Contrasting Flexible and Rigid Bioinspired Flapping Hydrofoils for Suspended Particles Discharge in Raceway Aquaculture

Abstract

1. Introduction

2. Physical Model

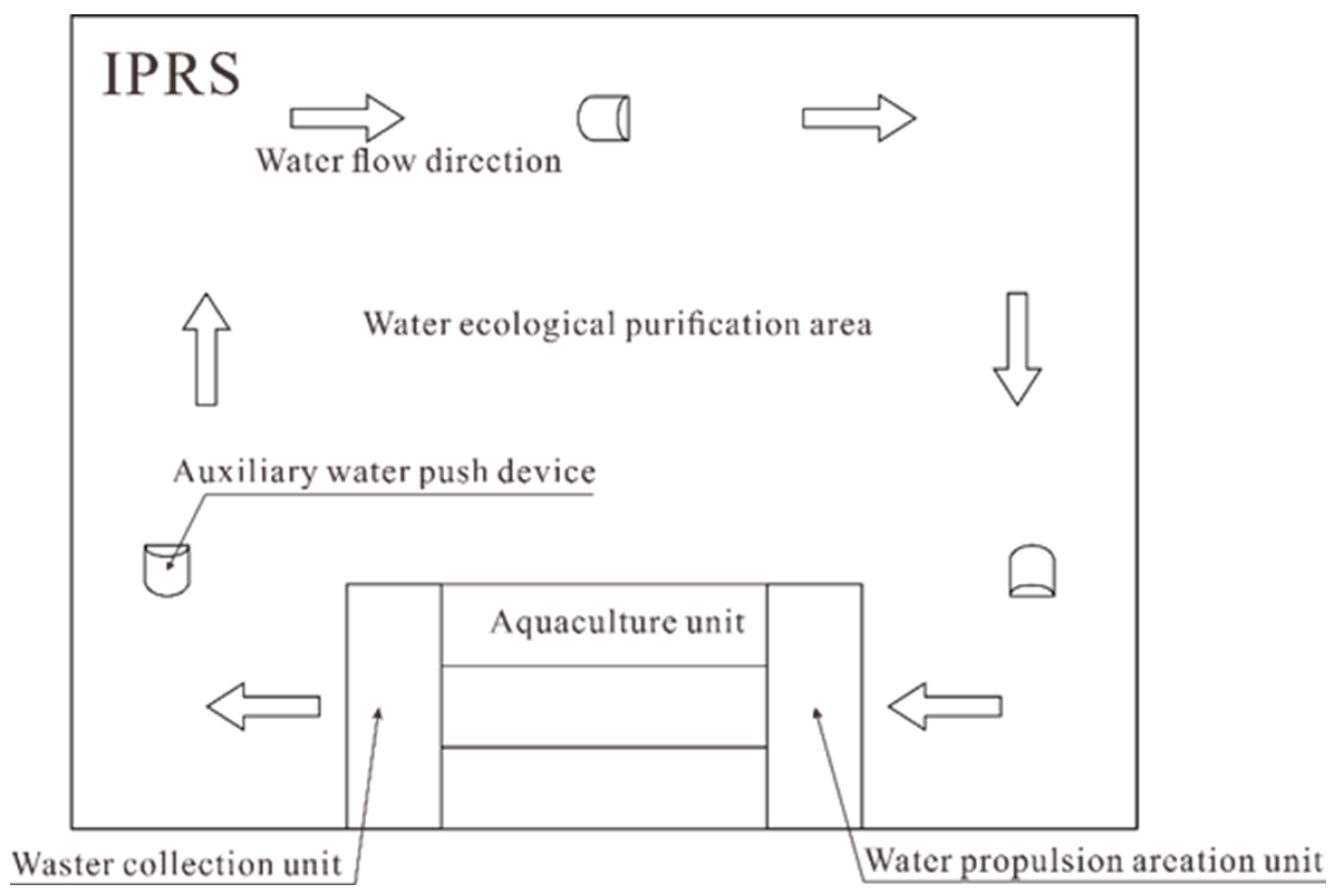

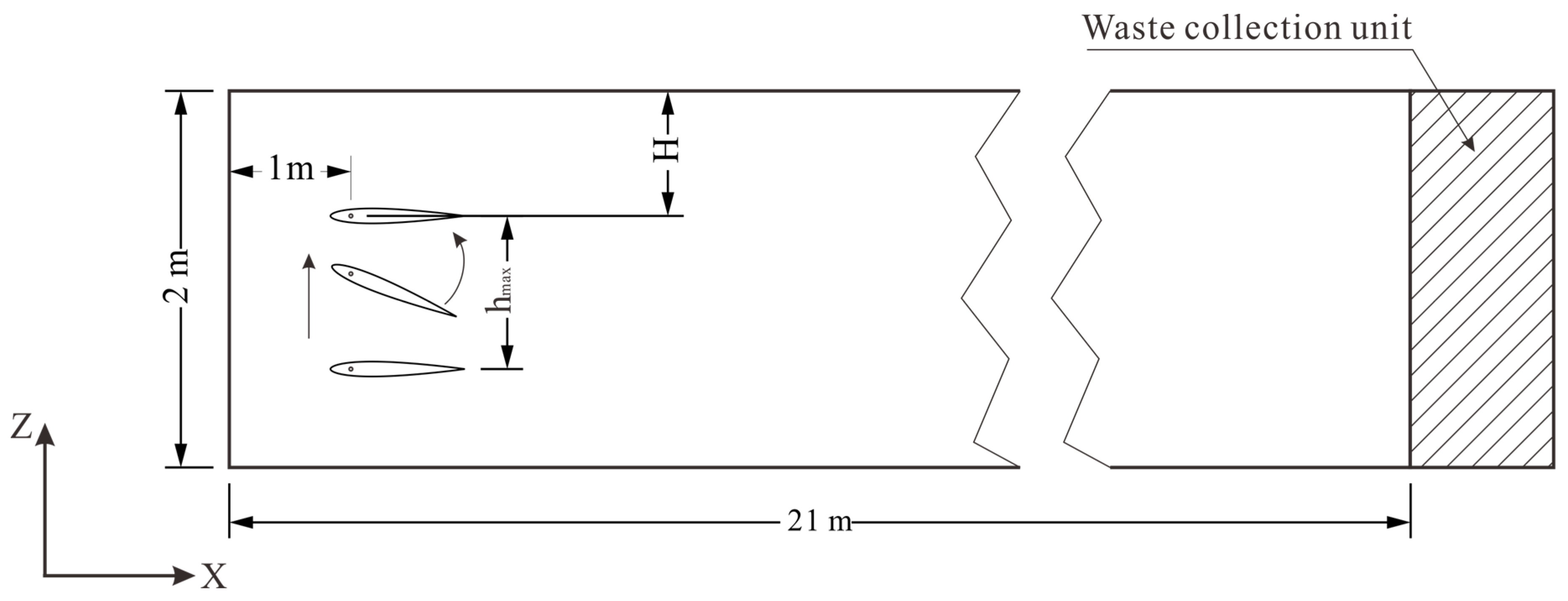

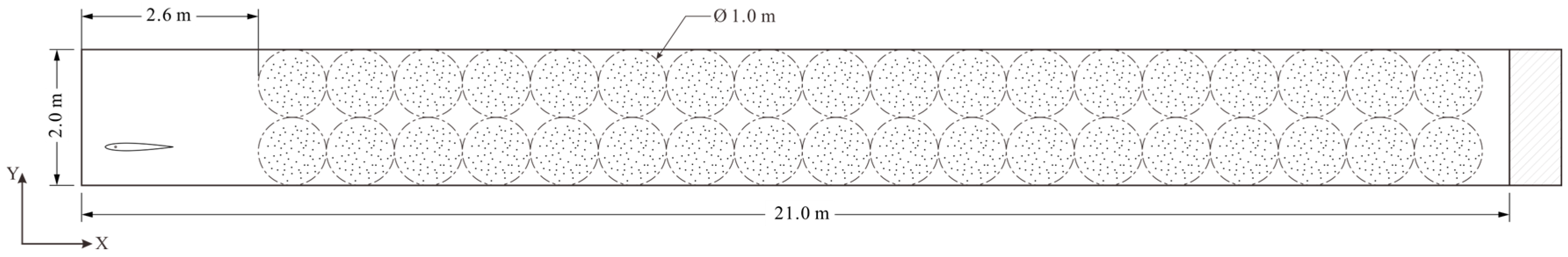

2.1. Raceway Aquaculture Model

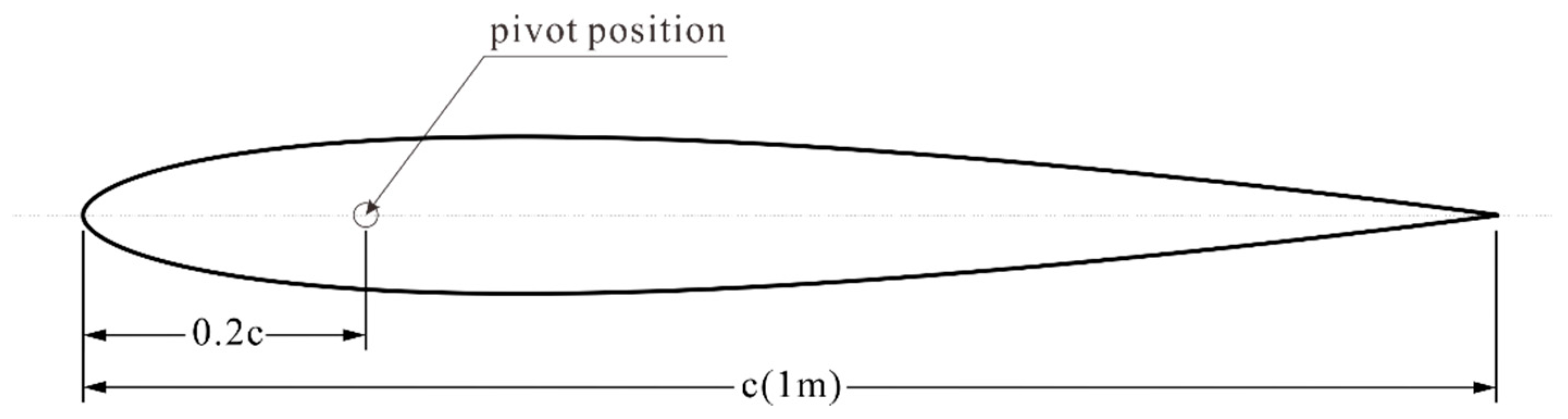

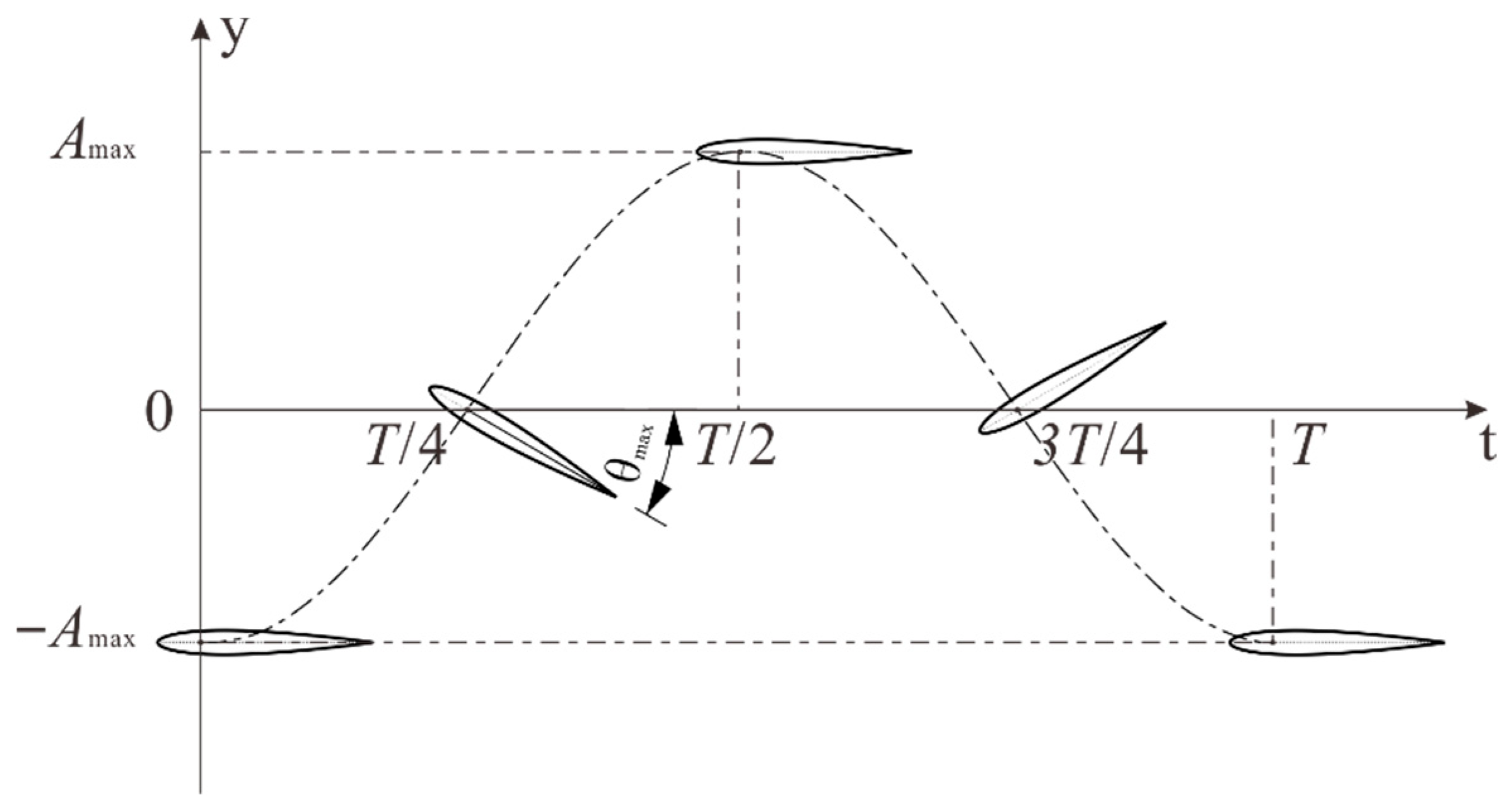

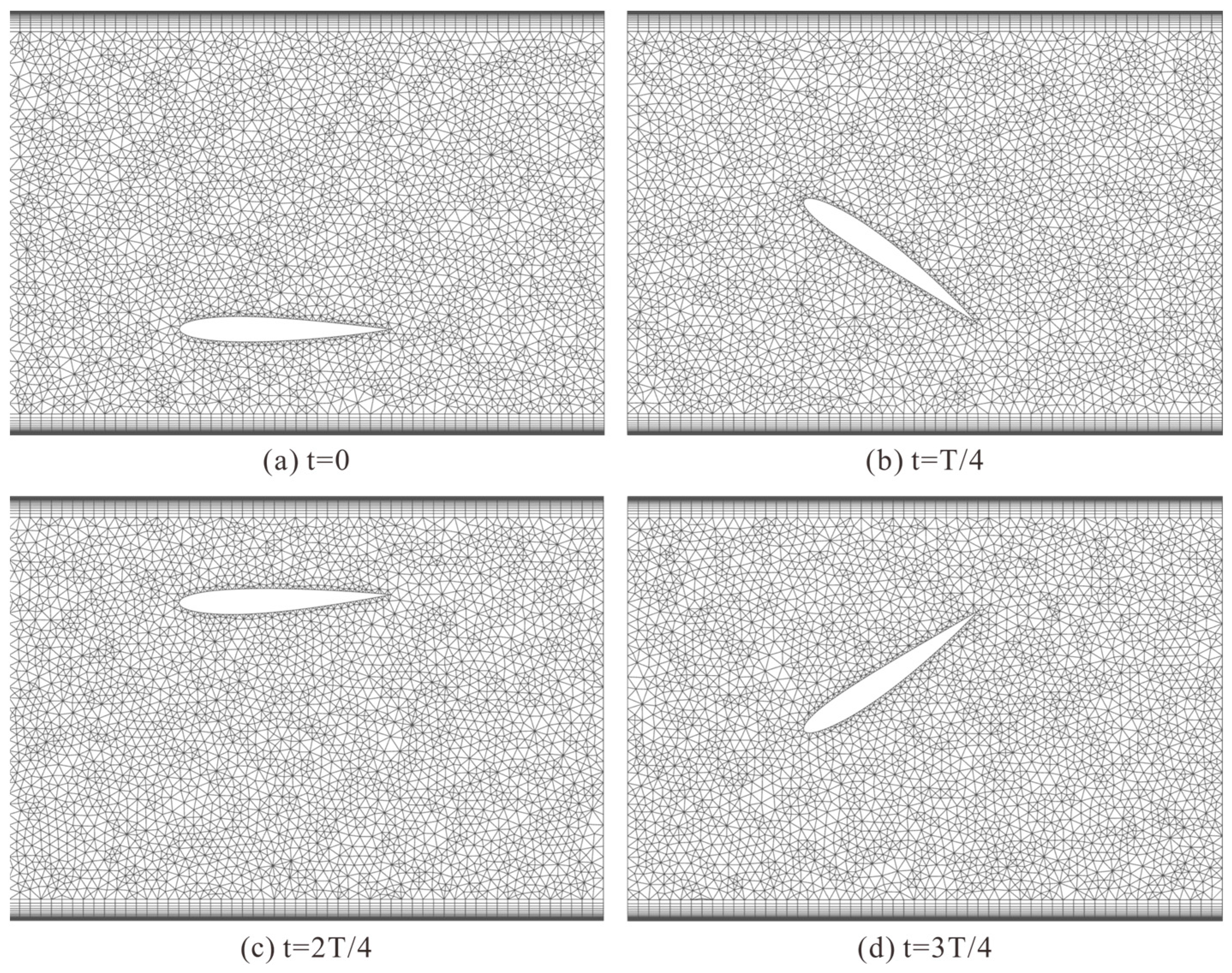

2.2. Hydrofoil Motion Model

2.3. Particle Phase Model and Discrete Phase Parameters

3. Numerical Methods and Validation

3.1. Fluid Domain Control Equations

3.2. Structural Domain Dynamic Equations

3.3. Particle Evaluation Metrics and Distribution Strategy

3.4. Two-Way Fluid–Structure Coupling Method

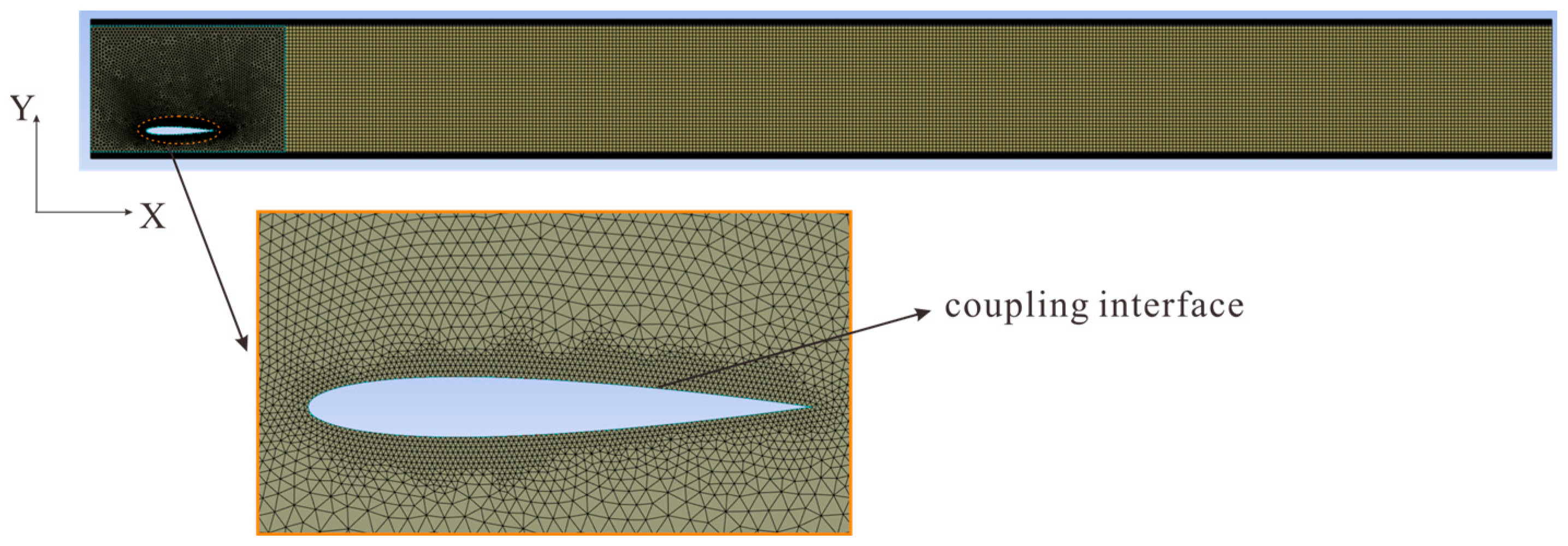

3.5. Mesh Generation and Solution Setting

3.6. Mesh Independence Verification

3.7. Time Step Selection

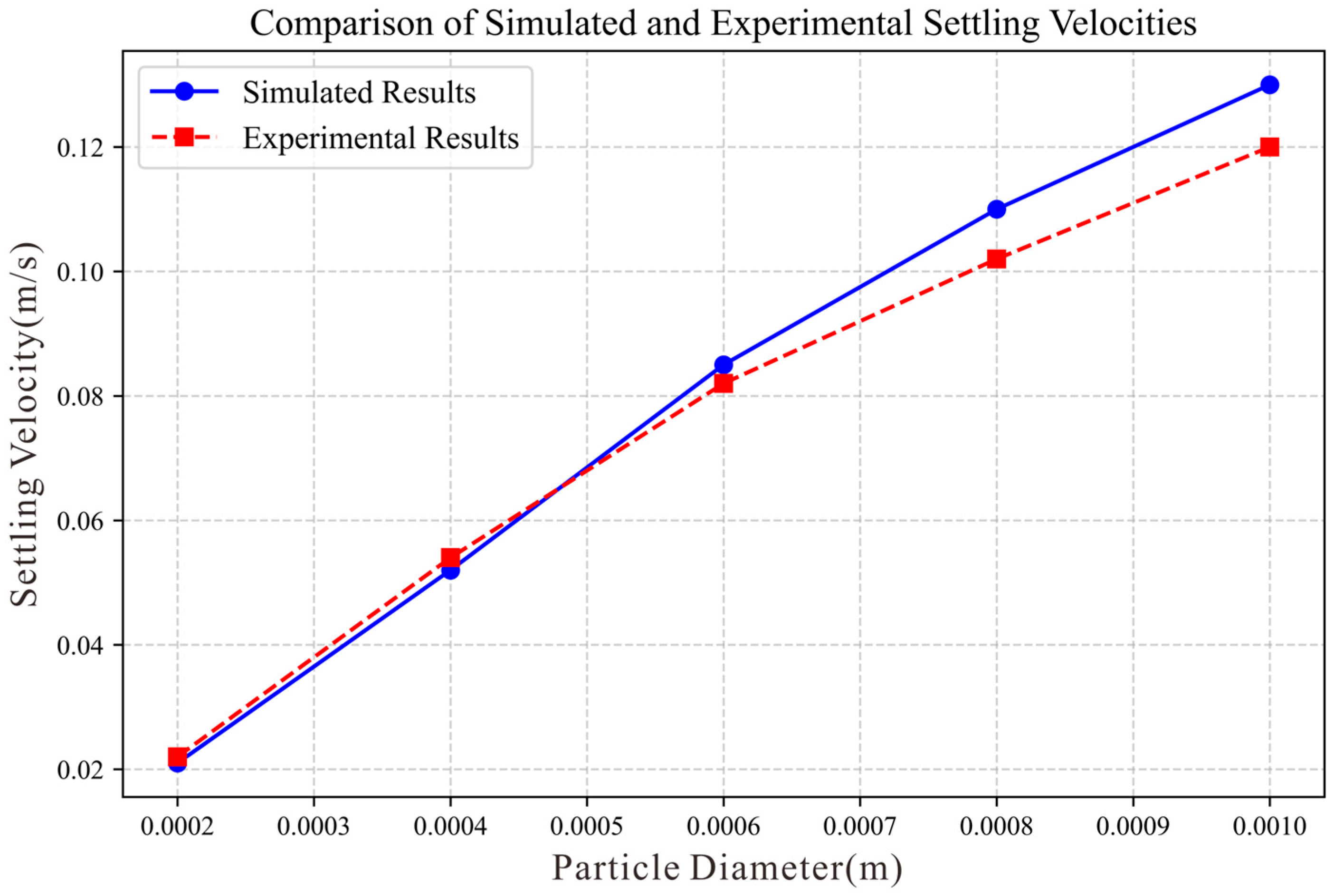

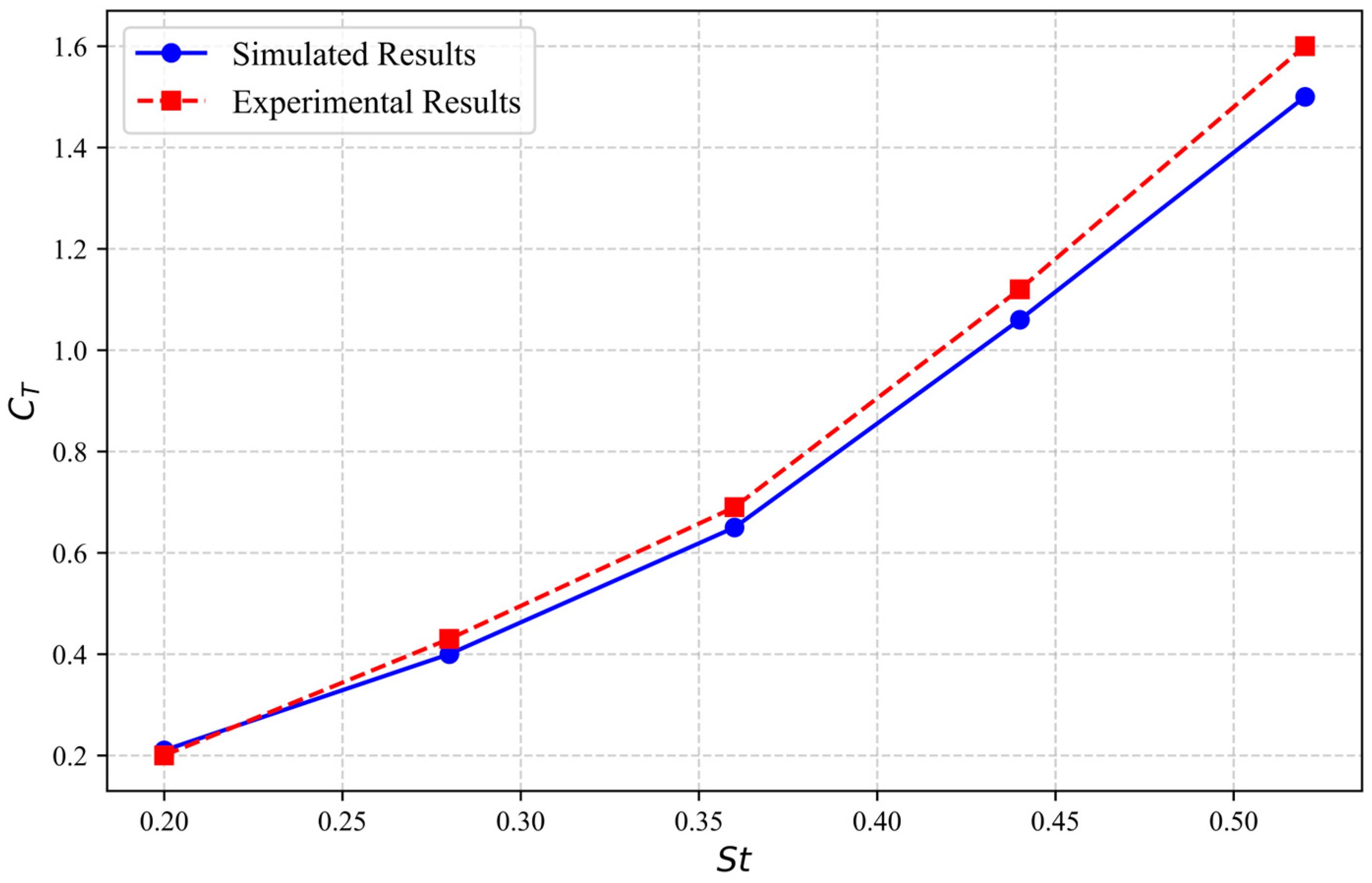

3.8. Method Validation

4. Results & Discussion

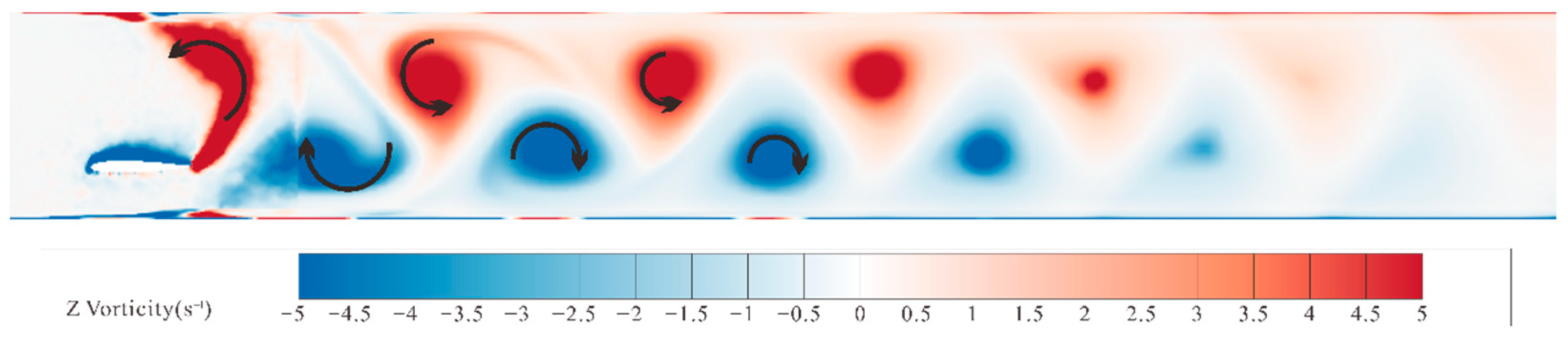

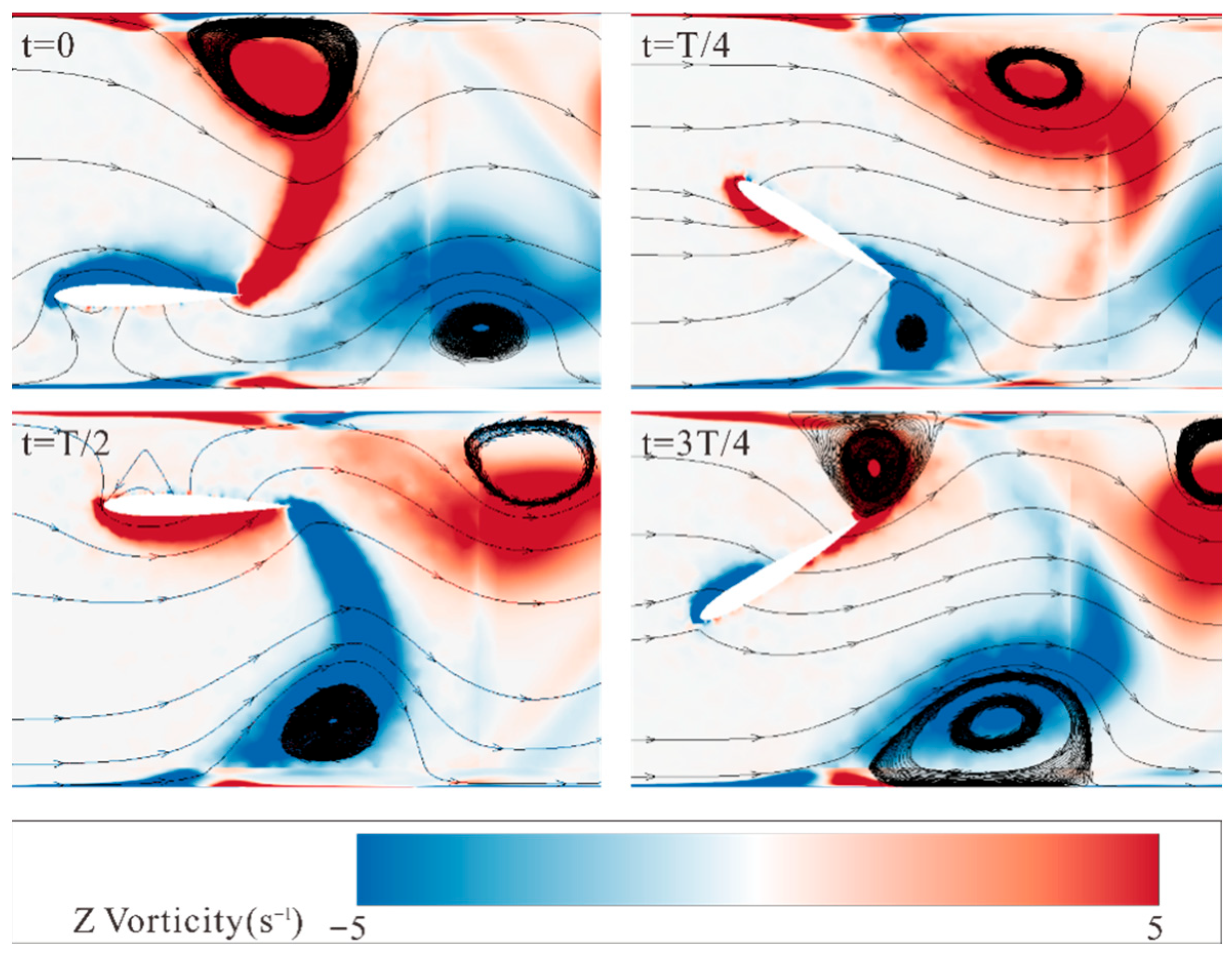

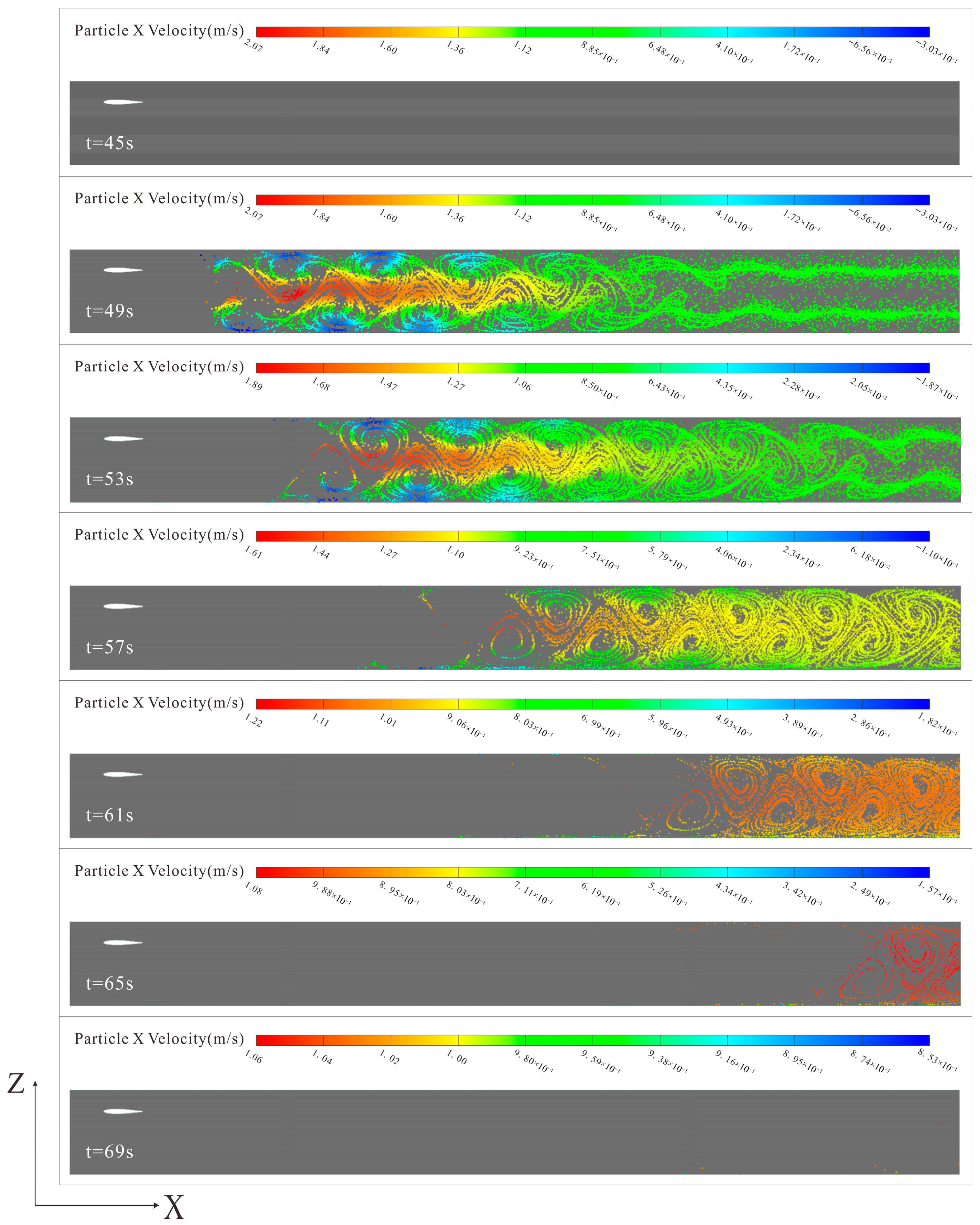

4.1. Effects of Hydrofoil Motion on Particulate Transport

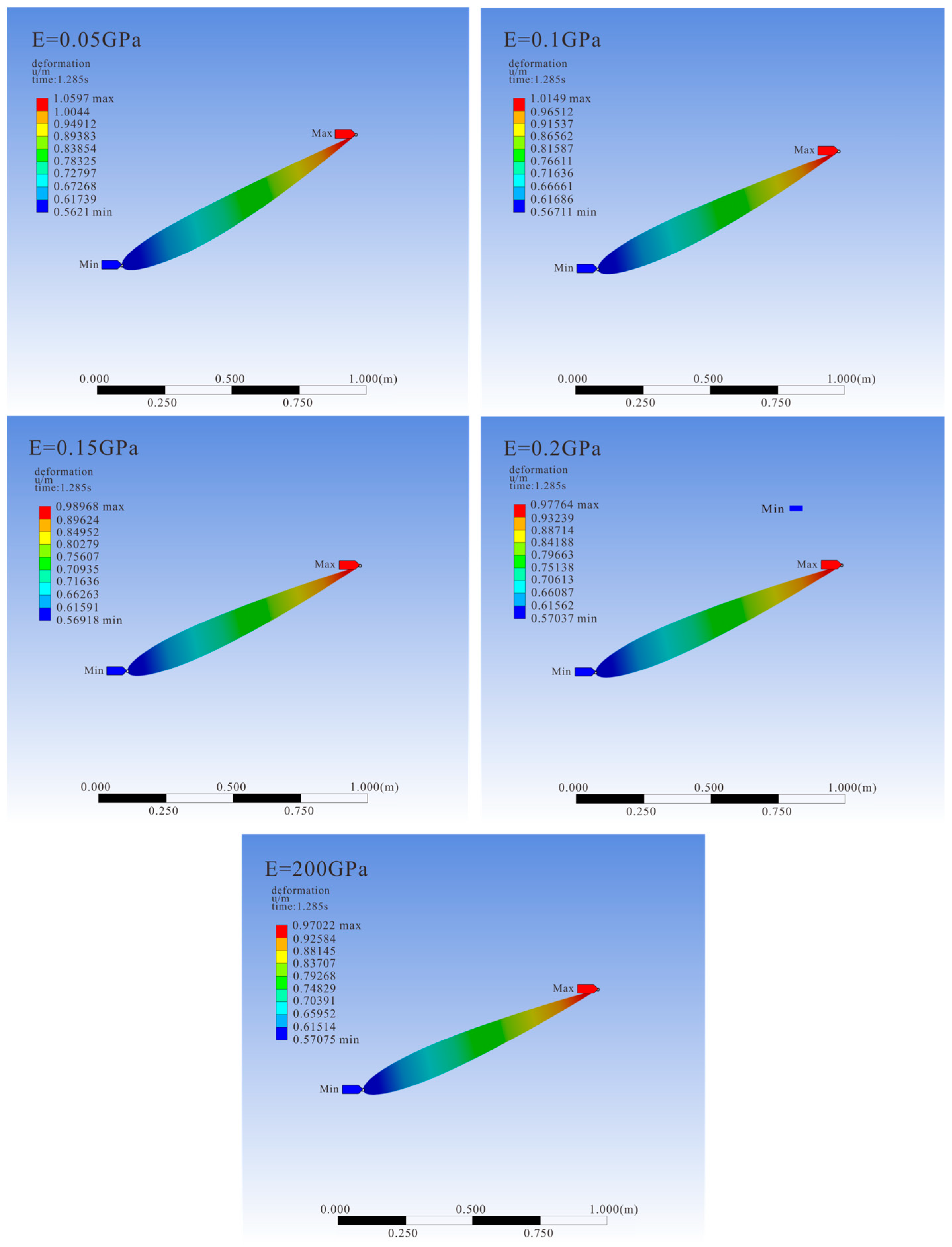

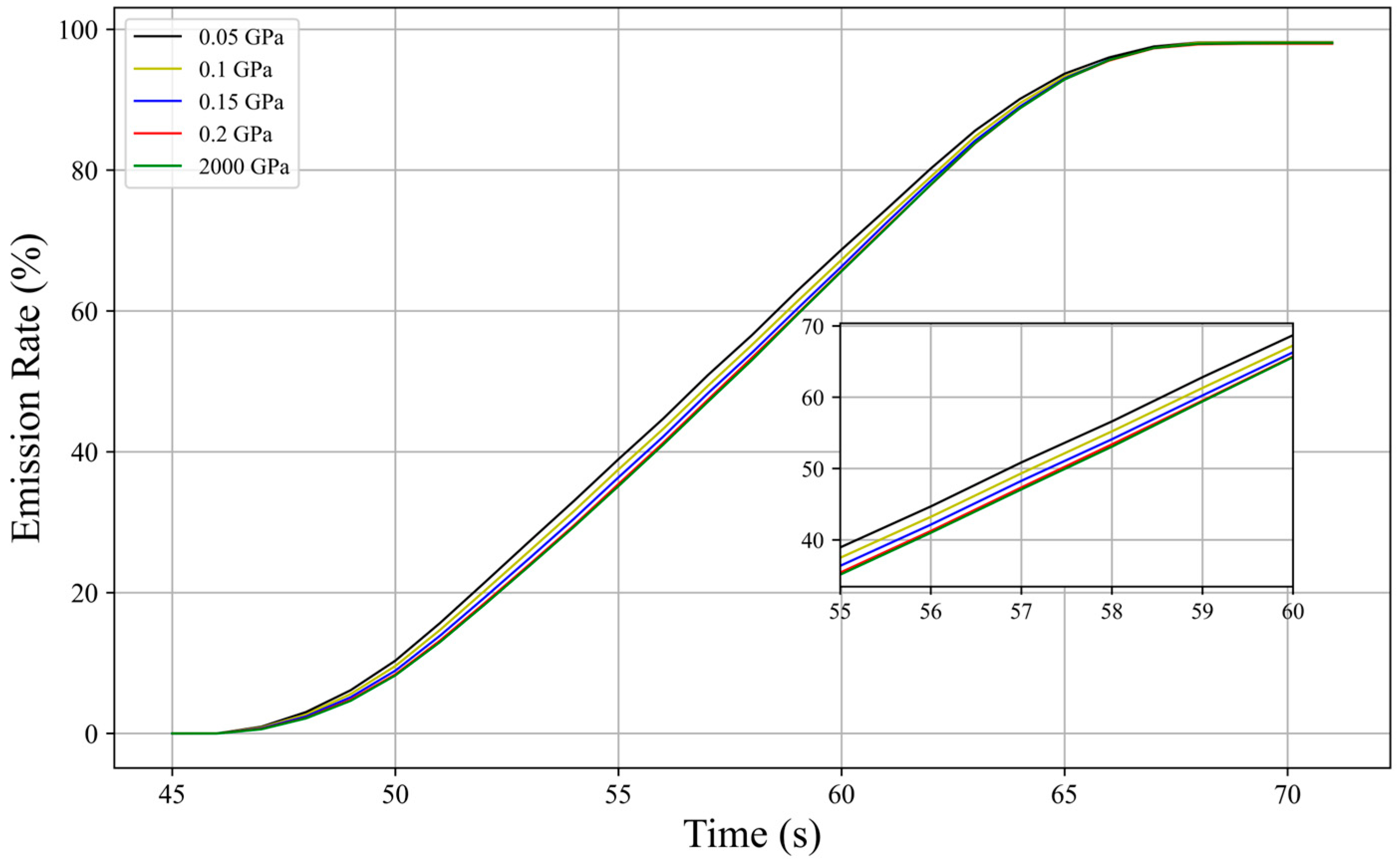

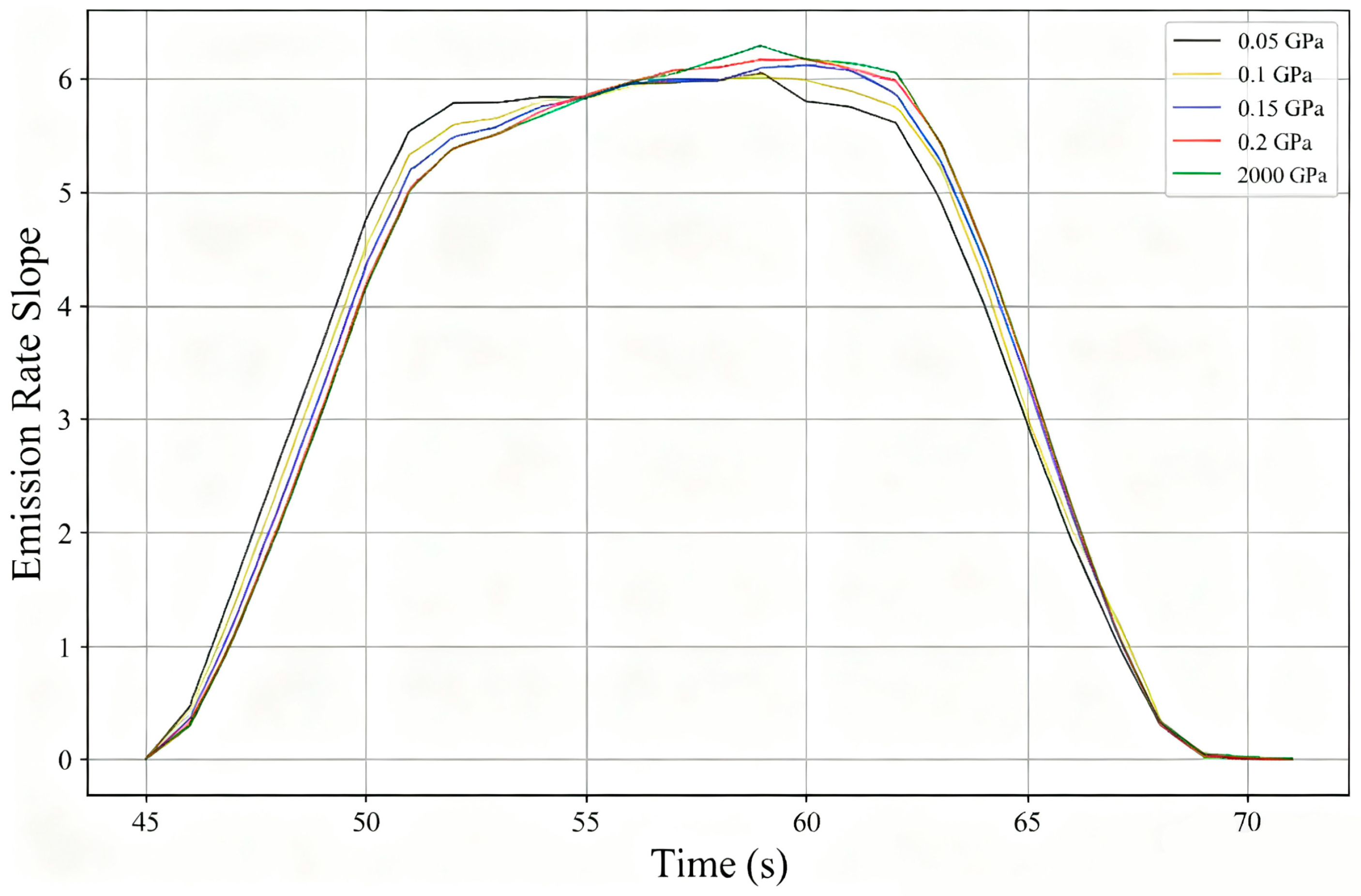

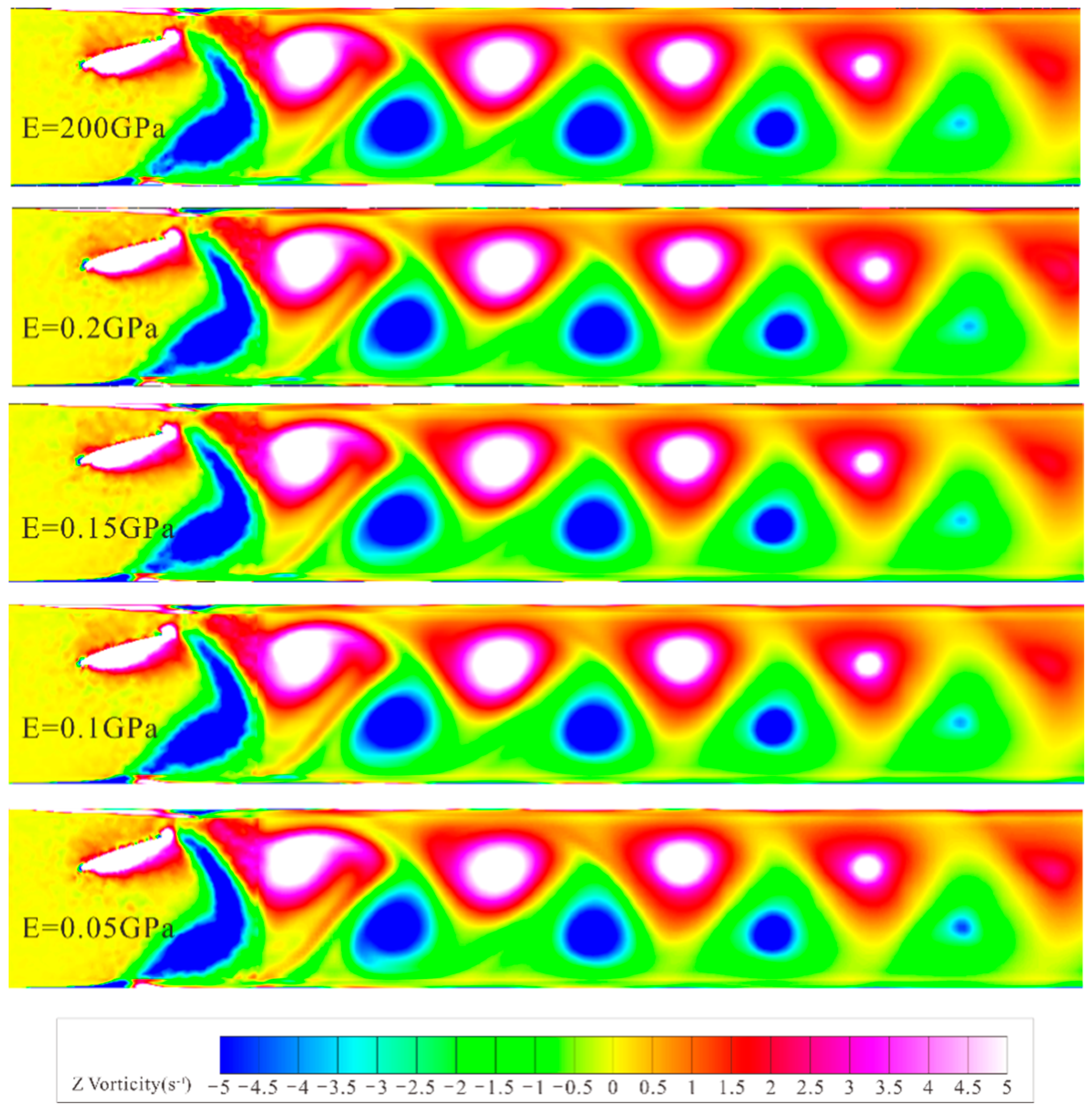

4.2. Influence of Hydrofoil Elastic Modulus on Particle Discharge Efficiency

5. Conclusions

- The reversed Kármán vortex street generated during the motion of the flapping hydrofoil can effectively enhance the flow effects of raceway aquaculture water, promoting the discharge of suspended particles.

- Within the range of elastic moduli tested, materials with lower elastic moduli show higher discharge efficiency for particles in the early to middle discharge periods, but there is no significant difference in the final discharge effect, with the discharge rate of suspended particles in all groups at around 97.8%.

- Compared to rigid flapping hydrofoils, the surface deformation of flexible hydrofoils is mainly concentrated in the trailing edge portion. The deformation of the trailing edge delays the time of tail vortex detachment, increases the duration of the tail vortex, and extends the distance over which the stratified velocity structure is maintained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ebeling, J.M.; Timmons, M.B. Recirculating aquaculture systems. In Aquaculture Production Systems; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Brown, T.W.; Chappell, J.A.; Boyd, C.E. A commercial-scale, in-pond raceway system for Ictalurid catfish production. Aquac. Eng. 2011, 44, 72–79. [Google Scholar] [CrossRef]

- Yin, Q.; Luo, Y.; Guo, Z.; Xiao, J.; Zhou, Y.; Wang, J.; Tang, Z. Research progress on pond engineering recirculating aquaculture model. J. Fish. Sci. 2019, 32, 76–82. (In Chinese) [Google Scholar] [CrossRef]

- Van Rijn, J. Waste treatment in recirculating aquaculture systems. Aquac. Eng. 2013, 53, 49–56. [Google Scholar] [CrossRef]

- Avnimelech, Y. Carbon/nitrogen ratio as a control element in aquaculture systems. Aquaculture 1999, 176, 227–235. [Google Scholar] [CrossRef]

- Bureau, D.P.; Hua, K. Towards effective nutritional management of waste outputs in aquaculture, with particular reference to salmonid aquaculture operations. Aquac. Res. 2010, 41, 777–792. [Google Scholar] [CrossRef]

- López-Rebollar, B.M.; García-Pulido, D.; Diaz-Delgado, C.; Gallego-Alarcón, I.; García-Aragón, J.A.; Salinas-Tapia, H. Sedimentation efficiency evaluation of an aquaculture tank through experimental floc characterization and CFD simulation. Aquac. Eng. 2023, 102, 102343. [Google Scholar] [CrossRef]

- Unger, J.; Brinker, A. Feed and treat: What to expect from commercial diets. Aquac. Eng. 2013, 53, 19–29. [Google Scholar] [CrossRef]

- Bash, J.; Berman, C.H.; Bolton, S. Effects of Turbidity and Suspended Solids on Salmonids; University of Washington Water Center: Seattle, WA, USA, 2001. [Google Scholar]

- López-Rebollar, B.M.; Salinas-Tapia, H.; García-Pulido, D.; Durán-García, M.D.; Gallego-Alarcón, I.; Fonseca-Ortiz, C.R.; García-Aragón, J.A.; Díaz-Delgado, C. Performance study of annular settler with gratings in circular aquaculture tank using computational fluid dynamics. Aquac. Eng. 2021, 92, 102143. [Google Scholar] [CrossRef]

- Gorle, J.M.R.; Terjesen, B.F.; Summerfelt, S.T. Influence of inlet and outlet placement on the hydrodynamics of culture tanks for Atlantic salmon. Int. J. Mech. Sci. 2020, 188, 105944. [Google Scholar] [CrossRef]

- Li, W.; Cheng, X.; Xie, J.; Wang, Z.; Yu, D. Hydrodynamics of an in-pond raceway system with an aeration plug-flow device for application in aquaculture: An experimental study. R. Soc. Open Sci. 2019, 6, 182061. [Google Scholar] [CrossRef]

- Wang, X.; Cui, K.; Li, H.; Jiang, Y.; He, J.; Zhang, J. Numerical simulation of flow field characteristics for aquaculture raceway and analysis of solid phase distribution in waste settling zone. Trans. Chin. Soc. Agric. Eng. 2019, 35, 220–227. (In Chinese) [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, Q.; Gui, F.; Zhang, Z.; Chen, Q.; Feng, D. Waste collection performance of the octagonal aquaculture tank driven by submersible flow propellers. J. Fish. China 2024, 48, 132–144. (In Chinese) [Google Scholar] [CrossRef]

- Wei, W.; Wei, J.; Wang, D.; Geng, L. Aeration and propulsion in oxidation ditch. Water Sci. Eng. Technol. 2011, 26–29. (In Chinese) [Google Scholar] [CrossRef]

- Bai, Y.; Zheng, M. Vortex-induced vibrations in an active pitching flapping foil power generator with two degrees of freedom. Phys. Fluids 2023, 35, 103612. [Google Scholar] [CrossRef]

- Ma, P.; Wang, Y.; Liu, H.; Xie, Y. Hydrodynamic performance analysis of improved oscillating wing model. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2017, 45, 65–69. (In Chinese) [Google Scholar] [CrossRef]

- Sun, G.; Wang, Y.; Xie, Y.; Ma, P.; Zhang, Y. Hydrodynamic and energy extraction properties of oscillating hydrofoils with a trailing edge flap. Appl. Ocean Res. 2021, 110, 102530. [Google Scholar] [CrossRef]

- Hu, F.; Zhao, W.; Huang, Y.; Yu, J.; Zhao, B.; Cui, J. Performance study of three-dimensional passive oscillating hydrofoil for wave glider propulsion. J. Mech. Eng. 2020, 56, 243–249. (In Chinese) [Google Scholar] [CrossRef]

- Hua, E.; Xiang, M.; Wang, T.; Song, Y.; Lu, C.; Sun, Q. Investigation of the Effect of Pumping Depth and Frequency of Flapping Hydrofoil on Suspended Matter Discharge Characteristics. Machines 2024, 12, 300. [Google Scholar] [CrossRef]

- Hua, E.; Wang, T.; Xiang, M.; Lu, C.; Song, Y.; Sun, Q. Study on the Influence of Chord Length and Frequency of Hydrofoil Device on the Discharge Characteristics of Floating Matter in Raceway Aquaculture. J. Mar. Sci. Eng. 2024, 12, 1584. [Google Scholar] [CrossRef]

- Ryu, Y.G.; Chang, J.W.; Chung, J. Aerodynamic characteristics of flexible wings with leading-edge veins in pitch motions. Aerosp. Sci. Technol. 2019, 86, 558–571. [Google Scholar] [CrossRef]

- David, M.J.; Govardhan, R.N.; Arakeri, J.H. Thrust generation from pitching foils with flexible trailing edge flaps. J. Fluid Mech. 2017, 828, 70–103. [Google Scholar] [CrossRef]

- Wang, Q.; Hou, Y.; Jin, Z.; Guo, Y. Numerical study on deformation of flexible flapping wing based on bidirectional fluid-structure coupling. Flight Dyn. 2021, 39, 27–33. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Y.; Niu, P.; Liu, S. Simulation analysis of aerodynamic performance of flexible flapping wing airfoil. Appl. Math. Mech. 2022, 43, 586–596. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Lei, J.; Guan, C.; Huang, B. Numerical simulation of the hydrodynamics within octagonal tanks in recirculating aquaculture systems. Chin. J. Oceanol. Limnol. 2017, 35, 912–920. [Google Scholar] [CrossRef]

- Behroozi, L.; Couturier, M.F. Prediction of water velocities in circular aquaculture tanks using an axisymmetric CFD model. Aquac. Eng. 2019, 85, 114–128. [Google Scholar] [CrossRef]

- Labatut, R.A.; Ebeling, J.M.; Bhaskaran, R.; Timmons, M.B. Exploring flow discharge strategies of a mixed-cell raceway (MCR) using 2-D computational fluid dynamics (CFD). Aquac. Eng. 2015, 66, 68–77. [Google Scholar] [CrossRef]

- Jin, W.; Luo, R.; Gu, R.; Xu, P. Review of pond engineering aquaculture system research. Fish. Mod. 2015, 42, 32–37. (In Chinese) [Google Scholar] [CrossRef]

- Xie, O.; Zhu, Q.; Jiang, Q.; Shen, Y. Study on wall effect characteristics of biomimetic robotic fish swimming near wall. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2018, 46, 59–63. (In Chinese) [Google Scholar] [CrossRef]

- Hua, E.; Su, Z.; Xie, R.; Chen, W.; Tang, S.; Luo, H. Optimization and experimental verification of pivot position of flapping hydrofoil. J. Hydroelectr. Eng. 2023, 42, 128–138. [Google Scholar]

- Du, X.; Zhang, Z. Numerical analysis of the influence of four flapping modes on underwater flapping wing propulsion performance. Eng. Mech. 2018, 35, 249–256. (In Chinese) [Google Scholar] [CrossRef]

- Ding, H.; Song, B.; Tian, W. Analysis of underwater bionic flapping-wing propulsion performance. J. Northwestern Polytech. Univ. 2013, 31, 150–156. [Google Scholar]

- Maxey, M.R.; Riley, J.J. Equation of motion for a small rigid sphere in a nonuniform flow. Phys. Fluids 1983, 26, 883–889. [Google Scholar] [CrossRef]

- Schiller, L. A drag coefficient correlation. Zeit. Ver. Deutsch. Ing. 1933, 77, 318–320. [Google Scholar]

- Becke, C.; Schumann, M.; Steinhagen, D.; Rojas-Tirado, P.; Geist, J.; Brinker, A. Effects of unionized ammonia and suspended solids on rainbow trout (Oncorhynchus mykiss) in recirculating aquaculture systems. Aquaculture 2019, 499, 348–357. [Google Scholar] [CrossRef]

- Liu, W.; Ke, H.; Xie, J.; Tan, H.; Luo, G.; Xu, B.; Abakari, G. Characterizing the water quality and microbial communities in different zones of a recirculating aquaculture system using biofloc biofilters. Aquaculture 2020, 529, 735624. [Google Scholar] [CrossRef]

- Duan, S.; Yang, C.; Song, X.; Huang, Z. Study on distribution law of micro-suspended particles in recirculating aquaculture system. Fish. Mod. 2021, 48, 7. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, J.H.; Wu, T.; Xu, D.; Gao, Y.; Tang, W. Feeding on feces, diets and cage farming sediments of Paralichthys olivaceus by Japanese scallop Patinopecten yessoensis. Prog. Fish. Sci. 2013, 34, 96–102. [Google Scholar]

- Chen, Q.; Xu, Z.; Zhang, Y. Application of RNG κ-ε model in numerical calculation of engineering turbulence. Q. Mech. 2003, 88–95. (In Chinese) [Google Scholar] [CrossRef]

- Li, M. Influence of Length-Width Ratio of Rectangular Arc-Angle Aquaculture Pond on Internal Flow Field and Sewage Discharge. Master’s Thesis, Dalian Ocean University, Dalian, China, 2023. (In Chinese). [Google Scholar]

- Donea, J.; Huerta, A. Finite Element Methods for Flow Problems; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Li, F.; Yu, P.; Deng, N.; Li, G.; Wu, X. Numerical analysis of the effect of the non-sinusoidal trajectories on the propulsive performance of a bionic hydrofoil. J. Appl. Fluid Mech. 2022, 15, 917–925. [Google Scholar] [CrossRef]

- Fang, H.; Shang, Q.; Zhao, H.; Wang, J. Experimental study on sedimentation of sediment particles after biofilm growth II: Calculation of settling velocity. J. Hydraul. Eng. 2012, 43, 386–391. (In Chinese) [Google Scholar] [CrossRef]

- Read, D.A.; Hover, F.S.; Triantafyllou, M.S. Forces on oscillating foils for propulsion and maneuvering. J. Fluids Struct. 2003, 17, 163–185. [Google Scholar] [CrossRef]

| Boundary/Region | Type | Numerical Setting |

|---|---|---|

| Left boundary | Pressure inlet | Gauge p = 0 Pa; Backflow TI = 3.53% |

| Right boundary | Pressure outlet | Same as inlet |

| Top boundary | Wall | No-slip |

| Bottom boundary | Wall | No-slip |

| Hydrofoil surface | Moving wall via two-way FSI | Motion prescribed on structural side; transferred each time step |

| Particles (DPM) | Walls/outlet | Walls: reflect; Outlet: escape; Inlet: none |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Hua, E.; Xiang, M. Contrasting Flexible and Rigid Bioinspired Flapping Hydrofoils for Suspended Particles Discharge in Raceway Aquaculture. Biomimetics 2025, 10, 779. https://doi.org/10.3390/biomimetics10110779

Xu F, Hua E, Xiang M. Contrasting Flexible and Rigid Bioinspired Flapping Hydrofoils for Suspended Particles Discharge in Raceway Aquaculture. Biomimetics. 2025; 10(11):779. https://doi.org/10.3390/biomimetics10110779

Chicago/Turabian StyleXu, Fangwei, Ertian Hua, and Mingwang Xiang. 2025. "Contrasting Flexible and Rigid Bioinspired Flapping Hydrofoils for Suspended Particles Discharge in Raceway Aquaculture" Biomimetics 10, no. 11: 779. https://doi.org/10.3390/biomimetics10110779

APA StyleXu, F., Hua, E., & Xiang, M. (2025). Contrasting Flexible and Rigid Bioinspired Flapping Hydrofoils for Suspended Particles Discharge in Raceway Aquaculture. Biomimetics, 10(11), 779. https://doi.org/10.3390/biomimetics10110779