Occupational Ergonomic Risks Among Women in Underground Coal Mining, South Africa

Abstract

1. Introduction

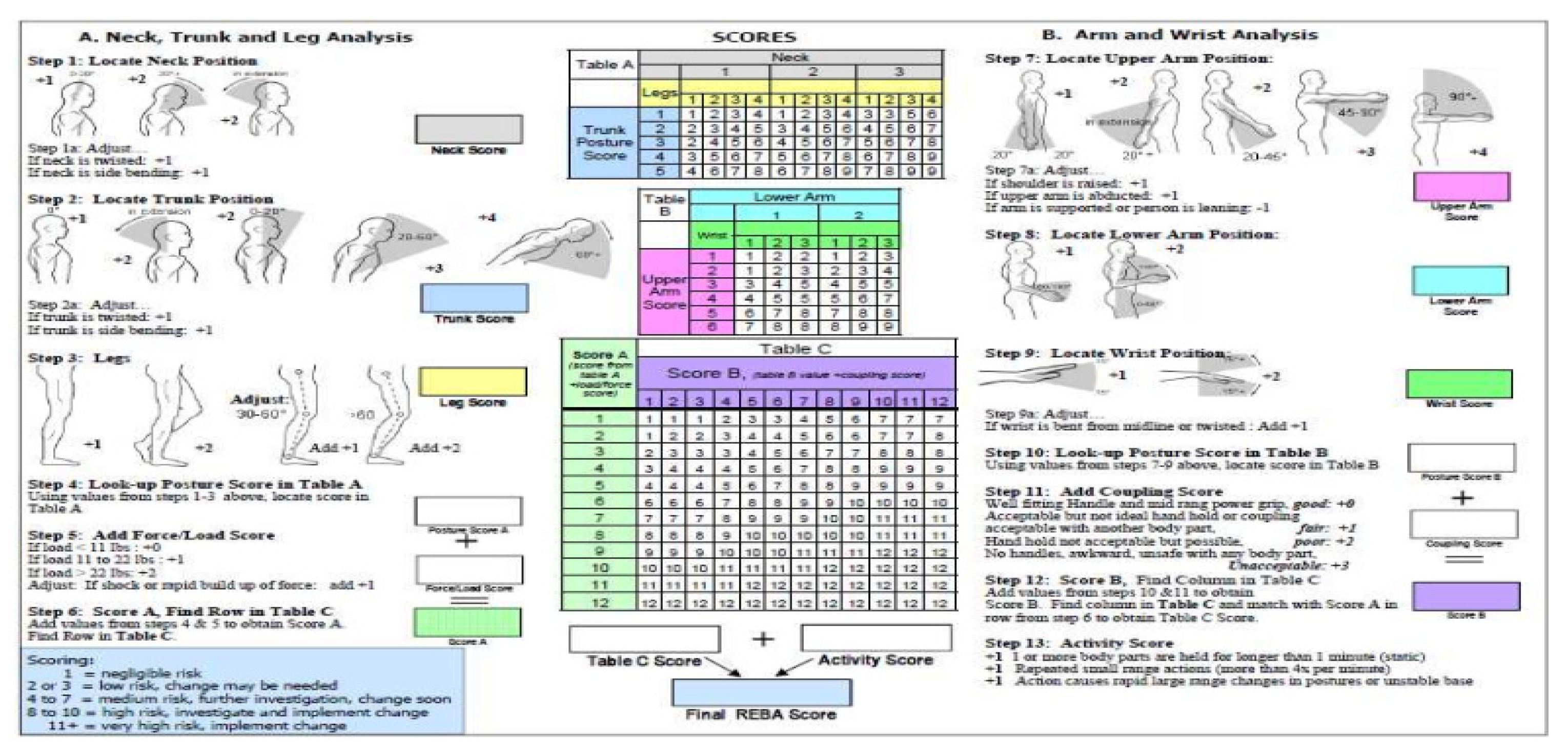

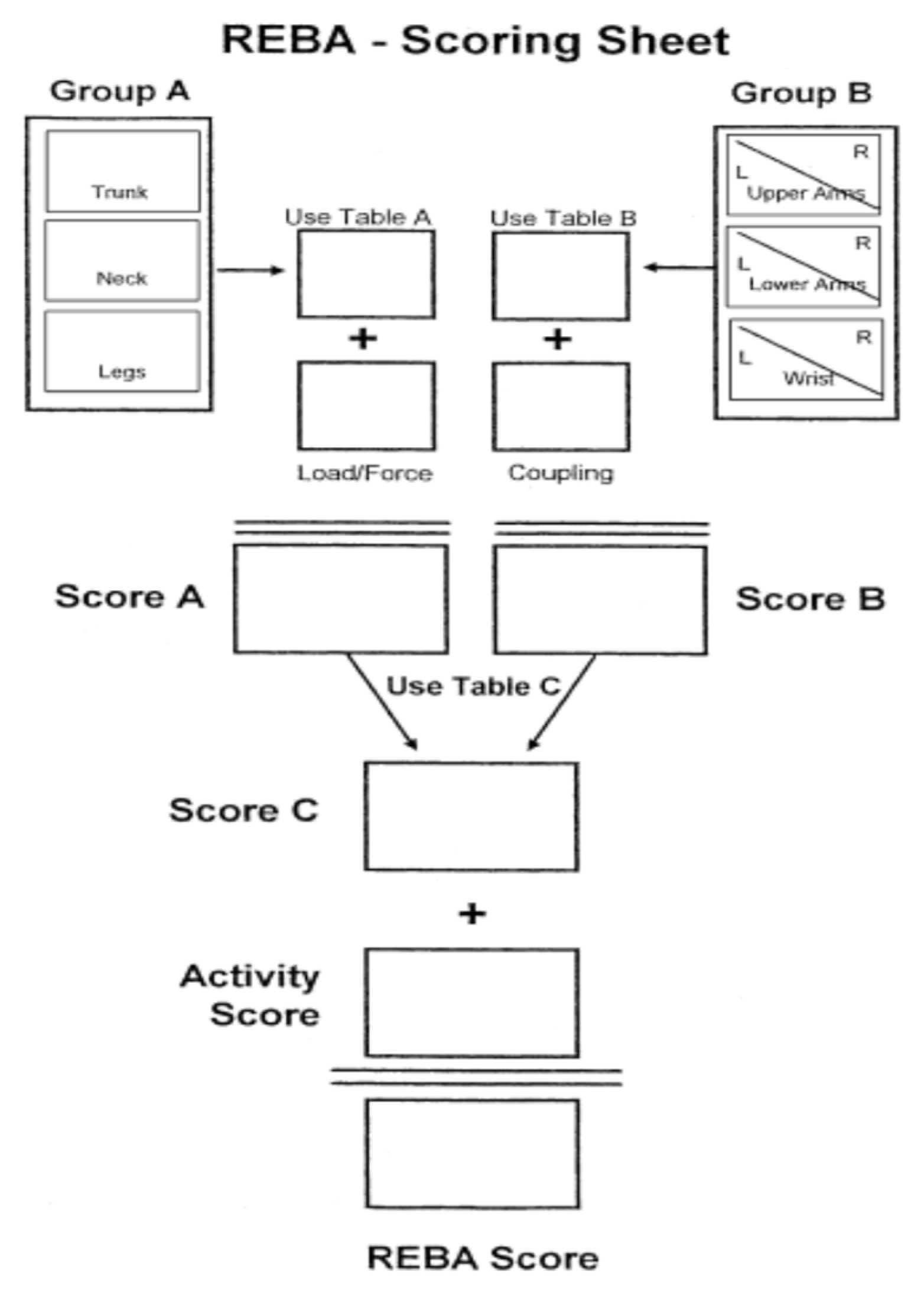

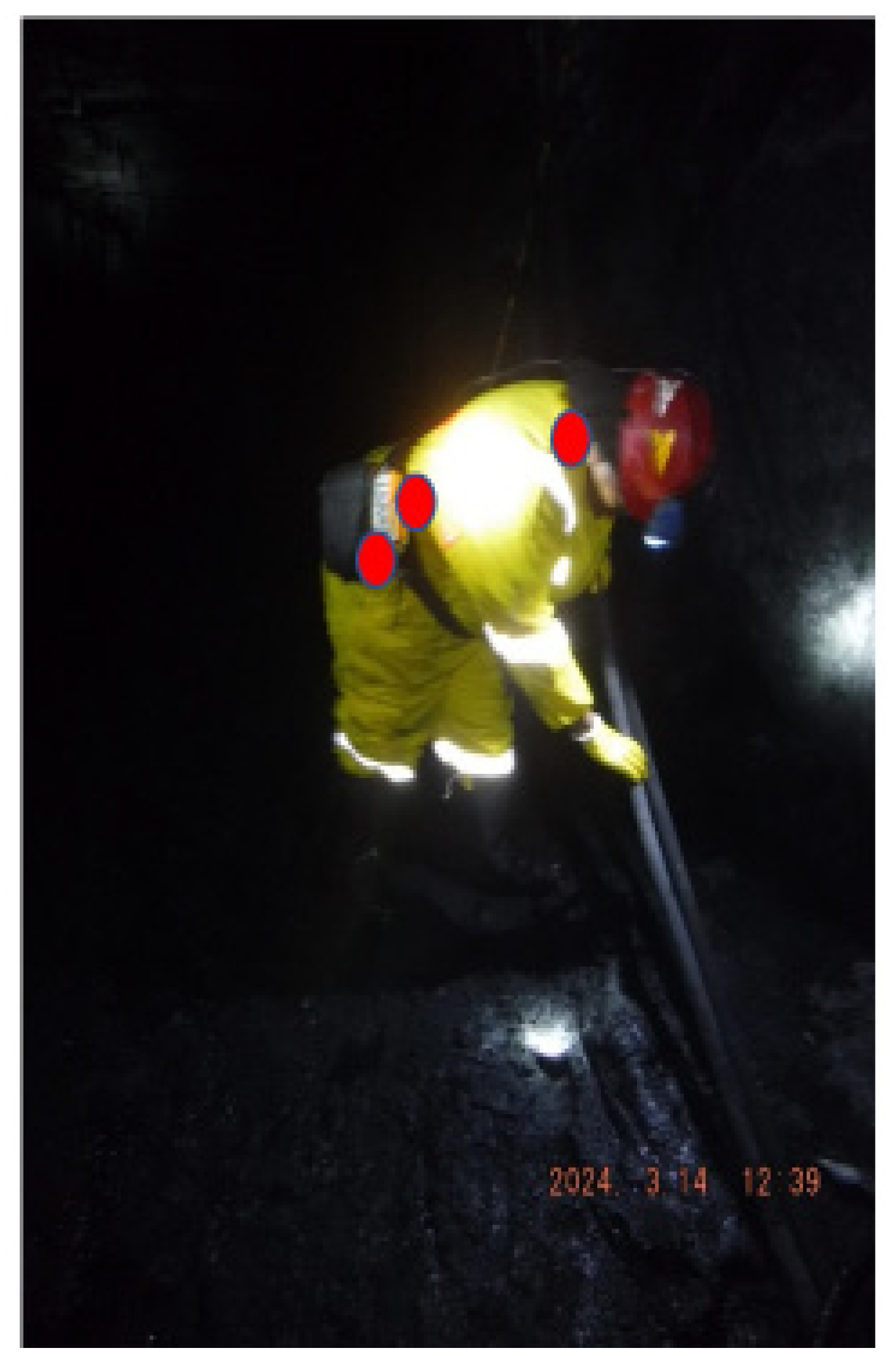

2. Materials and Methods

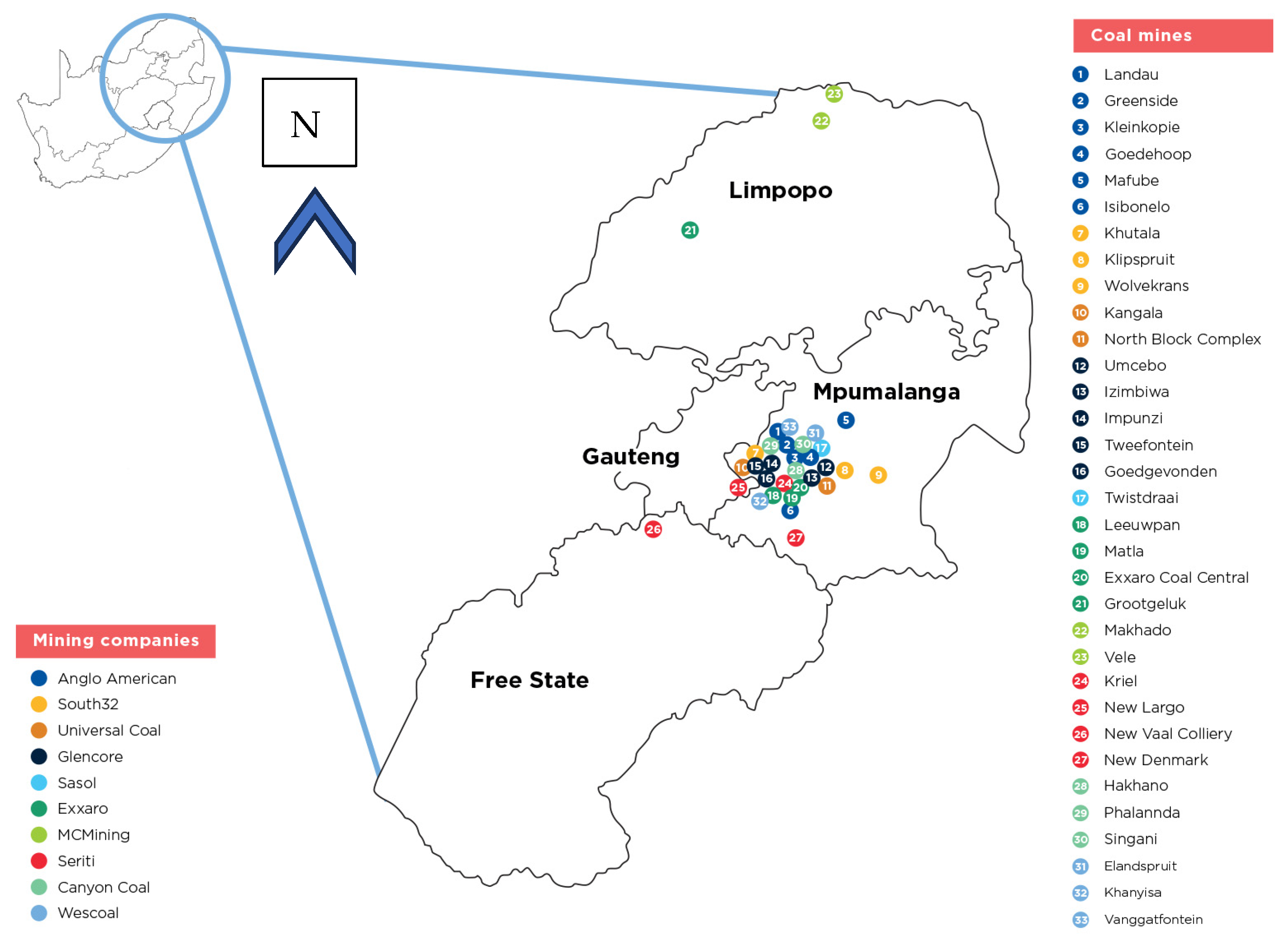

2.1. Study Area

2.2. Population and Sampling Size

2.3. Ethical Approval

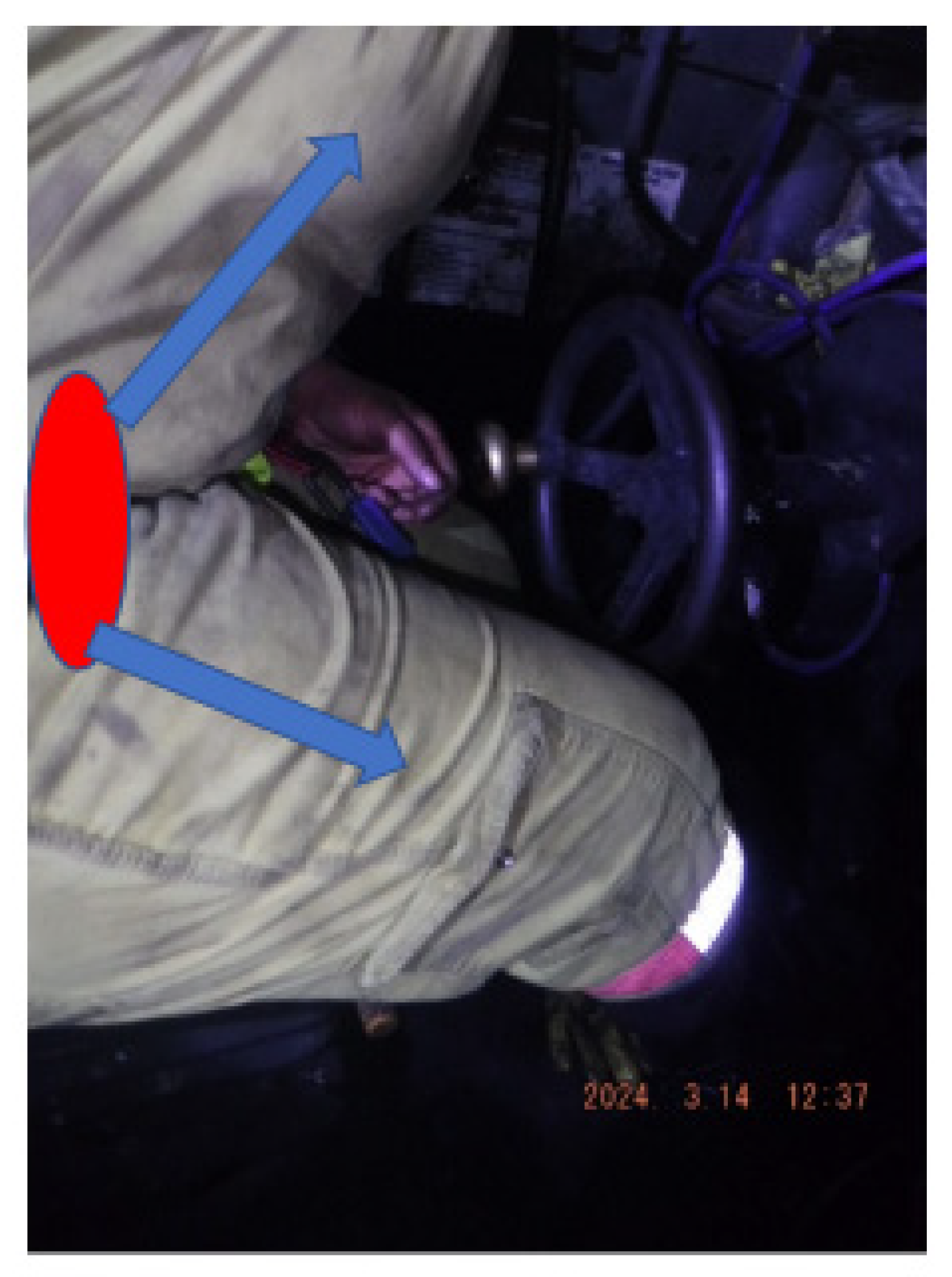

3. Results

4. Discussions

5. The Authors Acknowledge the Following Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Labour Organization. World Day for Safety and Health at Work Report: “Safety-in-Numbers”; International Labour Organization: Geneva, Switzerland, 2019. [Google Scholar]

- Chu, C.; Muradian, N. Safety and environmental implications of coal mining. Int. J. Environ. Pollut. 2016, 59, 250–268. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Rossell, J.M.; Vintró, C. Study of Spanish mining accidents using data mining techniques. Saf. Sci. 2015, 75, 49–55. [Google Scholar] [CrossRef]

- Mancini, L.; Sala, S. Social impact assessment in the mining sector: Review and comparison of indicators frameworks. Resour. Policy 2018, 57, 98–111. [Google Scholar] [CrossRef]

- Nguyen, N.B.; Boruff, B.; Tonts, M. Mining, Development and Well-Being in Vietnam: A Comparative Analysis. Extr. Ind. Soc. 2017, 4, 564–575. [Google Scholar] [CrossRef]

- Huerta-Díaz, M.A.; Muñoz-Barbosa, A.; Otero, X.L.; Valdivieso-Ojeda, J.A.; Amaro-Franco, E.C. High variability in geochemical partitioning of iron, manganese and harmful trace metals in sediments of the mining port of Santa Rosalia, Baja California Sur, Mexico. J. Geochem. Explor. 2014, 145, 51–63. [Google Scholar] [CrossRef]

- Foo, N.; Bloch, H.; Salim, R. The optimisation rule for investment in mining projects. Resour. Policy 2018, 55, 123–132. [Google Scholar] [CrossRef]

- Linton, A.; Stone, S. Ergonomics of underground mining: The role of equipment design in worker safety and efficiency. Int. J. Occup. Saf. Ergon. 2017, 23, 5–15. [Google Scholar]

- Department of Employment and Labour. Ergonomics Regulations, 2019; Government Printer: Pretoria, South Africa, 2019. Available online: https://www.labour.gov.za/DocumentCenter/Pages/Ergonomics-Regulation-2019-.aspx (accessed on 30 October 2025).

- International ergonomic association and international labour organization. Principles and Guidelines for HF/E Design and Management of Work Systems; Joint Document by IEA and the International Labour Organization (ILO); International Labour Organization: Geneva, Switzerland, 2019; Available online: https://araijournal.com/index.php/arai/article/view/326 (accessed on 24 June 2025).

- Kamijantono, H.; Sebayang, M.M.; Lesmana, A. Risk factors and ergonomic influence on musculoskeletal disorders in the work environment. J. Medihealtico 2024, 5, 660–670. [Google Scholar] [CrossRef]

- Pramudita, A.S.; Sari, M. Keluhan musculoskeletal disorders (MSDs) pada mahasiswa. J. Semesta Sehat 2024, 4, 23–31. [Google Scholar] [CrossRef]

- Ashworth, G.; Molapo, M.; Molefe, N.; Schutte, S.; Zitha, M. Human and Social Issues Influencing the Incorporation of Women Into the Mining Workforce. 2004. Available online: https://coaltech.co.za/wp-content/uploads/2019/10/Task-2.8.1-Human-and-social-issues-influencing-the-incorporation-of-women-into-the-mining-workforce-2004.pdf (accessed on 30 June 2021).

- Schutte, P.C. Fatigue risk management: Charting a path to a safer workplace. J. S. Afr. Inst. Min. Metall. 2010, 110, 53–55. [Google Scholar]

- Jäger, M.; Jordan, C.; Theilmeier, A.; Wortmann, N.; Kuhn, S.; Nienhaus, A.; Luttmann, A. Lumbar-load analysis of manual patient-handling activities for biomechanical overload prevention among healthcare workers. Ann. Occup. Hyg. 2013, 57, 528–544. [Google Scholar] [PubMed]

- Mandal, B.B. Implementation of DGMS Guidelines for ergonomic risk assessment of mining operations. In Proceedings of the National Workshop on Applied Ergonomics for Mining, Nagpur, India, 28 November 2014. [Google Scholar]

- Heine, A. A Model for Managing the Barriers of Introducing Women into a Mining Industry. 16 March 2012. Available online: http://hdl.handle.net/2263/28565 (accessed on 23 July 2021).

- Department of Mineral Resources. Guideline for the Mandatory Code of Practice on the Provision of Personal Protective Equipment for Women in the South African Mining Industry. 25 September 2015. Available online: www.gpwonline.co.za (accessed on 1 August 2021).

- Shongwe, B.N. The Impact of Coal Mining on the Environment and Community Quality of Life: A Case Study Investigation of the Impacts and Conflicts Associated with Coal Mining in the Mpumalanga Province, South Africa. Master’s Thesis, University of Cape Town, Cape Town, South Africa, 2018. [Google Scholar]

- Crossman, A. What Is a Convenience Sample? ThoughtCo. 18 July 2019. Available online: https://www.thoughtco.com/convenience-sampling-3026726 (accessed on 18 November 2024).

- Coal Mining—Minerals Council SA. 2016. Available online: https://www.mineralscouncil.org.za/sa-mining/coal (accessed on 2 February 2023).

- Babbie, E.; Mouton, J. The Practice of Social Research; Oxford University Press: Cape Town, South Africa, 2011. [Google Scholar]

- Schwartz, A.H.; Albin, T.J.; Gerberich, S.G. Intra-rater and inter-rater reliability of the rapid entire body assessment (REBA) tool. Int. J. Ind. Ergon. 2019, 71, 111–116. [Google Scholar] [CrossRef]

- Madani, D.A.; Dababneh, A. Rapid Entire Body Assessment: A Literature Review. Am. J. Eng. Appl. Sci. 2016, 9, 107–118. [Google Scholar] [CrossRef]

- Moradi, M.; Poursadeghiyan, M.; Khammar, A.; Hami, A.D.; Yarmohammadi, H. REBA method for the ergonomic risk assessment of auto mechanics postural stress caused by working conditions in Kermanshah (Iran). Ann. Trop. Med. Public Health 2017, 10, 589–594. [Google Scholar]

- Eger, T.; Stevenson, J.; Boileau, P.-E.; Salmoni, A.; Vibrg. Predictions of health risks associated with the operation of load-haul-dump mining vehicles: Part 1—Analysis of Whole-Body Vibration Exposure Using ISO 2631-1 and ISO 2631-5 Standards. Int. J. Ind. Ergon. 2008, 38, 726–738. [Google Scholar] [CrossRef]

- Marras, W.S.; Davis, K.G.; Heaney, C.A.; Maronitis, A.B.; Allread, W.G. The influence of psychosocial stress, gender, and personality on mechanical loading of the lumbar spine. Spine 2018, 43, E897–E905. [Google Scholar] [CrossRef] [PubMed]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 2020, 63, 457–467. [Google Scholar] [CrossRef] [PubMed]

- Pandarinath, M.; Rao, T.R.; Venkatesh, S. Evaluation of drivers seating posture by REBA analysis: Paper No. 2024-DF-07. ARAI J. Mobil. Technol. 2024, 4, 1138–1146. [Google Scholar] [CrossRef]

- da Costa, B.R.; Vieira, E.R. Risk factors for work-related musculoskeletal disorders: A systematic review of recent longitudinal studies. Am. J. Ind. Med. 2010, 53, 85–323. [Google Scholar] [CrossRef] [PubMed]

- South Africa. Mine Health and Safety Act, Act No. 29 of 1996; Department of Minerals and Energy: Pretoria, South Africa, 1996. Available online: www.gov.za/documents/mine-health-and-safety-act (accessed on 29 June 2021).

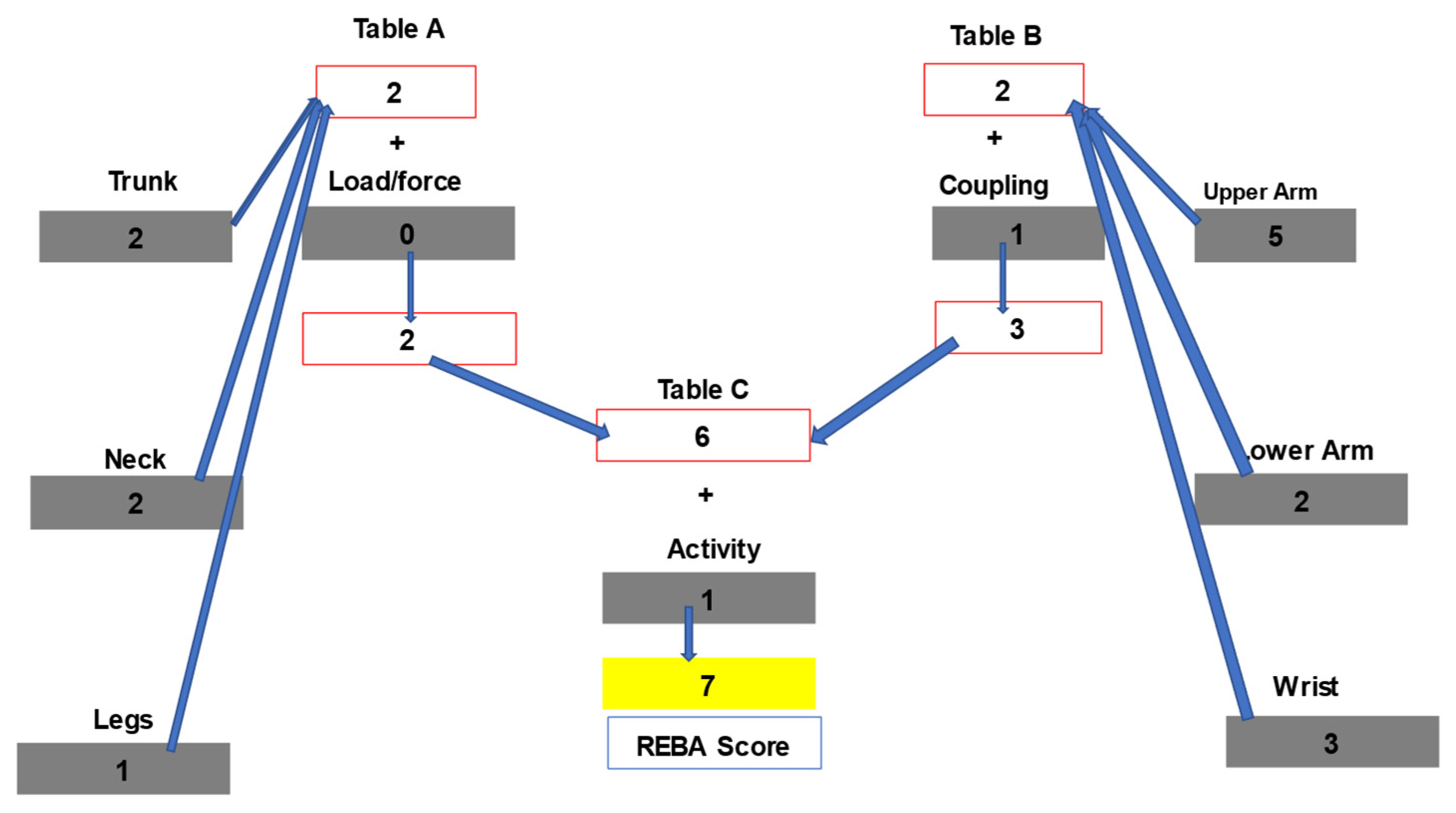

| Score | Level of MSD Risk |

|---|---|

| 1 | Negligible risk, no action required |

| 2–3 | Low risk, change may be needed |

| 3–7 | Medium risk, further investigation, change soon |

| 8–10 | High risk, investigate and implement change |

| 11+ | Very high risk, implement change |

| Sections of the Body | Shuttle Car 2 | Roof Bolter 1 | Roof Bolter 2 | Roof Bolter 3 | CM Cable Handler |

|---|---|---|---|---|---|

| Neck | 2 | 2 | 2 | 2 | 2 |

| Trunk | 3 | 1 | 1 | 1 | 4 |

| Leg | 1 | 1 | 1 | 1 | 2 |

| Trunk posture score | 2 | 2 | 2 | 2 | 6 |

| Force load | 0 | 1 | 1 | 1 | 2 |

| Posture + Force load | 2 | 3 | 3 | 3 | 8 |

| Upper arm | 5 | 5 | 5 | 5 | 3 |

| Lower arm | 2 | 2 | 2 | 2 | 1 |

| Wrist | 3 | 2 | 2 | 2 | 2 |

| Posture score | 8 | 8 | 8 | 8 | 4 |

| Coupling | 1 | 2 | 2 | 2 | 3 |

| Coupling score | 9 | 10 | 10 | 10 | 7 |

| Posture + Coupling score | 6 | 8 | 8 | 8 | 10 |

| Activity | 1 | 1 | 1 | 1 | 1 |

| REBA score | 7 | 9 | 9 | 9 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mokwena, O.S.; Shirinde, J.; Morodi, T.J. Occupational Ergonomic Risks Among Women in Underground Coal Mining, South Africa. Safety 2025, 11, 116. https://doi.org/10.3390/safety11040116

Mokwena OS, Shirinde J, Morodi TJ. Occupational Ergonomic Risks Among Women in Underground Coal Mining, South Africa. Safety. 2025; 11(4):116. https://doi.org/10.3390/safety11040116

Chicago/Turabian StyleMokwena, Ouma S., Joyce Shirinde, and Thabiso J. Morodi. 2025. "Occupational Ergonomic Risks Among Women in Underground Coal Mining, South Africa" Safety 11, no. 4: 116. https://doi.org/10.3390/safety11040116

APA StyleMokwena, O. S., Shirinde, J., & Morodi, T. J. (2025). Occupational Ergonomic Risks Among Women in Underground Coal Mining, South Africa. Safety, 11(4), 116. https://doi.org/10.3390/safety11040116