Application of Structural Equation Modeling (SEM) and an Adaptive Neuro-Fuzzy Inference System (ANFIS) for Assessment of Safety Culture: An Integrated Modeling Approach

Abstract

1. Introduction

2. Background

3. Methods and Procedures

3.1. Study Variables

- (1)

- Management commitment (MC)

- (2)

- Employees personnel attitude (EPA)

- (3)

- Coworkers safety support (CSS)

- (4)

- Workplace pressure (WP)

- (5)

- Safety management system (SMS)

- (6)

- Violation behavior (VB)

- (7)

- Personnel safety motivation (PSM)

- (8)

- Personnel error behavior (PEB)

3.2. Survey Questionnaire

3.3. Participants

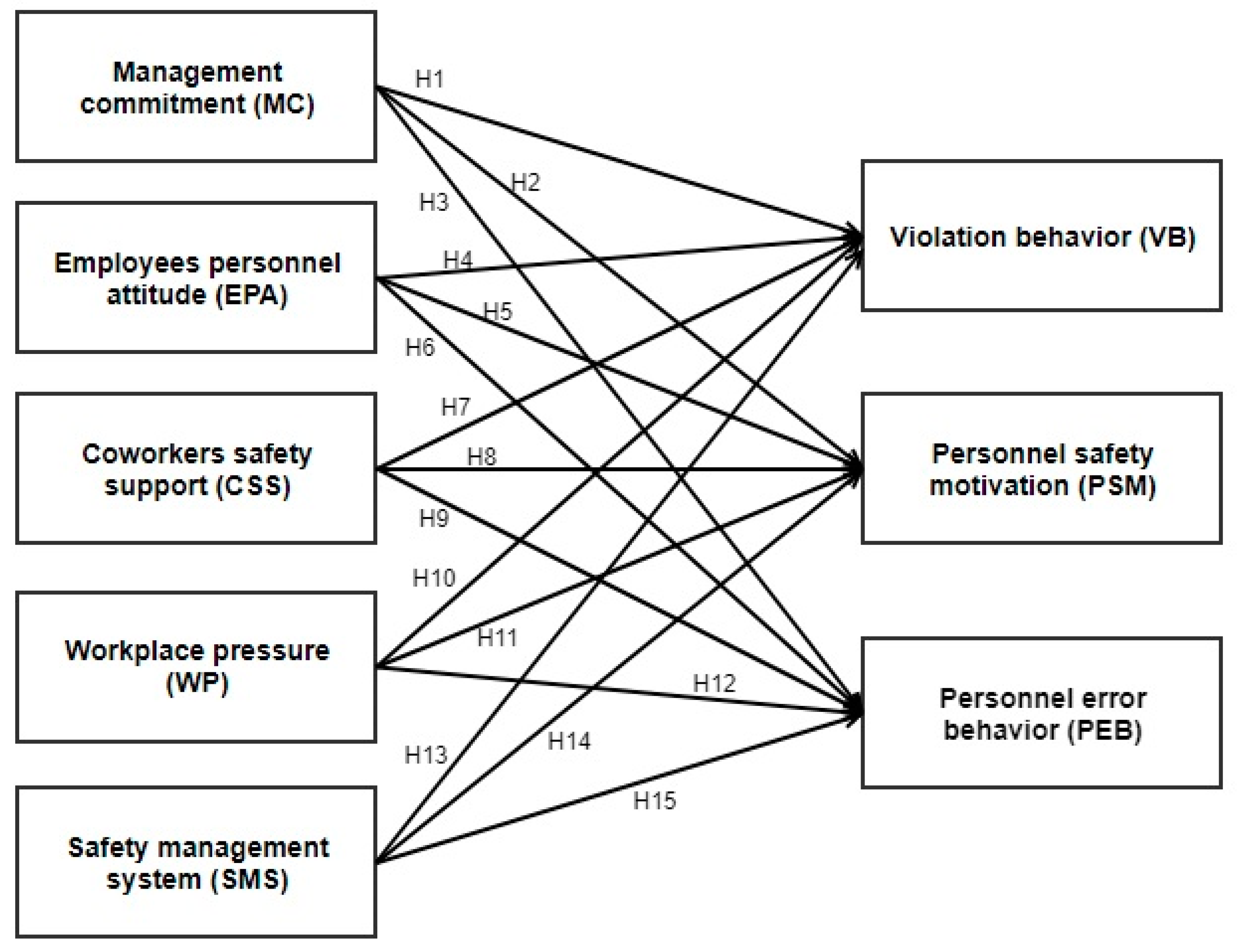

3.4. Study Hypotheses

4. Model Development and Analysis

4.1. Overview of Analyses

4.2. Multicollinearity Analysis

4.3. Reliability and Convergent Validity

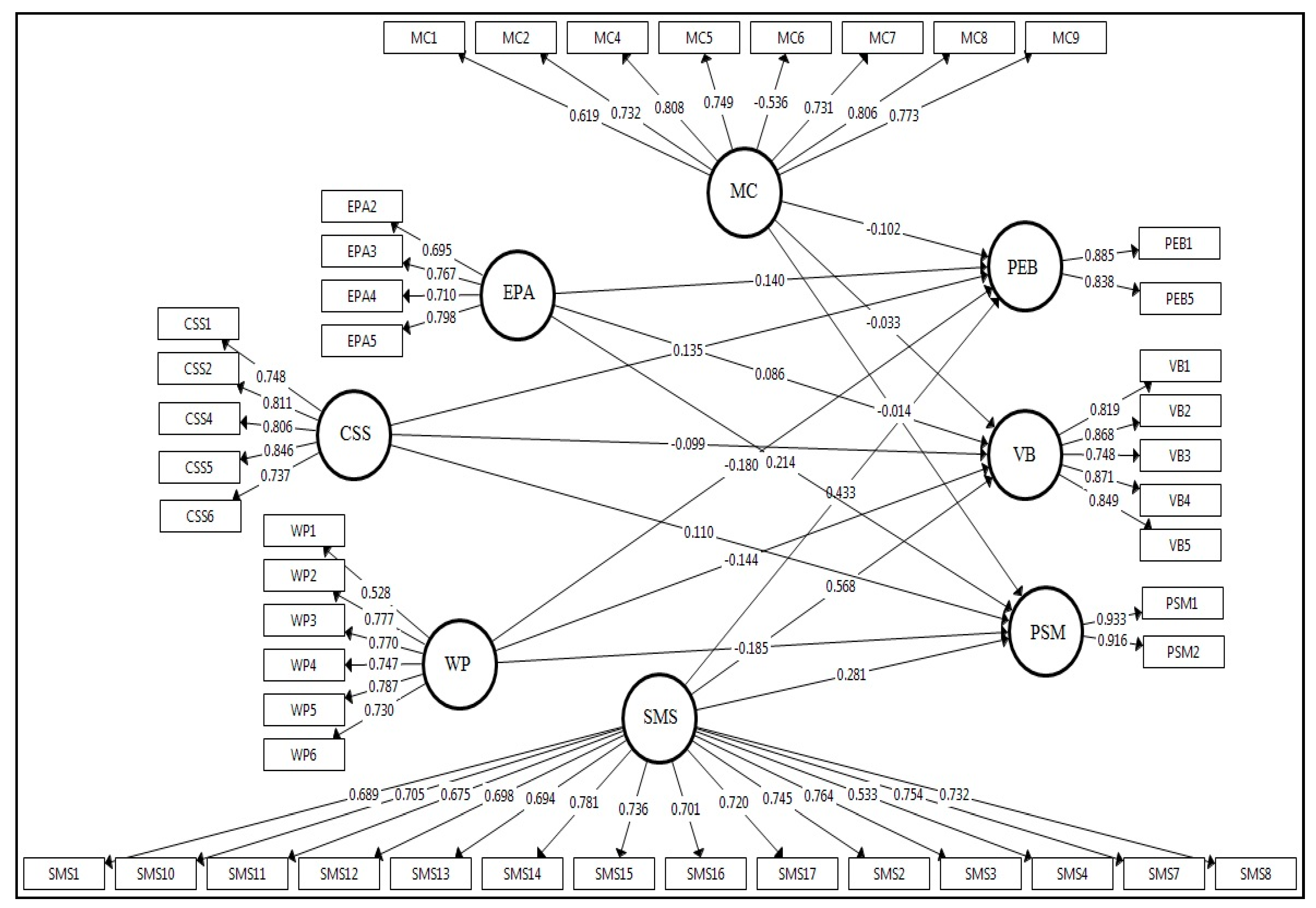

4.4. Structural Equation Modeling and Bootstrapping Test

4.5. Performance Criteria

5. Results and Discussion

5.1. Hypothesis Testing Results

- Management commitment was not statistically significantly associated with violation behavior (β = −0.033; p-value > 0.05); thus, H1 was rejected.

- A positive effect of the employees’ personnel attitude on violation behavior was identified in the petrochemical industry (β = 0.086; p-value < 0.05), which supports H2.

- Coworkers’ safety support negatively influenced personnel attitudes toward violations in the petrochemical industry (β = −0.099; p-value < 0.05), which supports H3.

- A negative effect of the workplace pressure on violation behavior was identified in the petrochemical industry (β = −0.144; p-value < 0.05), which supported H4.

- Safety management system positively influenced personnel attitudes toward violations in the petrochemical industry (β = 0.568; p-value < 0.05), which supports H5.

- Management commitment was not statistically significantly associated with personnel safety motivation. (β = −0.014; p-value > 0.05); thus, H6 was rejected,

- A positive effect of the employees’ personnel attitude on personnel safety motivation was identified in the petrochemical industry (β = 0.214; p-value < 0.05), which supports H7.

- Coworkers’ safety support positively influenced personnel safety motivation in the petrochemical industry (β = 0.110; p-value < 0.05), which supports H8.

- A negative effect of the workplace pressure on personnel safety motivation was identified in the petrochemical industry (β = −0.185; p-value < 0.05), which supported H9.

- Safety management system positively influenced personnel safety motivation in the petrochemical industry (β = 0.281; p-value < 0.05), which supports H10.

- Management commitment negatively influenced personnel error behavior in the petrochemical industry (β = −0.102; p-value < 0.05), which supports H11.

- A positive effect of the employees’ personnel attitude on personnel error behavior was identified in the petrochemical industry (β = 0.140; p-value < 0.05), which supports H12.

- Coworker’s safety support positively influenced personnel error behavior in the petrochemical industry (β = 0.135; p-value < 0.05), which supports H13.

- A negative effect of the workplace pressure on personnel error behavior was identified in the petrochemical industry (β = −0.180; p-value < 0.05), which supported H14.

- Safety management system positively influenced personnel error behavior in the petrochemical industry (β = 0.433; p-value < 0.05), which supports H15.

- Overall, thirteen of the postulated fifteen hypotheses were supported.

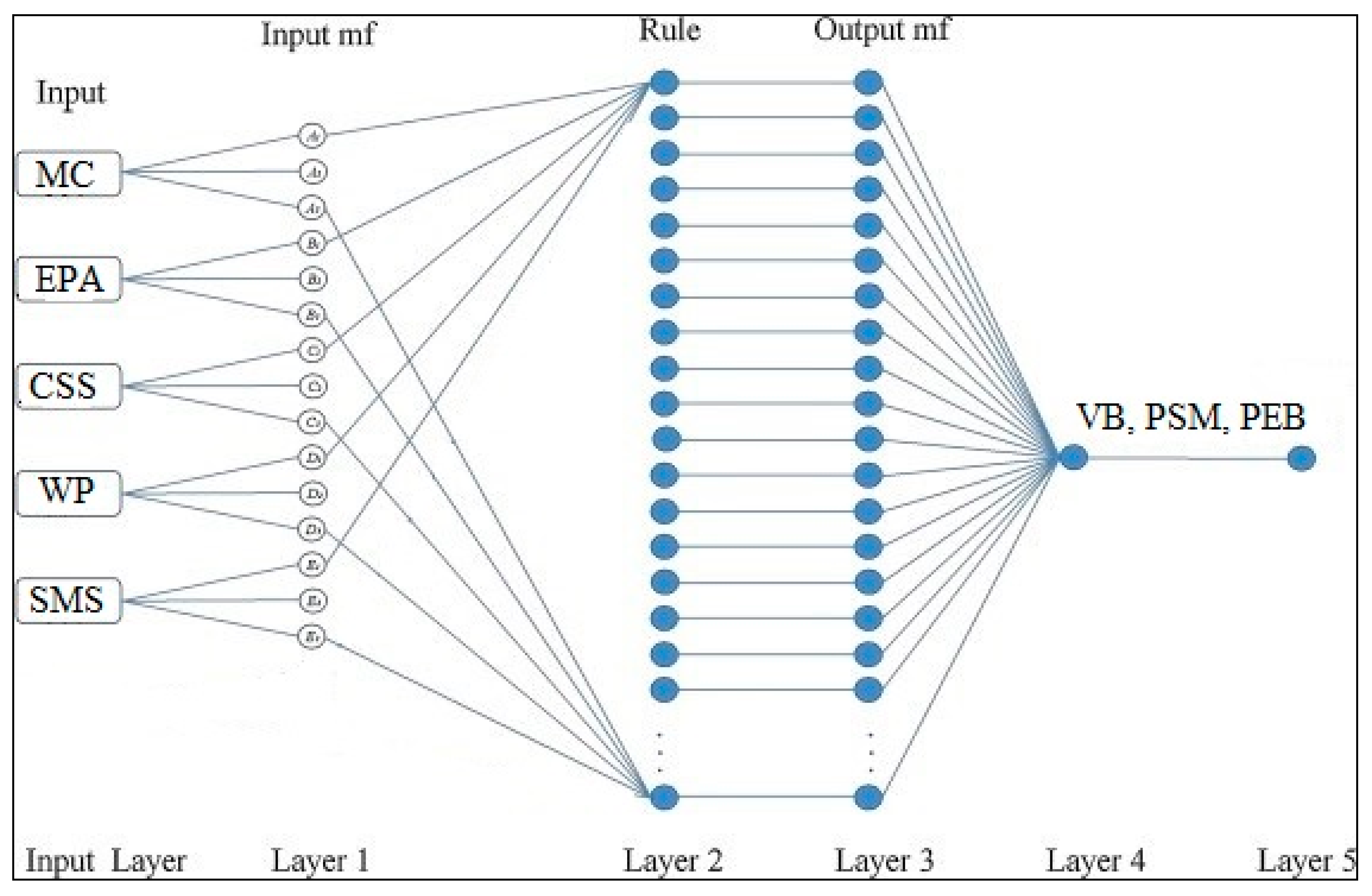

5.2. Application of ANFIS Approach

5.3. Sensitivity Analysis of Independent Variables

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boughaba, A.; Hassane, C.; Roukia, O. Safety Culture Assessment in Petrochemical Industry: A Comparative Study of Two Algerian Plants. Saf. Health Work 2014, 5, 60–65. [Google Scholar] [CrossRef]

- Mearns, K.; Flin, R. Assessing the state of organizational safety—culture or climate? Curr. Psychol. 1999, 18, 5–17. [Google Scholar] [CrossRef]

- Cooper, A.D. Towards a model of safety culture. Saf. Sci. 2000, 36, 111–136. [Google Scholar] [CrossRef]

- Goncalves Filho, A.; Waterson, P. Maturity models and safety culture: A critical review. Saf. Sci. 2018, 105, 192–211. [Google Scholar] [CrossRef]

- Health and Safety Commission (HSC). Organizing for Safety: Third Report of the ACSNI (Advisory Committee on the Safety of Nuclear Installations) Study Group on Human Factors; HSE Books: Sudbury, UK, 1993. [Google Scholar]

- Antonsen, S. Safety Culture: Theory, Method and Improvement; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Cooper, M.D. Navigating the Safety Culture Construct: A Review of the Evidence; B-Safe Management Solutions Inc.: Franklin, IN, USA, 2016. [Google Scholar]

- Pidgeon, N. Safety culture: Key theoretical issues. Work Stress 1998, 12, 202–216. [Google Scholar] [CrossRef]

- Milijić, N.; Mihajlović, I.; Nikolić, D.; Živković, Ž. Multicriteria analysis of safety climate measurements at workplaces in production industries in Serbia. Int. J. Ind. Ergon. 2014, 44, 510–519. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, K.; Chang, C. Practical application of safety climate: A case study in the Taiwanese steel industry. Int. J. Ind. Ergon. 2018, 67, 67–72. [Google Scholar] [CrossRef]

- Vecchio-Sadus, A.; Griffiths, S. Marketing strategies for enhancing safety culture. Saf. Sci. 2004, 42, 601–619. [Google Scholar] [CrossRef]

- Zohar, D. Thirty years of safety climate research: Reflections and future directions. Accid. Anal. Prev. 2010, 42, 1517–1522. [Google Scholar] [CrossRef]

- Guldenmund, F.W. Understanding and Exploring Safety Culture. Ph.D. Thesis, TU Delft. Delft University of Technology, Delft, The Netherland, 2010. [Google Scholar]

- Seo, D.; Torabi, M.R.; Blair, E.H.; Ellis, N.T. A cross-validation of safety climate scale using confirmatory factor analytic approach. J. Saf. Res. 2004, 35, 427–445. [Google Scholar] [CrossRef]

- Hall, M.E. Measuring the Safety Climate of Steel Mini-Mill Workers Using an Instrument Validated by Structural Equation Modeling. Ph.D. Thesis, The University of Tennessee, Knoxville, TN, USA, 2006. [Google Scholar]

- Li, Y.; Guldenmund, F.W. Safety management systems: A broad overview of the literature. Saf. Sci. 2018, 103, 94–123. [Google Scholar] [CrossRef]

- Molenaar, K.R.; Park, J.; Washington, S. Framework for measuring corporate safety culture and its impact on construction safety performance. J. Constr. Eng. Manag. 2009, 135, 488–496. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef] [PubMed]

- Fogarty, G.J.; Shaw, A. Safety climate and the Theory of Planned Behavior: Towards the prediction of unsafe behavior. Accid. Anal. Prev. 2010, 42, 1455–1459. [Google Scholar] [CrossRef] [PubMed]

- Itoh, K.; Andersen, H.B. A national survey on healthcare safety culture in Japan: Analysis of 20,000 staff responses from 84 hospitals. Management 2008, 4, 22–29. [Google Scholar]

- Wu, Y.; Fujita, S.; Seto, K.; Ito, S.; Matsumoto, K.; Huang, C.-C.; Hasegawa, T. The impact of nurse working hours on patient safety culture: A cross-national survey including Japan, the United States and Chinese Taiwan using the Hospital Survey on Patient Safety Culture. BMC Health Serv. Res. 2013, 13, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Freiwald, D.R. The Effects of Ethical Leadership and Organizational Safety Culture on Safety Outcomes. Ph.D. Thesis, Embry-Riddle Aeronautical University, Daytona Beach, FL, USA, 2013. [Google Scholar]

- Wilpert, B.; Itoigawa, N. Safety Culture in Nuclear Power Operations; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Takano, K.I.; Kojima, M.; Hasegawa, N.; Hirose, A. Interrelationships Between Organizational Factors and Major Safety Indicators. Saf. Cult. Nucl. Power Oper. 2001, 189–206. [Google Scholar]

- McKinley, I.G.; Grogan, H.A.; McKinley, L.E. Fukushima: Overview of relevant international experience. Genshiryoku Backend Kenkyu 2011, 18, 89–99. [Google Scholar]

- Funabashi, Y.; Kitazawa, K. Fukushima in review: A complex disaster, a disastrous response. Bull. At. Sci. 2012, 68, 9–21. [Google Scholar] [CrossRef]

- Holt, M.; Campbell, R.J.; Nikitin, M.B. Fukushima nuclear disaster. Congr. Res. Serv. 2012, 7–5700. [Google Scholar]

- Thomas, S. What will the Fukushima disaster change? Energy Policy 2012, 45, 12–17. [Google Scholar] [CrossRef]

- Lipscy, P.Y.; Kushida, K.E.; Incerti, T. The Fukushima Disaster and Japan’s Nuclear Plant Vulnerability in Comparative Perspective. Environ. Sci. Technol. 2013, 47, 6082–6088. [Google Scholar] [CrossRef] [PubMed]

- Hollnagel, E.; Fujita, Y. The Fukushima Disaster—Systemic Failures as The Lack of Resilience. Nucl. Eng. Technol. 2013, 45, 13–20. [Google Scholar] [CrossRef]

- Kastenberg, W.E. Ethics, risk, and safety culture: Reflections on Fukushima and beyond. J. Risk Res. 2014, 18, 304–316. [Google Scholar] [CrossRef]

- Mabon, L.; Kawabe, M. Engagement on risk and uncertainty—Lessons from coastal regions of Fukushima Prefecture, Japan after the 2011 nuclear disaster? J. Risk Res. 2016, 21, 1297–1312. [Google Scholar] [CrossRef]

- Hsu, S.H.; Lee, C.-C.; Wu, M.-C.; Takano, K. A cross-cultural study of organizational factors on safety: Japanese vs. Taiwanese oil refinery plants. Accid. Anal. Prev. 2008, 40, 24–34. [Google Scholar] [CrossRef]

- Huang, J.W. Taiwan’s Petrochemical Industry in Transition; Showwe: Taipei, 2007. (In Chinese) [Google Scholar]

- Hosny, G.; Ea, E.; Ea, S. A Comparative Assessment of Safety Climate Among Petroleum Companies. Egypt. J. Occup. Med. 2017, 41, 307–324. [Google Scholar]

- Kao, C.-S.; Lai, W.H.; Chuang, T.F.; Lee, J.-C. Safety culture factors, group differences, and risk perception in five petrochemical plants. Process Saf. Prog. 2008, 27, 145–152. [Google Scholar] [CrossRef]

- Alrehaili, O. Assessing Safety Culture among Personnel in Governmental Construction Sites at Saudi Arabia: A Quantitative Study Approach. Electronic Theses and Dissertations. 5261. University of Central Florida, USA. 2016. Available online: https://stars.library.ucf.edu/etd/5261 (accessed on 24 February 2020).

- Garson, G.D. Partial Least Squares: Regression and Structural Equation Models; Statistical Associates Publishers: Asheboro, NC, USA, 2016. [Google Scholar]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Cronbach, L.J. Coefficient alpha and the internal structure of tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef]

- Carmines, E.G.; Zeller, R.A. Reliability and Validity Assessment; Sage Publications: Thousand Oaks, CA, USA, 1979; Volume 17. [Google Scholar]

- Byrne, B.M. Structural Equation Modeling with Mplus: Basic Concepts, Applications, and Programming; Routledge: London, UK, 2013. [Google Scholar]

- Schumacker, R.E.; Lomax, R.G. A Beginner’s Guide to Structural Equation Modeling; Psychology Press: East Sussex, UK, 2004. [Google Scholar]

- Molenaar, K.; Washington, S.; Diekmann, J. Structural Equation Model of Construction Contract Dispute Potential. J. Constr. Eng. Manag. 2000, 126, 268–277. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM). Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Wiegmann, D.A.; Zhang, H.; Von Thaden, T.L.; Sharma, G.; Gibbons, A.M. Safety culture: An integrative review. Int. J. Aviat. Psychol. 2004, 14, 117–134. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Alper, S.J.; Karsh, B.T. A systematic review of safety violations in industry. Accid. Anal. Prev. 2009, 41, 739–754. [Google Scholar] [CrossRef] [PubMed]

- Laurence, D. Safety rules and regulations on mine sites–the problem and a solution. J. Saf. Res. 2005, 36, 39–50. [Google Scholar] [CrossRef]

- Wills, A.R.; Watson, B.; Biggs, H.C. Comparing safety climate factors as predictors of work-related driving behavior. J. Saf. Res. 2006, 37, 375–383. [Google Scholar] [CrossRef]

- Rundmo, T.; Hale, A.R. Managers’ attitudes towards safety and accident prevention. Saf. Sci. 2003, 41, 557–574. [Google Scholar] [CrossRef]

- Yadegaridehkordi, E.; Nilashi, M.; Nasir, M.H.N.B.M.; Ibrahim, O. Predicting determinants of hotel success and development using Structural Equation Modelling (SEM)-ANFIS method. Tour. Manag. 2018, 66, 364–386. [Google Scholar] [CrossRef]

- Ahani, A.; Rahim, N.Z.A.; Nilashi, M. Forecasting social CRM adoption in SMEs: A combined SEM-neural network method. Comput. Human Behav. 2017, 75, 560–578. [Google Scholar] [CrossRef]

- Liébana-Cabanillas, F.; Marinković, V.; Kalinić, Z. A SEM-neural network approach for predicting antecedents of m-commerce acceptance. Int. J. Inf. Manag. 2017, 37, 14–24. [Google Scholar] [CrossRef]

- Sharma, S.K.; Joshi, A.; Sharma, H. A multi-analytical approach to predict the Facebook usage in higher education. Comput. Human Behav. 2016, 55, 340–353. [Google Scholar] [CrossRef]

- Guldenmund, F.W. The nature of safety culture: A review of theory and research. Saf. Sci. 2000, 34, 215–257. [Google Scholar] [CrossRef]

| Construct and Item Measure Description | |

|---|---|

| Construct 1: Management commitment (MC) | |

| MC1 | The company’s management provides efficient work safety training for workers |

| MC2 | If I report a mistake to my supervisor, management supports me |

| MC3 | Management encourages workers to report every incident about safety to a supervisor |

| MC4 | Management strongly supports safety for workers |

| MC5 | Managers support work safety even if it causes a delay in work |

| MC6 | My managers sometimes ignore work safety violations |

| MC7 | My managers frequently speak unofficially with workers about safety |

| MC8 | My management allows workers to work by being sensitive to safety rules |

| MC9 | My supervisor gives importance to my opinion for improving work safety |

| Construct 2: Employees personnel attitude (EPA) | |

| EPA1 | Work safety rules provide a safer work environment |

| EPA2 | I make sure to use necessary safety equipment |

| EPA3 | I alert my colleagues who act contrary to work safety rules |

| EPA4 | If my colleagues do not take any notice, I notify my manager about unsafe work |

| EPA5 | I try to follow work safety rules, even if they decrease my performance |

| EPA6 | It is more likely to have an accident in a workplace where there are no work safety rules |

| EPA7 | Work safety rules are important and necessary to prevent accidents at my work |

| Construct 3: Coworkers safety support (CSS) | |

| CSS1 | Most workers notify personnel who are taking risks |

| CSS2 | Most workers support workplace safety policies |

| CSS3 | My colleagues usually suggest that I ignore work safety rules |

| CSS4 | My colleagues point out each other’s deficiencies in work safety |

| CSS5 | My colleagues want to help each other with work safety |

| CSS6 | My colleagues attach importance to the assessment for incidents that can cause accidents |

| Construct 4: Workplace pressure (WP) | |

| WP1 | Completing work is more important than doing work in safe ways |

| WP2 | I sometimes compromise on safety to finish the work on time |

| WP3 | Sometimes, it is expected from me to do more work than to do it safely |

| WP4 | It is difficult to work when applying all work safety rules |

| WP5 | In my workplace, cutting corners and risky attitudes are common because of the heavy workload |

| WP6 | I am sometimes not sure if work can be done by following work safety rules |

| WP7 | I can easily get necessary safety equipment from my workplace |

| Construct 5: Safety management system (SMS) | |

| SMS1 | Safety feedback and comments are always presented from and to management |

| SMS2 | There is an understanding that workers will be thanked for their safety |

| SMS3 | My company often offers safety incentives to site managers, site personnel and project engineers |

| SMS4 | Safety rewards presented by my company are valuable |

| SMS5 | Safety responsibility and accountability are clearly described |

| SMS6 | Site managers and field personnel place importance on safety |

| SMS7 | There are dedicated safety agents, and they usually observe and correct field personnel’s unsafe acts |

| SMS8 | Field personnel are aware that unsafe performance will be punished and not tolerated |

| SMS9 | Unsafe performance is consistently punished with reasonable levels that fit the violation |

| SMS10 | Safety is always reinforced, even if a violation occurred without accident |

| SMS11 | Management places importance on safety, and it is a strategic concern for top management |

| SMS12 | Everyone is responsible for safety, not just safety staff |

| SMS13 | My company policies and actions demonstrate a sincere commitment to safety |

| SMS14 | Hazard analysis, prevention and control are very important and often performed at the petrochemical site |

| SMS15 | Unsafe behavior identification with necessary corrections is often performed |

| Construct 6: Violation behavior (VB) | |

| VB1 | I feel it is essentially important to maintain safety at all times |

| VB2 | I believe safety in the workplace is a key issue |

| VB3 | I feel that it is compulsory to expend effort to decrease accidents and incidents at my workplace |

| VB4 | I feel it is important to encourage others to use safety practices |

| VB5 | I feel it is important to promote safety programs |

| Construct 7: Personnel safety motivation (PSM) | |

| PSM1 | I am capable of following all safety regulations and procedures |

| PSM2 | It is clear to me how to follow work safety rules and procedures |

| PSM3 | I have made safety errors due to not knowing how to work safely |

| PSM4 | I have rarely made errors that caused risks in working |

| Construct 8: Personnel error behavior (PEB) | |

| PEB1 | I carefully follow work safety rules and procedures when assigned a petrochemical task |

| PEB2 | I can perform a task with which I am familiar without looking at written procedures and manuscripts |

| PEB3 | I intentionally bend formal procedures to finish work on time |

| PEB4 | I have ignored some parts of procedures and do not record these to make work easier in abnormal circumstances |

| PEB5 | I am conscious of my responsibility about work safety |

| Demographic Variable | All (N = 883) | |

|---|---|---|

| Frequency | (%) | |

| Gender | ||

| 1. Male | 874 | 99 |

| 2. Female | 9 | 1 |

| Age | ||

| 1. Less than 26 | 134 | 15.2 |

| 2. 26-30 | 148 | 16.8 |

| 3. 31-35 | 80 | 9.1 |

| 4. 36-40 | 66 | 7.5 |

| 5. 41-45 | 112 | 12.7 |

| 6. Older than 45 | 343 | 38.8 |

| Work experience | ||

| 1. Less than 5 years | 167 | 18.9 |

| 2. 6–10 years | 216 | 24.5 |

| 3. 11–15 years | 60 | 6.8 |

| 4. 16–20 years | 77 | 8.7 |

| 5. More than 21 years | 363 | 41.1 |

| H1 | Management commitment has a statistically significant effect on violation behavior. |

| H2 | Employees personnel attitude has a statistically significant effect on violation behavior. |

| H3 | Coworkers safety support has a statistically significant effect on violation behavior. |

| H4 | Workplace pressure has a statistically significant effect on violation behavior. |

| H5 | Safety management system has a statistically significant effect on violation behavior. |

| H6 | Management commitment has a statistically significant effect on personnel safety motivation. |

| H7 | Employees personnel attitude has a statistically significant effect on personnel safety motivation. |

| H8 | Coworkers safety support has a statistically significant effect on personnel safety motivation. |

| H9 | Workplace pressure has a statistically significant effect on personnel safety motivation. |

| H10 | Safety management system has a statistically significant effect on personnel safety motivation. |

| H11 | Management commitment has a statistically significant effect on personnel error behavior. |

| H12 | Employees personnel attitude has a statistically significant effect on personnel error behavior. |

| H13 | Coworkers safety support has a statistically significant effect on personnel error behavior. |

| H14 | Workplace pressure has a statistically significant effect on personnel error behavior. |

| H15 | Safety management system has a statistically significant effect on personnel error behavior. |

| Mean | S.D. | MC | EPA | CSS | WP | SMS | VB | PSM | PEB | |

|---|---|---|---|---|---|---|---|---|---|---|

| MC | 3.85 | 0.53 | ||||||||

| EPA | 3.88 | 0.49 | 0.56 | |||||||

| CSS | 3.70 | 0.48 | 0.68 | 0.58 | ||||||

| WP | 1.56 | 0.52 | −0.54 | −0.53 | −0.49 | |||||

| SMS | 4.12 | 0.53 | 0.64 | 0.64 | 0.72 | −0.61 | ||||

| VB | 4.48 | 0.43 | 0.45 | 0.45 | 0.39 | −0.45 | 0.59 | |||

| PSM PEB | 1.38 2.88 | 0.74 0.41 | −0.31 0.53 | −0.32 0.57 | −0.33 0.57 | 0.49 −0.62 | −0.38 0.67 | 0.28 0.58 | −0.48 | - |

| Number of Items | Cronbach’s Alpha | Average Variance Extracted (AVE) | Composite Reliability | |||||

|---|---|---|---|---|---|---|---|---|

| Constructs | Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model |

| MC | 9 | 8 | 0.791 | 0.872 | 0.499 | 0.525 | 0.860 | 0.892 |

| EPA | 7 | 4 | 0.761 | 0.791 | 0.408 | 0.553 | 0.827 | 0.832 |

| CSS | 6 | 5 | 0.722 | 0.850 | 0.526 | 0.625 | 0.812 | 0.893 |

| WP | 7 | 6 | 0.729 | 0.821 | 0.459 | 0.531 | 0.810 | 0.870 |

| SMS | 15 | 14 | 0.883 | 0.924 | 0.489 | 0.506 | 0.910 | 0.934 |

| VB | 5 | 5 | 0.888 | 0.888 | 0.693 | 0.693 | 0.918 | 0.918 |

| PSM | 4 | 2 | 0.180 | 0.831 | 0.561 | 0.855 | 0.063 | 0.922 |

| PEB | 5 | 2 | 0.070 | 0.702 | 0.436 | 0.743 | 0.005 | 0.852 |

| Relationship | Path Coefficient (β) | t-Statistics | p-Value | Test Result: Hypothesis | R2 |

|---|---|---|---|---|---|

| MC → VB | −0.033 | 0.668 | 0.504 | H1: unsupported | 0.393 |

| EPA → VB | 0.086 | 2.126 | 0.034 | H2: supported | |

| CSS → VB | −0.099 | 2.257 | 0.024 | H3: supported | |

| WP → VB | −0.144 | 3.735 | 0.000 | H4: supported | |

| SMS → VB | 0.568 | 10.632 | 0.000 | H5: supported | |

| MC → PSM | −0.014 | 0.274 | 0.784 | H6: unsupported | 0.433 |

| EPA → PSM | 0.214 | 5.440 | 0.000 | H7: supported | |

| CSS → PSM | 0.110 | 2.223 | 0.027 | H8: supported | |

| WP → PSM | −0.185 | 4.909 | 0.000 | H9: supported | |

| SMS → PSM | 0.281 | 4.422 | 0.000 | H10: supported | |

| MC → PEB | −0.102 | 2.174 | 0.030 | H11: supported | 0.474 |

| EPA → PEB | 0.140 | 3.527 | 0.000 | H12: supported | |

| CSS → PEB | 0.135 | 2.745 | 0.006 | H13: supported | |

| WP → PEB | −0.180 | 4.635 | 0.000 | H14: supported | |

| SMS → PEB | 0.433 | 7.636 | 0.000 | H15: supported |

| Violation Behavior | Personnel Safety Motivation | Personnel Error Behavior | ||||

|---|---|---|---|---|---|---|

| Membership Function | Number of Membership Function | RMSE | Number of Membership Function | RMSE | Number of Membership Function | RMSE |

| DSIGMF | 2 | 1.659 | 2 | 2.348 | 2 | 2.345 |

| 3 | 46.398 | 3 | 41.538 | 3 | 44.927 | |

| GAUSS2MF | 2 | 1.798 | 2 | 2.603 | 2 | 1.880 |

| 3 | 47.215 | 3 | 29.042 | 3 | 63.680 | |

| GAUSSMF | 2 | 1.850 | 2 | 1.418 | 2 | 1.815 |

| 3 | 7.425 | 3 | 8.633 | 3 | 6.977 | |

| GBELLMF | 2 | 1.893 | 2 | 1.468 | 2 | 3.479 |

| 3 | 14.605 | 3 | 13.488 | 3 | 17.037 | |

| PIMF | 2 | 1.693 | 2 | 2.609 | 2 | 2.419 |

| 3 | 40.553 | 3 | 22.012 | 3 | 31.659 | |

| PSIGMF | 2 | 1.659 | 2 | 2.348 | 2 | 2.345 |

| 3 | 46.398 | 3 | 41.538 | 3 | 44.927 | |

| TRAPMF | 2 | 1.864 | 2 | 2.230 | 2 | 1.694 |

| 3 | 6.901 | 3 | 9.689 | 3 | 6.971 | |

| TRIMF | 2 | 0.883 | 2 | 1.070 | 2 | 0.723 |

| 3 | 11.787 | 3 | 6.613 | 3 | 9.343 | |

| RMSE | ||||

|---|---|---|---|---|

| Absent | Inputs | VB | PSM | PEB |

| - | MC, EPA, CSS, WP, SMS | 0.883 | 1.070 | 0.723 |

| MC | EPA, CSS, WP, SMS | 0.436 | 0.891 | 0.587 |

| EPA | MC, CSS, WP, SMS | 1.377 | 0.594 | 0.910 |

| CSS | MC, EPA, WP, SMS | 0.468 | 0.906 | 0.565 |

| WP | MC, EPA, CSS, SMS | 0.886 | 0.677 | 0.473 |

| SMS | MC, EPA, CSS, WP | 0.521 | 0.653 | 0.495 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çakıt, E.; Karwowski, W.; Murata, A.; Olak, A.J. Application of Structural Equation Modeling (SEM) and an Adaptive Neuro-Fuzzy Inference System (ANFIS) for Assessment of Safety Culture: An Integrated Modeling Approach. Safety 2020, 6, 14. https://doi.org/10.3390/safety6010014

Çakıt E, Karwowski W, Murata A, Olak AJ. Application of Structural Equation Modeling (SEM) and an Adaptive Neuro-Fuzzy Inference System (ANFIS) for Assessment of Safety Culture: An Integrated Modeling Approach. Safety. 2020; 6(1):14. https://doi.org/10.3390/safety6010014

Chicago/Turabian StyleÇakıt, Erman, Waldemar Karwowski, Atsuo Murata, and Andrzej Jan Olak. 2020. "Application of Structural Equation Modeling (SEM) and an Adaptive Neuro-Fuzzy Inference System (ANFIS) for Assessment of Safety Culture: An Integrated Modeling Approach" Safety 6, no. 1: 14. https://doi.org/10.3390/safety6010014

APA StyleÇakıt, E., Karwowski, W., Murata, A., & Olak, A. J. (2020). Application of Structural Equation Modeling (SEM) and an Adaptive Neuro-Fuzzy Inference System (ANFIS) for Assessment of Safety Culture: An Integrated Modeling Approach. Safety, 6(1), 14. https://doi.org/10.3390/safety6010014