1. Introduction

Accidents in gas stations may cause injury or even death to people. A recent fire in a gas station in Creeslough, Ireland, caused multiple fatalities, with 10 deaths [

1]. Twenty-five gas station accidents in Indonesia were recorded in 2022, which caused two deaths and 14 people injured [

2]. In February 2023, there have been two gas station fires in Indonesia. The first accident occurred in Toraja Utara Regency, South Sulawesi Province, on 7 February. A pick-up car caught fire while refueling gasoline. The driver was rushed to the hospital with burn injuries [

3]. Two days later, another fire occurred at a gas station in Lembongan village, Bali province [

4]. It is the only gas station in the village, which serves Lembongan and its neighbor village, Jungutbatu, with a total population of 9000 people [

5]. Even though there were no injuries, the fire forced the gas station to stop operations. Thus, fuel shortage in the area was inevitable, which forced locals to buy fuel from gas station in a nearby island [

6].

Apart from accidents related to fire and explosion, there are other occupational accidents in the operation of gas stations. Gas station workers are at risk of exposure to fuel inhalation and fuel contact with the skin or eyes [

7]. A study by Heng et al. [

8] showed that these types of accident had the second highest frequency after explosion. Other accidents include oil leakage, collision, and falls.

The gas station spread in Indonesia is not evenly distributed. In big cities, gas stations can be accessed easily, while in rural areas, one might need to travel a distance to purchase fuel [

9]. As a commodity sought by many, the availability of fuel is critical in driving the economy. A gas station fire may not only cause direct loss and injury, but also indirect losses as an effect of the difficulty of accessing fuel. Therefore, study on gas station fires and means to prevent them becomes essential.

Previous studies about gas station accidents found that the main contributor of accidents is the human factor [

10]. An investigation of 120 fuel station accidents between 2016 and 2018 by Indonesia’s Ministry of Energy and Mineral Resources also found three contributing factors to gas station accidents, i.e., lack of skill, culture, and competence (48%); lack of safety management (32%); and lack of engineering (20%) [

11]. To address the first factor, safety climate is frequently used. Since its first appearance a couple of decades ago, safety climate has been widely studied in various fields to explain the current condition of safety culture in an organization [

12]. A lot of research has been conducted in different countries, mainly the USA, Australia, and China [

13]. Despite the size of the country and its economy (being the largest in Southeast Asia), research of the safety climate in Indonesia is limited. From 19 studies between 2017 and 2022, most were in the construction sector, followed by healthcare, maintenance, manufacturing, and other sectors [

14]. In early 2023, two more research article were published, one in a healthcare distribution company [

15] and the other concerning safety climate assessment in fuel stations in West Java [

14]. Although safety climate has been used as an instrument to predict safety performance [

16], studies on the relationship between safety climate and safety performance in gas stations in Indonesia, in particular, are scarce.

Considering the frequency of gas station accidents and the potential harm when such an accident happens, maintaining high safety performance in gas stations is prominent. The pathway to high safety performance will be more effective when the connection between safety climate and safety performance is well known. Therefore, it is important to conduct further investigations to see how safety climate can improve safety performance, especially in this sector.

The aim of this study was to assess the level of safety climate in gas stations in Indonesia and establish the relationship between safety climate and safety performance. The research questions that arose from this objective are:

What is the state of safety climate in gas stations in Indonesia?

What is the influence of safety climate on safety performance?

Which safety climate dimensions are most important in improving safety performance?

2. Literature Review

2.1. Gas Station Accident Contributing Factors

The flammable characteristic of fuels in gas stations, especially gasoline, impose risks of gas vapor release, which may lead to fatal fire [

17]. Fire and explosion have been accounted as the top risk of gas station operations [

18]. Most fires involve consumer vehicles [

19]. Although tanker unloading was identified as the activity with most significant risk factor [

20], the frequency of this activity is much less than fuel dispensing, i.e., filling fuel to consumer vehicles. In addition, fuel dispensing activity involves interaction between gas station workers and the consumer driving the vehicles, for which unsafe behaviors often occur and need to be controlled [

2].

Moreover, Ahmed et al. [

21] argued that even though the design, construction, and installation phases are important in building the foundations of safety in gas stations, the operation and maintenance phases are more prone to accidents. They also identified housekeeping, transportation hazard, slips, trips and falls, carelessness, fire risk, and electrical faults as potential hazards present in gas stations.

2.2. Safety Climate

Safety climate has attracted interest from safety researchers and professionals [

22]. Initially, Zohar defined safety climate as the shared perception among workers on safety policies, procedures, and practices [

12]. The safety climate theory has been used as a foundation in various research and practice. Studies showed that the safety climate has a positive influence in improving individual safety behavior and protecting the workforce from harm and injuries [

23]. Furthermore, the use of safety climate has also extended from the personal level to a multi-level level construct, i.e., group level and organizational level [

24]. This extension leads to more research in safety climate. The number of publications on the safety climate topic averaged one article per year from the 1980s to 1997. From 1998 to 2002, this number increased to four publications per year, and the number grew up to more than fifty articles per year in 2018 [

25].

The increased number of studies on safety climate topics has also broadened the organization sectors involved. Most of the research can be found in the construction sector, followed by medicine sector [

26]. This is not surprising because these two sectors have recorded the most accidents causing deaths and injuries [

27]. Other sectors have much less exposure to safety climate study. In recent years, safety climate studies in the general oil and gas sector have been conducted in various countries, such as Norway [

28,

29], Denmark [

30], Canada [

31,

32], Nigeria [

33], United Arab Emirates [

34], Iran [

35], and Malaysia [

36,

37]. More specifically, in the gas station sector, there were only three publications found, two in Ghana [

38,

39] and the other in Indonesia [

14].

2.2.1. Safety Climate Measurement

Safety climate is usually represented as a construct with several latent variables. The latent variables consist of several observed variables, which are usually in the form of questionnaire statements. To measure safety climate, a self-reported questionnaire is often used. Several known safety climate questionnaires are the Nordic Occupational Safety Climate Questionnaire (NOSACQ-50) [

40] and the Safety Assessment Questionnaire (SAQ) [

41]. Other researchers develop questionnaires to be more specific for their need and purpose.

Even though different questionnaires use different dimensions for explaining safety climate, six dimensions are most frequently used. These are management and supervisor commitment to safety, safety policies, resources and training, coworkers’ involvement and commitment to safety, safety communication, and priority for safety [

42]. In a four-scale system, safety climate score above 3.30 is considered good, between 3.00 and 3.30 fairly good, between 2.70 and 3.30 fairly low, and below 2.70 classified as low [

43].

2.2.2. Safety Climate Research in Indonesia

Wibowo et al. [

14] provided a list of previous safety climate studies in Indonesia, which also showed the majority of research was in the construction and healthcare industries. Research in a rock mining company studied the influence of job stress and safety climate on safety performance. It was found that safety climate has a positive relationship on safety performance, while job stress has a negative influence [

44]. Wibowo et al. [

14] and Yovi et al. [

45] used the NOSACQ-50 questionnaire [

40] to assess safety climate in gas station and forestry workers, respectively. These studies found similar results for the fifth dimension—workers’ safety priority and risk non-acceptance—which showed that the majority of workers accept high-risk working conditions.

Moreover, three studies utilized the Safety Attitudes Questionnaire (SAQ) [

41] to assess safety climate. Ningrum et al. [

46] and Juliawati et al. [

47] conducted a validity test for the Bahasa Indonesia version of SAQ, and both concluded that it had good internal consistency, validity, and reliability. Furthermore, an investigation by Indarwati et al. [

48], which also used SAQ, attenuates that the staff’s work experience had a significant effect on safety climate, i.e., the longer the experience, the higher the safety perceptions were on the workers. Wibowo et al. [

14] also argued on this issue that less-experienced workers have higher demand in management’s commitment and intervention, while experienced workers tend to accept the condition as they were accustomed to.

Another more recent reference in safety climate questionnaire development is the one from Zou and Sunindijo [

49]. The questionnaire is divided into six dimensions: management commitment, safety communication, safety rules and procedures, supportive environment, personal safety involvement and needs, and safety training. The questionnaire was initially developed for the construction industry and initially tested in Australia, but it has been translated to Bahasa Indonesia and used to assess safety climate in the Indonesian construction industry by Lestari et al. [

50]. The research proposed a framework for occupational health and safety performance for construction industries in Indonesia. Furthermore, by using the same framework, quantitative safety climate data were also compared between construction industries in Indonesia, Australia [

51], and China [

52]. The overall result showed a degree of similarity between countries, but diving deeper into the dimensions and questions, the differences become apparent. For example, in the personal accountability dimension, Australians had good personal perception on safety because the Work Health and Safety (WHS) Act 2011 regulates workforce consultation. On the other hand, workers in China do not have the option to conflict with their managers, even if things start to jeopardize safety, and Indonesian construction workers are considered informal workers and have lower education, so safety is only about following instructions.

2.2.3. Safety Climate Studies in Gas Stations

Research on safety climate in gas stations is very limited. Three research articles were found in research databases, two of them were studies in Ghana and the other in Indonesia. In their study among gas station attendants in Accra, Ansah et al. [

39] stressed the importance of supervisor supports to their attendants to increase safety climate and achieve better state of safety and business sustainability. On the other hand, the study by Bakidamteh et al. [

38] concerned personal proactivity in safety. Their study suggested that personnels with proactive personalities tend to exhibit a higher level of safety compliance and safety participation.

Moreover, a safety climate assessment in gas stations in Indonesia using the NOSACQ-50 questionnaire in West Java Region, Indonesia, showed that personal risk-taking behavior remains an issue to be resolved [

14]. Another aspect specific to gas station safety is the involvement of the community in building safety awareness, since gas stations are usually located close to community dwellings [

2].

2.3. Safety Performance

Safety performance represents how well (or poorly) an organization performs in terms of safety [

23]. Although this definition is self-explanatory, scholars have proposed different approaches to measure safety performance. The most practical approach is using the lagging and leading indicators. Lagging indicators are indicators of safety performance by observing incidents after they happen. An incident could range from unsafe behaviors, near misses, injuries, and even death. These incidents are reported, and when meeting a pre-defined criterion, such as Occupational Safety and Health Authority’s (OSHA) recordkeeping regulation, the incidents are recorded. Furthermore, the records (in numbers or rates) are used as lagging indicators. Some commonly used lagging indicators are Total Recordable Incident Rate (TRIR); Lost Time Case (LTC); Lost Work Day Rate (LWD); Days Away, Restricted or Job Transfer (DART); Incident Rate (IR); Severity Rate (SR); and Risk Rate (RR) [

53].

On the contrary, leading indicators are measurements related to accident prevention [

54]. One way to record leading indicators is by counting the frequency of several safety management efforts in preventing an incident [

55]. Salas and Hallowell [

56] conducted predictive validation on examples of leading indicators, which are contractor safety audit sores, frequency of safety and non-compliance observations, pre-job safety meetings, client safety walkthroughs, subcontractor safety audits, contractor leadership and clients attending orientation sessions, project risk assessments, and drug tests. Other leading indicators as identified by Xu et al. [

57] are number of safety trainings, number of risk management plans and verifications, number of closed out inspection findings, and number of learning events.

Furthermore, Ali et al. [

58] divided leading indicator into two groups, i.e., driven leading indicator and observant leading indicator. Driven leading indicator is a group of safety management elements that would drive the safety performance of the workers and organization. Seven indicators are part of this group, namely, management commitment, workers’ involvement, hazard identification and assessment, hazard prevention and control, training and education, evaluation and improvement, and communication and coordination. Other scholars regard these indicators as safety climate [

59]. Observant indicator comprises the proximal safety antecedents (safety knowledge and safety motivation) and safety performance (safety compliance and safety participation), which are based on earlier safety performance indicators studied by Neal and Griffin [

60].

Another approach in acquiring a leading indicator is by conducting direct observations. The use of standardized observation on worksite conditions and safety behaviors, such as the TR Safety Index, have been used widely in the Finnish construction industry, and the method has been proven scientifically as a valid safety indicator [

61]. Furthermore, Bhagwat et al. [

62] introduced a method called jobsite safety inspection (JSI) to measure safety performance in projects. By observing unsafe behaviors and unsafe conditions and addressing the issues accordingly, the safety performance will improve [

63].

3. Research Method

To achieve the research objective, two main steps were taken. The first step was to conduct a safety climate assessment in the fuel stations, and the second step was to assess gas station safety performance observation. The safety climate assessment was administered using an online form, while the safety performance observation was carried out directly at the gas stations. Due to the limitations of the research resources and accessibility, convenient sampling was conveyed. A total of 130 gas stations located in three provinces in the West Java Region were selected as samples for data collection. From this number, 129 gas stations agreed to participate in the study, consisting of twenty gas stations in the Banten province, thirty-one in the Greater Jakarta province, and seventy-eight in the West Java province. The number of samples per province was proportional to the actual number of gas stations in operation in each area. All data collection was done quantitatively, and the results were analyzed using statistical computation software.

3.1. Safety Climate Assessment

The tools for assessing safety climate in gas stations for this study is derived from the safety assessment framework by Lestari et al. [

50] combined with the questions from NOSACQ-50 [

40]. The final questionnaire consists of forty-eight questions grouped into six dimensions, which are management commitment, communication, rules and procedures, supportive environment, personal accountability, and training. The questionnaire used a five-point Likert scale as opposed to the six-point scale used by Lestari et al. [

50]. and four-point scale in NOSACQ-50 [

40].

The respondents for the safety climate assessment were gas station workers of the previously selected gas stations. After receiving confirmation of participation from the gas station management, workers were asked to voluntarily fill in the safety climate questionnaire via an online platform. In total, 386 respondents participated in the safety climate assessment.

3.2. Safety Performance Measurement

For the safety performance observation to be accurate, a novel structured observation checklist was developed. The structured observation checklist was mainly derived from the gas station technical guidance published by Indonesia’s Ministry of Energy and Mineral Resources [

11]. Moreover, since tanker unloading, dispensing of fuel, and storage of fuel on site have been identified as the activities having the highest risk factor [

20], the observation checklist was developed specifically to focus on these areas. Observable parameters at gas stations were listed, consisting of unsafe actions and unsafe conditions, focusing on equipment and actions that can prevent gas station accidents, such as uncontrolled fuel release, fire/explosion, and sources of ignition [

20]. Finally, the observation items were grouped into 5 categories based on the weight determination of hazards in fuel stations [

64]. The five observation categories were Operation and Maintenance, Housekeeping, Fire and Emergency Readiness, Electrical Safety, and Behavior Control. Each of the categories had 5 observation items. The final observation checklist consisted of 25 items, as listed in

Table 1.

When conducting the observation, each item was given a score: one if the checklist item was confirmed, and zero if the observed condition differed from the checklist. The calculation of safety performance score for each fuel station was then calculated by adding the scores for each item and dividing it by the number of observation items. The value was then converted to a percentage. The higher percentage means better safety performance.

To minimize bias, the observation was done without the workers knowing they were being observed. This was done to let the workers work as they usually do, and not try to change their behavior upon observation. Only after the observation was finished did the research team approach the workers and their supervisor to inform them of the observation.

3.3. Data Analysis

After data collection had been completed, the first step was to perform data screening to remove any errors, outliers, or invalid responses. The next step was to calculate the safety climate score for each dimension by computing the average of respondents answer scores for that dimension. The safety climate score was then compared to other safety climate scores from other literature to answer the first research question. Next, the safety performance score was calculated using Equation (1). Safety observation results were also analyzed descriptively to explore the top 10 observation findings and the number of findings on each observation category.

To explain the influence of safety climate on safety performance (the second research question) and which of the safety climate dimensions have a greater impact on safety performance (the third research question), the collected data were analyzed statistically using multiple linear regression. Regression analysis was preferred because it can predict the effect of one variable to another [

65]. In previous research, this method was used to predict the relationship between safety climate and safety compliance [

28], mindful safety practice [

29], occupational injuries [

66], and safety leadership and safety performance [

67].

In this multiple linear regression analysis, the six dimensions of safety climate were set as the independent variables and the results of the safety performance score as the dependent variable.

4. Results

4.1. Safety Climate Scores

The safety climate assessment on 129 gas stations returned a mean score of 3.99 out of 5.00. This value fell slightly below 4.00, which is a good indicator of safety climate level. Management commitment and communication dimensions were the two highest scores, followed by supportive environment and training. The two dimensions with lowest scores were rules and procedure and personal accountability. The safety climate mean scores (per dimension and overall) can be viewed in

Table 2.

4.2. Safety Performance Results

On safety performance measurements, from twenty-five observation items, each gas station had a maximum of six failed items. The safety performance observation had a minimum score of 76%, the maximum score was 100%, and average score was 88%. While this result seems good, there were some observation items that many gas stations failed to comply with.

Table 3 shows the top ten most failed items in all gas stations.

Furthermore, by grouping the observation findings in all gas stations by category, the most unsafe condition was part of the Housekeeping category, followed by Operation and Maintenance. More detailed information can be observed in

Table 4. The percentage shows the number of unsafe findings divided by the total number of unsafe findings in all gas stations (235 findings).

4.3. Safety Climate Influence on Safety Performance

Analysis of safety climate effects on safety performance was done using multiple linear regression using the software JASP version 0.16.4 (University of Amsterdam, Amsterdam, The Netherlands) for Windows [

68]. The analysis used linear regression with backward iteration. In this method, initial calculation was done for all the independent variables or covariates and the software checks for covariates that had the least significant correlation to the dependent variable and removed it. This iteration was done until all the remaining covariates were those with a significant correlation to the dependent variable.

Table 5 shows the modelling iteration summary.

In the multiple linear regression model, the final value of R was 0.670, which shows the actual safety performance scores and the predicted safety performance scores. The final value of R2 was 44.9% while the adjusted R2 was 43.6%. For multiple linear regression, the adjusted R2 is preferred because it considers the predictive power of a predictor variable. In other words, the safety climate dimensions in this study accounted for 43.6% of the variance in safety performance. The value of the Durbin–Watson Statistic 1.936 indicates the correlations between residuals were low, which means the test was valid.

The next result is the Analysis of Variance (ANOVA), which provides information related to the significance of the regression model. The calculation was done for the 95% level of significance. The model is considered significant if the F-statistic value is greater than the F-table and the p-value is less than 0.05. Based on these parameters, all models were significant as presented in

Table 6. However, the F-statistic increased in each step of the iteration. The larger F-statistic value in the last model (34.007) showed it was more probable that the independent variable would have a significant effect on the dependent variable in the last model compared to the previous ones. This tells us that the final model fits better than the earlier models.

Although the ANOVA result showed significance, another test was necessary to determine the significance effect of each safety climate dimensions on safety performance. Therefore, the backward iteration regression analysis was conducted. In the first model, all six covariates were included in the analysis. In the second iteration, five covariates remained—rules and procedures were omitted because it had the highest

p-value (least significant). In the third model, the supportive environment dimension was removed from further analysis. In the last model, only three covariates remained, namely, management commitment, safety communication, and personal accountability. Since these three covariates showed statistical significance—

p value < 0.001—then the iteration stopped, and hence the final model was obtained. The backwards iteration results can be seen in

Table 7.

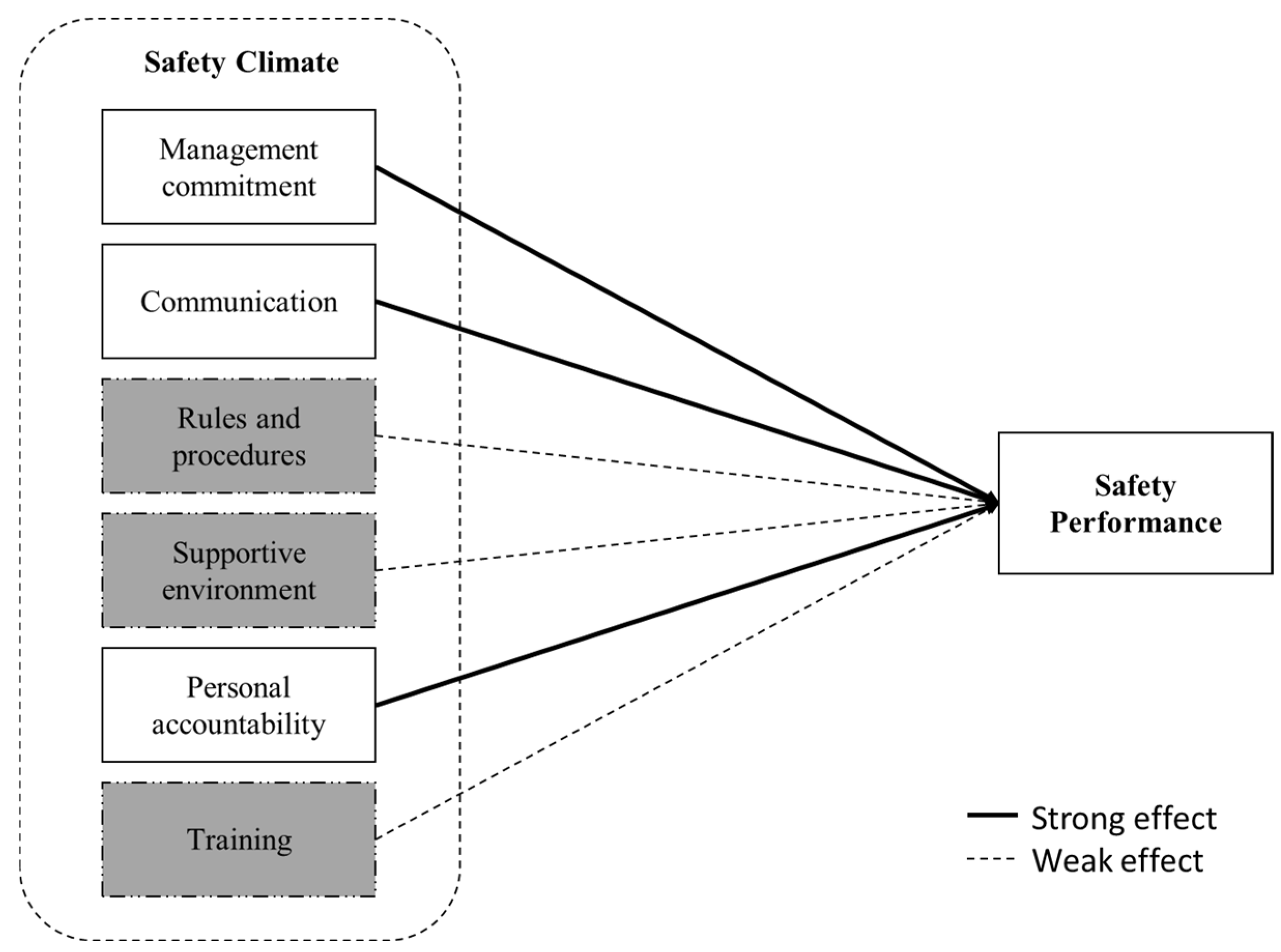

The results of this study showed that safety climate indeed had a positive influence on safety performance. However, from the backward multiple regression analysis, it showed that only three dimensions of safety climate had a significant influence on safety performance, namely, management commitment, communication, and personal accountability. The other three, i.e., rules and procedures, supportive environment, and training did not have a significant influence on safety performance. The influence of safety climate on safety performance is depicted in

Figure 1 below.

5. Discussion

5.1. Safety Climate Score Analysis

The average safety climate score of all the sampled gas stations was 3.99. As can be seen in

Table 8, this score is higher than other safety climate studies in the construction industry in Indonesia, which ranged from 3.14 to 3.76. The higher safety climate perception of gas station workers may be influenced by the high-risk characteristic of the workplace. Gas stations store flammable materials, which can cause fire and explosion [

18]. The management team and workers in this sector are more aware that they are facing a risk of higher severity than other sectors. Moreover, in the construction sector, much of the workers have had lower educational background or no formal education [

50], while gas stations are dominated by workers that are high school alumnus [

14]. Educational background has been proven to significantly affect employee perception on safety [

27].

Management commitment and communication were the two dimensions with the highest scores, showing that gas station owners and management have good commitment to safety, and they can communicate safety issues well with their employees. This result is similar to other safety climate studies in other sectors in Indonesia [

50,

69,

70]. To improve management commitment, the management team must demonstrate their commitment to health and safety by providing sufficient resources, including budget availability, and prioritize safety over production [

50]. Furthermore, the management commitment must be channeled through the middle management, i.e., supervisors, and ensure that supervisors maintain a close relationship with workers because the supervisor–worker relationship has a positive influence in reducing safety violations [

71].

The next two highest safety climate dimensions are supportive environment and training. A study on cross culture by Hofstede Insights reveals that Indonesia is a collectivist society, which means Indonesians prefer to act as groups, instead of as individuals [

72]. This also affects the supportive environment in an organization as people tend to look out for each other. Training dimension also had a similar score of slightly above four. This shows that the workers feel they have had enough training and have been given enough knowledge to do their work. Interestingly, a study by Wibowo et al. [

14] shows that more than a quarter of gas station workers in fuel stations did not receive adequate training. Therefore, this dimension still needs attention to make sure all employees receive sufficient training.

The last two dimensions that had the lowest scores are personal accountability and rules and procedures. Therefore, corrective action is required to make all rules and procedures available, easily accessible, and well understood by all gas station employees. This is an important aspect to make sure a high standard of safety is implemented during operations and get them prepared in an event of emergency. The personal accountability dimension has the lowest score, and the value is far from other dimensions, which needs to be addressed accordingly. In this dimension, it shows that workers do not really mind working in a high-risk environment. This might be affected by the high unemployment rate in Indonesia, which in August 2022 was a figure of 5.86% [

73]. In this case, people would consider working at a high-risk workplace to be better than being unemployed. Moreover, the fight between operational demands and safety also has a role in personal risk-taking behavior [

74]. In times when gas stations have long queues, workers tend to ignore some safety aspects so that they can work faster and serve more customers.

Table 8.

Safety climate score comparison with other sectors in Indonesia.

Table 8.

Safety climate score comparison with other sectors in Indonesia.

| Safety Climate Dimension | Current Study | Lestari * [50] | Kadir [70] | Sunindijo * [69] | Sunidijo * [69] |

|---|

| | Gas Station | Construction | Construction | Infrastructure Project | Building Project |

|---|

| Management Commitment | 4.19 | 4.02 | 4.37 | 3.96 | 4.08 |

| Communication | 4.11 | 3.95 | 4.41 | 3.89 | 4.00 |

| Rules and Procedures | 3.95 | 3.52 | 1.95 | 3.38 | 3.64 |

| Supportive Environment | 4.07 | 3.50 | 2.03 | 3.42 | 3.57 |

| Personal Accountability | 3.60 | 3.62 | 4.44 | 3.60 | 3.63 |

| Training | 4.03 | 3.87 | - ** | 3.86 | 3.87 |

| Overall score | 3.99 | 3.67 | 3.14 | 3.65 | 3.76 |

5.2. Safety Performance Analysis

From all twenty-five observation items, oil spill handling in the filling pot and oil sump area had the most finding among all sampled fuel stations. This item is part of the housekeeping category, which is considered important in establishing a safe workplace [

20]. It includes maintenance and cleaning of equipment and facilities on a regular basis. In gas stations, uncleaned oil spills may form puddles of flammable material, multiplying the risk of fire. Therefore, good housekeeping programs need to be prioritized in gas station operations management, as it has been a concern in other sectors [

21,

57,

75].

The next most prominent finding in the observation was adequate fire and emergency training. Twenty-three percent of the sampled gas stations cannot show proof of fire and emergency training. High-risk activities such as those in oil and gas industry—including gas stations—require routine drills, exercises, and refresher trainings to ensure employees have proper knowledge to make the best decisions in emergency situations [

76].

Another important finding is related to the operation and maintenance aspect. Many gas stations are unequipped with dispensing sumps―a device installed under the fuel dispenser that acts as a containment in case of spills inside the fuel dispenser―which is a critical part of the facility [

77]. In addition, work permit forms were also not available in some gas stations. Without the proper procedures in place, the risk of having an accident in maintenance activity increases. Both findings are related to management commitment. If the gas station management understands the importance of operation and maintenance, they should commit to these aspects.

Other non-compliance items, such as unauthorized activity and attachment of bonding cables during fuel unloading from trucks, are related to the consistency of implementing rules and procedures in the workplace. Many oil and gas accidents were caused by violations of safety rules and procedures [

28]. Violation of safety in one aspect, if not managed appropriately, may lead to other violations; therefore, corrective actions must be taken to minimize violations.

The observation method used in capturing safety performance has advantages that are not present in perception-based surveys such as the methods using questionnaires [

28,

29,

78]. First, it can capture actual conditions of safety compliance, not perception. Self-reported questionnaires are prone to bias because the participants can fill in the questionnaire based on how they want others to see them, instead of expressing their genuine thoughts or feelings [

38]. Second, the recommendations after observation can be clear, without the need of complex interpretations. With clear recommendations, the organization can plan corrective actions more accurately, and improvement results can be observed immediately [

62].

5.3. Safety Climate Influence on Safety Performance

Previous studies have found that management commitment has positive influence on safety performance [

23,

79,

80]. One form of management commitment that can be sensed by workers is through the leadership of site supervisors or managers. Good leadership traits of direct supervisors can affect workers’ willingness to perform better and comply to organization rules [

80]. Good leaders communicate with their subordinates. They give them guides and involve them in safety discussions and decision making [

81]. This involvement keeps the workers engaged and makes them feel equally responsible for workplace safety. On the other hand, unresponsible leaders create unpleasant ambience in the workplace. Leaders who fail to communicate well and create strong bonds with their employees will provoke a low-trust environment. When this is the case, it would be tough to achieve a high level of safety performance because the workers become rebellious and violate rules as an expression of dislike to their leaders.

Communication also showed positive influence on safety performance, and this dimension supports other dimensions of safety climate. As discussed earlier, management commitment needs to be communicated clearly to the workers. There are many types of communication media to choose from, e.g., verbal communication through safety talks and discussion, written communication by letters or posters, or even audio-visual through social media. The key to effective communication is to select the most appropriate means by considering the type and background (cultural and educational) [

27]. Management and supervisors should also consider two-way communication with workers [

2].

Personal accountability is the next dimension that has influence on safety performance. In this dimension, workers’ involvement, personal responsibility, and personal perception of risk is explored. This dimension affects safety performance because it is a representation of one’s values and norms, which will be manifested into action, whether it is to comply or violate safety rules. A worker may tend to comply to safety when he is positioned in a safety-strict environment but act differently in a looser environment. There is a link to management commitment and communication. Therefore, personal accountability to safety must be developed for every person in an organization.

The three other dimensions that were not significant in influencing safety performance are rules and procedures, supportive environment, and training. An organization may have various rules and procedures in place, but going by the book again requires commitment, communication, and personal will. The same goes for training. Providing long hours of training does not change people instantly. It is the commitment of making sure improvements are made and communicating the importance of some issues that will force workers to improve in safety performance. The low influence of supportive environment on safety performance might be related to personal accountability in safety. Workers struggling with their own personal perceptions on safety might not encourage others to work safely. Nevertheless, the low effects of these three dimensions must be investigated further in future research.

6. Limitations, Implications, and Future Research

This study showed the influence of safety climate dimensions on safety performance through structured observation. Even though conducting observations gives unbiased information on what is really happening in terms of safety performance, it needs more effort. With limited resources of the research team, this study was applied to a limited number of samples and had to use convenient sampling. Furthermore, the use of observation methods as a performance indicator must be improved, for example, by doing multiple observations in one subject comparing just once as performed in this study.

This method also has its drawbacks. First, the accuracy of safety performance is highly influenced by the items used in the observation. Therefore, observation items must be formulated contentiously, and must be reviewed from time to time. Secondly, spot observations only capture the conditions in that time, and thus it may not represent the overall condition. For example, observation done at an early shift schedule might result differently compared to near the end of a shift. In this case, the workers’ fatigue may affect their behavior regarding safety compliance. Third, if somehow the workers realize that they are being observed, behavior change may also occur. Therefore, these limitations must be addressed in future studies using this method.

However, this study has positive theoretical implications. The findings confirm that safety climate has a positive influence on safety performance [

78] in gas stations, an area that has rarely been investigated previously. This research also proposed a new practical method for assessing safety performance. By conducting observations directly, any recommendations for improvement or correction can be more practical and less conceptual. The structured observation checklist can be used by gas station companies as a reference in conducting safety observations on their sites.

Next research should combine different methods of safety performance assessment and compare them in one study so the indicator of safety performance can be improved. Further study of safety climate and safety performance should also be made in other sectors and different regions to enrich the research field.

7. Conclusions

In this study, it was shown that the sampled gas stations had good safety climates. From the six dimensions of safety climate, management commitment, safety communication, supportive environment, and training have good scores (above 4.00). Rules and procedures barely reached 4.00, but the dimension of personal accountability fell to 3.60. This provides the knowledge that on average, gas station management already has a good commitment to safety, and they have communicated it well to the workers. The working environment between workers and their supervisors is supportive towards safety, and training has been conducted quite well. Moreover, rules and procedures are available but need more dissemination to the workers. Nevertheless, these good efforts failed to drive the workers’ inner self to comply completely with the safety standards. Therefore, more thorough evaluation is critical to increase the personal accountability dimension.

The safety performance of gas stations is also good, as can be seen from the fact that no gas station had more than six failed items in the safety performance observations. However, there were the top ten similar failed items that need to be addressed. The top three findings regarded oil-spill handling, safety training, and safety equipment. The finding in this section further supports the safety climate findings where personal accountability on safety is an issue.

Finally, after analyzing the relationship between safety climate and safety performance, it was shown that only three out of six dimensions of safety climate had a significant effect on safety performance, which were management commitment, safety communication, and personal accountability. In this case, the low scores of personal accountability dimension drags the safety performance down, although safety commitment and safety communications have been developed quite well. Therefore, a decent amount of effort is needed to align the workers’ perception of safety with those of the managements and supervisors. By doing so, improvement in personal accountability might also increase safety performance.

Author Contributions

Conceptualization, F.L. and R.M.; methodology, F.L. and A.W.; validation, F.L., R.M. and R.Y.S.; formal analysis, F.L. and R.M.; writing—original draft preparation, A.W.; writing—review and editing, F.L., R.M. and R.Y.S.; supervision, R.Y.S.; project administration, R.M.; funding acquisition, F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Universitas Indonesia International Research Collaboration Grant number [NKB-1437/UN2.RST/HKP.05.00/2022].

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Research and Community Engagement Ethical Committee, Faculty of Public Health Universitas Indonesia (No. Ket-518/UN2.F10.D11/PPM.00.02/2023).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The dataset utilized and/or analyzed during the present study is available on reasonable request from the corresponding author.

Acknowledgments

The authors would like to thank the Occupational Safety and Health Department, Faculty of Public Health, Universitas Indonesia, Indonesian National Oil Company, participating gas stations, and all the respondents participating in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Page, C. Creeslough: Ten Dead after Donegal Petrol Station Explosion. Available online: https://www.bbc.com/news/world-europe-63183510 (accessed on 20 November 2022).

- Wibowo, A.; Lestari, F.; Modjo, R. Preventing fuel station accidents: The importance of community involvement. IOP Conf. Ser. Earth Environ. Sci. 2022, 1111, 012077. [Google Scholar] [CrossRef]

- Ariadi, R. Mobil Pikap Hangus Saat SPBU Di Toraja Utara Terbakar, Sopir Kritis. Available online: https://www.detik.com/sulsel/berita/d-6556644/mobil-pikap-hangus-saat-spbu-di-toraja-utara-terbakar-sopir-kritis (accessed on 9 April 2023).

- Negara, A.E.P. SPBU Nusa Ceningan Terbakar, Asap Hitam Tebal Membubung. Available online: https://www.detik.com/bali/berita/d-6559855/spbu-nusa-ceningan-terbakar-asap-hitam-tebal-membubung (accessed on 9 April 2023).

- Minarni, N.P. Nusa Penida Dalam Angka; Badan Pusat Statistik Kabupaten Klungkung: Klungkung, Indonesia, 2022. [Google Scholar]

- Dampak Kebakaran SPBU Ceningan: Stok Terbatas-Beli BBM Ke Nusa Penida Api Muncul Dari Motor Warga. Available online: https://www.detik.com/bali/berita/d-6561171/dampak-kebakaran-spbu-ceningan-stok-terbatas-beli-bbm-ke-nusa-penida (accessed on 9 April 2023).

- Cezar-vaz, M.R.; Rocha, L.P.; Bonow, C.A. Risk Perception and Occupational Accidents: A Study of Gas Station Workers in Southern Brazil. Int. J. Environ. Res. Public Health 2012, 9, 2362–2377. [Google Scholar] [CrossRef]

- Heng, L.; Longfu, Z.; Kaiyou, Y. Statistic analysis of safety accidents in filling stations based on big data. In Proceedings of the 3rd International Conference on Data Science and Information Technology, Xiamen, China, 24–26 July 2020; ACM International Conference Proceeding Series. Software Department, Chongqing Institute of Engineering: Chongqing, China, 2020. [Google Scholar]

- Data Indonesia Berapa Jumlah SPBU Di Indonesia? Available online: https://dataindonesia.id/sektor-riil/detail/berapa-jumlah-spbu-di-indonesia (accessed on 13 October 2022).

- Jaekel, C.; Verfondern, K.; Kelm, S.; Jahn, W.; Allelein, H.-J. 3D Modeling of the Different Boiling Regimes during Spill and Spreading of Liquid Hydrogen. Energy Procedia 2012, 29, 244–253. [Google Scholar] [CrossRef]

- Wachid, A.N.; Sampurna, B.; Rahman, A.F.; Octovia, A.; Sulistomo, T.R.; Kusumo, C.A.; Wibowo, M.A.; Murdaningsih, A.; Indriyaningsih, E.; Tisha, V.A.; et al. Keselamatan SPBU: Pedoman Teknis Dan Pembelajaran Dari Kejadian; Direktorat Jenderal Minyak dan Gas Bumi: Jakarta, Indonesia, 2018. [Google Scholar]

- Zohar, D. Safety Climate in Industrial Organizations: Theoretical and Applied Implications. J. Appl. Psychol. 1980, 65, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Huang, Y.; Tao, J.; Reniers, G.; Chen, C. Visualized Analysis of Safety Climate Research: A Bibliometric Data Mining Approach. Saf. Sci. 2023, 158, 105973. [Google Scholar] [CrossRef]

- Wibowo, A.; Lestari, F.; Modjo, R. Safety Climate Assessment in Fuel Stations in the West Java Region. Safety 2023, 9, 9. [Google Scholar] [CrossRef]

- Rahman, A.; Daryanto, E.; Aini, N. Pengaruh Safety Leadership dan Safety Climate Melalui Safety Behavior. J. Kesehat. Kedokt. 2023, 2, 20–28. [Google Scholar] [CrossRef]

- Pousette, A.; Larsson, S.; Törner, M. Safety Climate Cross-Validation, Strength and Prediction of Safety Behaviour. Saf. Sci. 2008, 46, 398–404. [Google Scholar] [CrossRef]

- Yurismono, H.; Sumarsono, D.A.; Indradjaja, I.M.; Nugroho, S. Development of Lower Flammability Limits Testing Apparatus for Gasoline Vapor—Air Mixture Using an Internal Vaporizer at Ambient Conditions. Transp. Res. Interdiscip. Perspect. 2022, 14, 100613. [Google Scholar] [CrossRef]

- Ma, G.; Huang, Y. Safety Assessment of Explosions during Gas Stations Refilling Process. J. Loss Prev. Process Ind. 2019, 60, 133–144. [Google Scholar] [CrossRef]

- Ahrens, M. Service or Gas Station Fires; National Fire Protection Association: Quincy, MA, USA, 2020. [Google Scholar]

- Mohsin, M.; Zhan-ao, W.; Shijun, Z.; Weilun, H.; Hengbin, Y. Risk Prioritization and Management in Gas Stations by Using Fuzzy AHP and IPA Analysis. J. Sci. Ind. Res. 2021, 80, 1107–1116. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Kutty, S.R.M.; Khamidi, M.F.; Othman, I.; Sharif, A.M. Hazard Contributing Factors Classification for Petrol Fuel Station. Int. J. Civ. Environ. Eng. 2012, 6, 1103–1114. [Google Scholar] [CrossRef]

- Bhandari, S.; Hallowell, M.R. Influence of Safety Climate on Risk Tolerance and Risk-Taking Behavior: A Cross-Cultural Examination. Saf. Sci. 2022, 146, 105559. [Google Scholar] [CrossRef]

- Syed-yahya, S.N.N.; Idris, M.A.; Noblet, A.J. The Relationship between Safety Climate and Safety Performance: A Review. J. Saf. Res. 2022, 83, 105–118. [Google Scholar] [CrossRef] [PubMed]

- Kapp, E.A. The Influence of Supervisor Leadership Practices and Perceived Group Safety Climate on Employee Safety Performance. Saf. Sci. 2012, 50, 1119–1124. [Google Scholar] [CrossRef]

- Bamel, U.K.; Pandey, R.; Gupta, A. Safety Climate: Systematic Literature Network Analysis of 38 Years (1980-2018) of Research. Accid. Anal. Prev. 2020, 135, 105387. [Google Scholar] [CrossRef]

- Han, B.; Son, S.; Kim, S. Measuring Safety Climate in the Construction Industry: A Systematic Literature Review. Sustainability 2021, 13, 10603. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, W.; Li, Z.; Hu, X. Influencing Factors, Mechanism and Prevention of Construction Workers’ Unsafe Behaviors: A Systematic Literature Review. Int. J. Environ. Res. Public Health 2021, 18, 2644. [Google Scholar] [CrossRef]

- Kvalheim, S.A.; Dahl, Ø. Safety Compliance and Safety Climate: A Repeated Cross-Sectional Study in the Oil and Gas Industry. J. Saf. Res. 2016, 59, 33–41. [Google Scholar] [CrossRef]

- Dahl, Ø.; Kongsvik, T. Safety Climate and Mindful Safety Practices in the Oil and Gas Industry. J. Saf. Res. 2018, 64, 29–36. [Google Scholar] [CrossRef]

- Rasmussen, H.B.; Ahsan, D.; Rasmussen, H.B. The Safety Programme as a Tool of Improvement for Safety Culture in the Workplace: An Exploratory Follow-up Study from the Danish Offshore Oil and Gas Sector an Exploratory Follow-up Study from the Danish Offshore Oil and Gas Sector. Int. J. Occup. Saf. Ergon. 2022, 28, 2173–2182. [Google Scholar] [CrossRef] [PubMed]

- Lefsrud, L.M.; McLarnon, M.J.W.; Gellatly, I.R. A Pattern-Oriented Approach to Safety Climate: An Empirical Example. Saf. Sci. 2021, 142, 105385. [Google Scholar] [CrossRef]

- Stackhouse, M.; Turner, N. How Do Organizational Practices Relate to Perceived System Safety Effectiveness? Perceptions of Safety Climate and Co-Worker Commitment to Safety as Workplace Safety Signals. J. Saf. Res. 2019, 70, 59–69. [Google Scholar] [CrossRef] [PubMed]

- Bensonch, C.; Argyropoulos, C.D.; Dimopoulos, C.; Varianou Mikellidou, C.; Boustras, G. Analysis of Safety Climate Factors and Safety Compliance Relationships in the Oil and Gas Industry. Saf. Sci. 2022, 151, 105744. [Google Scholar] [CrossRef]

- Almazrouei, M.; Khalid, K.; Davidson, R. Safety Climate of UAE Petroleum Industry: A Cross-Validation Using Confirmatory Factor Analytic Approach. J. Eng. Des. Technol. 2020, 19, 943–965. [Google Scholar] [CrossRef]

- Omidi, N.; Jafari Eskandari, M.; Omidi, M.R. The Effect of Safety Training Intervention on Safety Climate Among the Operational Staff of West Oil and Gas Company. Health Emergencies Disasters Q. 2021, 7, 15–20. [Google Scholar] [CrossRef]

- Mirza, M.Z.; Isha, A.S.N. Safety-Specific Transformational Leadership, Safety Climate and Occupational Accidents. J. Appl. Struct. Equ. Model. 2020, 4, 44–52. [Google Scholar] [CrossRef]

- Krasniqi, V.; Hoxha, A. The Effect of Psychosocial Safety Climate on Work Engagement Through Possibilities for Development and Cognitive Demands. IFAC-PapersOnLine 2022, 55, 88–93. [Google Scholar] [CrossRef]

- Bakidamteh, S.A.; Teye-kwadjo, E. Understanding the Role of Proactive Personality in Occupational Health and Safety at Oil and Gas Service Stations in Accra. SAGE Open 2022, 12, 215824402210899. [Google Scholar] [CrossRef]

- Ansah, E.W.; Kwarteng, J.; Mensah, O. Mediating Effect of Psychosocial Safety Climate and Job Resources in the Job Demands-Health Relation: Implications for Contemporary Business Management. Am. Int. J. Bus. Manag. 2020, 3, 74–83. [Google Scholar]

- Kines, P.; Lappalainen, J.; Mikkelsen, K.L.; Olsen, E.; Pousette, A.; Tharaldsen, J.; Tómasson, K.; Törner, M. Nordic Safety Climate Questionnaire (NOSACQ-50): A New Tool for Diagnosing Occupational Safety Climate. Int. J. Ind. Ergon. 2011, 41, 634–646. [Google Scholar] [CrossRef]

- Sexton, J.B.; Helmreich, R.L.; Neilands, T.B.; Rowan, K.; Vella, K.; Boyden, J.; Roberts, P.R.; Thomas, E.J. The Safety Attitudes Questionnaire: Psychometric Properties, Benchmarking Data, and Emerging Research. BMC Health Serv. Res. 2006, 6, 44. [Google Scholar] [CrossRef] [PubMed]

- Kalteh, H.O.; Mortazavi, S.B.; Mohammadi, E.; Salesi, M. The Relationship between Safety Culture and Safety Climate and Safety Performance: A Systematic Review. Int. J. Occup. Saf. Ergon. 2021, 27, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Interpreting the Nordic Occupational Safety Climate Questionnaire NOSACQ-50 Results. Available online: https://nfa.dk/da/Vaerktoejer/Sporgeskemaer/Safety-Climate-Questionnaire-NOSACQ50/How-to-use-NOSACQ50/Interpreting-NOSACQ50-results (accessed on 28 November 2022).

- Rifqi, M.; Yuni, M.; Bangun, R. Influence of Job Stress and Safety Climate on Safety Performance in Indonesia Rock Mining Company. Int. J. Appl. Bus. 2022, 6, 77–89. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Abbas, D.; Takahashi, T. Safety Climate and Risk Perception of Forestry Workers: A Case Study of Motor-Manual Tree Felling in Indonesia Motor-Manual Tree Felling in Indonesia. Int. J. Occup. Saf. Ergon. 2022, 28, 2193–2201. [Google Scholar] [CrossRef]

- Ningrum, E.; Evans, S.; Soh, S.-E. Validation of the Indonesian Version of the Safety Attitudes Questionnaire: A Rasch Analysis. PLoS ONE 2019, 14, e0215128. [Google Scholar] [CrossRef]

- Juliawati, M.; Darwita, R.R.; Adiatman, M.; Lestari, F. Patient Safety Culture in Dentistry Analysis Using the Safety Attitude Questionnaire in DKI Jakarta, Indonesia: A Cross-Cultural Adaptation and Validation Study. J. Patient Saf. 2022, 18, 486–493. [Google Scholar] [CrossRef]

- Indarwati, R.; Fauziningtyas, R.; Jalaludin, N.S.; Fauziah, A.; Efendi, F. The Factor of Resident Safety Culture in Nursing Homes in Indonesia. Work. Older People 2023, 27, 91–98. [Google Scholar] [CrossRef]

- Patrick, X.W.; Zou, R.Y.S. Safety climate and culture. In Strategic Safety Management in Construction and Engineering; Wiley Online Books; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 53–85. ISBN 9781118839362. [Google Scholar]

- Lestari, F.; Sunindijo, R.Y.; Loosemore, M.; Kusminanti, Y. A Safety Climate Framework for Improving Health and Safety in the Indonesian Construction Industry. Int. J. Environ. Res. Public Health 2020, 17, 7462. [Google Scholar] [CrossRef]

- Loosemore, M.; Sunindijo, R.Y.; Lestari, F.; Kusminanti, Y.; Widanarko, B. Comparing the Safety Climate of the Indonesian and Australian Construction Industries: Cultural and Institutional Relativity in Safety Research. Eng. Constr. Archit. Manag. 2019, 26, 2206–2222. [Google Scholar] [CrossRef]

- Martin, L.; Yosia, S.R.; Shang, Z. Comparative Analysis of Safety Climate in the Chinese, Australian, and Indonesian Construction Industries. J. Constr. Eng. Manag. 2020, 146, 04020129. [Google Scholar] [CrossRef]

- Elsebaei, M.; Elnawawy, O.; Othman, A.; Badawy, M. Elements of Safety Management System in the Construction Industry and Measuring Safety Performance—A Brief. IOP Conf. Ser. Mater. Sci. Eng. 2020, 974, 012013. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hainen, A.; Alzarrad, A. Incident Analysis and Prediction of Safety Performance on Construction Sites. CivilEng 2022, 3, 669–686. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Bhandari, S.; Alruqi, W. Methods of Safety Prediction: Analysis and Integration of Risk Assessment, Leading Indicators, Precursor Analysis, and Safety Climate. Constr. Manag. Econ. 2020, 38, 308–321. [Google Scholar] [CrossRef]

- Salas, R.; Hallowell, M. Predictive Validity of Safety Leading Indicators: Empirical Assessment in the Oil and Gas Sector. J. Constr. Eng. Manag. 2016, 142, 04016052. [Google Scholar] [CrossRef]

- Xu, J.; Cheung, C.; Manu, P.; Ejohwomu, O.; Too, J. Implementing Safety Leading Indicators in Construction: Toward a Proactive Approach to Safety Management. Saf. Sci. 2023, 157, 105929. [Google Scholar] [CrossRef]

- Ali, M.X.M.; Arifin, K.; Abas, A.; Ahmad, M.A.; Khairil, M.; Cyio, M.B.; Samad, M.A.; Lampe, I.; Mahfudz, M.; Ali, M.N. Systematic Literature Review on Indicators Use in Safety Management Practices among Utility Industries. Int. J. Environ. Res. Public Health 2022, 19, 6198. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Misra, S.C.; Kumar, V.; Kumar, U. Identification and Ordering of Safety Performance Indicators Using Fuzzy TOPSIS: A Case Study in Indian Construction Company. Int. J. Qual. Reliab. Manag. 2022, 39, 77–114. [Google Scholar] [CrossRef]

- Griffin, M.A.; Neal, A. Perceptions of Safety at Work: A Framework for Linking Safety Climate to Safety Performance, Knowledge, and Motivation. J. Occup. Health Psychol. 2000, 5, 347–358. [Google Scholar] [CrossRef]

- Gunduz, M.; Laitinen, H. Observation Based Safety Performance Indexing Method for Construction Industry—Validation with SMEs. KSCE J. Civ. Eng. 2018, 22, 440–446. [Google Scholar] [CrossRef]

- Bhagwat, K.; Delhi, V.S.K.; Nanthagopalan, P. Construction Safety Performance Measurement Using a Leading Indicator-Based Jobsite Safety Inspection Method: Case Study of a Building Construction Project. Int. J. Occup. Saf. Ergon. 2022, 28, 2645–2656. [Google Scholar] [CrossRef] [PubMed]

- Yuan, B.; Xu, S.; Chen, L.; Niu, M. How Do Psychological Cognition and Institutional Environment Affect the Unsafe Behavior of Construction Workers ?— Research on FsQCA Method. Front. Psychol. 2022, 13, 875348. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.M.; Kutty, S.R.M.; Khamidi, M.F.; Othman, I.; Dominic, P.D.D.; Emmanuel, O. Hazards Forecasting and Weights Determination during Operation and Maintenance of Petrol Fuel Station. Res. J. Appl. Sci. Eng. Technol. 2013, 6, 978–982. [Google Scholar] [CrossRef]

- Bewick, V.; Cheek, L.; Ball, J. Statistics Review 7: Correlation and Regression. Crit. Care 2003, 7, 451–459. [Google Scholar] [CrossRef]

- Memarbashi, E.; Mohammadizadeh, F.; Boroujeny, Z.A.; Lotfi, M.; Khodayari, M.T.; Nasiri, E.; Akhuleh, O.Z. The Relationship between Nurses’ Safety Climate in the Operating Room and Occupational Injuries: A Predictive Correlational Study. Perioper. Care Oper. Room Manag. 2021, 24, 100206. [Google Scholar] [CrossRef]

- Wu, T.C.; Chen, C.H.; Li, C.C. A Correlation among Safety Leadership, Safety Climate and Safety Performance. J. Loss Prev. Process Ind. 2008, 21, 307–318. [Google Scholar] [CrossRef]

- Wagenmakers, E.-J.; Ly, A.; Boutin, B.; Goosen, J.; van den Bergh, D.; Kucharský, Š.; Dofferhoff, R.; Derks, K.; van Doorn, J.; Bartoš, F.; et al. JASP, version 0.16.4. Computer Software. University of Amsterdam: Amsterdam, The Netherlands, 2022.

- Sunindijo, R.Y.; Loosemore, M.; Lestari, F.; Kusminanti, Y.; Widanarko, B.; Febrina, C.; Amelia, F. Comparing Safety Climate in Infrastructure and Building Projects in Indonesia. MATEC Web Conf. 2019, 258, 02024. [Google Scholar] [CrossRef]

- Kadir, A.; Lestari, F.; Sunindijo, R.Y.; Erwandi, D.; Kusminanti, Y.; Modjo, R.; Widanarko, B.; Ramadhan, N.A. Safety Climate in the Indonesian Construction Industry: Strengths, Weaknesses, and Influential Demographic Characteristics. Buildings 2022, 12, 639. [Google Scholar] [CrossRef]

- Su, Y.; Cong, W.; Liang, H. The Impact of Supervisor–Worker Relationship on Workers’ Safety Violations: A Modified Theory of Planned Behaviour. J. Civ. Eng. Manag. 2019, 25, 631–645. [Google Scholar] [CrossRef]

- Country Comparison—Indonesia. Available online: https://www.hofstede-insights.com/country-comparison/indonesia/ (accessed on 15 March 2023).

- Agustus 2022: Tingkat Pengangguran Terbuka (TPT) Sebesar 5.86 Persen Dan Rata-Rata Upah Buruh Sebesar 3.07 Juta Rupiah per Bulan. Available online: https://www.bps.go.id/pressrelease/2022/11/07/1916/agustus-2022--tingkat-pengangguran-terbuka--tpt--sebesar-5-86-persen-dan-rata-rata-upah-buruh-sebesar-3-07-juta-rupiah-per-bulan.html (accessed on 15 March 2023).

- Chen, H.; Li, H.; Goh, Y.M. A Review of Construction Safety Climate: Definitions, Factors, Relationship with Safety Behavior and Research Agenda. Saf. Sci. 2021, 142, 105391. [Google Scholar] [CrossRef]

- Beus, J.M.; Payne, S.C.; Jr, W.A.; Muñoz, G.J. The Development and Validation of a Cross-Industry Safety Climate Measure: Resolving Conceptual and Operational Issues. J. Manag. 2019, 45, 1987–2013. [Google Scholar] [CrossRef]

- Nwankwo, C.D.; Arewa, A.O.; Theophilus, S.C.; Esenowo, V.N. Analysis of Accidents Caused by Human Factors in the Oil and Gas Industry Using the HFACS-OGI Framework ABSTRACT. Int. J. Occup. Saf. Ergon. 2022, 28, 1642–1654. [Google Scholar] [CrossRef] [PubMed]

- A Guide for Service Station Operators under the Work Health and Safety Act 2011 Version 3; Workplace Health and Safety Queensland: Brisbane, Australia, 2018.

- Neal, A.; Griffin, M.; Hart, P. The Impact of Organizational Climate on Safety Climate and Individual Behavior. Saf. Sci. 2000, 34, 99–109. [Google Scholar] [CrossRef]

- Vithanage, S.C.; Sing, M.C.P.; Davis, P.; Newaz, T. The Influence of Organisational Safety Climate Factors on Offsite Manufacturing Safety Performance. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 042028. [Google Scholar] [CrossRef]

- Asad, M.; Kashif, M.; Sheikh, U.A.; Asif, M.U.; George, S.; Khan, G.u.H. Synergetic Effect of Safety Culture and Safety Climate on Safety Performance in SMEs: Does Transformation Leadership Have a Moderating Role? Int. J. Occup. Saf. Ergon. 2022, 28, 1858–1864. [Google Scholar] [CrossRef]

- Saleem, F.; Malik, M.I. Safety Management and Safety Performance Nexus: Role of Safety Consciousness, Safety Climate, and Responsible Leadership. Int. J. Environ. Res. Public Health 2022, 19, 13686. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

.jpeg)