Energy-Resolved Neutron Imaging for Reconstruction of Strain Introduced by Cold Working

Abstract

1. Introduction

2. Materials and Methods

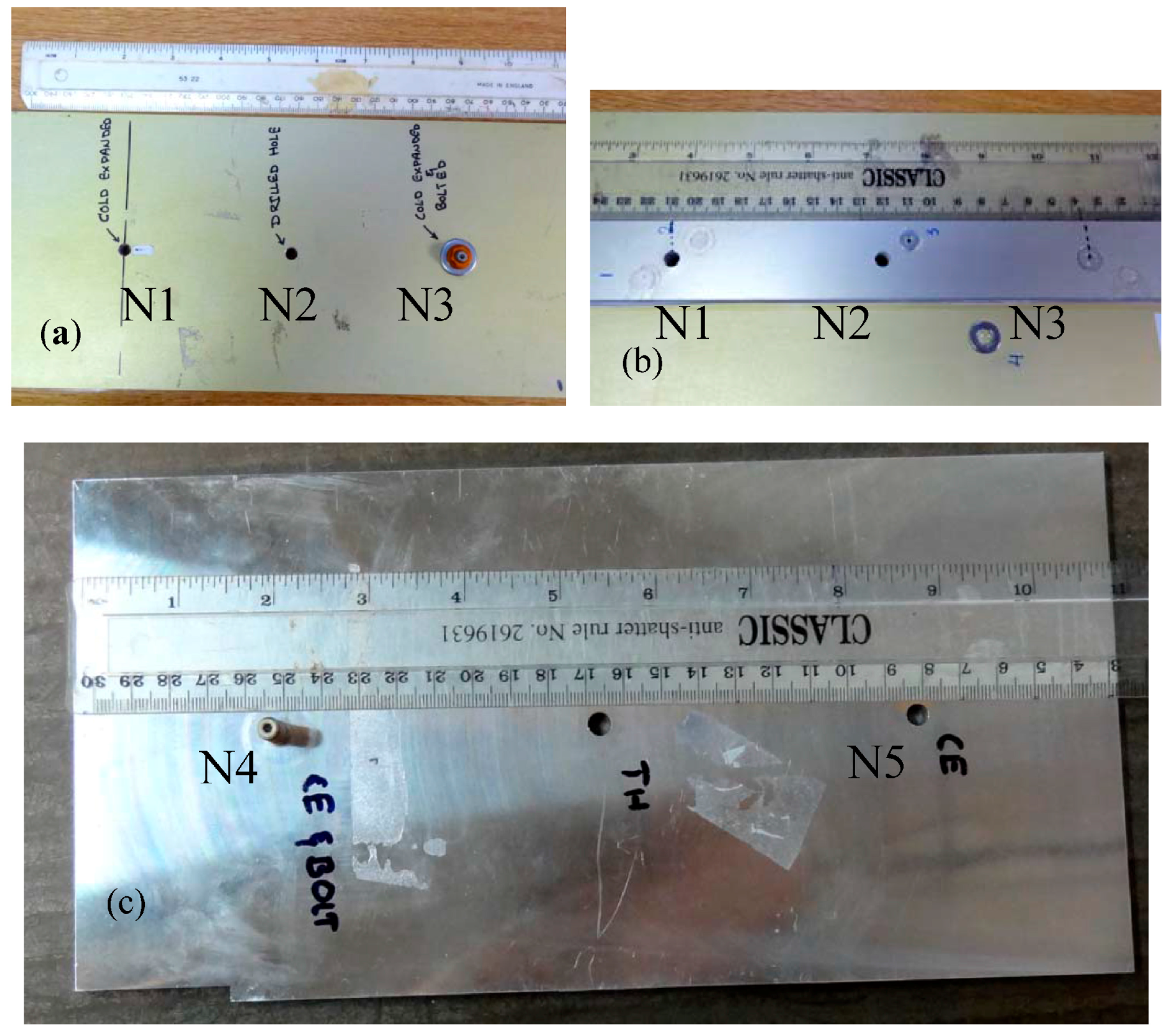

2.1. Samples

2.2. Experimental Set-Up

2.3. Reconstruction of Residual Strain from the Measured Transmisison Spectra

3. Results

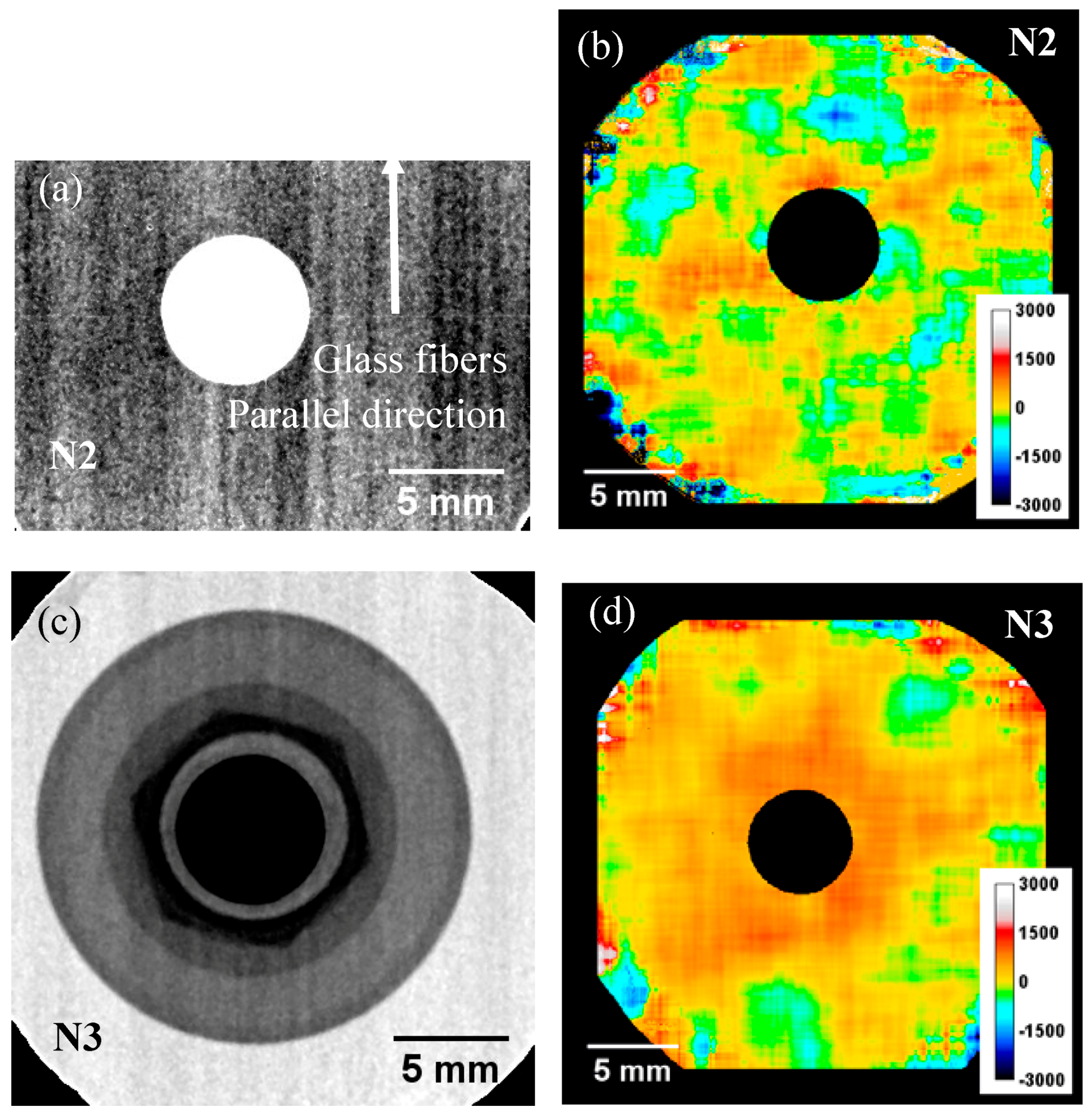

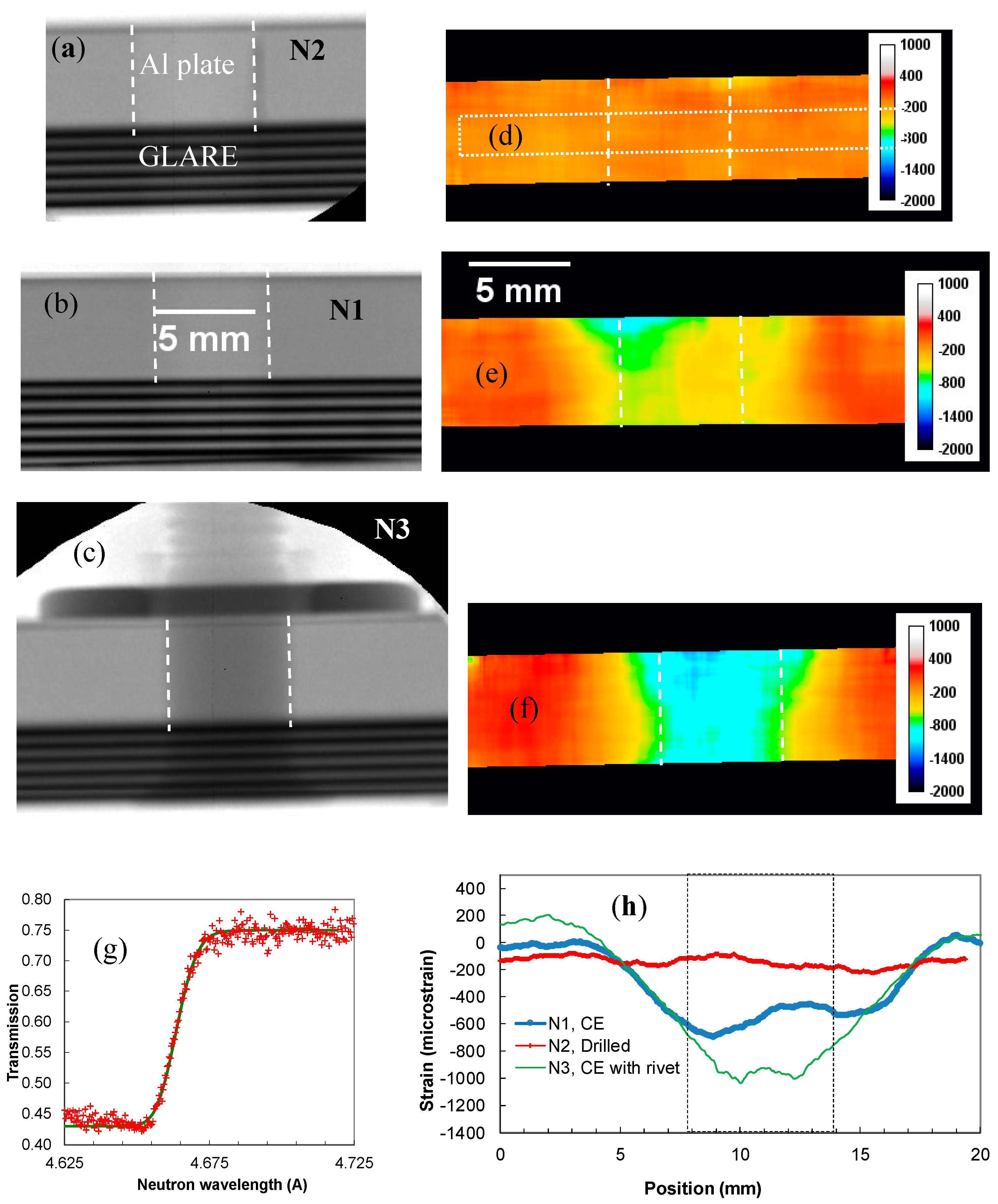

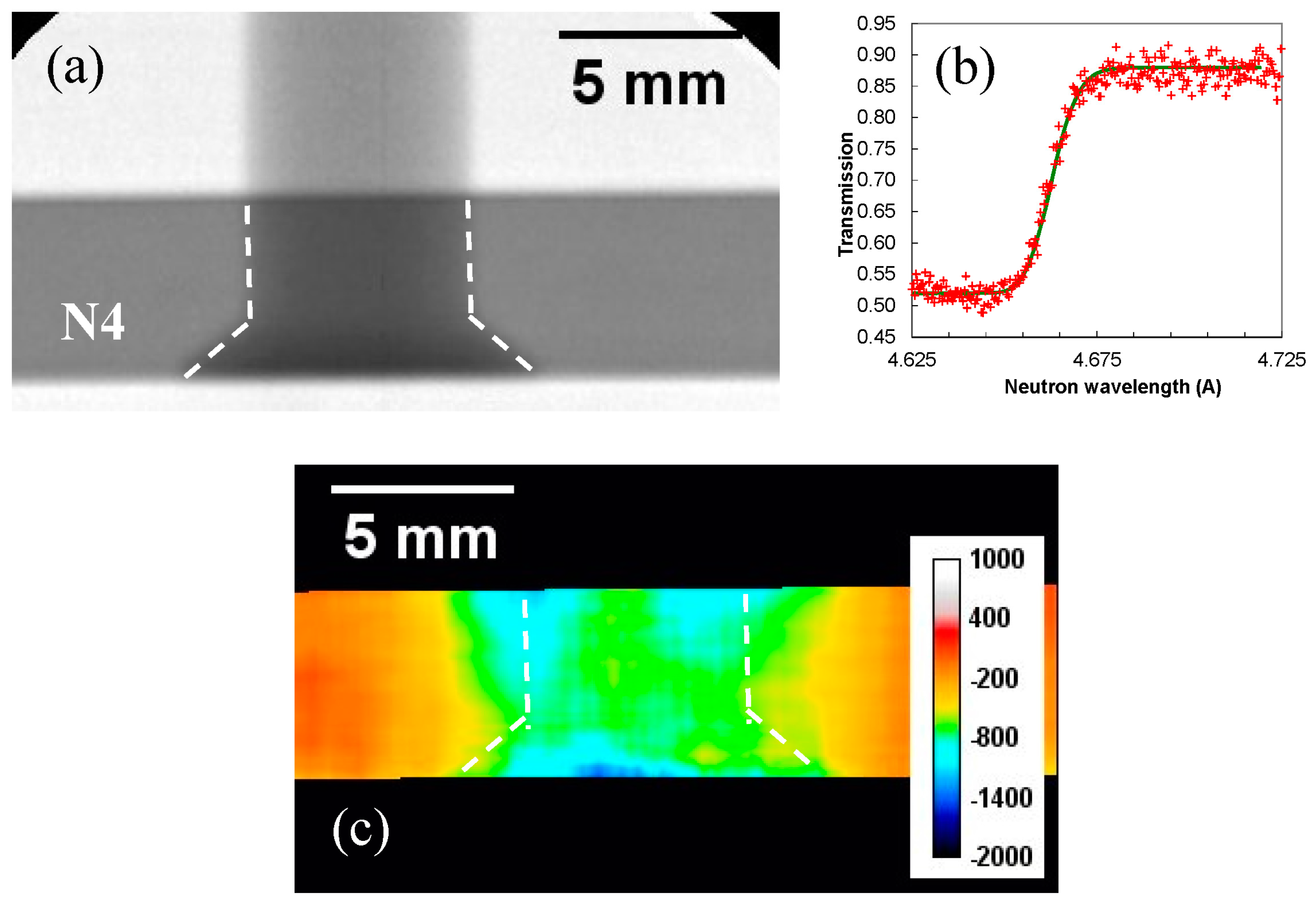

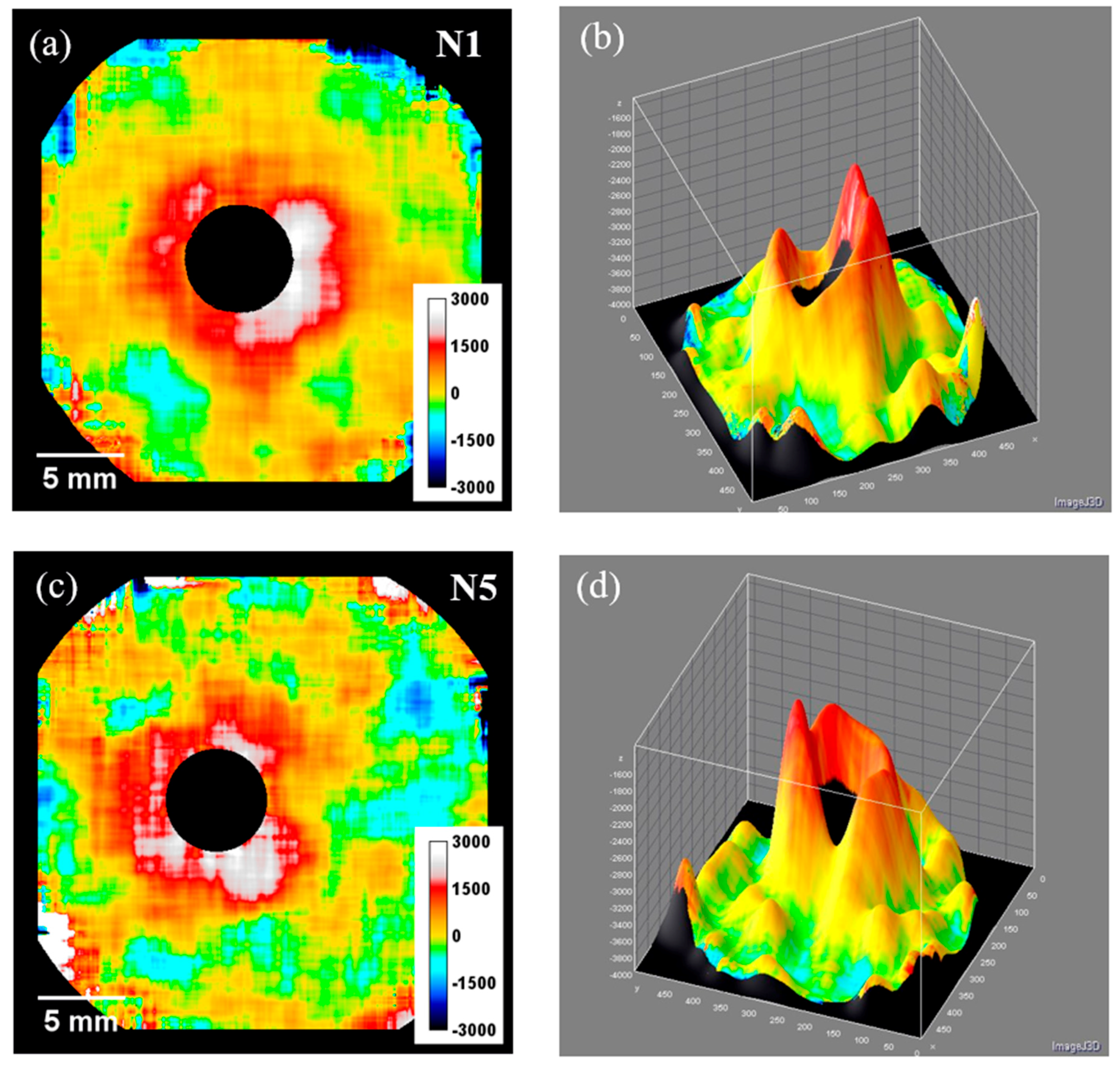

3.1. Asymmetry of Strain around Cold-Expanded Holes

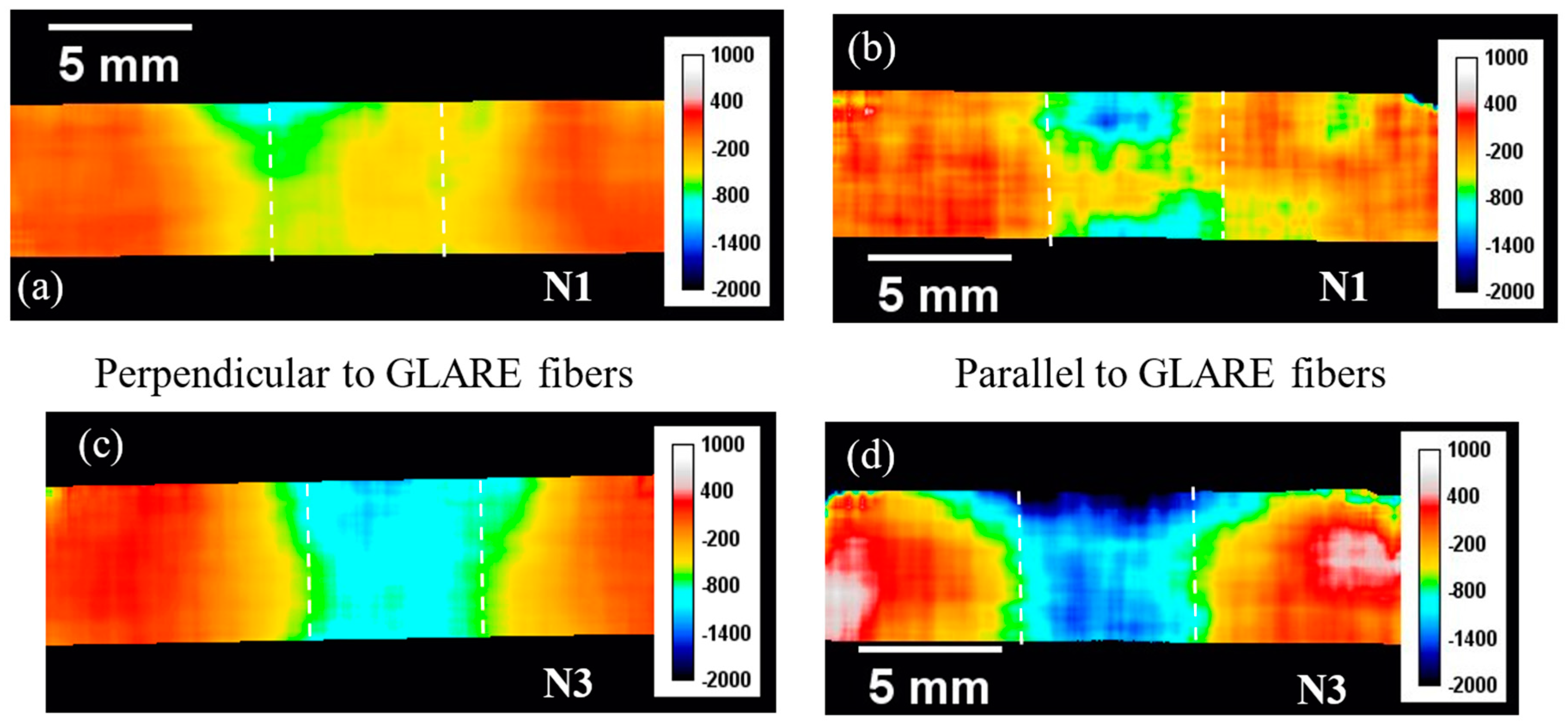

3.2. Strain Versus Direction of Glass Fibers in the GLARE Laminate

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mocko, M.; Muhrer, G.; Kelsey, C.T.; Duran, M.A.; Tovesson, F. Experimental measurement of the neutron time emission spectra at the Manuel Lujan Jr. neutron scattering center. Nucl. Instrum. Methods Phys. Res. Sect. A 2011, 632, 101–108. [Google Scholar] [CrossRef]

- Bilheux, H.; Herwig, K.; Keener, S.; Davis, L. Overview of the conceptual design of the future VENUS neutron imaging beam line at the Spallation Neutron Source. Phys. Procedia 2015, 69, 55–59. [Google Scholar] [CrossRef]

- Minniti, T.; Kockelmann, W.; Burca, G.; Kelleher, J.F.; Kabra, S.; Zhang, S.Y.; Pooley, D.E.; Schooneveld, E.M.; Mutamba, Q.; Sykora, J.; et al. Materials analysis opportunities on the new neutron imaging facility IMAT@ISIS. J. Instrum. 2016, 11, C03014. [Google Scholar] [CrossRef]

- Matsumoto, Y.; Segawa, M.; Kai, T.; Shinohara, T.; Nakatani, T.; Oikawa, K.; Hiroi, K.; Su, Y.H.; Hayashida, H.; Parker, J.D.; et al. Recent Progress of Radiography and Tomography at the Energy-resolved Neutron Imaging System RADEN. Phys. Procedia 2017, 88, 162–166. [Google Scholar] [CrossRef]

- Parker, J.D.; Hattori, K.; Fujioka, H.; Harada, M.; Iwaki, S.; Kabuki, S.; Kishimoto, Y.; Kubo, H.; Kurosawa, S.; Miuchi, K.; et al. Neutron imaging detector based on the µPIC micro-pixel chamber. Nucl. Instrum. Methods Phys. Res. Sect. A 2013, 697, 23–31. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Vallerga, J.V.; McPhate, J.B.; Siegmund, O.H.W. Optimization of high count rate event counting detector with Microchannel Plates and quad Timepix readout. Nucl. Instrum. Methods Phys. Res. Sect. A 2015, 787, 20–25. [Google Scholar] [CrossRef]

- Santisteban, J.R.; Edwards, L.; Steuwer, A.; Withers, P.J. Time-of-flight neutron transmission diffraction. J. Appl. Crystallogr. 2001, 34, 289–297. [Google Scholar] [CrossRef]

- Vogel, S. A Rietveld-Approach for the Analysis of Neutron Time-of-Flight Transmission Data. Ph.D. Thesis, Christian Albrechts Universität, Kiel, Germany, 2000. [Google Scholar]

- Sato, H.; Watanabe, K.; Kiyokawa, K.; Kiyanagi, R.; Hara, K.Y.; Kamiyama, T.; Furusaka, M.; Shinohara, T.; Kiyanagi, Y. Further improvement of the RITS code for pulsed neutron Bragg-edge transmission imaging. Phys. Procedia 2017, 88, 322–330. [Google Scholar] [CrossRef]

- Song, G.; Lin, J.Y.Y.; Bilheux, J.C.; Xie, Q.; Santodonato, L.J.; Molaison, J.J.; Skorpenske, H.D.; Dos Santos, A.M.; Tulk, C.A.; An, K.; et al. Characterization of Crystallographic Structures Using Bragg-Edge Neutron Imaging at the Spallation Neutron Source. J. Imaging 2017, 3, 65. [Google Scholar] [CrossRef]

- Sun, T.; Tremsin, A.S.; Roy, M.J.; Hofmann, M.; Prangnell, P.B.; Withers, P.J. Investigation of residual stress distribution and texture evolution in AA7050 stationary shoulder friction stir welded joints. Mater. Sci. Eng. A 2018, 712, 531–538. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Yau, T.Y.; Kockelmann, W. Non-destructive examination of loads in regular and self-locking Spiralock® threads through energy-resolved neutron imaging. Strain 2016, 52, 548–558. [Google Scholar] [CrossRef]

- Malamud, F.; Santisteban, J.R. Full-pattern analysis of time-of-flight neutron transmission of mosaic crystals. J. Appl. Cryst. 2016, 49, 348–365. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Vogel, S.C.; Mocko, M.; Bourke, M.A.M.; Yuan, V.; Nelson, R.O.; Brown, D.W.; Feller, W.B. Non-destructive studies of fuel rodlets by neutron resonance absorption radiography and thermal neutron radiography. J. Nucl. Mater. 2013, 440, 633–646. [Google Scholar] [CrossRef]

- Festa, G.; Perelli Cippo, E.; Di Martino, D.; Cattaneo, R.; Senesi, R.; Andreani, C.; Schooneveld, E.; Kockelmann, W.; Rhodes, N.; Scherillo, A.; et al. Neutron resonance transmission imaging for 3D elemental mapping at the ISIS spallation neutron source. J. Anal. At. Spectrom. 2015, 30, 745–750. [Google Scholar] [CrossRef]

- Kai, T.; Maekawa, F.; Oshita, H.; Sato, H.; Shinohara, T.; Ooi, M.; Harada, M.; Uno, S.; Otomo, T.; Kamiyama, T.; et al. Visibility estimation for neutron resonance absorption radiography using a pulsed neutron source. Phys. Procedia 2013, 43, 111–120. [Google Scholar] [CrossRef]

- Kamiyama, T.; Ito, J.; Noda, H.; Iwasa, H.; Kiyanagi, Y.; Ikeda, S. Computer tomography thermometry—An application of neutron resonance absorption spectroscopy. Nucl. Instrum. Methods Phys. Res. Sect. A 2005, 542, 258–263. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Kockelmann, W.; Pooley, D.E.; Feller, W.B. Spatially resolved remote measurement of temperature by neutron resonance absorption. Nucl. Instrum. Methods Phys. Res. Sect. A 2015, 803, 15–23. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Losko, A.S.; Vogel, S.C.; Byler, D.D.; McClellan, K.J.; Bourke, M.A.M.; Vallerga, J.V. Non-contact measurement of partial gas pressure and distribution of elemental composition using energy-resolved neutron imaging. AIP Adv. 2017, 7, 015315. [Google Scholar] [CrossRef]

- Shinohara, T.; Hiroi, K.; Su, Y.; Kai, T.; Nakatani, T.; Oikawa, K.; Segawa, M.; Hayashida, H.; Parker, J.D.; Matsumoto, Y.; et al. Polarization analysis for magnetic field imaging at RADEN in J-PARC/MLF. J. Phys. 2017, 862, 012025. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Perrodin, D.; Losko, A.S.; Vogel, S.C.; Bourke, M.A.M.; Bizarri, G.A.; Bourret, E.D. Real-time crystal growth visualization and quantification by energy-resolved neutron imaging. Sci. Rep. 2017, 7, 46275. [Google Scholar] [CrossRef] [PubMed]

- Iwase, K.; Sato, H.; Harjo, S.; Kamiyama, T.; Ito, T.; Takata, S.; Aizawa, K.; Kiyanagi, Y. In situ lattice strain mapping during tensile loading using the neutron transmission and diffraction methods. J. Appl. Crystallogr. 2012, 45, 113–118. [Google Scholar] [CrossRef]

- Ramadhan, R.S.; Syed, A.K.; Tremsin, A.S.; Kockelmann, W.; Dalgliesh, R.; Chen, B.; Parfitt, D.; Fitzpatrick, M.E. Mapping residual strain induced by cold working and by laser shock peening using neutron transmission spectroscopy. Mater. Des. 2018, 143, 56–64. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Ganguly, S.; Meco, S.; Pardal, G.R.; Shinohara, T.; Feller, W.B. Non-destructive studies of dissimilar metal welds by energy resolved neutron imaging. J. Appl. Crystallogr. 2016, 49, 1130–1140. [Google Scholar] [CrossRef] [PubMed]

- Syed, A.K.; Zhang, X.; Moffatt, J.E.; Maziarz, R.; Castelletti, L.; Fitzpatrick, M.E. Fatigue performance of bonded crack retarders in the presence of cold worked holes and interference-fit fasteners. Int. J. Fatigue 2017, 105, 111–118. [Google Scholar] [CrossRef]

- Cook, R.; Holdway, P. Residual stresses induced by hole cold expansion. Trans. Eng. Sci. 1993, 2, 91–100. [Google Scholar]

- Syed, A.K.; Fitzpatrick, M.E.; Moffatt, J.E. Effect of Thermal Residual Stresses on Bonded Structures Containing Cold Expanded and Bolted Holes. Adv. Mater. Res. 2014, 996, 682–687. [Google Scholar] [CrossRef]

- Santisteban, J.R.; Daymond, M.R.; James, J.A.; Edwards, L. ENGIN-X: A third-generation neutron strain scanner. J. Appl. Cryst. 2006, 39, 812–825. [Google Scholar] [CrossRef]

- Tremsin, A.S. High resolution neutron counting detectors with microchannel plates and their applications in neutron radiography, diffraction and resonance absorption imaging. Neutron News 2012, 23, 35–38. [Google Scholar] [CrossRef]

- Daymond, M.R.; Bourke, M.A.M.; Von Dreele, R.B.; Clausen, B.; Lorentzen, T.J. Use of Rietveld refinement for elastic macrostrain determination and for evaluation of plastic strain history from diffraction spectra. J. Appl. Phys. 1997, 82, 1554–1562. [Google Scholar] [CrossRef]

- Tremsin, A.S.; McPhate, J.B.; Steuwer, A.; Kockelmann, W.; Paradowska, A.M.; Kelleher, J.F.; Vallerga, J.V.; Siegmund, O.H.W.; Feller, W.B. High-resolution strain mapping through time-of-flight neutron transmission diffraction with a microchannel plate neutron counting detector. Strain 2012, 48, 296–305. [Google Scholar] [CrossRef]

| Hole N | Plate N | Cold-Expanded | GLARE | Rivet | Plate Thickness, mm | Hole Ø/mm |

|---|---|---|---|---|---|---|

| N1 | P1 | ✓ | ✓ | - | 5 | ~6 |

| N2 | P1 | - | ✓ | - | 5 | ~6 |

| N3 | P1 | ✓ | ✓ | ✓ | 5 | ~6 |

| N4 | P2 | ✓ | - | ✓ | 5 | ~6 |

| N5 | P2 | ✓ | - | - | 5 | ~6 |

| N6 | P3 | - | - | - | 6.4 | ~2.8 |

| N7 | P3 | ✓ | - | - | 6.4 | ~7.7 |

| Drilled (N2, N6) | Cold-Expanded, No Rivet, (Face-on) | Cold-Expanded, No Rivet, (Edge-on) | Cold-Expanded, with Rivet, (Face-on) | Cold-Expanded, with Rivet, (Edge-on) |

|---|---|---|---|---|

| ~0 ± 240 | 1500 ± 240 (N1, N5) 2000 ± 240 (N7) | −700 ± 240 (N1) | 800 ± 240 (N3) | −1000 ± 240 (N3, N4) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tremsin, A.S.; Kockelmann, W.; Kelleher, J.F.; Paradowska, A.M.; Ramadhan, R.S.; Fitzpatrick, M.E. Energy-Resolved Neutron Imaging for Reconstruction of Strain Introduced by Cold Working. J. Imaging 2018, 4, 48. https://doi.org/10.3390/jimaging4030048

Tremsin AS, Kockelmann W, Kelleher JF, Paradowska AM, Ramadhan RS, Fitzpatrick ME. Energy-Resolved Neutron Imaging for Reconstruction of Strain Introduced by Cold Working. Journal of Imaging. 2018; 4(3):48. https://doi.org/10.3390/jimaging4030048

Chicago/Turabian StyleTremsin, Anton S., Winfried Kockelmann, Joe F. Kelleher, Anna M. Paradowska, Ranggi S. Ramadhan, and Michael E. Fitzpatrick. 2018. "Energy-Resolved Neutron Imaging for Reconstruction of Strain Introduced by Cold Working" Journal of Imaging 4, no. 3: 48. https://doi.org/10.3390/jimaging4030048

APA StyleTremsin, A. S., Kockelmann, W., Kelleher, J. F., Paradowska, A. M., Ramadhan, R. S., & Fitzpatrick, M. E. (2018). Energy-Resolved Neutron Imaging for Reconstruction of Strain Introduced by Cold Working. Journal of Imaging, 4(3), 48. https://doi.org/10.3390/jimaging4030048