Abstract

To improve the microstructure and mechanical properties of fundamental materials including aluminum, stainless steel, superalloys, and titanium alloys, traditional manufacturing techniques have for years been utilized in critical sectors including the aerospace and nuclear industries. However, additive manufacturing has become an efficient and effective means for fabricating these materials with superior mechanical attributes, making it easier to develop complex parts with relative ease compared to conventional processes. The waste generated in additive manufacturing processes are usually in the form of powders, while that of conventional processes come in the form of chips. The current study focuses on the features and uses of various typical recycling methods for traditional and additive manufacturing that are presently utilized to recycle material waste from both processes. Additionally, the main factors impacting the microstructural features and density of the chip-unified components are discussed. Moreover, it recommends a novel approach for recycling chips, while improving the process of development, bonding quality of the chips, microstructure, overall mechanical properties, and fostering sustainable and environmentally friendly engineering.

1. Introduction

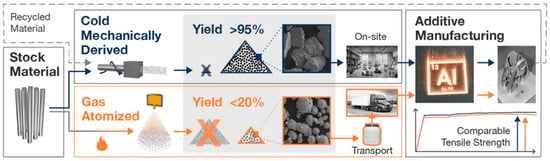

Aluminum (2024,6061,7075), stainless steel (SS304,316,316L), super alloys, and titanium alloys (Ti6Al4V) are used in aerospace [1], nuclear, and marine industries due to their properties like tensile strength and corrosion resistance. Due to high fatigue resistance, aluminum 2024 is commonly used in aerospace development [2]. Essentially, enriched aluminum–uranium alloys are used in nuclear reactor fuel elements [3], whereas in the marine industry they are used to increase the payload and fuel efficiency [4]. Titanium and titanium alloys are widely used in the aerospace industry for building aircraft frames and engine parts [5], and in marine applications for deep diving vehicles and submarines for producing pressure shells [6,7] and propellers [8]. In the nuclear industry, it is used for storing nuclear waste due to its chemical properties [9]. It can also be used to design nuclear reactor shields [10,11]. Stainless steel is used in the aviation industry for developing landing gear components, wings, and engines [1]. Nickel-based super alloys are used in the development of aircraft exhaust valves and turbine rotors due to their high creep resistance at higher temperatures [12]. Research has been carried out on improving the microstructure and mechanical properties of stainless-steel alloys [13,14,15,16,17,18,19], aluminum alloys [20,21,22,23,24,25,26], titanium alloys [27,28,29,30,31,32,33,34,35,36,37,38,39,40,41], and nickel-based super alloys [42,43] using different techniques like adding carbides [44,45,46,47], alloying elements [48,49,50,51], and heat treatments [20,21,42]. Conventional fabrication involves multiple processes and is time consuming. To streamline the fabrication process, industries are looking towards the new upcoming technology of additive manufacturing, which involves adding layer by layer of material for 3D printing of parts [52,53,54]. Different types of materials like plastics [55,56], concrete [57,58], composites [59,60], elastomers [61,62], polymers [63,64,65], metals and alloys [66,67,68,69,70,71,72], and non-metals [73,74] can be used for developing components. Commonly used 3D printing processes for stainless steel alloys, aluminum alloys, titanium alloys, and super alloys are laser powder bed fusion (LPBF) [75,76,77,78,79,80,81,82,83] wire arc direct energy deposition [84,85,86], laser metal deposition [87,88], and additive friction stir deposition [89,90,91] processes. The current research in additive manufacturing on aluminum alloys [92,93,94,95,96,97,98,99,100,101,102,103], stainless steel [104,105,106,107], titanium alloys [108,109,110,111,112,113,114,115,116], and nickel-based super alloys [117,118,119,120] aims at improving the microstructure and mechanical properties of materials by reducing the defects [121,122,123] in additive manufacturing. To optimize the cost and material utilization with a focus on sustainability, research has been carried out to recycle the material waste that is generated during the machining operations in industries while developing components. Direct recycling of metallic components or local production of powdered metal from readily available stock, including rod, machine chips, and wires, offers several benefits. These include reduced onsite powder storage, reduced lead times, increased availability of new alloys, waste reduction, and improved industrial hygiene (Figure 1) [124]. Currently, research is being carried out on recycling material waste in the form of chips/powders for use in additive manufacturing processes [125,126]. Figure 2 shows a typical LPBF microstructure. Figure 3 shows the generation process of the melt pools along the build direction during direct metal laser sintering process. In this paper, we review the recycling methods of materials through conventional and direct conversion methods and propose a way of recycling by converting material chips into wires for additive manufacturing process which can be energy efficient and environmentally friendly.

Figure 1.

Powder processing approaches [124].

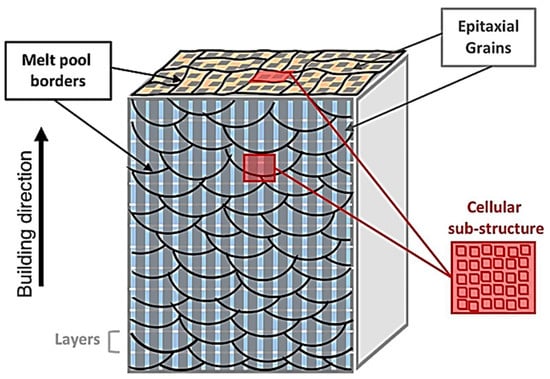

Figure 2.

Schematic representation of the typical LPBF microstructure [82].

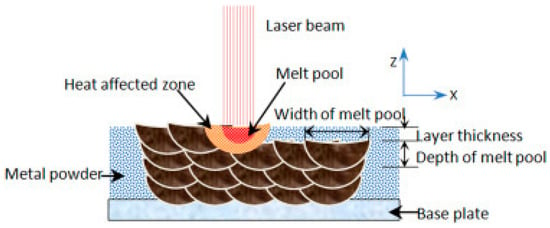

Figure 3.

Schematic diagram of the generation process of the melt pools along the build direction [83].

2. Research and Development in Recycling Materials

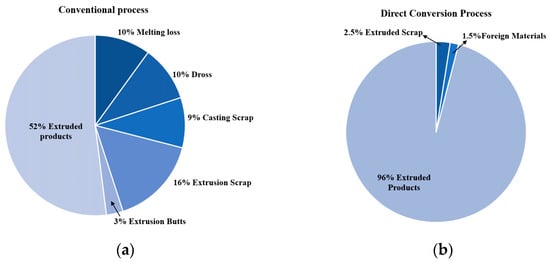

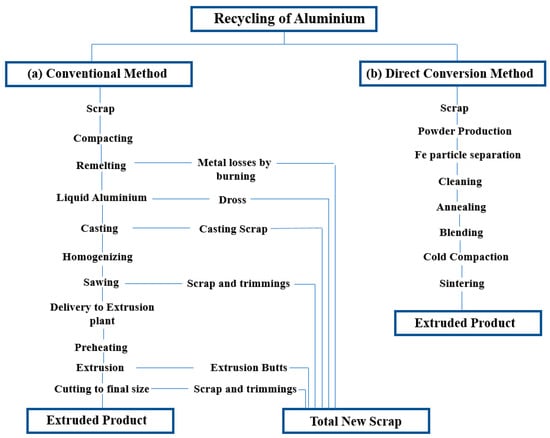

Increasing raw material and energy costs have led researchers to find alternative ways to recycle metal waste [127]. Chips are formed during machining operations like turning, milling, drilling, grinding, cutting, and sawing. There is a possibility for these chips to get chemically contaminated by coolants and emulsions during machining operations, hence they require a cleaning process before recycling. In direct conversion methods, chips are recycled without melting using solid-state recycling techniques [128,129], whereas in conventional methods [130], chips are melted for recycling, and it is important to understand this recycling process for different materials, as direct melting of some chips like aluminum alloys, which are covered by small layer of can be detrimental. It has been reported that aluminum alloy chips below the dimensions of 420 µm suspended in air or deposited in the form of a layer pose a risk of exploding if put in contact with an ignition source [131]. A comparison between the percentage of product extruded by conventional (52%) and direct conversion methods (96%) can be observed in Figure 4. Further discussions explore the chip cleaning process, conventional, direct conversion methods, powder metallurgy, and billet compaction for material recycling.

Figure 4.

Comparison between (a) conventional process and (b) the new technique using the direct conversion method (adapted with permission [132]).

2.1. Cleaning Chips

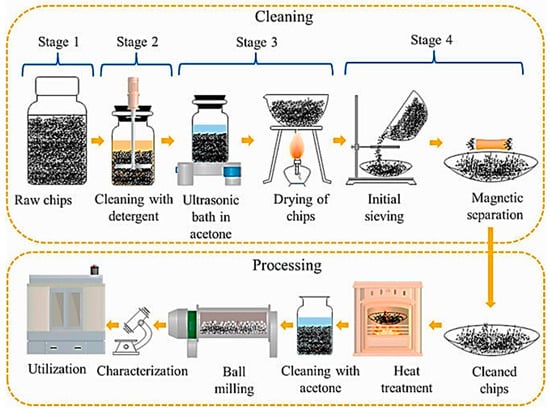

Chips formed during the machining operations in the metal industry are contaminated by lubricants, cooling, and anti-corrosion agents, hence it is important to clean chips before further processing. Chips contaminated by lubricants and coolants during machining operations can be treated with thermal or chemical methods to remove emulsions [132]. Chips can be cleaned by separating the cooling liquid and oil using a centrifuge [133]. They can also be removed by dissolving organic contaminants from chips into an organic solvent. It is possible that organic solvents might be carcinogenic and harmful to the environment. Vacuum separation is another method which can be used for cleaning chips. Chips are heated in a vacuum chamber up to 270 °C, where evaporation of the volatile components is accelerated by the low pressure which is pumped out and cooled at the required temperatures. Water and oil are separated, and oil recovered from this process is reused for machining [134]. Wang et al. [135] studied the effects of time, temperature, and cutting fluid type on the ultrasonic cleaning of titanium chips. It was determined that when using 40 kHz ultrasonic cleaning for 20 min and 5% sodium carbonate solution at 50 °C, an oil removal rate of 83.5% can be reached. The cleaning mechanism was analyzed, and influence modes were explained according to the young equation. Teke et al. [136] cleaned the Ti6Al4V alloy chips before melting by using detergent and ethyl alcohol (96% purity) to remove coolant oil. Dhiman et al. [137] cleaned Ti6Al4V swarf by washing it with detergent followed by cleaning it in a sonicator for 1 h which was later dried and sieved (Figure 5). Magnetic separation and later, heat treatment in a vacuum for 2 h at 800 °C was carried out. Before ball milling, chips were cleaned with acetone. Wang et al. [138] explored the ultrasonic cleaning of super alloy scrap using different liquid–solid ratios, cleaning temperatures, and cleaning times to find the optimal cleaning conditions for GH4169 super alloy scrap. Dziewinska et al. [139] provided details on the cleaning of uranium chips and turnings. Denkena et al. [140] studied the influence of cutting conditions on chip contamination to increase the recycling rate of titanium chips by investigating and adapting the influence of machining and process parameters on chip quality.

Figure 5.

Steps followed in cleaning and processing the Ti6Al4V swarf [137].

2.2. Conventional Methods

Chips can be recycled using methods like electric arc furnace (EAF) [141,142,143,144,145,146], electroslag remelting (ESR) [147,148,149,150,151,152], vacuum arc remelting [153,154,155,156], vacuum induction melting [136,157,158,159], electron beam melting [160,161,162,163,164], and plasma arc melting [165,166,167,168]. The various conventional processes for remelting chips generated from diverse materials can be further elaborated for understanding. Hence, outlining the major different processes of chips melting would be more beneficial for clarity. We have discussed below methods like electric arc furnace, electro slag remelting, vacuum arc remelting, electron beam melting, plasma arc melting, vacuum induction melting, induction melting furnace, and gas atomization.

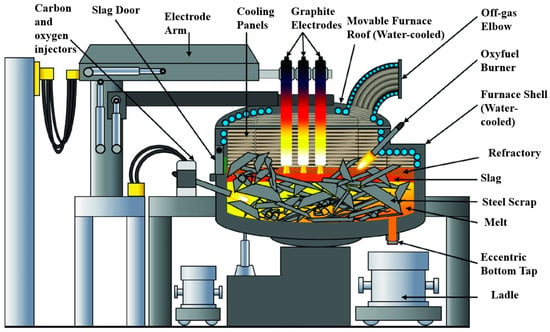

2.2.1. Electric Arc Furnace (EAF)

Iron and scrap are reduced from iron ore charged in the furnace. The furnace is refectory lined by a material which is infusible and heat resistant up to the highest temperature of steel making process. The heat is supplied by an arc which is created when the electric current is passed by carbon electrodes through the scrap to the furnace lining. Natural gas and oxygen can be used for providing additional heat to aid the melting process. Figure 6 shows an EAF process. Yang et al. [141] used an electric arc furnace to recycle stainless steel industrial waste and examined the effects of test conditions on carbon reduction of oxides in briquettes. Based on the observations, suggestions were made for the smooth operation of smelt reduction of briquettes using EAF or induction furnace. LAT et al. [169] recycled the zirconium alloy chips using two different techniques. One of the techniques used was melting the chips in EAF to obtain ingots which were heat-treated. A very high (up to 20%) burnout/oxidation loss can result due to remelting scrap in the electric arc furnace or the induction furnace [149,151,170,171]. Pereira et al. [172] recycled zirconium alloy chips using EAF. Hekimoğlu et al. [173] remelted the 390 A alloy and observed a uniform and equiaxed distribution of grains.

Figure 6.

Schematic illustration of an EAF [142].

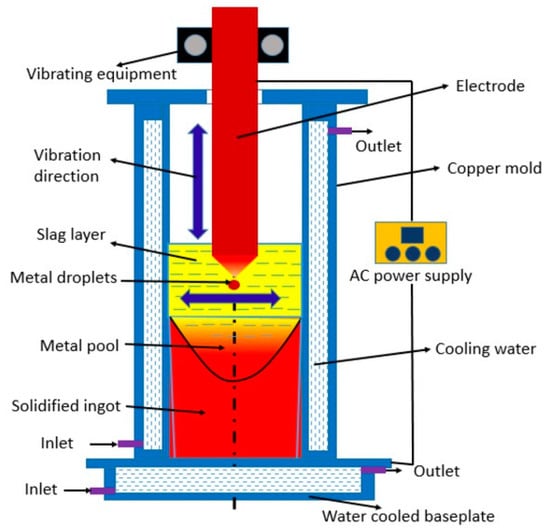

2.2.2. Electroslag Remelting (ESR)

Cylindrical parts are forged or cast into the consumable rods of the alloy which is to be remelt. The remelting process starts when the lower tip of the consumable rod gets immersed in a pool of molten slag. Figure 7 shows an ESR process. Recycling super alloy scraps is difficult due to problems associated with remelting. Recycling the scrap using vacuum melting techniques becomes difficult due to the high volume-to-weight ratio. Satyaprasad et al. [149,150] recycled wrought nickel based super alloy scrap using a non-consumable water-cooled electrode. Seo et al. [174] remelted and refined titanium scrap using direct current electro slag remelting in which graphite rod was used as anode.

Figure 7.

Schematic illustration of an ESR [175].

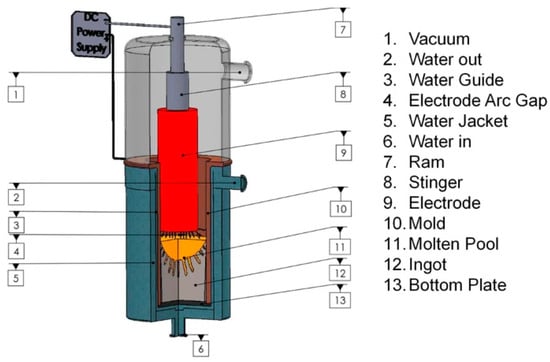

2.2.3. Vacuum Arc Remelting (VAR)

Vacuum arc remelting is commonly used to purify various alloys like nickel-based alloys, titanium-based alloys, and stainless-steel alloys. This method refines an impure alloy (electrode) through vacuum heated by a DC arc. As the tip of electrode melts, it generates droplets which drip through the vacuum and reach the molten pool. A high grade ultra-clean alloy forms in a water-cooled mold as the molten pool solidifies. Low density oxide inclusions are carried to the molten pool by the droplets and are transferred to the solidification rim near the mold. Figure 8 shows a VAR process. Under the vacuum conditions, unfavorable elements with high vapor pressure like Cu, Pb, As, Bi, Sn, and Te are evaporated under vacuum conditions [155]. To produce alloys used in nuclear fuel parts, the nuclear industry accepts only VAR furnaces as acceptable technology [156,176]. Ries et al. [156] studied the recycling of zirconium alloy chips scraps by melting in a VAR furnace. Kramer et al. [177] have described the process of recycling titanium chips. One of the steps mentioned is turning chips into stable compacts which can be remelted using a consumable electrode vacuum arc furnace. Berggreen [178] discusses the properties of titanium chips to be considered before remelting. The consumable electrode which is used in ESR and VAR furnaces is built using vacuum induction melting, in which a casting technique of pouring into top open mold is used. A substantial density of serious cracks is developed despite vacuum due to oxidizing conditions and turbulence accompanying the top pouring of the electrode. The biofilms (double oxide films), which are the cracks in the cast electrode, are responsible for major faults like fallen crown, white spots, and undetectable and horizontal macroscopic cracks in the VAR ingot. The solutions recommended to resolve these issues are a counter gravity cast electrode or an electrode cast in a vacuum or air such that it will be free from bifilm defects [154].

Figure 8.

Schematic illustration of VAR [155].

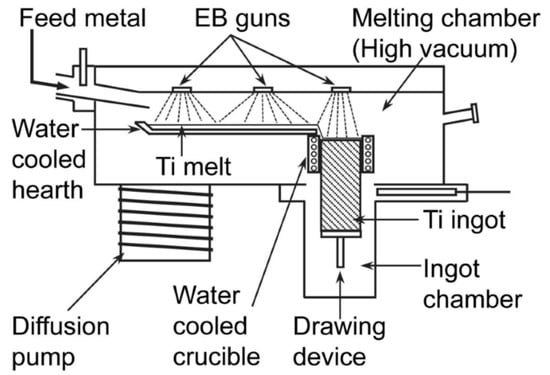

2.2.4. Electron Beam Melting (EBM)

EBM and refining process were developed as possible sole procedures for the processing of refractory and chemically active metals like Mo, W, Ti, Nb, Ta, Zr, Hf, V, and Pt, and now they are used for production of high purity metals and alloys in a vacuum and for recycling material scrap [159,162,164,179,180]. Figure 9 shows an EBM process. The beams in electron beam melting furnace are generated due to the emission of free electrons, and are accelerated under electrostatic field. These beams are targeted on the material to be processed. The beam energy converts into thermal energy, as the kinetic energy of the electron is deposited into the target, which leads to the melting of the material [157]. The material is not overheated with electron beams, which results in a high level of purification of metals from gases and metallic or nonmetallic admixtures, and results in the preservation of the structure, chemical composition, and properties of finished metallic ingots. The use of a water-cooled copper crucible for refinement, melting, and solidification helps in avoiding contamination due to its contact with the surface of the ceramic crucible used in ordinary metallurgy [181]. The EBM method avoids material wastage and is environmentally friendly. Vutova et al. [182] recycled technogenic hafnium and examined the possibility of removing metallic and non-metallic impurities from material during electron beam melting. Vutova et al. [181] recycled titanium and tantalum scrap using EBM. Essentially, the study determined the parameters of EBM for recycling Cu, Zr, and Hf. MaKoon recycled uranium scrap using EBM [179,183].

Figure 9.

Schematic illustration of EBM [180].

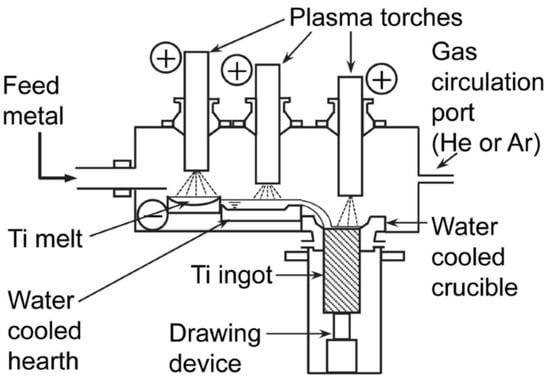

2.2.5. Plasma Arc Melting (PAM)

An intense and controllable stabilized electric arc discharge is used as a source of energy in PAM. The PAM process operates under a wide pressure range and inert atmosphere so that the melting process is not disrupted by the outgassing of feed material. Figure 10 shows a PAM process. VAR and EBM processes have limitations on the form and purity of material that can be processed. Electrical conductivity and structural integrity of the starting material is required in the VAR process. A constant vacuum for electron guns to function is required in EBM, which limits the amount of outgassing that can occur during melting. PAM offers the advantages of both EBM and VAR [166]. The advantage of PAM over EBM is its higher operating pressure of plasma systems (atmospheric or above) than EBM furnaces (Hard vacuum). The higher pressure in PAM helps avoid losses of low vapor-pressure alloying elements like aluminum and chromium [167]. Titanium-based alloys and nickel-based super alloys are widely used in aerospace industries, for example, in turbine compressor blades and compressor discs in jet aircraft engines. These materials, when molten, are very reactive and are susceptible to oxidation. The presence of small inclusions and other elements can lead to crack initiation sites. The PAF can carry out refining by removing high- and low-density inclusions during melting [167]. Blackburn et al. [167] have discussed the plasma arc melting technology for titanium alloys. Modrzynski et al. [168] recycled titanium alloys using PAF. Dunn et al. [166] recycled high interstitial contaminated tantalum powder. One of the conclusions drawn was that, due to excessive outgassing in high interstitial content material, PAM is the only alternative for its melting. Dunn et al. [184] used PAM to produce high quality ingots of titanium–tantalum alloys. Bhat. [185] mentions in his report that service life of plasma torches with electrodes is limited due to various factors like the type of material used for electrode, design configuration of electrodes, reactivity with plasma gases, and the nature of the current, AC or DC.

Figure 10.

Schematic illustration of PAM [180].

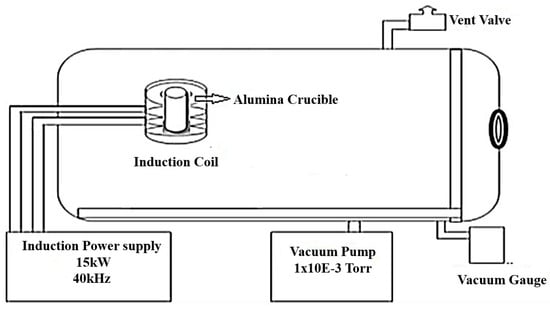

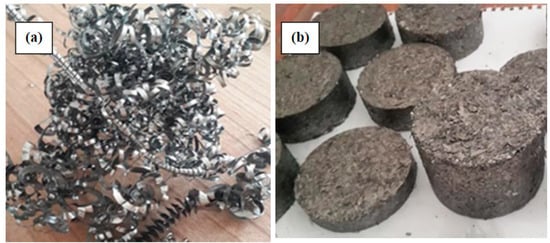

2.2.6. Vacuum Induction Melting (VIM)

In induction heating, an electrically conducting part is heated by passing an alternating current at a specific frequency through a copper coil to generate a variable electromagnetic field; this generates an induced eddy current in the vicinity of the coil. The part is placed within the coil and the eddy currents flowing through the part’s resistance heats it due to the Joule effect. The eddy currents are developed due to the part’s resistance and results in power loss, which results in heat. Figure 11 shows a VIM system. The advantages of the VIM process are a short melting time, precise control, homogenous mixing, and low cost. Teke et al. [136] developed a new melting system with vacuum induction to recover titanium alloy scraps. Figure 12 shows briquettes generated by pressing the Ti6A14V chips. Pereira et al. [157] recycled zircaloy scraps using vacuum induction melting and electron beam furnaces to obtain ingots. VIM has been used as a part of the process for recycling titanium aluminide [158,159].

Figure 11.

Vacuum induction melting system [136].

Figure 12.

(a) The Ti6Al4V chip, and (b) the briquettes pressed from their chip [136].

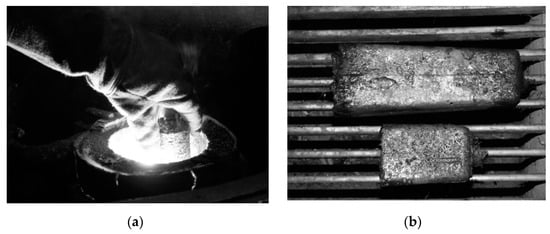

Stainless steel chips can be a source of alloying elements like nickel and chromium. Tokar et al. [186] conducted an experiment by separating structural steel and stainless-steel chips using magnetic separation. Chips were cleaned using two degreasing methods: (1) using laboratory furnace, chips were heated up to 400 °C to burn volatile gases; (2) by washing chips in trichloroethylene, a waste organic solvent. Dry chips were obtained from these methods. Dry and degreased chips were manually cold pressed into cylindrical compacts, which were then melted in a 20 kg induction melting furnace (Figure 13). In total, 13.01% Cr, 6.34% Ni, 0.86% Mo, and 0.45%Cu was the composition obtained from the investigated chips. It was confirmed from the experiment that compaction of chips in the form of briquettes was necessary for getting a better yield of material in melting process [186].

Figure 13.

(a) Charging of compact into melt. (b) Ingots composed of basic steel and added compacts [186].

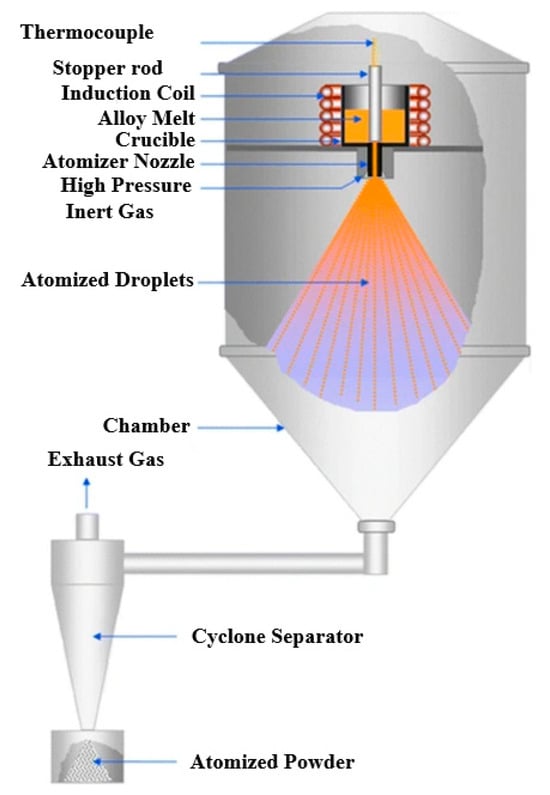

2.2.7. Gas Atomization (GA)

Material chips can also be recycled by using a method like gas atomization (GA) in which the material is heated to a melting point in the atomization process, and a nozzle of plasma or flowing gas breaks the liquid metal into fine particles, and they form spheres because of surface tension as they cool and fall through the atomization chamber [124]. Figure 14 shows a GA system. Chips can be recycled and developed into powdered form using GA. These powders can be used in additive manufacturing processes like powder bed fusion and wire arc direct energy deposition. Cacace et al. [187] used recycled AISI 316L and standard AISI 316L to produce powders using the GA process. They studied the feasibility of using recycled materials to produce powders for additive manufacturing. The results indicated that AISI 316L can be used for additive manufacturing, and it resulted in high mechanical properties and good processibility. Lagutkin et al. [188] developed a new method which combines pressure and gas atomization. White et al. [189] used a close coupled high pressure gas atomization method to produce a narrow distribution of coarse, spherical powders for Ni-based super alloys. Heidloff et al. [190] used close-coupled gas atomization for the production of fine spherical powder from the Ti alloy.

Figure 14.

Schematic diagram of gas atomization processing [191].

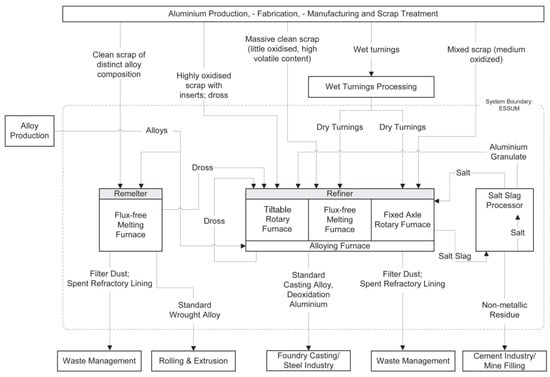

Remelting technologies like vacuum arc remelting (VAR), electron beam melting (EBM), and plasma arc melting (PAM) are used for melting titanium scrap as they minimize oxygen contamination. Volatile impurities like sodium and magnesium can be removed using EBM, as it is operated under a high vacuum. A combination of these methods, like EBM and VAR or PAM and VAR, are used for remelting [180]. Reitz et al. [158] recycled TiAl casting scrap by using vacuum induction melting, and detoxified it using pressure electroslag remelting. Vacuum arc melting was used to remove the dissolved reducing agents and impurities. Wang et al. [135] studied the effects of time, temperature, and cutting fluid type on the ultrasonic cleaning of titanium chips. It was determined that, when using 40 kHz ultrasonic cleaning for 20 min and 5% sodium carbonate solution at 50 °C, an oil removal rate of 83.5% can be reached. The cleaning mechanism was analyzed, and influence modes were explained according to the young equation. The production yield and processing process of the titanium alloy is low, about 50%. It is difficult to cut material and produces many chips [192]. The degraded utilization method and remelting recovery method are used for recycling titanium containing waste materials [180]. One of the ways for recycling titanium chips can be by using it in the development of Ferrotitanium. Ferrotitanium is used in steel making [193]. Titanium improves the steel microstructure and its wear properties and tensile strength. Pure titanium cannot be directly added to steel as it will be burnt, and titanium oxide will form inclusions inside the molten steel, affecting its quality [194]. Hence, the aluminothermic method or electro aluminothermic method is used to add titanium to liquid steel to obtain ferrotitanium alloy [195,196]. The traditional production method uses rutile and low phosphorus sulfur titanium as raw materials, which makes it difficult to control impurities [197,198,199], but by adjusting the proportion of ingredients, high titanium ferrotitanium can be produced by using titanium waste [200]. During processing and collection, the titanium chips can get contaminated by impurities like cutting fluid, dust, and mechanical oil. Oil stains such as lubricating oil, drawing oil, cutting oil, and anti-rust oil are difficult to clean from the titanium chip surface as they adhere to it, and this may lead to excessive carbon content in high titanium ferrotitanium after remelting [201]. High titanium ferrotitanium can be obtained by thoroughly cleaning chips. Jiao et al. [202] used the molten salt electrolysis method for recycling titanium scrap by which high purity titanium was collected from the cathode. In the aluminum recycling industry, aluminum is recycled using remelters and refiners (Figure 15). Casting alloys and deoxidation aluminum is produced by refiners, while wrought alloys are produced by remelters. Different aluminum alloys have to be separated while recycling in remelters, whereas in refiners, different alloys can be mixed to alloy-specific scrap batches before the scrap is loaded into the furnace. The feed in the remelter is clean scrap, which is not coated or oxidized, while the feed in refiner furnace is oxidized and coated [130]. The advantage of remelting chips over not remelting is that when the metal is in molten state, it is possible to correct its chemical composition by removing impurities.

Figure 15.

The framework for analysis of material flows into, out of, and within the European aluminum recycling industry [130].

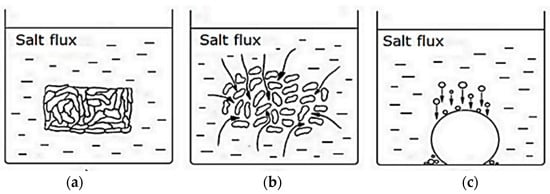

Earlier researchers have reported that, after remelting, the material recovery is around 54% during conventional recycling, as substantial losses occur during remelting of aluminum and aluminum alloys due to its low density, losses during casting (risers, shrink holes), and processing of aluminum ingots [203]. But Palimaka studied the metal chips formed during sawing process, with chip dimensions not exceeding 1 mm, and the chips were melted using thermal cleaning under controlled conditions of a gas atmosphere, and a high recovery yield of 94% and a degree of metal coalescence up to 100% was achieved [131]. Figure 16 shows a melting process of a compact. Figure 16a shows the heating of the compact. Figure 16b shows the melting, loss of the compact, penetration of molten salt, and absorption of impurities. Figure 16c shows sedimentation and coalescence of droplets.

Figure 16.

Stages of the compact’s melting process: (a) heating, (b) disintegration, salt penetration, beginning of coalescence, and (c) sedimentation and coalescence [131].

Critical raw materials (CRM) like Ta, Nb, Co, and Hf can be obtained by recycling super alloys. Pyrometallurgical, hydrometallurgical, and combined pyro- and hydro-metallurgical are the methods used for recycling of super alloys. In total, 3 to 6% of rare elements like ruthenium and rhenium are present in modern nickel super alloys. Once the chemical composition of the super alloy is analyzed with an XRF spectrometer, then the scrap should be sorted for recycling. Pyrometallurgical methods can be used for recycling scrap without rhenium content, whereas scrap with rhenium content (3 to 6 wt.%) can be recycled with hydrometallurgical methods [204]. In the pyrometallurgical process, scrap is remelted in an electric arc furnace followed by vacuum refining. The goal of the hydrometallurgical process is to obtain compounds or pure metals. Kim et al. [205] recycled PWA-1484 super alloy scrap using a two-step process for obtaining nickel and rhenium using hydrochloric acid solutions. Cui et al. [206] extracted nickel from a nickel-based super alloy using melting magnesium as the extraction medium. They investigated the effect of heating time, heating temperature, and mass ratio of alloy to magnesium on the extraction of metals in the alloy. Debarbadillo details the procedures for melting, handling, and refining nickel-based super alloy scrap [207]. Yagi et al. [208] used molten zinc as an extraction medium for extraction and separation of Ni from a Ni-based super alloy. Tian et al. [209] used molten Mg-Zn for selective extraction of Ni from super alloy scrap.

2.3. Direct Conversion Methods

In conventional recycling, there is a low recovery of material. For example, in conventional recycling of aluminum and aluminum alloys, the material recovery is around 54%, as substantial losses occur during remelting due to its low density, losses during casting (risers, shrink holes), and processing of aluminum ingots, whereas 95% of metal is recovered during direct conversion [203]. This method of direct recycling can be applied to iron, copper, and aluminum alloys [128,203,210,211,212]. The steps in the direct conversion method are comminution, cleaning, drying, cold pre-compacting, hot extrusion, and cutting to final size (Figure 17). The main requirement in recycling without remelting is that all the chips must be clean, homogenous in chemical composition, and should be from a single source. Low temperature processes are an alternative to the melting process. Here, a technique called sever plastic deformation [128] is used by processes like friction stir extrusion [213], cyclic extrusion compression [214], high pressure torsion [215], equal channel angular pressing [216], and KOBO extrusion process [217]. The plastic-deformed material is converted into a semi-finished solid product, followed by an extrusion operation into a final product. Noga et al. [218] recycled ALSi11 chips by compacting and co-extruding to obtain product in form of flat bars. Mathilde et al. [219] recycled AA 6060 aluminum chips and observed that the oxygen content increased during every step of the recycling process. We have discussed below several plastic deformation techniques and the hot extrusion method.

Figure 17.

Flow charts of recycling aluminum scrap: (a) by conventional method; and (b) direct conversion method (adapted with permission [132]).

2.3.1. Severe Plastic Deformation (SPD)

SPD is a plastic deformation process in which a large strain is imposed on a bulk process to obtain an ultra-fine-grained material [25,26,220,221]. Producing high strength and light weight parts is the main objective of the SPD process. The imposed plastic strain in conventional metal forming processes, like forging, rolling, and extrusion, is generally less than 2. The thickness and diameter of the material become very thin and are not suitable to be used for structural parts when multiple pass rolling, drawing, and extrusion are carried out up to a plastic strain of greater than 2. To impose large strain on bulk metal without changing its shape, many SPD processes have been developed [25]. Friction stir extrusion, Cyclic extrusion compression (CEC), High pressure torsion (HPT), and Equal Channel Angular Pressing (ECAP) are some of the processes which belong to this category, and have been used to recycle materials.

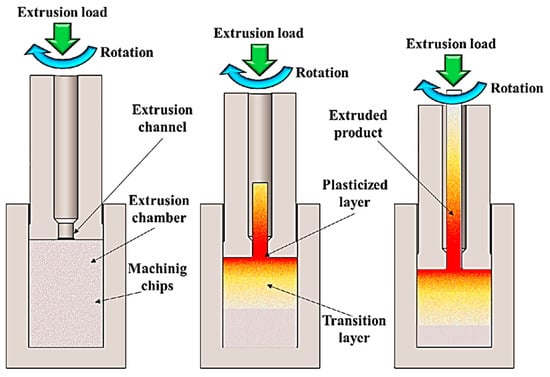

Friction Stir Extrusion (FSE)

Friction stir extrusion converts chips, powders, and other recyclable metal scrap into a usable product form in a single step by using extensive plastic deformation and frictional heating to mix, stir, and consolidate the material. Using an axial force, a cartridge filled with powder or swarf is pushed on to a plunger or die. Either the Plunger/die (backward friction extrusion) or the cartridge is rotated (forward friction extrusion) [222]. Figure 18 shows an FSE process. Baffari et al. [223] analyzed FSE process for recycling AA2050 for wire production with a primary energy demand perspective. They quantified the process of electrical energy demand with varying process parameters. They quantified and compared the primary energy demand of the whole recycling route with conventional and equal channel angular pressing and observed that FSE allowed for a reduction in energy demand up to 74% and 63% with respect to conventional and equal channel angular pressing. Buffa et al. [224] demonstrated that FSE can be implemented for the continuous recycling operation on light alloys like aluminum. They carried out numerical analysis which the FEM model was able to give information which cannot be directly measured experimentally. The model was able to guide the experimental investigation by providing useful input and output parameters. Hasan et al. [225] carried-out experiments to investigate the effect of process parameters on the extrude quality of AA2024, and a numerical model was developed to simulate the evolution of material flow. Reza-e-rabby et al. [226] studied the effects of die features and process parameters on response variables in friction extrusion. Asadi et al. [227] examined the sustainability of FSE technique for recycling of brass chips by comparing it with six different casting methods. Four sustainability indicators were calculated and compared for FSE and casting methods. Buffa et al. [228] recycled AZ31 magnesium alloy using friction stir extrusion process. Buffa et al. [229] recycled aluminum alloy chips into wires using FSE; these wires were found to have good microstructural and mechanical properties and can be used as wire feedstock for additive manufacturing.

Figure 18.

Sketch of friction stir extrusion process [230].

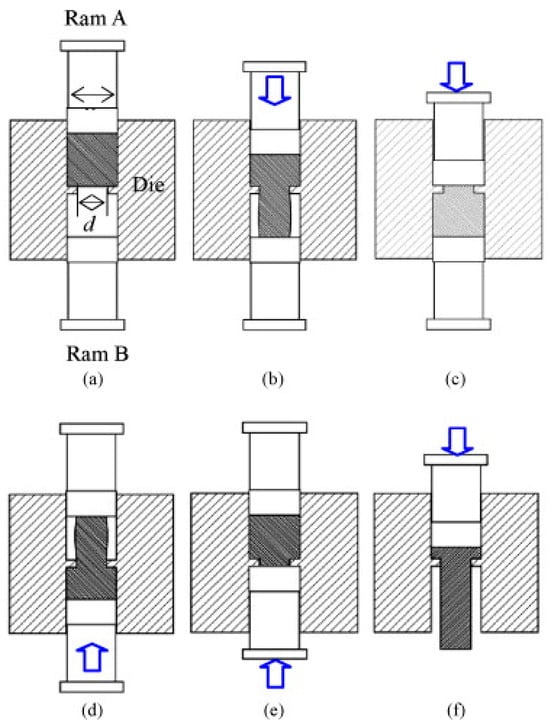

Cyclic Extrusion Compression (CEC)

CEC is a type of sever plastic deformation (SPD) [25] technique where a workpiece is pushed in a cylindrical die with two varying diameter sizes. Figure 19 shows a CEC process. Sever plastic deformation is used in the direct recycling of light weight and high strength materials; it produces material with ultra-fine grain size [214] due to large plastic strain imposed during process [25]. The most crucial stage of direct recycling technique is the compaction stage as it affects the material properties and microstructure of the material. We have discussed billet compaction in Section 2.5. Low billet density is one of the issues with direct compaction. Shahrom et al. [231] used cycling extrusion compression back pressure (CECBP) to improve the billet density which affects particle size, hardness, and chip boundaries of aluminum alloy 6061 chips during direct recycling of the hot forging process. Billet density, chip boundaries, and cyclic hardness were found to improve when aluminum chips were refined using the CECBP technique. Peng et al. [232] applied CEC for recycling of GW102K (Mg–10Gd–2Y–0.5Zr) magnesium alloy. They used GW102K alloy in two forms (chips and ingot) for investigation. Richert et al. [214] studied the effect of SPD during the CEC on strain hardening and grain refinement of AlMgSi (6082).

Figure 19.

Schematic representation of the steps of the cyclic extrusion compression (CEC) process (a) initial state, (b) extruding with a pushing pressure on the Ram A, (c) end of Ram A, (d) reverse extruding, (e) end of Ram B, and (f) final extruding to obtain a rod [232].

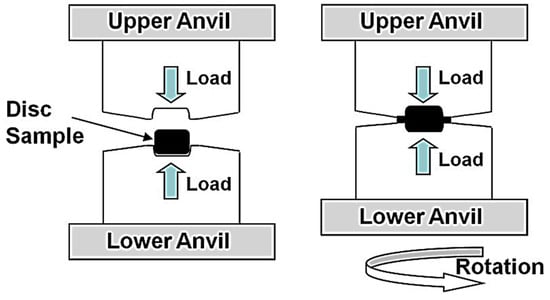

High Pressure Torsion (HPT)

In the HPT process, a sample disc is placed between the upper and lower anvil and is squeezed under high pressure and is concurrently strained by rotating the lower anvil with respect to the upper anvil [233]. Figure 20 shows an HPT process. HPT was used by Aal for recycling of pure Al chip, Al chip-20% and Al chip-20% SiC, and was able to produce ultrafine grain microstructure samples with relative densities ranging from 99.7–98.3% [215]. Yusuf et al. [234] applied HPT to additively manufactured SS316L fabricated using laser powdered bed fusion to produce ultrafine-grained and nano grained microstructures. Pandey et al. [235] recycled AA 6082 chips into cylindrical solid bars and hollow components like ring bush using HPT. The density of solid bars was observed to be 95–98% of the actual material density. The microstructural study indicated good bonding of chips at interface. Nezhad et al. [236] used HPT to recycle AA 7075 chips. They observed an improvement in mechanical properties with the addition of pure aluminum powder as a binder during the consolidation process, as it created lower porosity and better bonding between the chips. Castro et al. [237] used HPT to fabricate different Mg-Zn composites at room temperature. Guo et al. [238] hot-pressed Ti-5553 alloy chips and observed the strain to fracture of 0.98 ± 0.04%, ultimate tensile strength (UTS) of 675 ± 12 MPa, and bending strength of 1181 ± 28 MPa. Later, they double-aged samples at 600 °C for 4 h followed by 700 °C for 0.5 h, and they observed the strength and ductility of the hot-pressed Ti-5553 alloy to have significantly improved, with a UTS of 1425 ± 12 MPa, strain to fracture of 2.47 ± 0.07%, yield strength (YS) of 1390 ± 20 MPa, and a bending strength 2565 ± 35 MPa.

Figure 20.

Schematic illustration of high-pressure torsion (HPT) [233].

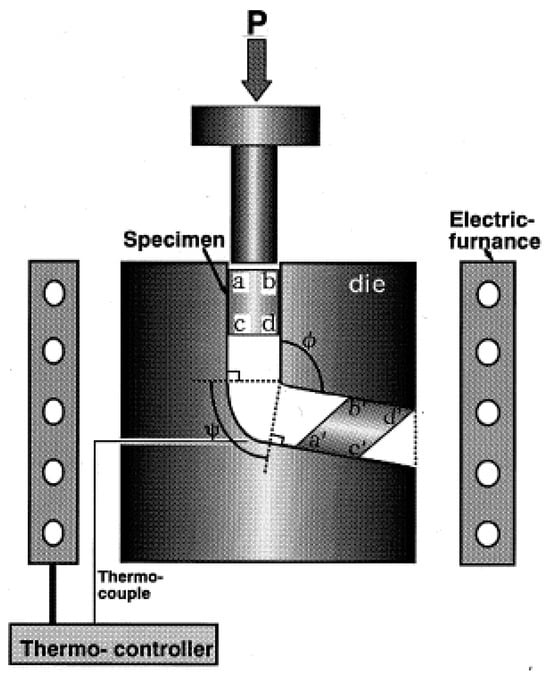

Equal Channel Angular Pressing (ECAP)

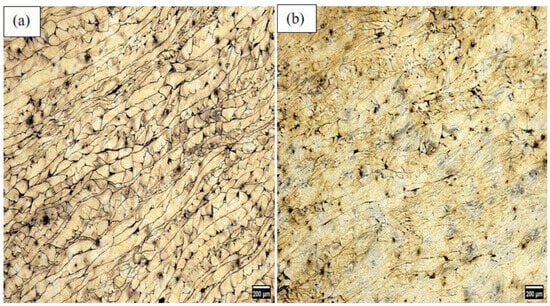

In the ECAP process, a large shear strain is introduced in the workpiece by pushing it through a die consisting of two channels having the same cross-sectional shape which meet each other at an angle to each other. Once the product is extruded, it can be pushed again through the entrance of the channel. Figure 21 shows the ECAP process, where ‘P’ is the force applied on the plunger to plastically deform the material. Plane a,b,c,d is the original plane whereas is the new deformed plane. Two channels of equal cross section are intersecting at an angle of ϕ 105° and ψ = 75°. Materials like Al, Cu, Mg, Ti, Ni, and their alloys have been processed using the ECAP technique [239,240,241,242,243,244,245,246]. Luo et al. [247] recycled titanium machining chips using ECAP; the results indicated fully dense bulk Ti with fine grain sizes having strength higher or comparable to commercial wrought pure Ti. Mohammad et al. [216] recycled AA 6061 chips using hot extrusion and subjected the material to the ECAP process. The study investigated the effects of ECAP in samples after 1, 2, and 4 cycles using die with 90° and 20° angles. The micro hardness, ultimate tensile strength, and yield strength improved with each pass and increased elongation to failure. Abbas et al. [248] recycled AA6061 chips. The final bulk material was developed in the following order of cold compaction, hot extrusion, and ECAP for one, two, and three passes. The surface roughness of the recycled material was investigated. Shi et al. [249] recycled Ti-Al-4V titanium alloy chips using ECAP. The results indicate that the ECAP process with back pressures allows consolidation of machine chips to near full consolidation of approx. 99.9%. The relative density of recycled samples increased with the applied number of passes and pressure. Maharbi et al. [250] recycled AZ31 magnesium chips using ECAP. The optical and scanning electron microscope data indicate that the quality of consolidation improves with the number of ECAP passes, as displayed in Figure 22.

Figure 21.

Schematic ECAP mechanism [251].

Figure 22.

Optical micrographs of consolidated AZ31 samples using ECAP at 300 C after (a) 1-A (one pass) and (b) 2-A (two passes). Extrusion direction (ED) is to the right [250].

Luo et al. [252] used ECAP to recycle pure titanium machined chips. Using continuous dynamic recrystallization, they achieved ultra-fine grain structure. Alimi et al. [253] recycled AA6061chips reinforced with different volumetric fractions of boron carbide using ECAP. The results indicated that boron carbide and the number of passes have a significant effect on the recycled AA 6061 chips. Krolo et al. [254] investigated the fatigue and corrosion behavior of the aluminum alloy EN AW 6082. The aluminum alloy EN AW 6082 chips underwent cold pre-compaction, hot extrusion, and ECAP. Mcdonald et al. [255] recycled Ti–6Al–4V machining chips using ECAP to produce bulk material which was further mill-annealed, which gave rise to an equiaxed microstructure. Due to the inclusion of chip boundary oxide layers, the recycled material had little tensile strength. After conventional mill annealing process, the material’s tensile yield strength was reported to be approximately 1150 Mpa. Hyodo et al. [256] recycled AA 7050 machine chips using both conventional and direct conversion methods by following the process of spray forming, hot extrusion, and ECAP.

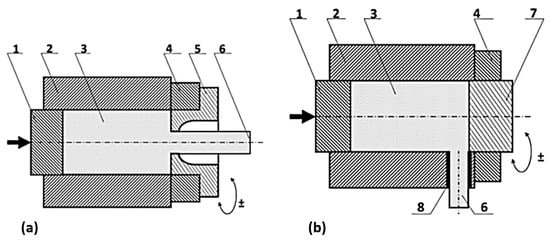

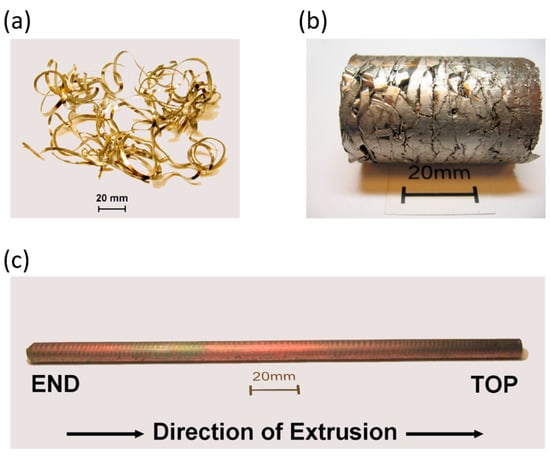

KOBO Extrusion Process (KEP)

In KEP, the die is reverse twisted to create an additional reverse twist of the metal, which are the conditions for the permanent change of the deformation path. As compared with the conventional method, KEP has two new parameters: (a) the angle, and (b) the frequency of twisting, which results in intense localized plastic deformation. This results in a significant drop in the strength of bonds in the crystal lattice, which lowers the metal’s viscosity coefficient value to the levels observed in liquids (108 Pa·s), creating conditions for the dominance of a stratified flow. A drop in plastic flow resistance occurs [257]. Figure 23 shows a KEP process. Bochniak et al. [257] studied the low temperature extrusion of hardly deformable materials in massive form (Mg4Li, AK11, Cu6.5P) and fragmented fractions (2014, 7075, AZ91, titanium grade 2). Topolski et al. [217] proposed a new technique of extruding titanium chips using the KOBO method (Figure 24). The recycled material’s microstructure had a homogenous grained structure. A small number of voids and randomly spread discontinuities were observed in it. Based on microhardness measurements and uniaxial compression tests, it was concluded that the mechanical properties of recycled material were comparable with those of solid cp-titanium grade 2. Later, in another piece of research, Topolski et al. [258] used an unconventional plastic working method of upsetting, heating, and extrusion with rotating die to convert titanium chips into briquettes. Two different grades of titanium, one with low quality and other with high quality, were investigated. Chips from these different grades of titanium were collected by machining operations like milling and turning without using coolants to avoid chemical contamination. The chips were cleaned in a direct conversion method using acetone and an ultrasonic washing machine. The materials obtained from this procedure exhibited a conventional grain structure and were free from any significant defects such as porosity and impurities. Topolski et al. [259] studied the structural aspects of the solid-state processing of titanium chips. Pure single-phase titanium Grade4 (Ti Gr4) was processed. Four geometries of chips were processed. Chips were compacted into briquettes, which were converted into rods using the KOBO method. The microstructure study of rods indicated a small number of internal defects. The rods exhibited proper structure for commercial titanium. Compression tests were carried out on the rods.

Figure 23.

Scheme of direct (a) and lateral (b) extrusion by the KOBO method: 1—punch, 2—container (recipient), 3—extruded material, 4—lock, 5—reversibly rotating die, 6—product, 7—reversibly rotating mandrel, and 8—die located on container’s side surface [257].

Figure 24.

Images of titanium taken at the successive stages of the recycling process: (a) titanium chips obtained after machining, (b) briquette obtained after pressing, and (c) the final product after KOBO extrusion—solid rod with a diameter of 8 mm [217].

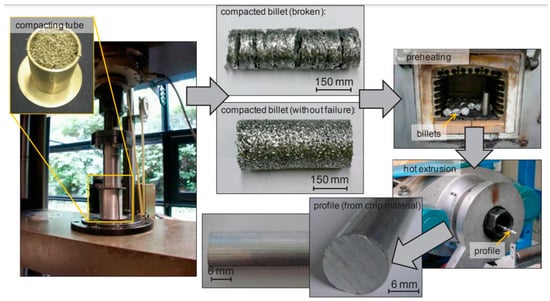

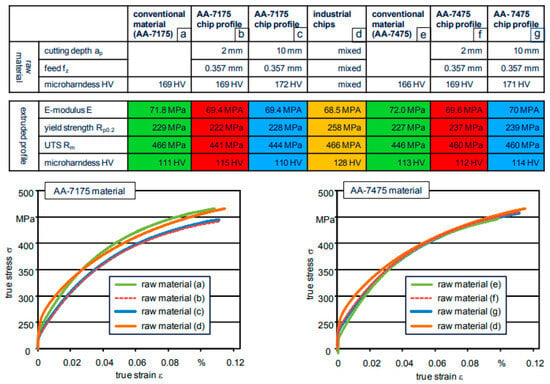

2.3.2. Hot Extrusion

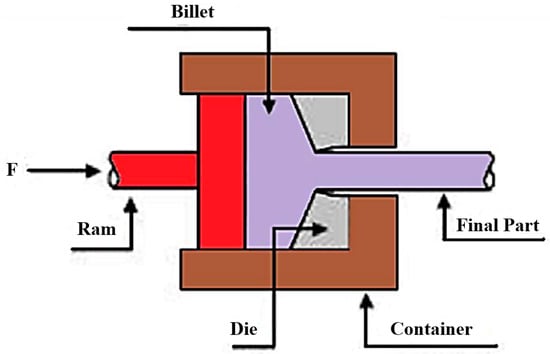

The scrap material is first compacted to form a billet. The billet is preheated before the extrusion [260]. The force applied on the ram pushes the billet on the die to extrude the part, as can be seen in Figure 25. Recycling aluminum using conventional methods using melting requires 25 times more energy than that needed for primary steel production. To overcome this problem, Pantke et al. [260] recycled aluminum scrap of AA-7175 and AA-7475 using hot extrusion process without remelting. Haase et al. [261] recycled machined AA6060 aluminum alloy chips using hot extrusion and subsequent cold extrusion. Taha et al. [262] recycled AA6061 aluminum alloy chips using the hot extrusion process followed by equal channel angular pressing (ECAP) and observed enhancement in corrosion resistance of the material. Selmy et al. [263] recycled AA6061 aluminum alloy chips using hot extrusion process followed by ECAP. Tekkaya et al. [264] hot extruded AA 6060 aluminum alloy chips and investigated the effects of chip type and process parameters on the final mechanical properties of the extruded profiles. Al et al. [265] recycled aluminum alloy AA6061 chips using hot extrusion and studied the effect of extrusion ratio and temperature on the microstructural evolution, physical, and mechanical properties of the material. Hosseini et al. [266] recycled phosphor bronze chips using hot extrusion process using aluminum powder as a metal binder for the fabrication of metal-fiber-reinforced aluminum matrix composite. They studied the microstructure and analyzed the fracture mechanism as a function of the volume fraction of phosphor bronze chips in fabricated composite. Alimi et al. [267] studied the effects of reinforcing aluminum AA6061chips mixed with boron carbide and zirconia particles. The results indicate that hardness and compressive strength increased with up to 5% added particles and beyond 5% the yield values decreased. The advantages and disadvantages of hot extrusion process have been provided in Table 1.

Figure 25.

Schematic of the hot extrusion process [268].

Table 1.

Comparative analysis of conventional and direct conversion methods.

2.4. Powder Metallurgy (PM)

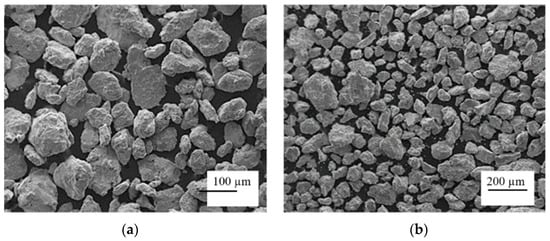

Metal chips can be recycled by turning them into powders by using processes like milling, gas atomization, and electrolytic decomposition. A high-end ball milling process using vanadium carbides has been studied by Mendonça et al. [281,282,283] for recycling stainless steel chips (Figure 26).

Figure 26.

(a) Without the addition of vanadium carbide (chip size 85–250 µm), and (b) with the addition of vanadium carbide (chip size 45 to 140 µm) [281].

Dhiman et al. [137] recycled Ti6Al4V swarf into powder feedstock suitable for additive manufacturing, and they observed that the characteristics of powder produced by ball milling were comparable or superior to the powder produced by gas atomization. Prior to using the chips for powder metallurgy, it is beneficial to conduct a cleaning process. Chips are easily contaminated by lubricants and coolants during machining operations, typically forming emulsions. These emulsions can easily be removed from the chips using either thermal or chemical methods [132].

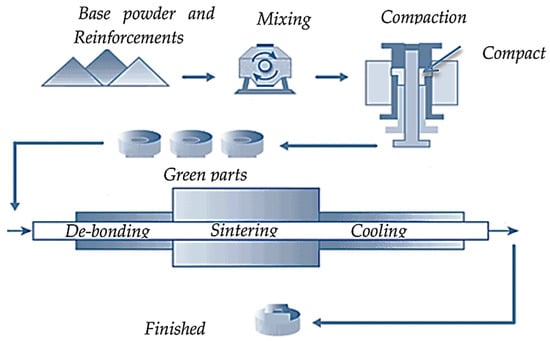

Powder generated from machine chips can be used as feedstock for powder metallurgy processes. The powder is mixed with metal/alloy powders along with a calculated amount of reinforcement materials. The obtained powder mixtures are consolidated by using rigid tool sets comprising punches and die. The green compacts obtained from this process are sintered for particle bonding to enhance the strength and integrity of the finished part [284]. Figure 27 shows a PM process. Lat et al. [169] recycled zircaloy using powder metallurgy. Demirel et al. [285] used CuSn10 as a matrix material and GGG40 cast iron as the reinforcement material for the production of composite material. Materials were turned into chips. Later, the chips were milled in a ball mill to achieve a homogenous structure. Grinded chips were sieved in 1–2 mm sieves to obtain chips in same form and size. The chips were weighed at a ratio of 10% GGG40–90% CuSn10 by weight with a precision of 0.001 g which were mixed in a conical mixer to obtain a homogeneous structure and were placed in the compression test specimen mold and pre-formed by a single effective press. The material was sintered in an ash furnace. During the sintering process, some graphite powder was used to minimize oxidation at high temperatures. Researchers have used powder metallurgy to recycle stainless steel chips [286]. Großwendt et al. [287] used a novel powder metallurgical method for recycling tool steel grinding sludge. Kem [288] produced steel deoxidation briquettes (recycled iron and aluminum) using powder metallurgy. Gonçalves et al. [289] recycled Vanadis®8 tool steel scrap using powder metallurgy. Umeda et al. [290] established a process for recycling coarse titanium chips Ti-6Al-4V to fine powders available for powder metallurgy. The formation of brittle TiH2 compounds due to heat treatment in hydrogen atmosphere improved the milling ability. Fine Ti-64 powders were reproduced using a suitable hydration temperature of 873 K in H2-Ar mixed gas. The reproduced green compact after vacuum sintering at 1273 K showed a relative density of about 93%, larger than that of the sintered material when using the commercial Ti-64 powder.

Figure 27.

Conventional powder metallurgy process [284].

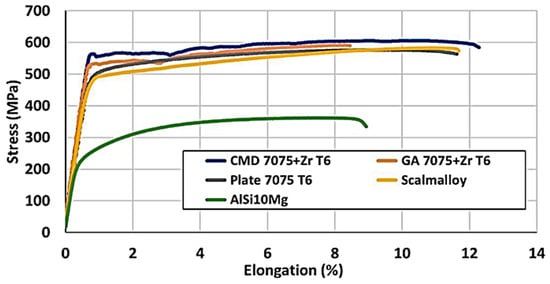

Chips can be recycled and developed into powdered form by the cold mechanically derived (CMD) technique [124]. Figure 28 shows the tensile response of gas atomization (GA) and CMD-derived material. The cold mechanically derived (CMD) technique is a new, direct low energy, solid state production process for powdered feedstock (Figure 1). Martin et al. [124] observed that CMD-derived materials showed higher tensile strength than GA-derived materials (Figure 28). The specimens produced from each type of powder were evaluated after heat treatment to separate the influence of residual porosity from that of the powder processing method. Hot isostatic pressing (HIP) was carried out to close porosity so that it could provide details on material properties without critical flaws. It was observed that both HIP’d and non-HIP’d CMD material showed improved strength and ductility over GA. However, material superiority over GA and wrought material is unclear due to varying processing parameters. One of the reasons provided to explain the improved tensile strength of CMD- over GA-derived materials was that increased vaporization of the strengthening elements in GA material probably decreased the strength, while additional changes in Zn/Mg/Cu ratios in the alloy could impact the final liquid composition during solidification, leading to a higher tendency for brittle grain boundary phase formation, such as S-phase.

Figure 28.

Tensile response of gas atomization (GA) and cold mechanically derived (CMD) material [124].

Researchers have worked on processing recycling chips into powders for aluminum alloys [124], stainless steel [291], and titanium alloys [140] so that they can be used for additive manufacturing. Wei et al. [292] have reviewed ball milling processes for converting machining chips into powders. Deshpande et al. [293] carried out solid state metal additive manufacturing using friction surfacing on metal chips of SS316L. The chips were produced by milling operation and were pressed into hollow 304L stainless steel rods. Cislo et al. [294] used the pulsed electric current sintering method for solid state recycling aluminum alloy chips. Thomas et al. [295] used a conform machine to extrude cold commercially available titanium powder into thin wires which were dense and had a fine recrystallized microstructure. Smythe et al. [125] used a conform machine to recycle titanium powder and swarf into thin wires to be used for additive manufacturing. Besekar et al. [296] recycled titanium by using it as a reinforcement in aluminum alloy A356, which led to an improvement in mechanical performance due to the refinement of dendrite size, partial diffusion of Ti into the Al matrix, and the uniform deposition of Ti particles. Jordon et al. [126] used waste machine chips as feedstock for an additive friction stir deposition process with no preprocessing steps, and were able to produce a fully dense additive manufacturing deposition.

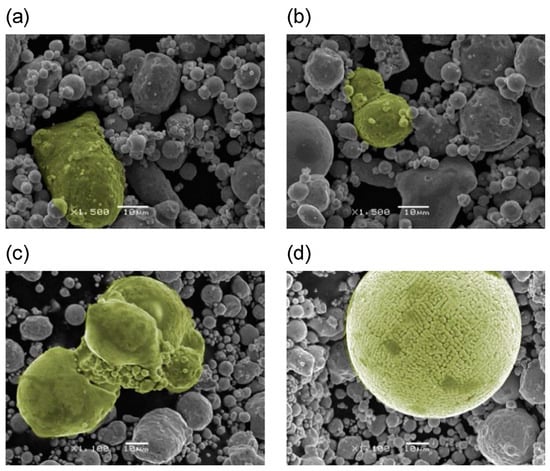

In additive manufacturing techniques like powder bed fusion processes, powder is distributed on the bed which will be melted by laser, but not all the initially distributed powder is used in the process [297,298]. This unmelted powder can be reused. Even though the powder has not been melted, it has been exposed to the thermal effects of the laser, and hence its morphology needs to be evaluated. Recycling powders have economic benefits like reducing the operational cost. A powder is considered good for processability if a 3D printed part developed from it has low porosity and defects. Research has been carried out to study and improve the morphology of the unmolten powders (Figure 29) for materials like aluminum alloys [299], stainless steel [187,297,300,301], and titanium alloys [302,303,304,305] so that they can be recycled and reused. There has also been research to identify the maximum number of times these powders can be recycled [297,306,307].

Figure 29.

SEM images at 1500× and 1100× magnification of P10 powder features: (a) particles with irregular or elongated shapes; (b) bonded particles; (c) bonded particles accumulations; and (d) particles with cerebellar textures [297].

2.5. Billet Compaction

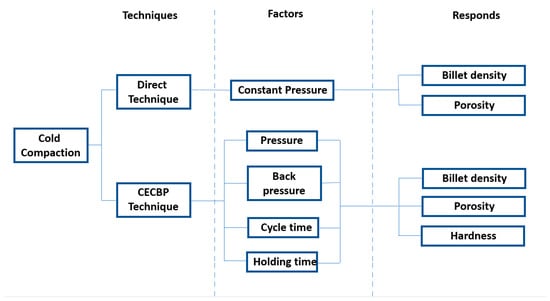

The first step in billet compaction is chip cleaning in case they are contaminated with oils, emulsions, cooling agents, etc. Chips are rinsed into a bath with an alkaline-based cleaning agent and kept for 15–30 min at 60 °C and washed with water. This step can be repeated multiple times in accordance with the level of surface pollution. The clean chips are left to dry in the air or are dried in a furnace designed for this purpose [264]. The processes of chip recycling can be carried out successfully by following the multistage procedure of (i) compacting—pressing, (ii) heating, and (iii) plastic working [217]. Tekkaya et al. [264] have mentioned a compaction force of 60 kN for compacting chips into billets. Misiolek et al. [308] have discussed three methods for billet compaction, (i) traditional compaction of entire chips volume in one stroke, (ii) multi-layer compaction for powder compaction [309], and (iii) front-pad approach for powder extrusion [310]. Factors which are necessary for recycling metallic chips using plastic working without re-melting are high pressure, high temperature, and large plastic strain [210,217,311]. The density of the recycled samples is measured by Archimedes’ method using de-ionized water [249]. Figure 30 shows the factors involved in cold compaction techniques. Shahrom et al. [231] identified pressure as the most significant factor affecting the properties of billet density and cyclic hardness. Peng et al. [232] studied the microstructure and mechanical properties of recycled magnesium alloy. Cyclic extrusion compression was used to recycle the material. Chips were first converted into low-intensity blocks using the pre-compaction method before CEC. Chips were compressed at 573 K with a pressure of 200 MPa in air. The effect of processing passes and processing temperature on the grain size was observed. They are important parameters in controlling the microstructure. The more the number of processing passes, the finer the grains were. Similarly, lower processing temperature resulted in finer grains. The 2- and 6-passes at 723 K resulted in the average grain sizes of recycled specimens to be 14 μm and 9 μm, whereas the 2- and 6-passes at 673 K resulted in 10 μm and 4 μm. The precipitation of the second-phase particles of the recycled specimens could be accelerated by high temperature CEC. Ductility of the recycled alloy 4-passes of CEC processing at 723 K, a combination of high strength and excellent ductility was obtained, and this was attributed to uniform distribution of oxide, the grain refinement, and the precipitation of Mg24(Gd,Y)5 as the second-phase particles. Table 2 provides comparative analysis of various direct conversion processes in relation to grain size and mechanical properties. Figure 31 shows the various steps hot extrusion process like compacting, billet formation, and hot extrusion with preheating. Figure 32 shows the effect of milling parameters on mechanical properties of hot extruded aluminum alloy chips.

Figure 30.

Comparison of cold compaction techniques in the hot forging direct recycling [231].

Table 2.

Comparative analysis of various direct conversion processes in relation to grain size and mechanical properties.

Figure 31.

Various steps involved in hot extrusion process like compacting, billet formation, and hot extrusion with preheating [260].

Figure 32.

The effect of milling parameters on mechanical properties of hot extruded aluminum alloy chips [260].

3. Summary and Future Prospects for Recycling of Chips Made of Different Metals and Alloys

Direct conversion methods of recycling are more energy efficient and environmentally friendly than conventional methods of recycling. Researchers have recycled powder/scrap to wires for additive manufacturing, but there is scope in recycling metal chips by converting them into briquettes and then converting them into thin wires for additive manufacturing. Briquettes can be developed and then subjected to severe plastic deformation techniques like ECAP to increase their density, and these high-density briquettes can then be converted into wire form for additive manufacturing using cold extrusion technique. Additionally, solid-state recycled chips may lead to the formation of a finer grain microstructure with minimal or no keyholes and pores, thus promoting mechanical properties comparable or higher than that of virgin materials.

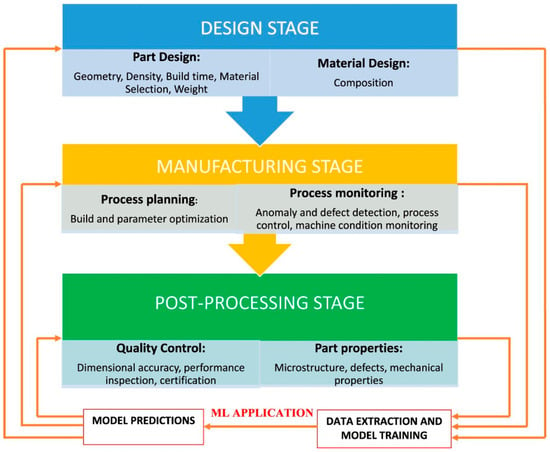

Artificial intelligence can be used to improve the quality of the additive manufactured parts being fabricated using recycled material. Machine learning can be applied at various stages of additive manufacturing, as displayed in Figure 33 [315]. AI-based technology can be used in additive manufacturing to improve material and geometric design and the optimization of process parameters, and likewise in situ and real-time monitoring can be implemented to detect abnormalities in material processing, prediction of part properties, as an intelligent recommender, and printability analysis. By leveraging all these innovative technologies in the fabrication, the remelting process can be precisely controlled, leading to improved mechanical properties and higher-quality components.

Figure 33.

Scope of machine learning at various stages of additive manufacturing [315].

Alloy composition design: Extensive and repetitive experimentation is required for developing alloy compositions which are cost- and time-consuming, and machine learning can expedite the alloy composition design process and can develop prediction models for alloy development and properties [316,317,318,319,320]. Predicting alloy structure: ML can be used to predict the microstructural changes that occur during additive manufacturing [321,322,323].

Material and geometric design: Design parameters can be fed as input parameters/features, and can be used to predict mechanical [324,325] or chemical properties [326,327,328,329], structure-property relations [330], process-structure-property analysis [331], predicting energy consumption [332,333], and structural optimization [334,335,336,337,338,339,340,341,342,343].

Optimization of process parameters: Traditional methods used for predicting product quality, which include trial and experimental approaches, can be time-consuming and expensive. Machine learning approaches, which are data driven, can enhance reliability, cost, quality, and can be time effective. ML can be effectively used to draw correlations between process–microstructure–properties [344], detect the presence of flaws for the combination of process parameters [345], dampen dimensional inaccuracies caused by residual stresses [346], print path-planning strategies [347,348], understand the effect of varying combinations of process parameters [349,350], uncertainty quantification [351,352,353,354], and quality control and repeatability [355].

Real-time monitoring: The fabrication process in 3D printing is prone to anomalies due to its complex number of process parameters and their interdependence on each other. The production of the quality part depends on the skill and expertise of the worker. To pace up the growth, in situ motoring methods are developed which include robust computer vison capabilities, advanced experimental equipment, and enhanced simulation methods. ML can be used to detect surface defects [356,357], improve surface quality and geometric accuracy [358,359], in multiple anomaly detection [360,361,362,363,364], in a real-time detection system [365,366,367,368], an in acoustic emission techniques to detect and monitor flaws [369,370,371,372,373].

Predicting part properties: ML can be used to prevent defects like cracking, porosity, and lack of fusion, which can lead to improving part quality and predict properties of the final product [374,375,376,377,378,379,380,381,382,383,384,385,386,387]. Feasibility analysis: Before allocating resources for 3D printing, a feasibility analysis can be carried out to ensure printability [388,389,390].

Author Contributions

Conceptualization, M.G., S.A.O. and M.K.; validation, M.G., S.A.O. and M.K.; formal analysis, M.G., S.A.O. and M.K.; investigation, M.G.; resources, M.G.; data curation, M.G.; writing—original draft preparation, M.G.; writing—review and editing, M.G., S.A.O. and M.K.; visualization, M.G., S.A.O. and M.K.; supervision, M.K.; project administration, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Garrison, W.M. Ultrahigh-strength steels for aerospace applications. JOM 1990, 42, 20–24. [Google Scholar] [CrossRef]

- Rambabu, P.; Prasad, N.; Kutumbarao, V.; Wanhill, R. Aluminium Alloys for Aerospace Applications. In Aerospace Materials and Material Technologies; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Setiawan, J.; Pribadi, S.; Jamaludin, A.; Sungkono, S.; Al Hasa, M.H. Structural analysis of Al alloys for nuclear fuel cladding. AIP Conf. Proc. 2020, 2262, 050002. [Google Scholar] [CrossRef]

- Wahid, M.A.; Siddiquee, A.N.; Khan, Z.A. Aluminum alloys in marine construction: Characteristics, application, and problems from a fabrication viewpoint. Mar. Syst. Ocean. Technol. 2019, 15, 1–11. [Google Scholar] [CrossRef]

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and Features of Titanium for the Aerospace Industry. Nippon. Steel Sumitomo Met. Tech. Rep. 2014, 106, 22–27. [Google Scholar]

- Wang, L.; Jiang, X.; Huang, L. Research on Collision Response of Titanium Alloy Cylindrical Pressure Shell. World J. Eng. Technol. 2020, 8, 658–664. [Google Scholar] [CrossRef]

- The Soviet Titanium Industry And its Role in Military Buildup, Sanitized Copy Approved for Release 2011/02/07: CIA-RDP86T00591R000200170005-0, March 1985. Available online: https://www.cia.gov/readingroom/docs/CIA-RDP86T00591R000200170005-0.pdf (accessed on 7 May 2024).

- Morton, A.G.S.; Lane, I.R. Titanium Castings for Marine Propellers. In Titanium Science and Technology; Jaffee, R.I., Burte, H.M., Eds.; Springer: Boston, MA, USA, 1973. [Google Scholar]

- Zhang, Q.; Huang, Y.; Blackwood, D.J.; Zhang, B.; Lu, D.; Yang, D.; Xu, Y. On the long term estimation of hydrogen embrittlement risks of titanium for the fabrication of nuclear waste container in bentonite buffer of nuclear waste repository. J. Nucl. Mater. 2020, 533, 152092. [Google Scholar] [CrossRef]

- Sirin, M. The effect of titanium (Ti) additive on radiation shielding efficiency of Al25Zn alloy. Prog. Nucl. Energy 2020, 128, 103470. [Google Scholar] [CrossRef]

- Jones, R.H.; Leonard Jr, B.R.; Johnson, A.B., Jr. Assessment of Titanium Alloys for Fusion Reactor First-Wall and Blanket Applications; Final Report; Battelle Pacific Northwest Labs.: Richland, WA, USA, 1980. [Google Scholar]

- Furrer, D.; Fecht, H. Ni-based superalloys for turbine discs. JOM 1999, 51, 14–17. [Google Scholar] [CrossRef]

- Yang, X.; Yu, C.; Yang, X.; Yan, K.; Qian, G.; Wang, B.; Yan, W.; Shi, X. Microstructure and Mechanical Properties of an Austenitic Heat-Resistant Steel after Service at 570 °C and 25.4 MPa for 18 Years. J. Mater. Eng. Perform. 2021, 30, 1030–1038. [Google Scholar] [CrossRef]

- Young, A.M.; Kral, M.V.; Bishop, C.M. Effects of aging and nitridation on microstructure and mechanical properties of austenitic stainless steel. J. Mater. Sci. 2023, 58, 10716–10735. [Google Scholar] [CrossRef]

- Byrnes, M.L.G.; Grujicic, M.; Owen, W.S. Nitrogen strengthening of a stable austenitic stainless steel. Acta Metall. 1987, 35, 1853–1862. [Google Scholar] [CrossRef]

- Bohnenkamp, U.; Sandström, R. Evaluation of the elastic modulus of steels. Steel Res. 2000, 71, 94–99. [Google Scholar] [CrossRef]

- Mathew, M.D.; Laha, K.; Ganesan, V. Improving creep strength of 316L stainless steel by alloying with nitrogen. Mater. Sci. Eng. A 2012, 535, 76–83. [Google Scholar] [CrossRef]

- Simmons, J.W. Mechanical properties of isothermally aged high-nitrogen stainless steel. Metall. Mater. Trans. A 1995, 26, 2579–2595. [Google Scholar] [CrossRef]

- Jiang, Z.-H.; Zhang, Z.-R.; Li, H.-B.; Li, Z.; Qi-Feng, M. Microstructural evolution and mechanical properties of aging high nitrogen austenitic stainless steels. Int. J. Miner. Metall. Mater. 2010, 17, 729–736. [Google Scholar] [CrossRef]

- Öksüz, K.E.; Bağirov, H.; Şimşir, M.; Karpuzoğlu, C.; Özbölük, A.; Demirhan, Y.Z.; Bilgin, H.U. Investigation of Mechanical Properties and Microstructure of AA2024 and AA7075. Appl. Mech. Mater. 2013, 390, 547–551. [Google Scholar] [CrossRef]

- Maisonnette, D.; Suery, M.; Nelias, D.; Chaudet, P.; Epicier, T. Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy. Mater. Sci. Eng. A 2011, 528, 2718–2724. [Google Scholar] [CrossRef]

- Terada, D.; Kaneda, Y.; Horita, Z.; Matsuda, K.; Hirosawa, S.; Tsuji, N. Mechanical properties and microstructure of 6061 aluminum alloy severely deformed by ARB process and subsequently aged at low temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012088. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Lee, S.; Minamino, Y. ARB (Accumulative Roll-Bonding) and Other New Techniques to Produce Bulk Ultrafine Grained Materials. Adv. Eng. Mater. 2003, 5, 338–344. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Zehetbauer, M.J.; Estrin, Y.; Höppel, H.W.; Ivanisenko, Y.; Hahn, H.; Wilde, G.; Roven, H.J.; Sauvage, X.; Langdon, T.G. The Innovation Potential of Bulk Nanostructured Materials. Adv. Eng. Mater. 2007, 9, 527–533. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Zhao, Y.; Xin, S.; Zeng, W. Effect of major alloying elements on microstructure and mechanical properties of a highly β stabilized titanium alloy. J. Alloys Compd. 2009, 481, 190–194. [Google Scholar] [CrossRef]

- Lee, Y.-R.; Han, M.-K.; Kim, M.-K.; Moon, W.-J.; Song, H.-J.; Park, Y.-J. Effect of gold addition on the microstructure, mechanical properties and corrosion behavior of Ti alloys. Gold Bull. 2014, 47, 153–160. [Google Scholar] [CrossRef]

- Rosalbino, F.; Delsante, S.; Borzone, G.; Scavino, G. Influence of noble metals alloying additions on the corrosion behaviour of titanium in a fluoride-containing environment. J. Mater. Sci. Mater. Med. 2012, 23, 1129–1137. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, M.; Kikuchi, M.; Okuno, O. Mechanical properties and grindability of experimental Ti-Au alloys. Dent. Mater. J. 2004, 23, 203–210. [Google Scholar] [CrossRef] [PubMed]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyk, M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys. In Titanium Alloys—Advances in Properties Control; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; He, Q.; Wei, W.; Guo, F.; Su, W.; Huang, C. A strong and ductile pure titanium. Mater. Sci. Eng. A 2022, 833, 142534. [Google Scholar] [CrossRef]

- Shan, D.B.; Zong, Y.Y.; Lv, Y.; Guo, B. The effect of hydrogen on the strengthening and softening of Ti-6Al-4V alloy. Scr. Mater. 2008, 58, 449–452. [Google Scholar] [CrossRef]

- Sun, Z.; Zhou, W.; Hou, H. Strengthening of Ti-6Al-4V alloys by thermohydrogen processing. Int. J. Hydrogen Energy 2009, 34, 1971–1976. [Google Scholar] [CrossRef]

- Zong, Y.; Wu, K. Thermo hydrogen treatment for microstructure refinement and mechanical properties improvement of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2017, 703, 430–437. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, B. Effects of hydrogen as a solid solution element on the deformation behavior of a near-alpha titanium alloy. Mater. Sci. Eng. A 2021, 815, 141269. [Google Scholar] [CrossRef]

- Gaddam, R.; Hörnqvist, M.; Antti, M.-L.; Pederson, R. Influence of high-pressure gaseous hydrogen on the low-cycle fatigue and fatigue crack growth properties of a cast titanium alloy. Mater. Sci. Eng. A 2014, 612, 354–362. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Xiao, S.; Chen, Y. Effect of hydrogenation on microstructure evolution, mechanical and electrochemical properties of pure titanium. J. Alloys Compd. 2019, 781, 1139–1149. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, X. Improvement of mechanical properties and microstructural refining of cast titanium alloys by coupling of electropulsing and temporary alloying element hydrogen. Mater. Sci. Eng. A 2022, 858, 144176. [Google Scholar] [CrossRef]

- Yadav, P.; Saxena, K.K. Effect of heat-treatment on microstructure and mechanical properties of Ti alloys: An overview. Mater. Today: Proc. 2020, 26 Pt 2, 2546–2557. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C.; Gysler, A. Microstructure and mechanical properties of titanium alloys. Microstruct. Prop. Mater. 2000, 2, 1–77. [Google Scholar] [CrossRef]

- Lu, H.; Yang, M.; Zhou, L.; Ma, Z.; Cui, B.; Yin, F.; Li, D. Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy. Metals 2022, 12, 2176. [Google Scholar] [CrossRef]

- Bi, L.; Yan, H.; Zhang, P.; Shi, H.; Li, Z.; Li, R. Influence of rare earth oxides on microstructure and mechanical properties of nickel-based superalloys fabricated by high energy beam processing: A review. J. Rare Earths 2023, in press. [CrossRef]

- Min, K.S.; Nam, S.W. Correlation Between Characteristics of Grain Boundary Carbides and Creep–Fatigue Properties in AISI, 321 Stainless Steel. J. Nucl. Mater. 2003, 322, 91–97. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.; Coy, A.; Viejo, F.; Carboneras, M.; Arrabal, R. Influence of Ti, C and N Concentration on the Intergranular Corrosion Behaviour of AISI, 316Ti and 321 Stainless Steels. Acta Mater. 2007, 55, 2239–2251. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent Developments in Stainless Steels. Mater. Sci. Eng. R. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Min, K.S.; Kim, K.J.; Nam, S.W. Investigation of the Effect of the Types and Densities of Grain Boundary Carbides on Grain Boundary Cavitation Resistance of AISI, 321 Stainless Steel Under Creep– Fatigue Interaction. J. Alloys Compd. 2004, 370, 223–229. [Google Scholar] [CrossRef]

- Ohkubo, N.; Miyakusu, K.; Uematsu, Y.; Kimura, H. Effect of Alloying Elements on the Mechanical Properties of the Stable Austenitic Stainless Steel. ISIJ Int. 1994, 34, 764–772. [Google Scholar] [CrossRef]

- Yiran, W.; Ruian, W.; Yimin, G. Effect of Co content on microstructure and mechanical properties of maraging steel. J. Mater. Res. Technol. 2023, 27, 3887–3899. [Google Scholar] [CrossRef]

- Wang, H.; Wang, A.; Li, C.; Yu, X.; Xie, J.; Liang, T.; Liu, C. Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel. Rev. Adv. Mater. Sci. 2022, 61, 873–887. [Google Scholar] [CrossRef]

- Meng, Q.; La, P.; Yao, L.; Zhang, P.; Wei, Y.; Guo, X. Effect of Al on Microstructure and Properties of Hot-Rolled 2205 Dual Stainless Steel. Adv. Mater. Sci. Eng. 2016, 2016, 7518067. [Google Scholar] [CrossRef]

- Srinivasan, D.; Meignanamoorthy, M.; Ravichandran, M.; Mohanavel, V.; Alagarsamy, S.V.; Chanakyan, C.; Sakthivelu, S.; Karthick, A.; Prabhu, T.R.; Rajkumar, S. 3D Printing Manufacturing Techniques, Materials, and Applications: An Overview. Adv. Mater. Sci. Eng. 2021, 2021, 5756563. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Haq, M.I.U. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-Pap. 2016, 49, 103–110. [Google Scholar] [CrossRef]

- Skoratko, A.; Katzer, J. Harnessing 3D Printing of Plastics in Construction-Opportunities and Limitations. Materials 2021, 14, 4547. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Jo, J.H.; Jo, B.W.; Cho, W.; Kim, J.-H. Development of a 3D Printer for Concrete Structures: Laboratory Testing of Cementitious Materials. Int. J. Concr. Struct. Mater. 2020, 14, 13. [Google Scholar] [CrossRef]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Herzberger, J.; Sirrine, J.M.; Williams, C.B.; Long, T.E. Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Gao, Q.; Fu, J.Z.; Chen, Q.Y.; Zhu, J.P.; Sun, Y.; He, Y. Multimaterial 3D Printing of Highly Stretchable Silicone Elastomers. ACS Appl. Mater. Interfaces 2019, 11, 23573–23583. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D printing of conducting polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Fan, W.; Liu, T. Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos. Commun. 2020, 21, 100413. [Google Scholar] [CrossRef]

- Hojjatzadeh, S.M.H.; Parab, N.D.; Yan, W.; Guo, Q.; Xiong, L.; Zhao, C.; Qu, M.; Escano, L.I.; Xiao, X.; Fezzaa, K.; et al. Pore elimination mechanisms during 3D printing of metals. Nat. Commun. 2019, 10, 3088. [Google Scholar] [CrossRef] [PubMed]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Qu, M.; Chuang, C.A.; Xiong, L.; Nabaa, A.; Young, Z.A.; Ren, Y.; Kenesei, P.; Zhang, F.; Chen, L. Phase transformation dynamics guided alloy development for additive manufacturing. Addit. Manuf. 2022, 59 Pt A, 103068. [Google Scholar] [CrossRef]

- Gutmann, B.; Köckinger, M.; Glotz, G.; Ciaglia, T.; Slama, E.; Zadravec, M.; Pfanner, S.; Maier, M.C.; Gruber-Wölfler, H.; Kappe, C.O. Design and 3D printing of a stainless steel reactor for continuous difluoromethylations using fluoroform. React. Chem. Eng. 2017, 2, 919–927. [Google Scholar] [CrossRef]

- Masek, P.; Fornusek, T.; Zeman, P.; Bucko, M.; Smolik, J.; Heinrich, P. Machinability The Aisi 316 Stainless Steel after Processing by Various Methods of 3D Printing. MM Sci. J. 2019, 2019, 3338–3346. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, J.; Zhang, H.; Kent, N.J.; Diamond, D.; Gilchrist, M.D. 3D Printing of Metallic Microstructured Mould Using Selective Laser Melting for Injection Moulding of Plastic Microfluidic Devices. Micromachines 2019, 10, 595. [Google Scholar] [CrossRef] [PubMed]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Bahar, A.; Belhabib, S.; Guessasma, S.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R. Mechanical and Thermal Properties of 3D Printed Polycarbonate. Energies 2022, 15, 3686. [Google Scholar] [CrossRef]

- Wang, G.; Wang, S.; Dong, X.; Zhang, Y.; Shen, W. Recent progress in additive manufacturing of ceramic dental restorations. J. Mater. Res. Technol. 2023, 26, 1028–1049. [Google Scholar] [CrossRef]

- Martinho, P.G. Chapter 9—Rapid manufacturing and tooling, In Plastics Design Library, Design and Manufacturing of Plastics Products; Pouzada, A.S., Ed.; William Andrew Publishing: Norwich, NY, USA, 2021; pp. 381–456. [Google Scholar]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. Manuf. Rev. 2014, 1, 2. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting-Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, S.; Singh, Y.P. Chapter 7—Additive manufacturing techniques used for preparation of scaffolds in bone repair and regeneration. In Additive Manufacturing Materials and Technologies, Advances in Additive Manufacturing; Kumar, A., Mittal, R.K., Haleem, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 103–127. [Google Scholar]

- Gao, B.; Zhao, H.; Peng, L.; Sun, Z. A Review of Research Progress in Selective Laser Melting (SLM). Micromachines 2023, 14, 57. [Google Scholar] [CrossRef] [PubMed]