1. Introduction

Machining parts on CNC machine tools, by means of milling (and/or other cutting operations) involves coordinated technological motions on three to five axes. These motions are controlled by means of a program, called NC code. The code contains all the geometric and technological information necessary to drive the tools on the toolpaths in order to obtain the required shape of the final parts and the machining accuracy, while also complying with the imposed cutting regime.

Metal cutting machining operation unfolded on machine tools are potentially dangerous for the machine operators due to the moving parts with high masses and velocities. Moreover, these parts are moving, not only during machining, but also during maintenance and cleaning operations, which may endanger the integrity of the machine operator [

1,

2]. However, modern machine tools for metal cutting are equipped with various safety systems, which, if used properly, provides comprehensive machine operators protection [

3].

However, there are some particularities when CNC machine tools are considered. For these types of equipment, most of the movements are performed automatically, and dangerous situations may arise which may affect the integrity of the machine to a greater extent and to a lesser extent the operator’s integrity. Of course, machine operator safety should always be considered paramount and given the outmost priority, but due to the high cost associated with the purchase, maintenance and repairing of CNC machine tools, machine tools integrity should also be considered important. When automatic movements of the CNC machine tools are considered, the risks are related to the safety features of the control systems, which were considered in [

4,

5], and to inaccurate setups and programming errors.

The stability of the machining process using data collected by microphone signal analysis was presented in [

6]. Tool wear is also considered as a major source of hazard when CNC machining is considered. A recent work presented in [

7] demonstrated the efficiency of using synchronized chaotic systems for tool wear identification.

Malfunction of important structural elements of the machine tools kinematic chains can also be considered an important source of hazards during CNC machining. For example, bearing malfunction can dramatically increase the level of vibrations and resistant torques. A new method of diagnosing the ball-bearing faults by means of the artificial fish-swarm algorithm was presented in [

8].

One of the most dangerous events which may occur during multi-axis CNC machine tools operations is the collision, seen as the unwanted contact between tools, workpiece, fixtures, and machine elements.

The work from [

9] presents a comprehensive review about collisions occurring during five-axis machining on CNC machine tools. The collisions are divided into local collisions (between tools and workpiece) and global collisions (between tools and machine elements and fixtures), emphasizing the fact that the later ones have much more severe consequences. As presented in [

9], collisions must be detected, using various algorithms, [

10,

11] and avoided, using various methods [

12,

13,

14].

Another work, presented in [

15], indicates the integration between tool path generation and simulation as an effective approach to avoid collisions during five-axis CNC machining.

Machine intelligence (mainly machine vision-based image processing) was also used for developing decision processes for providing solutions of collision avoidance in modern multi axis CNC machining [

16].

It can be stated that modern CNC controllers are fitted with some safety devices and systems which aid the user to operate the CNC machine tools in relatively safe conditions [

2,

4]. Additionally, the CAM (computer aided manufacturing) software packages, which are used for the automatic generation of the NC code use various algorithms and methods to generate collision-free toolpaths. However, there are still some sources of errors, called here hazards, which may lead to dangerous situations during CNC machine tools operation. With the increase in the complexity of the CNC machine tools (increase in the number of controlled axes, milling units equipping turning centers, high-speed machining), various new non-obvious hazards which can generate unwanted events during CNC machining have appeared. An identification of a hierarchy of these hazards is the main purpose of this work.

2. Materials and Methods

2.1. Dangerous Situations during CNC Machine Tool Operation

As stated in [

17], the authors have a close co-operation with a large manufacturing company and supplier of machined parts for the automotive industry, situated in the same town, COMPA S.A., Sibiu, Romania which has an endowment of more than 200 CNC machine tools. Thus, the hazard identification process described below was based on interviews and workshops with the engineers, technicians, and operators, focused on the main causes of collisions occurring during CNC machining processes. It is here noticeable that not all hazards which may occur during CNC machine tools operation were discussed, but only the ones related to collisions.

During the interviews and workshops the following situations were considered:

Situations which could lead to collisions but are not so obvious and easy to identify. For example, programming errors leading to collisions between the tool and workpiece are easy to be identified during program simulation, either on an external PC, when software packages are used for programming, or on the CNC operating panel, when manual programming is used. However, collisions which are not due to programming errors and, in addition, are not identifiable using normal simulation methods could occur;

Situations where correct settings for the process are not easy to be determined, and in addition, software packages do not offer straightforward solutions. The input parameters are depending on many variables and high-level expertise is required to set them correctly.

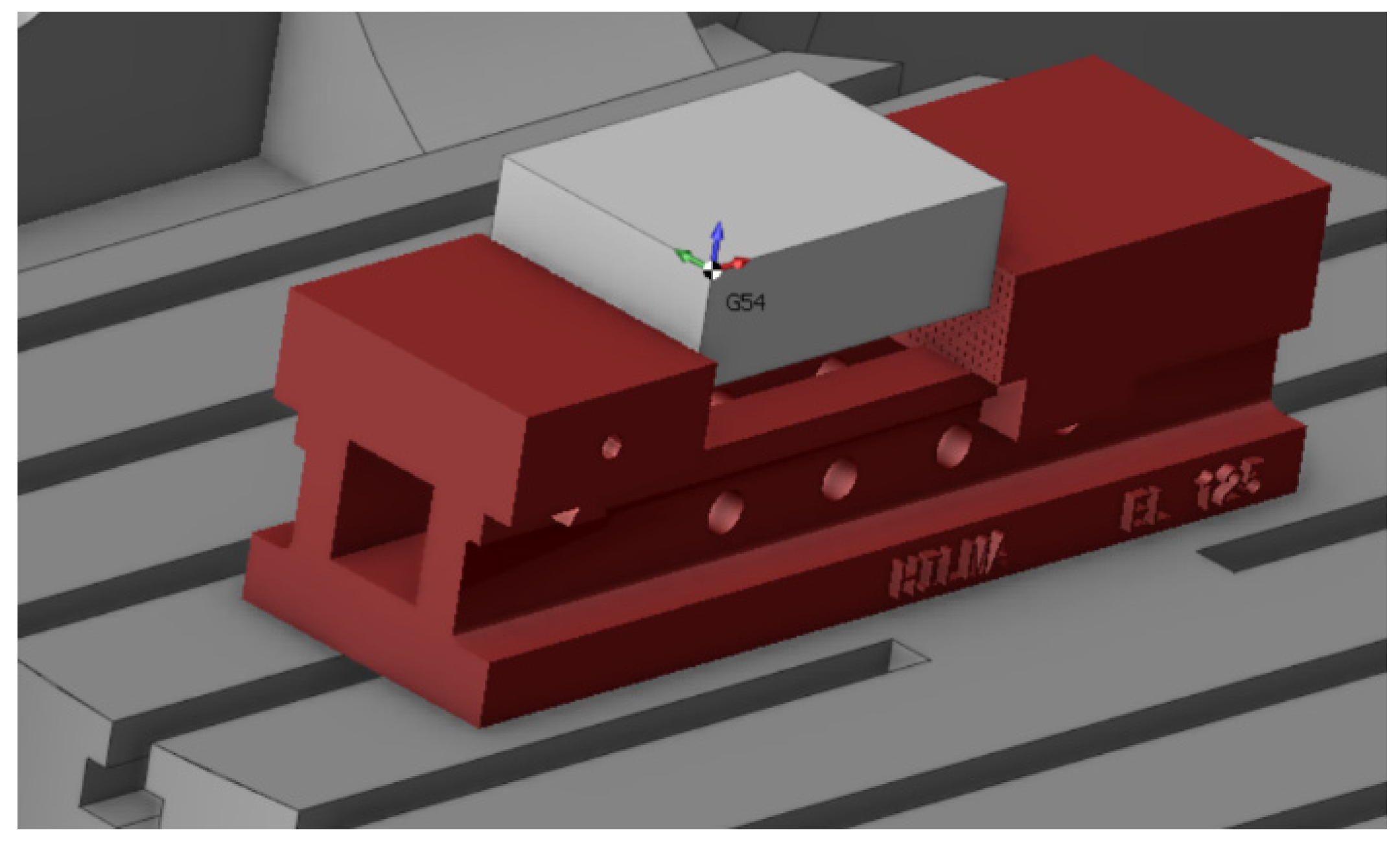

Inaccurate workpiece origin setup (IWS)—The geometric information within the NC code (positions and/or displacements along linear or around rotary axes of the CNC machine tool) are given in a Cartesian coordinate system. The origin of this system is called workpiece origin and it is chosen by the programmer and set by the machine operator. An example of such a workpiece origin (placed in the lower left corner of the workpiece, marked by G54), for a prismatic workpiece is presented in

Figure 1.

The process of setting up the workpiece origin is mostly a manual one, controlled by the machine operator and consequently it is subject to human errors. An erroneous workpiece origin could lead to many machining errors and, finally, to collisions. There are on the market devices which allow the machine-operator to perform the workpiece origin setup in a semi-automatic manner, but their price is quite high and the decision to purchase such a device is a difficult one.

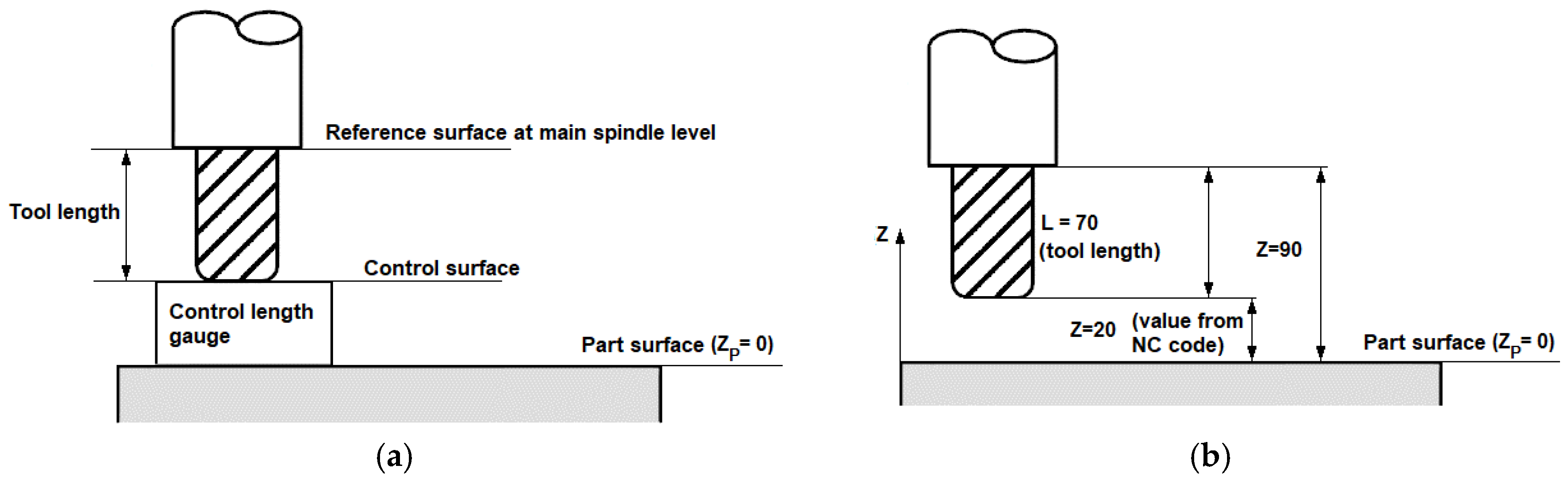

Inaccurate tools offset setup (ITS)—All positions/displacements on the Z-axis in the above-mentioned Cartesian coordinate system are given with reference to the main spindle level surface (

Figure 2a). Thus, every time a tool is used, every Z value within the NC code must be updated by the tool length.

For example, when the user wants to position the tool tip at 20 mm form the part surface (

Figure 2b), the Z value in the NC code will be Z20, but the NC controller will add 70 mm to it, which represents the tool length. Thus, the reference surface at the main spindle level will be positioned at 90 mm from the part surface and the tool tip at 20 mm from it. Neglecting to update the Z value with the correct value or updating it with an erroneous value will lead to collision. Consequently, all tools used during machining a part must be measured and tool offsets must be correctly set inside the CNC controller. Measuring the tools and setting the tool offsets is also a manual process performed by the machine operator and subject to human errors. Like the process of setting the workpiece origin, there are also devices designed to aid the operator to perform the tool measuring process in a semi-automatic manner, but they are also sold as expensive optional systems.

Erroneous cutting regime (ECR)—Cutting regime (type of tool, speed, feed, and cutting depths) must be set up by the user. Most of the CAM software packages provide some information about setting the proper cutting regime, but the results are highly dependent on the user input, and consequently subject to human error. An erroneous cutting regime, above other problems, could lead to tool breakage during the machining process and thus, to collisions.

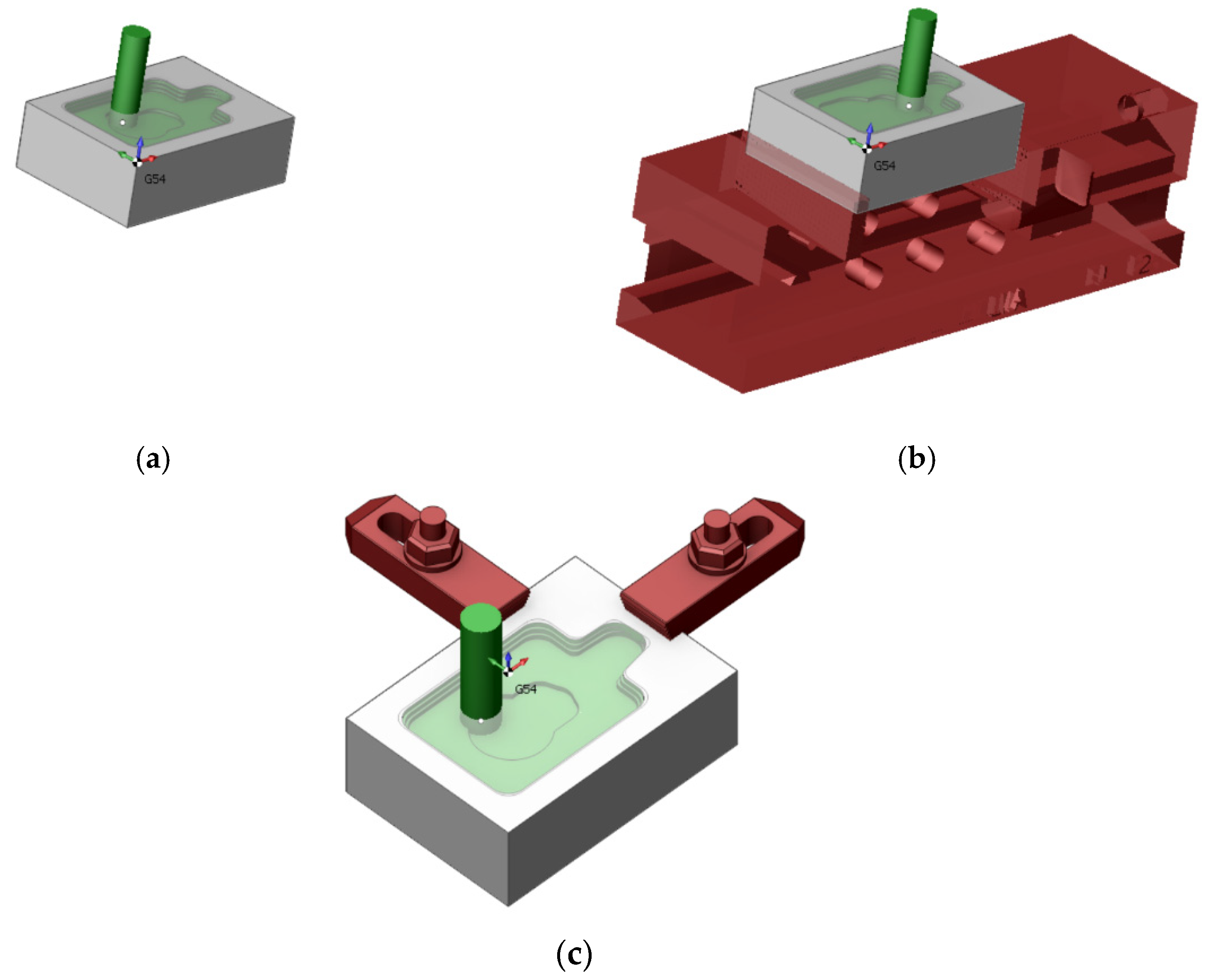

Collisions between tools and fixtures (CTF)—All CAM software packages, used for automatic generation of the NC code, can simulate the machining process to some extent. However, the quality of the simulation is very different from one software package to another and highly dependent of the software price. Some packages can simulate only the toolpaths, without simulating the process of material removal. Other packages can also simulate the material removal but cannot take into consideration the fixture systems (vices, clamps) neither during toolpath generation nor during simulation (

Figure 3a). Moreover, even for the systems which can consider fixture systems for generating collision-free toolpaths (

Figure 3b,c), some users fail (neglect or forget) to input the geometric information (3D models of vices and/or clamps) required by the software. Consequently, collisions between tools and fixtures are sometimes not identified in the simulation phase and occur during the machining process.

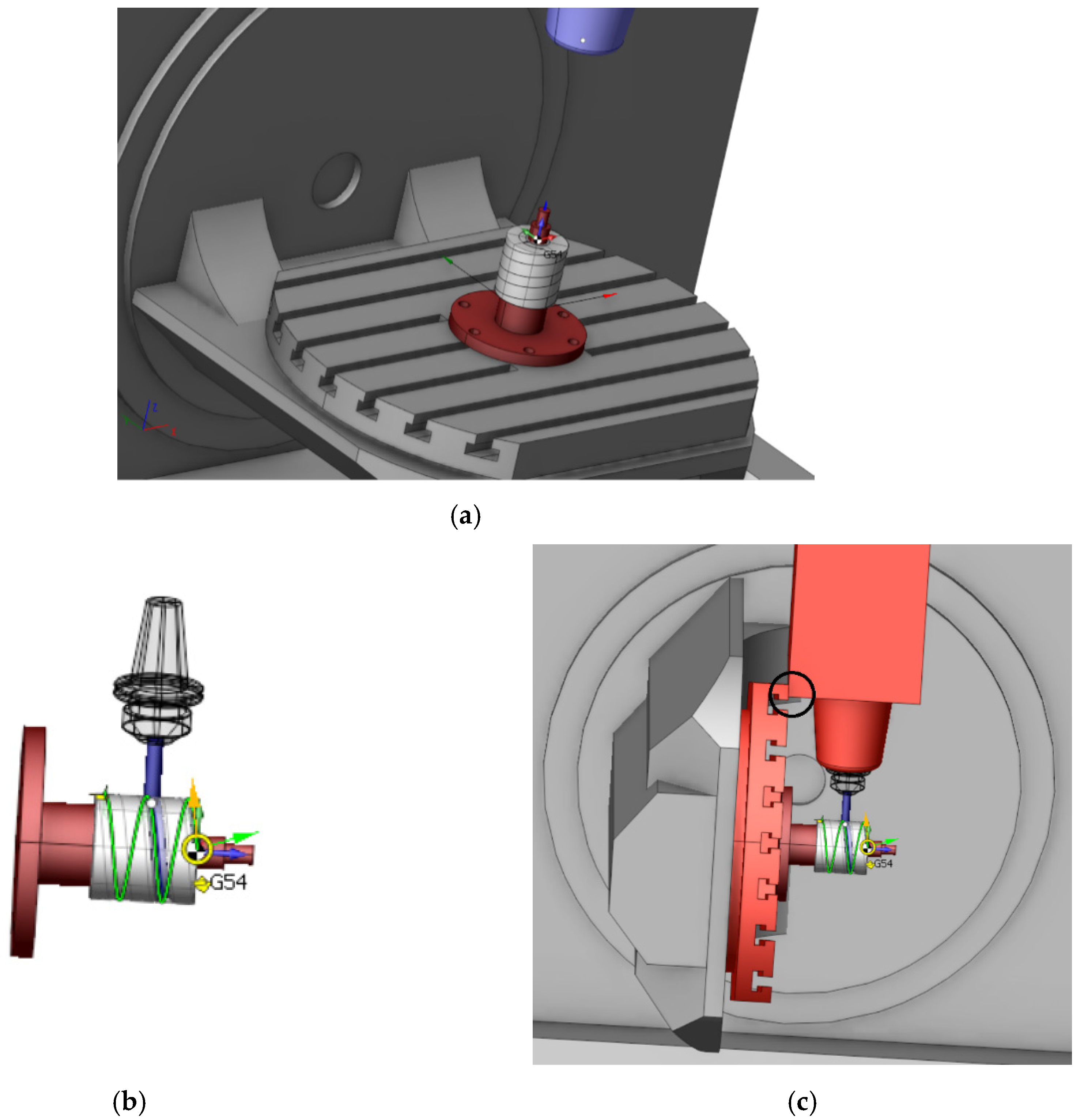

Collisions between the mobile elements of the machine tools such as linear slides and rotary tables (CME)—This issue is specific for five axis machining and usually does not occur for five axis machining. Thus, five axis machining also requires a kinematic model of the CNC machine tool in order to be able to identify all the possible collisions. Failing to do so (not using the machine tools model) will identify only the collisions between tools, the workpiece, and fixture systems. The collisions between the mobile elements of the CNC machine tool, involved in complex coordinated motions along linear axes and around rotary axes, will not be identified. For the situation presented in

Figure 4a (milling an external thread), while the kinematic model of the machine is not used, the simulation will report a collision-free situation (

Figure 4b), while when taking the machine kinematic into consideration (

Figure 4c), a collision between the table of rotary C axis with the linear unit of Z axis is identified (and, thus, avoided).

It should be mentioned that the use of a kinematic model is not yet implemented in every CMA software package. Moreover, even if the software allows its use, building such a kinematic model is a complex and expensive task and some users prefer to avoid it.

2.2. Criterion off Application AHP Method

The proposed approach aims to hierarchize the five hazards described above by using the AHP approach. AHP is a method used in multi-criteria decision-making processes [

18,

19,

20,

21,

22,

23,

24]. The literature has reported the use of the AHP method for risk assessment in manufacturing activities [

25]. Other approaches of using the AHP method in safety related fields were reported in [

26] where it was used to hierarchize safety systems for industrial machines and in [

27], for determining priority in a safety management system. Previous studies of the authors of this paper in implementing AHP to assess safety devices for CNC machine tools is presented in [

17].

Five hazards considered as not so obvious were identified and described in the previous section. Taking into consideration the fact that CNC machine tools are expensive technological equipment, measures must be taken to reduce or even remove any hazards during their operation. Moreover, due to high speeds and torques involved in CNC machining operations, hazards could also affect the human operators, despite the safety devices fitted on the machine tools.

Measures to reduce of remove the identified hazards usually involve high costs, so a strategy to address this issue in a cost-effective way must take into consideration how important each hazard is; in other words, it has to hierarchize them. Since creating such a hierarchy should take into consideration many aspects, a multi-criteria decision-making method (MCDM) has to be used. During this research, the AHP method was chosen as the MCDM tool and the data for implementing it was gathered by means of questionnaires. AHP is an intuitive method used to rank various alternatives based upon a set of given criteria, in order to fulfil an objective. In this work, the targeted objective is to hierarchize the five hazards identified in the previous section. Three criteria were used for the AHP and the analyzed hazards were considered alternatives to be ranked.

The five hazards identified in the previous paragraph will be hierarchized by means of AHP, taking into consideration three proposed criteria, introduced below:

C1—Possibility of occurrence represents a measure of how often the hazards may occur. For example, the collisions between machine elements (CME) due to the lack of using a kinematic model of the CNC machine tool could appear only during five-axis machining, while inaccurate workpiece origin setup (IWS) or inaccurate tools offset setup (ITS) could appear during any kind of machining operations, either three-axis or five-axis.

C2—Severity represent a measure of how serious the consequences of the occurrence of the considered hazards are. For example, a collision between a rotary table and a linear slide of the CNC machine tools is far much more serious than a tool breakage.

C3—Costs to avoid represent a measure of the financial effort necessary to avoid the occurrence of the hazards. For example, inaccurate tools offset setup (ITS) could be avoided if special devices which allow semi-automatic tools measuring are purchased, while the collisions between machine elements (CME) due to the lack of using a kinematic model of the CNC machine tool could be avoided if the costs of building such a kinematic model are assumed by the user.

2.3. Used Methods to Analyze Hazards that Technological Process on CNC Machine Tools

The steps of AHP can be synthesized as follows [

20,

22]:

define the goal (objective) and the problem to be solved;

structure the levels of decisions hierarchy (starting from the top, with the objective, continuing with the criteria of hierarchization and finishing with the alternatives);

build a set of matrices for pairwise comparisons of the elements (comparisons between pairs of elements are made using a specific priority scale;

determine the weight of the elements to each level of hierarchy (by normalizing the matrices and checking the consistency of the pairwise comparisons)

check the results (if discrepancies between the results and expectations are identified, the model can be improved by taking new criteria into consideration). Also benchmarks with the results of other organizations and sensitivity analysis are used to check the results; and

document the process to justify the results and for future implementation.

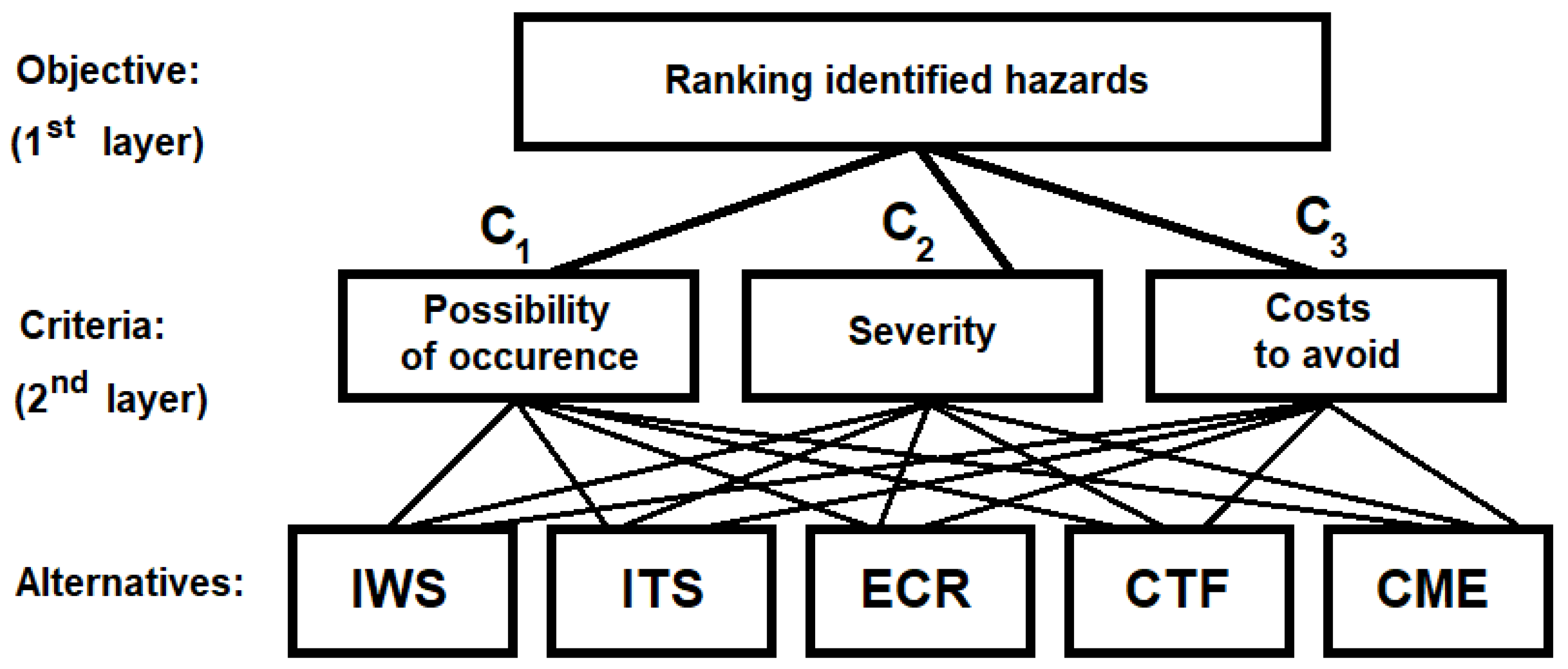

For this research the objective of AHP was to rank the identified hazards. The process was structured as a hierarchical structure with two layers, the firs one including the objective and the second one the considered criteria of hierarchization. The alternatives considered by the AHP analysis were the five identified hazards. A preference matrix was built and normalized, to hold the pairwise comparisons between the proposed criteria, while the comparisons were checked for consistency. Matrices holding the results of comparing each of the five hazards with regards of each of the three criteria were also built. Finally, after some calculations presented in the following section, the preference vector, showing the hierarchy of the analyzed hazard was determined. A sensitivity analysis was performed in order to check the results (the robustness of the hierarchization in the eventuality of changing the weights).

An explanatory diagram of the hierarchical structure used within this work is presented in

Figure 5.

The data required for AHP were collected by means of questionnaires distributed to CNC machine tool users (operators, technicians, engineers) from manufacturing companies around Sibiu, Romania (which is a highly industrialized area, with more than 50 industrial plants using CNC machine tools for manufacturing operations). An example of such questionnaire is presented in

Appendix A.

3. Results and Discussion

Running the AHP involves the pairwise comparison of the considered criteria against each other [

18,

19,

20]. The comparisons were made by comparing in pairs elements

i and

j and obtaining the

aij value:

A comparison scale introduced in [

19] was used for the comparisons:

1—equally important (two criteria/activities contribute equally to the objective [

19]);

3—weakly more important (experience and judgment slightly favor one criterion/activity over another [

19]);

5—strongly more important (experience and judgment strongly favor one criterion/activity over another [

19]);

7—demonstrably more important (a criterion/activity is favored very strongly over another, its dominance demonstrated in practice [

19]);

9—absolutely more important (the evidence favoring one criterion/activity over another is of the highest possible order of affirmation [

19]).

The values in between (2, 4, 6, and 8) represent compromise judgments (sometimes one needs to interpolate a compromise judgment numerically because there is no good word to describe it [

19]).

As a result of the comparison the

Table 1, holding the preference matrix A was generated.

The first line of

Table 1 has to be interpreted as:

Severity (C2) is considered here as weakly more important as the possibility of occurrence (C1);

Possibility of occurrence (C1) is considered to be weakly more important than the costs to avoid the occurrence of the hazards (C3).

The next step of AHP, according to [

18,

19,

20], requires the normalization of the preference matrix A and the generation of matrix B by using the formula:

The values for the normalized B matrix were stored in

Table 2.

Moreover, on the last column of B, by using the arithmetic averages for each row of B, Equation (3), where n = 3, the eigenvectors

w are introduced:

According to [

19,

20,

23,

24] the proposed comparisons must be checked for consistency. This was made here by using the following equation to calculate the maximal eigenvalue:

Table 3 holds the random consistency index, as introduced in [

18], allowing the user to calculate the consistency ratio CR (because the B matrix is three-dimensional, 0.58 was used as the

r value). The CR value is calculated according to the formula:

The consistency of the comparisons made during the generation of A and B matrices are certified by the fact that CR value is smaller than 10% (3.3327%) [

19,

20,

23,

24].

Further step involves the evaluation of the five hazards using the C1–C3 criteria as references. The evaluation was made, and the results are presented in

Table 4,

Table 5 and

Table 6.

Each last column of the

Table 4,

Table 5 and

Table 6 stores the eigenvectors, determined after normalizing each matrix from

Table 4,

Table 5 and

Table 6, according to Equation (2). The eigenvectors were calculated afterwards, as arithmetic averages of the elements of each line of the normalized matrixes, according to Equation (3), with

n = 5. For exemplification, in

Table 7, the normalized matrix from

Table 4, is presented.

The data from

Table 4,

Table 5 and

Table 6 allows the user to generate matrix C. The columns of C hold the eigenvectors from

Table 4,

Table 5 and

Table 6. The order of the columns of C was determined by the values of eigenvectors from

Table 2, ordered in descending order, as C2, C1, C3. Multiplying matrix C and the one column matrix w which holds the eigenvectors from matrix B, using Equation (6), the preference vector x is generated.

Finally, according to the results, the biggest value of preference vector x can be found on its first row, which according to AHP shows that the first position in the hierarchy of the considered hazards is occupied by IWF.

After running the AHP, the analyzed hazards were hierarchized in the following order: (1) IWS; (2) ITS; (3) CME; (4) CTF; and (5) ECR.

Thus, inaccurate workpiece origin setup (IWS) is the hazard which must be avoided with priority when C1–C3 criteria are considered. As stated before, there are on the market specialized devices, usually called “machine tool probes for component/workpiece setup” [

28], which allows the user to setup the workpiece origin in a semi-automatic way, significantly reducing the possibility of errors. Even if their price is quite high, this study has revealed that reducing or even eliminating the possibility of IWS occurrence makes the purchase of such devices an option to be taken into consideration. A similar conclusion could be drawn with regards of inaccurate tools offset setup (ITS), where the purchase of a specialized device for semi-automatic tool setting [

29] can also reduce or even eliminate the occurrence of this hazard.

It is also interesting the fact that collisions between the mobile elements of the machine tools such as linear slides and rotary tables (CME) is placed on the third place, out of five analyzed hazards. Even if at a superficial analysis this hazard could be considered as a reduced one, since it may occur only during complex five-axis machining operations, the severity of its consequences made the AHP to place it in the “top three” hazards to be avoided.

Collision between tools and fixtures (CTF) were placed by the AHP on the fourth place. Some explanations for this fact are that, aside from CME, the costs associated with them is not so high. Usually, these type of collisions leads to tool breakage, so, replacing the tool (with the associated costs) solves the problem. Additionally, most of the software packages offer the possibility of considering the 3D model of the fixtures during simulation process as standard feature, even for simple three axis milling operation, thus allowing the user to prevent CTF.

The hazard placed on the last place is the erroneous cutting regime (ERC). This could be explained by the fact that ERC does not necessary lead to instantaneous damages to the machine tool, tool and/or the processed part. It affects the productivity of the machining process and the lifetime of the cutting tools, but the severity of these consequences is strongly dependent on the degree of errors (how erroneous the cutting regime is). On the other hand, on long term, ERC will lead to machining damages, but this also depend on how often this type of hazard occurs. Additionally, avoiding ERC only implies a better training of the users in the field of machining technology, which usually is not associated with costs as high as the ones necessary for avoiding the other hazards considered by the analysis.

The results of the AHP can rise some doubts with regards of the determined eigenvector (weight), thus, results were checked by the point of view of reliability and robustness by means of sensitivity analysis [

24,

30].

According to [

30], the analysis was performed by changing the weights while keeping the previously determined rankings order. A coefficient α ≥ 0 was used in order to change the weights and the matrix A was transformed into

. If α > 1 more dispersed weights are obtained and if α < 1 the weights become more concentrated, without changing the previously determined rankings.

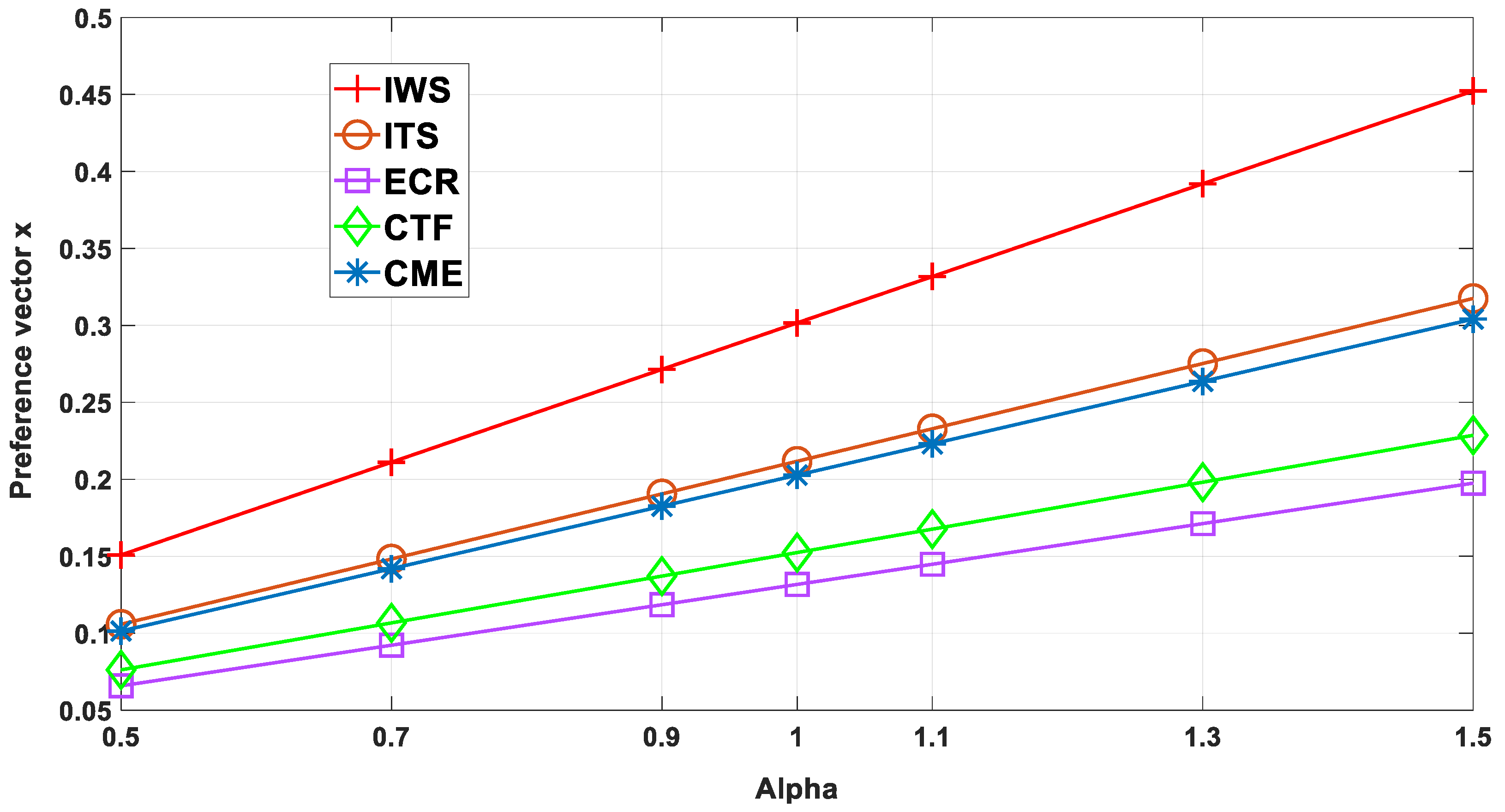

Table 8 was used to store the weights calculated for α = 0.5, 0.7, 0.9, 1.0, 1.1, 1.3, 1.5 [

24]. The results of re-calculating the preference vector x for the changed weights were stored in

Table 9. As can be noticed, the α coefficient does not change the ranking order of elements at an existing level of hierarchy, but it may influence the order of elements at the lower levels.

It is necessary to check how the results of the sensitivity analysis for the considered criteria influence the weights of the alternatives (the five considered hazards). Thus, it is required to evaluate the effects of a change in the weight of the evaluation criteria (resulted by means of the performed sensitivity analysis) on the final hierarchy of the alternatives.

The sensitivity analysis results synthesized in a graphical manner are presented in

Figure 6. From the figure it can be noticed that the hierarchy of the preference vectors x has not been changed and, consequently, the hierarchy of the analyzed hazard is preserved for the entire range of analysis.

4. Conclusions

The research presented in this paper had as main goal to provide information for both CNC machine tools designers and user for developing strategies and methods to avoid the occurrence of some not-so-obvious hazards during machining operations.

Implementing such measures and strategies in a cost-effective manner requires focusing the resources on the most important hazard, out of the identified ones, which can affect the CNC machine tools operation. Labelling a hazard as “the most important” is a cumbersome task which has to take into consideration many factors. An AHP hierarchization, based upon data gathered by means of questionnaires has pointed out the hazards which require the most attention, in term of the resources to be involved for their avoidance.

CNC machine tools represent the backbone of the manufacturing industry; consequently, their importance in machining processes is significant. In the age of digitalization, the evolution of these technological equipment is very fast, but their prices are also rising accordingly. Thus, it is very important to avoid any possibility of damaging such expensive machines, by removing any hazards which can appear during CNC machine tools operation. The research presented here, have identified five hazards, considered as not so obvious, which, generally, are not depending on the basic features and capabilities of the CNC machine tools. The hazards treated here are mostly depending on the way the machines are operated (operation strategies, auxiliary devices used during operation), the features of the programming (CAD/CAM) software used and the training level of the operators. Therefore, the task of eliminating these hazards is mainly a task of allocating the financial resources to purchase specialized auxiliary devices, high-end software packages, and to train the operators. However, which of these actions has to be considered the most important one and performed first? In order to avoid these hazards, for an existing inventory of CNC machine tools, the user has to hierarchize them in order to prioritize the use of the financial means required for this task. It is considered by the authors that the results of this work can provide users some with some landmarks with regards of this prioritizing activity.

As stated in the previous section, by the point of view of the CNC machine tools users, the avoidance of the hazards placed in the first and second places require the use of costly devices, while to avoid the third one, expensive software packages and complex training are required. The results of the research can consequently be used as an incentive for purchasing such devices and software packages, thus prioritizing the use of financial means. The results can also be used by the CNC machine tools designers even to provide existing systems for avoiding IWS and ITS hazards as standard equipment instead as optional ones or to develop new safety devices and systems as a solution to avoid CME hazard.

Further research will be oriented to find some ways to reduce the degree of subjectivity of the human input upon the gathered data and to consider more hierarchization criteria for the analyzed hazards. Moreover, experimental data will be gathered in order to confirm the hierarchization of the hazards performed during this research. Additionally, some comparison between the results obtained by other research teams are targeted in the future. At the present moment it is quite difficult to obtain data from other studies tackling the same problem, because it would require experimental data and most of it would record machining incidents, so this type of information is sensitive and hardly available. Thus, experimental data gathering will rely on co-operation with other research organizations and manufacturing companies and will take a certain amount of time.