Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste

Abstract

1. Introduction

- -

- Ensuring good compatibility of the properties of these wastes and other concrete components;

- -

- The possibility of effective integration of this additive into the composition and structure of concrete, subject to the choice of its rational dosage;

- -

- To confirm the feasibility of using biochar spent coffee grounds in concrete by conducting experiments to determine the physical, mechanical, and structural characteristics of the resulting green concrete.

2. Results and Discussion

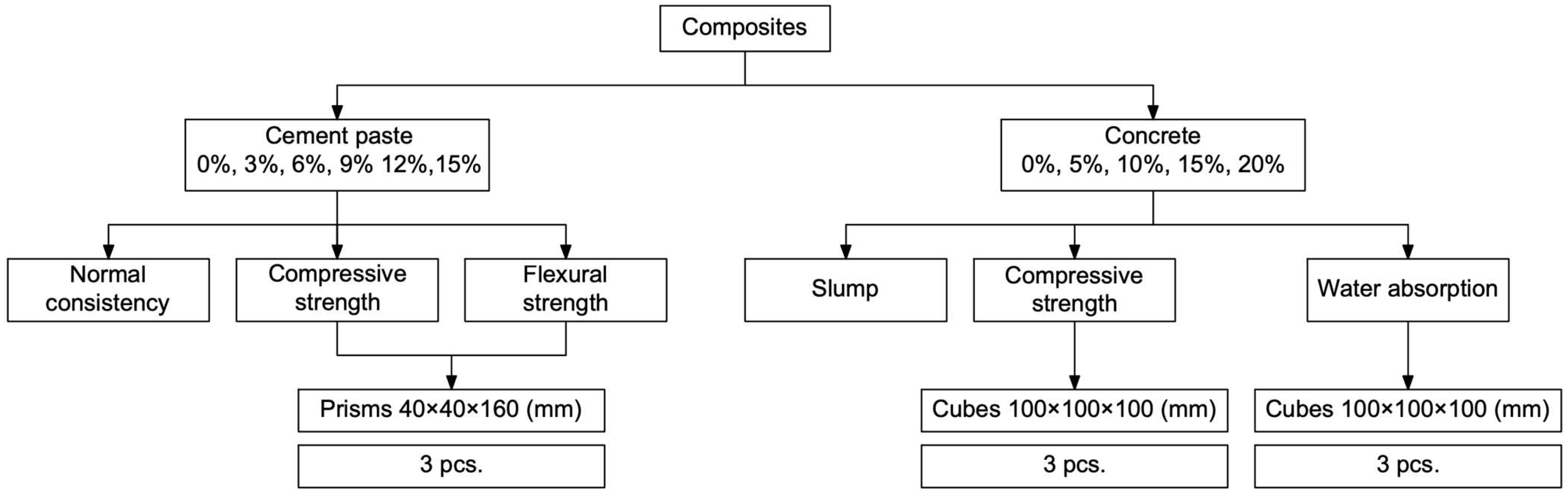

3. Materials and Methods

3.1. Materials

3.2. Methods

- -

- Dosing of raw compotes;

- -

- Making paste;

- -

- Placing the finished paste into molds in three layers, in which each layer was compacted with 60 blows on a shaking table (VNIR, Moscow, Russia);

- -

- Exposure of samples in a normal hardening chamber (KNT-1, RNPO “RusPribor”, St. Petersburg, Russia) for 1 day and removal of formwork;

- -

- Storing samples in a water bath for 27 days.

- F is the breaking load (N);

- b is the size of the square section of the prism sample (mm);

- l is the distance between the axes of the supports (mm).

- F is the breaking load (N);

- S is the area of the working surface of the plate (mm2).

- -

- Dosing of raw materials;

- -

- Loading cement, sand, and BSCG in dry form into a concrete mixer BL-10 (ZZBO, Zlatoust, Russia) and mixing for 1 min;

- -

- Introducing mixing water and stirring for 1 min;

- -

- Introducing crushed stone (CrS) and mixing until a homogeneous consistency;

- -

- Loading the mixture into molds and compaction on a vibrating platform;

- -

- Keeping the samples for one day and removing them from the molds;

- -

- Keeping the samples in a normal hardening chamber to acquire strength for another 27 days.

- F is the breaking load (N);

- A sample working section area (mm2);

- α is a coefficient taking into account the dimensions of the samples (for samples with a side of 100 mm α = 0.95).

- is the mass of the dry sample (g).

4. Conclusions

- (1)

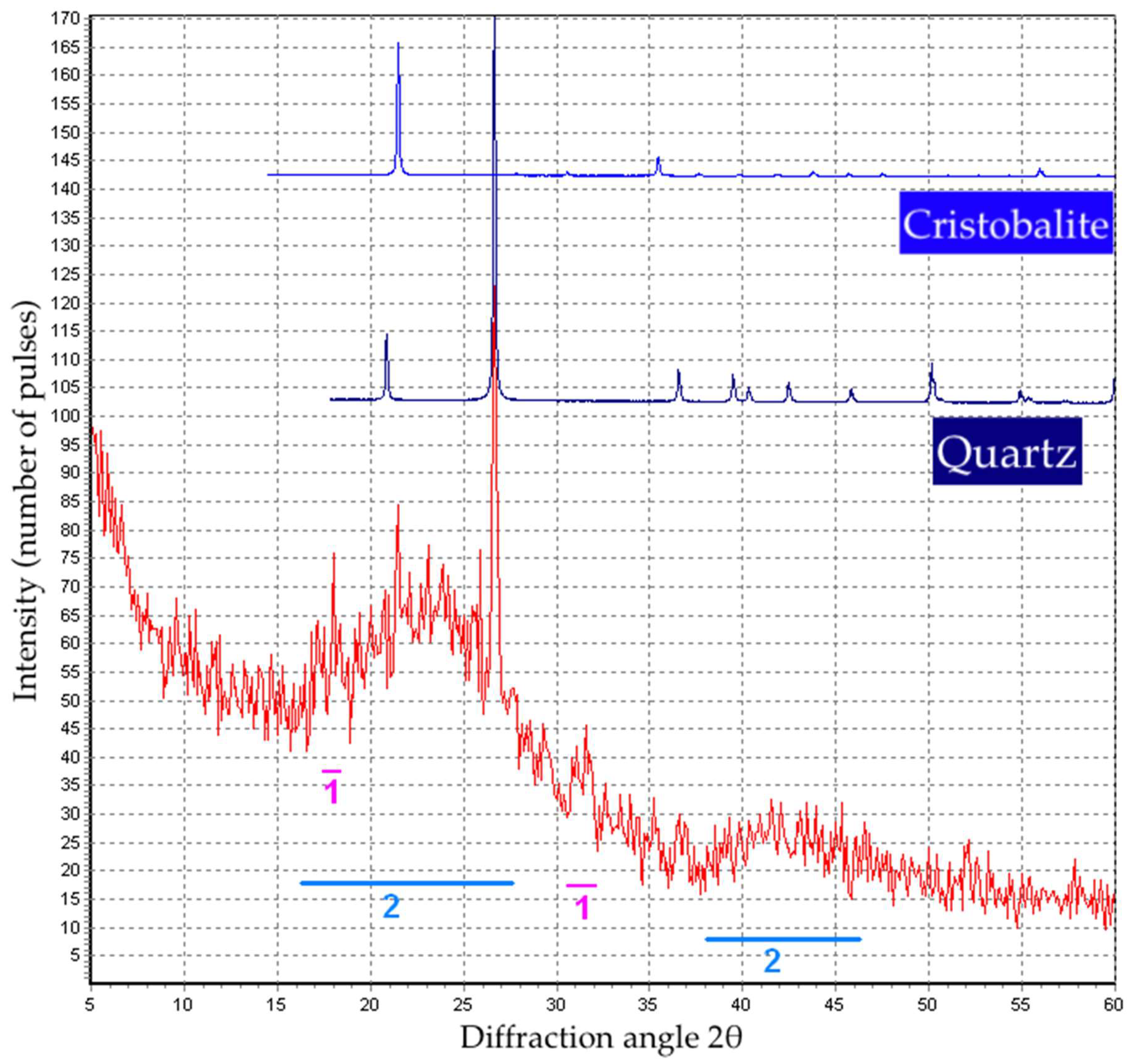

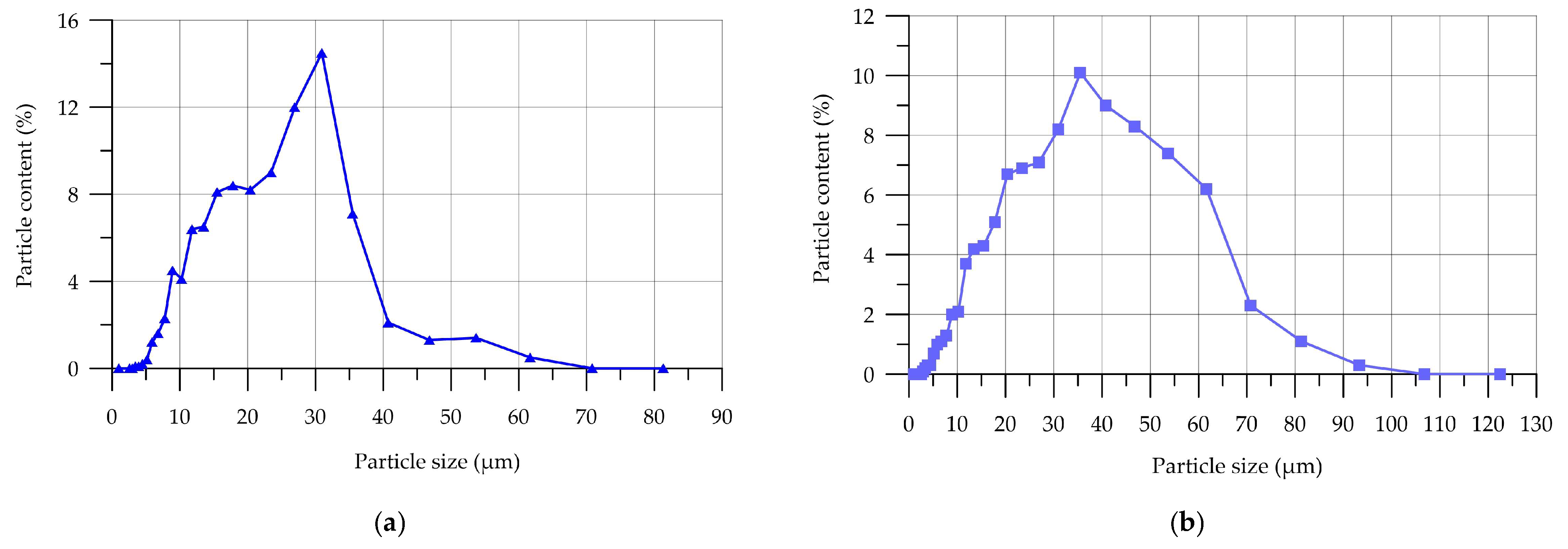

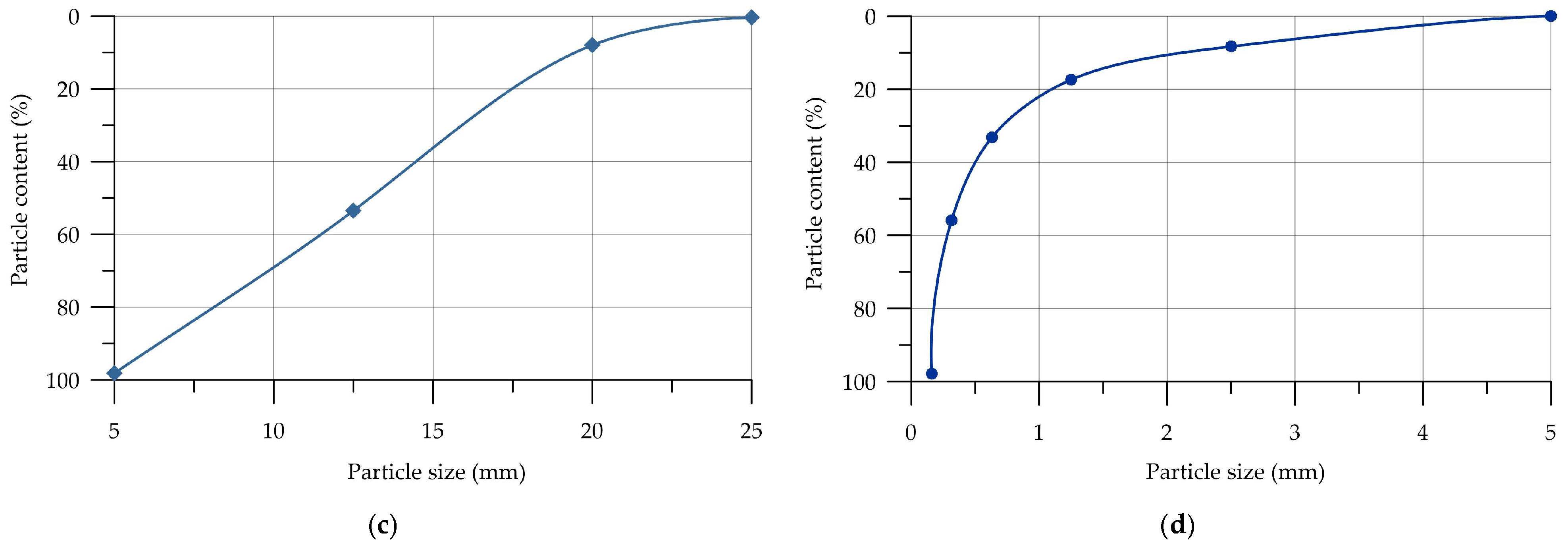

- A biochar-modifying additive was produced from waste coffee grounds via thermal treatment of these wastes and additional mechanical grinding after pyrolysis. The phase composition of the manufactured BSCG additive was determined, which is characterized by the presence of phases such as quartz, cristobalite, and amorphous carbon.

- (2)

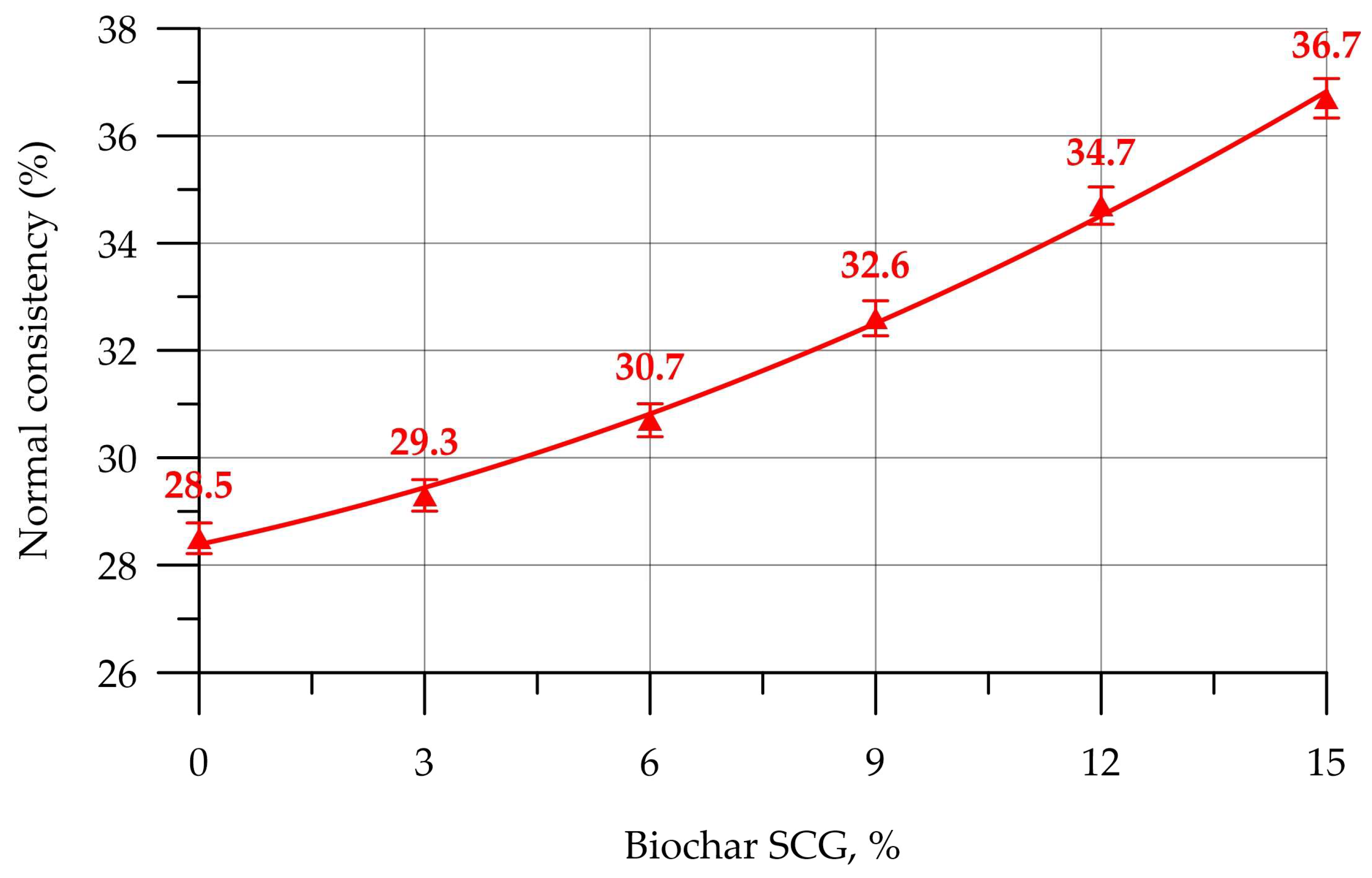

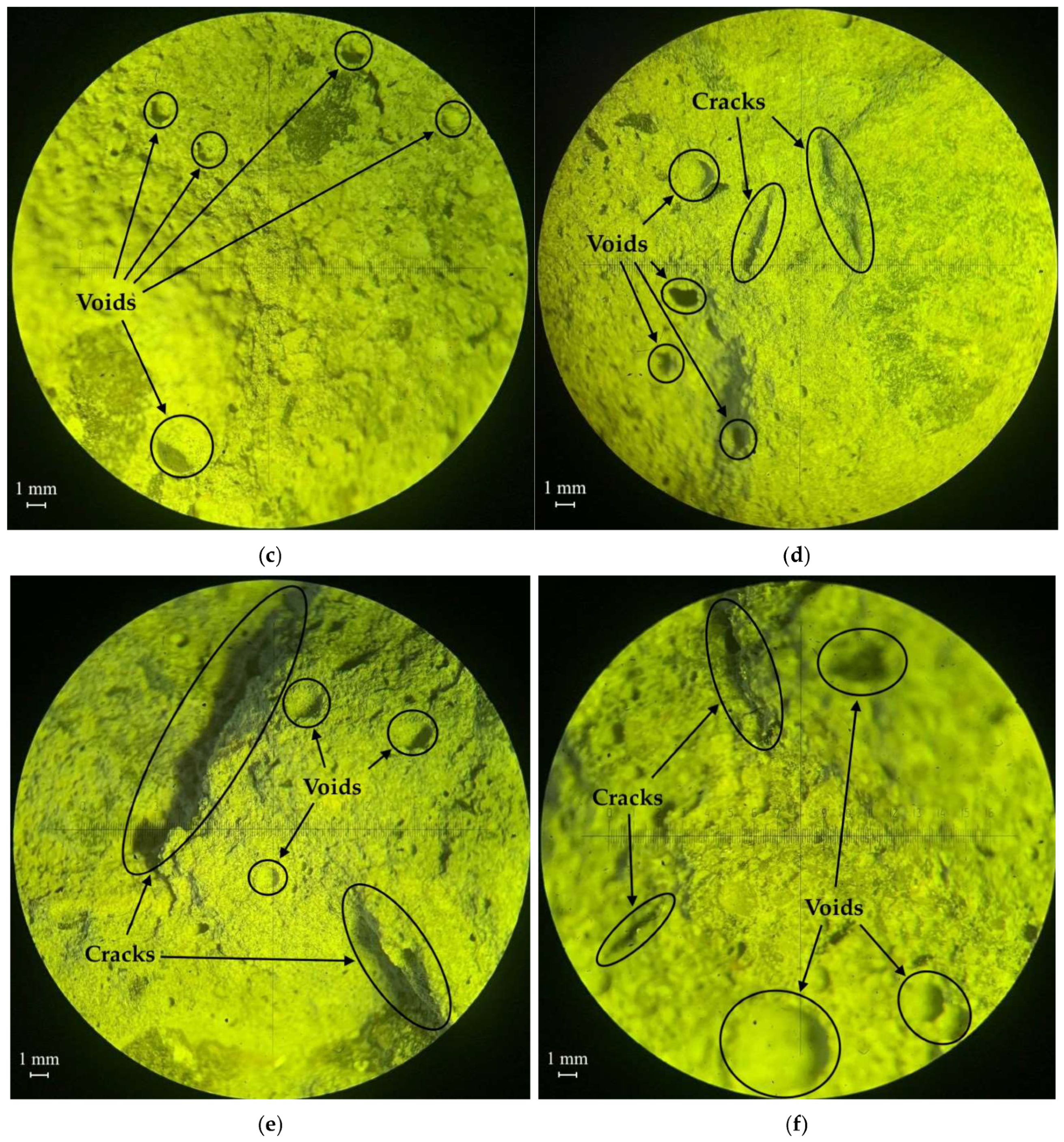

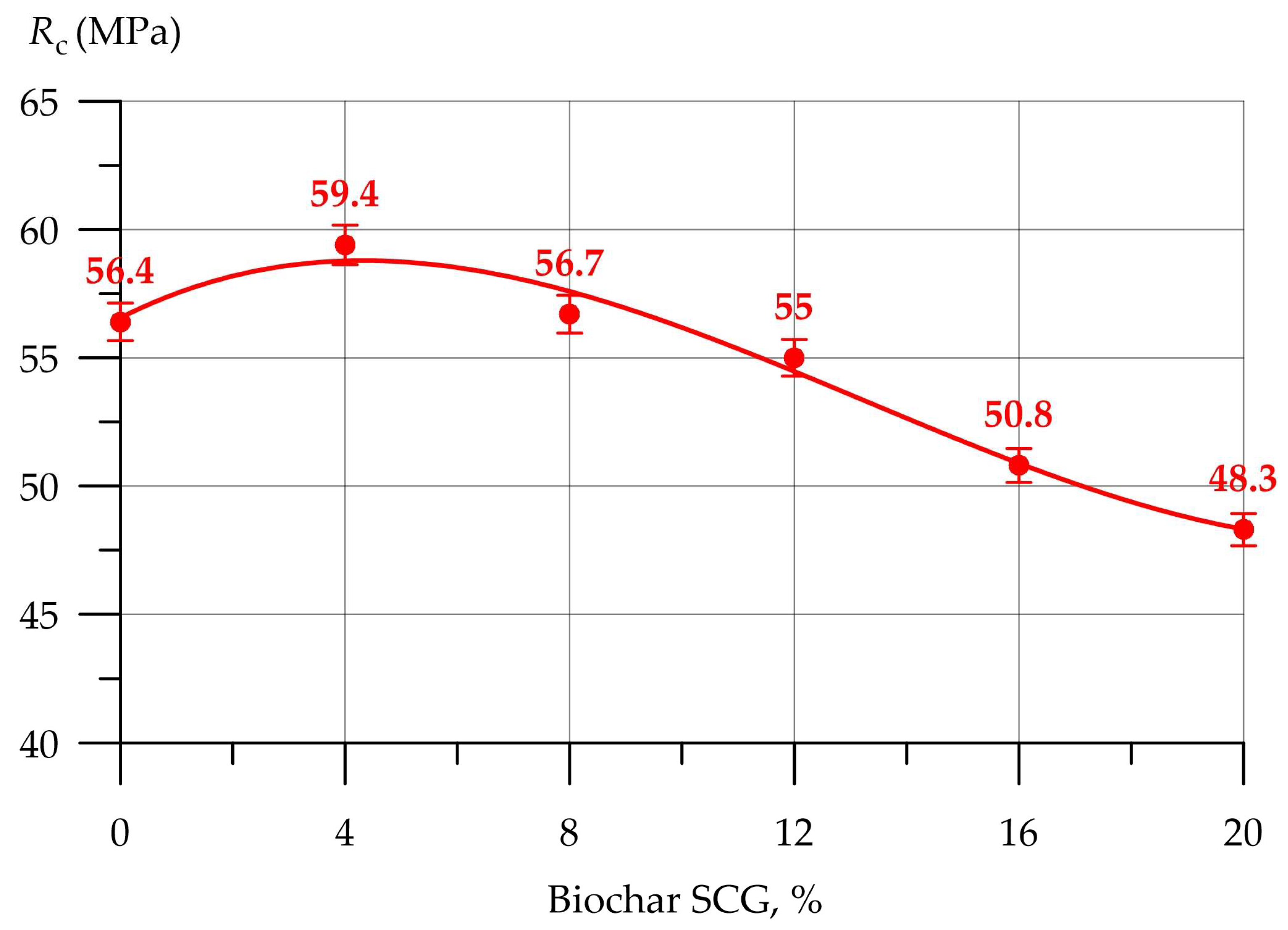

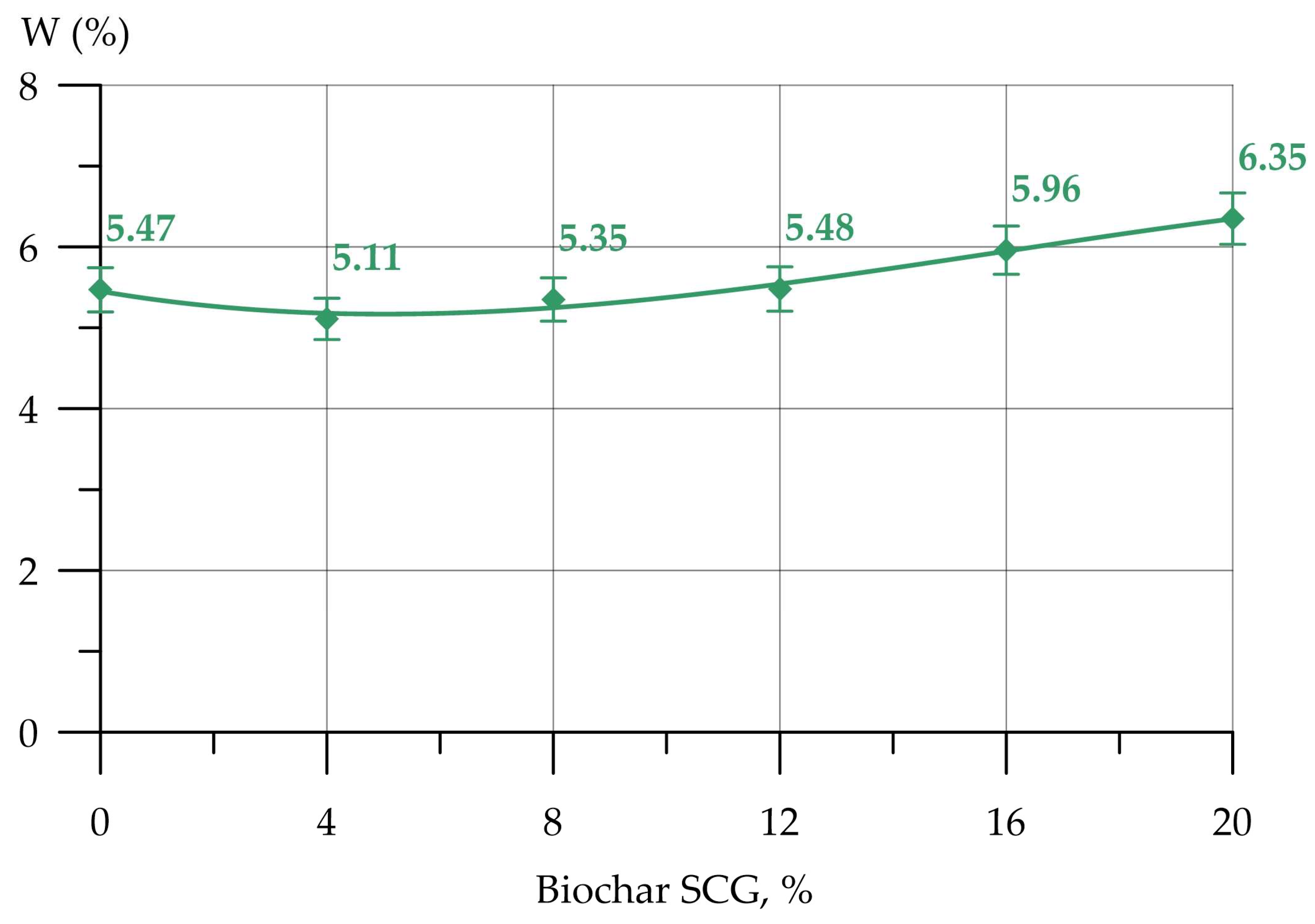

- The introduction of BSCG into the composition of cement pastes and concrete mixtures increases the water demand for cement pastes and worsens the workability of concrete mixtures because BSCG particles have a porous structure and absorb more water.

- (3)

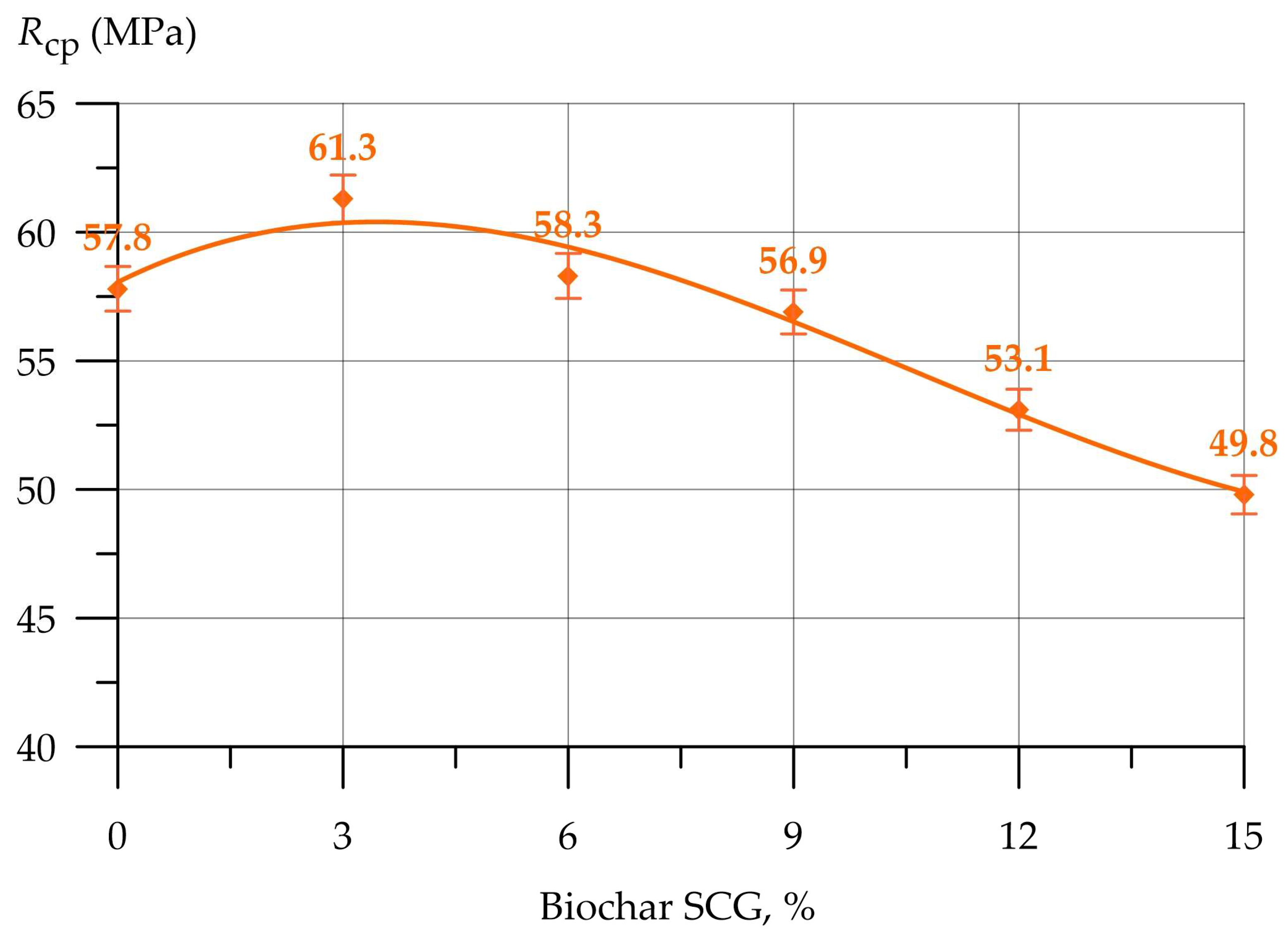

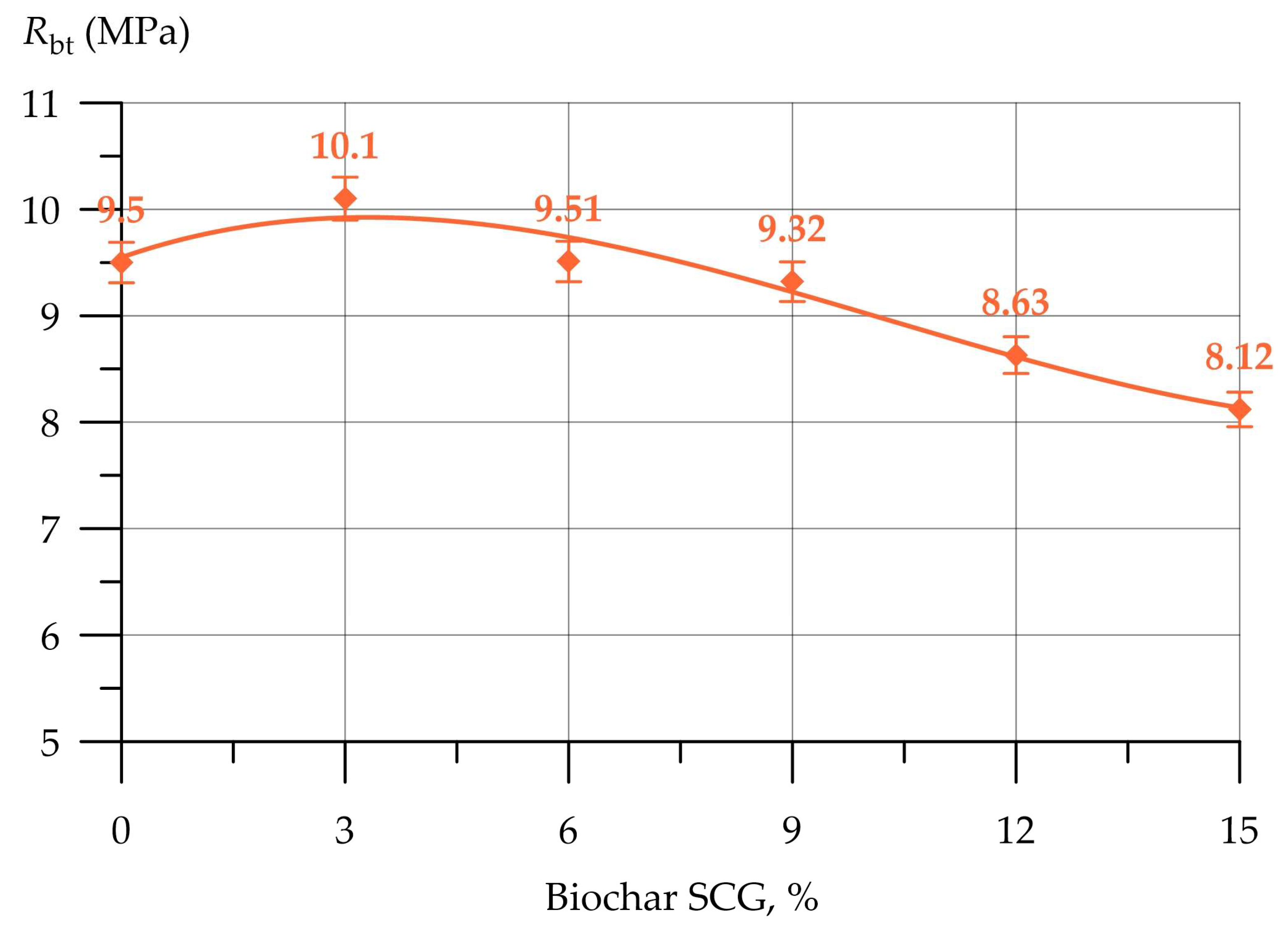

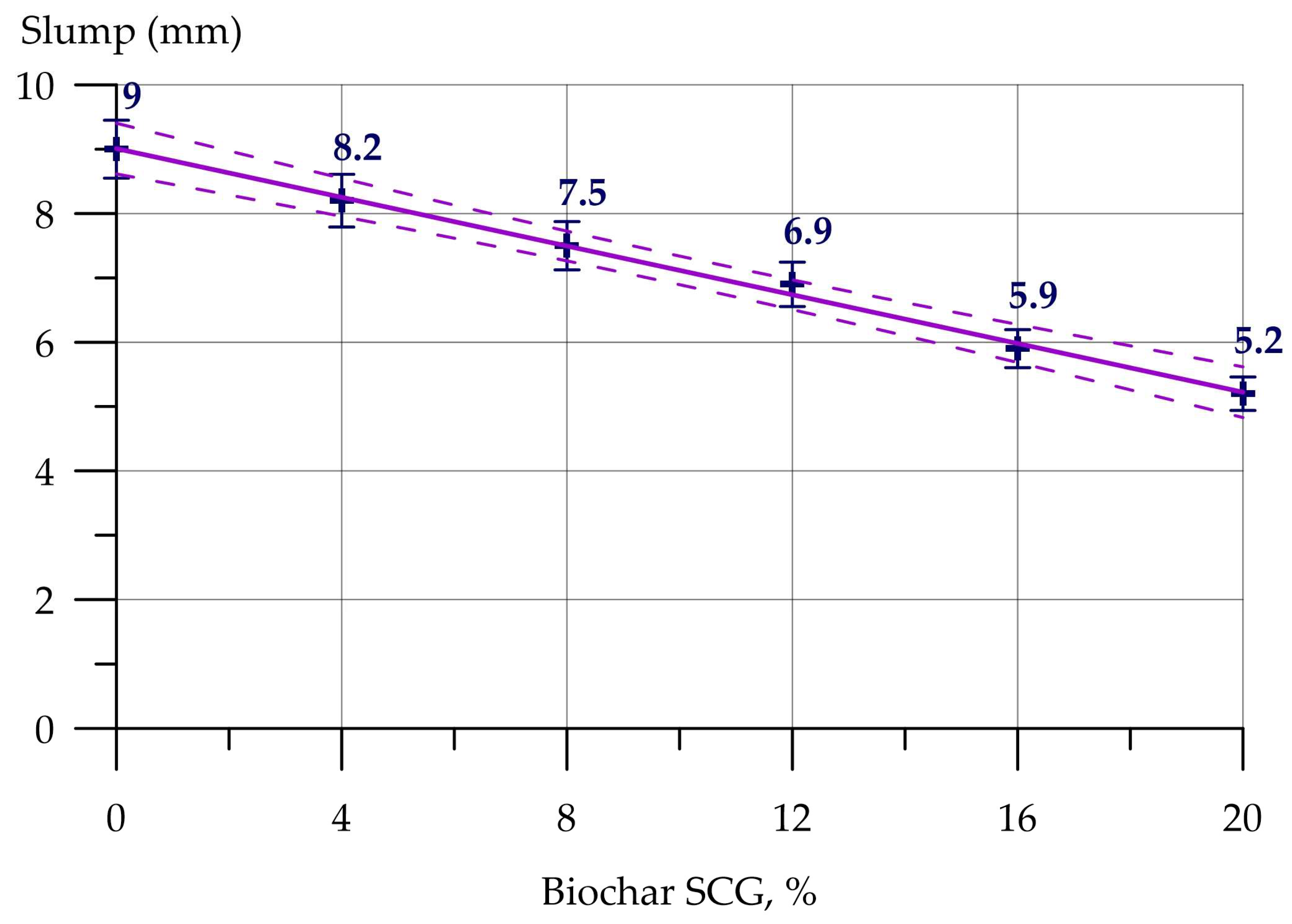

- The rational content of BSCG, which maintains the properties of cement pastes at the level of the control composition, is fixed at up to 9%. The best strength properties of the cement pastes were obtained when the composition was modified with 3% BSCG. The compressive and flexural strength increases were 6.06% and 6.23%, respectively.

- (4)

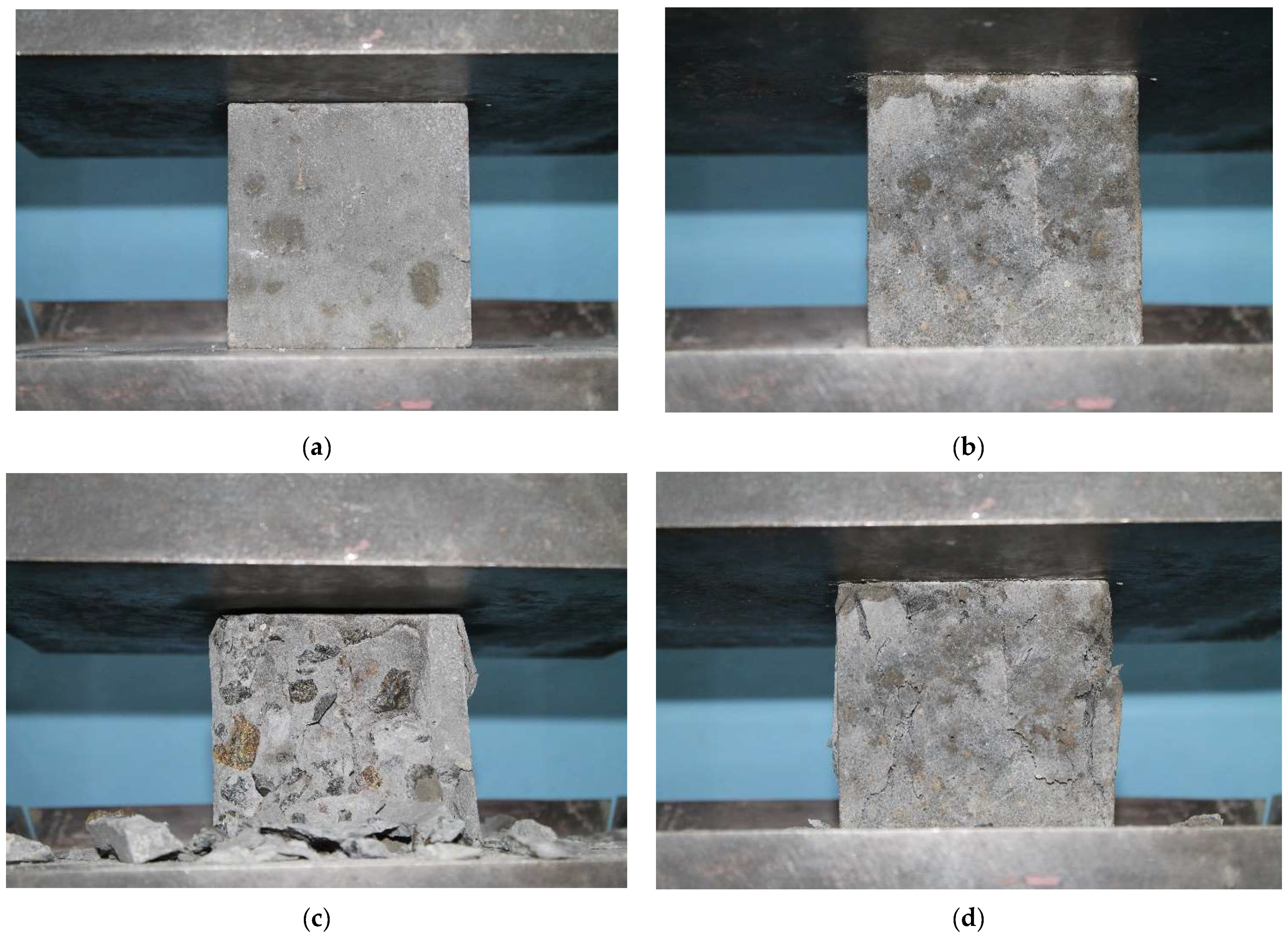

- For concrete, the optimal BSCG content should not exceed 8%. Concrete modified with 4% BSCG exhibits the best properties. The increase in strength was 5.85%, and water absorption decreased by 6.58% compared with the control samples.

- (5)

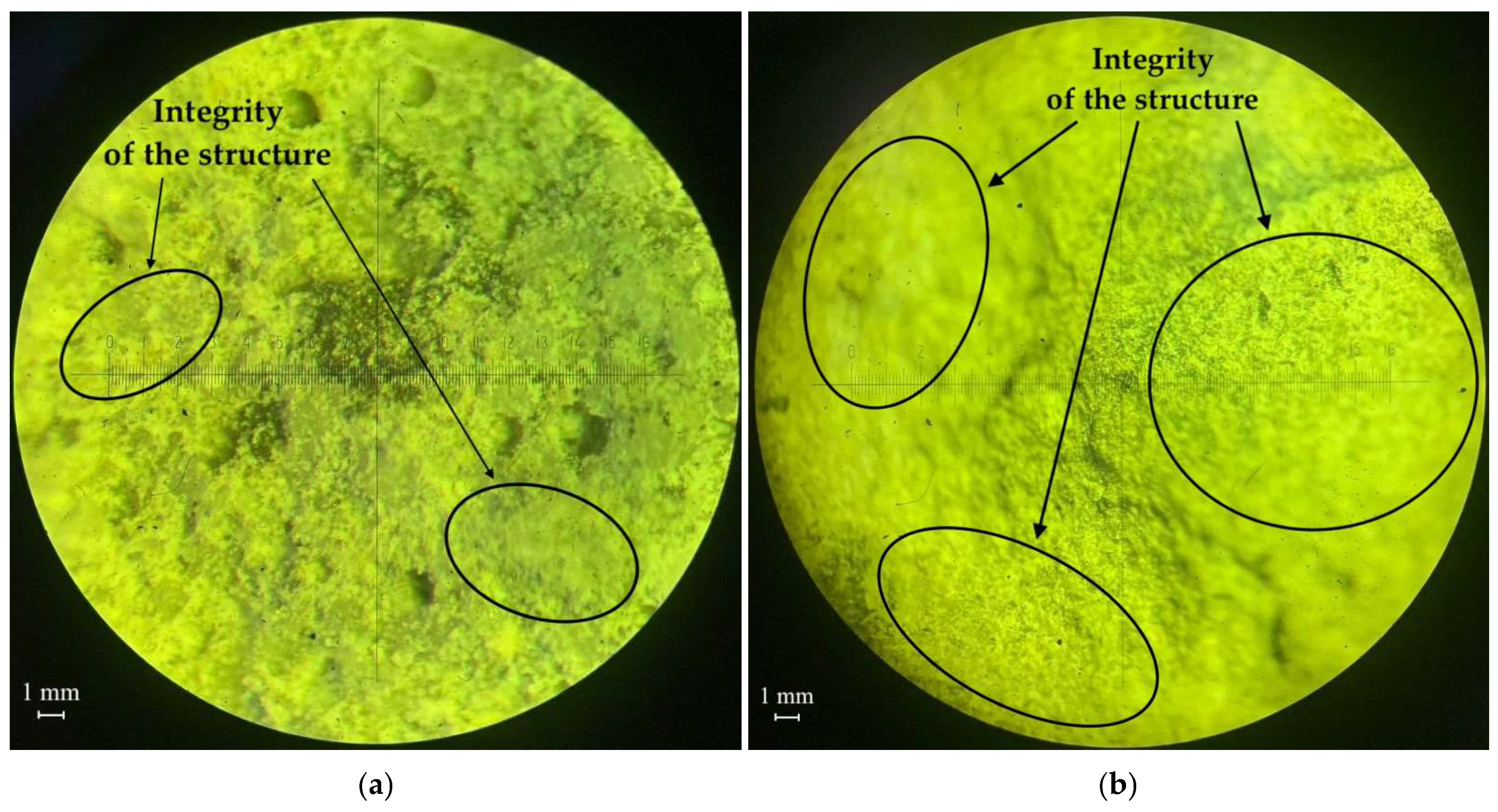

- The addition of rational dosages of BSCG to the cement composite composition acts as a filler.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hubert, J.; Grigoletto, S.; Michel, F.; Zhao, Z.; Courard, L. Development and Properties of Recycled Biomass Fly Ashes Modified Mortars. Recycling 2024, 9, 46. [Google Scholar] [CrossRef]

- Winters, D.; Boakye, K.; Simske, S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability 2022, 14, 4633. [Google Scholar] [CrossRef]

- Zito, S.V.; Irassar, E.F.; Rahhal, V.F. Recycled Construction and Demolition Waste as Supplementary Cementing Materials in Eco-Friendly Concrete. Recycling 2023, 8, 54. [Google Scholar] [CrossRef]

- Chen, W.; Wu, M.; Liang, Y. Effect of SF and GGBS on Pore Structure and Transport Properties of Concrete. Materials 2024, 17, 1365. [Google Scholar] [CrossRef] [PubMed]

- Oti, J.; Adeleke, B.O.; Mudiyanselage, P.R.; Kinuthia, J. A Comprehensive Performance Evaluation of GGBS-Based Geopolymer Concrete Activated by a Rice Husk Ash-Synthesised Sodium Silicate Solution and Sodium Hydroxide. Recycling 2024, 9, 23. [Google Scholar] [CrossRef]

- Maddikeari, M.; Das, B.B.; Tangadagi, R.B.; Roy, S.; Nagaraj, P.B.; Ramachandra, M.L. A Comprehensive Review on Use of Wastewater in the Manufacturing of Concrete: Fostering Sustainability through Recycling. Recycling 2024, 9, 45. [Google Scholar] [CrossRef]

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Beskopylny, N.; Chernil’nik, A.; El’shaeva, D. Insulation Foam Concrete Nanomodified with Microsilica and Reinforced with Polypropylene Fiber for the Improvement of Characteristics. Polymers 2022, 14, 4401. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Evtushenko, A.; Chernil’nik, A.; El’shaeva, D.; Karalar, M.; et al. Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash. J. Compos. Sci. 2023, 7, 356. [Google Scholar] [CrossRef]

- Malheiro, R.; Camões, A.; Meira, G.; Reis, R.; Nóbrega, A. Impact of Combined Action of Chloride and Carbonation on Cement-Based Materials with Fly Ash. Sci 2024, 6, 13. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Guler, S.; Osmanoğlu, F.; Kıvanç, M.R.; Khan, M. Evaluating Sustainable Colored Mortars Reinforced with Fly Ash: A Comprehensive Study on Physical and Mechanical Properties under High-Temperature Exposure. Buildings 2024, 14, 453. [Google Scholar] [CrossRef]

- Pignotti, G.B.; Matos, A.M.; Ferreira, F.G.d.S. Non-Structural Vibro-Compressed Concrete Incorporating Industrial Wastes. Recycling 2024, 9, 26. [Google Scholar] [CrossRef]

- Marzouk, H.A.; Arab, M.A.; Fattouh, M.S.; Hamouda, A.S. Effect of Agricultural Phragmites, Rice Straw, Rice Husk, and Sugarcane Bagasse Ashes on the Properties and Microstructure of High-Strength Self-Compacted Self-Curing Concrete. Buildings 2023, 13, 2394. [Google Scholar] [CrossRef]

- Avudaiappan, S.; Prakatanoju, S.; Amran, M.; Aepuru, R.; Saavedra Flores, E.I.; Das, R.; Gupta, R.; Fediuk, R.; Vatin, N. Experimental Investigation and Image Processing to Predict the Properties of Concrete with the Addition of Nano Silica and Rice Husk Ash. Crystals 2021, 11, 1230. [Google Scholar] [CrossRef]

- Domínguez, A.O.; Filho, R.D.T.; Gomes, J.A.d.C.P.; Silva, R.d.S.; de Souza, E.A.; Silva, A.B.d. Study of Reinforced Concrete with the Addition of Pozzolanic against the Penetration of Chlorides through Electrochemical Impedance Spectroscopy. Constr. Mater. 2024, 4, 194–215. [Google Scholar] [CrossRef]

- Lin, L.-K.; Kuo, T.-M.; Hsu, Y.-S. The application and evaluation research of coffee residue ash into mortar. J. Mater. Cycles Waste Manag. 2015, 18, 541–551. Available online: https://link.springer.com/article/10.1007/s10163-015-0351-5 (accessed on 1 June 2024). [CrossRef]

- Salas Montoya, A.; Chung, C.-W.; Kim, J.-H. High Performance Concretes with Highly Reactive Rice Husk Ash and Silica Fume. Materials 2023, 16, 3903. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Wei Kua, H. Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor. Appl. Fract. Mech. 2009, 104, 102376. [Google Scholar] [CrossRef]

- Song, N.; Li, Z.; Wang, S.; Li, S. Biochar as internal curing material to prepare foamed concrete. Constr. Build. Mater. 2023, 377, 131030. [Google Scholar] [CrossRef]

- França, S.; Sousa, L.N.; Saraiva, S.L.C.; Ferreira, M.C.N.F.; Silva, M.V.d.M.S.; Gomes, R.C.; Rodrigues, C.d.S.; Aguilar, M.T.P.; Bezerra, A.C.d.S. Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker. Buildings 2023, 13, 843. [Google Scholar] [CrossRef]

- Berenguer, R.A.; Capraro, A.P.B.; Farias de Medeiros, M.H.; Carneiro, M.P.A.; De Oliveira, R.A. Sugar cane bagasse ash as a partial substitute of Portland cement: Effect on mechanical properties and emission of carbon dioxide. J. Environ. Chem. Eng. 2020, 8, 103655. [Google Scholar] [CrossRef]

- Sebastin, S.; Priya, A.K.; Karthick, A.; Sathyamurthy, R.; Ghosh, A. Agro Waste Sugarcane Bagasse as a Cementitious Material for Reactive Powder Concrete. Clean Technol. 2020, 2, 476–491. [Google Scholar] [CrossRef]

- Ouedraogo, M.; Sawadogo, M.; Sanou, I.; Barro, M.; Nassio, S.; Seynou, M.; Zerbo, L. Characterization of sugar cane bagasse ash from Burkina Faso for cleaner cement production: Influence of calcination temperature and duration. Results Mater. 2022, 14, 1000275. [Google Scholar] [CrossRef]

- Rajagopal, M.R.; Ganta, J.; Pamu, Y. Enhancing the Strength and the Environmental Performance of Concrete with Pre-Treated Crumb Rubber and Micro-Silica. Recycling 2024, 9, 32. [Google Scholar] [CrossRef]

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, N.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A Review on Mechanical, Thermal, and Environmental Properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Bhandary, R.P.; Rao, A.U.; Shetty, P.P.; Blesson, S.; Thomas, B.S. Application of Coffee Husk Ash as Partial Replacement of Fine Aggregate in Concrete. Sustainability 2023, 15, 13328. [Google Scholar] [CrossRef]

- Ma, W.; Chen, S.; Zandi, Y.; Almujibah, H.; Ali, E.; Assilzadeh, H. Utilization of Waste Coffee Ground Ash as Fine Aggregates in Concrete: Enhancing Shear Strength through Activated Carbon Reinforcement. Case Stud. Constr. Mater. 2024, in press. [CrossRef]

- Roychand, R.; Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Zhang, G. Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength. J. Clean. Prod. 2023, 419, 138205. [Google Scholar] [CrossRef]

- Saeli, M.; Capela, M.N.; Piccirillo, C.; Tobaldi, D.M.; Scalera, F.; Striani, R.; Campisi, T. Development of energy-saving innovative hydraulic mortars reusing spent coffee ground for applications in construction. J. Clean. Prod. 2023, 339, 136664. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Olabimtan, S.B.; Balkis, A.P.; Rabiu, B.O.; Oluwole, B.O.; Ajuonuma, C.S. Effect of Biochar and Sewage Sludge Ash as Partial Replacement for Cement in Cementitious Composites: Mechanical, and Durability Properties. Sustainability 2024, 16, 1522. [Google Scholar] [CrossRef]

- Pokorný, J.; Ševčík, R.; Zárybnická, L.; Podolka, L. The Role of High Carbon Additives on Physical–Mechanical Characteristics and Microstructure of Cement-Based Composites. Buildings 2023, 13, 1585. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Falliano, D.; Carvajal, J.F.; Celi, A.C.B.; Ferro, G.A.; Tulliani, J.M.; Lavagna, L.; Restuccia, L. The Effect of Different Biochar on the Mechanical Properties of Cement-Pastes and Mortars. Buildings 2023, 13, 2900. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, J.; Tan, K.; Chen, Y. Enhancing Biochar Impact on the Mechanical Properties of Cement-Based Mortar: An Optimization Study Using Response Surface Methodology for Particle Size and Content. Sustainability 2023, 15, 14787. [Google Scholar] [CrossRef]

- Yang, X.; Lin, R.-S.; Han, Y.; Wang, X.-Y. Behavior of Biochar-Modified Cementitious Composites Exposed to High Temperatures. Materials 2021, 14, 5414. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Smolyanichenko, A.S.; Varavka, V.; Beskopylny, N.; Dotsenko, N. Influence of Electromagnetic Activation of Cement Paste and Nano-Modification by Rice Straw Biochar on the Structure and Characteristics of Concrete. J. Compos. Sci. 2022, 6, 268. [Google Scholar] [CrossRef]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials 2023, 16, 2809. [Google Scholar] [CrossRef]

- Neve, S.; Du, J.; Barhemat, R.; Meng, W.; Bao, Y.; Sarkar, D. Valorization of Vetiver Root Biochar in Eco-Friendly Reinforced Concrete: Mechanical, Economic, and Environmental Performance. Materials 2023, 16, 2522. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, N.; Song, Y.; Xiang, J. Modification of Iron-Tailings Concrete with Biochar and Basalt Fiber for Sustainability. Sustainability 2022, 14, 10041. [Google Scholar] [CrossRef]

- Gupta, S.; Kua Wei, H.; Sze Dai, P. Effect of biochar on mechanical and permeability properties of concrete exposed to elevated temperature. Constr. Build. Mater. 2020, 234, 117338. [Google Scholar] [CrossRef]

- Khan, K.; Aziz, M.A.; Zubair, M.; Amin, M.N. Biochar Produced from Saudi Agriculture Waste as a Cement Additive for Improved Mechanical and Durability Properties—SWOT Analysis and Techno-Economic Assessment. Materials 2022, 15, 5345. [Google Scholar] [CrossRef]

- Gupta, S.; Kua Wei, H.; Sze Dai, P.; Dixit, A. Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Guo, B.; Yang, J.; Hou, D. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Smolyanichenko, A.S.; Beskopylny, N. High-Performance Concrete Nanomodified with Recycled Rice Straw Biochar. Appl. Sci. 2022, 12, 5480. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Beskopylny, N.; El’shaeva, D. Enhanced Eco-Friendly Concrete Nano-Change with Eggshell Powder. Appl. Sci. 2022, 12, 6606. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Beskopylny, A.N.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; El’shaeva, D.; Chernil’nik, A.; Kurilova, S. Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate. Materials 2023, 16, 4422. [Google Scholar] [CrossRef]

- Jeong, J.; Jeon, G.; Ryu, S.; Lee, J.H. Ecofriendly and Electrically Conductive Cementitious Composites Using Melamine-Functionalized Biochar from Waste Coffee Beans. Crystals 2022, 12, 820. [Google Scholar] [CrossRef]

- El Hammouti, A.; Horma, O.; Charai, M.; Mezrhab, A.; Karkri, M. Thermophysical characteristics of cement-based mortar incorporating spent coffee grounds. Mater. Today Proc. 2022, 57, 867–870. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Kanavaris, F. Biochar-concrete: A comprehensive review of properties, production and sustainability. Case Stud. Constr. Mater. 2024, 20, e02859. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Restuccia, L.; Ferro, G.A. The use of Biochar to reduce the carbon footprint of cement-based materials. Procedia Struct. Integr. 2020, 26, 199–210. [Google Scholar] [CrossRef]

- Klyuev, A.V.; Kashapov, N.F.; Klyuev, S.V.; Zolotareva, S.V.; Shchekina, N.A.; Shorstova, E.S.; Lesovik, R.V.; Ayubov, N.A. Experimental studies of the processes of structure formation of composite mixtures with technogenic mechanoactivated silica component. Constr. Mater. Prod. 2023, 6, 5–18. [Google Scholar] [CrossRef]

- Asadi Zeidabadi, Z.; Bakhtiari, S.; Abbaslou, H.; Ghanizadeh, A.R. Synthesis, characterization and evaluation of biochar from agricultural waste biomass for use in building materials. Constr. Build. Mater. 2018, 181, 301–308. [Google Scholar] [CrossRef]

- Novoselov, O.G.; Sabitov, L.S.; Sibgatullin, K.E.; Sibgatullin, E.S.; Klyuev, A.V.; Klyuev, S.V.; Shorstova, E.S. Method for calculating the strength of massive structural elements in the general case of their stress-strain state (parametric equations of the strength surface). Constr. Mater. Prod. 2023, 6, 104–120. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Zherebtsov, Y.V.; Al-Tulaikhi, M.M. Researches of physicomechanical and design characteristics of vibrated, centrifuged and vibro-centrifuged concretes. Adv. Eng. Res. 2021, 21, 5–13. [Google Scholar] [CrossRef]

- GOST 30744-2001; Cements. Methods of Testing with Using Polyfraction Standard Sand. State Construction Committee of Russia, GUP CPP: Moscow, Russia, 2001. Available online: https://docs.cntd.ru/document/1200011363 (accessed on 30 March 2024).

- GOST R 57809-2017/EN 12350-2:2009; Testing Fresh Concrete. Part 2. Slump Test. Standartinform: Moscow, Russia, 2017. Available online: https://docs.cntd.ru/document/1200157288 (accessed on 30 March 2024).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 30 March 2024).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 30 March 2024).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 30 March 2024).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 30 March 2024).

- GOST 12730.3-2020; Concretes. Method of Determination of Water Absorption. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177301 (accessed on 30 March 2024).

- BS 1881-122:2011+A1:2020; Testing Concrete Method for Determination of Water Absorption. European Standards: Plzen, Czech Republic, 2020. Available online: https://www.en-standard.eu/bs-1881-122-2011-a1-2020-testing-concrete-method-for-determination-of-water-absorption/ (accessed on 30 March 2024).

| BSCG (%) | ΔRcp (%) | ΔRbt (%) |

|---|---|---|

| 0 | 0 | 0 |

| 3 | 6.06 | 6.32 |

| 6 | 0.87 | 0.11 |

| 9 | −1.56 | −1.89 |

| 12 | −8.13 | −9.16 |

| 15 | −13.84 | −14.53 |

| BSCG (%) | ΔSlump (%) | ΔRc (%) | ΔW (%) |

|---|---|---|---|

| 2 | −3.33 | 1.77 | −4.75 |

| 4 | −12.22 | 5.85 | −6.58 |

| 6 | −23.33 | −2.48 | 0.18 |

| 8 | −30.00 | −4.61 | 2.93 |

| 10 | −42.22 | −10.82 | 9.32 |

| Mixture Type | PC (g) | BSCG (g) |

|---|---|---|

| BSCG0 | 500 | 0 |

| BSCG3 | 485 | 15 |

| BSCG6 | 470 | 30 |

| BSCG9 | 455 | 45 |

| BSCG12 | 440 | 60 |

| BSCG15 | 425 | 75 |

| Mixture Type | PC (g) | PS (g) | Water (mL) | BSCG (g) |

|---|---|---|---|---|

| BSCG0 | 500 | 1350 | 225 | 0 |

| BSCG3 | 485 | 1350 | 225 | 15 |

| BSCG6 | 470 | 1350 | 225 | 30 |

| BSCG9 | 455 | 1350 | 225 | 45 |

| BSCG12 | 440 | 1350 | 225 | 60 |

| BSCG15 | 425 | 1350 | 225 | 75 |

| Mixture Type | PC (kg/m3) | QS (kg/m3) | CrS (kg/m3) | Water (L/m3) | BSCG (kg/m3) |

|---|---|---|---|---|---|

| BSCG0 | 371 | 756 | 1013 | 205 | 0 |

| BSCG2 | 363.58 | 756 | 1013 | 205 | 7.42 |

| BSCG4 | 356.16 | 756 | 1013 | 205 | 14.84 |

| BSCG6 | 348.74 | 756 | 1013 | 205 | 22.26 |

| BSCG8 | 341.32 | 756 | 1013 | 205 | 29.68 |

| BSCG10 | 333.9 | 756 | 1013 | 205 | 37.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Ananova, O.; Chernil’nik, A.; El’shaeva, D.; Pogrebnyak, A.; Dubinkin, I.; Madenci, E.; Aksoylu, C.; et al. Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste. Recycling 2024, 9, 94. https://doi.org/10.3390/recycling9050094

Beskopylny AN, Stel’makh SA, Shcherban’ EM, Ananova O, Chernil’nik A, El’shaeva D, Pogrebnyak A, Dubinkin I, Madenci E, Aksoylu C, et al. Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste. Recycling. 2024; 9(5):94. https://doi.org/10.3390/recycling9050094

Chicago/Turabian StyleBeskopylny, Alexey N., Sergey A. Stel’makh, Evgenii M. Shcherban’, Oxana Ananova, Andrei Chernil’nik, Diana El’shaeva, Anastasia Pogrebnyak, Ivan Dubinkin, Emrah Madenci, Ceyhun Aksoylu, and et al. 2024. "Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste" Recycling 9, no. 5: 94. https://doi.org/10.3390/recycling9050094

APA StyleBeskopylny, A. N., Stel’makh, S. A., Shcherban’, E. M., Ananova, O., Chernil’nik, A., El’shaeva, D., Pogrebnyak, A., Dubinkin, I., Madenci, E., Aksoylu, C., & Özkılıç, Y. O. (2024). Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste. Recycling, 9(5), 94. https://doi.org/10.3390/recycling9050094