An Analysis of Occupational Hazards Based on the Physical Ergonomics Dimension to Improve the Occupational Health of Agricultural Workers: The Case in Mayo Valley, Mexico

Abstract

1. Introduction

2. Literature Review

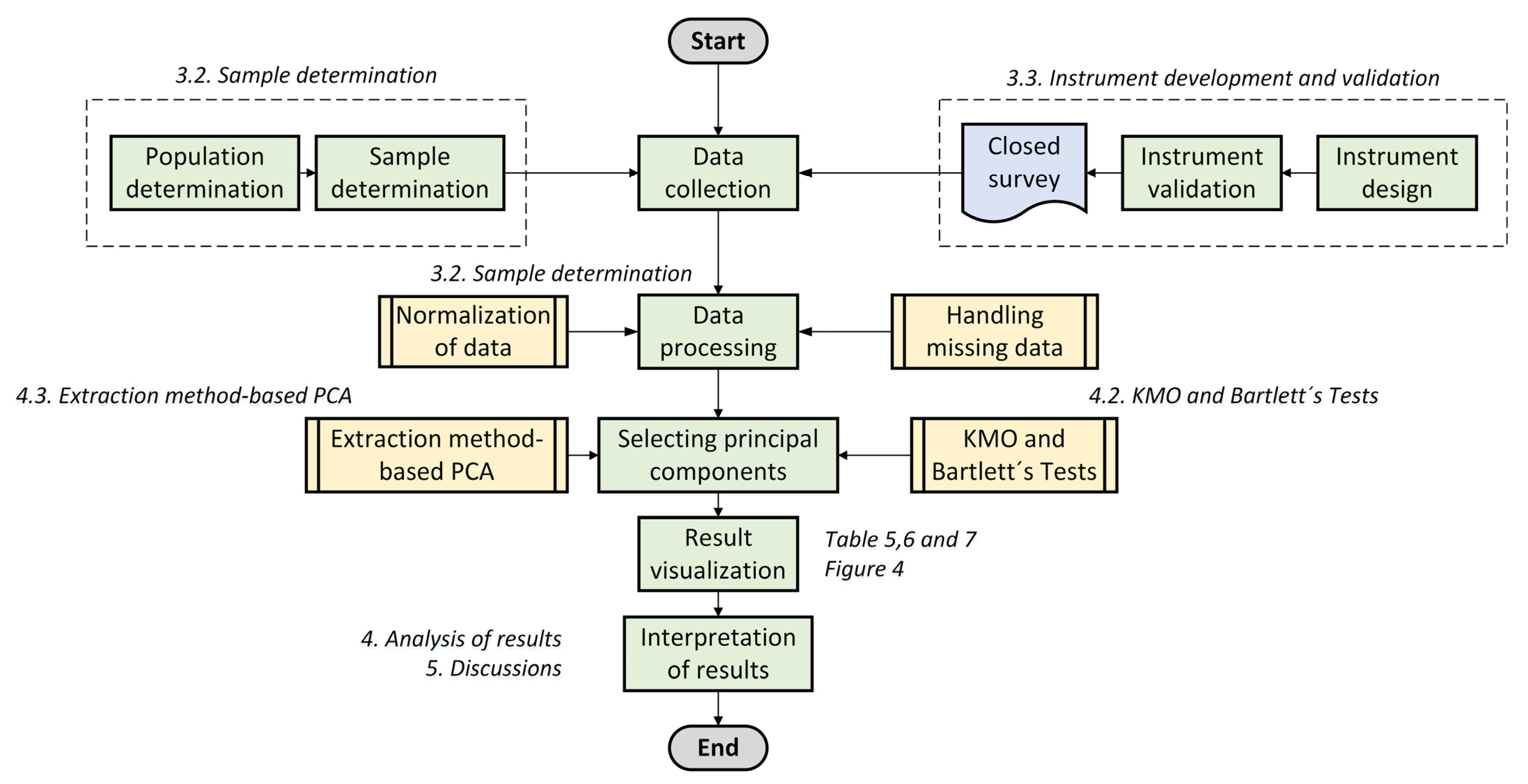

3. Methodology

3.1. Sample Determination

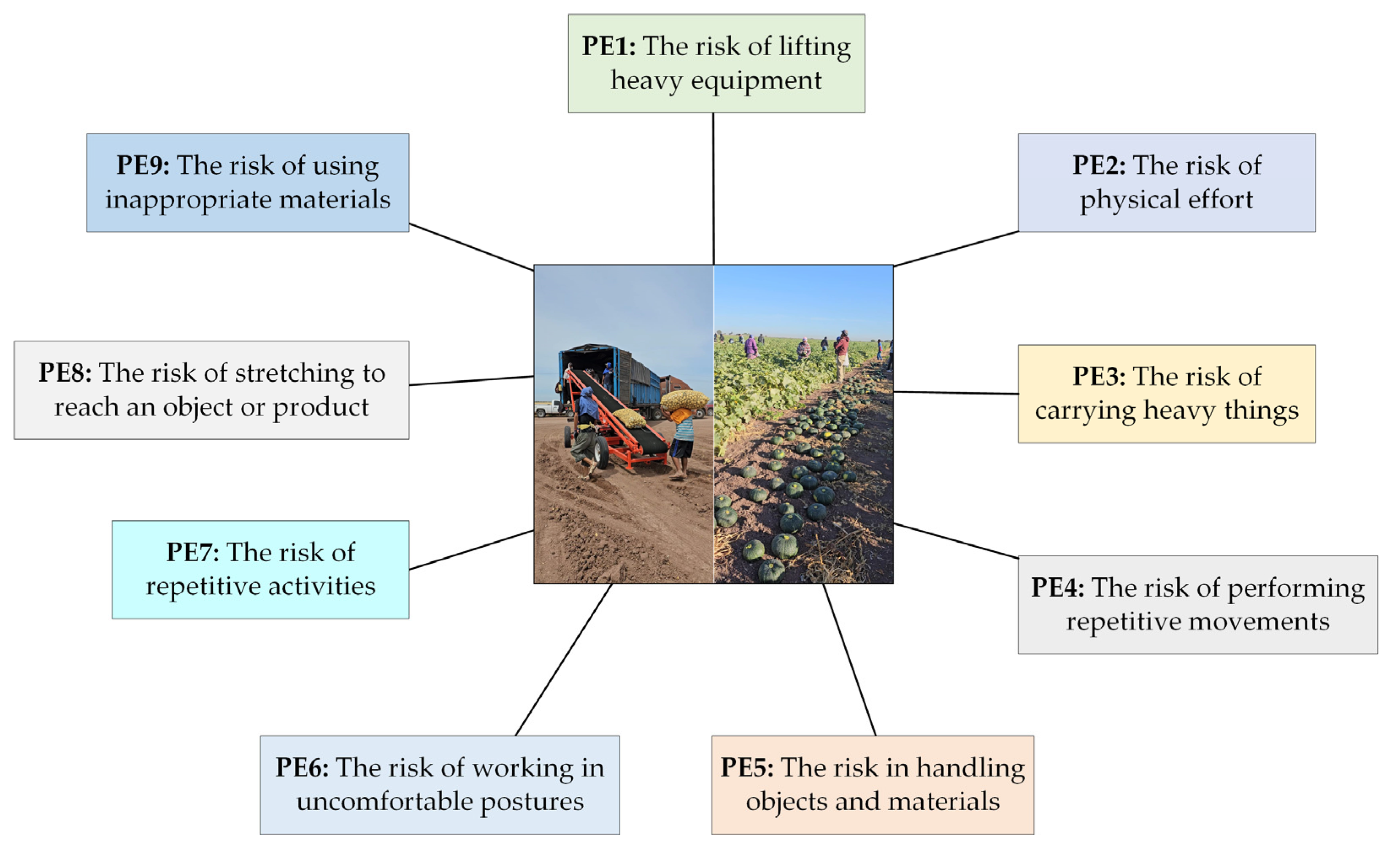

3.2. Instrument Development and Validation

3.3. Statistical Method

4. Analysis of Results

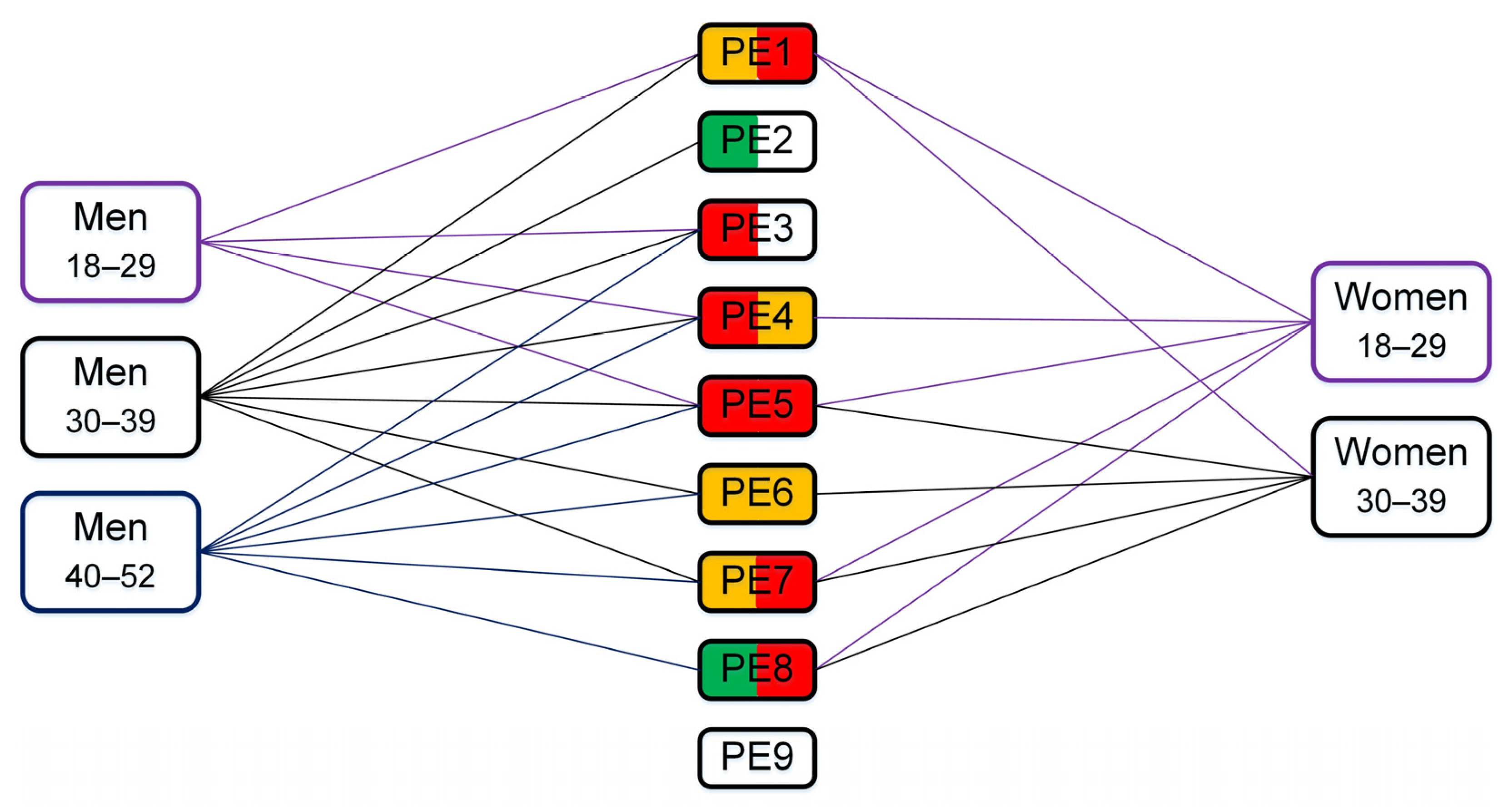

4.1. Statistical and Cronbach’s Alpha Gender Analysis

4.2. KMO and Bartlett’s Tests

4.3. Extraction Method-Based PCA

5. Discussions

- Finding 1: The risk of handling objects and materials (PE5) was the only physical ergonomics variable present for agricultural workers of both genders based on the PCA. This finding is strongly related to several studies on musculoskeletal disorders and pain in agricultural male workers and postmenopausal agricultural female workers [52,53,54]. In addition, this physical ergonomics variable has a more significant impact in low- and middle-income countries [53].

- Finding 2: The risk of using inappropriate materials (PE9) was the only physical ergonomics variable that was not present (not as important) for agricultural workers of both genders based on the PCA. This is because the factorial coefficient was less than 0.5. In this case, the results showed that the use of fertilizers, pesticides, herbicides, irrigation systems, seedlings, seeds, and farm machinery did not represent a significant risk to agricultural workers. The above can be related to the care taken by companies concerning the general uses of materials and machinery in the Mayo Valley region [27,55,56].

- Finding 3: Concerning the physical ergonomics variable related to the risk of carrying heavy things (PE3), this variable was significant for male agricultural workers, while it was not significant for female agricultural workers. This does not mean that the variable PE3 is not present in the opinion of the agricultural workers, but that there are other more important variables. In fact, there is evidence that a significant percentage of women working in agriculture suffer from back pain, joint pain, and leg pain [32,57]. In this way, this finding must be contextualized to the Mayo Valley and not generalized worldwide. Perhaps the working conditions of agricultural women in this region have certain characteristics that result in a factorial component value of less than 0.5 for the physical ergonomics variable studied.

- Finding 4: It should be noted that, in terms of the relationship between the explained variable and the factorial loading, Table 6 shows the variability of the male agricultural workers concerning the factorial loading, with a mean value of μM = 70.21% and a standard deviation of σM = 2.47%. This implies a coefficient of variation (CV = σ/μ) of 3.51%, whereas, for female agricultural workers (according to Table 7), the mean is μF = 66.12% and the standard deviation is σF = 9.72%. This gives a coefficient of variation of 14.7%. In this way, it can be seen that the CV of female agricultural workers was significantly higher than that of male workers. The above could be interpreted as a significant difference in the perception of physical ergonomics risk factors by women.

6. Conclusions

6.1. Implications and Recommendations

6.2. Limitations

6.3. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodríguez, Y.; Hignett, S. Integration of human factors/ergonomics in healthcare systems: A giant leap in safety as a key strategy during COVID-19. Hum. Factors Ergon. Manuf. Serv. Ind. 2021, 31, 570–576. [Google Scholar] [CrossRef]

- Akpan, I.J.; Offodile, O.F. The Role of Virtual Reality Simulation in Manufacturing in Industry 4.0. Systems 2024, 12, 26. [Google Scholar] [CrossRef]

- Mamani, H.R. Impact of ergonomics on productivity, a systematic review from 2016–2021. Qantu Yachay 2021, 1, 46–50. [Google Scholar] [CrossRef]

- Torres, Y.; Rodríguez, Y. Emergence and evolution of ergonomics as a discipline: Reflections on the school of human factors and 323 the school of ergonomics of the activity. Rev. Fac. Nac. Salud Pública 2021, 39, 1–9. [Google Scholar] [CrossRef]

- Koirala, R.; Nepal, A. Literature Review on Ergonomics, Ergonomics Practices, and Employee Performance. Quest J. Manag. Soc. Sci. 2022, 4, 273–288. [Google Scholar] [CrossRef]

- Songkham, W. The effect of an ergonomics intervention on psychosocial factors and musculoskeletal symptoms among health care workers in Thailand. Saf. Health Work. 2022, 13, S83. [Google Scholar] [CrossRef]

- Hilmi, D.A.H.; Hamid, D.A.R. Beyond Comfort: Ergonomics in Engineering Education and Design. Malays. J. Erg. 2024, 5, 1–20. [Google Scholar] [CrossRef]

- Escudero, S. Physical ergonomic risks loading and occupational low back pain. Rev. Libre Empre. 2016, 13, 125–129. [Google Scholar]

- Opone, A.L.; Douglas, K.; Wejie-Okachi, C. Remote Work Ergonomics and Musculoskeletal Health in Lagos, Nigeria: A Cross-sectional Study. J. Eng. Res. Rep. 2024, 26, 34–48. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L.; Wang, Y.; Lan, Y.; Zhang, Y. Characteristics of Publications on Occupational Stress: Contributions and Trends. Front. Public Health 2021, 9, 664013. [Google Scholar] [CrossRef]

- Hermel, G.C. Evolution of occupational health practices within a multidisciplinary team. Arch. Occup. Environ. Dis. 2024, 85, 101967. [Google Scholar] [CrossRef]

- Viswanathan, K.; Johnson, M.S.; Toffel, M.W. Do safety management system standards indicate safer operations? Evidence from the OHSAS 18001 occupational health and safety standard. Saf. Sci. 2024, 171, 106383. [Google Scholar] [CrossRef]

- Šolc, M.; Blaško, P.; Girmanová, L.; Kliment, J. The Development Trend of the Occupational Health and Safety in the Context of ISO 45001:2018. Standards 2022, 2, 294–305. [Google Scholar] [CrossRef]

- Koliev, F. Promoting international labour standards: The ILO and national labour regulations. Brit. J. Polit. Int. Rel. 2022, 24, 361–380. [Google Scholar] [CrossRef]

- Artvinli, F. The Ethics of Occupational Health and Safety in Turkey: Responsibility and Consent to Risk. Acta Bioeth. 2016, 22, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Sámano, R.M. Trabajo Infantil y Salud Ocupacional en México: Un Desafío para la Medicina. Rev. Med. Inst. Mex. Seguro Soc. 2017, 56, 550–557. [Google Scholar]

- Telles, F.S.; Garcés, D.E.; Hernández, J.A.F. Evaluation of the validity of the questionnaire of psychosocial risk factors and evaluation of the organizational environment proposed by NOM-035-STPS-2018. Contad. Adm. 2022, 67, 1–23. [Google Scholar] [CrossRef]

- Cano-Gutierrez, J.C.; Pérez-Morán, J.C.; Bernal-Baldenebro, B.; Arenas-Meneses, D.; Vazquez-Lira, R.; Olguín-Tiznado, J.E. Factor structure and measurement invariance of the psychosocial risk factors inventory of NOM-035-STPS-2018. Front. Psychol. 2023, 13, 1022707. [Google Scholar] [CrossRef] [PubMed]

- Wodajeneh, S.N.; Azene, D.K.; Berhan, E.; Sileyew, K.J. Impacts of ergonomic risk factors on the well-being and innovation capability of employees in the manufacturing industry. Int. J. Occup. Saf. Ergon. 2024, 30, 412–424. [Google Scholar] [CrossRef]

- Hasanain, B. The Role of Ergonomic and Human Factors in Sustainable Manufacturing: A Review. Machines 2024, 12, 159. [Google Scholar] [CrossRef]

- Aulia, Y.; Zuraida, R. Toward the Implementation of Digital Twin for Assessing the Ergonomic Aspects on Manufacturing Process. Int. J. Eng. Trends Technol. 2024, 72, 141–154. [Google Scholar] [CrossRef]

- Baratta, A.; Cimino, A.; Longo, F.; Nicoletti, L. Digital twin for human-robot collaboration enhancement in manufacturing systems: Literature review and direction for future developments. Comput. Ind. Eng. 2024, 187, 109764. [Google Scholar] [CrossRef]

- Ling, S.; Yuan, Y.; Yan, D.; Leng, Y.; Rong, Y.; Huang, G.Q. RHYTHMS: Real-time Data-driven Human-machine Synchronization for Proactive Ergonomic Risk Mitigation in the Context of Industry 4.0 and Beyond. Robot. Cim.-Int. Manuf. 2024, 87, 102709. [Google Scholar] [CrossRef]

- Tagoe, A. How to Ensure Health and Safe Working Conditions for All. Saf. Health Work 2022, 13, S69–S70. [Google Scholar] [CrossRef]

- Flores, L.; Edwards, M.C. A Historical Overview of Protected Agriculture in the State of Sinaloa, Mexico: Implications for Improving Rural Prosperity. J. Int. Agric. Ext. Educ. 2019, 26, 7–26. [Google Scholar] [CrossRef]

- González, O.M. The codependencies of the agro industry on Sinaloa, Mexico. Perf. Latinoam. 2023, 31, 1–28. [Google Scholar] [CrossRef]

- Hanke, D.; da Silva Nascimento, S.G.; Teixeira, K.; De Àvila, M.R. Quality of life in rural work: An analysis of the ergonomics operator relationship in agricultural machines in the region Pampa Gaúcho. Obs. Econ. Latinoam. 2024, 22, e3184. [Google Scholar] [CrossRef]

- Mishra, D.; Satapathy, S. Modified reaper for small-scale farmers: An approach for sustainable agriculture. Environ. Dev. Sustain. 2024, 26, 1451–1480. [Google Scholar] [CrossRef]

- Kapse, S.; Wu, R.; Thamsuwan, O. Addressing Ergonomic Challenges in Agriculture through AI-Enabled Posture Classification. Appl. Sci. 2024, 14, 525. [Google Scholar] [CrossRef]

- Reyes-Zárate, G.G. A Digital REBA System Based on Kinect and Its Benefits for Ergonomic Assessment. In Smart Innovation, Systems and Technologies; Barredo-Ibañez, D., Castro, L., Espinosa, A., Puentes-Rivera, I., Lopez-Lopez, P.C., Eds.; Springer Science and Business Media Deutschland GmbH: Singapore, 2024; Volume 375, pp. 3–11. [Google Scholar] [CrossRef]

- Mishra, Y.; Singh, A.K.; Meena, M.L.; Dangayach, G.S. Assessment of Ergonomic Risk Factors among Metal Sculpture Workers and Future Scope of AI Applications in Ergonomic Evaluation. Recent Pat. Eng. 2024, 18, 27–34. [Google Scholar] [CrossRef]

- Meenakshi, J.R.; Panneer, S. Occupational health of agricultural women workers in India. Indian J. Community Med. 2020, 45, 546–549. [Google Scholar] [CrossRef] [PubMed]

- Tabibi, R.; Tarahomi, S.; Ebrahimi, S.M.; Valipour, A.A.; Ghorbani-Kalkhajeh, S.; Tajzadeh, S.; Panahi, D.; Soltani, S.; Dzhsupov, K.O.; Sokooti, M. Basic occupational health services for agricultural workers in the south of Iran. Ann. Glob. Health 2018, 84, 465–469. [Google Scholar] [CrossRef] [PubMed]

- Irani, T.; Pierre, B.F.; Nesbit, T.S. Agricultural stakeholders’ perceptions of occupational health and safety in the southeastern U.S. coastal states. Int. J. Environ. Res. Public Health 2021, 18, 6605. [Google Scholar] [CrossRef]

- Susanto, T.; Rahmawati, I.; Wantiyah. Community-based occupational health promotion programme: An initiative project for Indonesian agricultural farmers. Health Educ. 2020, 120, 73–85. [Google Scholar] [CrossRef]

- Galvis, D.J.M.; Molina, A.L.V. Occupational safety and health in the agricultural sector: A bibliographic review. Rev. Bras. Med. Trab. 2023, 21, e20231137. [Google Scholar] [CrossRef]

- Noomnual, S.; Konthonbut, P.; Kongtip, P.; Woskie, S.R. Mental health disorders among Thai farmers: Occupational and non-occupational stressors. Hum. Ecol. Risk. Assess. 2024, 30, 180–200. [Google Scholar] [CrossRef]

- Pengpan, R.; Kopolrat, K.Y.; Srichaijaroonpong, S.; Taneepanichskul, N.; Yasaka, P.; Kammoolkon, R. Relationship between Pesticide Exposure Factors and Health Symptoms among Chili Farmers in Northeast Thailand. J. Prev. Med. Public Health 2024, 57, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Moradhaseli, S.; Colosio, C.; Farhadian, H.; Abbasi, E.; Ghofranipour, F. Designing an agricultural occupational health behavioral model. J. Agric. Sci. Technol. 2020, 22, 57–66. [Google Scholar]

- González, Y.V.; Zepeda, P.A.E.; González, C.R.N.; Corona, A.L.S.; Alarcon, R.Z.; Badilla, G.L. Evaluation of a New Industrial Process Flow and Ergonomic Methods to Increase the Productivity and Quality in an Agricultural Industry of Mexicali Valley, Mexico. Asian J. Basic Sci. Res. 2021, 3, 47–60. [Google Scholar] [CrossRef]

- Realyvásquez-Vargas, A.; García-Alcaraz, J.L.; Salazar-Ruíz, E. Detección de la prevalencia de trastornos musculoesqueléticos entre los trabajadores agrícolas mexicanos. Ergon. Investig. Desarro. 2023, 5, 61–76. [Google Scholar] [CrossRef]

- Benos, L.; Tsaopoulos, D.; Bochtis, D. A review on ergonomics in agriculture. part II: Mechanized operations. Appl. Sci. 2020, 10, 3484. [Google Scholar] [CrossRef]

- INEGI. Censo Agropecuario 2022 en el Estado de Sinaloa, 31 de mayo de 2023. Available online: https://www.inegi.org.mx/contenidos/programas/cagf/2022/doc/CA2022_ROSIN.pdf (accessed on 6 June 2024).

- Nitish, K.J.; Vethamoni, P.I.; Saraswathi, T.; Senthil, N.; Uma, D. Selection criteria and multivariate analysis for identification of Turkey berry (Solanum torvum) genotypes for genetic improvement by using correlation and principal components analysis. Electron. J. Plant Breed. 2023, 14, 884–892. [Google Scholar]

- Cantarelli, M.A.; Camiña, J.M.; Pettenati, E.; Marchevsky, E.M.; Pellerano, R.G. Trace mineral content of Argentinean raw propolis by neutron activation análisis (NAA): Assessment of geographical provenance by chemometrics. LWT—Food Sci. Technol. 2011, 44, 256–260. [Google Scholar] [CrossRef]

- Pérez, J.; La Rotta, D.; Sánchez, K.; Madera, Y.; Rodríguez, G.; Vanegas, M.; Parra, C. Identificación y caracterización de mudas de transporte, procesos, movimientos y tiempos de espera en nueve pymes manufactureras incorporando la perspec-tiva del nivel operativo. Ingeniare. Rev. Chil. Ing. 2011, 19, 396–408. [Google Scholar] [CrossRef]

- Beyoda, M.; González, U.; Vargas, O.; Severiche, S.C. Analysis of Main Components for Structural Characterization of Manufacturing SMES of Cartagena de Indias, Colombia. Lámpsakos 2017, 17, 52–59. [Google Scholar] [CrossRef]

- Al-Khayri, J.M.; El-Malky, M. Genetic Parameters and Principal Component Analysis for Quantitative Traits in Rice (Oryza sativa L.). SABRAO J. Breed. Genet. 2023, 55, 1547–1560. [Google Scholar] [CrossRef]

- Ruiz, Y.C. Application of principal component analysis as a technique to obtain synthetic indices of environmental quality. Scientia 2012, 4, 145–153. [Google Scholar]

- Mvuyekure, S.; Sibiya, J.; Derera, J.; Nzungize, J.; Nkima, G. Application of principal components analysis for selection of parental materials in rice breeding. J. Genet. Genom. Sci. 2018, 3, 2–7. [Google Scholar] [CrossRef]

- Garmendia, M.L. Análisis Factorial: Una Aplicación en el Cuestionario de Salud General de Goldberg, Versión de 12 Pregun-tas. Rev. Chil. Salud Pub. 2017, 11, 57–65. [Google Scholar] [CrossRef]

- Das, B. Work-related musculoskeletal disorders in agriculture: Ergonomics risk assessment and its prevention among Indian farmers. Work 2023, 76, 225–241. [Google Scholar] [CrossRef]

- Shivakumar, M.; Welsh, V.; Bajpai, R.; Helliwell, T.; Mallen, C.; Robinson, M.; Shepherd, T. Musculoskeletal disorders and pain in agricultural workers in Low- and Middle-Income Countries: A systematic review and meta-analysis. Rheumatol. Int. 2024, 44, 235–247. [Google Scholar] [CrossRef] [PubMed]

- Raczkiewicz, D.; Saran, T.; Sarecka-Hujar, B.; Bojar, I. Work conditions in agriculture as risk factors of spinal pain in postmenopausal women. Int. J. Occup. Saf. Ergon. 2019, 25, 250–256. [Google Scholar] [CrossRef] [PubMed]

- Belkher, A.A.A.; Masood, M.A. Occupational Health and Safety, Risk Assessment, and Management in the Machinery Sector. Afr. J. Adv. Pure Appl. Sci. 2023, 2, 187–199. [Google Scholar]

- Raza, M.M.S.; Li, S.; Issa, S.F. Global Patterns of Agricultural Machine and Equipment Injuries—A Systematic Literature Review. J. Agromed. 2024, 29, 214–234. [Google Scholar] [CrossRef]

- Meenakshi, J.R.; Sigamani, P. Socio Economic and Health Condition of Women Agricultural Workers in Thiruvarur District, Tamil Nadu. Glob. J. Res. Anal. 2020, 9, 1–3. [Google Scholar] [CrossRef]

| Gender | Frequency | % | Total |

|---|---|---|---|

| Women | 48 | 24 | 24% |

| Men | 152 | 76 | 100% |

| Total | 200 | 100 |

| Parameters | Age Data |

|---|---|

| Mean: | 29.36 |

| Median: | 28.00 |

| Mode: | 25 |

| Standard Deviation: | 6.734 |

| Range: | 34 |

| Minimum: | 18 |

| Maximum: | 52 |

| Percentiles: | |

| 25% | 25 |

| 50% | 28 |

| 75% | 34 |

| Physical Ergonomics Variables | Cronbach’s Alpha by Gender | |

|---|---|---|

| PE1 | The risk of lifting heavy equipment | Men: 0.850 Women: 0.814 |

| PE2 | The risk of physical effort | |

| PE3 | The risk of carrying heavy things | |

| PE4 | The risk of performing repetitive movements | |

| PE5 | The risk in handling objects and materials | |

| PE6 | The risk of working in uncomfortable postures | |

| PE7 | The risk of repetitive activities | |

| PE8 | The risk of stretching to reach an object or product | |

| PE9 | The risk of using inappropriate materials | |

| Category (Men) | Age Range | Number | % | Total |

|---|---|---|---|---|

| 1 | 18–29 | 83 | 54.61 | 54.61% |

| 2 | 30–39 | 55 | 36.18 | 90.79% |

| 3 | 40–52 | 14 | 9.21 | 100% |

| Total: | 152 | |||

| Category (Women) | Age Range | Number | % | Total |

| 1 | 18–29 | 28 | 58.33 | 58.33% |

| 2 | 30–39 | 20 | 41.67 | 100% |

| Total: | 48 |

| KMO and Bartlett’s Test | |||||

|---|---|---|---|---|---|

| Age Category (Men) | Kaiser-Meyer-Olkin Measure of Sampling Adequacy | Bartlett’s Test of Sphericity | |||

| Approx. Chi-Square | gl | Sig. (p-Value) | |||

| 1 | 18–29 | 0.795 | 144.308 | 6 | 0.001 |

| 2 | 30–39 | 0.865 | 288.225 | 21 | 0.001 |

| 3 | 40–52 | 0.811 | 58.643 | 15 | 0.001 |

| Age Category (Women) | Kaiser-Meyer-Olkin Measure of Sampling Adequacy | Bartlett’s Test of Sphericity | |||

| Approx. Chi-Square | gl | Sig. (p-Value) | |||

| 1 | 18–29 | 0.735 | 55.133 | 10 | 0.001 |

| 2 | 30–39 | 0.808 | 43.879 | 10 | 0.001 |

| Principal Component Analysis | |||

|---|---|---|---|

| Physical Ergonomics Risk Factors (Men) | (Category) Component | ||

| 18–29 | 30–39 | 40–52 | |

| PE1 | 0.897 | 0.952 | --- |

| PE2 | --- | 0.718 | --- |

| PE3 | 0.854 | 0.870 | 0.832 |

| PE4 | 0.812 | 0.827 | 0.871 |

| PE5 | 0.762 | 0.808 | 0.922 |

| PE6 | --- | 0.831 | 0.733 |

| PE7 | --- | 0.757 | 0.878 |

| PE8 | --- | --- | 0.877 |

| PE9 | --- | --- | --- |

| Total Variable Explained: | 69.35% | 68.29% | 73% |

| Physical Ergonomics Risk Factors (Women) | (Category) Component | |

|---|---|---|

| 18–29 | 30–39 | |

| PE1 | 0.897 | 0.811 |

| PE2 | --- | --- |

| PE3 | --- | --- |

| PE4 | 0.808 | --- |

| PE5 | 0.711 | 0.828 |

| PE6 | --- | 0.845 |

| PE7 | 0.702 | 0.913 |

| PE8 | 0.711 | 0.854 |

| PE9 | --- | --- |

| Total Variable Explained: | 59.21% | 73% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos-García, V.M.; López-Leyva, J.A.; Balderrama-Carmona, A.P.; Ochoa-Vázquez, I.; García-Ochoa, J.J.; Espinoza-Espino, M.d.J. An Analysis of Occupational Hazards Based on the Physical Ergonomics Dimension to Improve the Occupational Health of Agricultural Workers: The Case in Mayo Valley, Mexico. Safety 2024, 10, 61. https://doi.org/10.3390/safety10030061

Ramos-García VM, López-Leyva JA, Balderrama-Carmona AP, Ochoa-Vázquez I, García-Ochoa JJ, Espinoza-Espino MdJ. An Analysis of Occupational Hazards Based on the Physical Ergonomics Dimension to Improve the Occupational Health of Agricultural Workers: The Case in Mayo Valley, Mexico. Safety. 2024; 10(3):61. https://doi.org/10.3390/safety10030061

Chicago/Turabian StyleRamos-García, Víctor Manuel, Josué Aarón López-Leyva, Ana Paola Balderrama-Carmona, Iván Ochoa-Vázquez, Juan José García-Ochoa, and Manuel de Jesús Espinoza-Espino. 2024. "An Analysis of Occupational Hazards Based on the Physical Ergonomics Dimension to Improve the Occupational Health of Agricultural Workers: The Case in Mayo Valley, Mexico" Safety 10, no. 3: 61. https://doi.org/10.3390/safety10030061

APA StyleRamos-García, V. M., López-Leyva, J. A., Balderrama-Carmona, A. P., Ochoa-Vázquez, I., García-Ochoa, J. J., & Espinoza-Espino, M. d. J. (2024). An Analysis of Occupational Hazards Based on the Physical Ergonomics Dimension to Improve the Occupational Health of Agricultural Workers: The Case in Mayo Valley, Mexico. Safety, 10(3), 61. https://doi.org/10.3390/safety10030061