Neutron Imaging at Compact Accelerator-Driven Neutron Sources in Japan

Abstract

:1. Introduction

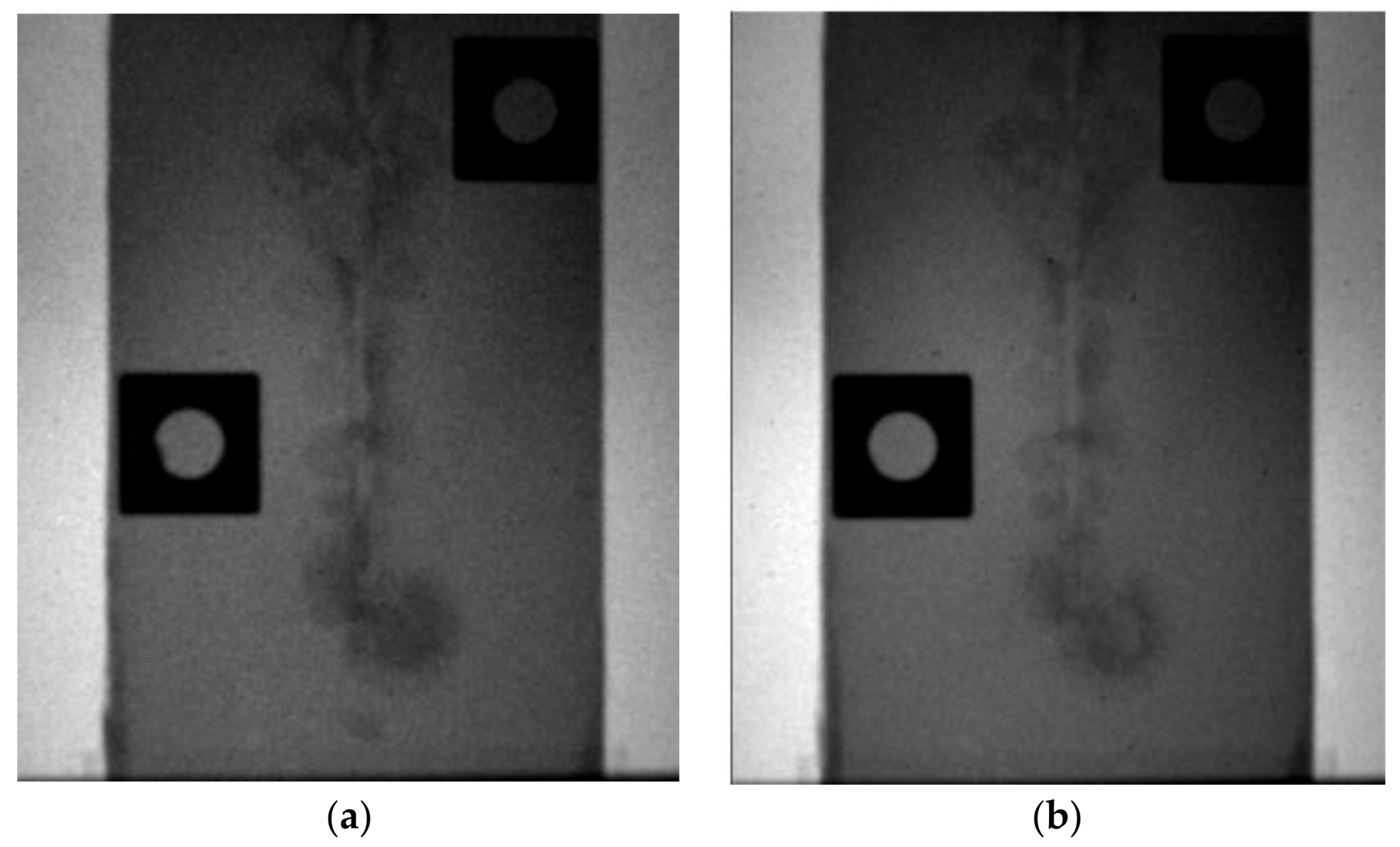

2. Neutron Facilities in Japan

3. Compact Accelerator-Driven Neutron Sources and Their Activities

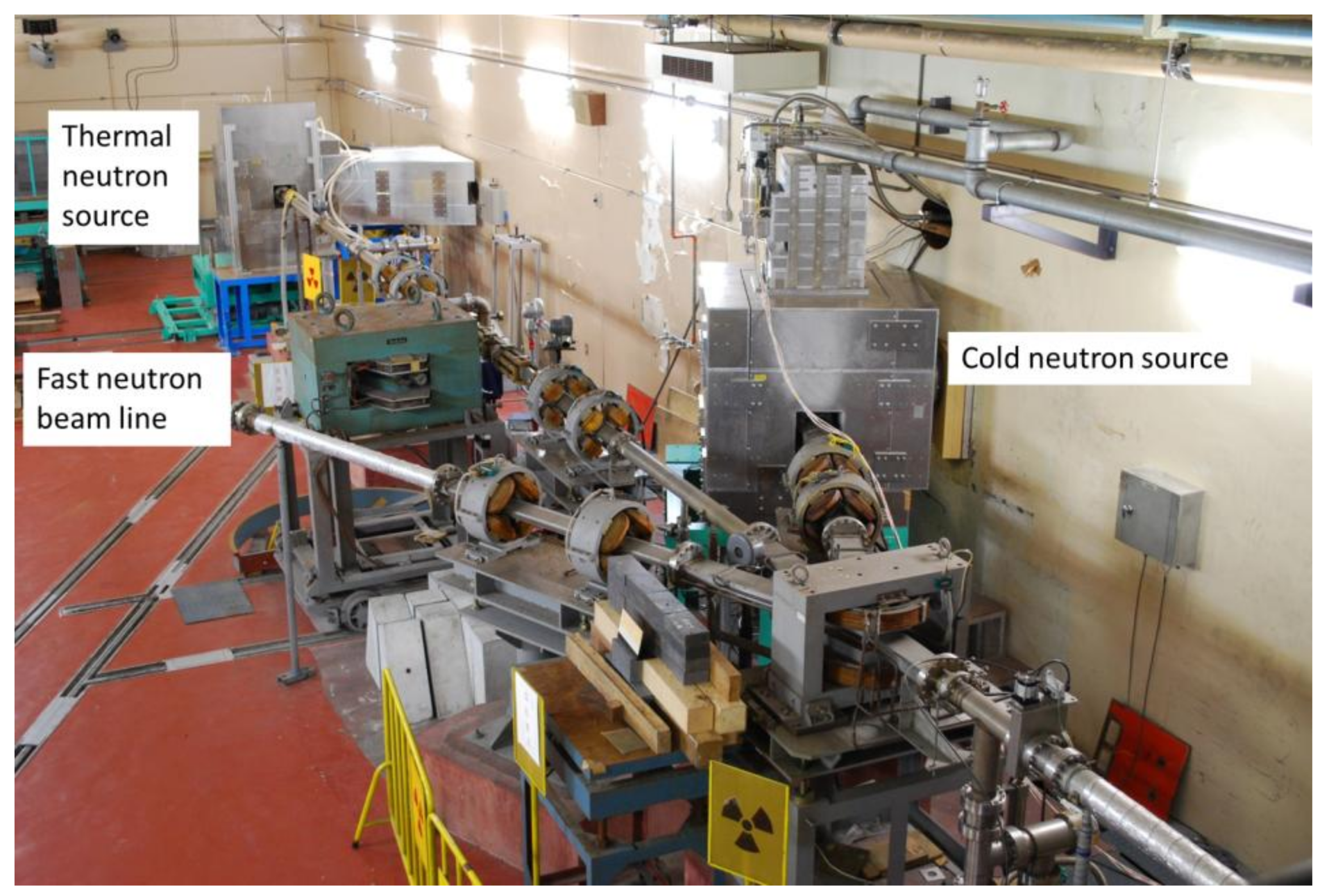

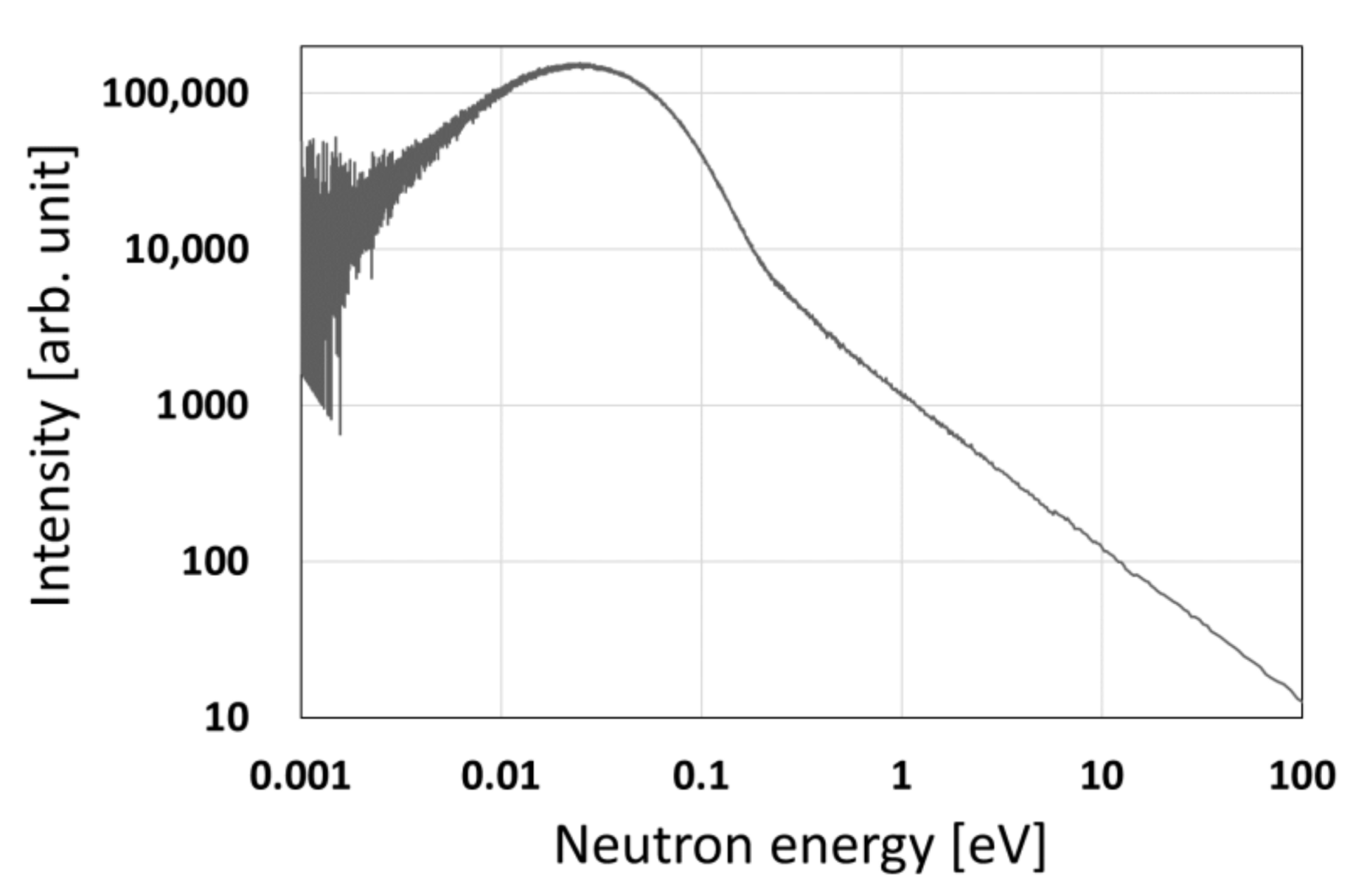

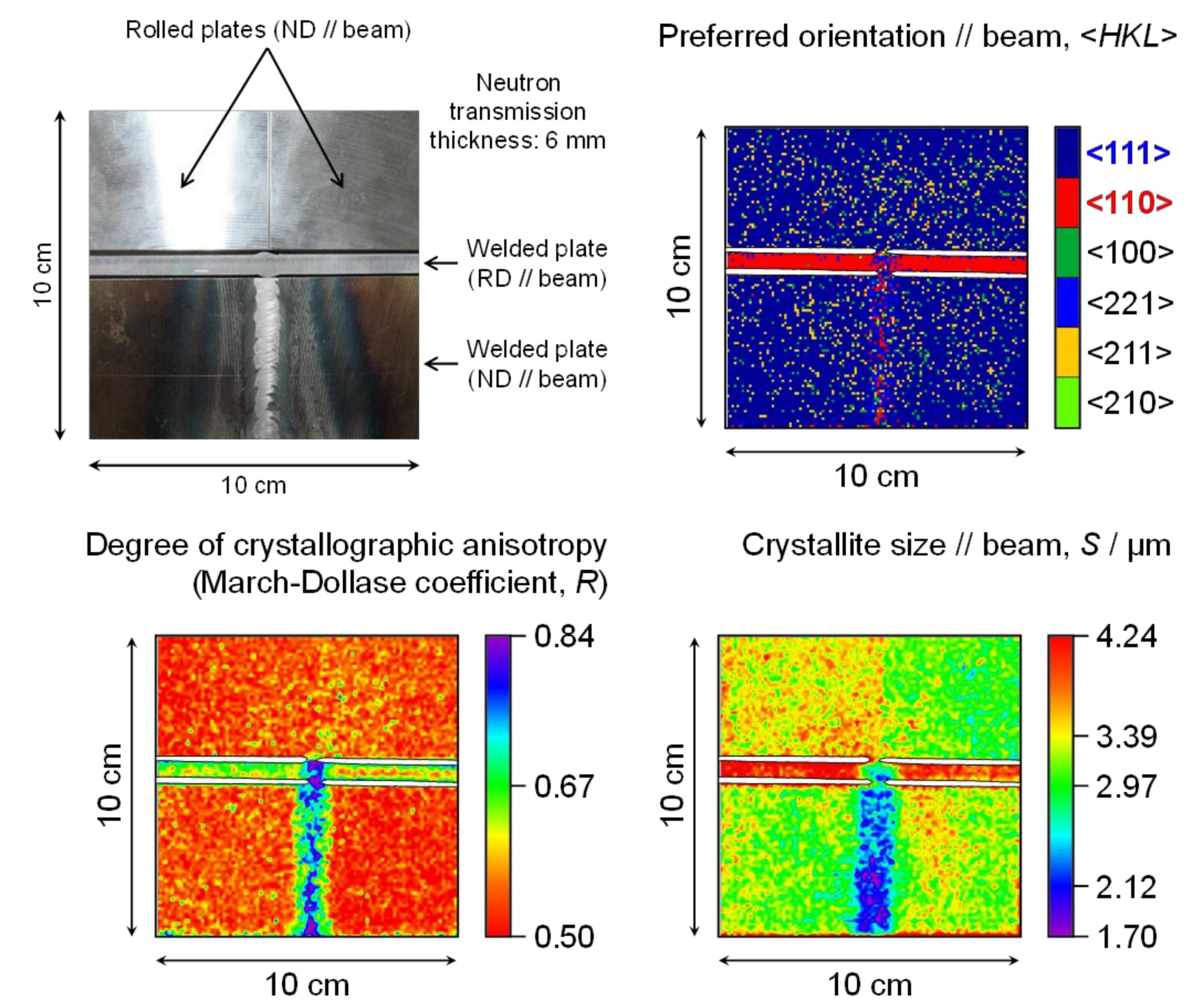

3.1. Hokkaido University Neutron Source (HUNS)

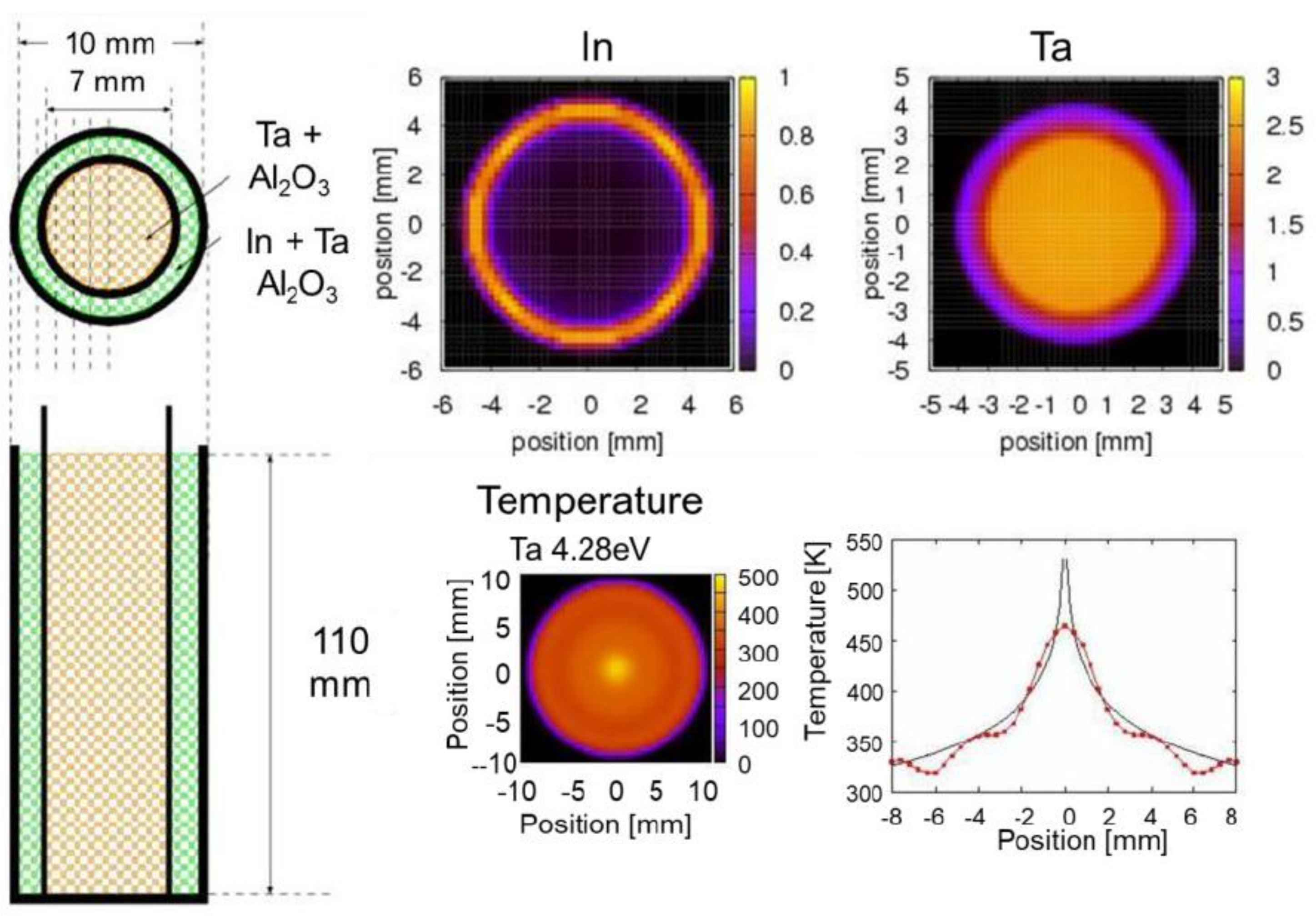

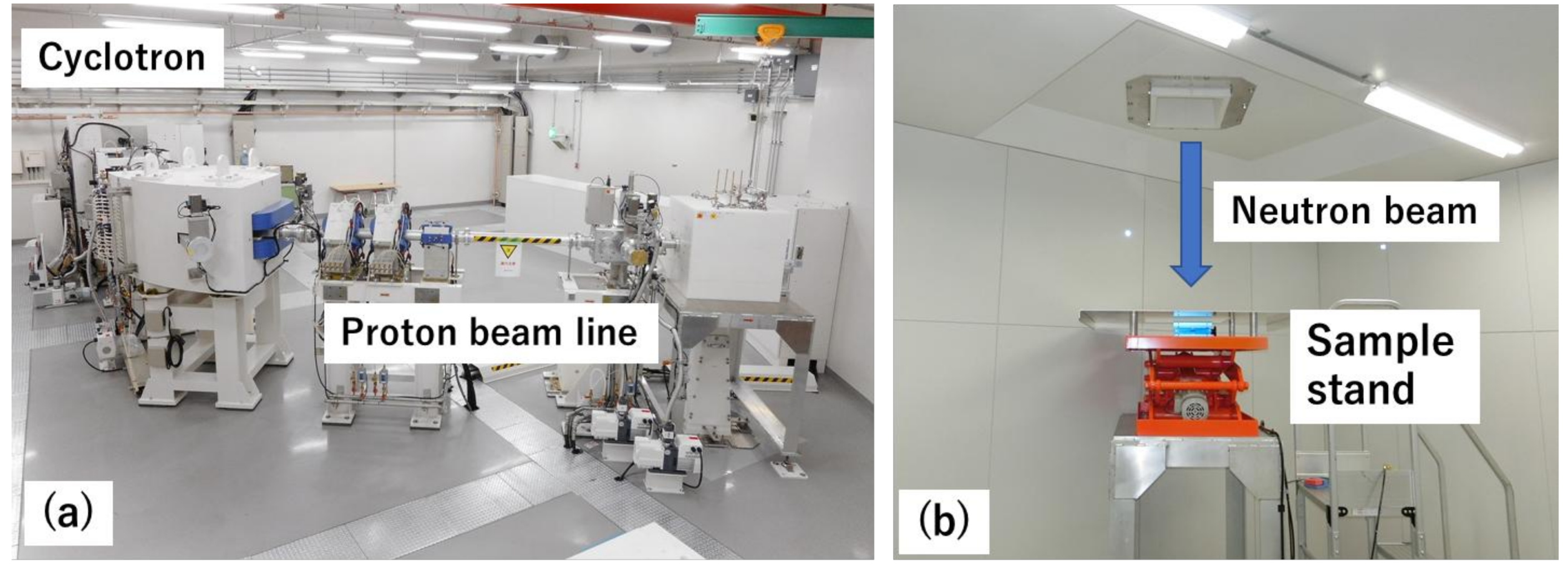

3.2. Aomori Prefecture Quantum Science Center

3.3. RIKEN Compact Accelerator-Driven Neutron Source (RANS)

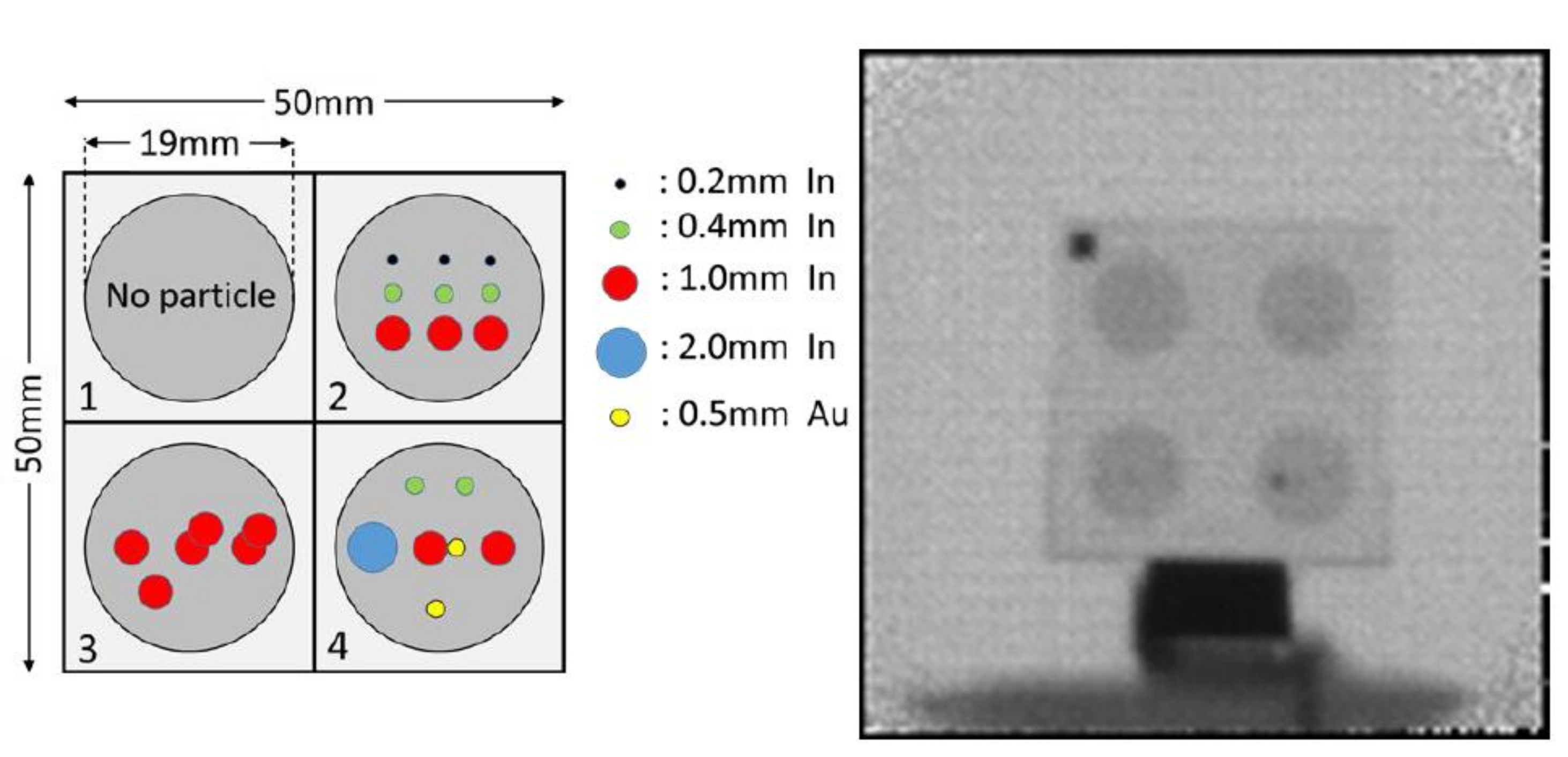

3.4. Kyoto University Accelerator-Driven Neutron Source (KUANS)

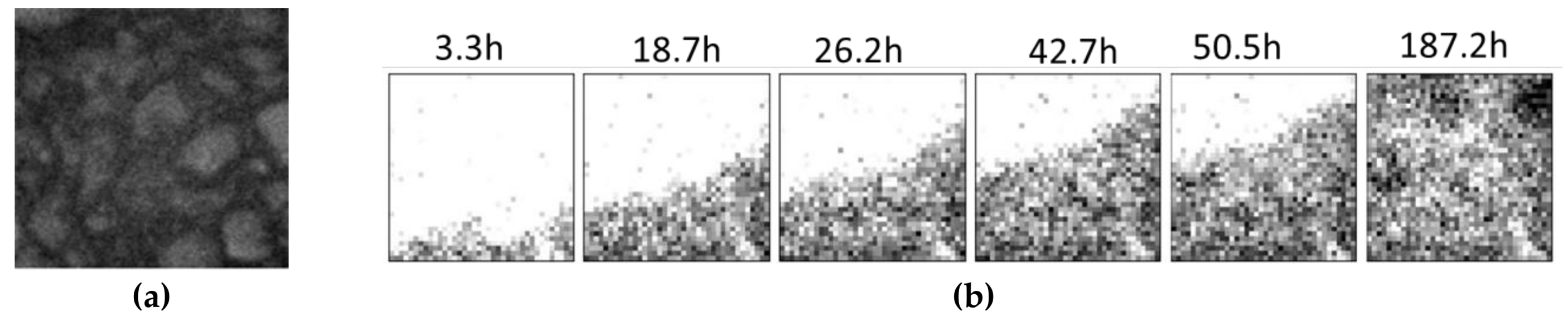

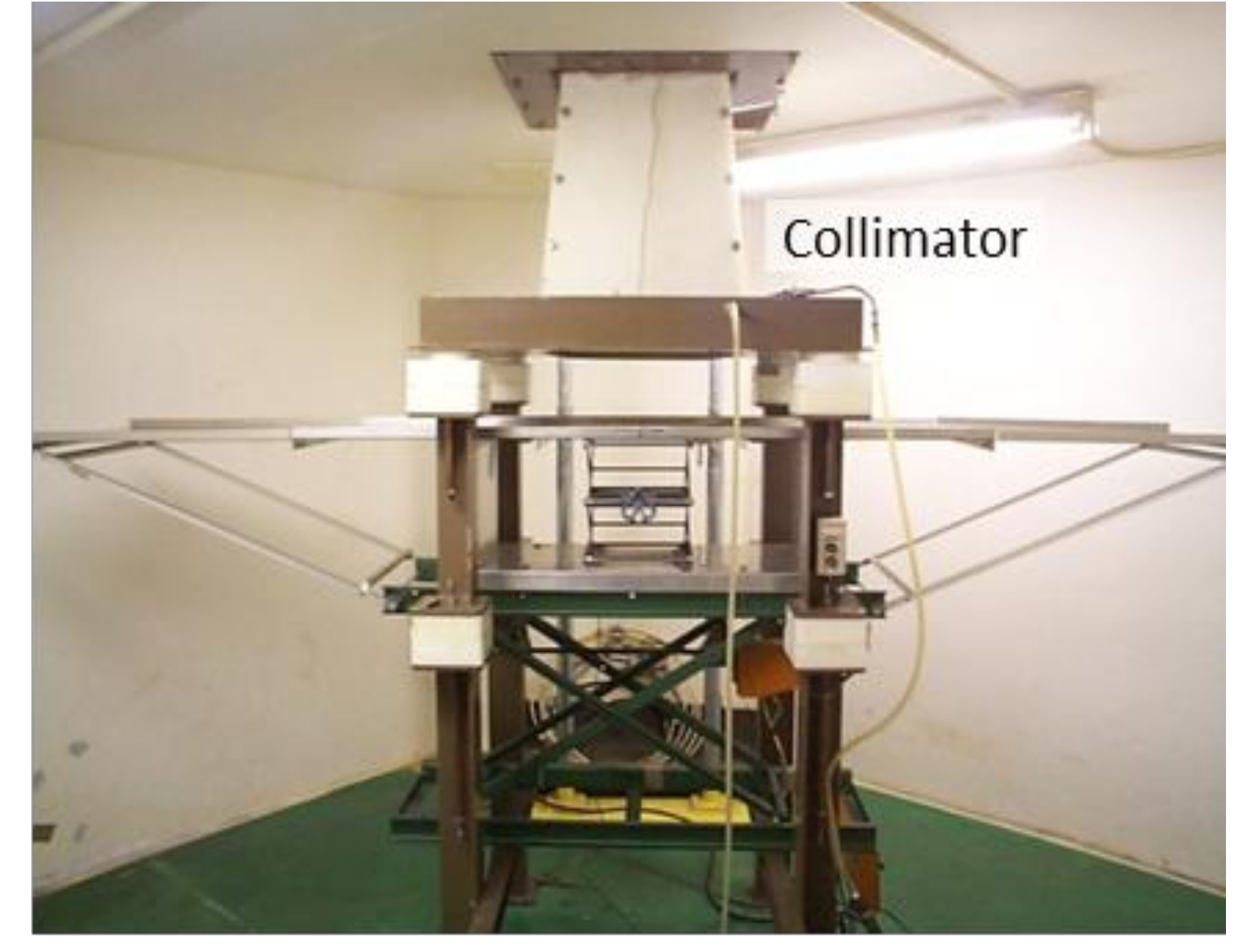

3.5. Kyoto University Research Reactor Institute LINAC (KURRI-LINAC)

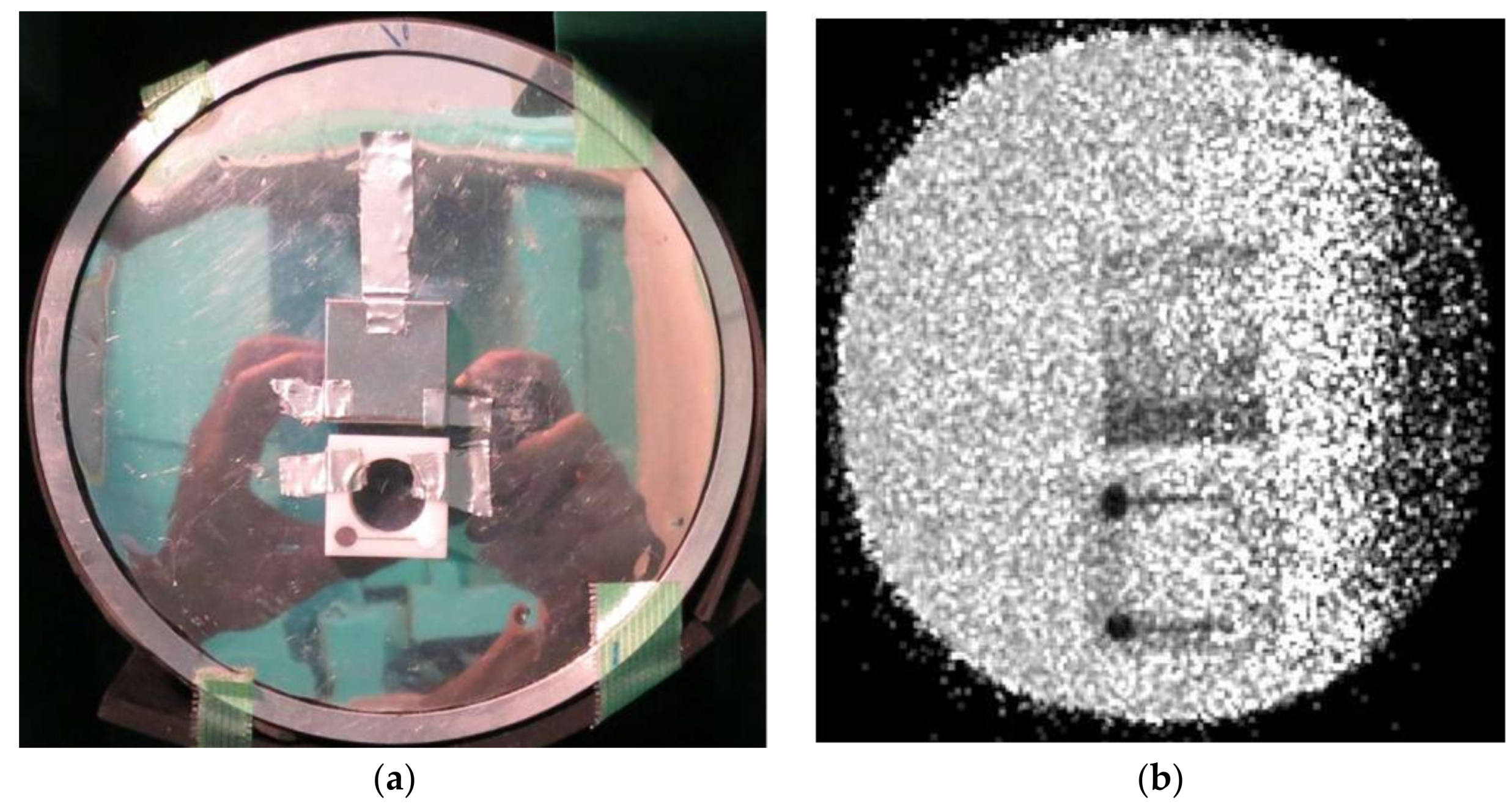

3.6. Sumitomo Heavy Industry ATEX (SHI-ATEX)

4. Summary

Acknowledgments

Conflicts of Interest

References

- Murakawa, H.; Sugimoto, K.; Miyata, K.; Asano, H.; Takenaka, N.; Yasuda, R. Visualization of water behavior in the in-plane and through-plane directions in a PEFC using a neutron image intensifier. Phys. Procedia 2013, 43, 277–281. [Google Scholar] [CrossRef]

- Lehmann, E.H.; Peetermans, S.; Betz, B. Instrumentation in neutron imaging—A world-wide overview. Neutron News 2015, 26, 6–10. [Google Scholar] [CrossRef]

- Kiyanagi, Y.; Sato, H.; Kamiyama, T.; Shinohara, T. A new imaging method using pulsed neutron sources for visualizing structural and dynamical information. J. Phys. Conf. Ser. 2012, 340, 012010. [Google Scholar] [CrossRef]

- Shinohara, T.; Kai, T.; Oikawa, K.; Segawa, M.; Harada, M.; Nakatani, T.; Ooi, M.; Aizawa, K.; Sato, H.; Kamiyama, T.; et al. Final design of the Energy-Resolved Neutron Imaging System “RADEN” at J-PARC. J. Phys. Conf. Ser. 2016, 746, 012007. [Google Scholar] [CrossRef]

- Otake, Y. A Compact proton linac neutron source at RIKEN. In Applications of Laser-Driven Particle Acceleration; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Sunaga, H.; Takamura, M.; Ikeda, Y.; Otake, Y.; Hama, T.; Kumagai, M.; Suzuki, H.; Suzuki, S. Texture evaluation in ductile fracture process by neutron diffraction measurement. J. Phys. Conf. Ser. 2016, 734 Pt B. [Google Scholar] [CrossRef]

- Takamura, M.; Ikeda, Y.; Sunaga, H.; Taketani, A.; Otake, Y.; Suzuki, H.; Kumagai, M.; Hama, T.; Oba, Y. Non-destructive Texture Measurement of Steel Sheets with Compact Neutron Source “RANS”. J. Phys. Conf. Ser. 2016, 734 Pt B. [Google Scholar] [CrossRef]

- Ikeda, Y.; Taketani, A.; Takamura, M.; Sunaga, H.; Kumagai, M.; Oba, Y.; Otake, Y.; Suzuki, H. Prospect for application of compact accelerator-based neutron source to neutron engineering diffraction. Nucl. Instrum. Methods A 2016, 833, 61–67. [Google Scholar] [CrossRef]

- Yamada, M.; Otake, Y.; Taketani, A.; Sunaga, H.; Yamagata, Y.; Wakabayashi, T.; Kono, K.; Nakayama, T. Non-Destructive Inspection of Under-Film Corroded Steels using A Compact Neutron Source. Tetsu-to-Hagane 2014, 100, 429–431. [Google Scholar] [CrossRef]

- Taketani, A.; Yamada, M.; Ikeda, Y.; Hashiguchi, T.; Sunaga, H.; Wakabayashi, Y.; Ashigai, S.; Takamura, M.; Mihara, S.; Yanagimachi, S.; et al. Visualization of Water in Corroded Region of Painted Steels at a Compact Neutron Source. ISIJ Int. 2017, 57, 155–161. [Google Scholar] [CrossRef]

- Takahashi, Y.; Kiyanagi, Y.; Watanabe, K.; Uritani, A.; Sano, T.; Hori, J.; Nakajima, K. Development of a neutron source for imaging at the electron linac facility in Kyoto University Research Reactor Institute. Physica B 2018. submitted. [Google Scholar]

- Baxter, D.V.; Rinckel, T. Status report on the Low Energy Neutron Source for 2015. Il Nuovo Cimento C 2016, 38, 183. [Google Scholar] [CrossRef]

- Wang, X.; Loong, C.K.; Guan, X.; Du, T. Recent Progress of the Compact Pulsed Hadron Source Project and Related Activities at Tsinghua University. Phys. Procedia 2014, 60, 97–100. [Google Scholar] [CrossRef]

- Guo, Z.; Lu, Y.; Zou, Y.; Zhu, K.; Peng, S.; Zhao, I.; Gao, S.; Wen, W.; Li, H.; Zhou, Q.; et al. Progress of PKUNIFTY—A RFQ Accelerator based Neutron Imaging Facility at Peking University. Phys. Procedia 2013, 43, 79–85. [Google Scholar] [CrossRef]

- Futakawa, M.; Maekawa, F.; Sakamoto, S. 1-MW Pulsed Spallation Neutron Source (JSNS) at J-PARC. Neutron News 2011, 22, 15–19. [Google Scholar] [CrossRef]

- Parker, J.D.; Harada, M.; Hayashida, H.; Hiroi, K.; Kai, T.; Matsumoto, Y.; Nakatani, T.; Oikawa, K.; Segawa, M.; Shinohara, T.; et al. Development of Energy-Resolved Neutron Imaging Detectors at RADEN. JPS Conf. Proc. 2018. submitted. [Google Scholar]

- Uno, S.; Uchida, T.; Sekimoto, M.; Murakami, T.; Miyama, K.; Shoji, M.; Nakano, E.; Koike, T.; Morita, K.; Satoh, H.; et al. Two-dimensional Neutron Detector with GEM and its Applications. Phys. Proc. 2012, 26, 142–152. [Google Scholar] [CrossRef]

- Parker, J.D.; Harada, M.; Hayashida, H.; Hiroi, K.; Kai, T.; Matsumoto, Y.; Oikawa, K.; Segawa, M.; Shinohara, T.; Su, Y.; et al. Development of the next-generation micro pixel chamber-based neutron imaging detector (μNID) for energy-resolved neutron imaging at the J-PARC/MLF. In Proceedings of the IEEE Nuclear Science Symposium, Medical Imaging Conference and Room-Temperature Semiconductor Detector Workshop (NSS/MIC/RTSD), Strasbourg, France, 29 October–6 November 2016. [Google Scholar] [CrossRef]

- Mizukami, K.; Sato, S.; Sagehashi, S.; Ohnuma, S.; Ooi, M.; Iwasa, H.; Hiraga, F.; Kamiyama, T.; Kiyanagi, Y. Measurements of Performance of a Pixel-Type Two-Dimensional Position Sensitive Li-glass Neutron Detector. Nucl. Instrum. Methods Phys. Res. A 2004, 529, 310–312. [Google Scholar] [CrossRef]

- Nittoh, K.; Konagai, C.; Noji, T.; Miyabe, K. New feature of the neutron color image intensifier. Nucl. Instrum. Methods Phys. Res. A 2009, 605, 107–110. [Google Scholar] [CrossRef]

- Furusaka, M.; Sato, H.; Kamiyama, T.; Ohnuma, M.; Kiyanagi, Y. Activity of Hokkaido University neutron source, HUNS. Phys. Procedia 2014, 60, 167–174. [Google Scholar] [CrossRef]

- Sato, H.; Kamiyama, T.; Kiyanagi, Y. A Rietveld-Type Analysis Code for Pulsed Neutron Bragg-Edge Transmission Imaging and Quantitative Evaluation of Texture and Microstructure of a Welded α-Iron Plate. Mater. Trans. 2011, 52, 1294–1302. [Google Scholar] [CrossRef]

- Kamiyama, T.; Narita, Y.; Sato, H.; Ohnuma, M.; Kiyanagi, Y. Structural change of carbon anode in a lithium-ion battery product associated with charging process observed by neutron transmission Bragg-edge imaging. Phys. Procedia 2017, 88, 27–33. [Google Scholar] [CrossRef]

- Sethuraman, V.A.; Hardwick, L.J. Surface structural disordering in graphite upon lithium intercalation/deintercalation. J. Power Sources 2010, 195, 3655–3660. [Google Scholar] [CrossRef]

- Kamiyama, T.; Noda, H.; Ito, J.; Iwasa, H.; Kiyanagi, Y.; Ikeda, S. Remote-sensing, Non-destructive, and Computed-tomography-assisted Thermometry by Neutron Resonance Absorption Spectroscopy. J. Neutron Res. 2005, 13, 97–101. [Google Scholar] [CrossRef]

- Kamiyama, T.; Miyamoto, N.; Tomioka, S.; Kozaki, T. Epithermal neutron tomography using compact electron linear accelerator. Nucl. Instrum. Methods Phys. Res. Sect. A 2009, 605, 91–94. [Google Scholar] [CrossRef]

- Yoshimura, Y.; Mizuta, M.; Sunaga, H.; Otake, Y. Study on Water Penetration Measurement in Concrete using Compact Neutron Source. Proc. Jpn. Concr. Inst. 2017, 39, 613–618. Available online: http://data.jci-net.or.jp/data_html/39/039-01-1095.html (accessed on 26 March).

- Yoshimura, Y.; Mizuta, M.; Sunaga, H.; Otake, Y.; Hayashizaki, N. Measurement of Water in Concrete by a Compact Accelerator-driven Neutron Source. In Proceedings of the 17th JSMS Symposium on Concrete Structure Scenarios, Kyoto, Japan, 12–13 October 2017. [Google Scholar]

| Facility Name | Accelerator Type | Acceleration Particle (Energy) | Accelerator Power (kW) | Moderator Type | Neutron Flux (n/cm2/s) | L/D |

|---|---|---|---|---|---|---|

| HUNS | Linac | Electron (35 MeV) | ~1 | Thermal Cold | ~few × 103 ~few × 104 | ~60 |

| Aomori Prefecture Quantum Science Center | Cyclotron | Proton (20 MeV) | 1 | Thermal | 6.1 × 105 | 44 |

| J-PARC RADEN | Synchrotron | Proton (3000 MeV) | 1000 | Cold | 2.6 × 107 | 180~7000 |

| RANS | Linac | Proton (7 MeV) | 0.7 | Thermal | ~few × 104 | 21~781 |

| KUANS | Linac | Proton (3.5 MeV) | 0.35 | Thermal | 1.2 × 103 | ~20 |

| KURRI-LINAC | Linac | Electron (40 MeV) | 6 | Thermal | 2.4 × 104 | ~85 |

| SHI-ATEX | Cyclotron | Proton (18 MeV) | 0.36 | Thermal | 2.0 × 105 | 44 |

| L/D | Detector Position L from Moderator (mm) | Viewing Moderator Size D (mm) |

|---|---|---|

| 33 | 5000 | 150 |

| 21~331 | 3500 | 10–170 |

| 781 (max) | 8000 | 10 |

| Detector | Converter | Photo Sensor | Spatial Resolution |

|---|---|---|---|

| Neutron Camera | LiF/ZnS(Ag) | Cooled CCD sensor | 40 μm |

| Color I.I. 1 | Gd2O3 | CMOS or | 45 μm |

| Color I.I. 2 | B4C | Cooled CCD sensor | 45 μm |

| 3He Position Sensitive Detector | 3He 10 atom | 3He Gas chamber | 1 cm |

| RPMT | LiF/ZnS Li grass | Position sensitive Photomultiplier Tube | 1 mm |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiyanagi, Y. Neutron Imaging at Compact Accelerator-Driven Neutron Sources in Japan. J. Imaging 2018, 4, 55. https://doi.org/10.3390/jimaging4040055

Kiyanagi Y. Neutron Imaging at Compact Accelerator-Driven Neutron Sources in Japan. Journal of Imaging. 2018; 4(4):55. https://doi.org/10.3390/jimaging4040055

Chicago/Turabian StyleKiyanagi, Yoshiaki. 2018. "Neutron Imaging at Compact Accelerator-Driven Neutron Sources in Japan" Journal of Imaging 4, no. 4: 55. https://doi.org/10.3390/jimaging4040055

APA StyleKiyanagi, Y. (2018). Neutron Imaging at Compact Accelerator-Driven Neutron Sources in Japan. Journal of Imaging, 4(4), 55. https://doi.org/10.3390/jimaging4040055