1. Introduction

Although numerous new technologies have been introduced onboard seagoing ships and in the seaborne transport system to reduce the number of accidents and improve safety, accidents at sea continue to occur. Shipping is considered to be a high-risk industry and its stakeholders are required to prevent accidents. The analysis of accidents involving seagoing ships indicates an active approach to accident reduction, i.e., accidents are investigated to reveal their root causes and therefore implement corrective measures that can reduce the risk of accident recurrence. However, this knowledge is mainly based on accidents and does not take into consideration events or dangerous occurrences that could lead to accidents. These events, which include near-misses, and consequent insights could also constitute an excellent approach to accident prevention based on a proactive approach. Therefore, the development of an efficient near-miss management system is beneficial for accident prevention and safety improvement in general. Near-miss reporting and analysis, and the implementation of adequate corrective measures based on investigation results, can prevent the recurrence of near-misses and accidents with the same root cause. Near-misses can be used for learning about and the prevention of possible accidents [

1].

Because near-misses are the precursors of accidents, the investigation and analysis of near-misses represent a proactive approach to the reduction in accidents [

2] and near-misses can be considered a leading indicator of a company’s safety performance [

3]. An accident is an exceptional event at sea with harmful consequences that places human lives, property, and the environment in immediate danger. In comparison, a near-miss is an exceptional event at sea that may have caused harm to human lives, property, and the maritime environment, but did not [

4,

5]. The International Maritime Organization (IMO) defines a near-miss as a chain of events that could have resulted in negative consequences, which were prevented by a lucky interruption of a sequence of events. Unrealized negative consequences, for example, could be injury, environmental pollution, or a negative impact on a company’s business [

4,

6,

7]. Craig et al. [

6] indicate that near-misses may be caused by inadequate training, human error, flawed or poor design, management errors, flawed procedures or systems, unanticipated outcomes, or any combination of the above.

There is a particular interest in near-miss events in high-risk industries, such as nuclear power plants, chemical production, civil aviation, health care, oil and gas, and transportation. Because international shipping is considered to be a high-risk industry, due attention must be paid to near-misses in this context.

Near-miss reporting is the focus of numerous research studies. Erdoğan [

8] identified the best near-miss reporting systems and determined the barriers to reducing the number of near-misses. The paper assumes that near-misses on ships are not reported in the manner expected and attempts to identify reasons for this lack of reporting. The results show that the surveyed companies instilled a no-blame culture and, by open communication and learning from mistakes and near-misses, increased the level of safety.

Storgard, Erdoğan, and Tapaninen [

9] claimed that serious accidents can be avoided by implementing the conclusions drawn from their analysis of accidents and near-misses. The objective of their paper was to demonstrate best practices in near-miss reporting, with the support of the shipping industry, for the better utilization of reported near-miss data. The authors of the paper set out the following prerequisites for the existence of a functional reporting system: the existence of a no-blame culture; commitment by company management to increase safety; good communication; feedback; training; and a system that is easy to use.

Vepsalainen and Lappalainen [

4] expected an increase in maritime traffic in the Baltic Sea, and therefore an increase in the risk of serious accidents. The study results indicated a lack of reports of accidents and near-misses, inconsistency in the maritime terminology related to accidents and near-misses, an uneven relationship in the flow of accident and near-miss data between ships and shore systems (i.e., the flow was predominantly from ships to shore systems), and the need for unification of Finnish accident and near-miss databases.

Kongsvik, Fenstad, and Wendelborg [

10] investigated the reporting of accidents and near-misses on offshore service vessels. The paper proves that there is a negative relationship between the observed external efficiency requirements and reporting levels; the higher the observed efficiency requirements, the lower the reporting level. It was also acknowledged that better reporting feedback increases the level of reporting and short-term seafarers’ contracts are associated with lower levels of reporting.

Oltedal and McArthur [

11] analyzed reporting practices in merchant shipping and identified the factors that influence the reporting frequency. According to the research results, enhanced safety-related training, trusting relationships among crewmembers, safety-oriented management, and feedback on reported near-misses are positively related to a higher reporting frequency. Conversely, a lower reporting frequency is related to a lack of attention paid to safety and demand for efficiency by shore management.

The IMO recognizes the importance of near-miss reporting, and via the International Safety Management (ISM) Code, it seeks to develop, implement, and maintain a safety management system. Near-miss reporting and the creation of an organizational atmosphere in which actors are willing to report are two of this system’s functional requirements [

5,

12]. However, despite IMO requirements and company policies regarding reporting, seafarers do not report appropriately [

4,

13,

14]. The indicators identified that near-miss reporting is deficient due to the following factors [

15]:

Seafarers conduct reporting as a regular checklist procedure;

Numerous meaningless reports are made;

Seafarers believe that reporting does not support improvements in safety;

Seafarers are afraid of being punished for reporting;

Reporting is considered to be unnecessary extra work.

Although most companies have written procedures prescribing reporting obligations within the safety management system, it has also been shown that they have not improved the reporting procedure [

4,

13,

14].

According to the literature review, barriers that prevent seafarers from reporting include, but are not limited to, inadequate knowledge on identifying a near-miss, the existence of blame culture (fear of blame and punishment), cultural differences, the leadership style, a lack of shore management commitment (poor feedback on previous near-miss reports, near-miss training not provided, or corrective actions not implemented), and the complexity of the near-miss reporting form [

9,

16,

17,

18,

19,

20,

21,

22,

23].

Considering the aforementioned points, this research focused on seafarers’ knowledge on identifying a near-miss occurrence, the existence of blame culture, and the complexity of reporting forms; these can be seen as the most prominent obstacles to appropriately dealing with near-miss reporting procedure and practice.

To report a near-miss, seafarers need to have adequate knowledge that enables them to identify a near-miss event and an understanding of possible near-miss consequences, because inadequate knowledge acts as a barrier to reporting and prevents the possibility of learning from incidents and improvement of shipboard safety [

11].

Fear of blaming and criticizing is a barrier that the ship’s leadership must attempt to overcome in order to increase the number of reported near-misses [

11,

22,

23,

24,

25,

26]. In a survey conducted by Erdoğan, some of the chief officers stated that there was no blame culture within the company, but it was still present on some ships [

8]. Crewmembers often blame each other if they report a near-miss, which causes the reporters to feel uncomfortable and creates a poor working atmosphere, and this can disrupt teamwork onboard a ship. Additionally, crewmembers might feel ashamed if they make a mistake at work which develops into a near-miss event [

4,

9,

23]. If seafarers have a fear of social sanctions, such as shame, blame, guilt, or disciplinary actions, it could prevent them from reporting [

23].

The goal of near-miss reporting is not to assign blame to persons, but to learn from it [

16]. In other words, if a seafarer believes that their senior ranking officer or colleagues will hold a grudge against them or consider them incompetent when they report a near-miss, or even worse, blame them, they will most probably not report it. Shore management must promote a no-blame culture onboard ships and support senior officers in creating a just and reporting culture on ships [

9]. All of the aforementioned points strongly encourage the implementation of an atmosphere where individuals are not blamed for reporting, but on the contrary, are considered as promoters of a safe working environment.

Reporting is conducted through a form that serves as a reporting tool. Williamsen [

27] argues that, when creating a reporting form, it is necessary to invest effort in the following:

Literacy—Can the forms be easily read and understood?

Language—Does the company provide multilingual forms if those are necessary?

Length—Are the forms short and clear?

Location—Are the forms easily accessible to crewmembers?

Logistics—Are the forms helpful with finding solutions to problems?

Near-miss reporting forms can be created in electronic or paper form. Oltedal [

12] confirmed that it is easier for near-misses to be reported electronically, and it is then easier to control feedback on the report via this type of form [

16]. However, some seafarers have a problem with using computers, making it easier to report and control via paper-based reports and feedback [

8]. The report’s contents are important for later possible analysis and must contain all relevant information about the near-miss.

Previous research studies indicate that certain factors either improve reporting or have a negative effect on it, and thus act as a barrier. Another issue is that of underreported near-misses, which lead to valuable data being lost. By reporting and analyzing near-misses and implementing corrective actions, it is possible to prevent serious accidents and similar events in the future [

28,

29,

30]. According to the ISM Code, casualties and near-misses have to be reported to discover root causes and implement effective corrective measures.

However, there is an uneven approach to the analysis of reported cases, as well as inadequate reporting and investigations of near-misses in shipping. This is an evident problem in the shipping industry and this paper presents an overview of seafarers’ attitudes towards and knowledge of near-miss management systems. The main aim of this research is to provide a clear picture of the influence of near-miss case reporting onboard ships on the overall near-miss management. To tackle this issue, answers to the following questions need to be articulated:

Do seafarers face difficulties in identifying near-miss events?

Does a blame culture exist onboard ships and does it affect the reporting of near-misses?

Are near-miss report forms too complex for the seafarers, and are they a barrier for near-miss reporting?

Do seafarers of different ranks report equally, or do some ranks report more than the others?

Furthermore, the objective of the paper is to assess near-miss reporting systems in shipping, identifying conceivable shortcomings and best practices, and recommending measures that will improve reporting practices onboard ships which will lead to an increase in safety in shipping.

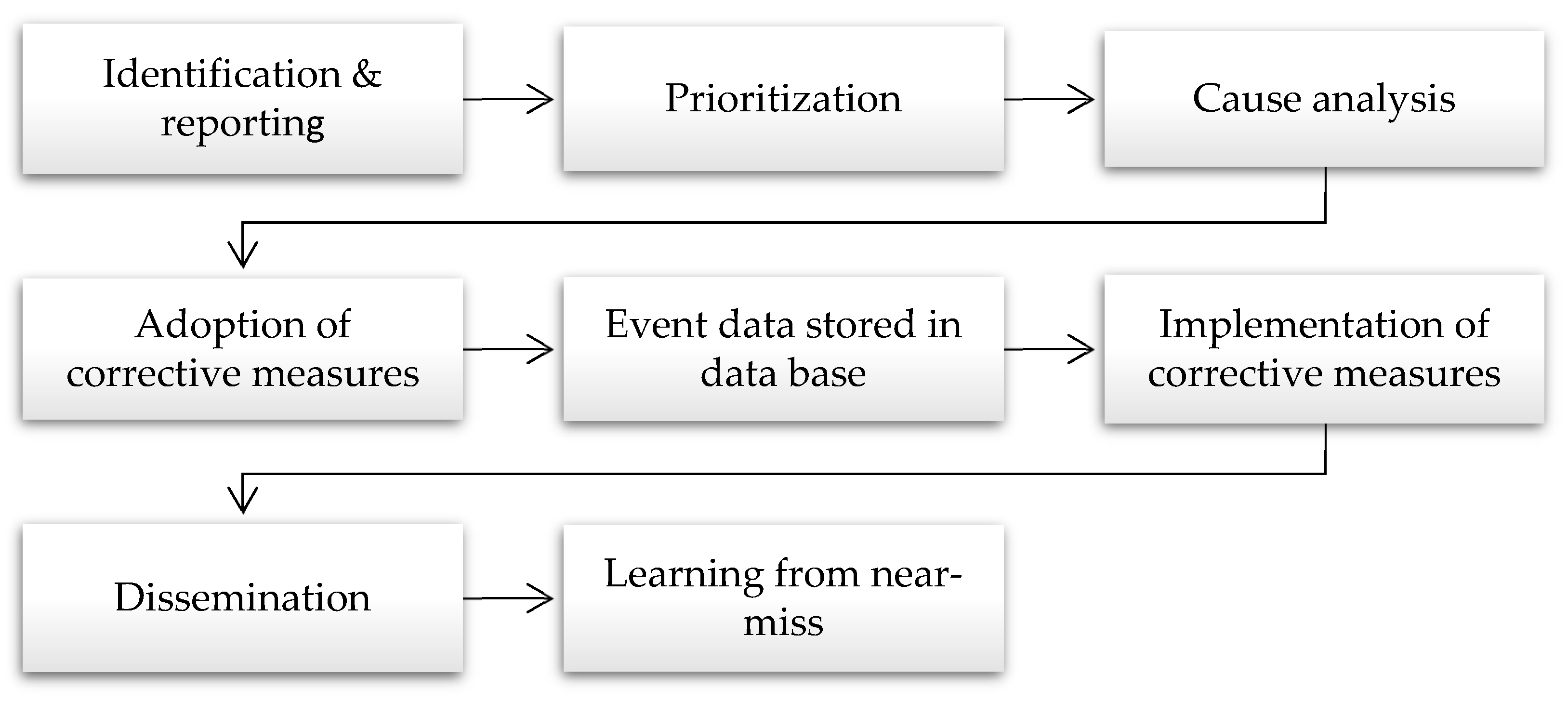

2. Near-Miss Management Systems in Shipping—An Overview

Near-miss management systems are a tool for accident prevention and by developing an effective and adequate system, the safety performance of a ship or company can be improved [

31]. Safety improvements based on near-miss events are dependent on near-miss management systems. The aim of those systems is to extract useful data from near-misses and handle them as a safety improvement tool. Near-miss management systems may vary between different industries. According to the available literature, near-miss management systems are composed of six to eight phases. After analyzing the existing literature and comparing available systems, we determined that each phase can be explained as follows:

Identification—a crewmember recognizes a near-miss event which occurred [

6,

32,

33,

34,

35,

36];

Reporting—a crewmember or master/safety officer reports the near-miss, and a reporting form is filled out [

6,

32,

33,

34,

35,

36,

37,

38];

Prioritization—assessment of the degree of attention that is to be given to the event, depth of the causation analysis, assessment of the means to be used for solution finding, and the implementation of corrective measures and the proportion of dissemination [

6,

32,

33,

34,

36,

37,

38];

Distribution—near-miss data are distributed to the person in charge of corrective actions. Data can be distributed publicly in order to increase awareness [

32,

33,

34,

35,

38];

Cause analysis—immediate and root causes are identified [

6,

32,

33,

34,

35,

36,

37].

Solution identification—corrective actions which will prevent recurrence or mitigate possible consequences are identified [

6,

32,

33,

34,

35,

36,

38];

Dissemination—corrective actions shared with persons who are in charge of their effective implementation. They can be disseminated to a broader audience in order to increase awareness and improve safety measures [

6,

32,

33,

34,

35,

37,

38];

Resolution—corrective actions are implemented and evaluated. It is important to periodically control implemented measures to ensure their adequacy and effectiveness [

32,

33,

34,

35,

36,

37,

38].

According to the aforementioned points, a comparison of near-miss management systems could be conducted (

Table 1).

Furthermore, Cooke and Rohleder developed a dynamic model of learning from near-misses and listed the management phases [

39]. In their model, the phases are identification and response, reporting, investigation, causal structure, corrective actions, learning, and dissemination. In the first phase, they add a response to the near-miss event because they consider that it is important to correct the unsafe condition resulting from a near-miss, such as providing first aid in the case of minor injuries or cleaning up a small oil spill. The causal structure is added as a separate management phase. There is usually more than one root cause, therefore their opinion is that efforts should be directed towards identifying causal relationships, which should reduce the investigation team’s temptation to make conclusions before all relevant data have been gathered and analyzed. Learning from near-misses is also added as a phase.

Following the literature review, a conceptual model of a near-miss management system in shipping could be shaped (

Figure 1).

The effectiveness of near-miss management depends on ships’ crews and shore-based safety-related management. Each of the listed management phases depends on the knowledge of crewmembers and the company’s designated person for investigating a near-miss and its positive effect on safety. To prevent incidents, it is necessary to report and disseminate near-misses and gain knowledge from lessons learnt. Near-miss identification and reporting are the first and crucial phases of an effective near-miss management system because, without them, there would not be any other phase, and valuable knowledge and benefits accepted from the near-miss implementation system would be missing. Therefore, it is of the utmost importance to enable the unhampered reporting of near-misses from ships.

The overview of a near-miss management system revealed that near-miss identification and reporting can be considered as the most important phase, whereas the inclusion of all crewmembers is of the utmost importance for the whole system. Additionally, the reporting frequency was found to be inadequate and several barriers to reporting were identified.

3. Methodology

Extensive research was carried out to determine the level, frequency, and overall near-miss reporting procedure, as well as to explain the whole reporting process and its influence on safety in shipping. The research was based on the following:

Data from the available literature review;

Data from 580 near-miss reports collected from various types of ships;

Data collected from two surveys that were distributed online (results were collected in 4 months).

To obtain a better insight into reporting practices onboard ships, 580 near-miss reports were collected from various types of ships (oil tankers, LNG tankers, and container ships). Filled reports were collected from six different shipping companies and additional empty report forms were compiled from three companies. The data obtained from reports were analyzed and incorporated into this research.

Based on the data collected from the reviewed literature and near-miss reports, conclusions were drawn, and two surveys were prepared to validate the findings. Surveys were developed based on the literature review and the authors’ expert opinions and were used as confirmation of reviewed literature data. They intended to reveal barriers and seafarers’ attitudes to near-miss reporting, as well as their knowledge of the near-miss definition. As professionals, the authors served on several types of ships and during the sea time period, they often encountered the issue of an inadequate near-miss management system. The authors’ expertise was used as a tool for the validation of survey questions. All questions within the survey were as neutral as possible to avoid stereotype bias. Furthermore, before final surveys, pilot surveys were prepared to avoid response bias. Surveys were available online (Google forms) from social media networks. A virtual snowball sampling method was used for the online survey. Several ship manning agencies were contacted and asked to send a link to an online survey to their employees so that they could distribute it further to their fellow seafarers. They could freely choose whether to participate in the surveys or not. In order to avoid biased participation, surveys were anonymous and confidential, and the authors did not offer any incentive because this could have resulted in speed runs of some respondents. The study was ethically conducted, and the protocol was approved by the Ethics Committee of University of Dubrovnik on 19 November 2020 (EA 1459/20).

The first survey was divided into three parts and consisted of open- and closed-type questions. The first part dealt with demographics (age, rank, years in rank, nationality, education, years of sea service, and type of ship on which they are serving), the second part included 25 questions regarding the near-miss management system onboard respondents’ ships, and the third part was reserved for ship safety officers and masters and consisted of 13 questions. A total of 45 questions were included in the survey to provide insight into reporting practices onboard ships, attitudes of seafarers towards reporting, and the adequacy of implemented near-miss management systems. Of the 45 questions, 23 are used in this paper because they are directly related to near-miss reporting (7 demographics questions, 15 from the second part, and 1 from the third part of the survey). Survey questions were mostly of a closed type: demographic questions; simple yes/no questions; and ranking questions (measured on a five-point Likert scale). Open-type questions were used when a definition of near-miss was asked for, as well as for comments on the survey.

The first survey was completed by 223 seafarers; 15 nationalities were represented. The majority of respondents were from Croatia (73.4%), followed by Indonesia (12.1%) and the Philippines (4.3%). In terms of age, 69.5% of seafarers were under 42. As for education, 57% of respondents declared that they had a higher maritime education and 78.4% of them had served more than five years at sea. Senior ranking officers (masters, chief engineers, chief officers, and second engineers) made up just over 50% of the respondents. Participants were serving on tankers, cruise ships, bulk carriers, and container ships.

The second survey served as a complement to the first one and was completed by 22 experienced seafarers. It aimed to measure seafarers’ knowledge of the near-miss definition. The first part of the survey tackled the demographics questions and the second part was conceived as a test and covered ten events (accidents, incidents, near-misses, unsafe acts, and unsafe conditions) taken from real-life reports and online databases. Seafarers were asked to identify each of the examples to the best of their knowledge and they were given options to choose from. To determine what the correct interpretation of a certain event was, the authors used literature for event no. 3, 6, 7, and 10, and for other events, the authors’ knowledge and experience. Four nationalities were represented, with the majority being from Croatia (70%), followed by the Philippines (20%). It was reported that 66.7% of respondents had a higher maritime education, and 76.2% had more than five years of sea service. Senior ranking officers (masters and chief officers) made up 23.8% of respondents.

The surveys and data from analyzed near-miss reports and near-miss management systems are a part of a Ph.D. research project, which deals with the enhancement of safety culture in shipping through the implementation of a near-miss management system.

4. Near-Miss Reporting Form Data

The authors collected near-miss report forms from nine shipping companies that operate various types of ships. Reporting forms should have included all data about near-miss events and their analysis should have made it possible to find corrective actions whose implementation could prevent the recurrence of an unwanted event. All collected reports were compared to see whether the same type of information was asked for from the person filling it in. An overview of data required by the collected report forms is shown in

Table 2. Due to the need for anonymity, companies were assigned letters from A to I.

Common elements found in all forms were the name of the ship, event identification, event description, and corrective action. Critical elements for learning from near-misses were the event description, immediate and root cause, and corrective actions. Moreover, different companies have an uneven approach to the drafting of near-miss report forms, which can additionally affect the reporting attitude of seafarers who frequently change employment companies.

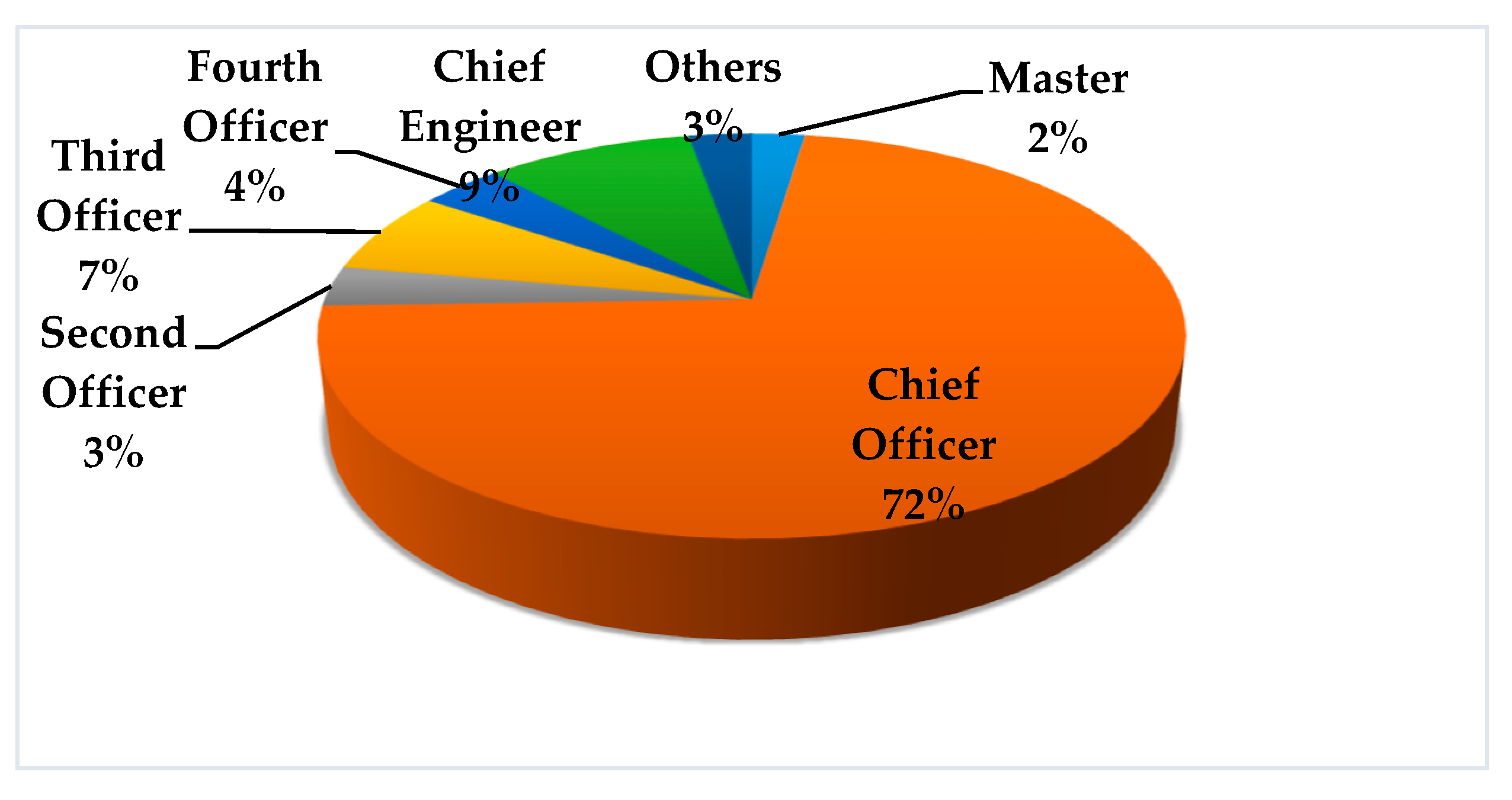

The reports collected were also used to verify the extent to which low-ranking seafarers reported near-misses in practice. An analysis of the collected near-miss reports revealed the following: 104 reports did not list the rank of the reporter, only their first and last name, and the reports were in electronic form; 9 were anonymous and reported by either the master or the ship’s safety officer; and in the remaining 467 reports, the rank of the reporter was indicated. Chief officers reported the most and crewmembers the least—only 3 reports out of 467 (

Figure 2). Other reporters included the 2nd engineer, 3rd engineer, 4th engineer, electrical officer, bosun, pumpman, and deck cadet.

An analysis of the collected data reports corroborated the lack of reporting by the low-ranking crewmembers indicated in the literature [

9,

17]. This can be considered a serious issue, because they are the ones who perform most of the physical work aboard ships during which near-misses happen. Some crewmembers stated that reporting was the job of the ship’s officers and that they did not have time to do so. They argued that too many “minor” near-misses occurred daily during ship operations and it would take too long to report all of them. Furthermore, some crewmembers thought that reporting was not part of the on-board culture, so they did not do it [

9,

17].

5. Near-Miss Reporting Survey Results

To gain insight into near-miss reporting, several questions were drafted. Data collected from the surveys were used to consolidate and validate research findings. Principal component analysis (PCA) with varimax rotation was applied to survey data (12 questions from the first survey), in order to reduce the number of measured items affecting near-miss reporting onboard ships and group them into a smaller set of composite factors. A Kayser–Meyer–Olkin (KMO) test confirmed that the data were appropriate for the analysis, giving an overall measure of sampling adequacy of 0.78. Programming language R (version 4.0.0 x64) specialized for statistical analysis, data mining, and machine learning and the RStudio (Desktop version 1.3.959.) set of integrated tools designed to utilize the usage of R were used for statistical data analysis. Factors were extracted based on the following analytical criteria: Eigen value of more than 1.0 and factor loading of more than 0.3. Items that did not reach the minimum loading of 0.3 were omitted from the analysis. PCA analysis resulted in the extraction of two factors, explaining 58.289% of the total variance (

Table 3).

The structure of extracted factors, together with the description of items and loadings, are presented in

Table 4. Loadings in bold indicate the factor on which the item is placed.

Factor 1 corresponded to the near-miss reporting attitude and Factor 2 corresponded to blame culture as a barrier to near-miss reporting. The reporting attitude reflected seafarers’ willingness to report the observed near-misses, and blame culture reflected their opinion on whether they could report near-misses freely, without fear of being blamed, embarrassed, getting someone into trouble, or feeling guilty.

Composite means of extracted factors were calculated and are presented in

Table 5. Composite means were additionally calculated separately for officers and crewmembers.

When calculating composite means, seafarers were divided in two groups: officers and crewmembers. Crewmembers’ composite mean values of extracted factors were higher than the composite mean calculated for officers (

Table 5). It can be concluded that officers have a better near-miss reporting attitude and they feel the existence of blame culture to a lesser extent than the crewmembers.

Regarding the existence of reporting forms onboard ships, a question of whether they had a near-miss report form on their ships was presented. The percent of seafarers who answered affirmatively was 92.3%, while 5% did not have such a form and 2.7% were unsure. When asked if it was in paper or electronic form, 63.4% of seafarers answered that they have an electronic form onboard and 36.6% reported a paper form. The question set for senior officers was “Do you think that crewmembers onboard your vessel report all near-misses they observe?” (Q11). Descriptive statistics of the answers are given in

Table 6.

One of the survey questions that was omitted from the PCA analysis due to low loading was “Have you ever reported a near-miss?” The percent of respondents who answered affirmatively was 82.9%, and 17.1% answered negatively.

Another question omitted from the PCA due to low loading was “Please rate the difficulty of filling out a near-miss report form on your ship” (Q12). Descriptive statistics of answers to the question are given in

Table 7.

The results from the survey confirmed that most of the seafarers did not see problems with near-miss reporting forms and considered them to be non-complex. The simpler the report form (short and clear questions), the more likely it was that the seafarers would report the near-misses. That is why it was important to adapt the report form to seafarers.

One of the possible barriers and an important issue is the ability to identify a near-miss event. If a seafarer is unable to define a near-miss, it is highly unlikely that the identification of a near-miss event will occur, and without identification, there is no reporting. The open question included in our survey was “What is a near-miss?” We found that 22% of the answers to this question were correct (a term explained or paraphrased). Further analysis of the answers may lead to the conclusion that the low-ranking crewmembers did not know what a near-miss was, but instead of explaining the term as an answer, they offered a practical example closely related to the job they performed onboard the ship. These crewmembers would most likely not be able to identify a near-miss if it happened in another ship’s department.

To establish the knowledge on the concept of a near-miss even more accurately, a supplementary survey was created. Events and their correct interpretations are presented in

Table 8.

The ratio of correct interpretation confirms that near-miss definition could still be seen as a “mystery” for a large number of crewmembers and it is a barrier that needs to be overcome to improve near-miss identification and thus reporting itself. Reporting is undoubtedly the most important phase of the near-miss management system, therefore measures to remove barriers that prevent seafarers from reporting need to be taken.

6. Discussion and Conclusions

A near-miss management system in shipping offers one of the most valuable instruments for improving safety onboard seagoing ships, which is the ultimate goal of modern shipping. To assess the current implementation of near-miss management systems, a thorough survey and literature review were carried out. An analysis of the survey results confirmed that current near-miss management in maritime shipping is inadequate and unsatisfactorily addressed, especially in relation to the reporting of near-misses. Therefore, near-miss management undoubtedly requires improvement. Seafarers understand the importance of near-miss reporting, but because of several barriers, they do not report all events they notice. In other words, the near-miss reporting frequency, and consequently its positive effect on the improvement of safety in shipping, is inadequate, and a lot of valuable data are thus lost. Probably the most important result of the presented survey is that 95.5% of seafarers consider that near-misses should be reported, but only 38.5% report each observed near-miss. This confirms the existence of reporting barriers among seafarers.

Reporting, as the most important phase of the system, is considered improper and insufficient, so the question of how to increase the reporting frequency and improve near-miss management systems in shipping remains. As evidenced by our survey results, seafarers face difficulties in identifying near-misses. This can be considered an alarming sign for shore management personnel, who should create an environment where near-misses can be dealt with in a better way. Against this background, one of the proposals that may improve near-miss identification and understanding of the benefits of reporting near-misses is the introduction of training. Shore management personnel should react and introduce training for all crewmembers, during which the definition of near-misses and near-miss reporting procedures could be explained. Near-miss management training could be carried out parallel to the shipboard familiarization training, which would improve seafarers’ knowledge about near-miss management. Several benefits of the implementation of near-miss training onboard ships and ashore have been identified and can be summarized as follows: Crewmembers would be familiar with the system; crewmembers would know how to identify and report a near-miss; and the reporting culture would be improved, which would thus increase the maritime safety.

Additionally, another barrier related to near-misses was identified by the survey and proved by the reviewed literature, which is the existence of a blame culture. Some seafarers do not report the observed near-misses due to the fear of blame, guilt, getting someone into trouble, or embarrassment. An analysis of the survey data revealed that blame culture is only a barrier for the minority of surveyed seafarers. Most of the seafarers believe that a blame culture exists to a very small extent onboard ships. Responsibility for implementing a just and reporting culture onboard ships primarily lies with company management and shipboard leadership. Shore management should guide senior officers onboard ships, which should foster a positive climate and remove reporting barriers by implementing an adequate leadership style.

The complexity of report forms is a barrier for a minority of seafarers, according to the analysis of survey data. Most of the respondents consider near-miss report forms as rather simple and as such, it is not considered a significant barrier. Furthermore, the unification of reporting forms and procedures could also help with overcoming reporting barriers and facilitate reporting, because seafarers who change companies could have difficulties due to differences in forms.

Seafarers, especially low-ranking ones, do not have a positive attitude towards near-miss reporting and are unwilling to report all observed near-misses. An analysis of the collected reports corroborated that low-ranking crewmembers are rarely involved in reporting. Chief officers, who usually serve as safety officers, report 72% of all near-misses. This means that not all ranks onboard ships report near-misses equally. It is necessary to discover what prevents them from reporting and try to act positively to remove these existing barriers and increase reporting, which may represent potential future research for dealing with near-miss management.

The most important findings of the research are that low-ranking seafarers are poorly involved in near-miss reporting and seafarers face difficulties in the identification of near-miss events. Shore management personnel and shipboard management should be aware of these facts and implement adequate corrective measures. In addition to the proposed shipboard near-miss management training, more information about near-misses and their effect on safety onboard ships should be a common topic during the education of new seafarers and shore-based training of active seafarers.

This paper provides a valuable insight into near-miss reporting systems and reporting practices onboard ships using a comprehensive overview consisting of a literature review, near-miss reports analysis, and data analysis revealed from surveys.

Uneven and inadequate reporting practices and existing barriers to reporting demand further research aimed at improving near-miss reporting, appropriately managing near-misses, and increasing safety onboard ships. The authors focused on some of the near-miss reporting barriers and it would be of interest to investigate and further research the effect of other barriers, such as the leadership style, lack of shore management commitment, and cultural differences of seafarers. Stakeholders in shipping could benefit from such research, because the results could be utilized for setting up a best-fit near-miss reporting model. Another important issue that needs to be addressed is the evaluation method of near-miss management systems in shipping. Currently, most of the shipping companies consider the number of reported near-misses as an indicator of the near-miss management quality, namely, the more reports, the better the quality. The authors consider this approach to be wrong, and future research will be directed towards discovering an adequate evaluation method.