Developing an IoT-Enabled Smart Helmet for Worker Safety: Technical Feasibility and Business Model

Abstract

Highlights

- Development of an IoT-enabled smart helmet for construction workers.

- Real-life feasibility of using IoT technology in construction safety.

- Ability to convert the idea into a viable business in the UAE.

Abstract

1. Introduction

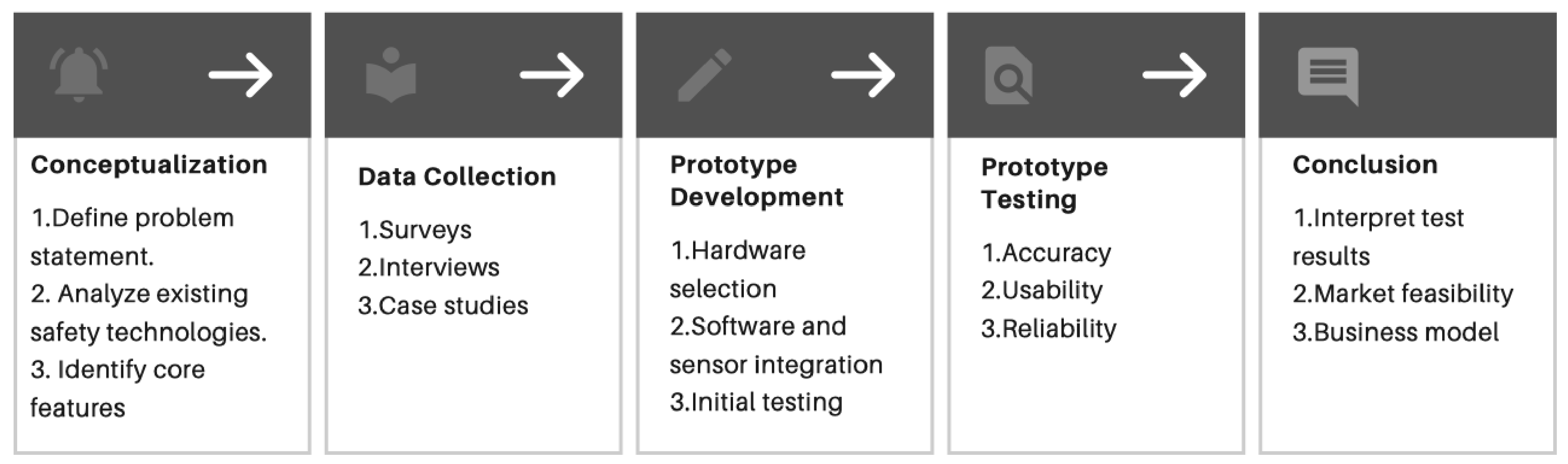

2. Methodology

2.1. Interviews

2.2. Online Survey—Questionnaire

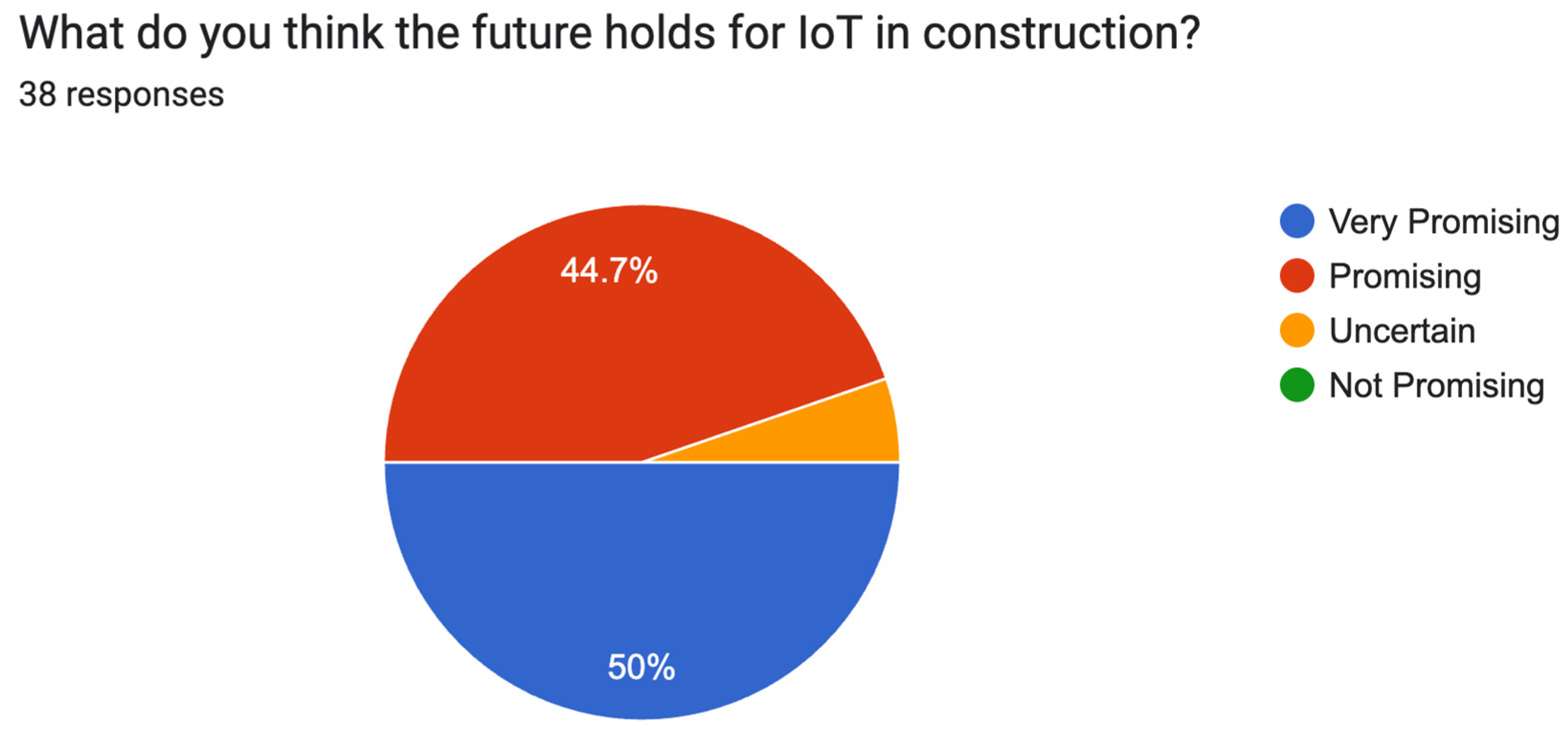

- What do you think the future holds for IoT in construction?

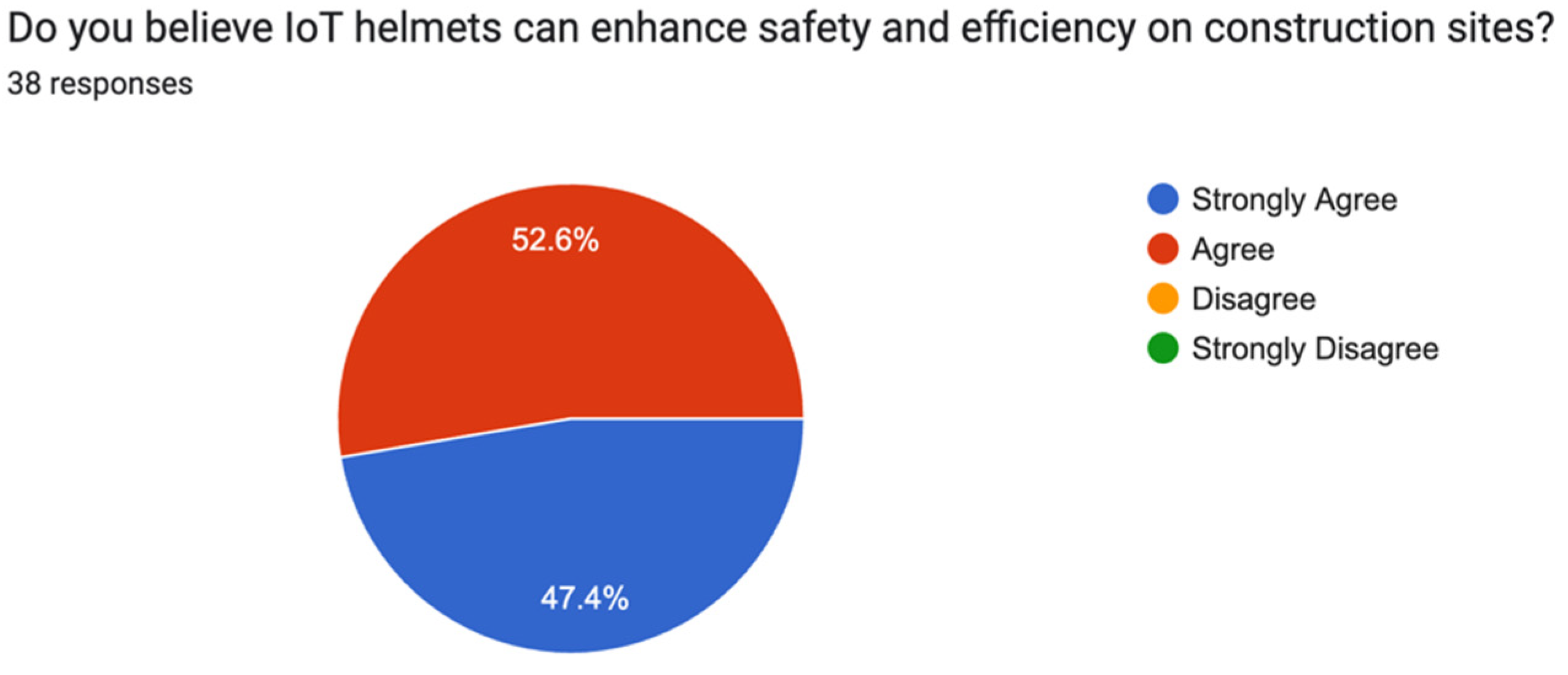

- Do you believe IoT helmets can enhance safety and efficiency on construction sites?

- Would you recommend IoT-enabled construction safety helmets for laborers?

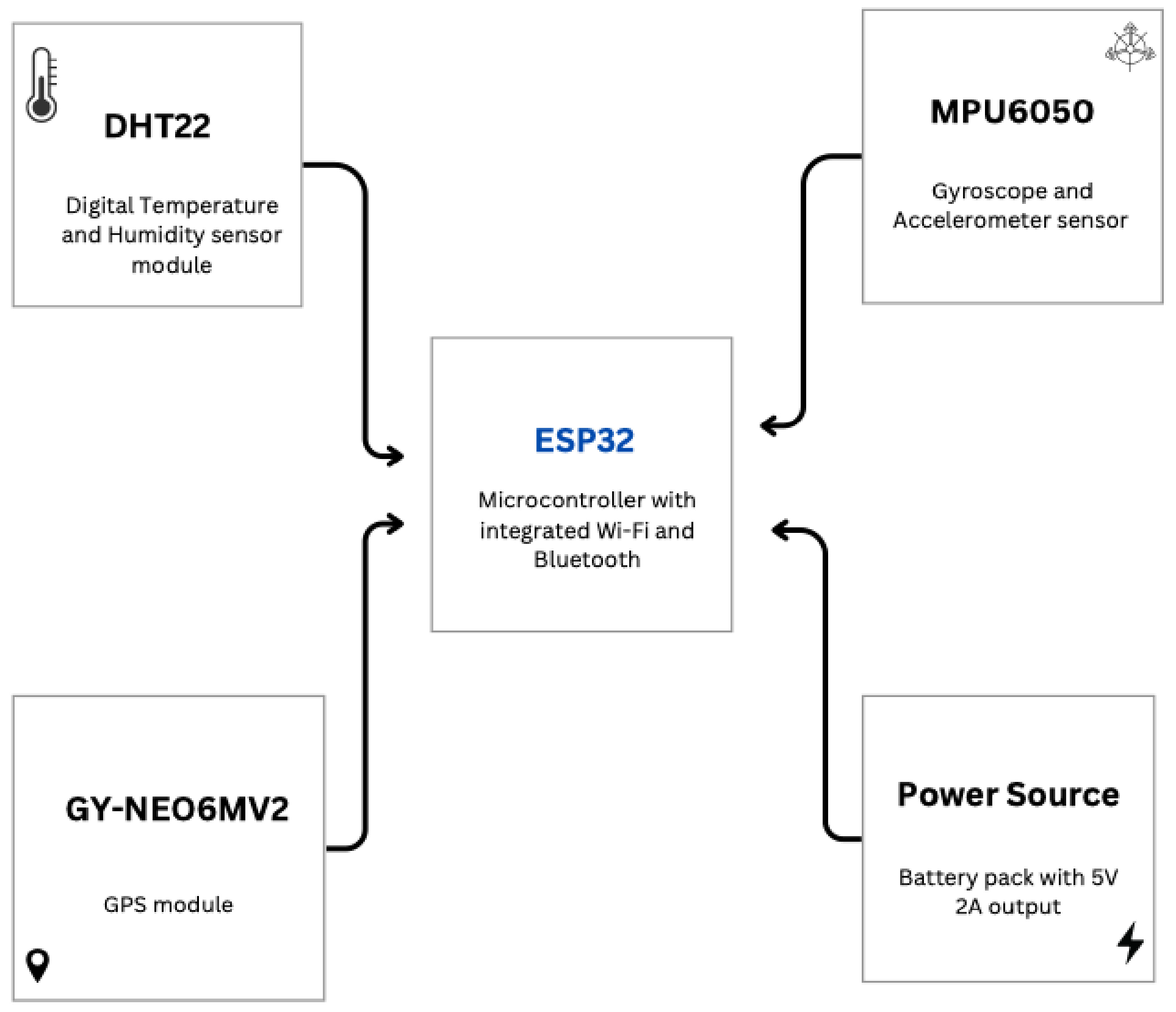

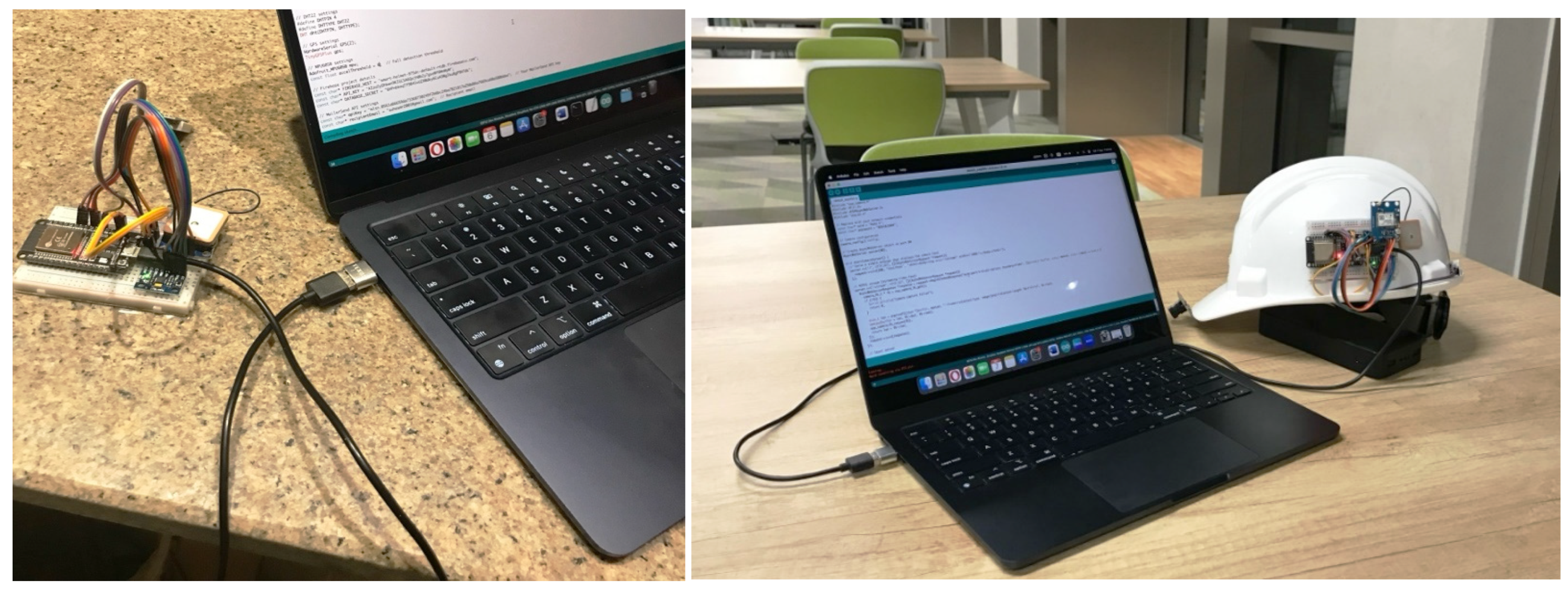

2.3. Helmet Setup

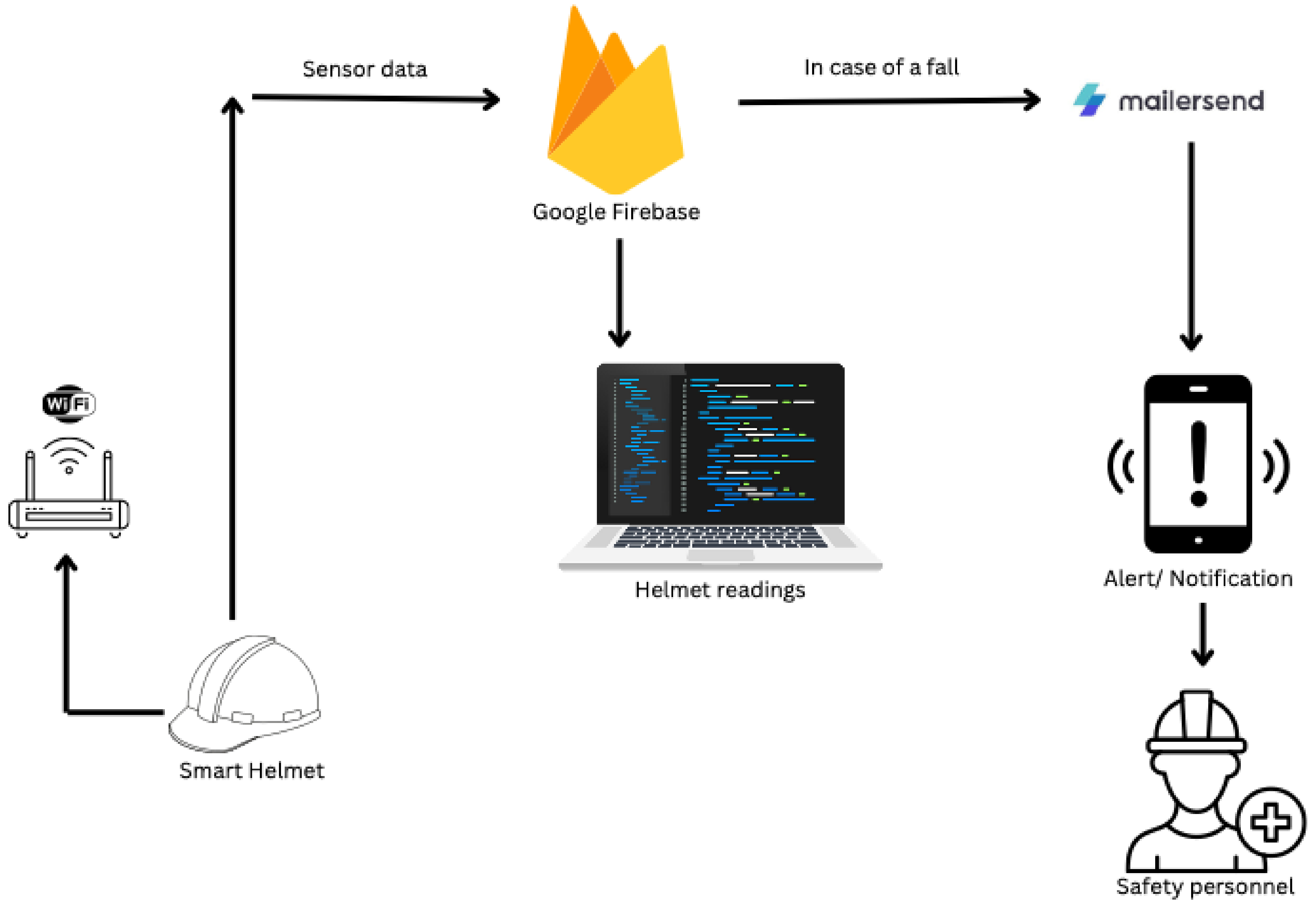

2.4. Operational Mechanism of the Smart Helmet

3. Limitations of the Safety Helmet Prototype

4. Results and Discussion

4.1. Qualitative Insights—Stakeholder Perspectives

4.2. Quantitative Analysis of Survey Data

- Cost concerns were frequently raised, with one respondent mentioning that the helmet might be “too expensive for smaller projects.” This feedback suggests that while the smart helmet could offer substantial benefits for large-scale projects, it may not be financially viable for smaller businesses or projects, where budget constraints are more pronounced.

- Battery life and wearability concerns emerged from a few respondents. These concerns echoed the feedback received from Assistant Executive Engineers (AEEs), who questioned the practicality of maintaining long battery life while ensuring worker comfort. Despite these concerns, prototype testing showed that the helmet was well-received in terms of comfort, with no significant issues reported regarding the helmet’s weight or wearability.

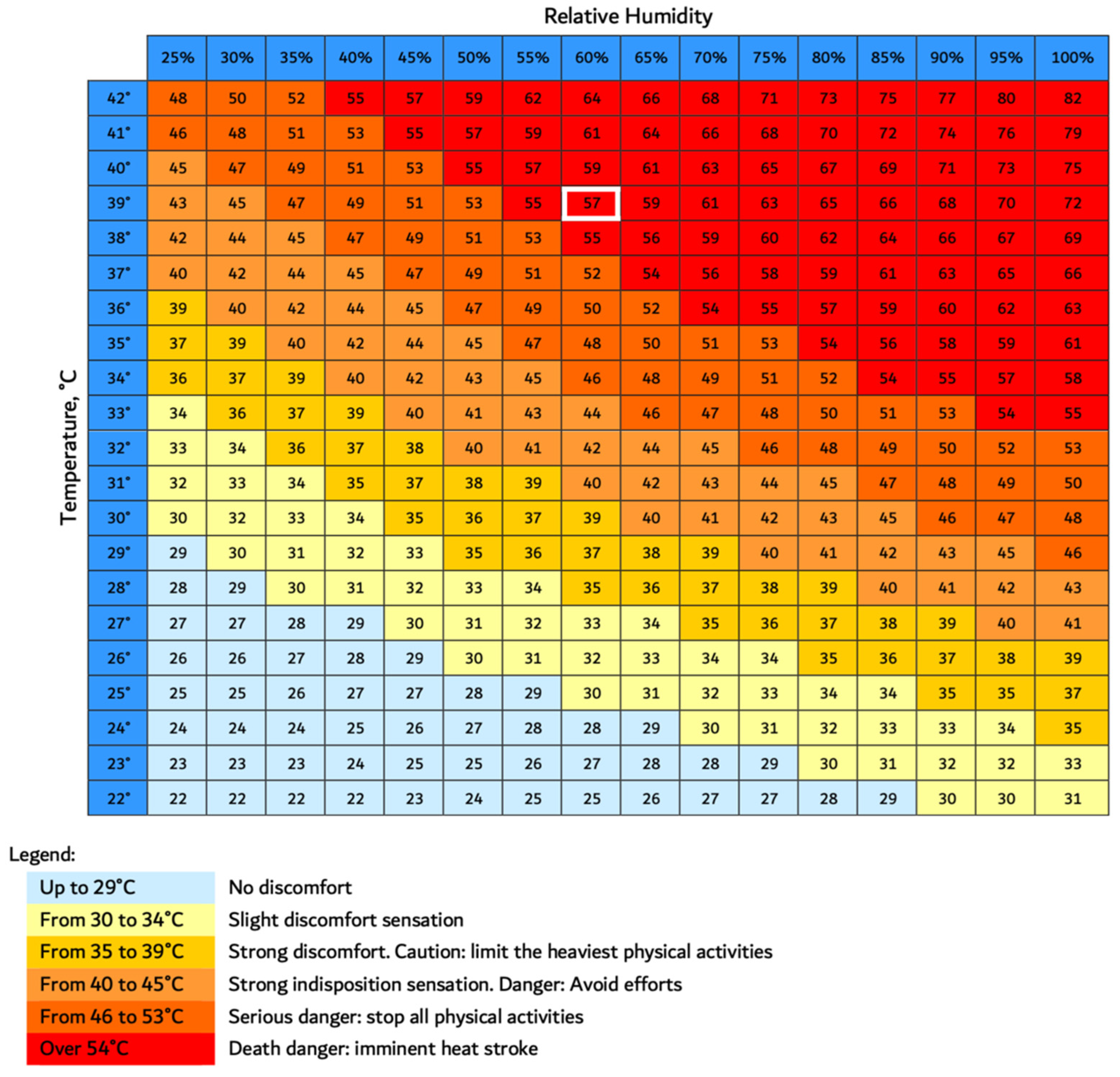

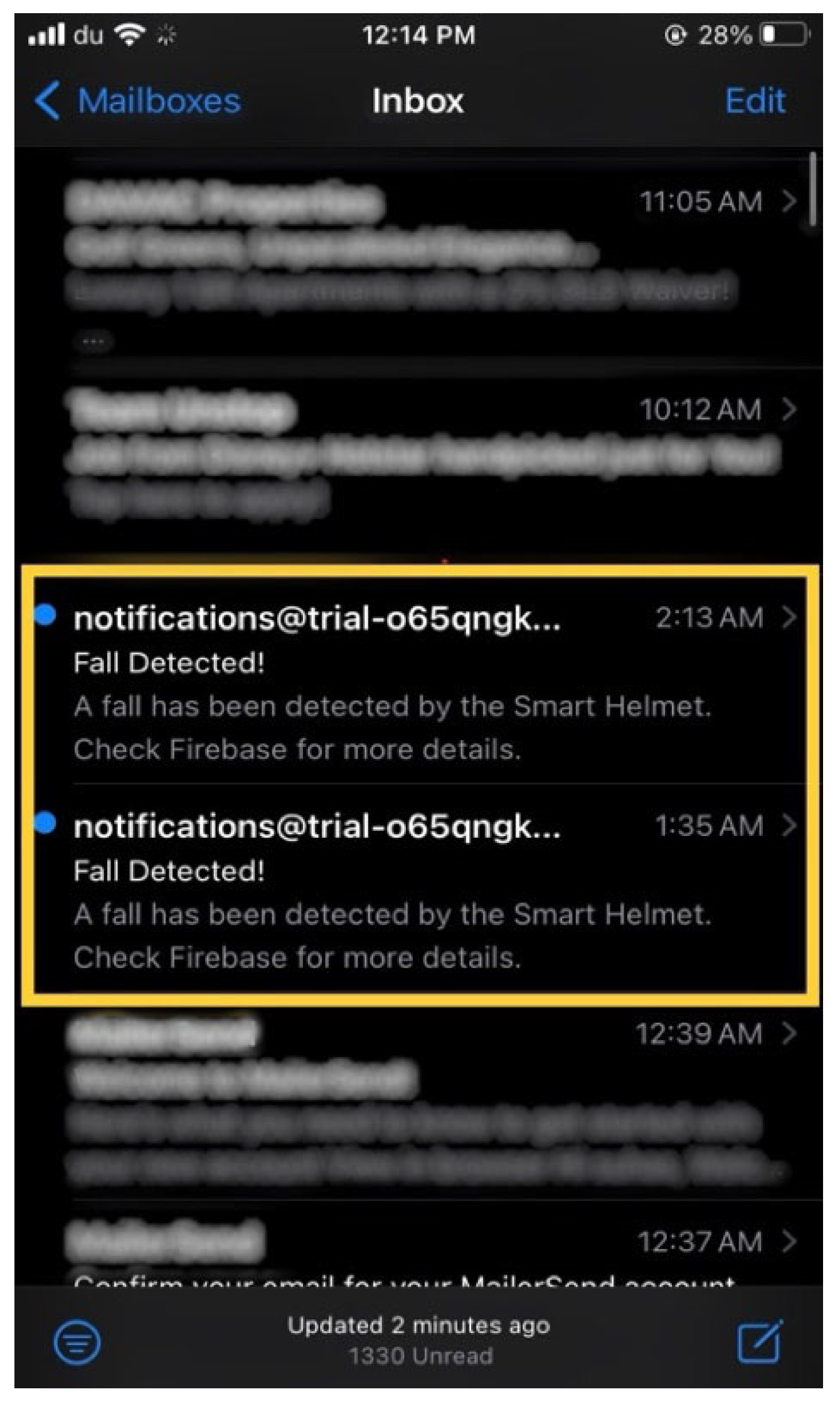

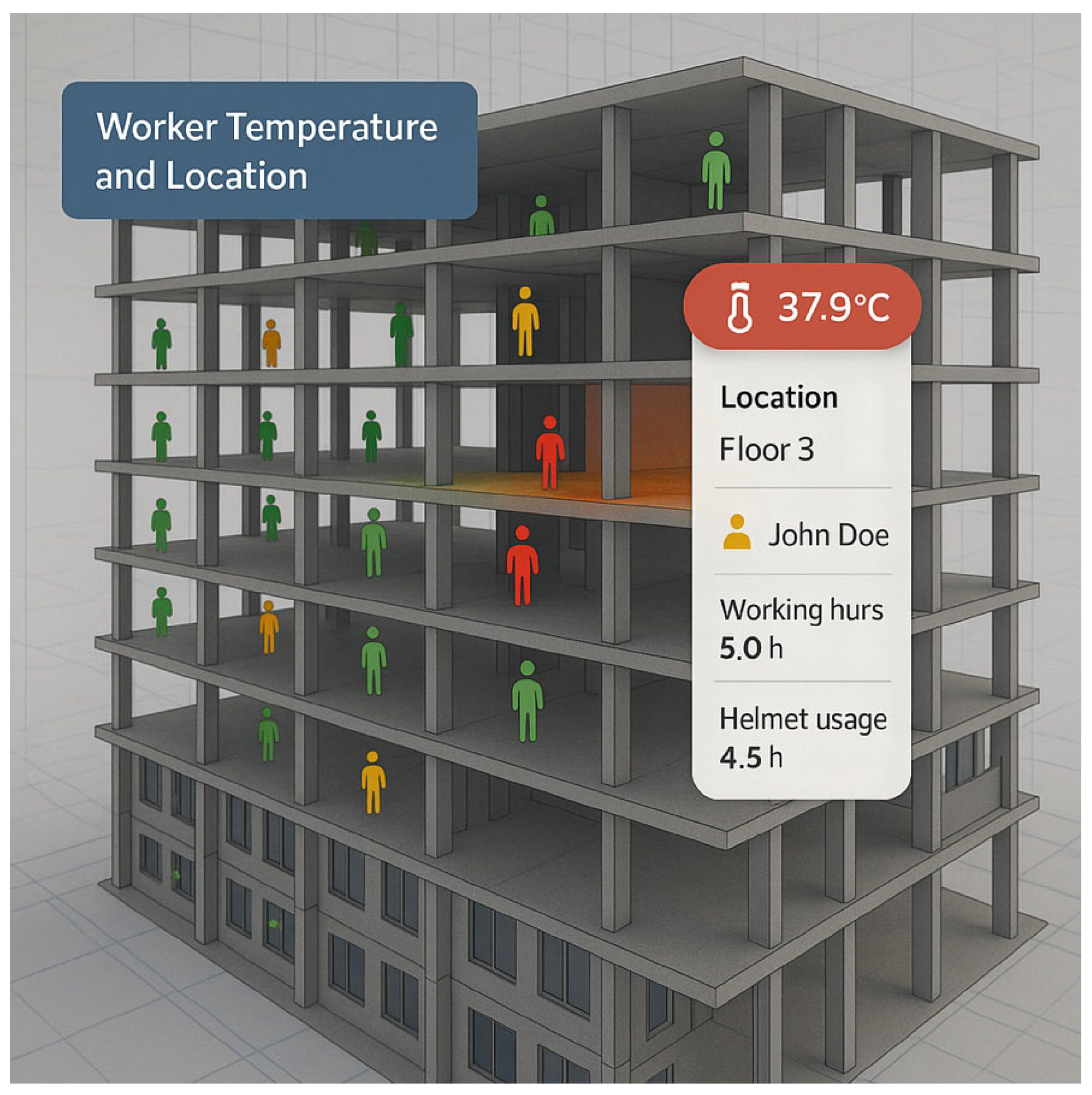

4.3. Outcomes of On-Site Prototype Testing

- Timestamp: dd/mm/yyyy_hh: mm: ss;

- Temperature (°C): [value];

- Humidity (%RH):;

- Longitude: [value];

- Latitude: [value].

- HI = Heat Index in °C;

- T = Ambient temperature in °C;

- RH = Relative humidity in %.

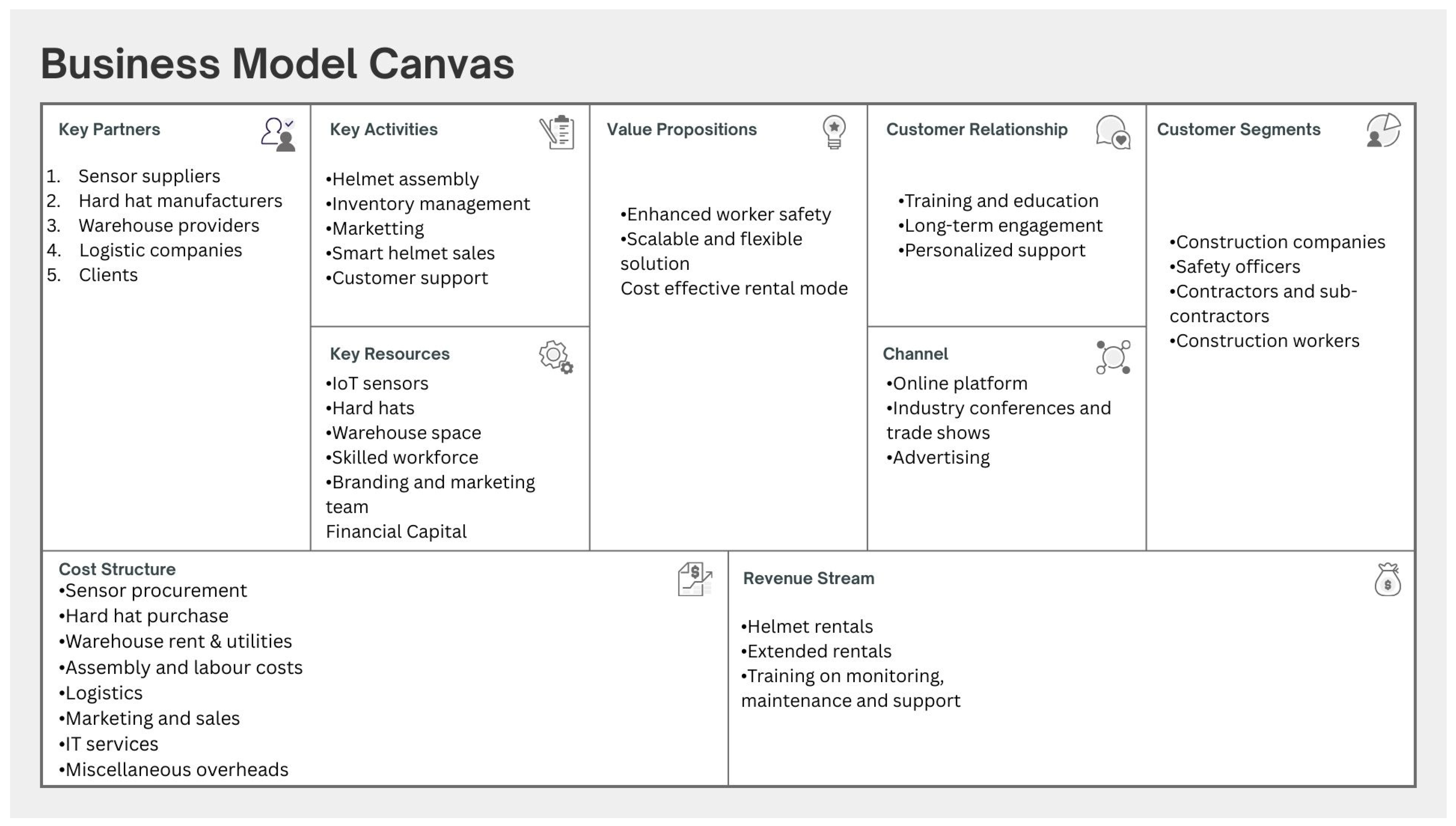

4.3.1. Business Model

4.3.2. Estimated Monthly Savings per Worker

4.3.3. Financial Projection

4.3.4. ROI and Breakeven Analysis

4.4. Comparative Analysis with Existing Solutions

4.5. Regulatory and Standardization Challenges

4.6. Scalability and Generalizability

4.7. Future Opportunities

5. Conclusions

- According to survey results, 91% of construction professionals understand the need to incorporate real-time safety and tracking technology into worker equipment, indicating a high demand for smart wearable solutions in the industry.

- Expert interviews revealed that, in addition to safety, the helmet’s potential to assist in staff management and productivity tracking might provide substantial economic value by linking technology adoption with profitability goals.

- Prototype testing demonstrated that the helmet could successfully gather and send real-time data on temperature, humidity, GPS location, and worker movement, demonstrating the proposed system’s technical feasibility.

- The study stated that a rental-based business model could increase adoption among construction businesses by allowing them to reap the benefits of smart monitoring without incurring large initial costs.

- Heat stress monitoring capabilities based on DHT22 sensor data were particularly welcomed during field trials, proving the ability to save downtime and prevent heat-related incidents on-site.

- Based on the business model and financial projections outlined in the cost sheet, the smart helmet rental business achieves break-even by renting 229 helmets annually or 500 helmets over 5.5 months, confirming the model’s financial feasibility and sustainable revenue potential within the first year of operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Labour Organization. Construction: A Hazardous Work. 2015. Available online: https://www.ilo.org/resource/construction-hazardous-work (accessed on 23 September 2024).

- World Health Organization. Climate Change, Heat and Health. 2024. Available online: https://www.who.int/news-room/fact-sheets/detail/climate-change-heat-and-health (accessed on 23 September 2024).

- Zhang, X.; Wang, Y.; Li, Z.; Liu, Y.; Zhang, L.; Zhang, X.; Liu, J.; Wang, H.; Zhang, Y.; Li, Y. The application of IoT in construction safety: A review. Autom. Constr. 2022, 125, 103634. [Google Scholar]

- Liu, J.; Zhang, Y.; Li, X.; Wang, L.; Zhang, H.; Liu, Y.; Wang, X.; Zhang, Z.; Li, Y.; Liu, Z. Development of an IoT-based smart safety helmet for construction workers. Saf. Sci. 2021, 133, 104989. [Google Scholar]

- UAE Federal Law No. 8 of 1980 (UAE Labor Code); Ministry of Labour and Social Affairs: Abu Dhabi, United Arab Emirates, 1980. Available online: https://natlex.ilo.org/dyn/natlex2/natlex2/files/download/11956/ARE11956.pdf (accessed on 23 September 2024).

- Smith, A.; Johnson, B.; Williams, C.; Brown, D.; Jones, E.; Garcia, F.; Martinez, G.; Robinson, H.; Clark, I.; Lewis, J. Challenges and opportunities in deploying IoT solutions in construction safety. J. Constr. Eng. Manag. 2020, 146, 04020076. [Google Scholar]

- Tabatabaee, S.; Mohandes, S.R.; Ahmed, R.R.; Mahdiyar, A.; Arashpour, M.; Zayed, T.; Ismail, S. Investigating the barriers to applying the Internet-of-Things-based technologies in construction site safety management. Int. J. Environ. Res. Public Health 2022, 19, 1831. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, Z.; Li, X.; Wang, L.; Zhang, H.; Liu, Y.; Wang, X.; Zhang, Z.; Li, Y.; Liu, Z. What hinders Internet of Things (IoT) adoption in the Chinese construction industry: A mixed-method. J. Civ. Eng. Manag. 2024, 30, 19961. [Google Scholar] [CrossRef]

- Dubai Research, Development, and Innovation Program (Dubai RDI Program). Research Priority Areas. 2024. Available online: https://dubairdi.ae (accessed on 29 March 2025).

- Dubai Future Foundation. Dubai’s RDI Grant Initiative Returns to Fund Groundbreaking Research. Dubai Future Foundation. 2 June 2025. Available online: https://www.dubaifuture.ae/latest-news/dubais-rdi-grant-initiative-returns-to-fund-groundbreaking-research/ (accessed on 24 July 2025).

- Dubai Future Foundation (DFF). The Global Future of Construction. 2024. Available online: https://www.dubaifuture.gov.ae (accessed on 4 March 2025).

- AliExpress. Electronics & Technology. Available online: https://www.aliexpress.com (accessed on 14 September 2024).

- Calculator.net. Heat Index Calculator. 2024. Available online: https://www.calculator.net/heat-index-calculator.html (accessed on 6 September 2024).

- Bianchi, F.; Redmond, S.J.; Narayanan, M.R.; Cerutti, S.; Celler, B.G.; Lovell, N.H. Falls event detection using triaxial accelerometry and barometric pressure measurement. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 6111–6114. [Google Scholar] [CrossRef] [PubMed]

- PwC. Startups & Scaleups. PwC Middle East. Available online: https://www.pwc.com/m1/en/services/startups-scaleups.html (accessed on 18 March 2025).

- UAE Federal Tax Authority. Corporate Tax Law Overview. UAE Government Portal. 2022. Available online: https://u.ae/en/information-and-services/finance-and-investment/taxation/corporate-tax (accessed on 18 March 2025).

- Rothfusz, L.P. The Heat Index Equation (or, More Than You Ever Wanted to Know About Heat Index); Technical Attachment (SR/SSD 90-23); National Weather Service (NWS): Fort Worth, TX, USA, 1990.

- Dubai Municipality. Occupational Safety and Health Guidelines for Extreme Heat; Dubai Government: Dubai, United Arab Emirates, 2023.

- Ministry of Human Resources and Emiratisation. Occupational Heat Stress Prevention Policy (Midday Work Ban). 2025. Available online: https://mohre.gov.ae/en/media-center/news/3/6/2025/mohre-to-implement-midday-break-for-the-21st-consecutive-year-from-15-june-to-15-september-2025?utm_source=chatgpt.com (accessed on 4 April 2025).

- Noury, N. A Smart Sensor for the Remote Follow-Up of Activity and Fall Detection of the Elderly. IEEE Sens. J. 2008, 8, 2059–2067. [Google Scholar]

- EmiFast. Dubai Mainland License Cost Explained: Everything Entrepreneurs Should Consider. 2023. Available online: https://emifast.com/blog/dubai-mainland-license-cost-explained-everything-entrepreneurs-should-consider/ (accessed on 1 November 2024).

- Kangas, M.; Vikman, I.; Wiklander, J.; Lindgren, P.; Nyberg, L.; Jämsä, T. Sensitivity and Specificity of Fall Detection in Older Adults Using Wearable Sensors. J. Biomech. 2015, 48, 3340–3346. [Google Scholar]

- Hsiao, H.; Simeonov, P. Preventing falls from roofs: A critical review. Ergonomics 2001, 44, 537–561. [Google Scholar] [CrossRef]

- Courtney, A.C.; Smith, J.D.; Johnson, M.K. Fatal Falls: Biomechanical Analysis of Impact Severity. J. Trauma Acute Care Surg. 2013, 74, 449–455. [Google Scholar]

- MailerSend. Transactional Email API Documentation. 2024. Available online: https://www.mailersend.com/features/email-api (accessed on 2 September 2025).

- Bablu, T.A.; Rashid, M.T. Edge Computing and Its Impact on Real-Time Data Processing for IoT-Driven Applications. J. Adv. Comput. Syst. 2025, 5, 26–43. [Google Scholar]

- Mahajan, G.; Narkhede, P. Integrating BIM with digital technology trends in the construction industry: Implementation insights for 2023. J. Constr. Innov. 2023, 15, 45–67. [Google Scholar]

- International Labour Organization (ILO). Digital Labour Platforms and the Future of Work: Towards Decent Work in the Online World; ILO: Geneva, Switzerland, 2018. [Google Scholar]

- Dubai Municipality. Construction Safety Manual and Violation Penalties; Dubai Municipality: Dubai, United Arab Emirates, 2023.

- MOHRE. Occupational Health and Safety Guidelines; UAE Government Portal: Dubai, United Arab Emirates, 2022.

- Gulf News. UAE Imposes Hefty Fines for Worker Safety Violations; Gulf News: Dubai, United Arab Emirates, 2022. [Google Scholar]

- Teizer, J.; Cheng, T. Wearable Sensing and Tracking Technology for Construction Workforce Safety and Productivity. Autom. Constr. 2015, 62, 24–37. [Google Scholar]

- Li, H.; Chan, G.; Skitmore, M. Real-Time Location Systems for Construction Workforce Management and Safety Control. Saf. Sci. 2016, 85, 160–168. [Google Scholar]

- Dubai Future Foundation. The Role of Emerging Technologies in UAE Construction Sites. 2021. Available online: https://www.dubaifuture.ae (accessed on 23 September 2024).

- MOHRE. Occupational Health and Safety Report: Heat Stress Management in the UAE; MOHRE: Dubai, United Arab Emirates, 2022.

- Harsha, D.; Al Hosani, H. Impact of Heat Stress on Productivity and Health in Gulf Construction Sites. J. Environ. Health 2016, 78, 36–42. [Google Scholar]

- International Labour Organization (ILO). Working on a Warmer Planet: The Impact of Heat Stress on Labour Productivity and Decent Work; ILO: Geneva, Switzerland, 2021. [Google Scholar]

- Gulf News. Midday Break Rules in UAE: Protecting Workers During Summer Heat. 2023. Available online: https://gulfnews.com (accessed on 23 September 2024).

- Zhang, L.; Chen, Y. Wearable sensors for monitoring heat stress in construction workers: Implications for productivity and labor management. Saf. Sci. 2020, 122, 104573. [Google Scholar]

- Dubai Future Foundation. Future Opportunities: The Global 50; Dubai Future Foundation: Dubai, United Arab Emirates, 2024. [Google Scholar]

- Wu, I.-L.; Chiu, M.-L. Examining supply chain collaboration with determinants and performance impact: Social capital, justice, and technology use perspectives. Int. J. Inf. Manag. 2018, 39, 5–19. [Google Scholar] [CrossRef]

- Ghosh, A.; Hosseini, M.R.; Edwards, D.; Kassem, M.; Matteo-Garcia, M. Use Cases for the Internet of Things (IoT) in the Construction Sector: Lessons from Leading Industries. In Proceedings of the 36th CIB (International Council for Research and Innovation in Building and Construction) W78 2019 Conference, Newcastle upon Tyne, UK, 18–20 September 2019; Available online: https://www.open-access.bcu.ac.uk/9900/1/Use%20cases%20for%20the%20Internet%20of%20Things%20in%20the%20construction%20sector.pdf (accessed on 2 September 2025).

- Ghosh, S.; Arif, M. Monitoring Labor Productivity and Overtime Trends in the Middle East Construction Sector. Int. J. Constr. Manag. 2018, 18, 205–214. [Google Scholar]

- Dubai Labour Law—Wages and Working Hours; UAE Ministry of Human Resources and Emiratisation: Dubai, United Arab Emirates, 2021. Available online: https://www.mohre.gov.ae/en/laws-and-regulations/laws.aspx (accessed on 23 September 2024).

- Occupational Safety and Health Administration (OSHA). Top 10 Most Frequently Cited Standards. 2022. Available online: https://www.osha.gov (accessed on 23 September 2024).

- Zhou, C.; Ding, L. Safety barrier warning system for underground construction sites using Internet-of-Things technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Rasheed, R. Improving Supervision Efficiency through Wearable IoT in Construction Sites. J. Constr. Eng. Manag. 2021, 147, 04021091. [Google Scholar]

- Al-Bouwarthan, M.; Quinn, M.M.; Kriebel, D.; Wegman, D.H. Assessment of Heat Stress Exposure among Construction Workers in the Hot Desert Climate of Saudi Arabia. Ann. Work. Expo. Health 2019, 63, 505–520. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Chi, S. Tracking Construction Labor Activities Using IoT Devices. Adv. Eng. Inform. 2020, 45, 101–115. [Google Scholar]

- BIM Forum. Emerging Role of IoT in Construction Project Monitoring. 2020. Available online: https://www.bimforum.org (accessed on 19 September 2024).

- Dubai Municipality. Midday Break Regulation: Protecting Workers from Summer Heat. 2023. Available online: https://www.dm.gov.ae (accessed on 14 March 2025).

- Indeed. Technician Salary in UAE. Available online: https://ae.indeed.com/career/technician/salaries (accessed on 12 January 2025).

- Daqri. Daqri Smart Helmet Product Overview. 2016. Available online: https://web.archive.org/web/20161025102416/http://daqri.com/products/smart-helmet/ (accessed on 8 April 2025).

- Lantronix. Guardhat: Protecting Workers with a Smart Hardhat and Edge IoT Connectivity. Available online: https://www.lantronix.com/resources/case-studies/guardhat/ (accessed on 25 May 2025).

- Dubai Municipality. “Regulations for Personal Protective Equipment (PPE) in the Emirate of Dubai,” DM Safety Manual; Dubai Municipality: Dubai, United Arab Emirates, 2023.

- Government of Dubai. “Dubai RDI Council Strategy and Innovation Labs,” RDI Annual Report; Government of Dubai: Dubai, United Arab Emirates, 2023.

- ElectroPeak Inc. ElectroPeak Official Website. Available online: https://electropeak.com/ (accessed on 4 September 2024).

- QuickBooks UAE. Dubai Business License Cost: Everything You Need to Know. 2023. Available online: https://quickbooks.intuit.com/ae/resources/small-business-and-self-employed/dubai-business-license-cost/ (accessed on 1 November 2024).

| Code | Designation | Organization | Location | Years of Experience |

|---|---|---|---|---|

| CEO | Chief Executive Officer | Construction technology startup | UAE | 12 |

| AVP | Vice President | Leading construction company | UAE | 18 |

| EE | Executive Engineer | Urban development | India | 20 |

| AEE1 | Asst. Executive Engineer | City municipal council | India | 20 |

| AEE2 | Asst. Executive Engineer | City municipal council | India | 15 |

| AEE3 | Asst. Executive Engineer | City municipal council | India | 13 |

| HSSE | Senior Officer—Safety | Construction company | UAE | 15 |

| Category | Description | Estimated Savings (EUR/Month) | Underlying Assumptions |

|---|---|---|---|

| Overtime (OT) Misuse Reduction | Eliminating inflated or fraudulent overtime claims through helmet usage tracking | EUR 11.30 (AED 48) | Based on site data, average misuse estimated at 2 h/month per worker. Considering an overtime (OT) rate of EUR 5.6/hour, the monthly saving per worker is EUR 11.30 [33,34,35] |

| Safety Compliance (Fine Avoidance) | Ensuring mandatory helmet usage to avoid regulatory fines and site penalties | EUR 1.64 (AED 7.00) | Industry data suggests approx. 1 PPE violation fine per 25 workers per month (avg. AED 1800 per fine). Pro-rated saving per helmet: AED 1800 ÷ 25 = AED 72; applying a 10% risk-adjusted factor gives AED 7 (EUR 1.64) [12,13,36,37] |

| Productivity Enhancement | Improved time efficiency through real-time location and motion monitoring | EUR 5.87 (AED 25.00) | Estimated time saved: 10 min/day/worker due to optimized supervision. Over 22 workdays: ≈3.6 h saved. Valued at EUR 5.87/hour, yields EUR 21.14; conservatively adjusted to EUR 5.87 [16,38,39,40,41] |

| Health Incident Reduction (Heat Stress) | Reducing lost workdays through early detection of heat stress. | EUR 7.05 (AED 30.00) | Based on prevention of lost workdays/month. At EUR 7/day (avg. wage), monthly saving is EUR 7 [6,42,43,44,45] |

| Labor Accountability | Reduced absenteeism and medical leaves via DHT-based heat stress alerts | EUR 3.52 (AED 15.00) | Based on prevention of 0.5 lost workday/month. At EUR 7/day (avg. wage + indirect productivity loss), the monthly saving is EUR 3.52 [46,47,48] |

| Total Estimated Savings | EUR 29.3 (AED 125.00) |

| Item | Amount (AED) | Remarks/Justifications |

|---|---|---|

| Revenue | ||

| Helmet rental income | EUR 70,469 (AED 300,000.00) | Assuming 500 helmets are rented for 12 months at EUR 11.74/month (500 helmets × EUR 11.74 × 12 months) |

| COGS (cost of goods sold) | ||

| Business setup fee | EUR 3523 (AED 15,000.00) | Business license in UAE [49,50] |

| Hard hat cost | EUR 1174 (AED 5000.00) | Based on EUR 2.35/helmet in bulk order from local supplier |

| IoT sensors | ||

| EUR 840 (AED 3578.25) | Based on bulk orders (500 units) from a Chinese supplier, Electro Peak [51] |

| EUR 1939 (AED 8257.50) | |

| EUR 2133 (AED 9083.25) | |

| EUR 1185 (AED 5046.25) | |

| Operating expenses | ||

| Warehouse rent | EUR 9395 (AED 40,000.00) | 720 sqft of warehouse space being rented annually in the UAE. |

| Labor salaries | EUR 6215 (AED 26,460.00) | A total of 3 technicians with EUR 635 per month salaries has been considered [52]. |

| Logistics (Shipping) | EUR 234 (AED 1000.00) | Local shipping partner Aramex has been considered, shipping 500 helmets with a total of 200 KG |

| DEWA | EUR 1174 (AED 5000.00) | Utility estimate for 12 months |

| Taxes | ||

| VAT (value added tax) 5% | EUR 0 (AED 0.00) | Applicable only to the sales |

| Corporate tax 9% | EUR 0 (AED 0.00) | Applicable only if net profits exceed EUR 88,086.11 (AED 375,000) in the UAE |

| Gross Profit | EUR 59,671 (AED 254,034.75) | (Revenue—COGS) |

| Operating Profit | EUR 42,651.24 (AED 181,574.75) | (Gross Profit—Operating expenses) |

| Net Profit | EUR 42,651.24 (AED 181,574.75) | (Operating Profit—Taxes) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raghunath, S.; Ghaffar, S.H. Developing an IoT-Enabled Smart Helmet for Worker Safety: Technical Feasibility and Business Model. Safety 2025, 11, 89. https://doi.org/10.3390/safety11030089

Raghunath S, Ghaffar SH. Developing an IoT-Enabled Smart Helmet for Worker Safety: Technical Feasibility and Business Model. Safety. 2025; 11(3):89. https://doi.org/10.3390/safety11030089

Chicago/Turabian StyleRaghunath, Suhas, and Seyed Hamidreza Ghaffar. 2025. "Developing an IoT-Enabled Smart Helmet for Worker Safety: Technical Feasibility and Business Model" Safety 11, no. 3: 89. https://doi.org/10.3390/safety11030089

APA StyleRaghunath, S., & Ghaffar, S. H. (2025). Developing an IoT-Enabled Smart Helmet for Worker Safety: Technical Feasibility and Business Model. Safety, 11(3), 89. https://doi.org/10.3390/safety11030089