 1990–2017: A systematic analysis for the Global Burden of Disease Study 2017. Lancet 2018, 392, 1789–1858. [Google Scholar] [CrossRef]

- Zorzenon, R.; Lizarelli, F.L.; Daniel, B.D. What is the potential impact of industry 4.0 on health and safety at work? Saf. Sci. 2022, 153, 105802. [Google Scholar] [CrossRef]

- Lind, C.M.; Abtahi, F.; Forsman, M. Wearable motion capture devices for the prevention of work-related musculoskeletal disorders in ergonomics—An overview of current applications, challenges, and future opportunities. Sensors 2023, 23, 4259. [Google Scholar] [CrossRef] [PubMed]

- Patel, V.; Chesmore, A.; Legner, C.M.; Pandey, S. Trends in workplace wearable technologies and connected-worker solutions for next-generation occupational safety, health, and productivity. Adv. Intell. Syst. 2022, 4, 2100099. [Google Scholar] [CrossRef]

- Kawamoto, H.; Sankai, Y. Power assist system HAL-3 for gait disorder person. In Proceedings of the International Conference on Computers for Handicapped Persons, Vienna, Austria, 14–16 September 1994; Springer: Berlin/Heidelberg, Germany, 2002; pp. 196–203. [Google Scholar] [CrossRef]

- Santoso, G.; Sugiharto, S.; Mughni, A.; Ammarullah, M.I.; Bayuseno, A.P.; Jamari, J. Chairless Chairs for Orthopedic Surgery Purpose–A Literature Review. Open Access Maced. J. Med. Sci. 2022, 10, 146–152. [Google Scholar] [CrossRef]

- Abdul Rahman, A.; Amin, Y.; Adon, M.Y. Association between awkward posture and musculoskeletal disorders (MSD) among assembly line workers in an automotive industry. Malays. J. Med. Health Sci. 2014, 10, 23–28. [Google Scholar]

- Wijegunawardana, I.; Ranaweera, R.K.; Gopura, R.A. Lower extremity posture assistive wearable devices: A review. IEEE Trans. Hum.-Mach. Syst. 2023, 53, 98–112. [Google Scholar] [CrossRef]

- Kuber, P.M.; Alemi, M.M.; Rashedi, E. A systematic review on lower-limb industrial exoskeletons: Evaluation methods, evidence, and future directions. Ann. Biomed. Eng. 2023, 51, 1665–1682. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, J.; Ma, G.; Gao, J.; Chen, B.; Zuo, S. Lockable Lower-Limb Exoskeleton Based on a Novel Variable-Stiffness Joint: Reducing Physical Fatigue at Squatting. J. Mech. Robot. 2023, 15, 051008. [Google Scholar] [CrossRef]

- Li, B.; Yuan, B.; Tang, S.; Mao, Y.; Zhang, D.; Huang, C.; Tan, B. Biomechanical design analysis and experiments evaluation of a passive knee-assisting exoskeleton for weight-climbing. Ind. Robot. Int. J. 2018, 45, 436–445. [Google Scholar] [CrossRef]

- Bonner, D.R. Wearable Chair. U.S. Patent 4,138,156, 6 February 1979. [Google Scholar]

- Tang, X.; Wang, X.; Xue, Y.; Wei, P. An Unpowered Knee Exoskeleton for Walking Assistance and Energy Capture. Micromachines 2023, 14, 1812. [Google Scholar] [CrossRef]

- Kim, J.H.; Shim, M.; Ahn, D.H.; Son, B.J.; Kim, S.Y.; Kim, D.Y.; Baek, Y.S.; Cho, B.K. Design of a knee exoskeleton using foot pressure and knee torque sensors. Int. J. Adv. Robot. Syst. 2015, 12, 112. [Google Scholar] [CrossRef]

- legX/suitX. 2019. Available online: https://www.suitx.com/legx (accessed on 7 May 2020).

- Pillai, M.V.; Van Engelhoven, L.; Kazerooni, H. Evaluation of a lower leg support exoskeleton on floor and below hip height panel work. Hum. Factors 2020, 62, 489–500. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, X.; Zhang, Y.; Chen, C.; Liu, S.; Liu, Y.; Peng, A.; Ma, Y. A semi-active exoskeleton based on EMGs reduces muscle fatigue when squatting. Front. Neurorobotics 2021, 15, 625479. [Google Scholar] [CrossRef]

- Mitsuda, T.; Wakabayashi, M.; Kawamura, S. Development of wearable chair using pneumatic passive elements. J. Robot. Mechatron. 2004, 16, 256–263. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, B.; Xu, D. Design and simulation of a lower-limb power-assist exoskeleton for hip joint based on deep squat. In Proceedings of the IEEE International Conference on Information and Automation (ICIA), Ningbo, China, 1–3 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 865–869. [Google Scholar] [CrossRef]

- Sado, F.; Yap, H.J.; Ghazilla, R.A.R.; Ahmad, N. Design and control of a wearable lower-body exoskeleton for squatting and walking assistance in manual handling works. Mechatronics 2019, 63, 102272. [Google Scholar] [CrossRef]

- Ju, H.; Li, H.; Guo, S.; Fu, Y.; Zhang, Q.; Zheng, T.; Zhao, J.; Zhu, Y. J-Exo: An exoskeleton with telescoping linear actuators to help older people climb stairs and squat. Sens. Actuators A Phys. 2024, 366, 115034. [Google Scholar] [CrossRef]

- Daines, K.; Lemaire, E.D.; Smith, A.; Herbert-Copley, A. Sit-to-stand and stand-to-sit crutch use for lower extremity powered exoskeletons. In Proceedings of the 2017 IEEE International Symposium on Robotics and Intelligent Sensors (IRIS), Ottawa, ON, Canada, 5–7 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 358–363. [Google Scholar] [CrossRef]

- Olson, J.S. Design and Development of Exoskeletons for Squatting, Gait Assistance, and Fall Prevention Applications. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2021. [Google Scholar]

- Bessler-Etten, J.; Schaake, L.; Prange-Lasonder, G.B.; Buurke, J.H. Assessing effects of exoskeleton misalignment on knee joint load during swing using an instrumented leg simulator. J. Neuroeng. Rehabil. 2022, 19, 13. [Google Scholar] [CrossRef]

- Zanotto, D.; Akiyama, Y.; Stegall, P.; Agrawal, S.K. Knee joint misalignment in exoskeletons for the lower extremities: Effects on user’s gait. IEEE Trans. Robot. 2015, 31, 978–987. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, P.; Peng, J.; Qiao, X.; Zhu, F.; Zhong, J. Design and optimization of lower limb rehabilitation exoskeleton with a multiaxial knee joint. Biomimetics 2023, 8, 156. [Google Scholar] [CrossRef] [PubMed]

- Chairless Chair 2.0. Available online: https://www.noonee.com/en/ (accessed on 17 March 2025).

- Bae, K.H.; Jung, K.M.; Kim, K.J.; Yoon, J.Y.; Hyun, D.J. Wearable Chair Having Four-Link Structure. U.S. Patent 10,993,861, 4 May 2021. [Google Scholar]

- Kong, Y.K.; Park, C.W.; Cho, M.U.; Kim, S.-Y.; Kim, M.-J.; Hyun, D.J.; Bae, K.; Choi, J.K.; Ko, S.M.; Choi, K.-H. Guidelines for working heights of the lower-limb exoskeleton (CEX) based on ergonomic evaluations. Int. J. Environ. Res. Public Health 2021, 18, 5199. [Google Scholar] [CrossRef]

- Available online: https://newatlas.com/lex-folding-wearable-chair/56211/ (accessed on 10 April 2025).

- ExoChair. Available online: https://orlovbel.wixsite.com/exochair/main (accessed on 10 April 2025).

- “OFREES Chair”. Available online: https://www.amazon.com/ofrees-wearable-portable-chairless-155cm-163cm/dp/b07s9wk8lj (accessed on 17 March 2025).

- Bijalwan, A.; Misra, A. Design and structural analysis of flexible wearable chair using finite element method. Open J. Appl. Sci. 2016, 6, 465–477. [Google Scholar] [CrossRef]

- Han, B.; Du, Z.; Huang, T.; Zhang, T.; Li, Z.; Bai, O.; Chen, X. Mechanical framework design with experimental verification of a wearable exoskeleton chair. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 4040–4045. [Google Scholar] [CrossRef]

- Zheng, H.; Shen, T.; Afsar, M.R.; Kang, I.; Young, A.J.; Shen, X. A semi-wearable robotic device for sit-to-stand assistance. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 204–209. [Google Scholar] [CrossRef]

- Irawan, A.P.; Utama, D.W.; Affandi, E.; Suteja, H. Product design of chairless chair based on local components to provide support for active workers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 508, 012054. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Y.; Zhang, W. Design of a passive exoskeleton chair with an auxiliary support mechanism for assembly tasks. In Proceedings of the 2021 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 6–10 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 199–203. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, C.; Wu, X.; Lu, F.; Wang, P.; Cai, S. On the mechanical design and control of a self-adaptive exoskeleton chair. In Proceedings of the 2015 IEEE International Conference on Information and Automation, Lijiang, China, 8–10 August 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 937–942. [Google Scholar] [CrossRef]

- Wijegunawardana, I.D.; Kumara, M.B.K.; De Silva, H.H.M.J.; Viduranga, P.K.P.; Ranaweera, R.K.P.S.; Gopura, R.A.R.C.; Madusanka, D.G.K. ChairX: A robotic exoskeleton chair for industrial workers. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, OR, Canada, 24–28 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 587–592. [Google Scholar] [CrossRef]

- Tu, Y.; Zhu, A.; Song, J.; Zhang, X.; Cao, G. Design and experimental evaluation of a lower-limb exoskeleton for assisting workers with motorized tuning of squat heights. IEEE Trans. Neural Syst. Rehabil. Engineering 2022, 30, 184–193. [Google Scholar] [CrossRef] [PubMed]

- Chenchen, L.; Zilin, X.; Fengjie, C.; Yingchao, Z.; Yijun, Z.; Ning, D.; Xi, W. Optimization design and manufacture of powerless human-assisted exoskeleton chair. Mach. Manuf. Autom. 2022, 51, 167–171. [Google Scholar] [CrossRef]

- Huimei, K.; Jing, G.; Qian, W.; Yuqi, F.; Zehao, X.; Yishe, X. Unpowered wearable exoskeleton seat structure design and optimization. Equip. Manuf. Technol. 2023, 9, 26. [Google Scholar]

- Junius, K.; Degelaen, M.; Lefeber, N.; Swinnen, E.; Vanderborght, B.; Lefeber, D. Bilateral, Misalignment-Compensating, Full-DOF Hip Exoskeleton: Design and Kinematic Validation. Appl. Bionics Biomech. 2017, 2017, 5813154. [Google Scholar] [CrossRef]

- Ikeuchi, Y.; Ashihara, J.; Hiki, Y.; Kudoh, H.; Noda, T. Walking assist device with bodyweight support system. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MS, USA, 10–15 October 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 4073–4079. [Google Scholar] [CrossRef]

- Al-Shuka, H.F.N.; Rahman, M.H.; Leonhardt, S.; Ciobanu, I.; Berteanu, M. Biomechanics, actuation, and multi-level control strategies of power-augmentation lower extremity exoskeletons: An overview. Int. J. Dyn. Control. 2019, 7, 1462–1488. [Google Scholar] [CrossRef]

- Lee, K.M.; Wang, D. Design analysis of a passive weight-support lower-extremity-exoskeleton with compliant knee-joint. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 5572–5577. [Google Scholar] [CrossRef]

- Wulong, H.; Xin’an, W.; Zheng, X. A Weight-Supporting Wearable Robot for Walking Assist. In Proceedings of the 7th International Conference on Intelligent Human-Machine Systems and Cybernetics, Hangzhou, China, 26–27 August 2015; IEEE: Piscataway, NJ, USA, 2016; pp. 416–419. [Google Scholar] [CrossRef]

- Lovrenovic, Z.; Doumit, M. Development and testing of a passive walking assist exoskeleton. Biocybern. Biomed. Eng. 2019, 39, 992–1004. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Khan, A.A.; Muzammil, M. Lower limb rehabilitation robotics: The current understanding and technology. Work 2021, 69, 775–793. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, Z.; Tao, C.; Ji, R. Structure design of lower limb exoskeletons for gait training. Chin. J. Mech. Eng. 2015, 28, 878–887. [Google Scholar] [CrossRef]

- Archelis. Available online: https://www.archelis.com/ (accessed on 10 April 2025).

- Jiashuo, C. Design and Analysis of Lower Extremity Exoskeleton for Gravity Support During Squatting. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2019. [Google Scholar] [CrossRef]

- Chen, S.; Stevenson, D.T.; Yu, S.; Mioskowska, M.; Yi, J.; Su, H.; Trkov, M. Wearable es for kneeling tasks in construction. IEEE/ASME Trans. Mechatron. 2021, 26, 1989–1996. [Google Scholar] [CrossRef]

- Yan, Z.; Han, B.; Du, Z.; Huang, T.; Bai, O.; Peng, A. Development and testing of a wearable passive lower-limb support exoskeleton to support industrial workers. Biocybern. Biomed. Eng. 2021, 41, 221–238. [Google Scholar] [CrossRef]

- Xuan, Z.; Shuo, F.; Zhenxian, C.; Jing, Z.; Zhongmin, J. Design idea and biomechanical analysis of a liquid spring self-force source knee assist orthosis. J. Biomed. Eng. 2022, 39, 1199–1208+1217. [Google Scholar]

- Hasegawa, Y.; Hoshino, T.; Tsukahara, A. Wearable assistive device for physical load reduction of caregiver-adaptive to caregiver’s motion during transferring support. In Proceedings of the 2016 World Automation Congress (WAC), Rio Grande, Puerto Rico, 31 July–4 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Yu, S.; Huang, T.H.; Di Lallo, A.; Zhang, S.; Wang, T.; Fu, Q.; Su, H. Bio-inspired design of a self-aligning, lightweight, and highly-compliant cable-driven knee exoskeleton. Front. Hum. Neurosci. 2022, 16, 1018160. [Google Scholar] [CrossRef]

- Lu, T.W.; Chang, C.F. Biomechanics of human movement and its clinical applications. Kaohsiung J. Med. Sci. 2012, 28, S13–S25. [Google Scholar] [CrossRef]

- Kadaba, M.P.; Ramakrishnan, H.K.; Wootten, M.E. Measurement of lower extremity kinematics during level walking. J. Orthop. Res. 1990, 8, 383–392. [Google Scholar] [CrossRef]

- Yumin, H.; Ting, L.; Siyu, G.; Jing, Z.; Yang, L.; Weiqi, L. A review of kinematics and dynamics of lower extremity exoskeleton. J. Ordnance Equip. Eng. 2023, 44, 285–293. [Google Scholar] [CrossRef]

- Tarokh, M.; Lee, M. Kinematics modeling of multi-leggedrobots walking on rough terrain. In Proceedings of the Second International Conference on Future Generation Communication and Networking Symposia, Hainan, China, 13–15 December 2008; Springer: Berlin/Heidelberg, Germany, 2008; pp. 12–16. [Google Scholar] [CrossRef]

- Mohdzawawi, M.Z.F.; Elamvazuthi, I.; Aziz, A.A.; Mazlan, S.F.; Ku Abd Rahim, K.N. Dynamie analysis of three degree of freedom (3-D0F) exoskeleton for lower extremities. In Proceedings of the 2016 2nd EEE International Symposium on Robotics and Manufacturing Automation (ROMA), Ipoh, Malaysia, 25–27 September 2016; The Institute of Electrical and Electronics Engineers, Inc. (EEE): Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, L.; Li, C. Dynamic analysis of horizontal lower limbs rehabilitativerobot. In Proceedings of the IEEE International Conference on Intelligent Computing and Intelligent Systems IEEE, Shanghai, China, 20–22 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 656–660. [Google Scholar] [CrossRef]

- Yajing, W. Biomechanical Study of Human Knee Joint Based on Dynamic Capture and Foot Pressure Test. Ph.D. Thesis, Xi ’an University of Technology, Xi’an, China, 2020. [Google Scholar] [CrossRef]

- Xiao, L.; Jianjun, Z.; Kaicheng, Q.; Gaowei, Y. Lower extremity exoskeleton variable axis knee joint configuration design and rod length optimization. Mech. Sci. Technol. 2020, 39, 1230–1236. [Google Scholar] [CrossRef]

- Wei, S.; Anmin, X.; Yubao, Z. Modeling and Simulation of Robot Dynamics Based on Kane ’s Method. Microcomput. Inf. 2008, 29, 222–223+196. [Google Scholar]

- Junxia, Z.; Youzhi, Y.I.; Quan, W. Structuredesign and simulation of dynamic walking-aid. J. Mach. Des. 2015, 32, 71–75. [Google Scholar] [CrossRef]

- Gang, T. Biomechanics Simulation Analysis for Typical Movements of Human. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2011. [Google Scholar]

- Qi, Q.; Cheng, S.; Zhang, D.; Zhou, M.; Yu, H. Mechanism design, kinematics and dynamics analysis of wearable seats. Tech Wind. 2017, 11, 6–7. [Google Scholar] [CrossRef]

- Zhanteng, G. Human Squat Motion Analysis and Exoskeleton Power Control Strategy Research. Ph.D. Thesis, Xinjiang University, Ürümqi, China, 2020. [Google Scholar] [CrossRef]

- Jianhui, W.; Xiulin, X. Human lower limb dynamics modeling and simulation research status. Rehabil. Theory Pract. China 2012, 18, 731–733. [Google Scholar]

- Murphy, M.C. Geometry and the Kinematics of the Normal Human Knee. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1990. [Google Scholar]

- Zlotnicki, J.P.; Naendrup, J.H.; Ferrer, G.A.; Debski, R.E. Basic biomechanic principles of knee instability. Curr. Rev. Musculoskelet. Med. 2016, 9, 114–122. [Google Scholar] [CrossRef]

- Celebi, B.; Yalcin, M.; Patoglu, V. AssistOn-Knee: A self-aligning knee exoskeleton. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 996–1002. [Google Scholar] [CrossRef]

- Bing, C.; Minzhou, L.; Shaoming, S.; Meiling, W.; Kun, W. Design of knee joint of energy-saving and vibration-reducing humanoid robot based on bionic principle. Robot 2014, 36, 218–223. [Google Scholar]

- Zhu, A.; Shen, Z.; Shen, H.; Wu, H.; Zhang, X. Design of a passive weight-support exoskeleton of human-machine multi-link. In Proceedings of the 2018 15th International Conference on Ubiquitous Robots (UR), Honolulu, HA, USA, 26–30 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 296–301. [Google Scholar] [CrossRef]

- Jiyuan, S.; Aibin, Z.; Yao, T.; Xinyu, W.; Yulin, Z.; Xu, Z. Prediction of the expected angle of lower limb exoskeleton joints by human-computer interaction force. J. Xi ’an Jiaotong Univ. 2021, 55, 55–63+69. [Google Scholar]

- Luo, S.; Meng, Q.; Li, S.; Yu, H. Research of intent recognition in rehabilitation robots: A systematic review. Disabil. Rehabil.: Assist. Technol. 2024, 19, 1307–1318. [Google Scholar] [CrossRef]

- Wenyuan, L.; Sheng, B. Perceptual interaction and control strategy of active rehabilitation training robot. Technol. News 2019, 37, 26–36. [Google Scholar]

- Rechy-Ramirez, E.J.; Hu, H. Bio-signal based control in assistive robots: A survey. Digit. Commun. Netw. 2015, 1, 85–101. [Google Scholar] [CrossRef]

- Reaz, M.B.I.; Hussain, M.S.; Mohd-Yasin, F. Techniques of EMG signal analysis: Detection, processing, classification and applications. Biol. Proced. Online 2006, 8, 11–35. [Google Scholar] [CrossRef]

- Inoue, T.; Matsuo, R. Prediction of Sit-to-Stand Time Using Trunk Angle and Lower Limb EMG for Assistance System. In Proceedings of the 2020 IEEE 2nd International Conference on Artificial Intelligence in Engineering and Technology (IICAIET), Kota Kinabalu, Malaysia, 26–27 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Wenjie, Z.; Xinqin, J.; Xiaodong, W.; Teaching Guidance Subcommittee of Industrial Design Specialty in Colleges and Universities of the Ministry of Education; Industrial Design Branch of China Mechanical Engineering Society; Industrial Design Teaching Committee of China Mechanical Industry Education Association. Research on squatting operation based on surface electromyography. In Proceedings of the 2016 National Industrial Design Education Seminar and International Industrial Design Summit Forum; Mechanical Engineering College of Harbin University of Science and Technology: Tianjin, China; 24–25 September 2016, p. 4.

- Yonglin, H.; Qing, T.; Xiaodong, Z.; Qingzheng, C. Electromyographic prediction method for multi-joint continuous motion of human lower limbs. Mach. Hydraul. 2023, 51, 112–119. [Google Scholar]

- Lloyd, D.G.; Besier, T.F. An EMG-driven musculoskeletal model to estimate muscle forces and knee joint moments in vivo. J. Biomech. 2003, 36, 765–776. [Google Scholar] [CrossRef]

- Xiaodong, Z.; Jiangcheng, C.; Gui, Y. EMG sensing and human-computer interaction control method of lower limb rehabilitation robot. Vibration.Test Diagn. 2018, 38, 649–657. [Google Scholar] [CrossRef]

- Wenfeng, L.; Zhigang, Y.; Xinyun, H. Effect of EMG signal selection on continuous motion estimation of lower limb joints. Mech. Des. Manuf. 2019, 3, 54–57. [Google Scholar] [CrossRef]

- Mohebbi, A. Human-robot interaction in rehabilitation and assistance: A review. Curr. Robot. Rep. 2020, 1, 131–144. [Google Scholar] [CrossRef]

- Cao, J.; Xie, S.Q.; Das, R.; Zhu, G.L. Control strategies for effective robot assisted gait rehabilitation: The state of art and future prospects. Med. Eng. Phys. 2014, 36, 1555–1566. [Google Scholar] [CrossRef]

- Meng, W.; Liu, Q.; Zhou, Z.; Ai, Q.; Sheng, B.; Xie, S. Recent development of mechanisms and control strategies for robot-assisted lower limb rehabilitation. Mechatronics 2015, 31, 132–145. [Google Scholar] [CrossRef]

- Shouyin, L.; Luhao, Y. Research progress of human-computer interaction control technology for rehabilitation robots. J. Shandong Jianzhu Univ. 2021, 36, 91–102. [Google Scholar]

- Unluhisarcikli, O.; Pietrusinski, M.; Weinberg, B.; Bonato, P.; Mavroidis, C. Design and control of a robotic lower extremity exoskeleton for gait rehabilitation. In Proceedings of the Intelligent Robots and Systems (IROS) 2011, San Francisco, CA, USA, 25–30 September 2011; IEEE/RSJ: Piscataway, NJ, USA; pp. 4893–4898. [Google Scholar] [CrossRef]

- Wei, W.; Shijia, Z.; Yuxuan, X.; Jihua, G.; Xichuan, L. A hip active assisted exoskeleton that assists the semi-squat lifting. Appl. Sci. 2020, 10, 2424. [Google Scholar] [CrossRef]

- Ke, W.; Xin, T. A review of human-computer interaction control based on exoskeleton robots. Mech. Eng. 2022, 8, 50–53+56. [Google Scholar]

- Yuqing, X. Review on human-computer interaction design of walking-aid rehabilitation robot. Pack. Eng. 2020, 41, 1–7. [Google Scholar] [CrossRef]

- EKSOBIONICS. Ekso GT Robotic Exoskeleton Cleared by FDA for Use with Stroke and Spinal Cord Injury Patients. Available online: http://ir.eksobionics.com/press-releases/detail/570/ekso-gt-roboticexoskeletoncleared-by-fda-for-use-with (accessed on 27 January 2021).

- Wu, Z.; Yang, M.; Xia, Y.; Wang, L. Mechanical structural design and actuation technologies of powered knee exoskeletons: A review. Appl. Sci. 2023, 13, 1064. [Google Scholar] [CrossRef]

- Tang, X.; Wang, X.; Xue, Y.; Yin, R.; Yang, J. A study of knee exoskeleton configuration based on lower limb motion characteristics analysis. Machines 2023, 11, 709. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches: A comparative review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Winter, D.A. Biomechanics and Motor Control of Human Movement; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Malcolm, P.; Galle, S.; Derave, W.; De Clercq, D. Bi-articular knee-ankle-foot exoskeleton produces higher metabolic cost reduction than weight-matched mono-articular exoskeleton. Front. Neurosci. 2018, 12, 69. [Google Scholar] [CrossRef]

- Li, Y.; Guan, X.; Han, X.; Tang, Z.; Meng, K.; Shi, Z.; Penzlin, B.; Yang, Y.; Ren, J.; Yang, Z.; et al. Design and preliminary validation of a lower limb exoskeleton with compact and modular actuation. IEEE Access 2020, 8, 66338–66352. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Vérité, F.; Bregoli, C.; Amici, C. Sensors and actuation technologies in exoskeletons: A review. Sensors 2022, 22, 884. [Google Scholar] [CrossRef]

- Li, Y.; Gan, J. Multidisciplinary evaluation metrics for the usability of wearable chairs. In Proceedings of the 2022 International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA), Ankara, Turkey, 9–11 June 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Yang, K.; Jiang, Q.F.; Wang, X.L.; Chen, Y.W. Structural design and modal analysis of exoskeleton robot for rehabilitation of lower limb. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018; Volume 1087, p. 062004. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Xu, P.; Zheng, D.; Liu, W.; Wang, Y.; Qiao, H. SolidWorks/SimMechanics-based lower extremity exoskeleton modeling procedure for rehabilitation. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Beijing, China, 26–31 May 2012; Springer: Berlin/Heidelberg, Germany, 2013; pp. 2058–2061. [Google Scholar] [CrossRef]

- Lei, T. Research on Motion Reliability Analysis Method of Lower Extremity Exoskeleton Mechanism. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Songcheng, X.; Rongsong, Y.; Qinghua, Z. Random vibration analysis of RV reducer based on ANSYS Workbench. Mech. Transm. 2021, 45, 111–116. [Google Scholar] [CrossRef]

- Li, H.; Sui, D.; Ju, H.; An, Y.; Zhao, J.; Zhu, Y. Mechanical compliance and dynamic load isolation design of lower limbexoskeleton for locomotion assistance. IEEE/ASME Trans. Mechatron. 2022, 27, 5392–5402. [Google Scholar] [CrossRef]

- Buldt, A.K.; Allan, J.J.; Landorf, K.B.; Menz, H.B. The relationship between foot posture and plantar pressure during walking in adults: A systematic review. Gait Posture 2018, 62, 56–67. [Google Scholar] [CrossRef] [PubMed]

- Moudy, S.C.; Tillin, N.A.; Sibley, A.R.; Strike, S. Foot strike alters ground reaction force and knee load when stepping down during ongoing walking. Gait Posture 2020, 76, 327–333. [Google Scholar] [CrossRef]

- Abe, D.; Fukuoka, Y.; Muraki, S.; Yasukouchi, A.; Sakaguchi, Y.; Niihata, S. Effects of load and gradient on energy cost of running. J. Physiol. Anthropol. 2011, 30, 153–160. [Google Scholar] [CrossRef]

- Luger, T.; Seibt, R.; Cobb, T.J.; Rieger, M.A.; Steinhilber, B. Influence of a passive lower-limb exoskeleton during simulated industrial work tasks on physical load, upper body posture, postural control and discomfort. Appl. Ergon. 2019, 80, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Gams, A.; Petrič, T.; Debevec, T.; Babič, J. Effects of robotic knee exoskeleton on human energy expenditure. IEEE Trans. Biomed. Eng. 2013, 60, 1636–1644. [Google Scholar] [CrossRef]

- Wioland, L.; Atain Kouadio, J.J.; Bréard, H.; Clerc-Urmès, I.; Paty, B. The Adoption of Occupational Exoskeletons: From Acceptability to Situated Acceptance, Questionnaire Surveys. Int. J. Hum. Comput. Interact. 2025, 41, 1446–1458. [Google Scholar] [CrossRef]

- Mohammed El Husaini, M.; Maberry, A.; Martin, A.E. Validation of a modified visual analogue scale to measure user-perceived comfort of a lower-limb exoskeleton. Sci. Rep. 2023, 13, 20484. [Google Scholar] [CrossRef]

- Chae, U.R.; Kim, K.; Choi, J.; Hyun, D.J.; Yun, J.; Lee, G.H.; Hyun, Y.G.; Lee, J.; Chung, M. Systematic usability evaluation on two harnesses for a wearable chairless exoskeleton. Int. J. Ind. Ergon. 2021, 84, 103162. [Google Scholar] [CrossRef]

- Hoffmann, N.; Prokop, G.; Weidner, R. Methodologies for evaluating exoskeletons with industrial applications. Ergonomics 2022, 65, 276–295. [Google Scholar] [CrossRef]

- Cha, J.S.; Monfared, S.; Stefanidis, D.; Nussbaum, M.A.; Yu, D. Supporting surgical teams: Identifying needs and barriers for exoskeleton implementation in the operating room. Hum. Factors 2020, 62, 377–390. [Google Scholar] [CrossRef] [PubMed]

- Gensheng, L.; Guoning, Y.; Fei, X. Research progress of lower extremity exoskeleton robot control strategy. Chin. J. Rehabil. Med. 2018, 33, 1488–1494. [Google Scholar] [CrossRef]

- Kwok, T.H.; Wang, C.C. Shape optimization for human-centric products with standardized components. Comput.-Aided Des. 2014, 52, 40–50. [Google Scholar] [CrossRef]

- Chester, M.R.; Rys, M.J.; Konz, S.A. Leg swelling, comfort and fatigue when sitting, standing, and sit/standing. Int. J. Ind. Ergon. 2002, 29, 289–296. [Google Scholar] [CrossRef]

- ISO 13482:2014; Robots and Robotic Devices—Safety Requirements for Personal Care Robots. International Organization for Standardization: Geneva, Switzerland, 2014.

| Medial-Support Exoskeleton Seats | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/Source | Support and Power Parts | Driver | Locking Mechanism | Quality | Assisting Effect | Graphical Representation | Market Launch | Technology Commercialization Barriers |

| Body weight Support System, Honda [45] | Buttock/hip/ knee | Dc motor | Auto; Stepless locking | 6.5 kg | The device reduced energy consumption by 11% and average muscle activity by 18% |  | √ |  FR FR EC EC(The battery life is limited during extended operational periods) |

| LEE, Georgia Institute of Technology, USA [47] | Buttock/knee | spring | / | 2.357 kg | Effective in alleviating knee joint stress during walking |  | / |  FR FR(Designed exclusively for level terrain walking) |

| Peking University, China [48] | buttock | Brushless DC motor | / | / | Experimental results show pressure relief at the knees and ankles |  | / |  TC TC(The control system is highly complex) |

| WAE, University of Ottawa, Canada [49] | Buttock/hip/ knee | Mechanical spring | / | 5.68 kg | Provides 9.41–26.18% body weight equivalent upward support in standing, and peak support of 14.02% during walking |  | / |  ED ED(Asymmetric load distribution between left and right legs) |

EC—Excessive Cos,

EC—Excessive Cos,  TC—Technological Complexity,

TC—Technological Complexity,  ED—Ergonomic Deficiencies,

ED—Ergonomic Deficiencies,  FR—Functional Restriction.

FR—Functional Restriction.| Squat-Assist Exoskeletons with Certain Joint Matching | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/ Source | Support and Power Parts | Driver | Locking Mechanism | Quality | Assisting Effect | Graphical Representation | Market Launch | Technology Commercialization Barriers |

| Archelis, Nito [52] | leg | / | Single lock | 3.3 kg | Muscle activity significantly reduced |  | √ | / |

| Huazhong University of Science and Technology, China [53] | knee | / | Auto; Stepless locking | 1 kg | Plantar pressure decreased by 65.16%, Rectus femoris and vastus lateralis activity reduced by 54.05% and 32.8%, respectively |  | / |  EC EC TC TC(High-Fidelity Dynamic Control) |

| Rutgers University, USA [54] | Thigh/ knee | Electric machine | / | 1.7 kg (unilateral) | Knee extensor/flexor activity reduced by up to 39%, and Knee–ground pressure reduced by up to 15% in the one-leg kneeling posture |  | / |  EC EC(QDD Actuator and Sensor System) |

| Huazhong University of Science and Technology, China [55] | Loin/ thigh/ knee | Torsion spring | Manual; Stepless locking | 2 kg | Muscle activity reduced by 44.8–71.5%, plantar pressure by 58.5–64.2% |  | / |  ED ED |

| Chang’an University, China [56] | Thigh/ knee | Micro silicone oil liquid spring | / | 1.223 kg | Femorotibial joint force reduced by 24.5%, patellofemoral force by 23.8%, quadriceps-ligament force by 21.2% |  | / |  EC EC(silicone Oil-Based Hydraulic Spring System) |

| Nagoya University, Japan [57] | Thigh/ knee | Gas spring | Fixed multistage locking | 3.7 kg | Physical load on biceps femoris and gluteus maximus was significantly reduced |  | / | / |

| Harbin Institute of Technology, China [58] | knee | Electric machine | / | 1.7 kg | Maximum postural deviation reduced by 49.3% during walking and 71.9% during squatting |  | / | / |

EC—Excessive Cos,

EC—Excessive Cos,  TC—Technological Complexity,

TC—Technological Complexity,  ED—Ergonomic Deficiencies.

ED—Ergonomic Deficiencies.| Comparison of Lower-Limb Squat-Assistant Wearable Device Types | ||||

|---|---|---|---|---|

| Side-Support | Rear-Support | Medial-Support | Certain Joint Matching | |

| Main Advantages | Focuses on lateral leg stability; simple structure. | Rearward center of gravity provides stable support and good energy transfer path. | Good stability, conforms to the leg; high support strength; matches the squatting center of gravity trajectory. | Natural motion, high alignment, closer to biomechanical movement patterns. |

| User Experience | Moderate wearing comfort; lateral supports may restrict some movements. | Stable squatting assistance, but slightly heavy to wear. | Helps maintain lower-limb symmetry and fits closely to the leg, but more sensitive to different body shapes. | Provides greater range of motion and higher comfort and naturalness; sensitive to individual differences. |

| Application Scenarios | Static factory work; frequent sit–stand transitions. | Low-speed walking and moderate activity levels; suitable for long-duration support or rear stability needs. | Long-duration static squatting tasks such as maintenance and assembly. | High-dynamic tasks, such as assisted walking or rehabilitation training. |

| Limitations | Poor stability, high motion interference; difficult to maintain dynamic balance. | Protrudes at the back, limited in confined spaces; significant motion interference; lacks dynamic adaptability. | Not suitable for high-dynamic environments; high body size matching requirements. | Complex structure, high manufacturing difficulty; strong dependence on control systems. |

| Usability | High; quick to use and suitable for beginners. | Moderate; requires adaptation to weight. | Moderate; requires individualized adjustment. | Low to moderate; highly dependent on control, requires training and adaptation. |

| Cost | Low; simple materials and manufacturing. | Medium; slightly more complex structure. | Medium to high; requires custom-fit structure. | High; involves multi-joint structure and control systems. |

| Technical Challenges | Poor dynamic stability; likely to disrupt natural gait. | Weight control and center-of-gravity coordination. | Balancing between size customization and comfort. | High-precision control and sensor fusion; difficult to achieve coordination with the human body. |

| Commercialization | Several lightweight products already on the market; suitable for workers. | High market acceptance; most common in commercial lower-limb assistive devices. | Internal support has entered the commercial market, but much research remains at the laboratory stage. | Mostly in lab validation or pilot application stages; low commercialization level but promising prospects. |

| Design Objective | Specific Measures |

|---|---|

| Size Adjustability | Implement multi-level or stepless height adjustment [28] |

| Adopt modular design with adjustable rod length [34] | |

| Utilize a three-support rod structure with adjustable height and size [35] | |

| Integrate adaptive seat board [39] | |

| Apply three-bar linkage mechanism to accommodate various sitting postures [40] | |

| Use stepless pneumatic rod adjustment with memory function [47] | |

| Employ elastic straps and adjustable support frame [54] | |

| Support Stability | Form a triangular support structure upon locking to distribute body weight and reduce lower-limb load [28] |

| Integrate triangular support frame [29] | |

| Use multi-bar and four-bar auxiliary mechanisms to enhance structural stability [38] | |

| Form triangular support in the seated position to effectively distribute pressure [47] | |

| Pressure Distribution | Fix the seat using an abdominal strap to avoid direct contact with thighs and calves, reducing constraint [19] |

| Employ cross-hip or underarm support to transmit force through the hip strap and relieve thigh/calf restraint [22] | |

| Integrate a load transfer module to shift folded device weight from shoulders to body core [31] | |

| Apply semi-wearable thigh plates to distribute contact pressure [36] | |

| Use carbon fiber ankle joint to reduce distal pressure [55] | |

| Optimize knee joint topology with flexible design to reduce joint pressure [47] | |

| Reduction of Motion Interference | Design footwear allowing foot rotation and tilting (e.g., heel lift) [19] |

| Utilize a biased crank–slider mechanism to improve hip flexion range during squatting [20] | |

| Apply dual support rods aligned with center-of-gravity trajectory to reduce hip constraints [57] | |

| Use aluminum linkage hinges (0–100° motion) to prevent knee joint torque imbalance [41] | |

| Implement a six-bar mechanism for dynamic support at various workstation angles [42] | |

| Employ flexible drive cables to minimize movement restriction [56] | |

| Others | Equip ankle connection with anti-slip rubber or magnetic fasteners to prevent detachment during walking [29] |

| Add cushioning pad to the seat for enhanced seated comfort [48] |

| Comparative Analysis of Actuation Methods | ||||||

|---|---|---|---|---|---|---|

| Actuation Method | Performance | Volume/Weight | Safety and Stability | Application Scenarios | Limitations | Cost and Commercialization Level |

| Servo motors [21,22,35,39,45,48,54,58] | Precise control over output timing, amplitude, and motion profile Suitable for programmable movement assistance | Relatively heavy Requires battery power | Sensors and motors sensitive to temperature/humidityRequires regular maintenance | Complex movement assistance Applications demanding fine-grained control | High cost of advanced motors and sensors Increased system complexity | High technological maturity Widely commercialized in wearable robotics |

| hydraulic drives [20] | High force and torque outputExcellent steady-state performance | Large and bulky | Risk of leakage and pressure instability High maintenance demand | Heavy-duty and high-torque tasks Industrial settings requiring deep squatting or strong resistance | Not suited for daily wearable use High R&D and upkeep costs | Commercialized in industrial-grade exoskeletons |

| pneumatic cylinder drives [19,31,36] | High instantaneous torque output Durable components with low maintenance | Lightweight system Requires external air supply | Strong interference resistance Stable across uneven terrain | Repetitive sit–stand transitions Static squatting Semi-mobile industrial workstations | Requires air source (tank/compressor)Slow response time Poor portability | Commercialized Low component cost and short development cycle |

| Pneumatic spring [35,38,57] | Instant reactive counterforce Compact and safe | Compact and lightweight | Environmentally robust High safety in confined spaces | Limited mobility range environmentsBackup support in hybrid systems | Limited output force Slight response delay | Low R&D and maintenance costsCommercial applications already in place |

| Mechanical Spring [47,49] | Fixed output forceShort response time | Compact and stable | High mechanical stability No electronics involved | Cost-sensitive or lightweight applications Passive or semi-active assistive devices | Cannot adaptively regulate assistance Potential long-term wearability concerns | Low development cost Early-stage commercialization achieved |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Chen, Z.; Hong, R.; Qu, Y.; Gao, X.; Wang, X. Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices. Biomimetics 2025, 10, 258. https://doi.org/10.3390/biomimetics10050258

Li L, Chen Z, Hong R, Qu Y, Gao X, Wang X. Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices. Biomimetics. 2025; 10(5):258. https://doi.org/10.3390/biomimetics10050258

Chicago/Turabian StyleLi, Lin, Zehan Chen, Rong Hong, Yanping Qu, Xinqin Gao, and Xupeng Wang. 2025. "Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices" Biomimetics 10, no. 5: 258. https://doi.org/10.3390/biomimetics10050258

APA StyleLi, L., Chen, Z., Hong, R., Qu, Y., Gao, X., & Wang, X. (2025). Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices. Biomimetics, 10(5), 258. https://doi.org/10.3390/biomimetics10050258