Perceived Factors Affecting the Implementation of Occupational Health and Safety Management Systems in the South African Construction Industry

Abstract

1. Introduction

1.1. Background of Studies

1.2. Internal and External Factors Affecting the Implementation of OHSMSs

1.3. Integrating Risk Management into OHSMSs

1.4. Using PDCA to Implement OHSMSs

1.5. Outline and Gaps of Study

2. Research Methodology

2.1. Type of Research Method Used

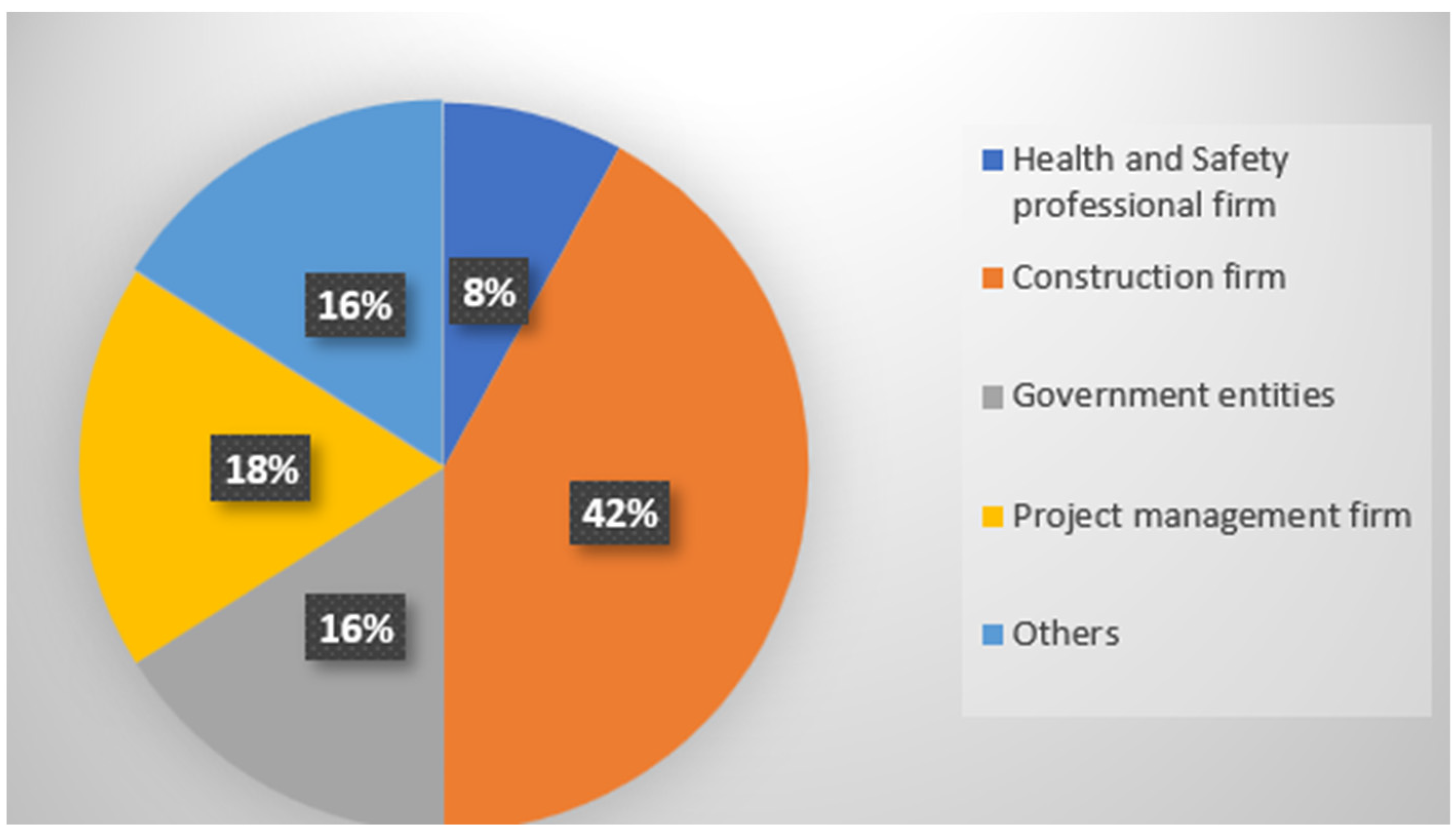

2.2. Population and Sampling Method

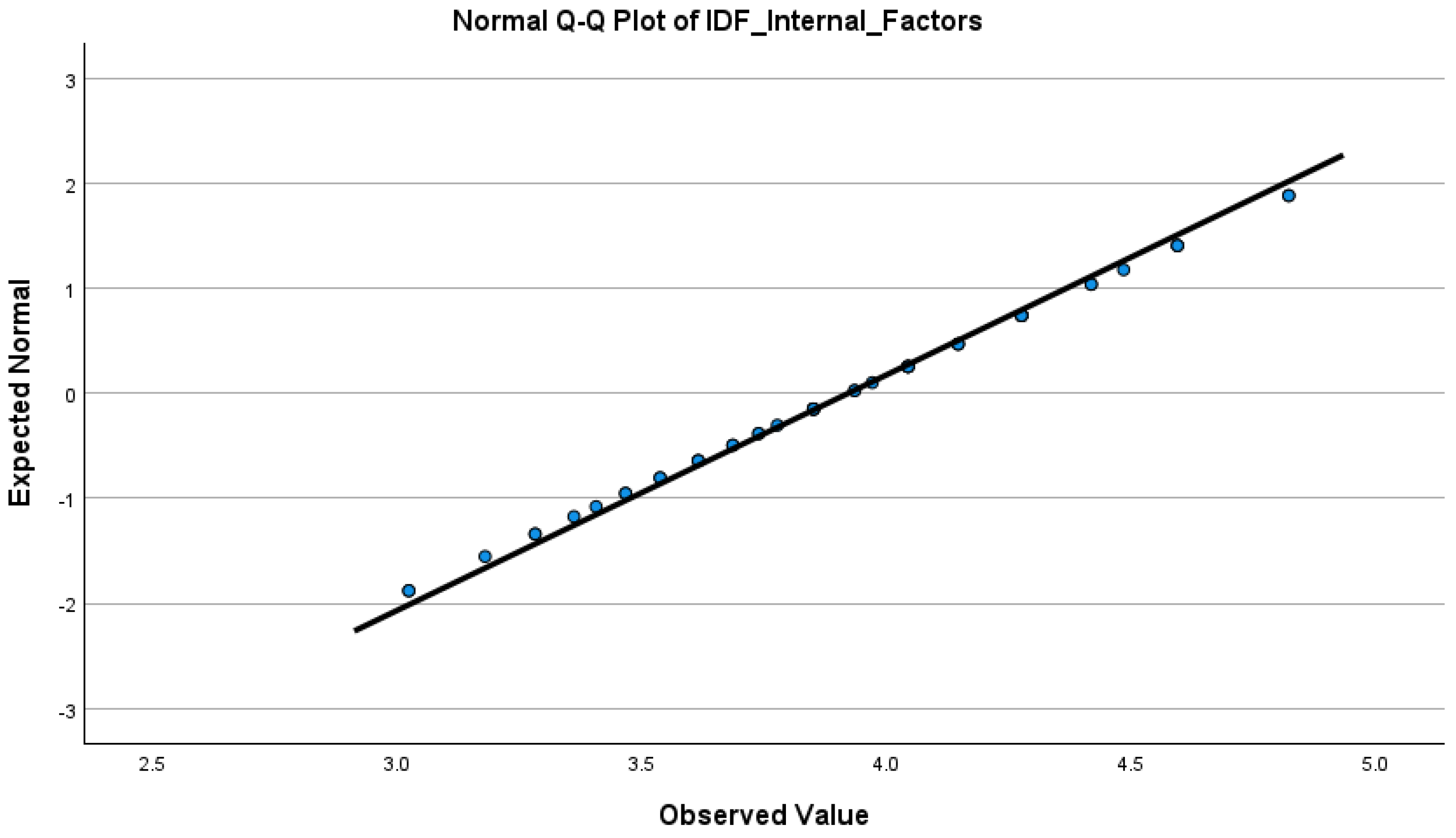

2.3. Reliability of Data

2.4. Data Analysis

3. Results

3.1. Section B: Internal and External Factors

3.1.1. Ranking of Internal Factors Affecting the Implementation of OHSMSs

3.1.2. Mean Ranking of External Factors Affecting the Implementation of OHSMSs

3.2. Section C Implementation of the OHSMS Using the PDCA Method by Analysing Construction Risks

3.2.1. Multiple Regression Analysis of the PDCA Method

- Planning (P) seems to have a positive influence on internal factors (β = 0.04) and external factors (β = 0.18) during the implementation of OHSMSs.

- The doing (D) phase indicated positive effects on both internal (β = 0.19) and external (β = 0.12) factors during the implementation of OHSMSs. Furthermore, an improved exploration of solutions to accidents on site was likely to result in positive contributions to both internal (β= 0.17) and external (β = 0.21) factors during the OHSMS implementation.

- The check (C) stage resulted in positive contributions to both internal (β = 0.17) and external (β = 0.03) factors during the OHSMS implementation.

- For the act stage (A), improved identification of gaps and corrective actions in the OHSMS were likely to negatively influence both internal (β = −0.64) and external (β = −0.35) OHS implementation.

- Lastly, continuous improvement in the OHSMS was likely to result in positive contributions to internal (β = 0.27) and negative influences on external (β = 0.18) factors during the OHSMS implementation.

- Overall, the results show that there is a strong relationship between the PDCA model and the implementing factors.

3.2.2. Formulation of the Risk Management Plan to Be Integrated into the PDCA Method

Risk Management Plan

4. Discussion

- What are the internal and external factors that affect the implementation of OHSMSs?

- How the PDCA method is used to implement the OHSMS, taking into consideration construction risks.

4.1. Internal Factors

- Risk control strategy

- Contrary to expectations, the risk control strategy was found to be the leading factor that would affect the implementation of OHSMSs, even though a previous study by da Silva and Amaral [13] did not list it as one of their top five factors. There are several possible explanations for this result, one of them being that their study was purely theoretical and was generalised with no reference to a particular industry. However, the current study was empirical, focusing on the construction sector in South Africa.

- Additionally, the construction risk for a developing country like South Africa would be higher as compared to a developed country due to advancements in areas such as personal protective equipment (PPE) and OHS technology. The literature reviewed has iterated that construction sites are high-risk areas where accidents are prone to occur, and organisations must take appropriate measures to control the risks. These could be controlled using methods such as risk reduction and risk avoidance, as shown in Table 5.

- Communication

- Communication remains an essential success factor [44]. The communication challenges in South Africa can also be attributed to the language barriers that exist, as there are eleven official languages and some OHS terms are difficult to explain and translate into the vernacular language of an unskilled labourer. Therefore, proper communication channels must be established. Furthermore, equipment design and improved work practices that promote proper communication procedures will result in an improved safety environment [47].

- Training, hazard perception, education, and risk awareness

- Although many respondents agreed that their organisations had made great positive strides toward training, hazard perception, education, and risk awareness on OHS, it was still ranked as a leading factor that affects the implementation of OHSMSs. These findings are consistent with a survey that found that the systematically inadequate behaviour, the inadequate involvement in OHS activities, and the lack of awareness of the relevance of OHS among employees made it difficult to implement OHSMSs [48].

- When implementing an OHSMS, it is crucial to reinforce risk assessment education [49].

- Safety culture

- By examining the safety culture factor, an organisation’s safety culture is determined by its values, attitudes, perceptions, and competencies, which determine its commitment to OHS and its style and proficiency in managing it. Workers need to understand the importance of managing OHS, different standards and attributes, and observing the company culture [13]. Previous studies found that employees create safe conditions through actions such as participation in safety training, voluntary OHS activities, and OHS-related decision making [46].

- Although the findings from the current study did not rank safety culture in its top three, previous findings showed that employees’ ignorance or negative attitudes toward OHS, a lack of safety culture, and employee participation were the most important factors [10]. This may be because their study was solely based on a literature review.

- Working conditions and scope of work

- Construction workplaces are potential risk areas where accidents and injuries are more likely to occur [3,4]. Although much effort has been made over the years to secure safe working conditions on site, the rapid growth of the construction sector in South Africa means that more construction risks have arisen, and most risk management plans would need to be updated to ensure safe working conditions. Construction sites are all unique and different; hence, the OHSMS needs to be constantly updated to reflect the current conditions.

- Senior management commitment and support

- Regarding the importance of senior management commitment and support, the results were consistent with those of empirical studies, as factors were considered as key driver constructs when implementing OHSMSs [13,44]. Management leadership and commitment towards OHS are the base factors when implementing OHSMSs [50].

- An important issue emerging from these findings was that most employees participated in OHSMS implementation. The success of a safety management system depends on the type of leadership and employee involvement [19]. Management commitment has a positive impact on worker safety behaviour and participation in safety management [51]. Similarly, senior management support should cover safety meetings, safety training, personnel protection, on-site inspections, performance assessments, incentives, and other major safety management affairs [52].

- Management commitment is a major driving force during the implementation of the OHSMSs. Top management obligations should go above and beyond, involving expertise in OHS hazards and a responsibility to ensure that management practices stimulate safety and health at work.

- Risk identification, management, and processes

- Risk identification, management, and processes are critical factors that are still prevalent on construction sites. Construction organisations in South Africa still need to continue addressing risk assessments when implementing OHSMSs. When implementing OHSMSs, it is crucial to reinforce risk assessment education [49].

- Allocation of resources

- The adequate allocation of resources towards OHS plays a significant role in OHSMS implementation. Project constraints and system limitations due to the unavailability of suitable construction resources affect the implementation of OHSMSs [44]. The high costs associated with OHS further make it difficult to implement OHSMSs [18].

- Most resources are channelled towards production, and the high costs associated with OHS further make it difficult to implement an OHSMS, especially in SMEs. Then, there is also the argument over who carries the OHS-related costs.

- OHS training

- OHS training is an important factor that affects OHSMS implementation. It is evident that most training interventions do not yield tangible benefits and may lead to the waste of resources [5]. Stakeholders in the construction industry must possess a good understanding of the characteristics of training interventions if they are to improve safety performance. Organisations that offer training in OHS have good positive results on their OHSMSs [49]. Senior managers and supervisors on construction sites are not mandated by the Department of Labour in South Africa to have an OHS qualification, which presents challenges when implementing OHSMSs.

- Incompetent employees can result in poor management decisions and the approval of incomplete procedures and instructions. This can be attributed to a failure to provide necessary training to employees [51].

- Safety training should be used to increase the safety awareness and knowledge of both management staff and workers [52]. Training interventions that integrate visual cues to guide hazard recognition, immersive experiences in virtual environments, pedagogical training principles, personalisation of training experiences, testing and feedback, and other elements can improve training effectiveness and outcomes [2].

- Safety policy

- The results showed safety policy to be the second most influential factor when implementing the OHSMS. This aligned with other results [50]. A safety policy ensures employee participation, and this was confirmed by the results, which showed that 70% agreed that employees in their firms participate in the implementation of OHSMSs.

- Cost of implementation

- One important issue emerging from these findings is the cost of implementing OHSMSs. The results showed that most clients did not accept the high costs related to OHS because it is viewed by most clients as part of company overhead. These findings were consistence with previous studies [13].

- The results also indicate that the cost of OHS must be carried by the contractor, making it difficult to successfully implement an OHSMS, especially when the contractor is a small or medium enterprise with limited available capital. Most clients argue that OHS-related costs should only be charged to the client where the client has included specifications in the tender document.

- It is, however, important to note that although the cost of implementing OHSMSs can be high, there is a significant company saving due to a decrease in accidents [36].

- Constrictive project durations

- Often, strict schedules and production take priority over the implementation of appropriate OHS procedures, and many employees may not fully comprehend the risks present on construction sites [53]. Constrictive project durations were found to be among the least important factors.

- Most construction sites operate on strict schedules to meet deadlines, and it is possible that by trying to meet schedules, OHS procedures may not be fully practiced.

- Organisational structure

- This study also validated the previous claim made in other studies that the organisational structure was a factor that had an impact when implementing OHSMSs [17]. The structure of OHS in organisations enables all employees to be given responsibilities and functions which would allow accountability.

- The organisational structure also affects the risk and safety culture of the organisation. Usually, large companies have a low-risk and positive safety culture as compared to smaller ones, as more resources are available to invest in OHSMSs, resulting in lower risks [54]. Therefore, the type of organisational structure has an impact on the implementation of OHSMSs.

- Uncertainty in reporting systems

- Uncertainty in reporting systems remains a major obstacle to implementation [13,49]. OHSMSs need to be designed with technology or hardware in mind in the initial design phase, which clearly outlines the reporting system. The lack of an ineffective information collection system poses a major challenge [55].

- To successfully implement an OHSMS and improve safety performance, construction companies must ensure that the reporting system is clear. A proper incident reporting and analysing structure is an important tool in OHSMS implementation [48].

- Retaining qualified internal auditors who are willing to address non-conformities and offer advice and suggestions is crucial. Therefore, non-conformities should be probed, and corrective actions should be proposed, whilst the potential for improvement should be identified [51].

- Lack of competent workers

- Another factor emerging from these findings was the lack of competent workers. The lack of knowledge about safety issues remains a big weakness of OHSMSs [56]. Whereas this study rated it low, this could be because most construction organisations usually subcontract specific trades, such as paintwork, plastering, etc., to third parties. Because these subcontractors are appointed on a short-term basis, this does not result in continuous training. Although this saves on training costs, it results in a lack of competent workers who have knowledge of OHS.

- Internal incentives

- The least important factor from these findings was that of internal incentives, which is supported by previous studies [20]. There is a lack of internal incentives, and the implementation of incentive programs could inspire employees to execute their OHS tasks safely. If management staff and workers receive a reward for good safety performance, they may be motivated to improve safety on sites [52].

- Construction companies must provide safety incentives and integrate them into all aspects of their safety management systems to enhance safety performance. As part of this, subcontractors could be included in safety meetings and training, and everyone involved could be given responsibility and authority.

4.2. External Factors

- Pressure from clients on project delivery

- Often, strict schedules and production take priority over the implementation of appropriate OHS procedures [53]. The findings from the study showed that pressure from clients on project delivery was the biggest factor when implementing the OHSMSs.

- Most construction project contracts include heavy penalties for the late completion of the works and OHS is usually regarded as time-consuming. Elements of OHS regulations have an impact on production, coupled with pressure from clients on project delivery [47].

- The results from this study showed that 78% of the respondents agreed that elements of OHS regulations had an impact on production. Often, production is prioritised over safety [57]. This poses a great challenge when implementing OHSMSs, as this usually results in non-compliance. This current study also found that non-compliance with OHS regulations results in accidents on site.

- Company reputation

- Further findings in this study classified the company’s reputation as an important factor that would affect OHSMS implementation. Usually, smaller companies find it difficult to have a functional OHSMS without support, as they need to build on their reputation first [56].

- OHS enforcement, government legislation and auditing procedures

- The findings showed that enforcement, government legislation, and auditing procedures were critical factors in implementing OHSMSs. This observation was also reported by Nowrouzi et al. [55].

- Rigorous legislation and bureaucracy had a significant effect on OHS. The high level of prerequisites in the regulations and the large amount of documentation required were found to be difficult to compile, especially in small and medium organisations [15].

- Research indicates that even though the South African Construction Regulations of 2014 impose a high level of requirements on clients, the desired benefits may not be realised without financial incentives due to the low fines and lack of enforcement [58]. The findings from this study revealed that any changes in the legislature and regulations from the Department of Employment and Labour affect the implementation of OHSMSs.

- Comply to regulations

- Another reason that may lead to non-compliance with OHS is the lack of awareness of OHS [3,59]. Most small and medium enterprises (SMEs) in South Africa have limited commitment to compliance with OHS [60]. Most organisations face difficulties when attempting to comply with regulations due to the high cost of implementation and maintenance [59].

- Support from OHS authorities

- An important issue emerging from these findings was support from OHS authorities and inspections. The findings show that even though routine OHS inspections were conducted at their organisations, there was still a need for support from OHS authorities.

- The lack of labour inspectors to oversee and inspect OHSMS implementation and the government not providing any special instruments for monitoring OHSMS implementation were crucial factors when implementing OHSMSs [17]. To assess the general effectiveness of an OHSMS, compliance audits and performance evaluations should be performed.

- The findings from this study confirmed that most organisations conducted routine OHS inspections, although the inspections were not specified as external or internal. According to the CIDB report [5], the OHS in South Africa is hampered by a lack of available statistics from the Compensation Commissioner to show the full extent of accidents and inspections.

- The findings were also consistent with previous studies that found that factors such as inadequate routine inspections on sites and unfamiliarity with regulatory obligations resulted in non-compliance [3].

- External incentives

- Another external factor in the results was external incentives. With economic incentives, clients are more likely to implement OHSMSs on construction sites; therefore, economic incentives have a critical impact on client OHS performance [58]. If clients continue to view themselves as non-essential OHS stakeholders in the absence of financial incentives, it will prevent them from effectively participating in the implementation of OHSMSs.

- International trends

- The least important factor in the present study was international trends. Trends and standards usually associate the OHS trends rating of an organisation with work-related performance, making it difficult for some organisations to obtain new contracts if they do not adjust to the latest international trends.

- The current study found it to be the lowest-ranked factor because some of the international trends have nothing to do with OHS regulations. Most organisations only pay attention to international standards, such as ISO 45001:2018, when implementing OHSMSs [17].

4.3. Implementation of the OHSMS Using the PDCA Method by Analysing Construction Risks

4.3.1. Risk Management Plan

4.3.2. Implementation of OHSMSs Using the PDCA Method

- Plan: The results from the current study show that during the plan stage, there was an improvement in risk assessments when the PDCA method was used to implement OHSMSs, as per Table 5. This can be attributed to the fact that a risk management plan is produced during the planning stage. Hence, all risks would have been identified and planned for. To be efficient, effective, and simple, risk management should be incorporated into management practices and systems in construction organisations [34].

- Do: The findings in the present study showed that the actual implementation of an OHSMS through the identification of a risk analysis showed a potentially positive effect on both internal and external factors. This is because this stage involves the actual implementation of an OHSMS [38].

- Check: An important issue emerging from these findings at the check stage was that there was also a positive relationship between both factors. This is because at this stage, an exploration of solutions to accidents is verified, and OHS checklists and audits are conducted [38]. However, no evidence of improved identification of gaps and corrective actions was detected, as the results showed a negative influence on both internal and external OHS implementation factors. The findings suggest that at this stage, OHSMS implementation would have been completed in the doing phase. Hence, those factors would only impact the doing stage.

- Act: Lastly, the findings indicated that continuous improvement in OHSMSs was likely to result in positive contributions to both internal and external OHS implementation. This is supported by previous studies that confirmed that analyses are conducted to identify the differences between the actual and projected results [39]. This includes determining the main causes for the variations, identifying the changes required to improve performance, and developing corrective actions to implement the changes.

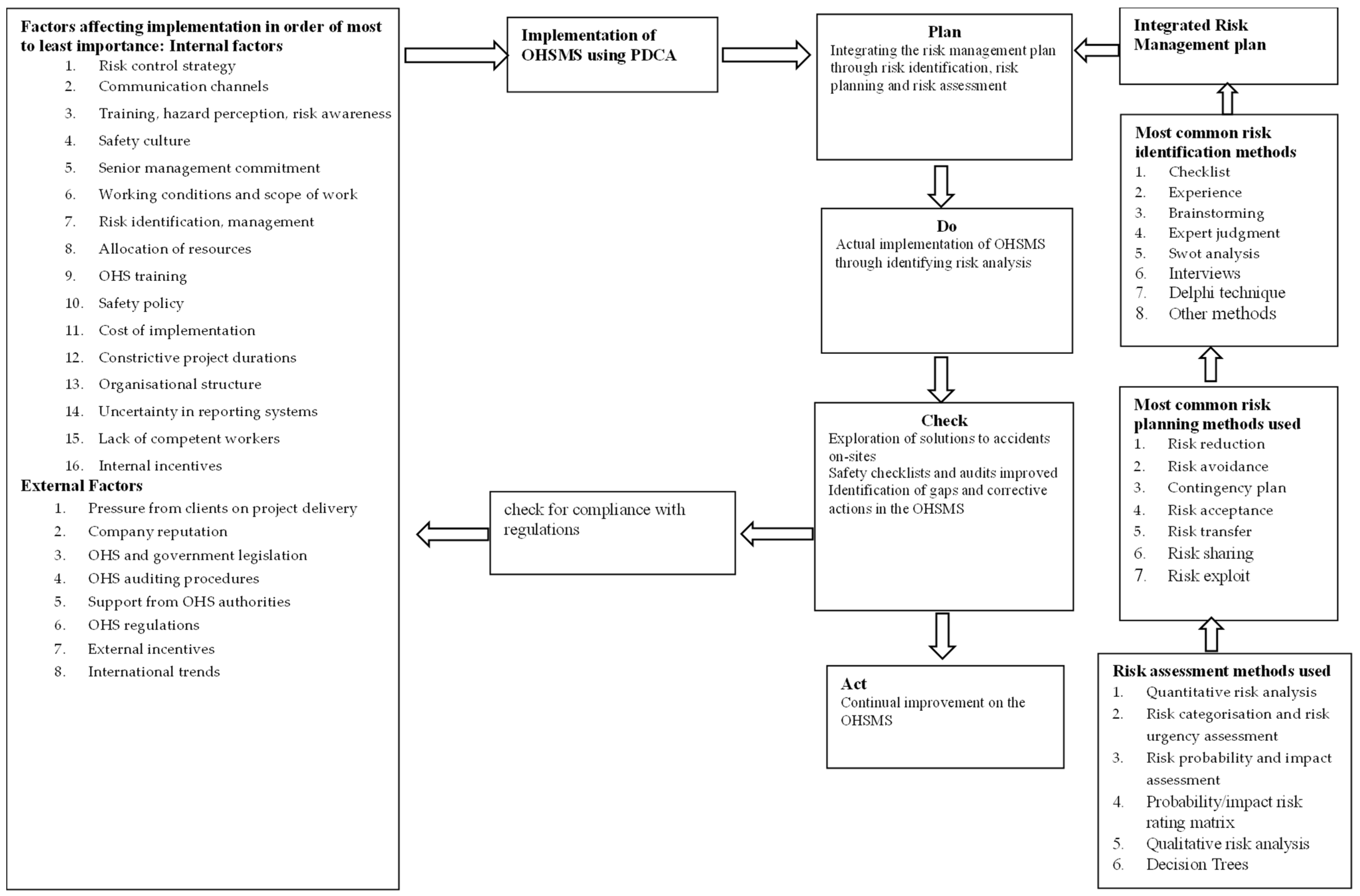

4.4. Operational Framework for Implementation of OHSMSs Using the PDCA Method

- The adequate application of the recommendations presented in this study should improve the implementation of OHSMSs.

- Based on the findings, both internal and external factors are listed in order of importance. The ranking of factors will enable organisations to identify factors that they need to prioritise. Once these factors have been identified, considered, and prepared for, the implementation can start.

- The framework further shows that the implementation is conducted using the PDCA method. Since risk management is a part of OHSMSs, the risk management plan needs to be integrated into the OHSMS during the planning stage of the PDCA model.

- Once the risk management is integrated, the “plan”, “do”, “check”, and “act” steps can commence.

- Once the OHSMS has been implemented, it needs to be checked to ensure its compliance with regulations, which is an external factor.

- The framework shows that the implementation of OHSMSs is interconnected with factors, risks, and the PDCA method. There is an interdependency between all the objectives outlined in this research.

- The framework further allows for checking the OHSM to comply with regulations during the checking stage. This is an important step, as it ensures that compliance with regulations is accounted for in the OHSMS structure.

5. Conclusions

5.1. Key Findings

5.2. Limitations

5.3. Recommendations for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Labour Organisation. International Labour Standards on Occupational Safety and Health. 2018. Available online: https://www.ilo.org/global/standards/subjects-covered-by-international-labour-standards/occupational-safety-and-health/lang--en/index.htm (accessed on 20 June 2023).

- Windapo, A.O.; Umeokafor, N.I.; Olatunji, O.A. Self-regulation amongst South African contractors in achieving legislative requirements on occupational health and safety. In Proceedings of the Coping with the Complexity of Safety, Health, and Wellbeing in Construction Joint CIB W099 and TG59 International Safety, Health, and People in Construction Conference, Salvador, Brazil, 1–3 August 2018; Available online: https://www.irbnet.de/daten/iconda/CIB_DC31504.pdf (accessed on 10 October 2023).

- Mashwama, N.; Aigbavboa, C.; Thwala, W. Occupational health and safety challenges among small and medium sized enterprise contractors in South Africa. In International Conference on Applied Human Factors and Ergonomics; Springer: Cham, Switzerland, 2018; pp. 68–76. [Google Scholar] [CrossRef]

- Osei-Asibey, D.; Ayarkwa, J.; Acheampong, A.; Adinyira, E.; Amoah, P. Impacts of accidents and hazards on the Ghanaian construction industry. Int. J. Constr. Manag. 2023, 23, 708–717. [Google Scholar] [CrossRef]

- Construction Industry Development Board (CIDB). Construction Health and Safety in South Africa. 2021. Available online: https://www.cidb.org.za/resource-centre/downloads-1/#45-59-wpfd-health-and-safety (accessed on 20 January 2023).

- Khodabandeh, F.; Kabir-Mokamelkhah, E.; Kahani, M. Factors associated with the severity of fatal accidents in construction workers. Med. J. Islam. Repub. Iran 2016, 30, 469. [Google Scholar] [PubMed]

- Esterhuyzen, E. Small business barriers to occupational health and safety compliance. S. Afr. J. Entrep. Small Bus. Manag. 2019, 11, 1–8. Available online: https://hdl.handle.net/10520/EJC-1fa3abcca6 (accessed on 10 October 2023). [CrossRef]

- Yorio, P.L.; Willmer, D.R.; Moore, S.M. Health and safety management systems through a multilevel and strategic management perspective: Theoretical and empirical considerations. Saf. Sci. 2015, 72, 221–228. [Google Scholar] [CrossRef]

- Yoon, S.J.; Lin, H.K.; Chen, G.; Yi, S.; Choi, J.; Rui, Z. Effect of occupational health and safety management system on work-related accident rate and differences of occupational health and safety management system awareness between managers in South Korea’s construction industry. Saf. Health Work 2013, 4, 201–209. [Google Scholar] [CrossRef]

- Pramono, D.; Purwanto, A.H.D.; Nugroho, R.E. Evaluation of occupational health and safety management system (OHSMS) Implementation at PT XYZ. Int. J. Soc. Manag. Stud. 2023, 4, 19–27. [Google Scholar] [CrossRef]

- Sadiq, A.W. Influence of Leadership Practices on Organizational Safety Performance. Ph.D. Thesis, University of Phoenix, Phoenix, AZ, USA, 2020. [Google Scholar]

- Sadiq, N. Establishing an Occupational Health and Safety Management System Based on ISO 45001; IT Governance: Ely, UK, 2019. [Google Scholar]

- Da Silva, S.L.C.; Amaral, F.G. Critical factors of success and barriers to the implementation of occupational health and safety management systems: A systematic review of literature. Saf. Sci. 2019, 117, 123–132. [Google Scholar] [CrossRef]

- Haupt, T.C.; Pillay, K. Investigating the true costs of construction accidents. J. Eng. Des. Technol. 2016, 14, 373–419. [Google Scholar] [CrossRef]

- Gomes, H.P.; Martins Arezes, P.M.F.; Fadel de Vasconcellos, L.C. A qualitative analysis of occupational health and safety conditions at small construction projects in the Brazilian construction sector. Dyna 2016, 83, 39–47. [Google Scholar] [CrossRef]

- Micheli, G.J.L.; Cagno, E.; Calabrese, A. The transition from occupational safety and health (OSH) interventions to OSH outcomes: An empirical analysis of mechanisms and contextual factors within small and medium-sized enterprises. Int. J. Environ. Res. Public Health 2018, 15, 1621. [Google Scholar] [CrossRef]

- Rahmi, A.; Ramdhan, D.H. Factors affecting the effectiveness of the implementation of application OHSMS: A systematic literature review. J. Phys. Conf. Ser. 2021, 1933, 012021. [Google Scholar] [CrossRef]

- Sumarni, C.; Listiani, T.; Harahap, R.; Maasir, L. The Mechanism of Implementing Occupational Safety and Health in Bandung Wetan District Office Bandung City. In Proceedings of the Fourth International Conference on Administrative Science (ICAS 2022), Bandung, Indonesia, 26 October 2022; Atlantis Press: Paris, France, 2023; pp. 386–396. [Google Scholar] [CrossRef]

- Khalid, U.; Sagoo, A.; Benachir, M. Safety Management System (SMS) framework development–Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Saf. Sci. 2021, 143, 105402. [Google Scholar] [CrossRef]

- Ghahramani, A. Factors that influence the maintenance and improvement of OHSAS 18001 in adopting companies: A qualitative study. J. Clean. Prod. 2016, 137, 283–290. [Google Scholar] [CrossRef]

- Umeokafor, N.; Isaac, D.; Umeadi, B. Determinants of compliance with health and safety regulations in Nigeria’s construction industry. J. Constr. Proj. Manag. Innov. 2014, 4 (Suppl. S1), 882–899. [Google Scholar]

- Kineber, A.F.; Antwi-Afari, M.F.; Elghaish, F.; Zamil, A.M.; Alhusban, M.; Qaralleh, T.J.O. Benefits of Implementing Occupa-tional Health and Safety Management Systems for the Sustainable Construction Industry: A Systematic Literature Review. Sustainability 2023, 15, 12697. [Google Scholar] [CrossRef]

- Skripnik, I.; Savelev, D.; Kaverzneva, T.; Rumyantseva, N. Implementation of a risk-based OHS management system at IMC mining company. E3S Web Conf. 2023, 376, 05031. [Google Scholar] [CrossRef]

- Badri, A. The challenge of integrating ohs into industrial project risk management: Proposal of a methodological approach to guide future research (case of mining projects in Quebec, Canada). Minerals 2015, 5, 314–334. [Google Scholar] [CrossRef]

- Ramos, D.; Costa, A.; Afonso, P. Integration of risk management in occupational health and safety systems. In Proceedings of the 2nd International Conference on Project Evaluation (ICOPEV 2014), Guimarães, Portugal, 26–27 June 2014; Available online: https://www.researchgate.net/publication/264788410 (accessed on 7 July 2023).

- Cooper, D.F.; Grey, S.; Raymond, G.; Walker, P. Project Risk Management Guidelines: Managing Risk in Large Projects and Complex Procurements; John Wiley & Sons: Hoboken, NJ, USA, 2021; Available online: http://eprints.itn.ac.id/id/eprint/13603 (accessed on 7 July 2023).

- Doval, E. Risk management process in projects. Rev. Gen. Manag. 2019, 29, 97–113. [Google Scholar]

- Project Management Institute. Guide to the Project Manager Body of Knowledge (PMBOK Guide), 5th ed.; Project Management Institute: Atlanta, GA, USA, 2013. [Google Scholar]

- Rehacek, P. Risk management standards for project management. Int. J. Adv. Appl. Sci. 2017, 4, 1–13. [Google Scholar] [CrossRef]

- Mhetre, K.; Konnur, B.A.; Landage, A.B. Risk management in the construction industry. Int. J. Eng. Res. 2016, 5, 153–155. [Google Scholar]

- Taghipour, M.; Hoseinpour, Z.; Mahboobi, M.; Shabrang, M.; Lashkarian, T. Construction projects risk management by risk allocation approach using PMBOK standard. J. Appl. Environ. Biol. Sci. 2015, 5, 323–329. [Google Scholar]

- Gory, A. Assessment and management of risk in improving the OHS management system. Syst. Saf. Hum.-Tech. Facil.-Environ. 2019, 1, 105–111. [Google Scholar] [CrossRef]

- Srinivas, K. Process of risk management. In Perspectives on Risk, Assessment and Management Paradigms; Hessami, A.G., Ed.; Intech Open: London, UK, 2019. [Google Scholar] [CrossRef]

- Sousa, V.; De Almeida, N.M.; Dias, L.A. Risk management framework for the construction industry according to the ISO 31000: 2009 standard. J. Risk Anal. Crisis Response 2012, 2, 261–274. [Google Scholar] [CrossRef][Green Version]

- Mohammad, M.; Osman, M.R.; Yusuff, R.M.; Ismail, N. Strategies and critical success factors for integrated management systems implementation. In Proceedings of the 35th International Conference on Computers and Industrial Engineering, Istanbul, Turkey, 19–25 June 2005; pp. 1391–1396. [Google Scholar]

- Ligade, A.S.; Thalange, S.B. Occupational health and safety management system (OHSMS) model for the construction industry. Int. J. Res. Eng. Technol. 2013, 1, 395–399. [Google Scholar]

- Moen, R.D.; Norman, C.L. Circling back. Qual. Prog. 2010, 43, 22. [Google Scholar]

- Johnson, C.N. The benefits of PDCA. Qual. Prog. 2016, 49, 45. [Google Scholar]

- Roberts, D. Integrating OHSMS, risk management & electrical safety. In Proceedings of the 2014 IEEE IAS Electrical Safety Workshop (ESW), San Diego, CA, USA, 4–7 February 2014; Curran Associates: Red Hook, NY, USA, 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Isniah, S.; Purba, H.H.; Debora, F. Plan Do Check Action (PDCA) method: Literature review and research issues. J. Sist. Dan Manaj. Ind. 2020, 4, 72–81. [Google Scholar] [CrossRef]

- Henn, M.; Weinstein, M.; Foard, N. A Short Introduction to Social Research; Sage: London, UK, 2005. [Google Scholar]

- Sharma, G. Pros and cons of different sampling techniques. Int. J. Appl. Res. 2017, 3, 749–752. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53. [Google Scholar] [CrossRef]

- Yiu, N.S.; Chan, D.W.; Shan, M.; Sze, N.N. Implementation of safety management system in managing construction projects: Benefits and obstacles. Saf. Sci. 2019, 117, 23–32. [Google Scholar] [CrossRef]

- Ngo, T.H.D.; La Puente, C.A. The steps to follow in a multiple regression analysis. SAS Glob. Forum 2012, 2012, 1–12. [Google Scholar]

- Mohammadfam, I.; Kamalinia, M.; Momeni, M.; Golmohammadi, R.; Hamidi, Y.; Soltanian, A. Developing an integrated decision-making approach to assess and promote the effectiveness of occupational health and safety management systems. J. Clean. Prod. 2016, 127, 119–133. [Google Scholar] [CrossRef]

- Ismail, Z.; Doostdar, S.; Harun, Z. Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 2012, 50, 418–423. [Google Scholar] [CrossRef]

- Garnica, G.B.; Barriga, G.D.C. Barriers to occupational health and safety management in small Brazilian enterprises. Production 2018, 28, e20170046. [Google Scholar] [CrossRef]

- Kajiki, S.; Mori, K.; Kobayashi, Y.; Hiraoka, K.; Fukai, N.; Uehara, M.; Adi, N.P.; Nakanishi, S. Developing a global occupational health and safety management system model for Japanese companies. J. Occup. Health 2020, 62, e12081. [Google Scholar] [CrossRef] [PubMed]

- Rajaprasad, S.V.S.; Chalapathi, P.V. Factors influencing implementation of OHSAS 18001 in Indian construction organizations: Interpretive structural modelling approach. Saf. Health Work 2015, 6, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Sklad, A. Assessing the impact of processes on the occupational safety and health management system’s effectiveness using the fuzzy cognitive maps approach. Saf. Sci. 2019, 117, 71–80. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Luo, X.; Zhao, T. Reliability model and critical factors identification of construction safety management based on system thinking. J. Civ. Eng. Manag. 2019, 25, 362–379. [Google Scholar] [CrossRef]

- Othman, A.A.E. A study of the causes and effects of contractors’ non-compliance with the health and safety regulations in the South African construction industry. Archit. Eng. Des. Manag. Archit. Eng. Des. Manag. 2012, 8, 180–191. [Google Scholar] [CrossRef]

- Nordlöf, H.; Wiitavaara, B.; Högberg, H.; Westerling, R. A cross-sectional study of factors influencing occupational health and safety management practices in companies. Saf. Sci. 2017, 95, 92–103. [Google Scholar] [CrossRef]

- Nowrouzi, B.; Gohar, B.; Nowrouzi-Kia, B.; Garbaczewska, M.; Chapovalov, O.; Myette-Côté, É.; Carter, L. Facilitators and barriers to occupational health and safety in small and medium-sized enterprises: A descriptive exploratory study in Ontario, Canada. Int. J. Occup. Saf. Ergon. 2016, 22, 360–366. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, F.A.S.; Peláez, G.I.C.; Alís, J.C. Integral diagnosis of occupational health and safety management in Colombian construction companies. J. Constr. Dev. Ctries. 2018, 22, 101–116. [Google Scholar] [CrossRef]

- Kim, N.K.; Rahim, N.F.A.; Iranmanesh, M.; Foroughi, B. The role of the safety climate in the successful implementation of safety management systems. Saf. Sci. 2019, 118, 48–56. [Google Scholar] [CrossRef]

- Musonda, I.; Pretorius, J.H.C. Effectiveness of economic incentives on clients’ participation in health and safety programmes. J. S. Afr. Inst. Civ. Eng. 2015, 57, 2–7. [Google Scholar] [CrossRef][Green Version]

- Salguero-Caparrós, F.; Pardo-Ferreira, M.D.C.; Martínez-Rojas, M.; Rubio-Romero, J.C. Management of legal compliance in occupational health and safety. A literature review. Saf. Sci. 2020, 121, 111–118. [Google Scholar] [CrossRef]

- Agumba, J.N.; Haupt, T.C. Construction health and safety culture in South African small and medium enterprises. Acta Structilia 2009, 20, 66–88. Available online: http://hdl.handle.net/11189/3354 (accessed on 13 June 2023).

- Windapo, A.O. Relationship between degree of risk, cost and level of compliance to occupational health and safety regulations in construction. Australas. J. Constr. Econ. Build. 2013, 13, 67–82. [Google Scholar] [CrossRef]

- Niciejewska, M.; Kiriliuk, O. Occupational health and safety management in ‘small size’ enterprises, with particular emphasis on hazard identification. Prod. Eng. Arch. 2020, 26, 195–201. [Google Scholar] [CrossRef]

- Garrido, M.C.; Morano, C.A.; Ribeiro, F.M.L.; Naked, H.A. Risk identification techniques knowledge and application in the Brazilian construction. J. Civ. Eng. Constr. Technol. 2011, 2, 242–252. [Google Scholar] [CrossRef]

| Respondents’ Professions | Frequency | Percentage |

|---|---|---|

| Project Manager/Operations Manager | 13 | 26% |

| Quantity Surveyor/Engineering Surveyor | 11 | 22% |

| Other positions | 11 | 22% |

| Health and Safety Manager | 3 | 6% |

| Health and Safety Officer | 3 | 6% |

| Site Manager | 2 | 4% |

| Architect | 2 | 4% |

| Site Foreman | 2 | 4% |

| Professional Health and Safety Agent | 2 | 4% |

| Contracts Manager | 1 | 2% |

| Total | 50 | 100% |

| Sections | Cronbach’s Alpha |

|---|---|

| Internal factors | 0.84 |

| Effects of internal factors | 0.79 |

| External factors | 0.79 |

| Effects of external factors | 0.79 |

| Integration of risk management plan | 0.87 |

| PDCA method when implementing OHSMSs | 0.84 |

| Factors | Effect of Factor Response % | Ranking Agree + Strongly Agree | Mean | Std, Dev. | |||||

|---|---|---|---|---|---|---|---|---|---|

| Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree | Agree + Strongly Agree % | ||||

| 1 | 2 | 3 | 4 | 5 | |||||

| Risk control strategies | 2 | 8 | 60 | 30 | 90 | 1 | 4.18 | 0.66 | |

| Communication channels | 12 | 62 | 26 | 88 | 2 | 4.14 | 0.61 | ||

| Training, hazard perception, education, risk awareness | 2 | 2 | 8 | 60 | 28 | 88 | 2 | 4.10 | 0.79 |

| Safety culture | 2 | 4 | 10 | 52 | 32 | 84 | 4 | 4.08 | 0.88 |

| Senior management commitment and support | 6 | 12 | 42 | 40 | 82 | 5 | 4.16 | 0.87 | |

| Working conditions and scope of work | 2 | 4 | 12 | 62 | 20 | 82 | 5 | 3.94 | 0.82 |

| Risk identification, management, and processes | 2 | 18 | 46 | 34 | 80 | 7 | 4.10 | 0.84 | |

| Allocation of resources | 2 | 6 | 12 | 44 | 36 | 80 | 7 | 4.06 | 0.96 |

| OHS training | 4 | 4 | 12 | 46 | 34 | 80 | 7 | 4.02 | 0.99 |

| Safety policy | 6 | 4 | 18 | 52 | 20 | 72 | 10 | 3.76 | 1.02 |

| Cost of implementation | 2 | 6 | 22 | 48 | 22 | 70 | 11 | 3.82 | 0.92 |

| Constrictive project durations | 14 | 16 | 58 | 12 | 70 | 11 | 3.68 | 0.87 | |

| Organisational structure | 6 | 28 | 42 | 24 | 66 | 13 | 3.84 | 0.87 | |

| Uncertainty in reporting systems | 2 | 10 | 24 | 46 | 18 | 64 | 14 | 3.68 | 0.96 |

| Lack of competent workers | 4 | 8 | 24 | 42 | 22 | 64 | 14 | 3.70 | 1.04 |

| Internal incentives | 20 | 22 | 46 | 12 | 58 | 16 | 3.50 | 0.95 | |

| Factors | Effect of Factor Response % | Ranking Agree + Strongly Agree | Mean | Std, Dev. | |||||

|---|---|---|---|---|---|---|---|---|---|

| Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree | Agree + Strongly Agree % | ||||

| 1 | 2 | 3 | 4 | 5 | |||||

| Pressure from clients on project delivery | 10 | 8 | 56 | 26 | 82 | 1 | 3.98 | 0.87 | |

| Company reputation | 4 | 14 | 64 | 18 | 82 | 1 | 3.96 | 0.70 | |

| OHS enforcement and government legislation | 2 | 6 | 12 | 60 | 20 | 80 | 3 | 3.90 | 0.86 |

| OHS auditing procedures | 6 | 18 | 60 | 16 | 76 | 4 | 3.86 | 0.76 | |

| COVID regulations | 2 | 10 | 12 | 62 | 14 | 76 | 4 | 3.76 | 0.89 |

| Support from OHS authorities | 2 | 6 | 22 | 50 | 20 | 70 | 6 | 3.80 | 0.90 |

| External incentives | 2 | 16 | 22 | 52 | 8 | 60 | 7 | 3.48 | 0.93 |

| International trends | 2 | 22 | 26 | 48 | 2 | 50 | 8 | 3.26 | 0.90 |

| PDCA Stages | OHSMS Implementation | ||||||

|---|---|---|---|---|---|---|---|

| Internal Factors | External Factors | ||||||

| Coef. (β) | (95% Conf. Interval) | Coef. (β) | (95% Conf. Interval) | ||||

| P | Risk planning, identification, analysis, and risk management | 0.04 | −0.40 | 0.48 | 0.18 | −0.22 | 0.58 |

| D | Doing phase of actual implementation of the OHSMS | 0.19 | −0.39 | 0.77 | 0.12 | −0.41 | 0.65 |

| Exploration of solutions to accidents on sites | 0.17 | −0.39 | 0.74 | 0.21 | −0.31 | 0.72 | |

| C | Has the health and safety checklists and audits improved | 0.17 | −0.40 | 0.73 | 0.03 | −0.49 | 0.55 |

| A | Identification of gaps and corrective actions in the OHSMS | −0.64 | −1.45 | 0.18 | −0.35 | −1.09 | 0.35 |

| Continual improvement on the OHSMS | 0.27 | −0.40 | 0.93 | −0.18 | −0.78 | 0.42 | |

| Risk Stage | Method | Freq. (%) | Ranking |

|---|---|---|---|

| Methods used to identify risk | Checklist | 24 | 1 |

| Experience | 22 | 2 | |

| Brainstorming | 19 | 3 | |

| Expert judgment | 19 | 3 | |

| Swot analysis | 13 | 4 | |

| Interviews | 10 | 5 | |

| Delphi technique | 6 | 6 | |

| Others | 3 | 7 | |

| Methods used during risk planning | Risk mitigation/reduction | 22 | 1 |

| Risk avoidance | 18 | 2 | |

| Contingency plan | 17 | 3 | |

| Risk acceptance | 13 | 4 | |

| Risk transfer | 10 | 5 | |

| Risk sharing | 10 | 5 | |

| Risk exploitation | 3 | 6 | |

| Methods used during risk assessment | Quantitative risk analysis through assessment of risk to determine the effect on time, cost, and duration of the project | 22 | 1 |

| Risk categorisation and risk urgency assessment through identification of threats | 16 | 2 | |

| Probability/impact risk rating matrix through risk rating, e.g., high, medium, or low | 16 | 2 | |

| Qualitative risk analysis through the probability and impact of risk | 14 | 3 | |

| Decision Trees | 12 | 4 | |

| Risk probability and impact assessment through evaluation of the likelihood of the occurrence of a specific risk and the impact of the risk | 10 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kunodzia, R.; Bikitsha, L.S.; Haldenwang, R. Perceived Factors Affecting the Implementation of Occupational Health and Safety Management Systems in the South African Construction Industry. Safety 2024, 10, 5. https://doi.org/10.3390/safety10010005

Kunodzia R, Bikitsha LS, Haldenwang R. Perceived Factors Affecting the Implementation of Occupational Health and Safety Management Systems in the South African Construction Industry. Safety. 2024; 10(1):5. https://doi.org/10.3390/safety10010005

Chicago/Turabian StyleKunodzia, Rejoice, Luviwe Steve Bikitsha, and Rainer Haldenwang. 2024. "Perceived Factors Affecting the Implementation of Occupational Health and Safety Management Systems in the South African Construction Industry" Safety 10, no. 1: 5. https://doi.org/10.3390/safety10010005

APA StyleKunodzia, R., Bikitsha, L. S., & Haldenwang, R. (2024). Perceived Factors Affecting the Implementation of Occupational Health and Safety Management Systems in the South African Construction Industry. Safety, 10(1), 5. https://doi.org/10.3390/safety10010005